#Aerospace supply chain partner

Explore tagged Tumblr posts

Text

The Role of an Aerospace Supply Chain Partner in the Defense Industry

In today’s rapidly evolving defense landscape, the importance of an aerospace supply chain partner cannot be overstated. As defense manufacturers strive to meet the stringent requirements of modern warfare, the collaboration with reliable and efficient supply chain partners becomes essential. Among these partners, ISO certified defense manufacturers play a pivotal role in ensuring quality, reliability, and compliance with international standards.

Understanding the Aerospace Supply Chain

The aerospace supply chain is a complex network of manufacturers, suppliers, and service providers that work together to deliver components and systems for aircraft and defense systems. An effective aerospace supply chain partner ensures that all parts are produced, tested, and delivered on time, minimizing delays and maintaining the integrity of the final product. This collaboration is particularly crucial in the defense sector, where the stakes are high, and any lapse in quality can have serious consequences.

The Significance of ISO Certification

ISO certification is a mark of quality that signifies a manufacturer’s commitment to maintaining standards in their processes and products. For defense manufacturers, obtaining ISO certification demonstrates adherence to rigorous quality management systems. An ISO certified defense manufacturer not only ensures that their products meet the required specifications but also fosters trust and confidence among clients, including government agencies and military organizations.

When partnering with an aerospace supply chain partner, it is imperative to consider their certifications. An ISO certified defense manufacturer will have established protocols for quality assurance, risk management, and continuous improvement. This commitment to excellence allows for smoother operations within the supply chain, as both parties can rely on consistent quality and performance.

Benefits of Collaborating with an Aerospace Supply Chain Partner

Quality Assurance: Working with an ISO certified defense manufacturer guarantees that the components used in aerospace applications meet international quality standards. This is crucial in the defense sector, where reliability is paramount.

Cost Efficiency: An effective aerospace supply chain partner can help reduce costs through optimized processes and economies of scale. By leveraging their expertise, defense manufacturers can focus on their core competencies while relying on their partners for quality components.

Regulatory Compliance: The defense industry is heavily regulated, and compliance with various standards is mandatory. An ISO certified defense manufacturer is well-versed in these regulations, ensuring that all products are compliant, which minimizes the risk of legal issues down the line.

Innovation and Technology: Collaborating with an aerospace supply chain partner often leads to innovation. These partners can provide cutting-edge technologies and materials that enhance the overall performance of defense systems.

Flexibility and Scalability: The defense sector often requires rapid adjustments to production levels based on changing demands. An aerospace supply chain partner can offer the flexibility and scalability needed to respond to these fluctuations effectively.

Challenges and Considerations

While the benefits of working with an aerospace supply chain partner are clear, challenges do exist. Ensuring that all partners maintain the same level of quality and compliance can be difficult. It is essential for defense manufacturers to conduct thorough assessments of potential partners, focusing on their certifications, past performance, and capability to meet specific needs.

Additionally, communication is key. Establishing clear lines of communication with an aerospace supply chain partner ensures that any issues are addressed promptly, preventing delays and maintaining project timelines.

Conclusion

In conclusion, the role of an aerospace supply chain partner is vital in the defense industry. Collaborating with an ISO certified defense manufacturer not only enhances quality and compliance but also drives innovation and efficiency. As the defense landscape continues to evolve, the importance of building strong partnerships within the aerospace supply chain will remain a cornerstone of success. By prioritizing quality and reliability, defense manufacturers can ensure they are well-equipped to meet the challenges of modern warfare.

0 notes

Text

The new tariffs imposed by the U.S. on China, Mexico, and Canada will have widespread effects on American goods and services. Here’s how they are likely to impact different aspects of the economy:

1. Higher Costs for Businesses and Consumers

Many American businesses rely on imported materials, components, and products from these countries. Tariffs increase the cost of these imports, forcing companies to either absorb the costs (reducing profits) or pass them on to consumers.

Industries such as automotive, electronics, manufacturing, and retail will see price hikes, making everyday goods more expensive for American consumers.

2. Inflationary Pressure

Tariffs function like a tax on imported goods, leading to higher prices across the board.

If companies pass increased costs to consumers, inflation could rise, making goods and services more expensive and potentially prompting the Federal Reserve to reconsider interest rate policies.

3. Supply Chain Disruptions & Business Uncertainty

Companies that rely on raw materials, electronics, and auto parts from these countries may face delays and shortages, forcing them to find alternative suppliers or move production, which takes time and money.

Some businesses might restructure their supply chains by sourcing materials from other countries or increasing domestic production, but this transition isn't immediate and could further increase costs.

4. Retaliation from Trading Partners

Canada, Mexico, and China have signaled that they may impose their own tariffs on U.S. exports, which could hurt American industries that depend on international trade, such as agriculture, aerospace, and manufacturing.

Farmers, in particular, could face declining demand for crops like soybeans, corn, and dairy products, which were previously targeted in retaliatory tariffs during the Trump-era trade war.

5. Impact on the Stock Market & Business Investment

Investors dislike uncertainty. If businesses anticipate lower profits due to higher costs or potential trade disruptions, stock markets may react negatively.

Companies may delay hiring or expansion plans due to concerns over higher operational costs and shifting trade dynamics.

6. Possible Job Losses in Affected Industries

If businesses face significantly higher costs and declining demand due to retaliatory tariffs, some industries could see layoffs or reduced hiring.

Manufacturing and export-dependent sectors, such as automotive, steel, and agriculture, may be hit the hardest.

Potential Silver Linings

Some industries, like domestic manufacturing and steel production, could see short-term gains if companies decide to shift production back to the U.S. instead of relying on imports.

The government may use tariff revenues to invest in domestic industries or subsidies, potentially offsetting some negative effects.

Bottom Line

The new tariffs will likely increase costs for businesses and consumers, contribute to inflation, and create uncertainty in financial markets and supply chains. While some domestic industries might benefit, the risk of retaliatory tariffs and economic slowdown poses a challenge for the broader U.S. economy.

