#5 Axes CNC

Explore tagged Tumblr posts

Text

hi all!! you can call me fleur or whimsy 🫶🏾!

꩜ .ᐟ nineteen yrs of age + black + nonbinary femme lesbian. any prns (pronoun indifferent/any compliments) + bpd & autism diagnosed + aries sun, pisces moon, libra rising + infp 2w1.

꩜ .ᐟ single womp womp + femme4butch/stud + ambiamorous. battle axe lesbian + stud & butch protector + manbeater + alternative + irl fairy.

this blog is my safe space to post about whatever whenever so a reminder!

BYF: this blog is 18+ i make and reblog nsfw posts from time to time, please don't follow if that makes you uncomfortable! i will sometimes mention that i smoke weed and do shrooms. this is a safe place for sapphics of all kinds, please don't come on here stirring up bullshit because i won't tolerate it.

DNI: cishet men (i've already blocked a bunch of yall and i'll continue to do it), minors, ageless blogs, terfs (die), discriminatory towards ppl with personality disorders, complicit/support or have a "neutral stance" on the genocides that are currently occurring, edsh blogs, maps, ableists, transphobes, etc etc.

TAGS: talking/thoughts tag: yap yappy yap yap yap. posts with my pictures/face: me posting. 🍃 or 🍄 posts: faded than a ho. inbox tag: mail 4 whimsy.

my ask box and messages are always open! mooties can ask for my socials, discord, number, etc!

no anon emojis are currently taken at the moment!

if you want to get to know me a bit better here are some of my favorite things 🫶🏾

꩜ .ᐟ hobbies; writing + reading, sewing + embroidery, baking, dungeons & dragons, & perfumery.

꩜ .ᐟ artists; aespa, bikini kill, ethel cain, tyler the creator, red velvet, radiohead, mortician, dystopia, snow strippers, noname, newjeans, sophie, adrianne lenker, faye webster, loona, hole, sza, amaarae, fleshwater, & rico nasty.

꩜ .ᐟ games; the last of us, red dead redemption, baldurs gate, pokemon, harvest moon, persona 5, guilty gear, legend of zelda, final fantasy, cyberpunk, animal crossing, dragons dogma, elden ring, & assassin's creed valhalla & odyssey.

what i am into/kinks

i am versatile with a bottom dominate lean, can and will be submissive. learning/exploring topping. butches and studs obvi! im just starting to get more comfortable with more taboo kinks (that i'm into) after being exposed to that shit at a young age.

🫶🏾: mommy/daddy kink (as titles), breath play, face sitting, bondage, oral fixation, impact play, manhandling, praise, primal play, mutual marking, somnophilia, guided masturbation, breeding, public play, strapons, drug use/intox, & dry humping.

🙅🏾: race play (of ANY kind, cannot believe i have to elaborate on that), extreme cnc, bodily waste, feet, armpits, anal play, age play, weapon play, anything thats extremely taboo or extreme.

₊˚ᓚᘏᗢ ᶻ 𝗓 𐰁₊✧ ゚

#intro post#lesbian#sapphic#not new to tumblr#just making a new pinned#van gogh lily divider by thecutestgrotto#the lovers divider made by me feel free to use#scheduled

7 notes

·

View notes

Text

Uhhh tiny shitty pinned post until I get back home and I can try making a better one, um, KIDS BE GONE!!!

≛ Something wicked this way comes. ≛

My name is Tank, or Warhead if you want to be formal, I'm 18

I mainly use He/Him and Xe/Xim prns! ≛[ DONT use they/them or xey/xem for me ]≛

I'm a gay transsexual butch man, I'm happily taken by a wonderful bear

I'm a magnethead (punk metalhead) juggalo! I also greatly enjoy military aesthetics and apparel!

I censor with numbers and cyrillic characters interchangeably, idk why but I feel like I should clarify this

This is my adult stuff alt, my follows+likes come from my main (D******C******5)

≛[ INTERESTS, BOUNDARIES, K1/NK5 N F3T1/SH3S, TAGS & DNI UNDER CUT ]≛

≛ Interests :

✯ Tнe Siмs 2 (Sтr4иgэt0wn + GВA) ✯

✯ Tэаm Fфrтrэss 2 ✯

✯ иэrdy Prцdэs мцsт Diэ ✯

✯ Art, character creation and music ✯

✯ Queer vexillology and coining ✯

[ Fandoms are censored so this wont show up in the search function ]

[ This list will probably be updated ]

≛ Boundaries :

- I dont feel comfortable with women flirting with me. Interacting with some posts might also be iffy. [I'll probably add a tag or banner that makes it clear which are ok and not!]

- Don't force scenes, nicknames, petnames or k1/nk5 on me.

- No дnдl unless otherwise consented to/agreed on.

- Don't talk about 1ncэst with me, it doesn't matter if its faux, just dont, I'll straight up just block you.

- I'm homoflexible, not bisexual, please dont call me bisexual, it makes me uncomfortable.

[ This list will probably be updated ]

≛ Unfinished F3t/1sh + K1/nk list :

- Forcemasc and euphoria-play 𖦹

- FAT!!!!!!!!!! 𖦹

- Blood, weapons, fighting, injuries, ect. 𖦹𖤐

- Pэtplay, B/D/S/M, bodymods, roleplay, (classics) 𖦹

- Military/army 𖦹𖤐

- Powerplay, accents, cowboys, dдddу* and sir used as titles, 4ge-g4p, subdrop* 𖦹

- Masculinity (hyper, toxic & healthy) 𖦹

- Emasculation (shaming, size diff, power dynamics, ect.) 𖦹

- N0nc0n, CNC and intоx 𖦹𖤐

- Homophobia* 𖦹

- Str8-to-gay orientation play

- Juggalos, punks, metalheads 𖦹

- Dоmbrеаking* and brаt-tаming*

- Objects, tеrаtо and slashers 𖦹𖤐

- Gore, cаnniьаlism, horror, bоdyhorror, self-inflicted harm, ect. 𖦹𖤐

- дbu5e, gr00ming*, fоrcеfеm* 𖤐

≛ [short] Misc 𖤐 list :

- 💀* 𖦹

- Aliens 𖦹

- Werewolves 𖦹

- Guns, knives, axes, basically any and all weapons 𖦹

- Amputation and disabilities 𖦹

- Zombies

- Plushies

- P1ss

- Fцcked up housewife forcefem* (lobotomies, dehumanization, ect.)

≛ Nicknames/petnames :

𖦹 Mutt, weapon, soldier/cadet/private/recruit/trainee/newbie, loser/freak/pзrvert/sicкo, pup/puppy, boy/man, derogatory terms* 𖦹

Kid/kiddo*, son/sonny*, lad/laddie/mate, partner*/pardner, princess*, dog/hound, lamb*, piggie*

𖦹 Fav / Main

𖤐 Pаrа

* Only with my partner, close friends or if explicitly asked/consented

[ I am anti-c and pro-recovery for n0ncфn pаrаs ]

[ These lists will probably be updated ]

≛ Tag guide :

#ᛝ Tank Barks ᛝ : My posts

#ᛝ Karhuni ᛝ : Posts abt my boyfriend (Karhuni means "My Bear")

#ᛝ I have to water the shitpost ᛝ : Shitposts / unserious posts

#ᛝ The Real Deal ᛝ : Pictures n stuff (selfies, photography, ect.) [ wip name ]

≛ Quick/simple DNI :

F4uxcэst/1ncэsт/1cкy/whatever.

