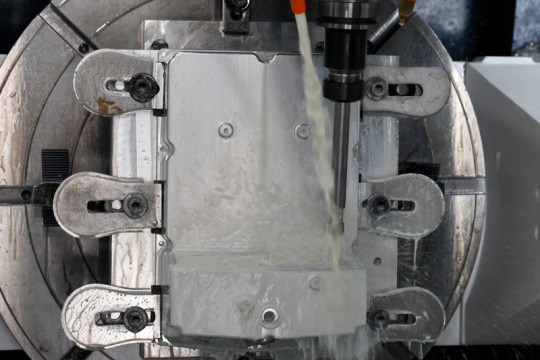

#5 axis machining services

Explore tagged Tumblr posts

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

CNC precision machining service

#business#design#autos#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#machining parts#cnc machining service#cnc services#cnc precision machining#5 axis cnc machining#5 axis precision machining#5 axis cnc#cnc machining parts

4 notes

·

View notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

PAC: 🥀

Fuck it heres why ur ass is single

Im in a mood today

Disclaimer: please take what I say with a grain of salt and not as the gospel. I just want to share some ideas of practicing and giving advice using the medium as often as I can with school, work, and my own personal studies and practice Started a Podcast draft today! Liking and sharing does a lot 🥰

Socials: TipJar/services | Follow me!

Pick a meme

1 2

3

The cards

Knight of disks 🛷

21° Leo to 20° Virgo, Earth of Assiah, Chokmah

You strive for a lot of material success and that at times makes you greedy and jealous. You want a relationship to LOOK a certain way but while people can change people rarely change in the way you want and you shouldn’t force people to be something they are not. You have a personal stubbornness about your idea of a relationship and it’s keeping you where you are

Defeat ⛸️

Venus 1. In Aquarius , Geburah in Air, 5 of swords

You are going through it lmao. Your world view will soon be shaped from pain and at times always taking fat Ls can have an impact on who you are as a person. You’re having many intellectual crisis and struggles against fate however you did sign the letter to your fate. Things only manifest because you did things to cause it. You’re single rn bc you are going through so much shit and your world view is changing so rapidly you deadass have no time and have no concept of what it would even look like.

The Tower 🥊

Saturn and Uranus, Mars, The Axis Netzach - Hod, fire

You’re single girlie bc you are straight up self destructing lmao. You’ve made a shocking realization about your current world view and since everything has been violently crumbling down around you. This is what happens when you wanna be so delulu that shit hits the absolute shit fuck fan. While there is good in destruction and we all have it your blind destruction is scaring the hoes. No one wants to be collateral.

Extras:

Story/vent:

I love you guys I am just eepy

#suitlifeofgerm#askgerm#pick a card#daily card#pick a picture#germ reads#shadow work#tarotoftheday#pac#cartomancy#thoth tarot#tarot deck#tarot blog#tarot witch#free tarot#tarot spread#daily tarot#tarot reading#tarot cards#tarot#tarot community#tarot reader#tarot spreads#tarotblr#tarotcommunity#divination#pick a reading#pick a image#pick a deck#pick a pile reading

71 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

The Gaming Revolution: Transformations Shaping the Industry

Gaming has undergone a remarkable transformation over the past few decades. From pixelated arcade classics to hyper-realistic virtual reality experiences, the industry has evolved in ways that were once unimaginable. Technological advancements, changing consumer preferences, and innovations in game development have fueled this revolution. Below, we explore the key factors driving this change and what the future holds for gaming.

The Rise of Cloud Gaming

Cloud gaming has eliminated the need for expensive hardware, making high-end gaming accessible to a broader audience. Services like NVIDIA GeForce Now, Xbox Cloud Gaming, and PlayStation Now allow players to stream games directly to their devices without requiring powerful GPUs. This shift enables instant access to a massive game library without large downloads or updates.