13 notes

·

View notes

Text

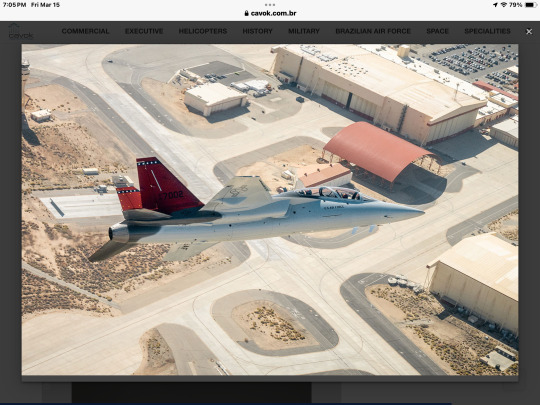

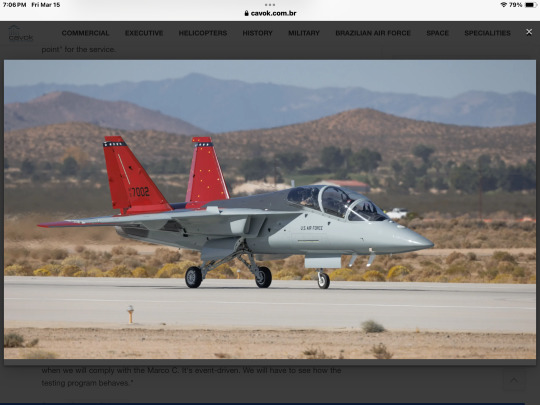

USAF: Boeing's KC-46A and T-7A face more delays

Fernando Valduga By Fernando Valduga 03/14/2024 - 11:00 in Military

The Air Force's head of acquisitions, Andrew Hunter, noted possible future problems for the KC-46A and said that production of the T-7A could start “a little later” than previously predicted, but he remained confident about the future of the two aircraft.

For years, the fixed price agreements that Boeing has signed for programs such as the air refueling plane KC-46A Pegasus and the coach T-7A Red Hawk have been headaches for the aerospace giant amid billions in losses due to delays, supply chain restrictions and development problems. And now, according to the U.S. Air Force acquisition leader, more delays for both efforts may be coming.

Testifying before the Chamber's Armed Services Maritime Power and Projection Forces Subcommittee on Tuesday, Andrew Hunter said that an update to the long-problematic vision system of the KC-46A would probably arrive in 2026, surpassing a projected field date already 19 months late, from October 2025. After the hearing, he told reporters separately that the service would "probably" approve the production of coach T-7A later than previously expected.

“There is some scheduling pressure,” Hunter told lawmakers about the implementation of a new vision system for the KC-46A, called RVS 2.0. "And depending on the completion of the airworthiness certification process of the Federal Aviation Administration (FAA), I cannot guarantee that we would be in a position to enter the field in 25. It could be '26. And that's really likely - I think it will probably take the field in 26."

After the hearing, Hunter explained to reporters that a possible Pegasus delay is linked to the FAA certification process, arguing that when RVS 2.0 is integrated, “you need to make sure that this will not affect anything else on the plane. Therefore, this makes the airworthiness process more complex than it may seem, because it is essentially more than just the cameras you are dealing with."

Hunter added that he is "confident" that USAF and Boeing "have the right project" and that the team "will go through the entire process of airworthiness in the near future".

So far, Boeing has reported losses of more than $7 billion in the Pegasus program due to its fixed price structure, although it is not clear whether more losses could be associated with an additional delay for RVS 2.0. Boeing has defured the questions to the U.S. Air Force, but the company had already praised the capabilities of the new vision system as providing marked improvements over the basic version.

Despite the problems in the vision system, the aircraft has been released for combat deployment and can refuel most of the U.S. fleet, except the A-10, due to a separate problem with an actuator on the tanker's boom, which should be resolved by fiscal year 26. Hunter suggested last year that the service was inclined to buy more tankers as part of a new strategy to continue the retirement of the service's former KC-135 refuelers, although a service official later said that a procurement strategy had not yet been decided.

Europe's Airbus positioned itself as an alternative if the U.S. Air Force decided to participate in a competition, after its partner Lockheed Martin announced that it was giving up.

In his testimony this week, Hunter said that autonomous capabilities could be incorporated into the future of air refueling, but told journalists that this would not be a requirement for the next installment of the acquisition of tankers.

"I think this would be something that we would consider as an independent effort and potentially put into practice in the future," he said about autonomous replenishment.

In a written statement on Tuesday [PDF], Hunter additionally said that the service would slightly expand its current contract with Boeing, adding four KC-46As for a total registration program of 183.

T-7A 'A little later than we expected'

Meanwhile, budget documents confirmed the decision of the U.S. Air Force to halve the 2025 fiscal acquisition of the T-7A Red Hawk training aircraft, intended to replace the former T-38 Talon, from 14 to seven, and indicate that delays in the program are also near.

This program was reformulated last year to reflect a delay of more than two years. A subsequent surveillance report found that problems with the flight control software and the jet's escape system continued to pose risks to the already delayed schedule, especially when the jet moved to enter flight tests, where the U.S. Air Force could discover new flight control deficiencies.

Now, it seems that the coach's schedule may be a little longer. According to the Fiscal Year 2025 budget documents released by the service on Monday night, a decision of the Marco C - or the point at which the service officially approves a program to go into production - is projected for May 2025. Previously, authorities planned the C-Mark for February 2025, although the program allocated a full year of schedule margin for the decision.

To help mitigate delays, Boeing began buying long-term parts to start making an eventual production decision. This approach required a special agreement between the U.S. Air Force, Boeing and the Defense Contracts Management Agency to oversee initial production, which the service said last year had been achieved.

In addition, as Aviation Week previously noted, budget documents also suggest that the initial operational capacity of the jet may be postponed for one year, from the second quarter of Fiscal Year 2027 to the second quarter of Fiscal Year 2028. So far, Boeing has reported losses of about $1.3 billion in the Red Hawk program, and it is not clear whether further delays could result in more charges. As with the KC-46, the company transferred questions about the T-7A to USAF, which did not immediately respond to a request for comment.

Speaking to reporters after Tuesday's hearing, Hunter explained that the decision to halve the purchase of T-7A in Fiscal Year 25 was mainly the result of high-level fiscal pressures. Still, he said that the size of the seven Red Hawks batch "is a good starting point" for the service.

He said that delays in the start of the flight test program may mean that the coach will be approved for production later than expected. The first USAF T-7A landed at Edwards Air Base in November.

“We entered the flight test program a little later than we expected, so we will probably start production a little later than we expected,” Hunter said. “At the moment, the flight test program is doing relatively well. If we don't discover something unexpected, I believe we will go into production in fiscal year 2025."

Asked if the date of the Marco C of February 2025 is at risk, he replied: "To define when we will comply with the Marco C. It's event-driven. We will have to see how the testing program behaves."

