#5 Axis CNC Machining Center

Explore tagged Tumblr posts

Text

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

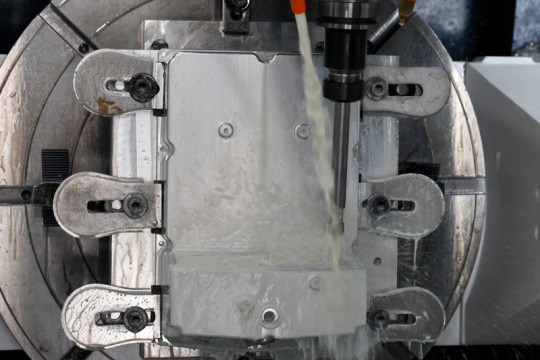

🔥Year-end sprint! The 5-axis CNC machine is running at full capacity, working overtime to rush the New Year's orders, and every cut is ingenious! 🎉Can you guess what masterpiece we are working on? #CNCProcessing #CraftsmanSpirit #NewYearNewAtmosphere

#CNC Machine Plywood#CNC Machine Programming Course#CNC Machining Center#CNC Machining For Medical Imaging#CNC Milling Machine For Sale#CNC Routers Machines#CNC Screw-Machining For Aviation#Diy CNC Machine#Haas CNC Milling Machine#Laser CNC Machine#Mazak CNC Machine#Mini CNC Milling Machine#What Is CNC Milling Machine#What Is CNC Routers Machine#5 Axis CNC Milling Machine

0 notes

Text

Unlock advanced precision and efficiency in your projects with our CNC Milling Machine 5 Axis CNC Machining Center for Graphite, perfect for intricate designs and high-quality finishes.

#CNC Milling Machine 5 Axis CNC Machining Center for Graphite#Graphite Milling Machines#CNC precision engraving machine#Graphite Lathe#Graphite Milling

0 notes

Text

Ultimate Guide to Precision CNC Machining: From Design to Delivery

Precision CNC machining services are essential for creating high-accuracy components used in industries like aerospace, automotive, and medical. This process involves designing parts using CAD software, selecting the right materials, and utilizing advanced CNC machines to achieve tight tolerances. Quality control and post-processing ensure durability and functionality, while timely delivery completes the cycle. Companies like Pangea Technologies excel in providing end-to-end precision CNC machining services, combining cutting-edge technology, skilled engineering, and rigorous quality checks. Whether for prototypes or large-scale production, Pangea Technologies delivers reliable, high-quality solutions, making them a trusted partner in precision manufacturing.

Understanding Precision CNC Machining Services

Precision CNC machining services involve the use of computer-controlled machines to manufacture parts with exceptional accuracy and consistency. These services are essential for industries such as aerospace, automotive, medical, and electronics, where even the smallest deviation can lead to significant issues. CNC machining ensures tight tolerances, high repeatability, and the ability to work with a variety of materials, including metals, plastics, and composites. Companies like Pangea Technologies specialize in providing state-of-the-art precision CNC machining services, leveraging advanced technology and skilled engineers to meet the most demanding requirements.

The Design Phase: Turning Ideas into Reality

The first step in precision CNC machining is the design phase. Engineers and designers use CAD (Computer-Aided Design) software to create detailed 3D models of the component. This phase is critical because it determines the feasibility, functionality, and manufacturability of the part. Pangea Technologies collaborates closely with clients during this phase, offering design-for-manufacturability (DFM) feedback to optimize the design for CNC machining. This ensures that the final product is not only functional but also cost-effective to produce.

Material Selection: The Foundation of Quality

Choosing the right material is crucial for the success of any precision CNC machining project. Factors such as strength, durability, thermal resistance, and machinability must be considered. Common materials used in CNC machining include aluminum, stainless steel, titanium, brass, and engineering plastics. Pangea Technologies provides expert guidance on material selection, helping clients choose the best option for their specific application. Their extensive material inventory ensures that clients have access to high-quality raw materials for their projects.

Machining Process: Precision at Its Finest

Once the design and material are finalized, the machining process begins. CNC machines, such as mills, lathes, and multi-axis machining centers, are programmed to follow the CAD model’s specifications. These machines use cutting tools to remove material from the workpiece, shaping it into the desired form. Precision CNC machining services offered by Pangea Technologies utilize advanced equipment, such as 5-axis CNC machines, to produce complex geometries with unparalleled accuracy. Their commitment to quality ensures that every part meets the highest standards.

Quality Control: Ensuring Perfection

Quality control is a critical aspect of precision CNC machining. Each part undergoes rigorous inspection using tools like coordinate measuring machines (CMMs), optical comparators, and surface finish testers. This ensures that the final product adheres to the specified tolerances and quality standards. Pangea Technologies employs a comprehensive quality control process, combining advanced inspection techniques with skilled technicians to guarantee the accuracy and reliability of every component.

Post-Processing: Adding the Finishing Touches

After machining, parts often require post-processing to enhance their appearance, functionality, or durability. Common post-processing techniques include anodizing, powder coating, polishing, heat treatment, and plating. These processes not only improve the part’s performance but also protect it from environmental factors like corrosion and wear. Pangea Technologies offers a wide range of post-processing services, ensuring that every component meets the client’s exact requirements. Their expertise in finishing techniques adds value to the precision CNC machining process.