The Impact of Artificial Intelligence in Gaming

AI has revolutionized game design, improving NPC behavior, procedural content generation, and adaptive gameplay experiences. Advanced machine learning algorithms enable games to dynamically adjust difficulty levels, personalize player interactions, and create more immersive storytelling. AI-driven automation is also streamlining the development process, reducing costs and increasing efficiency.

The Evolution of Graphics and Game Engines

From 8-bit sprites to ray-traced 4K visuals, graphical fidelity has improved dramatically. Game engines like Unreal Engine 5 and Unity have set new standards for realism, incorporating real-time lighting, high-definition textures, and physics simulations. These technologies make gaming experiences more lifelike and engaging than ever before.

The Growth of Esports and Competitive Gaming

Esports has transformed gaming into a professional industry, attracting millions of viewers and generating billion-dollar revenues. Titles like League of Legends, Dota 2, and Counter-Strike: Global Offensive have built massive competitive scenes, with professional players earning sponsorships and substantial prize pools. Streaming platforms like Twitch and YouTube Gaming have further fueled the rise of esports.

The Expansion of Virtual Reality and Augmented Reality

VR and AR technologies are pushing gaming beyond traditional screens. Devices like the Oculus Quest and PlayStation VR offer fully immersive experiences, while AR games like Pokémon GO integrate digital elements into the real world. As these technologies become more refined and affordable, their adoption is expected to grow significantly. Visit - https://tepiarus.id/

The Influence of Blockchain and NFTs in Gaming

Blockchain technology and non-fungible tokens (NFTs) are introducing new monetization models in gaming. Play-to-earn games like Axie Infinity allow players to own and trade in-game assets with real-world value. While controversial, blockchain gaming presents opportunities for decentralized economies and player-driven content ownership.

The Shift to Cross-Platform Play

Cross-platform compatibility is breaking barriers between gaming ecosystems. Players can now enjoy seamless multiplayer experiences across different consoles, PCs, and mobile devices. Games like Fortnite, Call of Duty: Warzone, and Minecraft have embraced this model, fostering inclusive and connected gaming communities.

The Role of Subscription Services

Subscription-based gaming services such as Xbox Game Pass, PlayStation Plus, and Apple Arcade are changing how players access games. Instead of purchasing individual titles, gamers can access a vast library for a monthly fee, making high-quality gaming more affordable and convenient.

The Social and Cultural Impact of Gaming

Gaming is no longer just a form of entertainment—it has become a cultural phenomenon. Online communities, virtual concerts, and in-game collaborations with brands and celebrities have blurred the lines between gaming and other forms of media. Gaming is shaping modern pop culture and influencing industries like music, fashion, and film.

The Future of Gaming: What Lies Ahead?

With advancements in AI, cloud technology, and immersive experiences, gaming will continue to evolve rapidly. The metaverse concept, where virtual worlds serve as interconnected digital spaces, is gaining traction. Whether through decentralized economies, AI-driven narratives, or ultra-realistic simulations, the gaming landscape will keep transforming, bringing new opportunities and challenges.

Gaming is at the forefront of technological evolution, reshaping entertainment and interaction on a global scale. As these innovations continue to unfold, one thing remains certain—gaming’s future is more exciting than ever.

0 notes

Text

Ultimate Guide to Precision CNC Machining: From Design to Delivery

Precision CNC machining services are essential for creating high-accuracy components used in industries like aerospace, automotive, and medical. This process involves designing parts using CAD software, selecting the right materials, and utilizing advanced CNC machines to achieve tight tolerances. Quality control and post-processing ensure durability and functionality, while timely delivery completes the cycle. Companies like Pangea Technologies excel in providing end-to-end precision CNC machining services, combining cutting-edge technology, skilled engineering, and rigorous quality checks. Whether for prototypes or large-scale production, Pangea Technologies delivers reliable, high-quality solutions, making them a trusted partner in precision manufacturing.

Understanding Precision CNC Machining Services

Precision CNC machining services involve the use of computer-controlled machines to manufacture parts with exceptional accuracy and consistency. These services are essential for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can lead to significant issues. CNC machining ensures tight tolerances, high repeatability, and the ability to work with a variety of materials, including metals, plastics, and composites. Companies like Pangea Technologies specialize in providing state-of-the-art precision CNC machining services, leveraging advanced technology and skilled engineers to meet the most demanding requirements.

