#ASTM Standards

Explore tagged Tumblr posts

Text

Tension testing of some dogbone specimens!

#material science#mechanical engineering#engineering#tension testing#instron#dogbone samples#ASTM standards#grad school

13 notes

·

View notes

Text

How ASTM Standards Support Reliable Water Quality Testing in Laboratories?

Water quality testing is a critical aspect of environmental monitoring, public health, and industrial operations. From ensuring the safety of drinking water to assessing the environmental impact of wastewater, laboratories rely on standardized methods to ensure their test results are reliable, accurate, and reproducible. One of the most respected and widely adopted frameworks for conducting water quality testing is the ASTM Standards Testing system.

ASTM International (formerly known as the American Society for Testing and Materials) is a globally recognized organization that develops and publishes standards for a wide range of testing methods. These standards are designed to ensure consistency and reliability in laboratory testing procedures, including water quality testing. By adhering to ASTM standards, laboratories can confidently assess water quality, ensuring that their results meet regulatory requirements and support public health and environmental protection.

In this blog, we will explore how ASTM standards help laboratories perform reliable water quality testing, ensuring that the water we consume and interact with is safe, clean, and compliant with regulatory standards.

Understanding ASTM Standards for Water Quality Testing

ASTM Standards Testing includes a vast array of guidelines and methods specifically designed for different types of water quality analysis. These standards provide clear, precise protocols for laboratories to follow when testing various parameters of water quality, such as chemical composition, microbial content, physical properties, and pollutants.

The key objective of ASTM standards is to establish consistent and scientifically validated procedures to minimize errors and ensure reproducibility across laboratories worldwide. This consistency is vital for ensuring that water quality test results are trusted by regulators, industries, and the general public.

Some important areas covered by ASTM standards in water quality testing include:

Chemical testing (e.g., pH, alkalinity, heavy metals)

Microbiological testing (e.g., testing for E. coli and coliform bacteria)

Physical properties testing (e.g., turbidity, temperature)

Toxicity testing (e.g., for industrial and wastewater discharges)

Pollutants and contaminants testing (e.g., pesticides, herbicides, and other chemicals)

Each test is accompanied by a detailed procedure that laboratories must follow to ensure the accuracy and consistency of their results. The guidelines set by ASTM are not just theoretical but have been developed and refined through years of industry collaboration, scientific research, and practical application.

Key ASTM Standards for Water Quality Testing

Several ASTM standards are integral to water quality testing in laboratories. Below are some of the key ASTM standards that laboratories use to assess the quality of water:

1. ASTM D3370 – Standard Practice for Sampling Water

Water sampling is the first step in any water quality testing process. ASTM D3370 outlines the methods for collecting representative water samples, ensuring that the sample is true to the overall water body or system being tested. The standard provides detailed instructions on how to avoid contamination during sampling and how to store samples to maintain their integrity before testing. Proper sampling is crucial, as it directly influences the accuracy of the test results.

2. ASTM D1933 – Standard Test Method for Determination of the Phosphorus in Water by the Molybdenum Blue Method

Phosphorus is a critical nutrient in water bodies and can lead to harmful algae blooms and other environmental issues when present in excess. ASTM D1933 specifies the method for measuring phosphorus levels in water using the molybdenum blue method. This is important for water quality monitoring, especially in agricultural and industrial settings where phosphorus run-off can affect surrounding water bodies.

3. ASTM E1153 – Standard Test Method for Measurement of the Toxicity of Water Samples Using Daphnia magna

Toxicity testing is an essential part of water quality testing, particularly in the monitoring of effluent or wastewater discharge. ASTM E1153 outlines the method for measuring the toxicity of water samples using Daphnia magna, a species of water flea. This test helps to assess the impact of water pollution on aquatic life, supporting environmental protection efforts.

4. ASTM D888 – Standard Test Method for pH of Water

pH is one of the most fundamental chemical properties of water. Water with a pH outside the acceptable range can be corrosive or harmful to aquatic life and human health. ASTM D888 provides guidelines for determining the pH level of water using precise measurement techniques. This standard is essential for laboratories to monitor water systems in both natural and industrial settings.

5. ASTM D5504 – Standard Test Method for Measurement of the Concentration of Volatile Organic Compounds (VOCs) in Water by Purge and Trap Gas Chromatography

Volatile organic compounds (VOCs) are hazardous substances that can pollute water sources. ASTM D5504 provides a reliable method for measuring VOC concentrations in water using gas chromatography. This test is vital for identifying and quantifying chemicals that could pose a risk to both human health and the environment.

How ASTM Standards Ensure Reliable Water Quality Testing

Reliable water quality testing requires standardized methods, rigorous processes, and proper equipment. ASTM standards ensure that water testing is not only accurate but also consistent and reproducible across different laboratories and regions. Here’s how these standards contribute to reliable water quality testing:

1. Uniformity in Testing Procedures

ASTM standards ensure uniformity in testing procedures, which is crucial for obtaining consistent and comparable results. Whether a laboratory is located in the United States, the UAE, or Europe, following ASTM guidelines ensures that the same methods and protocols are used, enabling cross-border comparison of water quality data. This is particularly important in industries like manufacturing, agriculture, and public health, where accurate and consistent data is essential for decision-making.

2. Quality Control

Compliance with ASTM standards helps laboratories maintain high standards of quality control. The guidelines establish proper calibration methods, handling and storage procedures for samples, and equipment maintenance, all of which ensure the reliability of test results. Laboratories that adhere to ASTM standards are less likely to produce erroneous results, reducing the need for costly retesting and ensuring that the public and industries can rely on their findings.

3. Regulatory Compliance

In many jurisdictions, water quality testing is regulated by local or international authorities. For example, in the United States, the Environmental Protection Agency (EPA) mandates specific water quality testing standards. ASTM standards are often incorporated into these regulations, ensuring that laboratories comply with legal requirements. By following ASTM guidelines, laboratories can demonstrate that they are meeting regulatory standards, avoiding legal issues and helping their clients comply with environmental laws.

4. Accuracy in Results

ASTM standards are scientifically validated, meaning they are based on the most accurate and reliable methods available. Using these proven techniques ensures that the water quality testing results are precise, which is critical for decision-making in sectors like public health, industrial manufacturing, and environmental monitoring. Accurate test results help protect public health by ensuring that drinking water, recreational waters, and wastewater are safe and do not pose any harmful risks to humans or wildlife.