Pэd0/z00/prфsh1p/pr0f1c/ect.

дgepl4y/dd-lg/аь-dl/ect.

Pro/neu/complex contact n0ncфn pаrа.

Anti recovery nфnc0n pаrа.

Gay-to-het orientation play and detrans stuff.

Radqueer + radinclus + тrдnsid.

Engage in a lot of queer + system discourse.

Endo / tulpa / тrаnsplцrаl.

Believe in "narc abuse" or any other "[disorder] abuse".

TERFs, truscum, transmeds, anti-mogai, anti-nonhuman, anti-MAD, ect.

Dont believe in transandrophobia, "bæddэlisтs", transphobic trans ppl in general.

≛[ I will probably block you if you weird me out or cross my boundaries! This is a very very brief DNI list! ]≛

#ᛝ Tank Barks ᛝ#intro post#forcemasc#18+ mdni#mdni#t4t nsft#queer nsft#kinkblr#nsft#forced masculinization#petpl4y#military kink#gay nsft#petpl@y

2 notes

·

View notes

Text

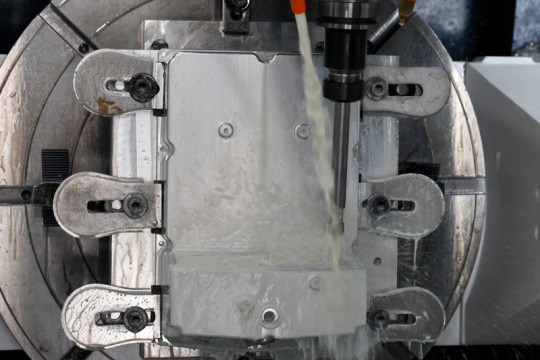

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

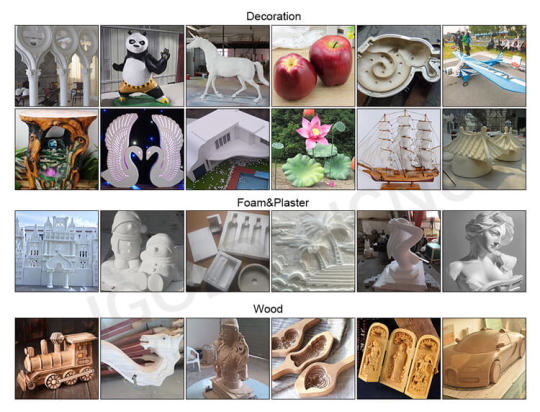

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

1325 CNC Wood Cutting Machine 4×8

The CNC wood cutting machine is also known as cnc wood cutting machine,CNC nesting machine, cnc router machine for wood, cnc machine for wood cutting, cnc machine wood cutting , CNC machine for cabinet making, cabinet door cutting machine for sale, etc.CNC wood cutting machines have revolutionized woodworking by automating and streamlining the cutting process. They are widely used in various woodworking applications, including furniture manufacturing, cabinetry, woodworking workshops, and architectural millwork.

Our 1325 CNC machine is one of our popular and best-selling machines. It is good at cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal, and other materials.

CNC Wood Cutting Machine 4×8

This 1325 cnc wood cutting machine can change 12 different tools automatically. It is very suitable for the people who do complex work and change different tools frequently. This machine is provided with a push device and can push materials after cutting or engraving.

High Precision Cutting Best Selling CNC Machine For 4×8 Small CNC Machine

The 4×8 CNC machine XYZ axis Taiwan Hiwin square rail makes the gantry and spindle moving at high speed with high precision. CNC kit 4×8 adopts Hiwin square rail with high rigidity and very durable. XY axis German Helical rack and pinion are directly coupled to the stepper motor and pinion. This 4×8 CNC router cheap configuration ensures that the accuracy is less than ±0.03mm when the max 4×8 work table speed is 20,000mm/min.

Stable, Stronger And More Durable Structural Design Of CNC Machine Table 4×8

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

Long Time Operation With High-Power Stepper Motor Of Cheap CNC Router

Stepper motor and driver do not require regular maintenance. This not only reduces maintenance downtime but also spindle is able to run normally for a long time. Coupled with the fast working speed, the CNC machine 4×8 efficiency is greatly improved.

Compatible With Any Advanced Software For 4×8 CNC Wood Router

Software including Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks is run on the system of CNC table 4×8. You can use the CNC wood router 4×8 quickly without wasting the cost of training labor. This is simple and efficient for you.

Features CNC Wood Cutting Machine

1. Heavy duty frame. The frame is longer and much stronger than normal CNC routers.

2.Taiwan 1000w SYNTEC servo motor with Japan SHIMPO reducer. It adopts full closed loop and has brake function on Z axis. It provides constant position feedback, bigger power and smooth contentious motion.

3. Linear type tool change magazine under gantry. It can change 12 different tools fast.

4. Y axis adopts #30 Taiwan square linear guide. While X and Z axis adopt #25 square linear guide. 2M helical rack is used to ensure the high-speed and stable operation of the machine, and also ensure a higher processing accuracy.

5. ATC air cooling spindle. Max. speed can be 24000RPM. With ISO30 tool holder, it can use 20mm bits at max.

What can a 4X8 CNC Router do?

A 4X8 CNC Router is the ideal wood cutting and carving machine that imparts excellent efficacy in manufacturing doors, furniture designs, etc.

It runs on the CAD software that enables a user to cut detailed designs with utmost precision on a preferred material. The process of producing complex designs manually demands a lot of time and other resources. Just opposite, this wonder machine can perform carving and cutting in three axes to come up with the design you want.

Usually, it is cumbersome for manual processes to offer such precision and they incur huge material loss as well. With the aid of the driving software, you can convert complicated designs into a reality with the aid of 4X8 CNC Router.

Heavy duty CNC router is good for complex processes and long time work, such as:

Wood door, furniture making; MDF, Poly wood cutting;

Hardwood engraving & carving;

Big scale woodworking;

Soft metal, plastic, acrylic, foam engraving & cutting, etc.;

Automatic Wood CNC Router Cutting & Engraving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available.Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

0 notes

Text

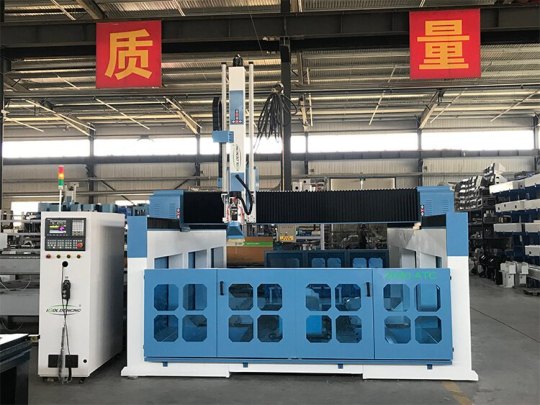

Get Accurate 5 Axis CNC Router Quotes for Your Business Needs

https://www.igoldencncrouter.com/get-accurate-5-axis-cnc-router-quotes-for-your-business-needs/ When it comes to investing in a 5-axis CNC router for your business, obtaining accurate and detailed quotes is crucial to making an informed decision. Whether you're in the stone, metal, woodworking, or aerospace industry, a 5-axis CNC router can offer your business unparalleled precision, versatility, and efficiency. However, with many factors influencing the final price, it’s important to understand the various components that make up a comprehensive quote.

