#TitaniumManufacturing

Explore tagged Tumblr posts

Text

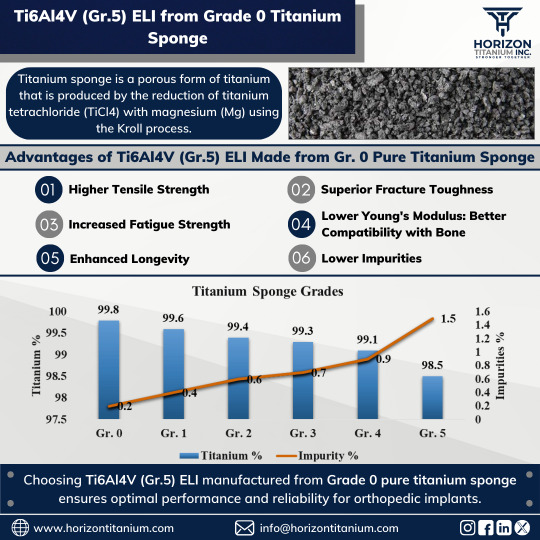

Titanium is vital in the medical field due to its biocompatibility, strength, and corrosion resistance. However, the quality of medical-grade titanium depends on the grade of titanium sponge used in production. Let's explore how titanium sponge impact the quality of titanium for medical devices and implants.

What is Titanium Sponge? Titanium sponge, made through the Kroll process, is a porous, brittle form of titanium. It needs further processing and alloying with elements like aluminum and vanadium (Ti6Al4V (Gr.5) ELI) to be used in manufacturing medical devices. Its quality and purity are critical for the final titanium properties.

Importance of Choosing the Right Grade The grade of titanium sponge used to manufacture titanium material for medical applications has a profound impact on the quality and performance of the final product. By selecting the right grade, manufacturers can ensure that medical devices made from high-purity Sponge Gr. 0 material will meet the stringent standards required for medical use, providing safe and effective solutions for patients.

If you need any further information, reach out at [email protected]

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumSpongeGrade0#TitaniumManufacturing#KrollProcess#Ti6Al4VELI#Grade5ELI#HigherTensileStrength#SuperiorFractureToughness#IncreasedFatigueStrength#LowerYoungModulus#EnhancedLongevity#LowerImpurities#MaterialScience#TitaniumQuality#MedicalGradeTitanium#TitaniumImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

EXPLORING THE WORLD OF FERRO TITANIUMMANUFACTURERS IN INDIA

Ferro Titanium Manufacturers in India: India, with its flourishing steel industry, boasts numerous ferrotitanium manufacturers. These manufacturers play a crucial role in meeting the demand for quality ferro titanium products. While we cannot provide direct information about specific manufacturers, you can explore reputable online directories, industry associations, and trade fairs to discover the diverse range of manufacturers operating in India.

Factors to Consider: When searching for ferro titanium manufacturers, several factors should be considered to ensure a reliable and reputable partnership:

Experience and Expertise: Look for manufacturers with substantial experience in producing ferrotitanium. Seasoned manufacturers are often well-versed in the nuances of the manufacturing process, leading to superior quality products.

Quality Certifications: Check if the manufacturers hold relevant quality certifications, such as ISO9001, which demonstrate their commitment to maintaining stringent quality standards.

Production Capacity: Evaluate the production capacity of manufacturers to ensure they can meet your requirements in terms of volume and timely delivery.

Customization Capabilities: Assess whether the manufacturers can provide tailored ferrotitanium products based on your specific needs, including particle size, composition, and other parameters.

Reputation and Customer Reviews: Research the reputation of the manufacturers by reading customer reviews and testimonials. This can provide insights into their reliability, customer service, and product quality.

Conclusion: Ferro titanium manufacturers in India contribute significantly to the steel industry and various other sectors by providing high-quality ferro titanium powder. As a versatile alloy, it enhances the performance and longevity of steel alloys used in critical applications. By considering the factors mentioned above and conducting thorough research, businesses can establish reliable partnerships with reputable ferro titanium manufacturers in India.

If you have any further questions or need assistance with any other topic, please feel free to ask.

☎ : +91 9899 738234 | : [email protected]

0 notes

Photo

Titanium Products Manufacturers Grade 2, Grade 5 Suppliers, Titanium Pipe, Tube, Plate, Flange, Fastener, Wire, Rod, Nut Bolts, Sheet, Hexagonal Bar, etc .

0 notes

Video

tumblr

SHENZHEN YATAIXIN METAL CO.LTD is a high-technology enterprises, which is specialized in the production, research and development of titanium, Titanium plate, Titanium wire,Titanium screw,Titanium clad copper, Platinized titanium electrode and the related finished products.Our company is a professional manufacturer of titanium products.

If you need any titanium products just let us know ,we can provide competitive price to make your products competitive in this market .