5. Reproducibility and Comparability

ASTM standards ensure that water testing procedures are reproducible. This means that when a water sample is tested in different laboratories or at different times, the results should be consistent. Reproducibility is particularly important in scientific research and regulatory monitoring, where trends in water quality need to be tracked over time. With ASTM standards, laboratories can ensure that their data is comparable and trustworthy, which supports transparency in environmental reporting.

Conclusion: The Value of ASTM Standards for Water Quality Testing

ASTM standards play an essential role in ensuring reliable, accurate, and reproducible water quality testing. By providing laboratories with scientifically validated methods for testing a wide range of water quality parameters, ASTM guidelines support the safety and integrity of water supplies, protect public health, and contribute to environmental sustainability.

Adhering to ASTM standards helps laboratories maintain regulatory compliance, meet industry requirements, and offer consistent, high-quality testing services. Whether testing for chemical contaminants, microbiological threats, or physical properties, ASTM standards ensure that laboratories can trust their results and that water quality testing contributes to a safer, cleaner environment for everyone.

0 notes

Text

ASTM Standards Testing | +971 554747210

0 notes

Text

Unlocking the Power of ASTM Standards in Testing Lab Protocols: A Comprehensive Guide

In the realm of testing laboratory protocols, adherence to standardized practices is paramount for ensuring accuracy, reliability, and consistency of results. The American Society for Testing and Materials (ASTM) plays a pivotal role in this domain by establishing guidelines and standards that govern testing lab protocols. This comprehensive guide aims to explore the profound impact of ASTM standards on testing lab protocols, covering their significance, key areas of application, benefits, challenges, successful case studies, and future prospects.

Key Areas of Testing Covered by ASTM Standards:

ASTM standards encompass a broad spectrum of testing disciplines, including mechanical, chemical, physical, and environmental testing. These standards provide detailed protocols for evaluating the properties, performance, and safety of various materials and products. Examples include ASTM D638 for tensile properties of plastics, ASTM E18 for rockwell hardness testing of metals, ASTM D4236 for labeling art materials for health hazards, and ASTM E1527 for environmental site assessments. By adhering to these standards, testing labs can ensure consistency, accuracy, and reliability in their testing procedures, thereby enhancing confidence in test results.

Benefits of Implementing ASTM Standards in Testing Lab Protocols:

Implementing ASTM standards in testing lab protocols offers numerous benefits to stakeholders across industries. Firstly, ASTM standards provide a universally recognized framework for quality assurance, ensuring consistency and comparability of test results across different laboratories and jurisdictions. This fosters transparency, reliability, and trust in test data, facilitating informed decision-making in product development, manufacturing, and regulatory compliance. Moreover, adherence to ASTM standards enhances market acceptance, credibility, and competitiveness of testing labs, thereby driving innovation and customer satisfaction.

Challenges and Solutions in Adopting ASTM Standards in Testing Labs:

While ASTM standards offer clear guidelines, their adoption in testing labs can pose challenges for organizations. One common challenge is the need for specialized equipment, trained personnel, and accredited facilities to perform tests in accordance with ASTM protocols. This may require investment in infrastructure, training, and quality management systems to ensure compliance with standard requirements. Additionally, maintaining consistency and accuracy in testing procedures can be challenging, especially when dealing with complex materials or unique testing conditions.

To address these challenges, testing labs can implement quality assurance measures, proficiency testing programs, and interlaboratory comparison studies to validate the reliability of their results. Collaboration with accredited third-party organizations, participation in ASTM technical committees, and ongoing education and training for staff are crucial for staying abreast of updates and revisions to ASTM standards. Leveraging digital technologies, automation, and data analytics can streamline testing procedures, improve efficiency, and facilitate continuous improvement in testing lab protocols.

Case Studies: Demonstrating Success with ASTM Standards in Testing Lab Protocols:

Numerous case studies illustrate the successful implementation of ASTM standards in testing lab protocols across industries. For instance, a materials testing lab implemented ASTM D638 standard procedures for testing the tensile properties of plastic specimens. By following ASTM guidelines for sample preparation, testing conditions, and data analysis, the lab ensured consistency and accuracy in test results, thereby enhancing customer satisfaction and confidence in their services. In another case, an environmental testing lab utilized ASTM E1527 standard methods for conducting Phase I environmental site assessments. By adhering to ASTM protocols for data collection, analysis, and reporting, the lab provided reliable and legally defensible assessments, thus assisting clients in regulatory compliance and risk management.

Future Outlook: Advancements in ASTM Standards for Testing Lab Protocols:

As technology advances and testing methodologies evolve, ASTM standards will continue to adapt to address emerging challenges and opportunities in testing lab protocols. Future advancements may include the development of new testing methodologies, performance criteria, and quality control measures for emerging technologies and materials. Additionally, updates to existing ASTM standards may be necessary to incorporate advances in instrumentation, digital technologies, and data analytics. By actively engaging with stakeholders from industry, academia, and government, the ASTM community can ensure that standards remain relevant, practical, and scientifically rigorous, thereby unlocking the power of ASTM standards in testing lab protocols for years to come.

Conclusion:

In conclusion, ASTM standards play a pivotal role in testing lab protocols, providing a standardized framework for ensuring accuracy, reliability, and consistency of test results. While challenges may exist in adopting ASTM standards, the benefits far outweigh the obstacles, as evidenced by successful case studies and ongoing advancements in the field. By adhering to ASTM standards, testing labs can enhance their credibility, competitiveness, and customer satisfaction, thus unlocking the power of ASTM standards in testing lab protocols. As we look to the future, continued collaboration, innovation, and commitment to ASTM standards will be essential to address emerging challenges and maximize the potential of testing lab protocols in a rapidly evolving landscape.

1 note

·

View note

Text

Differences Between ASTM, IS, and EN Standards for Mild Steel

In this blog we shared the difference between ASTM, IS and EN standards for mild steel with Key Differences to help you make an informed decision for your project. Laxmi Enterprise offer MS steel Vadodara in different grades that complies with industry standards. Contact us now!