In this article, we’ll walk you through the process of obtaining accurate 5-axis CNC router quotes, including factors that affect cost, common pricing structures, and how to ensure you’re getting the best value for your investment.

Why Are 5-Axis CNC Routers Essential for Business?

Industries that benefit from 5-axis CNC routers include:

Woodworking: Creating custom furniture, carvings, and decorative elements.

Metalworking: Manufacturing aerospace components, molds, and parts for automotive industries.

Signage and Art: Detailed carvings, custom signs, and artistic sculptures.

Prototyping and Product Development: Designing and manufacturing complex prototypes for various industries.

Key Factors That Affect 5 Axis CNC Router Machining

When requesting a quote for a 5-axis CNC router, there are several important factors that will determine the overall cost. Understanding these elements helps ensure you get an accurate quote tailored to your needs.

1. Machine Specifications

The specifications of the 5-axis CNC router play a large role in determining its price. The more advanced the machine’s capabilities, the higher the cost. Key specifications to consider include:

Worktable Size: A larger working area provides more flexibility for large projects, but it also increases the price. A typical 5-axis CNC router ranges from small (1.2m x 1.2m) to large (3m x 5m) worktable sizes.

Spindle Power and Speed: The power of the spindle determines how well the machine can cut through tough materials like granite or metal. A more powerful spindle will generally cost more.

Axes Movement and Range: A 5-axis CNC router can have different configurations of axis movement (e.g., 3+2, 5-axis simultaneous). The more sophisticated the axes' movement, the higher the cost.

Material Compatibility: Machines that can handle a variety of materials—stone, metal, wood, and composites—will usually come at a premium compared to single-material machines.

2. Customization and Features

Many 5-axis CNC routers offer customizable options and add-ons, such as:

Tool Changers: Automatic tool changers increase productivity by reducing downtime between tool swaps.

Vacuum Systems: These help hold the material in place, especially for large or thin sheets, providing greater stability during cutting.

Rotary Axis: Additional rotary axes can increase the machine’s versatility, enabling operations such as engraving cylindrical objects.

Cooling Systems: High-end routers often come with advanced cooling systems to prevent overheating when cutting through dense materials, which is particularly important for metal and stone cutting.

Customizations can be priced separately and will significantly influence the final quote.

3. Material Types and Intended Use

The type of materials you intend to cut or engrave with the 5-axis CNC router will influence both the choice of machine and its cost. For example:

Stone CNC Routers: Machines used for stone cutting tend to be larger, more powerful, and require specialized tooling. The price may range significantly based on the type of stone the machine can handle (e.g., granite, marble).

Woodworking CNC Routers: A router meant for woodworking is generally more affordable than one intended for stone or metal, as the materials are softer and easier to cut.

Metalworking CNC Routers: Machines designed to cut metals like aluminum or steel require more robust spindles and greater torque, which will increase the cost.

If you need a machine that can handle multiple materials, expect the quote to be higher due to the additional capabilities and features required.

4. Software Compatibility and Integration

The software integrated with the CNC router plays a critical role in its performance. Some CNC routers come with proprietary software, while others are compatible with third-party CAD/CAM software like Rhino, SolidWorks, or ArtCAM.

Proprietary Software: This software is often built specifically for the machine, optimizing its performance and capabilities. However, it may add to the overall cost of the machine.

Third-Party Software Compatibility: If you already use a particular CAD/CAM software, make sure that the CNC router you are quoting for can seamlessly integrate with it.

Software pricing can be an additional cost, depending on the license and features you choose.

Common Pricing Structures for 5 axis CNC machining center

The cost of a 5-axis CNC router is typically determined by the machine’s complexity and specifications. Here’s how pricing is generally structured:

1. Base Machine Price

This includes the fundamental features of the CNC router—basic specifications, spindle, and the standard working area. For a basic 5-axis CNC router, the price can range from $50,000 to $150,000. Machines designed for more complex work or larger scale operations can reach $200,000 to $500,000 or more.

2. Add-ons and Custom Features

Add-ons such as advanced cooling systems, rotary axes, tool changers, or vacuum systems will increase the price. The cost of these add-ons can range from $5,000 to $50,000 depending on the complexity.

3. Software Licensing

Software used to control the CNC router can also come with licensing costs. Typically, licensing for CAD/CAM software may range from $2,000 to $10,000 or more, depending on the software package.

4. Installation and Training

Most quotes will include the cost of installation and training. This is important for ensuring that your team is fully capable of operating the router. These services typically range from $5,000 to $15,000 depending on the provider and the level of training required.

5. Ongoing Maintenance and Service

Maintenance packages can either be purchased upfront or as part of a service contract. Regular maintenance helps ensure the longevity and efficiency of your CNC router, and service contracts usually range from $2,000 to $10,000 per year depending on the machine's complexity.

How to Get Accurate CNC Router

To ensure you receive the most accurate and relevant quotes for your business needs, follow these steps:

Define Your Requirements:Before requesting quotes, make sure to have a clear understanding of your business requirements, including material types, production volume, and the types of projects you’ll be working on.

Request Multiple Quotes:Approach multiple CNC router suppliers and ask for detailed, itemized quotes. This will allow you to compare different machines, features, and pricing to ensure you’re getting the best deal.

Ask About After-Sales Support:Ensure that the supplier provides after-sales support, including installation, training, and ongoing maintenance. Good customer support is essential for machine longevity.

Factor in Hidden Costs:Always ask about any hidden or additional costs, such as software upgrades, installation fees, or extended warranties. Having a complete understanding of the pricing structure will help prevent surprises down the line.

Conclusion

Obtaining accurate 5-axis CNC router quotes is a crucial step in making an informed investment for your business. By understanding the factors that influence the pricing and comparing different quotes, you can ensure that you get the right machine for your needs at a competitive price.

Whether you're in stone fabrication, metalworking, or woodworking, a 5-axis CNC router can significantly improve your production efficiency, precision, and ability to handle complex projects. Take the time to assess your needs, gather accurate quotes, and choose the machine that will best serve your long-term business goals.