Source: Breaking Defense

Tags: Military AviationKC-46A PegasusT-7A Red HawkUSAF - United States Air Force / U.S. Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. He uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

Russia releases video of destruction of Ukrainian helicopters in Donetsk

14/03/2024 - 09:00

SMOKE SQUADRON

IMAGES: Smoke Squadron holds demonstrations in Pernambuco

14/03/2024 - 08:21

MILITARY

USAF's NGAD program will receive US$ 3.4 billion in the 2025 budget

13/03/2024 - 18:43

MILITARY

Taiwan acquires additional MQ-9B SkyGuardian drones from the US

13/03/2024 - 18:18

HELICOPTERS

Bell receives contract to manufacture the AH-1Z attack helicopters for Nigeria

13/03/2024 - 16:00

ARMAMENTS

US approves sale of JASSM-ER, AMRAAM and Sidewinder missiles to Poland

13/03/2024 - 14:00

12 notes

·

View notes

Text

Industry Insights: Where We Supply Tool Steel - Virat Special Steels

Virat Special Steels stands tall as India’s largest stockiest, importer, and supplier of HSS Steel, Hot Work Steel, Cold Work Steel & Plastic Mould Steel. Representing top manufacturers of special steels worldwide, we enjoy global recognition for our unwavering commitment to quality.

Serving Industries: 🔧 Forging Industry: Shaping metal using compressive forces with a hammer or press, classified into cold forging, warm forging, or hot forging.

🏗️ Pressure Die Casting: Forcing molten metal under high pressure into a mold cavity, made using two hardened tool steel dies.

🚗 Aluminum Extrusions: Material pushed through a die to the desired cross-section, creating complex parts with excellent surface finishes.

🚙 Automotive Industry: Involved in manufacturing, design, and development of motor vehicles.

⛽ Oil & Gas Industry: Supplying more than 60% of our nation’s energy, including natural gas for electricity.

🧩 Plastic Industry: Manufacturing polymer materials for aerospace, construction, electronics, packaging, and transportation.

🍶 Glass Industry: Involves float glass process and glassblowing, producing sheet glass and containers.

🚲 Cycle Parts: Manufacturing components like bearings, chains, chain sets & cranks, handlebars, forks.

🚉 Railways: Manufacturing railway components such as gear holders, bogie cast parts, axles, pins, ground lever frames, adjustable cranks, compressor pistons, and bearings.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is your trusted partner, supplying premium tool steels to diverse industries in India and globally.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#viratsteels#india#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#db6 steel#h13diesteel#h13steel#h13steelbarexporter#h11steel#din 2714#din 2344#din2343#din2738#d2steel#m2steels#m35#p20ni

3 notes

·

View notes

Text

Fueling Progress: The Crucial Role of Roasted Molybdenum Concentrate in Modern Industry

In the dynamic landscape of modern industry, where technological advancements and innovation shape the future, certain elements play a pivotal role in driving progress. Among these, Roasted Molybdenum Concentrate emerges as a key contributor, empowering various sectors with its unique properties and versatile applications. As a leading supplier, trader, and distributor of Roasted Molybdenum Concentrate, Palvi Chemicals stands at the forefront of facilitating industrial growth and innovation.

Understanding Roasted Molybdenum Concentrate

Roasted Molybdenum Concentrate: A Brief Overview

Roasted Molybdenum Concentrate, often derived from molybdenite ore, undergoes a meticulous process to attain its concentrated form. The roasting process involves heating the raw material to high temperatures, resulting in the conversion of molybdenite into molybdenum oxide. The resulting concentrate is a versatile substance, boasting exceptional heat resistance, corrosion resistance, and mechanical strength.

The Role of Roasted Molybdenum Concentrate in Industry

1. Enhancing Strength and Durability

In industries where strength and durability are paramount, Roasted Molybdenum Concentrate finds widespread use. From the construction of high-stress components in aerospace engineering to the production of robust machinery in heavy manufacturing, the addition of molybdenum enhances the structural integrity of materials, ensuring they withstand challenging conditions.

2. Catalyst for Sustainable Energy Solutions

As the global focus shifts towards sustainable energy, Roasted Molybdenum Concentrate emerges as a catalyst for progress. The substance plays a crucial role in the manufacturing of catalysts for hydrotreating processes in oil refineries, facilitating the production of cleaner fuels and reducing environmental impact.

3. Corrosion Resistance in Chemical Processing

Industries involved in chemical processing rely on materials that can withstand corrosive environments. Roasted Molybdenum Concentrate, with its exceptional corrosion resistance, becomes an indispensable component in the construction of chemical reactors, pipelines, and other equipment critical to chemical manufacturing.

Palvi Chemicals: Your Trusted Partner

As a leading supplier, trader, and distributor of Roasted Molybdenum Concentrate, Palvi Chemicals has established itself as a reliable partner for industries seeking high-quality materials for their processes. Our commitment to quality assurance, timely delivery, and customer satisfaction sets us apart in the competitive landscape.

1. Quality Assurance

Palvi Chemicals adheres to stringent quality control measures throughout the production and distribution processes. Our Roasted Molybdenum Concentrate undergoes rigorous testing to ensure it meets the highest industry standards, guaranteeing optimal performance in diverse applications.

2. Timely Delivery

Understanding the importance of timelines in industrial operations, Palvi Chemicals prioritizes efficient logistics and timely delivery. Our well-established distribution network enables us to reach clients globally, ensuring a seamless supply chain that aligns with the dynamic demands of the industry.

3. Customer Satisfaction

At Palvi Chemicals, customer satisfaction is at the core of our business philosophy. We work closely with clients to understand their unique requirements and provide customized solutions that cater to their specific needs. Our customer-centric approach has earned us the trust of industries across the globe.

Partnering for a Sustainable Future

As industries continue to evolve, the demand for innovative materials that contribute to sustainability and efficiency is on the rise. Roasted Molybdenum Concentrate, with its versatile properties, is positioned as a key player in this transformative journey.

By choosing Palvi Chemicals as your Roasted Molybdenum Concentrate supplier, trader, or distributor, you are not just acquiring a product; you are forging a partnership that fuels progress and fosters a sustainable future. Join us in the pursuit of excellence as we contribute to the advancements that shape the industries of tomorrow. Together, let's build a stronger, more resilient, and sustainable world.

#Roasted Molybdenum Concentrate distributor#Roasted Molybdenum Concentrate trader#Roasted Molybdenum Concentrate supplier#Roasted Molybdenum Concentrate

6 notes

·

View notes

Text

I had to look this up and learned from that excellent journal 'Composite World' that:

HAV Airlander project is approved for £7 million investment

South Yorkshire leaders sanction support for HAV’s investment in facilities, talent and supply chains to progress production and bring its first composite Airlander 10 hybrid aircraft to the air by 2026.

Hybrid Air Vehicles (HAV, Bedford, U.K.), a sustainable, hybrid airship company producing the highly composite Airlander 10 aircraft, has been approved for an investment and support package by South Yorkshire’s Mayor Oliver Coppard and the South Yorkshire Mayoral Combined Authority (SYMCA) to produce its low-carbon aircraft in Doncaster, U.K.