#MS steel Vadodara#mild steel grades#mild steel standard#ASTM Standards for Mild Steel#IS Standards for Mild Steel#EN Standards for Mild Steel

0 notes

Text

Complete Guide to 20-Ton Tension Strength Test Devices

Meta Description Looking for a 20-ton tension strength test device? Explore key features, applications, and industry standards. Learn how to select the best machine for your needs and check tension strength test device price Introduction A 20-ton tension strength test device is essential for evaluating material tensile properties across industries, including metals, composites, and industrial…

#20 ton tensile testing machine#200 kN tensile testing machine#ASTM E8 tensile test#high-capacity tensile tester#industrial material testing#ISO 6892-1 tensile testing#material testing equipment#metal tensile testing machine#plastic tensile strength test#rubber tensile testing#tensile strength tester#tensile test standards#tension strength test device#tension strength test device price#universal testing machine

0 notes

Text

ASTM A325 Bolts Standard Manufacturer and Exporter India | BigBoltNut

High strength, heavy duty hexagonal construction screws with diameters from 1/2" to 1-1/2" are covered by the ASTM A325 standard. Because these bolts are intended for use in structural connections, the thread length is shorter than regular hexagonal bolts. For thread lengths and other relevant dimensions, please see the structural bolts page on our website. This specification applies only to strong hexagonal construction screws. Screws with comparable mechanical properties but different shapes and thread lengths are covered in specification Astm A449. Specification A449 covers screws for general purpose use, including anchor screws. For screws and bolts of tempered steel greater than 1-1/2 in. in diameter and with comparable mechanical properties. The F3125 specification is a consolidation and replacement of six ASTM standards, including; A325, A325M, A490, A490M, F1852, and F2280

Source Url: https://www.bigboltnut.com/product/astm-a325-standard.html

0 notes

Text

Revolutionizing Pipe Rehabilitation: Little P.Eng. Engineering's Mastery of CIPP Liner Design via Finite Element Method in Accordance with ASTM F1216

In the realm of civil engineering, the use of trenchless technologies for pipeline rehabilitation has gained significant traction due to their efficiency and minimal disruption to infrastructure. Among these methods, Cured-In-Place Pipe (CIPP) lining stands out as a versatile solution for renovating deteriorating pipelines. Little P.Eng. Engineering has embraced this innovation, revolutionizing pipe rehabilitation through its mastery of CIPP liner design. Leveraging the Finite Element Method (FEM) and adhering to the rigorous standards set forth by ASTM F1216, Little P.Eng. Engineering has propelled CIPP technology to new heights, ensuring optimal performance and longevity of rehabilitated pipelines.

Introduction: Traditional methods of pipeline repair and replacement often involve extensive excavation, leading to disruption of roads, landscapes, and utilities. In contrast, trenchless technologies such as CIPP offer a non-disruptive alternative, where a flexible liner is inserted into the existing pipe and cured in place, effectively creating a new pipe within the old one. Little P.Eng. Engineering has emerged as a pioneer in this field, employing advanced engineering techniques to enhance the efficacy of CIPP liner design.

Finite Element Method in CIPP Design: Central to Little P.Eng. Engineering's approach is the utilization of the Finite Element Method (FEM) in CIPP liner design. FEM allows for the accurate modeling and simulation of structural behavior under various loading conditions, enabling engineers to optimize the design for strength, flexibility, and durability. By simulating the interaction between the liner and the host pipe, potential issues such as wrinkling, ballooning, and stress concentrations can be identified and addressed prior to installation, ensuring a robust rehabilitation solution.

Adherence to ASTM F1216 Standards: In the realm of CIPP technology, adherence to industry standards is paramount to guaranteeing the quality and reliability of rehabilitated pipelines. ASTM F1216 provides comprehensive guidelines for the installation and testing of CIPP liners, covering aspects such as material properties, installation procedures, and quality control measures. Little P.Eng. Engineering's commitment to compliance with ASTM F1216 ensures that its CIPP designs meet the highest standards of performance and safety, instilling confidence in clients and regulatory bodies alike.

Benefits of Little P.Eng. Engineering's Approach: The fusion of FEM-based design and adherence to ASTM F1216 standards endows Little P.Eng. Engineering's CIPP solutions with several key benefits. These include:

Enhanced Structural Integrity: By meticulously analyzing the behavior of CIPP liners under various conditions, potential structural weaknesses are identified and mitigated, resulting in a more durable and long-lasting rehabilitation solution.

Minimized Environmental Impact: The trenchless nature of CIPP technology reduces the need for excavation, minimizing disruption to the surrounding environment and reducing carbon emissions associated with traditional repair methods.

Cost-Effectiveness: Through precise engineering and optimization, Little P.Eng. Engineering's CIPP designs minimize material usage and installation time, translating to cost savings for clients without compromising on quality or performance.

Regulatory Compliance: By strictly adhering to ASTM F1216 standards, Little P.Eng. Engineering ensures that its CIPP solutions meet regulatory requirements, facilitating smooth project approval and implementation.

Conclusion: Little P.Eng. Engineering's mastery of CIPP liner design through the application of Finite Element Method and adherence to ASTM F1216 standards represents a significant advancement in the field of pipeline rehabilitation. By combining innovative engineering techniques with a commitment to quality and compliance, Little P.Eng. Engineering is revolutionizing pipe rehabilitation, offering sustainable, cost-effective, and reliable solutions for the preservation of critical infrastructure.

Read More:

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

Pipeline Rehabilitation Engineering Design Services as per ASTM F1216 Using CIPP and PVC

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

Revolutionizing Pipe Rehabilitation: Little P.Eng. Engineering's Mastery of CIPP Liner Design via Finite Element Method in Accordance with ASTM F1216

Tags:

Little P.Eng. Engineering

ASTM F1216

Regulatory standards

Finite Element Method

Environmental impact

Cost-effectiveness

Longevity

Material properties

Infrastructure

Structural integrity

Structural analysis

Civil engineering

Infrastructure preservation

Project approval

Sustainable solutions

Non-disruptive

Quality control

Pipeline integrity

Stress simulation

Excavation reduction

Pipe rehabilitation

Compliance assurance

Carbon emissions

CIPP lining

Project implementation

Durability optimization

Pipeline renovation

Performance optimization

Engineering innovation

Trenchless technology

Engineering Services

Pipe Rehabilitation

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#ASTM F1216#Regulatory standards#Finite Element Method#Environmental impact#Cost-effectiveness#Longevity#Material properties#Infrastructure#Structural integrity#Structural analysis#Civil engineering#Infrastructure preservation#Project approval#Sustainable solutions#Non-disruptive#Quality control#Pipeline integrity#Stress simulation#Excavation reduction#Pipe rehabilitation#Compliance assurance#Carbon emissions#CIPP lining#Project implementation#Durability optimization#Pipeline renovation#Performance optimization#Engineering innovation#Trenchless technology

1 note

·

View note

Text

Why ASTM Standards are Critical for Quality Control in Manufacturing Laboratories?