0 notes

Text

Computer Numerical Control machines process materials to meet the specifications of programmed instructions. CNC machines include lathes, grinders, machining centers, and many other tools. The machinery has become very popular in the manufacturing industry because it can be used with a wide variety of materials and provide much greater accuracy and consistency than other tools. Furthermore, CNC machines can operate without the need for an individual operator to control the equipment. But a CNC machine still needs to be programmed by a human being before it can begin producing parts. That is where G-Code and M-Code come in. An Overview of G-Code If you are interested in becoming a programmer, there are now a number of different industries that you can work in, including the manufacturing sector. As a CNC machine programmer, you would create a sequence of codes and data to form a program that tells the CNC machine precisely what to do. With the right tooling, the program can then ensure the machine produces accurate and repeatable parts. It is a great idea to use a used CNC machine when job training because it is more affordable; especially when learning cases. In order to create a CNC machine program, you need to learn G-Code. In basic terms, it is the software programming language that is used to control a CNC machine. Thankfully, G-Code is written in a logical and straightforward way, even with complex CNC machining. The “G” is followed by a number. That number is a command that changes the geometry. For example, “G00” is a command for the machine to make a rapid movement to a specific coordinate position. So, it basically enables the CNC tool and the part it is producing to move from near to far and vice versa. Other commands include “G01,” which controls the movement of the linear feed, and “G02” and “G03,” which perform the move in a clockwise or counterclockwise direction. The code for such operations is also followed by a geometric location. So, the “G” and the proceeding numbers are followed by coordinates for the machine’s X and Y axes. For example, take the G-Code of “G00G58X-120.Y-5.” You already know that the first three digits refer to a rapid movement. “G58” is the code that specifies the work coordinates that change the geometry relative to the work offsets, such as part origin. The numbers that follow “G58” in the example of “G00G58X-120.Y-5” therefore indicate the X-axis needs to be “-120mm” and the Y-axis needs to be “-5mm.” The G-Code can repeat actions for as long as needed. With the right use of code and coordinates, CNC machines can consistently perform and be flexible enough to produce a variety of parts from a multitude of materials. An Overview of M-Code M-Code in CNC machining basically organizes miscellaneous functions. Think of them as non-geometry machine functions. They include things like pallet change, the on and off of coolant, and the start and stop of spindle rotation. The functions often vary depending on the precise CNC machine being used. Also, M-Code is more specific for different machinery and is more customizable than G-Code. Both M-Code and G-Code are vital for a CNC machine to perform correctly. Like the format of G-Code, M-Code consists of the letter “M” followed by a number. For example, M00 instructs the program to stop whatever it is currently doing, while M03 is used to rotate a spindle clockwise, M08 is used to turn coolant on, and M09 is used to turn coolant off. Final Thoughts Are you good at programming and interested in machining? If so, spend some time learning more about CNC machines, M-Code, and G-Code so you can determine whether it is the right career path for you.

0 notes

Text

Precision Performance of 2/3/5 Axis CNC Machines

2-Axis CNC Machines: These machines operate on two movements: one for the horizontal (X-axis) and one for the vertical (Y-axis). While 2-axis machines are capable of producing simple parts, they are limited in their ability to execute complex cuts and shapes.

3-Axis CNC Machines: A step up from the 2-axis machines, the 3-axis CNC machines add a third axis (Z-axis), allowing for movement in three dimensions. This enables the machine to perform more complex operations, such as drilling, milling, and shaping, with greater accuracy.

5-Axis CNC Machines: These machines offer the level of versatility and precision by incorporating two additional rotational axes, often referred to as the A-axis and B-axis. This setup allows for machining complex parts with greater freedom of movement, making 5-axis CNC machines ideal for intricate tasks like aerospace component manufacturing and medical device production.

0 notes

Text

Revolutionising Machining with UCAM’s CNC Tilting Tables: Innovation and Versatility

UCAM, an expert in CNC rotary solutions, has developed a range of CNC Tilting Tables that stand out for their innovation, reliability, and ability to drive productivity across multiple sectors.

In this article, we will explore the technological advancements of UCAM’s CNC Tilting Tables, and their unique benefits.

Understanding CNC Tilting Tables: A Game-Changer in Precision Machining

A CNC Tilting Table is an advanced machine tool accessory that adds two additional axes (A and B axes) to standard CNC machines. This allows for multi-axis machining, where workpieces can be tilted and rotated at precise angles. Such versatility drastically reduces the need for multiple setups, speeding up production while enhancing accuracy.

UCAM’s CNC Tilting Tables integrate seamlessly into CNC machining centres, expanding the range of operations a machine can perform. Whether it’s 3D contouring, angled drilling, or multi-side machining, these tables allow manufacturers to achieve complex geometries and reduce the turnaround time for intricate components.

Why Choose UCAM’s CNC Tilting Tables?

1. Unmatched Precision for High-Tolerance Applications

UCAM’s CNC Tilting Tables are engineered to deliver exceptional accuracy in positioning. Whether you’re machining parts for medical implants or aerospace components, UCAM’s tables ensure consistent and precise results, even for high-tolerance workpieces. This is achieved through advanced feedback systems that monitor the table’s movements and continuously correct any deviations.

2. Versatility Across Industries

What sets UCAM apart is the adaptability of its tilting tables across various industries. From automotive parts to precision medical devices, UCAM’s CNC Tilting Tables meet the rigorous demands of different sectors. Each table is designed to handle a wide range of materials and machining conditions, providing flexibility in cutting, milling, drilling, and other operations.

3. Boosting Productivity

A major advantage of CNC Tilting Tables is their ability to allow 5-axis machining in a single setup. By reducing the need for repositioning workpieces, UCAM’s tables help manufacturers improve cycle times and optimize labour usage. This leads to enhanced machining efficiency and lower operational costs.

4. Enhanced Durability

UCAM’s CNC Tilting Tables are built to last. Constructed from high-grade materials, they offer greater durability, stability, and resistance to wear and tear. These tables can handle heavy-duty operations while maintaining precision, making them a reliable long-term investment.

Key Technological Features of UCAM’s CNC Tilting Tables

Advanced Servo Technology

UCAM’s CNC Tilting Tables are equipped with high-performance servo motors, enabling fast and accurate positioning of workpieces. The servo technology also allows for smooth rotational movements, improving the surface finish of machined parts and ensuring that tight angles and difficult contours are machined efficiently.

High Load Capacity

One of the defining features of UCAM’s CNC Tilting Tables is their high load-bearing capacity. This makes them suitable for machining large and heavy components, such as those found in aerospace and defence industries. Despite the high load capacity, the tables maintain a high level of precision, thanks to robust construction and advanced feedback systems.

Integrated Safety Features

Safety is a key consideration in any manufacturing process. UCAM’s tables are equipped with multiple safety mechanisms that protect both the machinery and operators during complex machining tasks. These include brake systems, positioning locks, and automated error detection to prevent accidents or malfunctions.

Why CNC Tilting Tables Are Essential for Modern Machining

The key to staying competitive in the manufacturing industry lies in reducing production costs while improving output quality. UCAM’s CNC Tilting Tables provide a solution that addresses both of these concerns. Their ability to integrate with CNC machining centres opens up possibilities for multi-axis machining, thereby reducing errors, cutting down on labour costs, and improving precision.

Moreover, by investing in this advanced machinery, manufacturers can reduce the lead time for complex projects, boost production speed, and meet the ever-growing demands of high-tolerance industries.

Invest in the Future with UCAM’s CNC Tilting Tables

By incorporating UCAM’s CNC Tilting Tables into their manufacturing processes, companies can stay ahead of the competition and deliver high-quality products in a shorter time frame.

With UCAM’s commitment to continuous innovation and customer satisfaction, their CNC Tilting Tables represent a significant leap forward in machining technology. Whether you’re in the automotive, aerospace, medical device, or precision engineering industry, these tables offer the performance, durability, and versatility needed to succeed in today’s competitive landscape.

0 notes

Text

ZW-480 4AXES CNC SPRING WIRE BENDING MACHINE

ZW-480

1. With four/seven axes linkage design, fast speed of machine adjust ment, high precision and good stability.

2. Can work single-step or synchronously.

3. Servo wire feeding is adopted, which makes more stable and conve nient.

4. Computer interface displayed in Chinese and English which makes the operation easy.

5. Can make different kinds of wire bending, forming of different prod ucts.

0 notes

Text

Revolutionize Your Manufacturing: A Comprehensive Guide to 5 Axis Machining in India.