️+8618129970360 [email protected]

#titanium #titaniummaterials #titaniumsheet #titaniumplate #titaniumsheets #titaniumplates #titaniumrod #titaniumrods #titaniumbar #titaniumbars #titaniumwire #titaniumwires #titaniumcoil #titaniumcoils #titaniumtube #titaniumpipe #titaniumbasket #titaniumanode #titaniumdisc #titaniumracks #titaniumcoolingpipe #titaniumplatingracks #titaniumjig #electroplating #anodizing #titaniummesh #titaniumscrews #titaniumcustom #titaniummanufacturer #titaniumfactory #titaniumshenzhen #titaniumshanxi #titaniumchina #mailus #phoneus #highquality #supplier#[email protected] #18129970360

1 note

·

View note

Link

We OZAIRTRADELINK are the leading brand in the market to provide our clients the best range of Titanium Sheets and Plates. The provided product is precisely manufactured by skilled professionals using the best quality basic material and modern technology. These products are nicely packaged in appropriate material and are made by our experts with use of best grade raw material.

#TITANIUMSHEETS#TITANIUMPLATES#TITANIUMCOILS#TITANIUMSUPPLIERS#TITANIUMMANUFACTURERS#TITANIUMEXPORTERS#TITANIUMSHEETSSUPPLIERS

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Today, in our ongoing video series on Titanium bar manufacturing, we've highlighted the final stages of manufacturing. This part highlights how we carefully mark and pack the Titanium Round bars to make sure they're top quality and easy to track.

Distinguishing Marking and Packaging Process Parameters:

Marking: Our Titanium Round bars marked with “Company name, ASTM/ISO standards, Grade, Size, Length, Heat number, and Lot number”

Packaging: Based on Size 1-50 No’s bundle preparation Each bundle packed in the recycling plastic bag Each bundle packed in an export-worthy wooden box

Distinguishing Marking and Packaging Process Benefits:

Marking: Traceability Compliance Quality assurance Process efficiency Customer confidence

Packaging: Surface protection Systematic organization Environmental responsibility Safe transport

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Marking#ASTMF136#ISO5832_3#Size#Length#HeatNumber#LotNumber#Packaging#BundlePreparations#EcoFriendlyPlasticBag#ExportWorthyWoodenBox#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In our ongoing video series about the manufacturing process of Titanium bars, today we've shared the finishing steps of manufacturing. Here, we focus on chamfering and ensuring that Titanium Round Bars are of the highest quality.

Distinguishing Process Parameters:

Chamfering: Controlled feed rate Controlled cutting speed Controlled depth of cut Continuous coolant and lubrication

Quality Analysis: Material qualifications as per ASTM and ISO international specification Testing carried out as per International Testing Procedures

Distinguishing Chamfered and Tested Bars Quality:

Reduced stress concentration at both side edges Machining benefits Easy to handle Enhanced workpiece functionality Chemical analysis, Tensile testing, Ultrasonic testing, Metallurgical analysis, Dimensional analysis, and Analysis reports

Stay tuned as we take a closer look at how we make Titanium bars for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Chamfering#EasytoHandle#ReduceStressConcentrations#QualityAnalysis#ISO#ASTM#Testing#MaterialQualifications#Specifications#Standards#ChemicalAnalysis#TensileTesting#UltrasonicTesting#MetallurgicalAnalysis#DimensionalAnalysis#AnalysisReports#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we push forward in our commitment to perfect Titanium bar production, we've now arrived at a pivotal point—the ninth step. This phase revolves around the intricacies of Peeling and Centerless Grinding for Titanium Round Bars.

Distinguishing Process Parameters:

Peeling: Controlled peel depth Controlled feeding rate Controlled workpiece temperature Continuous coolant and lubrication Peeling forces monitoring

Centerless Grinding: Controlled workpiece speed Controlled grinding wheel speed Controlled residual stress Controlled grinding wheel gap Continuous coolant and lubrication

Distinguishing Peeled and Centerless Grinded Bars Quality:

Free from Alpha Case layer Precise tolerance with a 10-micron diameter difference throughout the lot size Mirror-finished surface Free from surface imperfections

Stay tuned as we navigate this journey together, granting you a comprehensive view of our production methods. Our enthusiasm lies in unveiling each essential stage in the precise manufacturing of Titanium bars, exclusively intended for medical use.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#PeelingProcess#CenterlessGrinding#FreeofAlphaCase#PreciseTolerance#MirrorFinishedSurface#FreefromSurfaceImperfections#Polishing#Microstructure#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Continuing our journey to enhance Titanium bar production, we've reached a critical juncture—the eighth step. This phase involves the removal of Hydrogen from Titanium Round Bars using a Vacuum Heat Treatment Furnace.