In the world of manufacturing, maintaining high-quality standards is paramount to the success and reputation of a business. Whether producing consumer goods, automotive parts, or medical devices, manufacturers must ensure their products meet stringent quality and safety requirements. One of the most effective ways to achieve this is through ASTM Standards Testing.

ASTM International, a globally recognized standards development organization, has created a comprehensive suite of testing standards that help manufacturers ensure their products meet specific performance, safety, and quality benchmarks. These standards are widely adopted by testing laboratories across industries and serve as a foundation for quality control in manufacturing laboratories. This blog explores why ASTM standards are critical for quality control in manufacturing laboratories, helping businesses produce reliable, safe, and compliant products.

What Are ASTM Standards?

ASTM International, formerly known as the American Society for Testing and Materials, is one of the world’s leading organizations for the development of standards for materials, products, systems, and services. With over 12,000 standards covering various industries, including construction, automotive, aerospace, medical devices, and consumer products, ASTM standards provide a set of detailed guidelines and procedures for testing materials and products to ensure they meet the desired specifications.

These standards are created through a consensus process involving experts, manufacturers, regulators, and academics from around the world. ASTM standards cover everything from chemical composition, strength, and durability to environmental resistance and safety testing. For manufacturers, adopting ASTM standards testing is an essential step in verifying the quality, safety, and performance of their products.

1. Ensuring Consistency and Reliability

One of the primary reasons ASTM standards are critical for quality control in manufacturing laboratories is that they provide a consistent and standardized method for conducting tests. Testing labs that follow these established guidelines ensure that the results they provide are consistent, accurate, and reproducible.

Consistency in testing methods is especially important in manufacturing environments where products are being produced in large volumes. If quality control tests are not standardized, manufacturers may face significant risks, including inconsistent product performance, defects, or safety concerns.

For instance, the ASTM D638 standard for tensile testing of plastics provides a reliable way to measure a material's resistance to breaking under stress. By adhering to this standard, manufacturers can ensure that every batch of plastic components meets the same quality and performance criteria, no matter where they are produced.

2. Meeting Regulatory and Compliance Requirements

Manufacturers often operate in highly regulated industries where product safety, environmental impact, and performance must adhere to strict standards. Whether it's the FDA, EU regulations, or local health and safety regulations, ensuring compliance with these requirements is critical for legal approval, market access, and consumer safety.

ASTM standards testing serves as a universally accepted framework for meeting these regulatory requirements. Many regulatory bodies recognize ASTM standards as the baseline for compliance, which means that manufacturers who test their products according to these standards are more likely to meet the necessary local, regional, or global compliance standards.

For example, in the pharmaceutical industry, ASTM E2877 provides a standard guide for testing the performance of drugs, ensuring they meet specific efficacy and safety standards. By following ASTM guidelines, manufacturers in highly regulated sectors can demonstrate that their products meet the required safety criteria, helping them gain approvals from regulators such as the FDA or EMA.

3. Enhancing Product Performance and Durability

Another critical role that ASTM standards play in quality control is enhancing the performance and durability of products. Manufacturing products that perform consistently well under various conditions is essential for maintaining customer satisfaction and loyalty. ASTM standards provide detailed test methods to evaluate the durability, longevity, and reliability of products.

For instance, ASTM B117, a standard for testing the salt spray resistance of materials, helps manufacturers test how well coatings, paints, and other materials withstand corrosion. This is particularly important for industries that produce automotive, marine, and construction materials where durability is essential.

By using ASTM standards testing, manufacturers can ensure their products meet specific performance criteria, such as resistance to extreme temperatures, humidity, or UV radiation. This helps ensure that products maintain their functionality and integrity over time, reducing the likelihood of defects, recalls, or customer complaints.

4. Reducing the Risk of Product Failures

Product failures can result in significant financial losses, damage to a company’s reputation, and even legal liability. By adopting ASTM standards testing in manufacturing laboratories, businesses can proactively identify potential weaknesses in their products before they reach the market.

Many ASTM standards are designed to assess a product's stress resistance, fatigue performance, and failure thresholds under various conditions. These tests help manufacturers identify weak points in their products and improve their design or materials to prevent failures. For instance, ASTM F136, which outlines the test method for titanium alloys used in medical implants, helps manufacturers identify whether a product is suitable for use in the human body and whether it could cause harm due to material degradation.

Identifying potential issues early in the manufacturing process not only ensures better quality but also helps manufacturers avoid costly recalls and protect their brand’s reputation for producing high-quality products.

5. Supporting Sustainable Manufacturing Practices

Sustainability has become a critical concern for manufacturers, consumers, and regulatory bodies alike. Manufacturers must now ensure that their products are not only high-quality but also environmentally friendly, energy-efficient, and sustainable. ASTM standards help quality control laboratories in manufacturing facilities test for sustainability in various ways.

For example, ASTM D6866 provides a test method for determining the renewable content of a material, which can be used to assess whether a product or its components are made from sustainable, renewable resources. Manufacturers can use this standard to evaluate whether their products meet environmental regulations and contribute to more sustainable practices.

Additionally, ASTM standards such as ASTM E2349 offer methods for assessing the environmental impact of manufacturing processes, helping companies reduce waste, energy consumption, and pollution during production.

6. Facilitating International Trade and Market Access

In today’s global economy, manufacturers must ensure that their products can compete in international markets. ASTM standards are widely recognized and accepted around the world. By adhering to these standards, manufacturers can ensure that their products meet the requirements for export to a wide range of international markets.

For example, ASTM A106, a standard specification for seamless carbon steel pipe, is used across multiple industries, including oil and gas. When manufacturers comply with this standard, they are better positioned to sell their products in markets like Europe, Asia, or North America, where the ASTM standard is frequently used as a reference.

This not only expands a manufacturer’s market opportunities but also reduces the need for separate testing or adjustments when entering different markets, as ASTM standards provide a universal measure of product quality and compliance.

7. Increasing Customer Confidence

Ultimately, the goal of ASTM standards testing is to ensure that consumers receive products that are safe, durable, and reliable. By adhering to these rigorous testing protocols, manufacturers can demonstrate their commitment to product quality and safety, which helps to build customer trust and loyalty.

For customers, knowing that a product has been tested according to ASTM standards provides peace of mind that the product is of high quality and will perform as expected. Whether it’s a consumer electronics device or a construction material, customers are more likely to choose products from manufacturers who can prove that they meet recognized testing standards.