The Design Phase: Turning Ideas into Reality

The first step in precision CNC machining is the design phase. Engineers and designers use CAD (Computer-Aided Design) software to create detailed 3D models of the component. This phase is critical because it determines the feasibility, functionality, and manufacturability of the part. Pangea Technologies collaborates closely with clients during this phase, offering design-for-manufacturability (DFM) feedback to optimize the design for CNC machining. This ensures that the final product is not only functional but also cost-effective to produce.

Material Selection: The Foundation of Quality

Choosing the right material is crucial for the success of any precision CNC machining project. Factors such as strength, durability, thermal resistance, and machinability must be considered. Common materials used in CNC machining include aluminum, stainless steel, titanium, brass, and engineering plastics. Pangea Technologies provides expert guidance on material selection, helping clients choose the best option for their specific application. Their extensive material inventory ensures that clients have access to high-quality raw materials for their projects.

Machining Process: Precision at Its Finest

Once the design and material are finalized, the machining process begins. CNC machines, such as mills, lathes, and multi-axis machining centers, are programmed to follow the CAD model’s specifications. These machines use cutting tools to remove material from the workpiece, shaping it into the desired form. Precision CNC machining services offered by Pangea Technologies utilize advanced equipment, such as 5-axis CNC machines, to produce complex geometries with unparalleled accuracy. Their commitment to quality ensures that every part meets the highest standards.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of precision CNC machining. Each part undergoes rigorous inspection using tools like coordinate measuring machines (CMMs), optical comparators, and surface finish testers. This ensures that the final product adheres to the specified tolerances and quality standards. Pangea Technologies employs a comprehensive quality control process, combining advanced inspection techniques with skilled technicians to guarantee the accuracy and reliability of every component.

Post-Processing: Adding the Finishing Touches

After machining, parts often require post-processing to enhance their appearance, functionality, or durability. Common post-processing techniques include anodizing, powder coating, polishing, heat treatment, and plating. These processes not only improve the part’s performance but also protect it from environmental factors like corrosion and wear. Pangea Technologies offers a wide range of post-processing services, ensuring that every component meets the client’s exact requirements. Their expertise in finishing techniques adds value to the precision CNC machining process.

Delivery: Bringing Your Vision to Life

The final step in the precision CNC machining journey is delivery. Once the parts have passed all quality checks and post-processing, they are carefully packaged and shipped to the client. Timely delivery is essential to ensure that the client’s production schedule remains on track. Pangea Technologies prides itself on its efficient logistics and reliable delivery services. Their commitment to customer satisfaction ensures that every project is completed on time and to the highest standards.

Conclusion

Precision CNC machining services are at the heart of modern manufacturing, enabling the production of high-quality, complex components with unmatched accuracy. From design to delivery, every step in the process requires expertise, advanced technology, and a commitment to quality. Companies like Pangea Technologies exemplify the best in precision CNC machining services, offering end-to-end solutions that meet the needs of diverse industries. By combining cutting-edge technology, skilled engineers, and a customer-centric approach, Pangea Technologies ensures that every project is a success. Whether you’re developing a prototype or scaling up production, partnering with a trusted provider like Pangea Technologies can help you achieve your goals with precision and efficiency. Embrace the future of manufacturing with precision CNC machining services that deliver results you can count on.

0 notes

Text

Top Boons of 5-axis CNC Machining

5 axis machining is now the most feasible choice for all types of machining jobs, not only the most difficult ones that require longer tool reach. 5-axis CNC machining is widely utilized for the most complex and precise jobs. This manufacturing approach is expected to provide significantly improved precision.

5-axis custom machining services provide a variety of advantages

Higher speed

5-axis machining allows the use of shorter cutting tools since the head may be lowered and the cutter is directed to the surface. You might expect better outcomes by increasing cutting speed and tool vibration.