The loan investment, worth £7 million, will be used to support HAV to begin investing in facilities, talent and supply chains in South Yorkshire. HAV’s plans will create more than 1,200 high-value and highly skilled jobs in new green technologies, and further jobs and opportunities from growth across the company’s supply chains. By 2026, the company aims to deliver the first completed orders to its customers and build 12 new Airlander 10 aircraft per year in Doncaster thereafter.

The Airlander 10 is an ultra-low emissions aircraft, capable of carrying 100 passengers or 10 tonnes of freight; CW reported on its progress in March 2021. The hybrid aircraft will deliver 90% fewer per-passenger emissions in flight than traditional aircraft and aims to enable zero emissions operations by the end of the decade.

The agreement with SYMCA is reported to be a major milestone for HAV’s plans to bring Airlander to market. The loan will enable the company to begin investing in the region and paves the way for it to invest up to £310 million into its production program. HAV is also set to work with other partners across the region, including the Advanced Manufacturing Research Centre (AMRC) at the University of Sheffield, and Doncaster UTC.

“At Hybrid Air Vehicles we are revolutionizing views of what aviation is, and Airlander is designed for us to rethink the skies,” Tom Grundy, CEO of Hybrid Air Vehicles, says. “From day one, Mayor Oliver Coppard has bought into our vision, so I am delighted that he has announced this investment. We will work with regional partners, including Mayor Ros Jones and Doncaster Metropolitan Borough Council, Doncaster UTC, the AMRC and the University of Sheffield, to establish a world-leading cluster for green aerospace technologies, skills and supply chains.”

HAV is progressing plans to build a flagship new production facility in Doncaster, which will include facilities for the assembly of new Airlander 10 aircraft, as well as testing and certification for the new aircraft. It plans to announce the specific site and unveil the design of its production facilities in the months ahead.

To maximize the potential of this program, SYMCA, HAV and Doncaster Council will also work in partnership to develop the region’s skills, talent and supply chains, with the aim of creating a new green aerospace manufacturing cluster in Doncaster and South Yorkshire.

HOW AREN'T THERE MORE TUMBLR POSTS ABOUT THE GIANT AIRSHIP THE AIRLANDER 10 WHY DID I ONLY JUST FIND OUT ABOUT IT

IT LOOKS WORSE AT EVERY ANGLE

NO

#and somehow Composite World failed to mention its... appearance#A buttockform aircraft#Looks comfy!

44K notes

·

View notes

Text

GB Gummi – Leading Rubber Sheet Manufacturer in India

GB Gummi is a trusted Rubber Sheet Manufacturer in India, offering premium-quality rubber sheets for various industrial applications. With years of expertise, advanced technology, and a commitment to quality, we provide durable and high-performance rubber sheets that meet international standards.

Why Choose GB Gummi as Your Rubber Sheet Manufacturer in India?

As a leading Rubber Sheet Manufacturers in India, we focus on delivering superior rubber sheets that cater to multiple industries, including automotive, construction, mining, and manufacturing. Our rubber sheets are designed for excellent resistance to wear, heat, chemicals, and environmental factors.

High-Quality Materials – We use top-grade rubber compounds to ensure durability and efficiency.

Customization Options – Our rubber sheets can be customized in thickness, size, and material composition.

Industry Compliance – We follow strict quality control measures to meet industry standards.

Competitive Pricing – Our rubber sheets offer the best value without compromising quality.

Types of Rubber Sheets We Manufacture

Natural Rubber Sheets – Excellent elasticity and resistance to wear.

Nitrile Rubber Sheets – Ideal for oil and fuel resistance.

EPDM Rubber Sheets – Great for weather and ozone resistance.

Silicone Rubber Sheets – Heat-resistant and food-grade applications.

Neoprene Rubber Sheets – Versatile and resistant to chemicals and aging.

Viton Rubber Sheets – Suitable for extreme temperatures and harsh environments.

Applications of Our Rubber Sheets

Being a reputed Rubber Sheet Manufacturer in India, our products are widely used in:

Automobile Industry – Sealing, gaskets, and vibration control.

Construction & Infrastructure – Flooring, insulation, and roofing.

Oil & Gas Industry – Fuel-resistant applications.

Electrical & Electronics – Insulation and anti-static uses.

Marine & Aerospace – High-performance sealing and protection.

Quality Assurance & Manufacturing Excellence

At GB Gummi, quality is our priority. We use state-of-the-art machinery and rigorous testing to ensure that each rubber sheet meets the highest standards. Our manufacturing unit follows strict quality control protocols to deliver reliable rubber sheets to our clients.

Why GB Gummi is the Best Rubber Sheet Manufacturer in India?

Experience & Expertise – Years of industry knowledge.

Wide Range of Products – Rubber sheets for every application.

Customization & Bulk Orders – Tailored solutions for all needs.

Timely Delivery – Fast and efficient supply chain management.

Contact GB Gummi – Your Reliable Rubber Sheet Manufacturer in India

Looking for high-quality rubber sheets? GB Gummi is your trusted partner. We supply top-grade rubber sheets across India and internationally. Contact us today for the best rubber sheet solutions.

0 notes

Text

Experience the Power of Dry Ice with Dryice Abudhabi – The Leading Dry Ice Supplier & Manufacturer in Abu Dhabi, UAE!

When it comes to high-quality Dryice for various applications, Dryice Abudhabi is your trusted partner. We are the leading Dryice manufacturer in Abudhabi and Dryice supplier in Abudhabi, delivering top-grade dry ice solutions for industrial, commercial, and creative needs.

Why Choose Dry Ice? Discover Its Incredible Benefits!

❄ Superior Cooling Capabilities

Dry ice is much colder than regular ice (-78.5°C) and provides long-lasting cooling without leaving behind any water residue. This makes it perfect for food preservation, medical storage, and transportation.

♻ Eco-Friendly & Residue-Free

Unlike traditional cooling agents, dry ice sublimates into gas, leaving no waste behind. It is environmentally friendly and eliminates the need for chemical coolants.

⚙ Industrial Cleaning – Powerful & Non-Damaging

Dry ice blasting is a revolutionary cleaning method used in industries like automotive, aerospace, and manufacturing. It removes dirt, grease, and contaminants without damaging surfaces, making it an efficient and cost-effective cleaning solution.

🍽 Food & Beverage Industry – Perfect for Preservation

Dry ice helps restaurants, catering businesses, and food suppliers keep perishable items fresh during transport. It is also widely used for special effects in food presentations and cocktails.

🏥 Medical & Pharmaceutical Industry – Ensuring Safe Storage

Hospitals, laboratories, and pharmaceutical companies rely on dry ice for the safe storage and transport of vaccines, medical samples, and sensitive medications.