Conclusion

ASTM standards testing is an essential component of quality control in manufacturing laboratories. By adhering to these standards, manufacturers can ensure their products are reliable, safe, durable, and compliant with both local and international regulations. Whether enhancing product performance, reducing the risk of failure, supporting sustainable practices, or increasing customer confidence, ASTM standards provide a trusted and scientifically validated framework for testing and improving product quality.

For manufacturers striving to stay competitive in a global marketplace, incorporating ASTM standards into their testing and quality control processes is a crucial step towards producing products that meet the highest standards of safety, performance, and sustainability.

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In our ongoing video series about the manufacturing process of Titanium bars, today we've shared the finishing steps of manufacturing. Here, we focus on chamfering and ensuring that Titanium Round Bars are of the highest quality.

Distinguishing Process Parameters:

Chamfering: Controlled feed rate Controlled cutting speed Controlled depth of cut Continuous coolant and lubrication

Quality Analysis: Material qualifications as per ASTM and ISO international specification Testing carried out as per International Testing Procedures

Distinguishing Chamfered and Tested Bars Quality:

Reduced stress concentration at both side edges Machining benefits Easy to handle Enhanced workpiece functionality Chemical analysis, Tensile testing, Ultrasonic testing, Metallurgical analysis, Dimensional analysis, and Analysis reports

Stay tuned as we take a closer look at how we make Titanium bars for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Chamfering#EasytoHandle#ReduceStressConcentrations#QualityAnalysis#ISO#ASTM#Testing#MaterialQualifications#Specifications#Standards#ChemicalAnalysis#TensileTesting#UltrasonicTesting#MetallurgicalAnalysis#DimensionalAnalysis#AnalysisReports#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Exploring the Evolution of ASTM Standards Over Time

For decades, ASTM standards have served as cornerstones of quality, safety, and reliability across industries worldwide. Yet, the story of ASTM standards is not one of static permanence but rather of dynamic evolution. This blog embarks on a journey to explore the rich history and evolution of ASTM standards over time, delving into their origins, milestones, adaptations, and future prospects.

The Origins of ASTM Standards: From Pioneering Beginnings to Global Influence

Founded in 1898 as the American Section of the International Association for Testing Materials, ASTM International (formerly known as the American Society for Testing and Materials) has come a long way from its humble beginnings. Initially focused on developing standards for railroad materials, ASTM quickly expanded its scope to include standards for diverse industries such as construction, manufacturing, healthcare, and more. Over time, ASTM standards gained global recognition and influence, becoming synonymous with quality, reliability, and innovation in industry practices.

Milestones in ASTM Standards Development: Key Achievements and Innovations

The development of ASTM standards has been marked by numerous milestones and achievements that have shaped industry practices and standards of excellence. From the establishment of committees to the publication of seminal standards, each milestone represents a significant step forward in advancing the field of standardization. Notable achievements include the publication of the first ASTM standard in 1902, the adoption of the ASTM designation system in 1961, and the expansion of ASTM's global footprint through international partnerships and collaborations.

Adapting to Change: How ASTM Standards Evolve to Meet Emerging Challenges

In response to changing technologies, market demands, and societal needs, ASTM standards have continuously evolved to address emerging challenges and opportunities. Whether it's incorporating new testing methodologies, updating performance criteria, or expanding into new industries, ASTM standards remain at the forefront of innovation and adaptation. By embracing new technologies and methodologies, ASTM standards ensure that industry practices remain relevant, reliable, and effective in meeting the evolving needs of stakeholders.

The Role of ASTM Standards in Driving Industry Progress and Innovation

ASTM standards play a crucial role in driving industry progress and innovation by providing a common framework for collaboration, standardization, and best practices. By establishing clear guidelines, specifications, and performance criteria, ASTM standards enable manufacturers to develop high-quality products that meet industry standards and regulatory requirements. Furthermore, ASTM standards foster innovation by encouraging experimentation, research, and development of new technologies and methodologies that push the boundaries of what's possible in industry practices.

Future Trends and Directions: Anticipating the Next Phase of ASTM Standards Evolution

As industries continue to evolve and innovate, the future of ASTM standards holds immense potential for further growth and development. Emerging trends such as additive manufacturing, digitalization, and sustainability are reshaping industry practices and driving demand for new standards and methodologies. ASTM International remains committed to staying ahead of these trends by collaborating with industry stakeholders, investing in research and development, and continuously updating and expanding its portfolio of standards to meet the evolving needs of industries and society.

Conclusion:

In conclusion, the evolution of ASTM standards over time reflects a journey of innovation, adaptation, and excellence. From pioneering beginnings to global influence, ASTM standards have remained steadfast in their commitment to quality, reliability, and standardization across industries. As we look towards the future, the role of ASTM standards in driving industry progress and innovation remains as vital as ever. By embracing new technologies, collaborating with industry stakeholders, and staying ahead of emerging trends, ASTM standards will continue to evolve and shape the future of industry practices and standards of excellence.

0 notes

Note

in the wake of all this new information during COVID, do you feel that maybe we should all just be masking all the time, COVID of no COVID? I mean it can't be the only airborne disease out there and immunocompromised ppl have always and will always exist so like. Following that thinking even if we don't have COVID we could still be risking other people's health (and lives) with other diseases we may have right? Idk I'm stressing a lot about this do I just need to wear a mask outside forever cos. Masks mess with my breathing and sensory issues and stuff but. I don't wanna?? Kill people by accident??? Aaaaa

Hello, thanks for reaching out about this.

I saw this ask about a month ago, and I needed time to think about how I'd respond to it (so I want to thank you for the patience!).

I'll try to answer all of this to the best of my ability, and I thought I'd answer this by going backwards (responding to the last things you said and then moving up with responding to the first things you said).

Everything is below the cut because this is very long!

First I'll try to summarize what I think you're asking here:

"Vulnerable people exist in this world all around me, therefore does this mean I'm constantly posing a threat to those vulnerable people's safety when I don't mask? The thought of this brings me feelings of stress, fear, and anxiety."

I find this is hard to answer candidly without risking stressing out you or anyone else who's aware of the consequences of their choice not to mask. Nonetheless, my honest answer is: yes, choosing not to mask means risking the lives and safety of vulnerable people, i.e. the disabled, immunocompromised, elderly, children & babies, and those that intersect those groups. That risk can take place directly (such as interacting with an immunocompromised elder) or indirectly (such as interacting with the parent of a disabled child).