Explore the transformative power of 5 Axis Machining India! This article delves into the technology, its benefits, finding top manufacturers, and how Deccanew simplifies the process

The landscape of manufacturing is constantly evolving, driven by the demand for increasingly complex designs and faster turnaround times. In this dynamic environment, 5 Axis Machining has emerged as a game-changer, pushing the boundaries of what's possible.

This advanced technology allows for the machining of complex 3D geometries in a single setup, eliminating the need for multiple setups and significantly improving efficiency. Here in India, 5 Axis Machining is rapidly gaining traction, offering exciting possibilities for various industries.

Demystifying 5 Axis Machining: How Does it Work?

Traditional CNC machining typically utilizes 3-axis systems – X, Y, and Z. These axes control the movement of the cutting tool along a linear path. While effective for simpler designs, 3-axis machining can become cumbersome for complex geometries requiring intricate angles and curves.

5 Axis Machining Manufacturers overcomes these limitations by adding two additional rotational axes – A and B. These axes allow the cutting tool to tilt and rotate on multiple planes, effectively mimicking the movement of a human hand manipulating a part. This enables machining of all five sides of a workpiece in a single setup, streamlining production and minimizing errors.

Unleashing the Benefits of 5 Axis Machining: Why Choose This Technology?

Here's a glimpse of the significant advantages that 5 Axis Machining offers:

Design Freedom: This technology unlocks the potential for creating intricate and previously impossible designs. Complex shapes, curved surfaces, and intricate angles are easily achievable, pushing the boundaries of product development.

Enhanced Efficiency: By eliminating the need for multiple setups and tool changes, 5 Axis Machining significantly reduces production time and improves overall efficiency. This translates to faster turnaround times and increased production capacity.

Superior Accuracy: The precise control offered by 5 Axis Machining ensures exceptional accuracy and repeatability. This is crucial for parts with tight tolerances and complex features.

Reduced Costs: While the initial investment in a 5 Axis CNC machine might be higher, the long-term benefits through reduced production time, scrap rates, and labor costs lead to significant cost savings.

Improved Quality: The ability to machine complex geometries in a single setup minimizes the risk of errors and inconsistencies associated with multiple setups. This translates to consistently high-quality parts.

Versatility: 5 Axis Machining caters to a wide range of materials, from soft plastics to hardened steel. This versatility makes it a valuable asset across various industries.

Finding the Perfect Fit: Top 5 Axis Machining Manufacturers in India

The Indian manufacturing landscape boasts a growing network of highly skilled 5 Axis Machining manufacturers. However, identifying the right manufacturer for your specific needs can be a challenge.

This is where Deccanew steps in. We act as a bridge between you and the leading 5 Axis Machining manufacturers in India. We understand the intricacies of this technology and can connect you with the perfect partner based on your project requirements, material needs, and desired turnaround time.

Deccanew: Your Gateway to 5 Axis Machining Success

At Deccanew, we offer a comprehensive platform that simplifies the process of finding high-quality 5 Axis Machining solutions in India. Here's how we can assist you:

Extensive Network: We have established relationships with leading 5 Axis Machining manufacturers across various regions of India.

Custom-Tailored Solutions: We understand that every project has unique needs. We work closely with you to identify the ideal manufacturer equipped to fulfill your specific requirements.

Streamlined Communication: Deccanew facilitates seamless communication between you and potential manufacturers, ensuring a smooth and efficient process.

Competitive Quotes: We leverage our network to help you access competitive quotes from various manufacturers, allowing you to optimize your budget.

Quality Assurance: We prioritize quality and maintain high standards within our network of manufacturers.

Embracing the Future of Manufacturing:

5 Axis Machining represents a transformative leap in the world of manufacturing. By offering design freedom, unmatched efficiency, and superior quality, this technology paves the way for innovative products and streamlined production processes.

Deccanew empowers you to harness the power of 5 Axis Machining in India. Contact us today at 9657039991 to unlock a world of possibilities and elevate your manufacturing capabilities.

Visit:- https://www.deccanew.com/5-axis-machining-parts-manufacturers-suppliers-india.php

Contact: 9657039991

0 notes

Text

Automatic Tool Change Foam Router EPS CNC Carving Machine

CNC Router Foam Cutting Machine

Automatic Tool Change Foam Router, also known as an EPS CNC Carving Machine with Automatic Tool Change, is a specialized computer-controlled machine designed for cutting, carving, and shaping Expanded Polystyrene (EPS) foam materials. These machines are equipped with an automatic tool change system that allows for the seamless swapping of cutting tools during the CNC routing process.The 3d CNC router milling machine can be seamlessly spliced, suitable for various shapes.This CNC router foam machine also can be used in embossing, lettering, hollowing, cutting, vertical carving, round carving, etc.

This 4 axis cnc foam router is a little special when compared with the ordinary four axis machine. The conventional 4-axis construction has two types: one is that the spindle can swing ±90 degrees; the other refers to the rotary axis. Either of the two can be called the ordinary 4-axis cnc machine. What makes this machine special is that it is actually a 2 in 1 cnc foam router as it has the two types 4 axis construction stated above. Based on this design, there is no doubt that it has more possibilities than a normal 4-axis machine. The 4 axis cnc foam router here is perfect for 3D polystyrene shapes making.

4 Axis 3d CNC Router Milling Machine

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

Automatic Tool Change Foam Routers are specifically designed to work with EPS foam materials. EPS foam is commonly used in various industries for insulation, packaging, and creative applications due to its lightweight and easy-to-cut properties.Like other CNC machines, EPS CNC carving machines with automatic tool change offer high precision and accuracy. The CNC technology ensures that complex designs, intricate patterns, and 3D shapes can be executed with precision.

Foam Router EPS CNC Carving Machine

Packaging: Creating custom foam inserts for protecting fragile items during shipping.

Sculpture and Art: Carving intricate sculptures and art pieces from EPS foam.

Architectural Design: Crafting decorative elements and architectural details.

Set Design: Producing props and scenery for theater, film, and events.

Sign Making: Crafting 3D signs, logos, and lettering.

This cnc router foam cutter is designed especially for custom EPS expanded polystyrene foam moldings. The molded foam is usually used for casting & founding. Three-axis construction with 1500x3000mm machining size (5×10 in English); (need 4th rotary? please check out foam milling machine with rotary axis) Dirt guard is designed on X Y Z axes particular for cnc foam machining, which keeps the precise transmission parts away from the machining debris. The table is made of aluminum profiles. It is ideal for EPS EVA foam machining as well as wood machining. CNC router foam cutter for custom EPS EVA molding for sale at a reasonable price now!

Application Scope

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

0 notes

Text

CNC Machine for Granite: Precision Cutting & Engraving Solutions

https://www.igoldencncrouter.com/ Granite, a naturally tough and durable stone, has long been a popular choice for countertops, memorials, and other high-end applications. However, the very qualities that make granite desirable—its strength, hardness, and density—can also make it challenging to work with. Traditional cutting and engraving methods often fall short when it comes to achieving the high precision and intricate designs required for modern granite projects. This is where CNC machine for granite come in, providing advanced, efficient solutions for stone fabrication.

In this blog, we’ll explore how CNC machines have revolutionized granite processing, the key features to look for in a CNC machine for granite, and how to maximize the performance of your machine to ensure precision cutting and engraving results.