🎭 Events & Entertainment – Creating Magical Effects

Dry ice is an essential element in stage performances, concerts, weddings, and parties. It creates dramatic fog effects, adding a touch of mystery and elegance to any event.

🚛 Logistics & Transportation – Keeping Shipments Cold

For industries that require frozen shipments, dry ice ensures that temperature-sensitive goods remain fresh, whether it’s seafood, dairy products, or biological samples.

🐜 Pest Control – A Safe & Natural Solution

Dry ice is an effective pest control solution, eliminating bed bugs, insects, and rodents by freezing them without harmful chemicals.

Why Dryice Abudhabi? The Leading Dry Ice Supplier in UAE!

At Dryice Abudhabi, we pride ourselves on being the most trusted Dryice supplier in Abudhabi and Dryice manufacturer in Abudhabi. Here’s why customers choose us:

✅ High-Quality Dry Ice: Our dry ice is manufactured using advanced technology to ensure purity and performance. ✅ Reliable Supply Chain: We guarantee timely delivery to meet your business needs. ✅ Eco-Friendly Solutions: Committed to sustainable and chemical-free cooling. ✅ Affordable Pricing: Premium quality at competitive prices. ✅ Expert Support: Our team provides guidance on the best dry ice applications for your industry.

Order Dry Ice Today!

Looking for the best Dryice supplier in Abudhabi? Contact us now for premium dry ice solutions tailored to your needs!

📞 Call/WhatsApp for Orders: +971553635753 🌍 Visit Us: https://dryiceabudhabi.com/

0 notes

Text

Maximizing Efficiency: The Role Of Advanced Aog Solutions In Aerospace And Beyond

In the fast-paced world of aerospace, where every second counts, AOG (Aircraft on Ground) situations can significantly disrupt operations. The power to swiftly and effectively address these issues is crucial not only for minimizing downtime but also for ensuring the safety and reliability of aircraft. This is where advanced AOG solutions come into play, providing the tools and resources necessary to get aircraft back in the air with minimal delay. Companies like PTX Defense, an ISO-certified defense manufacturer, are at the forefront of delivering these essential solutions, ensuring that the aerospace industry remains operationally efficient and safe.

Understanding AOG: What It Means and Why It Matters

AOG refers to situations where an aircraft is grounded due to technical issues, requiring immediate attention to avoid delays and operational losses. This can be a nightmare for airlines, as the cost of an aircraft sitting idle on the tarmac can escalate rapidly. Beyond the immediate financial impact, AOG situations can disrupt schedules, inconvenience passengers, and potentially damage the reputation of the airline. Therefore, addressing AOG scenarios swiftly is not just a matter of financial prudence; it's also about maintaining customer trust and ensuring the safety of air travel.

Key Components of Advanced AOG Solutions

Advanced AOG solutions are built on several key components that work together to ensure efficiency and reliability. These include:

Predictive Maintenance: Applying data analytics and machine learning, predictive maintenance allows operators to identify potential issues before they lead to an AOG situation. This proactive ability reduces the likelihood of unexpected failures, keeping aircraft in the air and out of the repair hangar.

Real-Time Communication: In an AOG scenario, communication is key. Advanced solutions facilitate real-time communication between all parties involved, including manufacturers, suppliers, and maintenance teams. This ensures that everyone is on the same page, enabling faster decision-making and resolution.

Comprehensive Inventory Management: Having the right parts available when needed is critical in resolving AOG situations quickly. Advanced inventory management systems track and manage spare parts efficiently, ensuring that they are readily available whenever an issue arises.

Skilled Personnel: Even with the best tools and technologies, skilled technicians are essential for executing AOG solutions effectively. Continuous training and certification programs ensure that the personnel involved are equipped to handle the complexities of modern aircraft maintenance.

How AOG Solutions Drive Operational Efficiency in Aerospace

The impact of advanced AOG solutions on operational efficiency in aerospace cannot be overstated. By minimizing downtime, these solutions help airlines maintain their schedules, reduce costs, and enhance overall productivity. Moreover, the proactive nature of modern AOG solutions contributes to better resource allocation, as issues can be addressed before they escalate into costly problems. This not only improves the efficiency of individual airlines but also has a positive ripple effect across the entire aerospace industry.

Choosing the Right AOG Partner for Maximum Efficiency

Selecting the right partner is crucial for maximizing the efficiency of AOG solutions. Companies like PTX Defense stand out in this regard, offering a comprehensive suite of services built to enhance commercial capabilities through design and distribution. PTX Defense combines design expertise with a robust manufacturing network to deliver top-notch technology and component solutions. Their partnerships with leading manufacturers enable them to provide a diverse range of high-quality products, catering to businesses of all sizes, from startups to large corporations.

In addition, PTX Defense excels in supply chain management with integrated manufacturing capabilities, ensuring that critical parts and technologies are delivered on time, significantly reducing downtime. Their rapid response and meticulous inspection processes are crucial to getting aircraft back in operation quickly. With an extensive inventory and cutting-edge logistics, PTX Defense ensures that the exact parts required are provided with exceptional speed and accuracy. Their dedicated support team, available 24/7, offers expert guidance and personalized assistance, making them a trusted partner in delivering advanced AOG solutions.

Conclusion

Advanced AOG solutions are indispensable in today's aerospace industry, playing a critical role in maintaining operational efficiency and safety. By choosing the right AOG partner, such as PTX Defense, airlines and aerospace companies can ensure that they are well-equipped to handle any AOG situation swiftly and effectively, minimizing downtime and maximizing productivity. The integration of proactive strategies, real-time communication, and a robust aerospace supply chain partner is essential for staying ahead in this highly competitive industry.

0 notes

Text

Find the Best SS Rods and Fasteners in Ernakulam – Marthilo Tradex

Introduction

Stainless steel (SS) products are widely used in various industries due to their durability, corrosion resistance, and versatility. Whether for construction, manufacturing, or infrastructure projects, stainless steel perforated sheets, rods, and fasteners play a crucial role. If you are in Ernakulam and looking for a reliable dealer, Marthilo Tradex India Pvt Ltd is your trusted partner for high-quality stainless steel products.

About Marthilo Tradex India Pvt Ltd

Marthilo Tradex India Pvt Ltd is a well-established supplier and dealer of stainless steel products in India. With years of expertise in the industry, they offer a diverse range of stainless steel items, including perforated sheets, rods, and fasteners, catering to various industries and applications. Their commitment to quality and customer satisfaction makes them a preferred choice in Ernakulam and beyond.