Increased productivity

One of the most time-consuming parts of 3-axis machining is setting up a workpiece many times because it needs to be reoriented. This is required if an item needs to be machined on all or multiple sides, as the cutting tool remains at a fixed angle. A machinist must be physically present to rotate the component once machining on one side is completed for these 3-axis operations, and this human need can be a significant bottleneck in production.

5-axis machining by 5 axis machining manufacturer significantly minimizes the need for repeated setups since the movement of the table or spindle allows the cutting tool to approach the workpiece from various angles without removing it from the machine and resetting it. This leads to higher productivity throughout the whole process.

Hiring a dependable 5-axis machining services

Make sure your production team has been in operation for a significant amount of time. They should be highly experienced and qualified to ensure the quality of the job and timely completion. A corporation should be dependable and trustworthy.

Before selecting a firm, do not be afraid to ask questions regarding their 5-axis machining capabilities. A machine must also be of superior quality and capable of doing this task within a certain timeframe.

Inquire about the pricing of their services. Make sure you pay for what you get, and that the price matches the quality of the goods. Also, be informed of the materials they will be employing.

Main Source: https://bolesolutions.mystrikingly.com/

#5 axis machining manufacturer#5 Axis Machining Supplier#5 axis machining services China#5 Axis Machining Center

2 notes

·

View notes

Text

5 axis cnc machining parts service

#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#machining parts#precision machining#5 axis cnc machining#5 axis milling#5 axis cnc milling#5 axis cnc#cnc 5 axis machining#cnc machining service#cnc machining parts#precision cnc machining#precision cnc milling#cnc milling#cnc milling machining

2 notes

·

View notes

Text

Simultaneous 5-axis CNC milling is an advanced processing technique that can manufacture high-precision and complex part. Every part will be perfectly splendid machined by 5 axis milling.

0 notes

Text

How To Choose the Right Hospital Laboratory Equipment?

When it comes to setting up a hospital laboratory, choosing the right equipment is crucial. The quality of laboratory equipment directly impacts the accuracy of test results, the safety of the laboratory environment, and the overall efficiency of the hospital's operations. Whether you are setting up a new laboratory or upgrading an existing one, selecting the appropriate equipment requires careful consideration of various factors. In this blog, we will guide you through the essential steps to choose the right hospital laboratory equipment and highlight 5-6 key pieces of equipment with their definitions. We will also explore the reliable and trustworthy hospital laboratory equipment manufacturers and suppliers in India.

Understanding Your Laboratory Need

Before selecting the various components, there is a need to determine some basic issues with respect to the specific hospital laboratory. One of the great variations is in the types of equipment that different hospitals have, depending on the type of tests conducted, their frequency, and the type of facility.

Key considerations:

Test Types

Quantity of Tests

Equipment Require Specialization

Budget Limitations

Research and Compare the Equipment Option

Having keenly ascertained the requirements of the Hospital Laboratory, the next step is to conduct a research on the equipment available. Focus on Reliable and trustworthy hospital laboratory equipment manufacturers and suppliers for supplying quality and reliable laboratory apparatus. Branch out and study different models, peruse reviews, and talk to colleagues in other hospitals’ laboratories concerning the equipment’s efficiency and stability.

Ensure Compliance with Standards and Regulations

Laboratory services in hospitals have legal or other regulatory requirements to maintain the purity and accuracy of their activities. When procuring laboratory devices, one must verify that all related standards and regulations are met. Such requirements will not only shield your hospital from legal problems but will also assure the well-being of your employees and patients as well.

Key considerations:

ISO certifications

FDA approvals (if applicable)

National and international safety regulations

Consider The Total Cost of Ownership

It is important to accept the overall ownership net cost, which is the net cost incurred by the equipment procurement or leasing. Maintenance cost, consumables, energy cost and the effective operating time of operation are included in this! Sometimes it is worthwhile to spend a little more money on new equipment that is effective in energy utilization and long-lasting in nature so that your facility can cut on future expenses.