Delivery: Bringing Your Vision to Life

The final step in the precision CNC machining journey is delivery. Once the parts have passed all quality checks and post-processing, they are carefully packaged and shipped to the client. Timely delivery is essential to ensure that the client’s production schedule remains on track. Pangea Technologies prides itself on its efficient logistics and reliable delivery services. Their commitment to customer satisfaction ensures that every project is completed on time and to the highest standards.

Conclusion

Precision CNC machining services are at the heart of modern manufacturing, enabling the production of high-quality, complex components with unmatched accuracy. From design to delivery, every step in the process requires expertise, advanced technology, and a commitment to quality. Companies like Pangea Technologies exemplify the best in precision CNC machining services, offering end-to-end solutions that meet the needs of diverse industries. By combining cutting-edge technology, skilled engineers, and a customer-centric approach, Pangea Technologies ensures that every project is a success. Whether you’re developing a prototype or scaling up production, partnering with a trusted provider like Pangea Technologies can help you achieve your goals with precision and efficiency. Embrace the future of manufacturing with precision CNC machining services that deliver results you can count on.

0 notes

Text

5 Key Industries That Rely on Precision CNC Machining Services

Precision CNC machining services play a crucial role in various industries, ensuring high accuracy, efficiency, and quality in manufacturing. The aerospace industry depends on CNC machining for complex components like turbine blades and aircraft parts. In the automotive sector, CNC machining helps produce engine components, transmission parts, and custom prototypes. The medical industry relies on CNC machining for surgical instruments, implants, and medical devices requiring extreme precision. The electronics industry benefits from CNC machining in manufacturing circuit boards, connectors, and enclosures. Lastly, the defense and military sector uses CNC machining for weapon systems, armor, and specialized equipment. These industries trust CNC technology for its reliability, repeatability, and ability to create intricate parts with tight tolerances.

Aerospace Industry: High-Tolerance Manufacturing

The aerospace industry demands extreme precision, reliability, and high-performance materials. Precision CNC machining services are essential for producing complex aircraft components such as turbine blades, engine housings, and landing gear parts. Advanced CNC milling and turning processes ensure tight tolerances, superior surface finishes, and compliance with stringent FAA and aerospace standards. The ability to machine lightweight materials like titanium and aluminum makes CNC machining a cornerstone of aerospace manufacturing.

Automotive Industry: Enhancing Efficiency and Performance

The automotive sector relies on CNC machining for manufacturing critical engine components, transmission systems, and brake parts. CNC lathes, milling machines, and multi-axis machining centers produce high-precision parts that enhance vehicle performance, fuel efficiency, and durability. The rapid prototyping capabilities of CNC machining also allow for the development of innovative automotive technologies, such as electric vehicle (EV) components and advanced driver-assistance systems (ADAS).

Medical Industry: Precision and Compliance in Healthcare

In the medical field, precision cnc machining services plays a vital role in producing surgical instruments, prosthetics, and complex implants. Medical-grade materials such as stainless steel, titanium, and PEEK require high-precision machining to meet FDA and ISO standards. Multi-axis CNC milling and micromachining ensure accuracy in producing intricate components like orthopedic screws, dental implants, and diagnostic equipment. CNC machining’s ability to maintain biocompatibility and sterility makes it indispensable in medical device manufacturing.

Electronics Industry: Micro-Machining for High-Tech Devices

The electronics industry benefits from CNC machining’s ability to manufacture precision components for circuit boards, connectors, and semiconductor equipment. Miniature parts require tight tolerances and ultra-fine machining to ensure optimal performance. CNC micro-machining processes enable the production of heat sinks, enclosures, and housings for consumer electronics, telecommunications, and industrial automation systems. The demand for miniaturization and advanced materials like copper and aluminum alloys makes CNC machining crucial in the electronics sector.

Defense and Military Industry: Durable and High-Performance Parts

The defense industry depends on precision cnc machining services for producing robust components used in firearms, armored vehicles, missile systems, and aerospace defense applications. CNC machining ensures high-strength materials like titanium, Inconel, and hardened steels meet the stringent requirements of military-grade equipment. Multi-axis CNC machining and EDM processes enhance precision and durability, ensuring mission-critical parts withstand extreme conditions and heavy operational loads.

Energy Sector: Precision in Renewable and Traditional Power Systems

From wind turbines to oil and gas extraction equipment, the energy sector requires high-precision CNC-machined parts. CNC machining supports the production of turbine blades, drilling components, and heat exchangers that must endure high pressures, extreme temperatures, and corrosive environments. Advanced CNC processes, such as 5-axis milling and CNC turning, allow for the fabrication of intricate components for renewable energy solutions, including solar panel frames and hydroelectric turbines.

Industrial Equipment Manufacturing: Custom Machined Components

Industrial machinery and automation systems rely on CNC machining for custom parts, gears, and bearings. CNC-machined components improve the efficiency and longevity of manufacturing equipment, robotics, and conveyor systems. With CNC milling, turning, and grinding, manufacturers can create durable and precise machine parts for diverse industrial applications. CNC machining’s adaptability ensures compatibility with materials like stainless steel, brass, and engineered plastics, meeting the high demands of industrial production.

Conclusion

Precision CNC machining services are the backbone of numerous industries, ensuring the production of high-quality, reliable, and complex components. Whether in aerospace, automotive, medical, electronics, defense, energy, or industrial manufacturing, CNC machining delivers accuracy, efficiency, and consistency. As technology advances, CNC machining continues to evolve, driving innovation and meeting the growing demands of modern industry. The combination of automation, multi-axis capabilities, and high-tolerance machining ensures CNC machining remains a critical force in global manufacturing.