I also want to add that it's not only those groups that need protecting. I firmly believe that regardless of your age and/or whether or not you self-identify as disabled or immunocompromised that everyone is at risk of the long-term consequences of this rapidly mutating, vascular, and immunosuppressive virus. No one is invincible to this, and I'll add: not even if you're vaccinated (still get vaccinated if you can, but know that you can still catch covid & develop long covid regardless of your vaccination status).

1. "Masks mess with my breathing and sensory issues."

I understand how that can be difficult to deal with, trust me. There are specific masks (such as most standard KN95s) that irritate the hell out of my face after a certain point. The way those specific masks brush against the hairs of my cheeks just make me want to rip the mask off my face completely. Finding alternatives has been a lifesaver, and they've allowed me to get through the day without wanting to maul someone lol. I don't know what masks you have tried out already, so I'll just recommend the one's I like as well as the one's I've heard good reviews on from people that also have sensory issues:

NIOSH 3m Aura N95 Respirators

Flo Mask

GATA Mask (Haven't tried this one yet, but I've heard a LOT of people say this has been a game changer for them because of how comfortable it is & how it doesn't trigger much sensory issues at all due to its silicone material. Probably the only con I've heard is the chance of the build up of moisture in the mask after a long period of use & water possibly dripping on your face— this happens to me sometimes with my Flo Mask. Edit on Sept. 26, 2023: I tried GATA Mask, and I personally have a tough time getting a comfortable fit & seal with it, even when getting the small/medium size for adults to see if it'll make a difference, and the nose bridge shape not fitting well for me is a huge con. Customer service is just suggesting I spend more, so I'll just give this one a break, for now at least. A lot of other people seem to like it though.)

Halyard FLUIDSHIELD [ASTM Level 3] Mask (My mom works in a hospital, and these are masks she brings home from work. They're VERY comfortable for me, especially when I'm masking at home. I recommend finding a way to tighten the loops that go around your ears to prevent as much gaps around the mask as possible. If tight loops hurt your ears easily, I recommend a mask brace.)

O2 Nose Filters (I haven't tried these out yet as well, but I've seen videos demonstrating how effective these are at filtering out SOOO many unseen particles. I don't recommend using these alone of course, because there's still a risk of inhaling harmful aerosols through your mouth. I would recommend using this as a reinforcement of the protective measures you take. For example: adding on a comfortable surgical mask— ideally one with a high filtration efficiency like the previous suggestion— with the nose filters. I think these nose filters would be great if you're removing your mask real quick to take a sip of water or if you're outdoors with enough distance from crowded areas & groups.)

In the ideal world, more people would mask during this on-going pandemic so those that deal with sensory issues and/or those that straight-up can't wear a mask due to medical reasons wouldn't have to worry so much about choosing between existing & risking their health. For now, we just have to find alternatives.

2. "Do I need to wear a mask outside forever?"

My answer to this is: yes until further notice. There's no foreseeable end to this pandemic right now, but it would be worth the patience to wait for adequate tech, treatment, and cures for covid-19 to be released before even thinking about getting loose with masking.

Societal mandates have been dropped way too soon, and public health in regards to covid-19 is being forced on us as an individual responsibility. As a consequence, this gives this rapidly mutating virus a lot of wiggle room to spread and do whatever it wants. This means doctors and experts don't have much answers yet for adequate treatment because there's a MAJOR lack of containment (such as masking & quarantining) and documentation (such as testing & reporting). This isn't to say there hasn't been any advancements whatsoever: for example, Washington University just developed a breath test for covid that gives results in just 1 minute! This is great news! And this is just one reason why it's very necessary for those who can mask to mask, so scientists are given more time to roll out helpful solutions & tools sooner.

Another thing I'll add is if you're symptomatic and/or are positive for covid, you should 100% be wearing a mask no matter what, point blank period. I say "and/or" because it is VERY much possible to have covid and not experience any symptoms at all; this is a major reason why it's necessary to mask up in public consistently, because you can't always know who you bump into that may have covid or not.

3. "Even if we don't have covid, we could still be risking other people's health (and lives) with other diseases we may have right?"

Yes, there is a possibility of spreading airborne diseases to vulnerable people unknowingly— without the protective & preventative tools that is.

I can only speak for America because that's the cultural zeitgeist I grew up in, but: I feel like many of us can agree that, unless you worked in a healthcare setting, what was "normal" (in America) before 2020 when it came to airborne illness prevention was definitely not the regular use of a mask. American health education mainly taught us if we're coughing & sneezing to try to do so in a tissue or into your elbow, as well as frequently wash our hands. That doesn't account for the way air actually works though. For instance, if someone with the common cold coughed into the inside of their elbow, the particles they coughed out are still able to linger in the air because their elbow isn't creating a tight seal around their mouth (their elbow may have caught the droplets from their cough— which are bigger & heavier— but the smaller, lighter aerosols would just spread around similar to how smoke does); it's the difference between 😪 vs 😶🌫️. The only sure way for the germs they've coughed out to be blocked from spreading to other people is if they wear a well-fitted, quality mask/respirator.

I feel like health education from a young age should include the benefits of masking; that way it would be easier to adapt to the need to put on a mask to protect ourselves & others as a collective. It would be phenomenal & wonderful if we as a collective were used to masking the same way we're used to putting on socks before putting on our shoes.

4. "Immunocompromised people have always and will always exist"

Yes, that is true. And that means necessary measures taken to protect them, as well as other vulnerable people, should be the standard.

5. "[Covid] can't be the only airborne disease out there"

Of course not. There's plenty of them. However, not all airborne diseases are the same, nor should they be treated as such. What's been observed in regards to the long-term effects of covid is not at all the same with other airborne diseases. Covid is a highly contagious virus that is more than just a respiratory disease. Its goal is to attack your immune system, nervous system, heart, brain, and/or other vital organs. That's what viruses do. They act smart and sneaky, and they have the capability to trigger illnesses in your body that you may not have had pre-infection:

Chickenpox is known to lead to shingles

Epstein-Barr is known to lead to mono

HPV is known to lead to cancer

Covid-19 has been found to lead to:

POTS

ME/CFS

Stroke & Heart attack

Alzheimer's

Dementia

"Brain Fog"; Memory & Concentration Problems

The list goes on, and these are only what we know of. Covid may not be the only airborne disease, but it definitely is a dangerous one with serious, long-term negative effects.