Selecting Right Hospital Laboratory Equipment

Now that we’ve covered the steps to choose the right hospital laboratory equipment, let’s explore some essential pieces of equipment and their definitions:

Centrifuges

Centrifuges refer to containers or machines that rotate around an axis in order to separate the different elements of a liquid. For instance, many hospital laboratories use this instrument for separating blood from its component parts such as plasma.

Autoclaves

Autoclaves are devices that use steam and high pressure to disinfect or sterilize laboratory items and equipment. This is critical especially when there is a need to use the equipment without the introduction of foreign materials such as microorganisms.

Spectrophotometer

A spectrophotometer quantifies the light absorbed by a given sample. Its application can be exemplified by the determination of concentration of some substances in a solution, for instance, measuring glucose, protein, or enzyme content from blood samples.

According to Wikipedia, A subfield of electromagnetic spectroscopy and spectrophotometry measures a material's transmission or reflection characteristics quantitatively as a function of wavelength. Photometers, sometimes referred to as spectrophotometers, are used in spectrophotometry to measure the intensity of a light beam at various wavelengths. Modern spectrophotometers may examine large portions of the electromagnetic spectrum, including x-ray, ultraviolet, visible, infrared, and/or microwave wavelengths, even though spectrophotometry is most frequently used to measure ultraviolet, visible, and infrared radiation.

Microscope

A microscope is an instrument for viewing objects that are small. It makes an enlarged image of a small object that we can’t see through our naked eyes. In the hospital laboratories, they are used to view and analyze blood cells, bacteria, and other parasites.

Incubator

An incubator is defined as an apparatus that is meant to grow and preserve cultures of microbes or tissues under strict regulations. This is of vital importance in microbiological testing and research in hospitals.

Blood Gas Analyzer

A blood gas analyzer checks concentrations of oxygen, carbon dioxide and other gas in the sample. It is used in the clinical laboratory to determine the ventilation and acid-base status of a patient.

Why Opt for Science Lab Export?

Science lab Export is one of the top Hospital laboratory equipment manufacturers in India. We provide reliable and high-quality laboratory equipment. As a leading Hospital laboratory equipment supplier, we understand how essential it is to have appropriate tools in a Medical laboratory. Our products are made according to international standards regarding quality and safety. For unmatched service and quality in your search for hospital laboratory supplies, consider Science lab Export.

Buying good Hospital laboratory equipment means you are investing in educational prospects. With Science lab Export, you get assurance about getting excellent items that meet all your learning requirements.

#hospital laboratory equipment manufacturers and suppliers in India#hospital laboratory equipment manufacturers and suppliers#hospital laboratory equipment manufacturer

0 notes

Text

Solutions for Belt Misalignment in Belt Conveyors

Belt misalignment is a common and challenging problem in the operation of belt conveyors. The root cause of misalignment lies in the net external forces acting on the belt in the width direction, which is not zero, or uneven tensile stress perpendicular to the belt width. This imbalance causes the reaction force from rollers or drums to exert a sideways force on the belt, leading to misalignment. This article analyzes the causes of belt misalignment and provides effective corrective measures.

Causes of Belt Misalignment

1. Misalignment of Centers

The head, tail, and middle frames may not align properly. This misalignment often occurs due to improper installation, causing the belt's longitudinal centerline to be non-perpendicular to the drum axis, affecting operation.

2. Incorrect Roller Position

All rollers must be installed perpendicular to the belt centerline and parallel to the horizontal plane. If this requirement is not met, the belt will shift to one side.

3. Improper Belt Joint

Whether using mechanical or vulcanized joints, any irregularities in the joint can lead to uneven tension on both sides, causing misalignment during operation.

4. Misaligned Roller Frame

The centerline of the roller group must align with the centerline of the machine frame. The allowable error is no more than 3.0 mm. If the roller frame is improperly installed or bolts are loose, the belt may misalign.

5. Belt Damage

If the degree of damage is inconsistent on both sides of the belt, it may cause uneven stretching and result in misalignment.