0 notes

Text

Top-Quality 4 Axis Machining Manufacturers for Precision Engineering

4 Axis Machining Manufacturers and Suppliers: Precision Engineering by Sinnar Ureplas

In today’s advanced manufacturing landscape, precision and efficiency are crucial for producing high-quality components. This is where 4-axis machining comes into play. It has revolutionized the way industries handle complex machining tasks, offering unparalleled accuracy and flexibility. Sinnar Ureplas, a leading name in the industry, is renowned for being one of the most trusted 4 Axis Machining Manufacturers and 4 Axis Machining Suppliers in India. We specialize in crafting precision-engineered 4-axis components to meet the growing demands of various industries.

What is 4 Axis Machining?

4-axis machining is an advanced method of computer numerical control (CNC) machining that incorporates an additional rotational axis to the traditional three-axis system. This fourth axis enables the machining tool to rotate around the X-axis, allowing for enhanced precision and the ability to work on multiple sides of a component without repositioning. This advanced capability is especially useful for creating intricate designs and machining components with complex geometries.

Applications of 4 Axis Machining

4-axis machining is widely used in industries requiring precise and efficient manufacturing of complex parts. Some key applications include:

Automotive: Production of engine components, gearboxes, and custom parts.

Aerospace: Manufacturing of turbine blades, airframe components, and other critical parts.

Medical: Precision machining for surgical instruments, prosthetics, and implants.

Electronics: Fabrication of intricate casings and connectors.

Industrial Machinery: High-precision components for heavy machinery and equipment.

Why Choose Sinnar Ureplas?

As a leading name among 4 Axis Machining Manufacturers and Suppliers, Sinnar Ureplas offers cutting-edge solutions tailored to the unique needs of our clients. Here’s why we stand out:

1. State-of-the-Art Technology

Our advanced 4-axis CNC machining centers are equipped with the latest technology to ensure precision and consistency in every project. With our modern infrastructure, we can handle projects of varying complexities and sizes.

2. Expert Team

Our team of skilled engineers and technicians has extensive experience in 4-axis machining. They ensure that every component meets the highest standards of quality and precision.

3. Custom Solutions

We understand that each project is unique. That’s why we offer customized solutions to meet the specific requirements of our clients, whether it’s a prototype or high-volume production.

4. Quality Assurance

At Sinnar Ureplas, quality is non-negotiable. Each component undergoes rigorous testing and inspection to ensure it meets the desired specifications and industry standards.

5. Timely Delivery

We pride ourselves on delivering projects on time without compromising quality. Our streamlined processes and efficient workflow ensure quick turnaround times.

6. Competitive Pricing

We offer cost-effective solutions without compromising on quality, making us a preferred choice for clients across India.

4 Axis Components in India

As a trusted supplier of 4 Axis Components in India, Sinnar Ureplas caters to various industries with precision-engineered parts. Our components are designed to meet the demanding requirements of industries such as automotive, aerospace, and medical. By leveraging advanced 4-axis machining technology, we deliver components that are not only precise but also durable and reliable.

Partner with Sinnar Ureplas

When you choose Sinnar Ureplas, you’re partnering with one of the best in the business. Our commitment to quality, innovation, and customer satisfaction has made us a leader in 4 Axis Machining Manufacturers and Suppliers. We work closely with our clients to understand their requirements and deliver solutions that exceed expectations.

For high-quality 4 Axis Components in India, look no further than Sinnar Ureplas. Contact us today to discuss your machining needs and experience the difference of working with industry experts!

If you looking for 4 Axis Machining Manufacturers or 4 Axis Machining Suppliers visit or contact Sinnar Ureplas!

Contact us: +918975322242

Visit us: https://www.sinnar-ureplas.com/4-axis-machining-manufacturers-suppliers-india.php

#4 Axis Machining Manufacturers#4 Axis Machining Suppliers#4 Axis Components India#4AxisMachiningManufacturers#4AxisMachiningSuppliers#4AxisComponentsIndia

0 notes

Text

0 notes

Text

CNC Foam Router for Professional Foam Shaping and Design

In the world of professional foam shaping and design, precision is key. From creating intricate sculptures to producing custom packaging solutions, foam is used in a wide variety of industries, and the demand for precision-cut foam continues to rise. The solution to this demand lies in the CNC foam router—a state-of-the-art tool that revolutionizes foam cutting, carving, and shaping.

Use a rotary cutting tool (router bit) to carve and shape foam. Suitable for detailed 3D carving, engraving, and milling. Can handle a wider range of foam types, including polyurethane and polyethylene.A CNC foam cutter is a specialized type of CNC machine designed to cut and shape foam materials with high precision and efficiency. These machines are commonly used in various industries, including packaging, prototyping, model making, insulation, and more.

What is a CNC Foam Router?

CNC foam router is a specialized machine that uses computer numerical control (CNC) technology to cut, carve, and shape foam materials with remarkable accuracy. These routers are designed to work with various types of foam, including expanded polystyrene (EPS), polyethylene (PE), polyurethane (PU), and more. CNC foam router machine is a specialized type of CNC machine designed for cutting, shaping, and carving foam materials. These machines are widely used in industries such as packaging, prototyping, model making, and even in the production of theater and movie props.

The CNC foam router operates based on pre-programmed instructions from CAD (computer-aided design) software. This allows operators to create highly detailed designs and shapes in foam quickly and consistently. The process is automated, reducing the chances of human error and ensuring uniformity across multiple pieces.