Distinguishing Process Parameters:

Heat treatment under vacuum atmosphere Controlled gas atmosphere Controlled pressure, heating and cooling rate Monitoring and control systems

Distinguishing Vacuum Heat-Treated Bars Quality:

High Purity Free of microstructure imperfections Low hydrogen content Higher fracture toughness and fatigue strength

Stay connected as we journey through this exploration, providing you with an in-depth view of our production techniques. We are enthusiastic about unveiling every critical stage in the precise creation of Titanium bars designed exclusively for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#VacuumHeatTreatment#HydrogenRemoval#Heating#ELI#HighPurity#Microstructure#FractureToughness#FatigueStrength#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we advance through our Titanium bar manufacturing process, we've now reached the pivotal sixth step, where we craft Titanium round bars from Titanium Billet using a hot rolling process

Distinguishing Process Parameters:

Controlled rolling temperature Controlled deformation speed Uniform and close tolerance Process monitoring and control systems

Distinguishing Hot Rolled Bars Quality:

Material consistency Uniform microstructure Dimensional accuracy Defect-free bar

Stay connected along with us as we continue on this journey, providing you with an in-depth exploration of our production process. We are excited to share every important stage in the creation of high-quality Titanium bars designed specifically for medical applications

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumHotRolledBars#PreFinishing#PreHeating#TitaniumHotRolling#HotRolling#SizeReduction#SemiAutomaticHotRolling#ELI#UniformMetallurgy#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In the progression of our Titanium bar manufacturing process, we now arrive at the fifth essential step, which entails forming the Titanium Billet through an automatic robotic forging process.

Distinguishing Process Parameters:

Controlled forging pressure Controlled deformation speed Real-Time Monitoring and Feedback Automation and Robotics

Distinguishing Forged Billet Quality:

Material homogeneity Consistent microstructure Precise dimensions High strength Free of defects and inclusions

Stay tuned as we progress through this journey, offering you a comprehensive look at our production process. We're enthusiastic about sharing each significant step in the manufacture of top-quality Titanium bars tailored for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumBillet#TitaniumForging#RoboticForging#HighStrength#ELI#HomogeneousMetallurgy#HighPurity#Metallurgy#UniformMicrostructure#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Let's explore the fourth key step of our Titanium bar manufacturing process: the production of the Titanium Ingot through Vacuum Arc Re-melting.

Distinguishing Process Parameters:

Extra impurities removal Melting completely under vacuum

Distinguishing Three-Times Melted Ingot Quality:

Uniform chemical composition Uniform metallurgy High purity High strength

Stay connected as we move forward on this journey, giving you a detailed glimpse into our production process. We're enthusiastic about sharing each vital stage of crafting top-notch Titanium bars designed for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumElectrode#VacuumArcRemeltingFurnace#VAR#ThreeTimesMelting#TitaniumIngot#ELI#HomogeneousMetallurgy#UniformStructure#HighPurity#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

At Horizon Titanium Inc., we are dedicated to empowering our valued customers with the information and transparency they deserve when it comes to purchasing superior Titanium materials. Today, we share the first step in our Titanium bar manufacturing process: creating the Titanium-Aluminium-Vanadium master alloy.

Quality Ingredients

Grade 0 Titanium Sponge: We start with the purest grade 0 Titanium sponge for superior implant strength and biocompatibility.

Premium Aluminium and Vanadium: We use the highest-quality Aluminium and Vanadium to ensure exceptional properties like strength, durability, and corrosion resistance.

Precision Matters

Our skilled experts oversee alloying with precision and adhere to rigorous quality control standards.

Stay tuned for more insights into our manufacturing process as we continue to unveil each step that culminates in the creation of best quality Titanium bars for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#MasterAlloyPreparation#QualityTitanium#SpongeGrade0#PremiumAluminum#PremiunVanadium#PatentedMixer#Mixing#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Titanium Sheets and roundbars Manufacturers india

Titanium Stockiest & Suppliers.

grade1 / grade2 /grade9 / 6Al-4V or grade 5 / 6AL-4V ELI or grade 23 / grade 12.

Available in Roundbars,Wires,Sheets,Plates,Welding rods,flanges & fittings.

Titanium is known as a transition metal on the periodic table of elements denoted by the symbol Ti. It is a lightweight, silver-gray material with an atomic number of 22 and an atomic weight of 47.90. It has a density of 4510 kg/m 3 , which is somewhere between the densities of aluminum and stainless steel.as we titanium Sheets and roundbars Manufacturers india It has a melting point of roughly 3,032°F (1,667°C) and a boiling point of 5,948°F (3,287 C). It behaves chemically similar to zirconium and silicon. It has excellent corrosion resistance and a high strength to weight ratio.

#titaniummanufacturers#titaniumsuppliers#titaniumroundbars#titaniumsheetsandplates#titaniumpipes#titaniumflanges#tianiumfittings#titaniumwires#titaniumelectrode

0 notes