6. Improper Discharge Point

Uneven material discharge can lead to uneven force distribution on the belt, causing it to misalign. If the discharge point is off-center, it should be adjusted promptly.

7. Impact from Material Drop

When material falls onto the belt, its weight and inertia can cause the belt to shift.

8. Accumulated Material

Sticky materials can accumulate on rollers or drums, leading to uneven tension and causing misalignment.

9. Incorrect Roller Angle

If the roller installation angle is not accurate, it can cause the belt to shift in the carrying section.

10. Belt Quality Issues

If the density of the belt is uneven, this can lead to uneven tension and result in misalignment.

11. Tensioning Device Issues

Improper installation or adjustment of the tensioning device can lead to uneven tension and cause misalignment.

12. Aging from Long-Term Use

Over time, belts can loosen, increasing the risk of misalignment.

13. Frame Inclination

If the frame is tilted, it can exert lateral force on the belt.

14. Equipment Vibration

Severe vibrations during operation, particularly radial movement of rollers, can cause the belt to misalign.

15. Small Curvature Radius

If the curvature radius of a concave section is too small, the belt may lift during startup.

Corrective Measures for Belt Misalignment

To address the above causes, the following measures can be implemented:

Align the Head, Tail, and Middle Frames: Ensure all three components are aligned on the same centerline.

Correct Roller Position: Ensure the roller axis is perpendicular to the belt and parallel to the horizontal plane.

Adjust Belt Joints: Remove any improperly aligned joints and ensure they are straight.

Realign Roller Frames: Move the roller frame on the misaligned side and recalibrate as necessary.

Enhance Maintenance: Regularly inspect the belt and promptly repair or replace any damaged sections.

Adjust Discharge Point: Ensure the discharge point is centered on the belt.

Design Appropriate Material Guides: Avoid direct drops of large objects and install buffer rollers at the discharge point.

Clear Accumulated Material: Keep roller and drum surfaces clean and maintain the operation of cleaning devices.

Adjust Roller Group Position: Modify the installation holes based on the direction of misalignment.

Choose Reputable Manufacturers: Ensure quality equipment and good after-sales service.

Install Tensioning Devices Properly: Make sure the centerline is perpendicular to the roller axis and follow installation requirements.

Conduct Regular Inspections: Replace aging or deformed belts promptly.

Correct Frame Inclination: Reinstall the frame to ensure it is level.

Identify and Address Vibration Issues: Resolve any sources of equipment vibration.

Add Pressure Rollers: Install pressure rollers in concave sections to prevent the belt from lifting.

In the operation of belt conveyors, it is essential to monitor belt misalignment closely. Timely identification of the causes and implementation of appropriate measures are key to maintaining efficient and stable operation. By following these corrective actions, you can effectively reduce the risks associated with misalignment and enhance production efficiency.For further inquiries or assistance, please feel free to contact us! We are here to help and support you.

0 notes

Text

Precision Engineering with 5 Axis Machining in India Trusted Manufacturers & Suppliers

In the era of advanced manufacturing, 5 Axis Machining India is transforming industries with its precision, efficiency, and ability to create complex components. As leading 5 Axis Machining Manufacturers, Sinnar Ureplas specializes in high-quality machining solutions, catering to aerospace, automotive, medical, and industrial sectors. Our state-of-the-art CNC technology ensures superior accuracy, reduced production time, and cost-effective solutions.

As trusted 5 Axis Machining Suppliers, we provide intricate 5 Axis Machining India, ensuring durability and performance. Read on to learn about the benefits, applications, and why Sinnar Ureplas is the preferred partner for precision machining.

Precision Engineering with 5 Axis Machining in India – Trusted Manufacturers & Suppliers

Manufacturing industries are evolving rapidly, demanding higher precision, faster production, and cost-effective solutions. 5 Axis Machining in India has emerged as a game-changer, allowing manufacturers to produce highly intricate parts with exceptional accuracy. Sinnar Ureplas, a trusted name among 5 Axis Machining Manufacturers, offers advanced machining solutions that cater to industries requiring high-quality precision components.