Types of CNC Foam Cutter

4 Axis Foam CNC Router

The 4-axis CNC Router machine refers to the computer numerical control equipment including X, Y, Z, and additional rotation axis. It has 3 straight coordinates and 1 rotating coordinate. 4-axis CNC Router engraving machines are usually equipped with rotating axes or rocking spindles, so they can contact the workpiece from different angles and effectively work, so as to realize the 3D processing of cylindrical, curved and circular surfaces.

4 axis CNC router is quite good at processing 3D workpieces. It generally falls into two types. The first type described hereunder is equipped with a rotating spindle that can swing by 180°. It can engrave 3D patterns and drill holes on side surfaces of wood, MDF, acrylic, foam, rubber, and other materials. For example, 3D letters, signs, reliefs, and sculptures.

5 Axis CNC Foam Router

The 5 axis CNC Router machine, also known as the 5 axis CNC machining center, is equipped with a 3D CNC system.Designed as a 5 axis CNC processing solution with high cost-effectiveness, it refers to the machine's capacity to move tools or parts on five different axes for complex surface processing. As a piece of advanced CNC equipment, the 5 axis CNC machining center or CNC router is crafted especially for complex curved surfaces. It finds extensive application in industries like aviation, aerospace, automotive, military, scientific research, precision instruments, high-precision medical equipment, etc. Also, it can handle a wide variety of materials such as wood, metals, stones, plastic, styrofoam, composites, and so on.

Features of a CNC Foam Cutting Machine

Key Advantages of CNC Foam Cutting Machine

One of the primary benefits of a CNC foam router is its precision and accuracy. Unlike traditional manual cutting methods, which can lead to inconsistencies and material waste, CNC foam routers provide highly precise cuts. This ensures that foam materials are cut to exact specifications, minimizing waste and producing uniform, high-quality results.

In addition to precision, CNC foam routers are highly customizable. They can easily accommodate a wide range of intricate designs, from basic geometric shapes to more elaborate, complex patterns. With CAD software, designers can create any shape or pattern, which is then executed with exact precision by the router. This flexibility makes the CNC foam router ideal for a variety of custom applications, including sculptures, packaging, and prototypes.

Efficiency and Automation

Another major advantage of CNC foam routers is their versatility. These machines can handle different types of foam, from rigid materials like polyurethane and PVC to softer options like polystyrene. This makes CNC foam routers suitable for diverse industries, from packaging and architectural modeling to artistic sculpture and prototypes.

Speed and efficiency are also key benefits of CNC foam routers. Unlike traditional manual cutting methods, which can be slow and labor-intensive, CNC machines work quickly and continuously, cutting large volumes of foam in a fraction of the time. This makes them ideal for businesses with high-volume production needs, helping to meet tight deadlines.

Additionally, automation is a major selling point. Once the design is input into the system, the CNC foam router takes over the cutting process, reducing the need for skilled labor and minimizing human error. This automation increases productivity, reduces mistakes, and frees up resources for other tasks, significantly enhancing operational efficiency.

Applications of CNC Foam Milling

Common Applications of CNC Foam Milling

CNC foam routers offer remarkable versatility, making them ideal for various industries. In foam sculptures and artwork, artists and designers use these machines to craft intricate, detailed designs for art installations and commercial displays. From simple shapes to complex textures, CNC foam routers excel in transforming creative concepts into tangible pieces with precision.

In the packaging industry, CNC foam routers are used to create custom foam inserts for the safe transport of fragile items, such as electronics, medical devices, and automotive parts. By carving foam to exact specifications, these routers ensure products are securely packaged, minimizing the risk of damage during transit. Similarly, CNC foam routers play a significant role in prototypes and models, where engineers and designers rely on foam to create accurate initial product models before progressing to more expensive materials.

Expanding Industries for CNC Foam Routers

CNC foam routers are also widely used in architectural models, where architects rely on them to create detailed foam models of buildings and landscapes. Foam is a cost-effective material, and CNC routers can efficiently turn 3D digital designs into physical models, which are essential for presentations and design development.

In advertising and signage, CNC foam routers carve custom shapes, letters, and logos from foam, which are then painted for use in eye-catching displays, signs, and banners. The ability to create bold and intricate designs makes these routers ideal for large-scale advertising projects. Additionally, in the entertainment industry, CNC foam routers are employed for set design, crafting foam props, stage sets, and scenery. These routers allow designers to construct realistic environments for theater, film, and television productions.

Why Choose a CNC Foam Cutting for Your Business?

There are numerous reasons why investing in a CNC foam router is a wise decision for your business. Here are some of the most compelling reasons:

Increased Productivity:CNC foam routers dramatically improve productivity. With automation, the router can work continuously without requiring breaks, unlike manual labor. This not only speeds up the production process but also allows your business to handle more orders in less time, increasing overall throughput.

High-Quality Results:Because CNC foam routers offer extreme precision, the quality of the final product is significantly higher. Whether you're cutting a foam model, creating packaging inserts, or producing intricate sculptures, the results will be uniform and exact. Consistent quality across every product is essential for customer satisfaction and long-term business success.

Cost-Effectiveness:Although the initial cost of a CNC foam router may seem high, the long-term savings are considerable. These machines reduce labor costs, material waste, and production time, which translates into significant cost savings. Additionally, CNC foam routers can help companies meet tight deadlines, avoiding costly delays.