Stainless Steel Perforated Sheets in Ernakulam

What Are Stainless Steel Perforated Sheets?

s s perforated sheet dealer in ernakulam are metal sheets that feature a pattern of holes, slots, or decorative shapes punched into them. These sheets are widely used in industries such as construction, automotive, filtration, and architecture due to their strength, durability, and aesthetic appeal.

Applications of SS Perforated Sheets

Architectural Design – Used for facades, ceilings, and interior designs.

Filtration Systems – Common in oil and gas, food processing, and chemical industries.

Acoustic Panels – Helps in noise reduction and soundproofing.

HVAC Systems – Used in ventilation and air conditioning systems.

Security & Safety – Used in fences, barriers, and security enclosures.

Why Choose Marthilo Tradex for SS Perforated Sheets?

High-quality stainless steel materials ensuring durability and resistance to corrosion.

Customization options available for different hole sizes and patterns.

Competitive pricing with bulk order discounts.

On-time delivery in Ernakulam and nearby areas.

Stainless Steel Rods in Ernakulam

What Are Stainless Steel Rods?

s s rod dealer in ernakulam, also known as SS bars, are solid cylindrical metal pieces available in different diameters and grades. They are widely used in construction, manufacturing, and engineering applications.

Applications of SS Rods

Construction Industry – Used in beams, columns, and reinforcement structures.

Manufacturing – Essential for machining parts, automotive components, and tools.

Medical Equipment – Used in surgical instruments and implants.

Marine Industry – Resistant to rust and saltwater corrosion.

Furniture & Handrails – Ideal for making durable and sleek designs.

Why Buy SS Rods from Marthilo Tradex?

Wide range of grades available, including 304, 316, and 410.

Precision-cut rods as per customer specifications.

Superior strength and finish, ensuring longevity and durability.

Reliable supply chain ensuring timely availability.

Stainless Steel Fasteners in Ernakulam

What Are Stainless Steel Fasteners?

s s fastener dealer in ernakulam include bolts, nuts, screws, washers, and rivets, used to join two or more components together. These fasteners are highly corrosion-resistant and durable, making them suitable for harsh environments.

Applications of SS Fasteners

Construction & Infrastructure – Used in bridges, buildings, and highways.

Aerospace & Automotive – Essential for assembling parts and components.

Food & Beverage Industry – Prevents contamination due to non-reactive properties.

Marine & Offshore – Resistant to saltwater and extreme conditions.

Electronics & Electrical – Used in power distribution panels and enclosures.

Why Choose Marthilo Tradex for SS Fasteners?

Extensive inventory of various fastener types and sizes.

High-strength and corrosion-resistant materials.

Customization options for specialized applications.

Bulk supply availability for large-scale projects.

Why Choose Marthilo Tradex India Pvt Ltd in Ernakulam?

1. Unmatched Product Quality

Marthilo Tradex ensures that all their stainless steel products meet international standards, providing durability, precision, and reliability.

2. Comprehensive Product Range

From perforated sheets to rods and fasteners, they offer a diverse selection to meet the needs of various industries.

3. Competitive Pricing

Their direct sourcing and bulk trading enable them to offer competitive prices without compromising on quality.

4. Timely Delivery

With a strong supply chain and distribution network, they ensure prompt delivery to clients in Ernakulam and surrounding areas.

5. Excellent Customer Support

Their experienced team provides expert guidance on choosing the right stainless steel products for your specific requirements.

Contact Marthilo Tradex India Pvt Ltd

If you are looking for premium stainless steel products in Ernakulam, contact Marthilo Tradex India Pvt Ltd today.

Phone: ++91-6282664465 Email: [email protected] Website: www.marthilo.com

Conclusion

When it comes to high-quality stainless steel perforated sheets, rods, and fasteners in Ernakulam, Marthilo Tradex India Pvt Ltd is your trusted dealer. Their commitment to quality, customer satisfaction, and timely delivery makes them the preferred choice for businesses and industries. Whether you need SS sheets for architectural purposes, rods for structural applications, or fasteners for industrial use, Marthilo Tradex has you covered. Contact them today to get the best stainless steel solutions in Ernakulam!

#s s perforated sheet dealer in ernakulam#s s rod dealer in ernakulam#s s fastener dealer in ernakulam#s s weld mesh dealer in ernakulam#s s sheet dealer in ernakulam kerala

0 notes

Text

Showcasing Accromet's Excellence: Supplying High-Quality 330 Stainless Steel Sheets

When it comes to sourcing premium-grade stainless steel sheets, Accromet has earned a reputation as a trusted supplier. With years of expertise and a commitment to excellence, we proudly provide 330 stainless steel sheets to meet the demands of diverse industries. Known for their exceptional properties, including heat resistance, industrial-grade strength, and corrosion resistance, our stainless steel sheets are designed to perform under the most challenging conditions. Here’s why Accromet is your go-to supplier for high-temperature stainless steel solutions.

Why Choose Accromet for 330 Stainless Steel Sheets?

1. Expertise in Material Quality

At Accromet, quality is our top priority. Our heat-resistant stainless steel sheets are manufactured to meet stringent industry standards, ensuring they perform reliably in high-temperature environments. Whether your application involves furnaces, heat exchangers, or chemical processing, our industrial-grade stainless steel sheets deliver unmatched durability.

2. Wide Range of Applications

We understand the unique requirements of various industries. Our 330 stainless steel sheets are widely used in applications such as:

Aerospace components

Chemical processing equipment

Industrial heating systems

Furnace parts

These sheets offer excellent resistance to scaling and oxidation, making them a top choice for demanding projects.

3. Focus on Customer Satisfaction

What sets Accromet apart is our unwavering dedication to customer satisfaction. We work closely with our clients to understand their specific needs, offering tailored solutions and technical support. Our knowledgeable team is always ready to guide you in selecting the right corrosion-resistant stainless steel for your project.

4. On-Time Delivery and Reliability

With an efficient supply chain and a commitment to timely deliveries, we ensure that you receive your orders without delay. At Accromet, we value your time and strive to build long-term partnerships through reliability and trust.

Frequently Asked Questions (FAQs)

Q1: What makes 330 stainless steel sheets ideal for high-temperature applications?

A: The unique composition of 330 stainless steel sheets provides excellent resistance to oxidation and scaling at elevated temperatures, making them suitable for use in furnaces, heat exchangers, and other high-heat environments.

Q2: Are Accromet’s stainless steel sheets customizable?

A: Yes, we offer customization options for thickness, dimensions, and finishes to meet your specific requirements.

Q3: How do I ensure I’m selecting the right stainless steel sheet for my project?

A: Our team of experts is here to assist you. We’ll help you evaluate your application’s demands and recommend the best industrial-grade stainless steel sheets for your needs.

Q4: Can you provide large quantities of 330 stainless steel sheets?