What is 5 Axis Machining?

5 Axis Machining refers to CNC (Computer Numerical Control) machining that operates along five different axes simultaneously. Unlike traditional 3-axis machines, which move only along the X, Y, and Z axes, 5 Axis Machines offer two additional rotational movements, allowing for intricate shaping and detailing. This multi-directional capability enhances flexibility, precision, and efficiency in the production of complex components.

Key Benefits of 5 Axis Machining

✅ Higher Precision & AccuracyWith advanced movement control, 5 Axis Machining ensures extreme precision, reducing errors and eliminating the need for multiple setups.

✅ Enhanced Production SpeedUnlike traditional machining, 5 Axis Machining Manufacturers reduce processing time by cutting materials from multiple angles in a single operation.

✅ Complex Component ManufacturingIndustries such as aerospace, medical, and automotive rely on 5 Axis Machining Suppliers for creating intricate parts that require detailed contouring.

✅ Cost-Effective SolutionsBy minimizing material waste and reducing manual intervention, 5 Axis Machining lowers production costs while improving efficiency.

✅ Superior Surface FinishWith fewer tool changes and seamless movement, the final product has a smoother surface finish, eliminating the need for additional polishing.

Process of 5 Axis Machining at Sinnar Ureplas

1️⃣ Client Consultation & Design Analysis – Understanding project requirements and optimizing designs. 2️⃣ Material Selection & Preparation – Choosing the right materials for durability and performance. 3️⃣ CNC Programming & Machine Setup – Ensuring precision cutting and minimal waste. 4️⃣ Machining & Quality Inspection – High-precision manufacturing with rigorous quality checks. 5️⃣ Final Product Delivery – On-time delivery of customized 5 Axis Parts in India.

If you are looking for precision-driven 5 Axis Machining in India, Sinnar Ureplas is your ideal partner. With advanced CNC technology, skilled engineers, and a commitment to quality, we provide machining solutions that exceed industry expectations.

Contact us today to learn more about our 5 Axis Machining Services and get a custom quote!Visit: https://sinnar-ureplas.com/5-axis-machining-manufacturers-suppliers-india.php

Contact: +91 89753 22242

0 notes

Text

5 Key Industries That Rely on Precision CNC Machining Services

Precision CNC machining services play a crucial role in various industries, ensuring high accuracy, efficiency, and quality in manufacturing. The aerospace industry depends on CNC machining for complex components like turbine blades and aircraft parts. In the automotive sector, CNC machining helps produce engine components, transmission parts, and custom prototypes. The medical industry relies on CNC machining for surgical instruments, implants, and medical devices requiring extreme precision. The electronics industry benefits from CNC machining in manufacturing circuit boards, connectors, and enclosures. Lastly, the defense and military sector uses CNC machining for weapon systems, armor, and specialized equipment. These industries trust CNC technology for its reliability, repeatability, and ability to create intricate parts with tight tolerances.

Aerospace Industry: High-Tolerance Manufacturing

The aerospace industry demands extreme precision, reliability, and high-performance materials. Precision CNC machining services are essential for producing complex aircraft components such as turbine blades, engine housings, and landing gear parts. Advanced CNC milling and turning processes ensure tight tolerances, superior surface finishes, and compliance with stringent FAA and aerospace standards. The ability to machine lightweight materials like titanium and aluminum makes CNC machining a cornerstone of aerospace manufacturing.

Automotive Industry: Enhancing Efficiency and Performance

The automotive sector relies on CNC machining for manufacturing critical engine components, transmission systems, and brake parts. CNC lathes, milling machines, and multi-axis machining centers produce high-precision parts that enhance vehicle performance, fuel efficiency, and durability. The rapid prototyping capabilities of CNC machining also allow for the development of innovative automotive technologies, such as electric vehicle (EV) components and advanced driver-assistance systems (ADAS).