Flexibility and Customization:The customization potential offered by CNC foam routers is unparalleled. From prototypes to large-scale production, CNC foam routers can be programmed to cut any design imaginable. The flexibility to produce both large quantities of identical parts and unique one-off items makes the CNC foam router an indispensable tool in many industries.

Reduced Labor Requirements:Manual foam cutting can be labor-intensive and physically demanding. CNC foam routers reduce the need for skilled manual labor, allowing operators to focus on machine operation, design programming, and oversight. The automation process also reduces human error, ensuring that each cut is accurate.

Choosing the Right Machine

Selecting the right CNC foam router for your business involves considering several factors, including:

Machine Size and Cutting Area:The size of the foam you plan to work with will determine the size of the CNC foam router you need. Larger machines are capable of cutting larger sheets of foam, while smaller machines are suitable for more intricate designs and smaller foam pieces.

Cutting Capabilities:Different CNC foam routers have different cutting capabilities. Some may be better suited for simple, straight cuts, while others are equipped to handle more complex designs, including curves and 3D shapes. Consider your business's specific needs when selecting a machine.

Software Compatibility:Most CNC foam routers are compatible with popular CAD/CAM software. Make sure the machine you choose integrates well with the software you use for design and programming.

Cost and Budget:CNC foam routers vary in price depending on their size, features, and brand. Make sure to assess your business's budget and weigh the potential return on investment when selecting a machine. While the initial investment may be high, the long-term benefits in terms of productivity and quality will justify the cost.

Technological Advancements in CNC Foam Cutter Machines

Integration with CAD/CAM Software

Modern 3D CNC foam router machines are often integrated with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This integration allows for seamless design and manufacturing processes, reducing errors and improving overall efficiency.

Automation and Robotics

The incorporation of automation and robotics into CNC machining has further enhanced productivity. Automated 3D CNC foam router machines can perform multiple tasks without human intervention, increasing throughput and reducing the risk of human error.

IoT and Industry 4.0

The advent of the Internet of Things (IoT) and Industry 4.0 has brought about significant changes in CNC machining. Machines are now connected to networks, allowing for real-time monitoring, predictive maintenance, and improved decision-making processes.

Conclusion

CNC foam router is an indispensable tool for businesses in industries that require precision foam cutting and shaping. From custom packaging to artistic sculptures and prototypes, CNC foam routers offer unmatched precision, speed, and versatility. By automating the foam cutting process, these machines not only enhance productivity but also reduce material waste and labor costs, allowing businesses to scale efficiently.

Investing in a CNC foam router is a smart decision for any company looking to stay competitive in the rapidly evolving foam industry. Whether you're cutting foam for practical applications or creating detailed artistic designs, a CNC foam router will give you the flexibility and control to meet the demands of your customers and grow your business.

0 notes

Text

UCAM: Leading Precision Engineering and Innovative Rotary Solutions

UCAM is a pioneering manufacturer of 4th and 5th Axis CNC Rotary Tables in India and has been at the forefront of precision engineering since its inception in 1986. With over three decades of expertise, our state-of-the-art manufacturing facility is equipped with the latest technology and advanced machinery, enabling us to produce CNC Rotary Tables with unparalleled precision and durability. Known for customizing rotary solutions to meet specific needs, we serve various sectors, including Agriculture, Automobile, and Medical, both domestically and internationally.

In addition to CNC Rotary Tables, UCAM encompasses other specialized verticals. Nimble Machines, for example, focuses on high-precision Gear Hobbing Machines, with the VAJRA and TARANG Series representing the latest advancements in this area. Similarly, Nimble Electric provides an array of high-precision Torque Motors and Direct Drives, highlighted by the ORION series. These complementary products reflect UCAM’s commitment to meeting diverse industry requirements with precision and adaptability.

UCAM to Showcase Its Wide Range of Rotary Tables at IMTEX 2025

At IMTEX 2025, to be held in Bangalore from January 23-29, 2025, UCAM will exhibit an extensive range of technologies designed to promote productive and sustainable manufacturing practices. Our 4th and 5th-axis Rotary Tables are known for delivering high levels of precision and repeatability. In particular, our latest URQ-200HS Rotary Table offers enhanced speed and clamping torque, making it ideal for high-demand applications requiring both efficiency and precision.

UCAM’s Premier Product Lineup at IMTEX Exhibition:

URQ-200HS 4-Axis Rotary Table:

This model is a versatile, high-speed machining solution catering to a variety of production needs. With its modular structure and compact design, the URQ-200HS is ideal for space-constrained environments. It features straightforward maintenance, including easy backlash adjustments that ensure maximum repeatability. Especially well-suited for drill tap centers that require high-speed indexing, this series is a valuable asset for achieving increased productivity and accuracy in precision machining.

Our range of rotary tables addresses the needs of multiple industries. At IMTEX 2025, we will spotlight solutions specifically for the Machine Tool, Automotive, Defense, and General Engineering sectors.

Rotary Production System – URPQ 200:

Engineered for precision and versatility, this 4th-axis solution boosts machining productivity by accommodating multiple workpieces with similar operations. It guarantees high accuracy and repeatability, featuring a robust support system, a faceplate tailstock, and a modular fixture plate for enhanced stability and flexibility. An optional drop-in rotary union is available to facilitate greater clamping power for components. Its highly rigid base plate maintains alignment, making it particularly suitable for mass production scenarios demanding top-tier accuracy.