A: Absolutely. We are equipped to handle bulk orders while maintaining consistent quality and on-time delivery.

Call to Action

Ready to elevate your projects with Accromet’s 330 stainless steel sheets? Contact us today to learn more about our products and services. Whether you need heat-resistant stainless steel sheets for industrial use or corrosion-resistant stainless steel for specialized applications, we have you covered. Let’s work together to achieve your goals!

At Accromet, we don’t just supply materials – we provide solutions. Partner with us and experience the difference of working with a team that values quality, expertise, and customer satisfaction above all else.

#330 stainless steel sheets#Heat-resistant stainless steel sheets#Industrial-grade stainless steel sheets#High-temperature stainless steel

0 notes

Text

Industry Insights: Where We Supply Tool Steel - Virat Special Steels

Virat Special Steels stands tall as India’s largest stockiest, importer, and supplier of HSS Steel, Hot Work Steel, Cold Work Steel & Plastic Mould Steel. Representing top manufacturers of special steels worldwide, we enjoy global recognition for our unwavering commitment to quality.

Serving Industries:

🔧 Forging Industry: Shaping metal using compressive forces with a hammer or press, classified into cold forging, warm forging, or hot forging.

🏗️ Pressure Die Casting: Forcing molten metal under high pressure into a mold cavity, made using two hardened tool steel dies.

🚗 Aluminum Extrusions: Material pushed through a die to the desired cross-section, creating complex parts with excellent surface finishes.

🚙 Automotive Industry: Involved in manufacturing, design, and development of motor vehicles.

⛽ Oil & Gas Industry: Supplying more than 60% of our nation’s energy, including natural gas for electricity.

🧩 Plastic Industry: Manufacturing polymer materials for aerospace, construction, electronics, packaging, and transportation.

🍶 Glass Industry: Involves float glass process and glassblowing, producing sheet glass and containers.

🚲 Cycle Parts: Manufacturing components like bearings, chains, chain sets & cranks, handlebars, forks.

🚉 Railways: Manufacturing railway components such as gear holders, bogie cast parts, axles, pins, ground lever frames, adjustable cranks, compressor pistons, and bearings.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is your trusted partner, supplying premium tool steels to diverse industries in India and globally.

Learn more: Virat Steels Serving Industries: https://www.viratsteels.com/serving-industries.php

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📩[email protected] 📲+91-98140-21775

#ludhiana#viratsteels#india#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#iso9001#toolsteels#steelindustries#forging#diecasting#aluminumextrusions#automotive#oilandgas#plasticindustry#glassindustry#cycleparts#railways#DB6Steel#H13Steel#H11Steel

2 notes

·

View notes

Text

Aimtron: Your Guide to PCB Assembly Manufacturing Excellence in Illinois

Printed Circuit Boards (PCBs) form the backbone of modern electronic devices. From smartphones to medical equipment, these intricate pieces of technology ensure the smooth operation of countless systems. For businesses in Illinois and beyond, finding a reliable partner for PCB Assembly Manufacturing is paramount. Enter Aimtron Corporation — a name synonymous with precision, innovation, and excellence in PCB Assembly and Electronics Manufacturing.

Why PCB Assembly Matters

PCB Assembly is critical to the functionality of any electronic device. It involves the precise placement and soldering of components onto the PCB, ensuring optimal performance and reliability. High-quality PCB Assembly Services guarantee efficiency, durability, and safety in devices, making their production a cornerstone of the electronics supply chain.

Aimtron: A Legacy of Excellence

Based in Illinois, Aimtron Corporation has carved a niche as a leader in PCB Assembly Manufacturing and Electronics Manufacturing Services. With years of experience and a commitment to staying at the forefront of technological advancements, Aimtron delivers unparalleled service to its clients.

What Sets Aimtron Apart?

State-of-the-Art Facilities Aimtron’s facilities are equipped with cutting-edge technology to ensure precision and efficiency in PCB Assembly. The company leverages advanced machinery for surface-mount technology (SMT), through-hole technology, and Turnkey PCB assembly.

End-to-End Solutions Aimtron Corporation offers a comprehensive range of services, including PCB Design, prototyping, mass production, and rigorous testing. This end-to-end approach ensures seamless integration at every stage of the product lifecycle.

Commitment to Quality Quality is at the core of Aimtron’s operations. With certifications like ISO 9001, ISO 13485 (for medical devices), and AS9100 (for aerospace), Aimtron Corporation meets and exceeds industry standards, providing clients with reliable and durable PCB Assembly Services.

Customized Services No two projects are the same, and Aimtron understands this. The company works closely with clients to tailor solutions that meet their specific needs, whether it’s a small batch of prototypes or high-volume production.

Sustainability Focus Aimtron Corporation is committed to environmentally responsible practices. From energy-efficient processes to recycling initiatives, the company prioritizes sustainability in its operations.

Serving Diverse Industries

Aimtron Corporation’s expertise spans a wide range of industries, including:

Consumer Electronics: Producing reliable PCB Assemblies for devices that power our daily lives.

Medical Devices: Ensuring precision and safety in life-saving equipment.

Aerospace and Defense: Delivering robust solutions for high-stakes applications.

Automotive: Supporting the growing demand for advanced electronics in vehicles.

Why Choose Aimtron ?

For businesses seeking a trusted partner for PCB Assembly Manufacturing in Illinois, Aimtron offers:

Expertise: A team of seasoned professionals with a deep understanding of PCB Design and Electronics Manufacturing.

Flexibility: Scalable solutions to meet diverse project requirements.

Timely Delivery: Efficient processes to ensure projects stay on schedule.

Cost-Effectiveness: Competitive pricing without compromising on quality.

Partner with Aimtron Today

Aimtron Corporation isn’t just a manufacturer; it’s a partner in innovation. By choosing Aimtron, you gain access to a wealth of expertise, cutting-edge technology, and a commitment to excellence that ensures your products are built to thrive in today’s competitive market.

Ready to elevate your PCB Assembly Manufacturing? Contact Aimtron Corporation today and experience the difference that quality, precision, and dedication can make.

0 notes

Text

Hiwin Linear Bearing Distributors: Precision Motion Solutions by Jai Krishna Bearing House

In the realm of motion control systems, Hiwin linear bearings have set a benchmark for reliability, precision, and durability. These bearings are indispensable in various industries, enabling smooth, accurate, and efficient linear motion.

If you’re searching for reliable Hiwin linear bearing distributors, Jai Krishna Bearing House is your trusted partner. As an authorized distributor of Hiwin products, we cater to industries worldwide, delivering genuine and high-quality solutions tailored to your unique needs.

Why Hiwin Linear Bearings?