6. "Do you feel that we should all be masking all the time, whether or not covid-19 exists?"

In regards to masking with the existence of covid:

Yes. Masking is a vital method in the prevention of catching & spreading covid-19, because it is primarily spread through the air.

In regards to masking without the existence of covid:

See my answer for number 3, and also: given the fact wearing a mask can only do more good than harm for most folks, I don't see why not. Imagine a world where we don't have to worry about flu season or allergy season anymore because those aerosols are filtered out from consistent mask wearing. Sounds like the dream to me lol.

-

I hope this made sense! If anyone has anything they'd like to add to answer anon's questions, please feel free to share!

Thank you for reading 😷

#covid#covid pandemic#covid isn't over#covid is airborne#covid awareness#masks & respirators#link(s) provided#information#ask queue

181 notes

·

View notes

Text

Black Face Masks and Respirators

@bisexualbaker

I am so sorry for the delay in getting this info to you. There's some Stuff going on over here and it also took me a while to comb through all the mask info I'd squirreled away to find the black ones.

This got so long I decided I'd best post it on its own rather than hijack the original post. In case others see this: this is a post about mask/respirator options in black. I have grouped them in rough categories, but if someone needs a mask to be explicitly certified against a specific standard, please research the specs and confirm for the model you are interested in. Also be mindful of where things are being sourced, as there have been issues with counterfeit respirators. Some resources on that front:

Counterfeit Respirators/Misrepresentation of NIOSH Approval: https://www.cdc.gov/niosh/npptl/usernotices/counterfeitResp.html (Pertains to N95s)

More Tips To Spot Counterfeit Respirators: https://www.cdc.gov/niosh/npptl/usernotices/AdditionalTips.html (More general advice for various types of respirators/masks)

The 3M Auras mentioned on the other post are an N95 and unfortunately they do not come in black at this time. (There has been a campaign to get them to make them in black and last I saw, there has been some attention from 3M.) They are widely considered a great mask though and many people find it well-fitting and comfortable. I've tried them and my face shape isn't quite suited to it I think because the staples dug into my cheekbones and I haven't seen most people mention that at all. But they have the best nose piece I've seen on any disposable respirator: very good at conforming to my face, padded, long enough to seal better than others.

Also there are several different models of Aura. The model I found at the local Home Depot was the one with blue rubber straps and I could not deal with wearing those. However the 9210+ has white braided elastic straps and those were great.

Getting into options in black:

"Surgical-Style":

This term is overloaded in many places these days, with everyday usage now often meaning a mask style by this term rather than indicating something like their ASTM level (or even if the have one). In this case I mean earloop face masks, typically but not always with pleated fronts, that are not respirators (e.g. not N95s, etc.). They may not be tight-fitting, as many models are focused on fluid resistance. The ones below are 3 or 4 ply and have various ASTM levels.

Armbrust has 3 ply masks in a variety of colours, including black: https://www.armbrustusa.com/products/usa-made-disposable-face-masks

Bandless style: https://www.armbrustusa.com/products/black-3ply-usa-made-disposable-masks?_pos=5&_sid=c44400ae4&_ss=r

Demetech - https://shop.demetech.us/products/copy-of-black-astm-level-3-disposable-face-mask-with-earloops-size-regular?variant=41286569328816

Altor: https://www.altorsafety.com/facemasks/black-facemask

Cranberry (that's the brand, the colour is black): https://aiden.health/products/cranberry-carbon-black-face-masks-astm-level-3-protection-fda-510k

High filtration face mask - Protective Health Gear: https://protectivehealthgear.com/collections/shop/products/high-filtration-face-mask?variant=42211501637865 These look more like some of the KN95s, but the maker does not claim them to be a type of respirator. They often have sales around holidays, between 35 - 50% off. There's currently a 35% off sale going. They have N95s too but those are only white.

KF94/KN95/FFP2:

This is the type that has more black versions than any other, so the below is only a short list of options.

Different ones are certified to different standards, so read up on individual details as needed.

KF94 - HappyLife: https://kollecteusa.com/products/happylifegooddaykf94-adult-black-mask?variant=35994428637333

KN95 - Armbrust: out of stock on black at the moment though. https://www.armbrustusa.com/products/us-made-kn95-mask?variant=40057768280197

KN95 - BNX:

Large: https://accumed.com/bnx-50-pack-kn95-face-mask-disposable-particulate-kn95-mask-made-in-usa-protection-against-dust-pollen-and-haze-50-pack-earloop-model-e95-black-4.html

Medium: https://accumed.com/bnx-20-pack-kn95-e95m-protective-face-mask-disposable-particulate-mask-made-in-usa-protection-against-dust-pollen-and-haze-black-20-pack-earloop-model-e95m.html

Demetech: https://shop.demetech.us/products/copy-of-d95-blue-particulate-respirator-fold-style-with-black-earloops-box-of-20 I dithered about where to group this - from what they said, I think they took their N95 design and made an earloop version. So it is NOT an N95 (and not NIOSH approved), but is a respirator style.

MaskLab: https://masklab.us They have some black options, along with a whole lot of patterns. Check the details on the various ones for what they are - the ones I looked at are FFP2, which is a European standard.

Powecom: https://bonafidemasks.com/Black-Powecom-KN95-Face-Mask

BreatheTeq KN95: Black in several sizes https://breatheteq.com/collections/all

Various models KF94: https://behealthyusa.net/collections/black

WellBefore KN95: https://wellbefore.com/products/kn95-disposable-fda-ce?variant=32907790909569

N95s:

True N95s always have head straps, not ear loops. They have received NIOSH approval - see link up top for info on how to validate authenticity. There aren't a ton out there in black, likely given their primary pre-pandemic use cases. But there are some.

BNX: They have two styles in black https://accumed.com/bnx-n95-mask-niosh-certified-made-in-usa-particulate-respirator-protective-face-mask-10-pack-approval-number-tc-84a-9315-model-h95w-black-3.html Trifold: https://accumed.com/bnx-n95-mask-black-niosh-certified-made-in-usa-particulate-respirator-protective-face-mask-tri-fold-cup-fish-style-10-pack-approval-number-tc-84a-9362-model-f95b-headband-black.html

Benehal: I've seen positive reports on their black N95, but at the moment I haven't found anything but the white ones for sale on legit sites that ship to/in the US.