Rotary Tilting Table – Q Series:

The Q Series embodies engineering excellence with a robust, rigid design tailored for complex machining tasks. Users have the option of pneumatic or hydraulic clamping, and the tables come in both short and large swing variants to accommodate different workpiece sizes. Maintenance is user-friendly, with adjustments made easy for consistent repeatability. The Q Series Tilting Tables, including the USSR-200q and ULSR-200q models, integrate seamlessly with existing 3-axis setups to enable full 5-axis movement, supporting complex machining requirements.

Committed to innovation and customer satisfaction, UCAM will showcase its state-of-the-art solutions, reinforcing our position as a leader in the precision engineering field. We look forward to demonstrating how our products can enhance productivity and precision in manufacturing.

UCAM Pvt Ltd

www.ucamind.com

0 notes

Text

What Industries Is Precision Machining Applicable To?

Precision machining is applicable to a wide range of industries including, but not limited to automotive, aerospace, biomedical, petrochemical, energy, environmental protection, etc. due to its high accuracy, quality and flexibility.

Aerospace The aerospace sector places extremely high demands on the precision, strength and weight of parts and assemblies. Precision machining technology is used in the manufacturing of engine components, turbine blades, turbine disks, aeronautical instruments, propulsion systems, satellite parts and structural components such as hulls, wings and empennage. These parts require extremely high geometric accuracy, surface quality and material properties to ensure the performance, safety and reliability of the aerocraft. (Ultra-precision machining technology is used in the manufacturing of precision engine parts, aerospace structural components, guidance and control elements, etc., which is widely used in satellite manufacturing, automatic spacecraft rendezvous and docking, satellite guidance and control, etc.)

Biomedical Ultra-precision machining technology is used in the manufacturing of diagnostic devices, medical devices, medical equipment parts, surgical instruments, artificial human implants such as artificial joints, bone plates, spinal screws, cardiac stents, etc. in which medical devices are manufactured with stringent requirements for precision and quality to ensure their safety and effectiveness in clinical use. These devices require precise dimensions and shapes, as well as smooth surfaces to minimise human rejection and increase biocompatibility.

Automobile

Automobiles are made up of thousands of precision parts, and the fineness of these parts directly affects their performance and safety. In automotive manufacturing, precision machining technology is used to produce key components such as engine parts, braking systems, steering systems, transmission components, suspension systems parts, precision instruments and body electronics. CNC Precision Machining can help manufacturers produce more accurate, safe and durable automotive parts. High precision machining not only improves the performance and reliability of automobiles, but also promotes the automation and intelligent development of the automotive industry.

Petrochemical, Energy and Environmental Protection

Ultra-precision machining technology is used in the manufacturing of gases, liquids and solid tanks, wind and solar power generation heavy machinery equipment, electrical equipment and nuclear reactor components, etc., in addition to the manufacturing of environmental protection equipment, metrology equipment and so on.

Electronic Device

Modern electronic products such as smartphones, computers, and wearable devices rely on precision machining technology for many of their internal key components. For example, mobile phone housings, chip packages, miniature sensors and circuit boards all require high precision machining technology to ensure product performance and stability.

Optics and Photoelectricity

Optical instruments such as microscopes, telescopes, astronomical telescopes, camera lenses, optical lens, fibre optic communication devices, laser components, etc. require precision machining technology in their manufacturing process to ensure the accuracy and surface quality of optical components. Small errors in these components can have a significant impact on imaging quality.

Semiconductor

The semiconductor industry also has a high demand for precision machining technology. The production, packaging and testing of semiconductor wafers requires the use of high-precision equipment and processes to ensure product quality and performance.

Railway

In the field of rail transportation, such as high-speed trains, underground vehicles and other rail vehicles above the precision electronic equipment shell of custom and structural components, such as the manufacturing and processing, need to be supported by precision machining technology.

To summarize, precision machining technology plays a vital role in modern industry, covering multiple fields from high-tech products to daily necessities. The application areas of precision machining technology will continue to expand as technology continues to advance and demand continues to increase.

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc precision machining#precisionmanufacturing#high precision#5 axis machining#cnc parts company#cnc parts factory#cnc machining center

1 note

·

View note

Text

youtube

Machining center cnc milling turning machining parts

We make cnc precision machining custom stainless steel parts, 3/4/5 axis precision cnc machining part, cnc machining parts aluminum, milling turning service cnc machining parts, cnc turning mechanical component parts, cnc custom machining milling turning parts, custom industrial 5 axis cnc milling turning.

----------------------------------------------------------

0 notes

Text

Revolutionize your machining capabilities with the New Graphite CNC Machining Center 5 Axis, offering unparalleled precision and flexibility for complex designs.

#New Graphite CNC Machining Center 5 Axis#Graphite Processing Machines#Graphite cnc#Graphite Processing#Graphite Mould