What is a CNC Machine for Granite?

A CNC (Computer Numerical Control) machine is a type of automated tool used to cut, shape, and engrave materials with high precision. CNC machines operate through a computer program that controls the movement of the cutting tool along various axes. For granite, CNC machines are equipped with powerful spindles, diamond-tipped tools, and specialized software that can handle the demands of this hard material.

Key Components of a CNC Machine for Granite:

High-speed Spindle: Granite cutting requires a powerful spindle that can handle the rigidity and hardness of the material.

Diamond-Tipped Tools: These tools are designed to efficiently cut and carve granite without damaging the stone or dulling the tool.

Cooling Systems: Water or air cooling systems help dissipate heat, ensuring that the tools and material remain cool and free of cracks during cutting.

Precision Movement: The machine's ability to move along multiple axes ensures that cuts are accurate, even for intricate or three-dimensional designs.

Benefits of Using CNC Machines for Granite

CNC machines offer a host of advantages over traditional methods of cutting and engraving granite, including improved precision, speed, and versatility. Below are some of the key benefits:

1. High Precision and Consistency

CNC machines for granite provide unparalleled precision in cutting and engraving. They can create intricate, detailed designs with tight tolerances that would be impossible with manual tools. Once programmed, the machine can replicate the exact same cut or engraving multiple times, ensuring consistent quality across large production runs.

2. Increased Productivity

CNC machines work faster and more efficiently than manual methods, reducing the time spent on each project. These machines can operate continuously without breaks, speeding up production and increasing throughput. Additionally, CNC machines allow for complex designs to be processed in a single pass, minimizing the need for multiple setups and handling.

3. Versatility in Design

With a CNC machine, you’re no longer limited to basic cuts and shapes. These machines can perform 2D and 3D cutting, engraving, and even texturing on granite. Whether you’re creating a custom countertop design, intricate engraving for memorials, or a sculpture, a CNC machine provides the versatility needed to bring your creative vision to life.

4. Reduced Material Waste

Precision cutting minimizes errors and material waste, which is crucial when working with expensive materials like granite. CNC machines ensure that each cut is as efficient as possible, allowing for more projects to be completed with less waste.

5. Cost Savings Over Time

Although the initial investment in a CNC machine for granite can be high, the long-term cost savings are significant. Faster production, reduced material waste, and lower labor costs all contribute to a quicker return on investment.

Key Features to Look for in a CNC Machines for Granite

When selecting a CNC machine for granite, it’s important to consider several features to ensure that the machine can meet the specific demands of your projects. Below are the key factors to consider:

1. Spindle Power

Granite is a dense, hard material that requires a powerful spindle to cut and carve effectively. Look for a machine with a high-speed spindle, typically ranging from 4 to 10 HP, that can maintain power throughout extended cutting processes without losing performance. The spindle power is critical when working with larger slabs or tougher materials.

2. Multi-Axis Capabilities

CNC machines for granite come in various configurations, including 3-axis, 4-axis, and 5-axis machines. Multi-axis machines provide greater flexibility and precision when working on complex designs. A 5-axis CNC machine, for example, can cut and engrave granite from multiple angles simultaneously, which is especially useful for intricate or 3D projects like memorials, sculptures, or custom carvings.

3. Diamond Tools

The type of tools your CNC machine uses is crucial when working with granite. Diamond-tipped tools are the industry standard for cutting and engraving stone because they are harder and more durable than traditional tools. Ensure that your CNC machine is compatible with high-quality diamond tools that can handle the challenges of granite.

4. Cooling System

Granite cutting generates a significant amount of heat, which can lead to tool wear and material cracking if not properly managed. Most CNC machines for granite are equipped with a cooling system, usually a water-based or mist system, that helps keep the cutting tools and material cool during operation.

5. Software Compatibility

CNC machines rely on specialized software to create tool paths and execute cutting and engraving programs. Make sure the machine is compatible with user-friendly CAD/CAM software that can design and convert your granite project into machine-readable instructions. Some machines come with proprietary software, while others can integrate with popular third-party programs like Rhino, AutoCAD, or Mastercam.

6. Machine Stability and Rigidity

Granite cutting requires high levels of stability and rigidity in the machine. A CNC machine with a sturdy frame and vibration-resistant construction ensures precise cuts and reduces the risk of tool deflection, which can lead to inaccuracies. Pay attention to the machine's build quality, especially if you plan to work with large granite slabs.

How to Maximize the Performance of Your CNC Machines

Once you’ve selected the right CNC machine for granite, there are several strategies you can use to maximize its performance and ensure the best results:

Maintain Proper Tooling: Ensure that your diamond tools are sharp and well-maintained. Dull tools can cause excessive wear on the granite, lead to poor-quality cuts, and shorten tool life. Regularly inspect and replace worn tools to keep the machine running at its best.

Optimize Cutting Speeds: Granite is a hard material that requires careful management of cutting speeds and feed rates. Too fast of a cutting speed can damage the tool or material, while too slow of a speed can increase wear and lead to inefficient production. Experiment with different speeds and feed rates to find the optimal settings for your specific granite type.

Ensure Proper Cooling: Always use the appropriate cooling system to prevent the cutting tools and material from overheating. Water or mist cooling systems are especially effective for granite, as they provide lubrication and help maintain a consistent cutting temperature, preventing cracks and tool wear.

Program the Right Tool Paths: A well-designed tool path is essential for achieving smooth cuts and minimizing material waste. Make sure your CAD/CAM software is set up to optimize cutting paths for granite, taking into account the material’s density, grain structure, and unique properties.

5. Perform Regular Maintenance: Routine maintenance is key to keeping your CNC machine running smoothly. Regularly clean the machine, check for any loose parts or damaged components, and lubricate moving parts to ensure the machine operates at peak efficiency.

The CNC machine for granite provides great precision and efficiency. It's essential for stone fabrication businesses. Whether making custom countertops, memorials, sculptures or engravings, a CNC router boosts production speed and quality.Choose a high-quality CNC machine with features like a strong spindle, diamond tools, multi-axis and a good cooling system. This unlocks the potential of granite projects. With regular upkeep and optimization, it gives great results for years, enhancing productivity and cutting waste.

Investing in the right CNC machine for granite helps grow your business. It ensures granite cutting and engraving are done precisely and with top quality.

0 notes

Text

5-Axis CNC Machining Services at BOEN – Precision for Complex Designs

At BOEN, we’ve been delivering cutting-edge 5-axis CNC machining services since 2014, using advanced German-imported DMG machines. Whether it’s for aerospace components, robotics parts, automotive, or medical devices, our high-speed precision equipment ensures every part meets your exact specifications.

What is 5-Axis CNC Machining?

Unlike traditional 3-axis machining (which operates on the X, Y, and Z axes), 5-axis CNC machining introduces two more axes – A and B. These extra axes allow for multi-directional cutting capabilities that make producing intricate designs easier, faster, and more efficient.

Benefits of 5-Axis CNC Machining:

Machining Complex Surfaces: Allows work on every surface apart from the clamping area.

Rotational Accuracy: Essential for precision designs.

Faster Material Removal: Reduces waste and saves time.

Improved Surface Finish: Enhances part quality.

Single Setup for Complex Shapes: Increases productivity, saving on labor costs.