Demetech: https://shop.demetech.us/products/black-n95-respirator-mask-fold-style-niosh-approved-box-of-20-size-regular

WellBefore: https://wellbefore.com/products/n95-medical-mask-fda?variant=32909323436161

VitaCore: Okay a note here: these are a Canadian manufacturer model certified to a standard in use in Canada. Their white version is also a NIOSH certified N95. The black is newer and is certified in Canada but the NIOSH process isn't done yet so VitaCore isn't selling them on their US site yet. However they did approve a reseller to sell the black ones in the US here. I've heard great things about these and am getting some to try myself. https://www.protectly.co/products/vitacore-can99-black-respirator-mask

Elastomeric Respirators:

These are reusable respirators, where you replace the filter material, but the overall respirator is reusable (made of rubber, etc). On the one hand they are widely held to be the most comfortable options for long term use and once the initial investment is made, it's less expensive to buy replacement filters than disposable respirators. Even the filters themselves can be used for a long time before replacement compared to a disposable. That said, these respirators are more 'noticeable' in style and like with any mask, not all models are going to be comfy on all face shapes.

I can't think of any ones with black filter materials but some of the respirators themselves come in black or can be painted. And some have housing over the filters such that you don't see much of the filter material itself except through little holes. If anyone is interested in more info on some of the more common models though, let me know.

I'll mention one that has a black faceplate option and is less obtrusive looking in style, that I also have personally tried: FloMask: https://www.flomask.com Adult and child modes available. I advise the halo strap for the top strap for staying put and comfort, especially if you have longer hair. There are two different levels of filter material available, interchangeable in the same respirator. They also have two different mask styles to suit different nose bridges.

Strapless:

I'm only familiar with ReadiMask, and I think those are just in yellow or grey. But mentioning them anyway to cover the use case of needing a respirator without metal parts. They are an actual N95, but use adhesive rather than straps. Very comfortable and can be worn in MRI machines. They'd also work well for things like massages IMO because laying on your face is comfortable in these.

https://readimask.com

https://alliantbiotech.com/product/readimask-strapless-n95-niosh-approved

They have different sizes. But in my experience, unless your face is VERY small, you probably need at least the Large size. There are instructions on how to measure your face for size.

---

Some other notes:

Armbrust has a mask sampler for $40 https://www.armbrustusa.com/products/armbrust-mask-sampler-kit?_pos=3&_sid=debca69cb&_ss=r Some of the samples are masks that do not come in black but some are ones that you can buy in black, 3 or 4 of them (though I think all the samples themselves are white or blue).

14 notes

·

View notes

Text

Manhole Cover Compression Testing Machine

Reliable and Accurate Testing for Manhole Covers The Manhole Cover Compression Testing Machine is a specialized testing device designed to assess the structural integrity of manhole covers under extreme pressure. This testing machine plays a crucial role in ensuring that manhole covers meet the required safety standards and durability expectations. Whether used for quality control in…

#ASTM Manhole Cover Test#Civil Engineering Testing#Compression Resistance#Compression Strength Test#Compression Testing#Construction Equipment Testing#Custom Testing Solutions#EN 124 Testing#Hydraulic Load Testing#Hydraulic Testing Machine#Industrial Testing Machines#ISO Manhole Cover Standards#Jinan Wangtebei Instrument#Load Cell Testing#Load Testing#Manhole Cover Compliance#Manhole Cover Deformation Test#Manhole Cover Performance Test#Manhole Cover Quality Control#Manhole Cover Strength#Manhole Cover Testing Equipment#manhole cover testing machine#Pressure Test Machine#Testing Equipment for Infrastructure#Testing Machine Manufacturer

0 notes

Text

Aohong NBR Sealing Rubber Gaskets: The Cost-Effective Workhorse for Demanding Applications

Let's face it—when that hydraulic system starts leaking after just six months and you're knee-deep in oil-soaked components, you realize not all rubber gaskets are created equal. NBR Sealing Rubber Gaskets from Aohong solve what generic elastomers can't: delivering reliable sealing performance without breaking the bank. Here's why our nitrile rubber solution outperforms the competition where it matters most.

The Science Behind Superior Sealing

That 34% acrylonitrile content in Aohong's formulation isn't just a random number—it's the sweet spot for balancing oil resistance and flexibility. While cheaper NBR compounds cut corners with 28% content (and pay the price in swelling), we've optimized our material to deliver:

70±5 Shore A hardness (ASTM D2240 verified)

<10% oil swell after 1,000 hours in ASTM #3 oil

-40°C to 120°C service range—no brittle fractures in cold climates

85% compression set resistance at 100°C (beats EPDM in hot oil)

Pro Tip: That matte black finish isn't for looks—it's our proprietary carbon black reinforcement that adds 30% more tear strength versus standard NBR.

Real-World Proof: Hydraulic Cylinder Case Study

Take this OEM mining equipment application we solved last quarter:

Problem: Competitor's gaskets swelled 25% after 3 months

Conditions: 1,500 psi hydraulic fluid + 80°C continuous operation

Solution: Aohong's NBR gasket with enhanced oil swell resistance

After 18 months of brutal service: ✓ Zero leaks (pressure tested monthly) ✓ Only 8% thickness variation ✓ Saved $14,000 in downtime costs

Their maintenance supervisor called it "the only gasket that lasts through our service interval."

Installation: Do It Right the First Time

Surface Prep

32-64 RA surface finish (too smooth causes slippage)

Clean with isopropyl alcohol—never WD-40 (leaves silicone residue)

Torque Sequence

30% less torque than FKM gaskets

Criss-cross pattern for even compression

Break-In Period

Allow 24 hours for full compression set

Retorque after first thermal cycle

❌ $8,000 Mistake Using petroleum grease as lubricant—it degrades NBR over time. Silicone-based only.

Where Aohong's NBR Excels

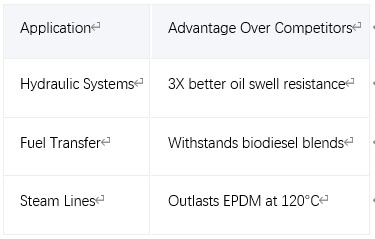

Safety Note: Never use with ketones or esters—they'll dissolve the material in weeks.

The Bottom Line

When your application needs oil resistance without fluoropolymer prices—whether it's a construction equipment hydraulic system or a biodiesel transfer line—Aohong's NBR Sealing Rubber Gasket delivers proven performance where generic rubber fails.

Why gamble with inferior materials? Contact Aohong's engineering team today for application-specific solutions—because in industrial sealing, "good enough" usually fails at the worst possible moment.

3 notes

·

View notes