Hiwin linear bearings are engineered for precision-driven applications, offering superior performance in environments where accuracy and reliability are paramount. These components minimize friction, enhance load capacity, and ensure smooth linear motion, making them ideal for diverse industrial applications.

Features of Hiwin Linear Bearings

High Precision Hiwin linear bearings deliver exceptional accuracy, ensuring precise and repeatable linear motion for critical operations.

Durable Construction Made from premium materials, these bearings are designed to withstand high loads, wear, and challenging environmental conditions.

Low Friction Design The innovative design minimizes friction, resulting in quieter operations, reduced maintenance, and extended product life.

Versatility Hiwin linear bearings are available in various configurations, making them suitable for a wide range of applications.

Corrosion Resistance Many Hiwin linear bearings are treated to resist corrosion, ensuring durability in humid or harsh environments.

Applications of Hiwin Linear Bearings

Hiwin linear bearings find applications in various industries, including:

Industrial Automation: Conveyor belts, robotic systems, and pick-and-place machinery.

CNC Machinery: Precision machining tools for cutting, engraving, and milling.

Medical Technology: Diagnostic equipment, surgical tools, and rehabilitation systems.

Aerospace and Automotive: Testing equipment, assembly systems, and specialized machinery.

Semiconductor Manufacturing: High-precision positioning systems for chip production.

Jai Krishna Bearing House: Trusted Hiwin Linear Bearing Distributors

As a leading Industrial Hiwin Bearing Dealers in Delhi, Jai Krishna Bearing House has built a reputation for excellence, authenticity, and customer-centric service. Here’s why businesses trust us:

1. Authorized Distributor

We are an authorized Hiwin Distributor, ensuring that every product we deliver is 100% genuine and meets international quality standards.

2. Global Presence

With a vast client base spanning Italy, Bulgaria, Romania, Ukraine, Austria, Nigeria, the Indian Subcontinent, Australia/New Zealand, East Europe, the Middle East, and Southeast Asia, our network is a testament to our reliability.

3. Extensive Inventory

Our spacious warehouse allows us to maintain a robust inventory of Hiwin linear bearings, ensuring prompt delivery for all orders.

4. Expert Support

Our experienced team provides technical assistance, helping clients select the right Hiwin linear Bearings for their specific needs.

5. Competitive Pricing

We offer premium Hiwin products at competitive rates, making us a cost-effective partner for businesses of all sizes.

Why Choose Hiwin Linear Bearings from Jai Krishna Bearing House?

Hiwin linear bearings are renowned for their ability to enhance operational efficiency and reliability. At Jai Krishna Bearing House, we ensure that these high-quality components are accessible to businesses worldwide, backed by unparalleled service and support.

Benefits of Partnering with Jai Krishna Bearing House

Authenticity Guaranteed: Receive genuine Hiwin linear bearings with full manufacturer support.

Technical Expertise: Get expert guidance on product selection and application.

Reliable Supply Chain: Enjoy timely deliveries and consistent availability.

Customer-Centric Approach: Experience transparent business practices and long-term support.

Conclusion

Hiwin linear bearings are essential for industries requiring precision and efficiency in linear motion systems. As one of the leading Hiwin linear bearing distributors, Jai Krishna Bearing House is dedicated to providing authentic products and exceptional service to clients across the globe.

Whether you’re in automation, medical technology, or manufacturing, we have the expertise and inventory to meet your requirements. Contact Jai Krishna Bearing House today to explore our range of Hiwin linear bearings and discover how we can help you achieve precision and success in your industrial applications.

#hiwin linear bearing distributors#hiwin linear bearings#hiwin linear guide distributors#hiwin linear guideways

0 notes

Text

The Unsung Hero: Unpacking the Value of NSN 5960-00-023-8965

In the intricate world of supply chains and logistics, precision and standardization are key. Enter the National Stock Number (NSN), a system that ensures globally recognized identification for components and materials. Among these, NSN 5960-00-023-8965 plays a crucial role, particularly in the realm of electronics and optical devices. This unique identifier simplifies procurement, guarantees compatibility, and fuels efficiency across diverse industries.

Decoding NSN 5960-00-023-8965

NSN 5960-00-023-8965 is a distinctive identifier assigned to specific high-performance electronic and optical components. These components are pivotal in maintaining accuracy, reliability, and functionality in critical systems. Governed by stringent classification standards, this NSN ensures compatibility across global applications, making it an indispensable asset for industries requiring precision engineering.

Diverse Applications Across Industries

The versatility of NSN 5960-00-023-8965 is evident in its widespread adoption across sectors that demand consistent performance and reliability. Key industries leveraging this NSN include:

Aerospace and Defense: Essential in crafting secure communication systems and navigation solutions critical for operational success.

Telecommunications: Foundational in building robust network infrastructures that enable seamless data exchange and connectivity.

Industrial Automation: Integral to ensuring precision in optical inspection systems and automated manufacturing processes.

Medical Equipment: Enhances the performance of diagnostic imaging tools and advanced healthcare devices.

This wide-ranging applicability makes NSN 5960-00-023-8965 a cornerstone in driving technological innovation and operational efficiency.

Standardized Components: Why They Matter

The value of NSN 5960-00-023-8965 transcends its immediate functionality. Standardization under this NSN ensures that components meet uniform specifications, regardless of the supplier or manufacturer. This minimizes discrepancies, enhances compatibility, and streamlines inventory management. Organizations benefit from reduced downtime, seamless integration, and enhanced reliability—hallmarks of an optimized supply chain.

ChipsOnSale.com: Your Partner in Precision

Sourcing high-quality components like NSN 5960-00-023-8965 can be a daunting task, especially for industries with tight timelines and demanding standards. ChipsOnSale.com has emerged as a trusted name in simplifying this process.

Why Rely on ChipsOnSale.com?

Extensive Inventory: A vast catalog ensures availability of both commonly used and rare NSNs, including 5960-00-023-8965.

Verified Quality: Every component undergoes rigorous testing and quality checks to meet industry standards.

Global Delivery Network: Efficient logistics systems facilitate timely delivery, no matter where your operations are based.

With ChipsOnSale.com, industries gain a reliable partner capable of addressing their sourcing challenges while upholding quality and efficiency.

NSN 5960-00-023-8965: A Key to Progress

In a world where precision drives innovation, NSN 5960-00-023-8965 stands as a beacon of reliability and standardization. Its role in fostering seamless operations and technological advancements spans across aerospace, telecommunications, healthcare, and beyond.

When coupled with the expertise and service excellence of ChipsOnSale.com, industries gain access to not just components but a pathway to innovation and growth. By leveraging the power of NSN 5960-00-023-8965, organizations are better equipped to navigate the challenges of tomorrow with confidence and precision.

0 notes