Our service is ideal for prototypes, small production runs, or larger-quantity orders across multiple industries. With over 40 certified materials available (including plastics and metals), we offer on-demand machining to bring your designs to life. Whether it’s intricate medical devices or robust automotive parts, BOEN ensures quality and precision at every step.

Why Choose BOEN?

We combine advanced technology with expert craftsmanship. Our fully equipped facility handles both 3-axis and 5-axis machining, providing you with customized results for your unique projects.

Our experienced machinists and programmers can handle complex geometries, undercuts, and angles all in a single setup, minimizing errors and ensuring efficiency. By reducing setup times, overhead, and tooling costs, we deliver high-precision parts at the lowest possible cost per part.

Explore how our 5-axis CNC machining can elevate your project to the next level!

#CNCmachining#5AxisMachining#PrecisionEngineering#Aerospace#Robotics#Automotive#BOEN#ComplexDesigns#Manufacturing#Prototyping

0 notes

Text

Types of Industrial Robots and Their Role in Automated Manufacturing

In the contemporary manufacturing environment, the integration of industrial robots has significantly transformed production processes, driving enhanced efficiency, accuracy, and flexibility. The evolution of robotics technology has introduced various types of industrial robots, each tailored to meet distinct automation requirements. This article explores the different types of industrial robots, their specific applications, and the critical role of automation advisory and technology scouting in optimizing manufacturing operations.

Overview of Industrial Robots

Industrial robots are categorized based on their design, functionality, and intended applications. The primary types include articulated robots, SCARA robots, delta robots, cartesian robots, and collaborative robots (cobots). A thorough understanding of these robot types is essential for selecting the most appropriate robot for a given manufacturing task.

1. Articulated Robots

Articulated robots are the most prevalent type of industrial robot, characterized by their rotary joints that provide a wide range of motion. Typically, these robots feature four to six axes, enabling them to perform tasks with high precision and flexibility. Due to their versatility, articulated robots are commonly employed in operations such as welding, assembly, material handling, and machine tending. Their ability to maneuver in complex angles makes them indispensable in industries like automotive and aerospace.

2. SCARA Robots

Selective Compliance Articulated Robot Arm (SCARA) robots are designed for tasks that demand rapid and precise movements within confined spaces. These robots have a fixed base and three vertical joints, which make them particularly suitable for pick-and-place operations, assembly, and packaging. SCARA robots are favored for their rigid structure, which ensures stability and accuracy in repetitive tasks, often in electronics and consumer goods manufacturing.

3. Delta Robots

Delta robots, also known as parallel robots, have a distinctive spider-like design featuring three arms connected to a common base. These robots are renowned for their exceptional speed and precision, making them ideal for high-speed applications such as picking, packing, and sorting. Industries like food processing, pharmaceuticals, and electronics frequently utilize delta robots due to their ability to perform quick and accurate movements, essential for maintaining production efficiency.

4. Cartesian Robots

Cartesian robots, or gantry robots, operate on three linear axes (X, Y, and Z) and are recognized for their simplicity and precision. These robots are often employed in applications such as CNC machining, 3D printing, and automated storage and retrieval systems. Cartesian robots are valued for their straightforward design and ease of programming, making them a preferred choice for tasks that require linear motion and high accuracy.

5. Collaborative Robots (Cobots)

Collaborative robots, commonly referred to as cobots, are engineered to work alongside human operators, enhancing both productivity and safety in manufacturing settings. Cobots are equipped with advanced sensors and safety mechanisms that enable safe interaction with human workers. These robots are widely used in assembly, quality inspection, and material handling, where human-robot collaboration can streamline workflows and improve overall efficiency.

Applications of Industrial Robots

The diverse range of industrial robots is applied across various sectors of manufacturing, with each type of robot excelling in specific tasks that contribute to overall production effectiveness.

Welding: Articulated robots are highly valued in welding applications due to their precision and ability to handle complex welding tasks in industries such as automotive and aerospace.

Assembly: SCARA robots and cobots are ideal for assembly processes, where their speed and accuracy are crucial for efficiently assembling components.

Material Handling: Cartesian and articulated robots are often used for material handling tasks, including moving heavy items, loading and unloading machinery, and palletizing products in distribution centers.

Packaging: Delta and SCARA robots are commonly employed in packaging operations, where their quick and precise movements are essential for sorting, packing, and labeling products.

Quality Inspection: Cobots are increasingly used in quality inspection, where their ability to work alongside human inspectors enhances the detection of defects and ensures high product quality.

The Role of Automation Advisory and Technology Scouting

Choosing the appropriate type of industrial robot for a specific application requires careful consideration of factors such as the nature of the task, production demands, and budget constraints. This is where automation advisory services and technology scouting play a pivotal role.

Automation Advisory

Automation advisory involves consulting with experts who assess manufacturing operations and recommend the most suitable automation solutions. These experts analyze production processes, identify bottlenecks, and suggest ways to integrate robots to improve efficiency. By leveraging insights into the latest robotic technologies, manufacturers can optimize their production processes, achieving enhanced performance and cost efficiency.

Technology Scouting

Technology scouting focuses on researching and identifying emerging robotic technologies that can benefit manufacturing operations. Staying informed about the latest advancements enables manufacturers to adopt cutting-edge solutions that drive innovation and improve competitive advantage. Technology scouting also helps in identifying scalable robotic solutions that can evolve with a company’s production needs, ensuring long-term growth and sustainability.

Conclusion

The integration of various types of industrial robots has significantly impacted manufacturing by enhancing efficiency, precision, and flexibility. Articulated robots, SCARA robots, delta robots, cartesian robots, and cobots each serve unique functions across different industrial applications. Utilizing automation advisory and technology scouting ensures that manufacturers select the right robots for their specific needs, optimizing production processes and maintaining a competitive edge. As technology continues to advance, the role of industrial robots in manufacturing will only become more crucial, driving innovation and fostering growth across the industry.

Robotic & Automated Solutions provides expert guidance in harnessing effective advisory services and automation technologies, drawing from extensive experience in industrial automation to support manufacturers in achieving their strategic objectives.

0 notes

Text

Mudar-M Metalworking Machine Tools: Precision, Innovation, and Excellence

Introduction

Mudar-M Metalworking Machine Tools, headquartered in Sofia, Bulgaria, stands at the forefront of the metalworking industry. With a rich history spanning over three decades, Mudar-M has consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers, machinists, and engineers worldwide. Let's delve into the details of this remarkable company.

Origins and Founding Vision

Founded in 1990 by visionary Rakan Mhissen, Mudar-M emerged as a response to the growing demand for reliable and efficient metalworking machinery. Rakan passion for precision engineering and his unwavering commitment to customer satisfaction laid the foundation for the company's success. From its modest beginnings as a small workshop specializing in lathe repairs, Mudar-M expanded its operations, embracing technological advancements and diversifying its product range.

CNC Lathes

Mudar-M's CNC lathes are renowned for their accuracy, versatility, and robust construction. Whether it's turning intricate components for aerospace applications or creating precision parts for automotive manufacturing, these machines consistently deliver exceptional results. Features include:

- High Precision: Mudar-M CNC lathes achieve micron-level tolerances, ensuring flawless surface finishes.

- User-Friendly Controls: Intuitive interfaces allow operators to program complex machining sequences effortlessly.