0 notes

Text

Computer Numerical Control machines process materials to meet the specifications of programmed instructions. CNC machines include lathes, grinders, machining centers, and many other tools. The machinery has become very popular in the manufacturing industry because it can be used with a wide variety of materials and provide much greater accuracy and consistency than other tools. Furthermore, CNC machines can operate without the need for an individual operator to control the equipment. But a CNC machine still needs to be programmed by a human being before it can begin producing parts. That is where G-Code and M-Code come in. An Overview of G-Code If you are interested in becoming a programmer, there are now a number of different industries that you can work in, including the manufacturing sector. As a CNC machine programmer, you would create a sequence of codes and data to form a program that tells the CNC machine precisely what to do. With the right tooling, the program can then ensure the machine produces accurate and repeatable parts. It is a great idea to use a used CNC machine when job training because it is more affordable; especially when learning cases. In order to create a CNC machine program, you need to learn G-Code. In basic terms, it is the software programming language that is used to control a CNC machine. Thankfully, G-Code is written in a logical and straightforward way, even with complex CNC machining. The “G” is followed by a number. That number is a command that changes the geometry. For example, “G00” is a command for the machine to make a rapid movement to a specific coordinate position. So, it basically enables the CNC tool and the part it is producing to move from near to far and vice versa. Other commands include “G01,” which controls the movement of the linear feed, and “G02” and “G03,” which perform the move in a clockwise or counterclockwise direction. The code for such operations is also followed by a geometric location. So, the “G” and the proceeding numbers are followed by coordinates for the machine’s X and Y axes. For example, take the G-Code of “G00G58X-120.Y-5.” You already know that the first three digits refer to a rapid movement. “G58” is the code that specifies the work coordinates that change the geometry relative to the work offsets, such as part origin. The numbers that follow “G58” in the example of “G00G58X-120.Y-5” therefore indicate the X-axis needs to be “-120mm” and the Y-axis needs to be “-5mm.” The G-Code can repeat actions for as long as needed. With the right use of code and coordinates, CNC machines can consistently perform and be flexible enough to produce a variety of parts from a multitude of materials. An Overview of M-Code M-Code in CNC machining basically organizes miscellaneous functions. Think of them as non-geometry machine functions. They include things like pallet change, the on and off of coolant, and the start and stop of spindle rotation. The functions often vary depending on the precise CNC machine being used. Also, M-Code is more specific for different machinery and is more customizable than G-Code. Both M-Code and G-Code are vital for a CNC machine to perform correctly. Like the format of G-Code, M-Code consists of the letter “M” followed by a number. For example, M00 instructs the program to stop whatever it is currently doing, while M03 is used to rotate a spindle clockwise, M08 is used to turn coolant on, and M09 is used to turn coolant off. Final Thoughts Are you good at programming and interested in machining? If so, spend some time learning more about CNC machines, M-Code, and G-Code so you can determine whether it is the right career path for you.

0 notes

Text

The Future of Manufacturing: Explore CNC Milling India Technology

Explore the world of CNC Milling India! Learn about its benefits, leading manufacturers, and how Deccanew delivers high-quality CNC Milling Machines.

In today's competitive manufacturing landscape, precision and efficiency are paramount. This is where Computer Numerical Control (CNC) Milling steps in, offering a revolutionary approach to machining complex parts with unmatched accuracy and repeatability. This comprehensive guide delves into the world of CNC Milling in India, exploring its advantages, leading manufacturers, and how Deccanew stands out as a trusted provider of high-performance CNC Milling Machines.

Understanding CNC Milling: A Powerful Machining Technique

CNC Milling utilizes a computer-controlled machine that maneuvers a rotating cutting tool to remove material from a workpiece, creating intricate three-dimensional shapes. The computer program dictates the exact path of the cutting tool, ensuring consistent and precise results. This technology offers numerous benefits over traditional machining methods, including:

Unmatched Precision: CNC Milling machines can achieve tolerances of microns, allowing for the creation of highly detailed and intricate parts with consistent quality.

Increased Efficiency: Automation through CNC programming significantly reduces machining time compared to manual processes.

Enhanced Repeatability: CNC ensures consistent results across every machined piece, eliminating human error and maintaining quality throughout production runs.

Material Versatility: CNC milling machines can work with a wide variety of materials, including metals, plastics, and wood, making them suitable for diverse manufacturing applications.

Complex Design Capabilities: With CNC, intricate designs and geometries are easily achievable, offering greater design flexibility compared to traditional techniques.

Leading the Way: Top CNC Milling Manufacturers in India

India boasts a thriving CNC Milling industry, with numerous manufacturers offering a wide range of machines. Here are some key factors to consider when choosing a CNC Milling machine from an Indian manufacturer:

Machine Quality: Look for manufacturers recognized for their commitment to high-quality materials and robust build processes.

Technological Advancements: Consider the level of technology integrated into the CNC machines, including features like automatic tool changers and advanced software.

Machine Options: Select a manufacturer that offers a diverse range of CNC Milling Manufacturers to suit your specific project requirements and budget.

Customer Support: Reliable pre- and post-sales support is crucial for a smooth user experience and maximizing the capabilities of your CNC machine.

Deccanew: Your Trusted Partner for CNC Milling Solutions

Deccanew has established itself as a leading manufacturer and supplier of CNC Milling Machines in India. We take pride in our unwavering commitment to providing innovative and high-precision CNC solutions that empower businesses to take their manufacturing capabilities to the next level. Here's what sets Deccanew apart:

Uncompromising Quality: We use only the finest components and implement stringent quality control measures to ensure the durability and long-lasting performance of our CNC mills.

Advanced Technology: Our CNC machines integrate cutting-edge technology like high-speed spindles, sophisticated control systems, and user-friendly software.

Diverse CNC Milling Range: At Deccanew, you'll find a comprehensive range of CNC Milling Machines, including vertical machining centers (VMCs), horizontal machining centers (HMCs), and 5-axis machines, catering to a wide variety of needs.

Unparalleled Support: Our team of dedicated engineers and technicians is available to provide expert assistance throughout the pre-sales, installation, and post-sales process, ensuring you get the most out of your Deccanew CNC Milling Machine.

Why Choose Deccanew for Your CNC Milling Needs?