Medical Industry: Precision and Compliance in Healthcare

In the medical field, precision cnc machining services plays a vital role in producing surgical instruments, prosthetics, and complex implants. Medical-grade materials such as stainless steel, titanium, and PEEK require high-precision machining to meet FDA and ISO standards. Multi-axis CNC milling and micromachining ensure accuracy in producing intricate components like orthopedic screws, dental implants, and diagnostic equipment. CNC machining’s ability to maintain biocompatibility and sterility makes it indispensable in medical device manufacturing.

Electronics Industry: Micro-Machining for High-Tech Devices

The electronics industry benefits from CNC machining’s ability to manufacture precision components for circuit boards, connectors, and semiconductor equipment. Miniature parts require tight tolerances and ultra-fine machining to ensure optimal performance. CNC micro-machining processes enable the production of heat sinks, enclosures, and housings for consumer electronics, telecommunications, and industrial automation systems. The demand for miniaturization and advanced materials like copper and aluminum alloys makes CNC machining crucial in the electronics sector.

Defense and Military Industry: Durable and High-Performance Parts

The defense industry depends on precision cnc machining services for producing robust components used in firearms, armored vehicles, missile systems, and aerospace defense applications. CNC machining ensures high-strength materials like titanium, Inconel, and hardened steels meet the stringent requirements of military-grade equipment. Multi-axis CNC machining and EDM processes enhance precision and durability, ensuring mission-critical parts withstand extreme conditions and heavy operational loads.

Energy Sector: Precision in Renewable and Traditional Power Systems

From wind turbines to oil and gas extraction equipment, the energy sector requires high-precision CNC-machined parts. CNC machining supports the production of turbine blades, drilling components, and heat exchangers that must endure high pressures, extreme temperatures, and corrosive environments. Advanced CNC processes, such as 5-axis milling and CNC turning, allow for the fabrication of intricate components for renewable energy solutions, including solar panel frames and hydroelectric turbines.

Industrial Equipment Manufacturing: Custom Machined Components

Industrial machinery and automation systems rely on CNC machining for custom parts, gears, and bearings. CNC-machined components improve the efficiency and longevity of manufacturing equipment, robotics, and conveyor systems. With CNC milling, turning, and grinding, manufacturers can create durable and precise machine parts for diverse industrial applications. CNC machining’s adaptability ensures compatibility with materials like stainless steel, brass, and engineered plastics, meeting the high demands of industrial production.

Conclusion

Precision CNC machining services are the backbone of numerous industries, ensuring the production of high-quality, reliable, and complex components. Whether in aerospace, automotive, medical, electronics, defense, energy, or industrial manufacturing, CNC machining delivers accuracy, efficiency, and consistency. As technology advances, CNC machining continues to evolve, driving innovation and meeting the growing demands of modern industry. The combination of automation, multi-axis capabilities, and high-tolerance machining ensures CNC machining remains a critical force in global manufacturing.

0 notes

Text

🤯 Weird CNC processing scene! It is obviously a rounded corner processing, but the finished product turns into a cube in seconds? Reveal the truth behind it!

Weird CNC processing effect: It looks like a rounding processing method, but the actual product is in the shape of a cube. What is the reason?

#CNCProcessing #WeirdManufacturing #5AxisMachining #PrecisionEngineering #ManufacturingMagic #CubeOrRound #IndustrialTech #MachiningEffects

0 notes

Text

Reliable CNC Machining Service Suppliers in China

China’s CNC machining service suppliers provide reliable and scalable solutions for producing precision-engineered components. With extensive capabilities, including 3-, 4-, and 5-axis machining, they handle complex geometries and diverse materials with ease. Their commitment to quality assurance and fast turnaround times ensures customer satisfaction across industries such as robotics, medical, and telecommunications. Combining technological expertise with competitive pricing, China CNC Machining Service Suppliers have become trusted partners for businesses seeking innovative manufacturing solutions on a global scale.

#cnc machining services#cnc machining in china#china cnc machining#cnc machining china#cnc machining service china#china cnc machining service#cnc machining services china#custom cnc machining services#custom cnc machining china#china cnc custom machining

0 notes