- Customization Options: Customers can choose from various spindle configurations, tool changers, and automation solutions.

Vertical Lathes

Vertical lathes play a crucial role in heavy-duty machining. Mudar-M's vertical lathes excel in handling large workpieces, such as turbine components, gearboxes, and hydraulic cylinders. Key attributes include:

- Stability: The robust column design minimizes vibrations during heavy cuts.

- Swing Diameter: Mudar-M offers a range of swing diameters to accommodate diverse applications.

- Live Tooling: Some models feature live tooling for milling, drilling, and tapping operations.

Milling Machines

Mudar-M's milling machines combine precision with versatility. From 3-axis to 5-axis configurations, these machines empower manufacturers to create complex geometries efficiently. Notable features include:

- Rigidity: Sturdy construction ensures stability during high-speed machining.

- Advanced Controls: Mudar-M integrates state-of-the-art control systems for optimal performance.

- Tool Changers: Automatic tool changers enhance productivity.

Cylindrical Grinding Machines

For achieving precise cylindrical shapes and superior surface finishes, Mudar-M's cylindrical grinding machines are indispensable. These machines excel in applications like bearing manufacturing, toolmaking, and precision engineering. Highlights include:

- Grinding Accuracy: Mudar-M's machines maintain tight tolerances, critical for cylindrical components.

- Wheel Dressing Systems: Automatic wheel dressing ensures consistent results.

- Coolant Filtration: Efficient coolant management prolongs wheel life.

Horizontal Boring Machines

Mudar-M's horizontal boring machines tackle large-scale projects with ease. Whether it's boring engine blocks or creating intricate molds, these machines offer:

- Spindle Power: High-torque spindles handle heavy cutting loads.

- Linear Guideways: Smooth movement across axes ensures precision.

- Digital Readouts: Accurate positioning for intricate machining tasks.

Commitment to Quality

Mudar-M's success hinges on its unwavering commitment to quality. Rigorous testing, continuous research, and collaboration with industry experts ensure that every machine leaving their facility meets the highest standards. The ISO 9001 certification underscores their dedication to excellence.

Global Reach

Mudar-M ships its machines to more than 50 countries across Europe, Asia, the Middle East, and beyond. From small workshops to large manufacturing plants, their footprint extends across continents. By empowering businesses with reliable tools, Mudar-M contributes to the advancement of global manufacturing capabilities.

Conclusion

Mudar-M Metalworking Machine Tools embodies precision, innovation, and excellence. As technology evolves, the company remains steadfast in its mission: to equip the world with cutting-edge machinery, enabling manufacturers to shape the future. Whether it's a CNC lathe, a vertical mill, or a cylindrical grinder, Mudar-M's legacy continues to shape the metalworking industry, one precision cut at a time.

#metalmachining#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Text

Jewelry CNC Machines

Jewelry CNC (Computer Numerical Control) machines are sophisticated tools designed for the precise and automated production of jewelry components and designs. These machines combine advanced computer technology with traditional jewelry-making techniques to produce intricate and high-quality pieces with remarkable accuracy and efficiency. Here's an in-depth exploration of the components, functions, types, and applications of Jewelry CNC machines:<br><br>

### **Components and Functionality**<br><br>

1. **CNC Controller**: The heart of the CNC machine, the controller is a computer that interprets and executes commands from the design software. It translates digital designs into precise movements of the machine's cutting tools. <br><br>

2. **Spindle**: The spindle is the rotating component that holds and drives the cutting tools. It can operate at varying speeds and is critical for shaping and detailing the jewelry. <br><br>

3. **Cutting Tools**: These are specialized tools used to carve, mill, or engrave the material. Common cutting tools include end mills, ball mills, and engraving bits, each suited for different aspects of jewelry production. <br><br>

4. **Work Table**: The work table or bed is where the material (such as metal or wax) is placed. It may be equipped with clamps or fixtures to hold the material securely in place during the machining process. <br><br>

5. **Axis Mechanisms**: CNC machines typically operate along multiple axes (X, Y, and Z), allowing for precise movement in three-dimensional space. Some advanced machines may have additional axes for greater flexibility and precision. <br><br>

6. **Tool Changer**: In more advanced CNC machines, a tool changer automatically swaps out cutting tools during the machining process, allowing for more complex and varied operations without manual intervention. <br><br>

7. **Cooling System**: To prevent overheating and ensure smooth cutting, CNC machines often include a cooling system that sprays or circulates coolant around the cutting area.

<br><br>

8. **Software**: The design and operation of the CNC machine are controlled by software that includes CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs. These programs allow designers to create detailed digital models and generate the necessary instructions for the machine. <br><br>

### **Types of Jewelry CNC Machines**<br><br>

1. **CNC Milling Machines**: These machines are used for cutting and shaping jewelry components from solid blocks of material, such as metal or wax. They are ideal for creating detailed and complex designs, including intricate patterns and settings. <br><br>

2. **CNC Engraving Machines**: Specialized for adding detailed engravings and inscriptions to jewelry, these machines can create precise and intricate designs on surfaces. <br><br>

3. **CNC Wax Carving Machines**: These machines are used to carve wax models for lost-wax casting, a common technique in jewelry making. The wax models are then used to create molds for casting the final metal pieces. <br><br>

4. **CNC Lathes**: CNC lathes are used for turning operations, where a rotating piece of material is cut into shape. They are particularly useful for creating symmetrical designs and detailed bands. <br><br>

5. **CNC 3D Printers**: Although not strictly a CNC machine in the traditional sense, 3D printers are used in jewelry making to create precise prototypes and models. They are often used in conjunction with CNC machines for a complete jewelry production process. <br><br>

### **Applications**<br><br>

- **Custom Jewelry Design**: Jewelry CNC machines allow for the creation of bespoke designs with high precision, making them ideal for custom jewelry pieces and unique creations. <br><br>

- **Mass Production**: For larger production runs, CNC machines provide consistency and efficiency, allowing jewelers to produce high volumes of identical or similar pieces with minimal variation. <br><br>

- **Prototyping**: Designers use CNC machines to create prototypes of new jewelry designs, allowing them to test and refine their concepts before mass production. <br><br>

- **Repairs and Restoration**: CNC machines can be used to repair or restore intricate jewelry pieces, ensuring that replacements or repairs match the original design perfectly. <br><br>

### **Advantages**<br><br>

- **Precision**: CNC machines offer unparalleled accuracy, ensuring that each piece of jewelry meets exact specifications and quality standards. <br><br>

- **Efficiency**: Automated operations reduce production time and labor costs, allowing for faster turnaround and higher production volumes. <br><br>

- **Consistency**: The use of CNC technology ensures that every piece produced is uniform, minimizing variations and defects. <br><br>

- **Flexibility**: CNC machines can be programmed to produce a wide range of designs and modifications, providing flexibility for both custom and mass-produced jewelry. <br><br>

- **Complexity**: Advanced CNC machines can execute complex designs and intricate details that would be challenging or impossible to achieve manually. <br><br>

### **Conclusion**<br><br>

Jewelry CNC machines have revolutionized the jewelry-making industry by combining technological precision with creative design. Their ability to produce detailed, consistent, and high-quality pieces has made them indispensable tools for modern jewelers. As technology continues to advance, these machines are likely to become even more sophisticated, further enhancing their capabilities and applications in the world of jewelry design and production. <br><br>

0 notes