By partnering with Deccanew for your CNC Milling requirements, you gain access to several key advantages:

Increased Production Efficiency: Deccanew's high-performance CNC Milling machines streamline your manufacturing process, leading to faster production cycles.

Enhanced Product Quality: The exceptional precision of our machines ensures consistently high-quality parts that meet your demanding specifications.

Reduced Production Costs: By minimizing material waste and maximizing production efficiency, Deccanew's CNC Mills help you optimize your production costs.

Improved Design Flexibility: Unlock the potential for intricate and complex designs with Deccanew's advanced CNC Milling technology.

Contact Deccanew Today!

Ready to unleash the power of precision in your manufacturing process? Deccanew is here to help! Contact us today at +9657039991 or visit our website to explore our comprehensive range of CNC Milling India Machines and connect with our expert team to discuss your specific requirements. Let us work together to revolutionize your manufacturing capabilities!

Visit:- https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.php

Contact: 9657039991

0 notes

Text

Exploring Advanced CNC Machine and Vertical Machining Center (VMC) at ATPL

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. ATPL, a leading provider of industrial machinery, offers a comprehensive range of cnc machine designed to meet the diverse needs of modern manufacturing. This article delves into the advanced cnc machine and Vertical Machining Centers (VMC) available at ATPL, highlighting their features, benefits, and applications.

Understanding cnc machine

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by automating the control of machining tools through computer programming. These machines are capable of producing highly precise and complex parts with minimal human intervention. ATPL’s collection of cnc machine is designed to cater to various industrial requirements, ensuring high productivity and consistent quality.

Advanced cnc machine at ATPL

ATPL’s advanced cnc machine are engineered to deliver superior performance, accuracy, and reliability. These machines are equipped with state-of-the-art technology, making them suitable for a wide range of applications, from automotive and aerospace to electronics and medical devices. Some key features of ATPL’s advanced cnc machine include:

1. High Precision and Accuracy

ATPL’s cnc machine are designed to achieve tight tolerances, ensuring that each part produced meets exact specifications. This level of precision is crucial for industries where even the smallest deviation can lead to significant issues.

2. Enhanced Productivity

With advanced automation and efficient programming, ATPL’s cnc machine can operate continuously with minimal downtime. This leads to increased production rates and reduced lead times, allowing manufacturers to meet tight deadlines and high-volume demands.

3. Versatility

ATPL offers a variety of cnc machine that can handle different materials, including metals, plastics, and composites. This versatility makes them suitable for a wide range of applications, from prototyping to mass production.

4. User-Friendly Interface

The cnc machine at ATPL come with intuitive control panels and software, making it easy for operators to program and monitor the machining process. This reduces the learning curve and enhances operational efficiency.

Vertical Machining Centers (VMC) at ATPL

Vertical Machining Centers (VMC) are a type of CNC machine where the spindle axis is vertically oriented. VMC machines are widely used in the manufacturing industry due to their versatility, precision, and ease of use. ATPL offers a range of VMC machines that cater to various machining needs. Some key features of ATPL’s VMC machines include:

1. Robust Construction

ATPL’s VMC machines are built with a sturdy frame and high-quality components, ensuring durability and long-term reliability. This robust construction minimizes vibrations and enhances machining accuracy.

2. High-Speed Machining

The VMC machine at ATPL is equipped with high-speed spindles and rapid traverse rates, allowing for faster material removal and reduced cycle times. This is particularly beneficial for industries that require high-speed machining for increased productivity.

3. Multi-Axis Capabilities

Many of ATPL’s VMC machines come with multi-axis capabilities, enabling complex machining operations such as contouring, drilling, and tapping. This versatility allows manufacturers to produce intricate parts with ease.

4. Advanced Tool Management

ATPL’s VMC machines feature advanced tool management systems, including automatic tool changers and tool presetters. These systems enhance efficiency by reducing tool change times and ensuring optimal tool performance.

5. Precision and Repeatability

The VMC machines at ATPL are designed to deliver consistent precision and repeatability, ensuring that each part produced meets the required specifications. This is essential for industries where quality and consistency are critical.

Applications of CNC and VMC Machines

ATPL’s CNC and VMC machines find applications in various industries, including:

1. Automotive

CNC and VMC machines are used to produce engine components, transmission parts, and other critical automotive parts with high precision and consistency.

2. Aerospace

The aerospace industry relies on CNC and VMC machines to manufacture complex components such as turbine blades, aircraft frames, and landing gear parts.

3. Electronics

CNC and VMC machines are used to produce intricate electronic components, including circuit boards, connectors, and enclosures.

4. Medical Devices

The medical device industry uses CNC and VMC machines to manufacture precision components for surgical instruments, implants, and diagnostic equipment.

5. Tool and Die Making

CNC and VMC machines are essential for producing molds, dies, and tooling components with high accuracy and repeatability.

Conclusion

ATPL’s range of advanced cnc machine and Vertical Machining Center (VMC) offers manufacturers the tools they need to achieve high precision, efficiency, and versatility in their machining operations. With robust construction, high-speed capabilities, and user-friendly interfaces, these machines are designed to meet the diverse needs of modern manufacturing. Whether you are in the automotive, aerospace, electronics, medical devices, or tool and die making industry, ATPL’s CNC and VMC machines provide the reliability and performance required to stay competitive in today’s fast-paced market. Explore ATPL’s offerings to find the perfect CNC and VMC machines for your manufacturing needs.

#vmc machine#cnc machine#verticle machining center#advanced cnc machines#heavy machinery#machinery#machine

0 notes