#3d Printed Circuits

Explore tagged Tumblr posts

Text

Maximizing Efficiency: The Role of Mechatronic Integrated Devices

In the ever-evolving landscape of technological innovation, the integration of mechanical, electronic, and control engineering has given rise to mechatronics. At the forefront of this revolution are mechatronic integrated devices, playing a pivotal role in enhancing efficiency across various industries. This blog delves into the multifaceted aspects of mechatronic integrated devices, exploring their functions, benefits, and the transformative impact they have on efficiency.

1. Introduction to Mechatronic Integrated Devices

Mechatronic integrated devices represent a synergy of mechanical and electronic components, seamlessly combined to create intelligent and adaptive systems. These devices leverage the principles of mechatronics to optimize performance, automate processes, and elevate overall efficiency in diverse applications.

2. Enhanced Precision and Control

One of the primary advantages of mechatronic integrated devices is their ability to provide enhanced precision and control in complex systems. By integrating mechanical components with intelligent electronic control systems, these devices can execute tasks with unprecedented accuracy, minimizing errors and improving overall system performance.

3. Automation for Increased Productivity

Automation lies at the core of mechatronics, and integrated devices take this to the next level. With sensors, actuators, and control systems working seamlessly together, tasks that once required manual intervention can now be automated. This not only reduces labor-intensive processes but also significantly boosts productivity.

4. Adaptive and Intelligent Systems

Mechatronic integrated devices are designed to be adaptive and intelligent. Through the use of sensors and feedback mechanisms, these devices can respond dynamically to changes in the environment or operating conditions. This adaptability ensures optimal performance even in variable situations, contributing to increased efficiency.

5. Energy Efficiency and Sustainability

Efficiency in mechatronics extends beyond productivity gains; it also encompasses energy efficiency and sustainability. Mechatronic integrated devices are engineered to optimize energy consumption, leading to reduced operational costs and a smaller environmental footprint. This aligns with the growing emphasis on sustainable practices across industries.

6. Application in Manufacturing

In the realm of manufacturing, mechatronic integrated devices play a crucial role in optimizing production processes. From assembly lines to robotics, these devices enhance precision, streamline workflows, and contribute to the creation of smart factories. The result is faster production cycles, reduced downtime, and improved product quality.

7. Robotics and Mechatronic Integration

Robotic systems are a prime example of the transformative impact of mechatronic integration. By combining mechanical structures with electronic control systems, robotic devices can perform intricate tasks with unmatched precision. This not only revolutionizes industries such as healthcare and logistics but also opens new possibilities for automation in various sectors.

8. Mechatronics in Automotive Engineering

The automotive industry has embraced mechatronics to enhance vehicle performance, safety, and efficiency. Mechatronic integrated devices in modern vehicles control everything from engine management to advanced driver assistance systems (ADAS). This integration contributes to fuel efficiency, reduced emissions, and improved overall driving experience.

9. Challenges and Future Trends

While mechatronic integrated devices bring forth a myriad of benefits, they also pose challenges, including increased complexity in design and potential integration issues. However, ongoing research and technological advancements are addressing these challenges. The future holds promise for even more sophisticated mechatronic systems, leveraging artificial intelligence and the Internet of Things (IoT) for unparalleled efficiency.

10. Conclusion

In conclusion, mechatronic integrated devices stand as beacons of efficiency in the technological landscape. From precision engineering to adaptive control systems, these devices are shaping the future of industries by maximizing efficiency in ways previously unimaginable. As technology continues to advance, the role of mechatronic integrated devices will undoubtedly expand, ushering in a new era of intelligent, adaptive, and efficient systems across diverse applications.

#3d printed electronic#3d electronic#3d printed circuit board#laser direct structuring process#3d Printed Circuits#3d integrated circuits

0 notes

Text

i want to take touichirou apart like a computer

#he's so sexy from an objectification pov#circuit aura doing heavy lifting#guys what would i be if i was an object. i think i would be a building#or something small black shiny anthropogenic#3d printed cat figurine#obsidian scalpel#prized chinese inkstick#i dont know....#yap

4 notes

·

View notes

Text

The model looks about the same as the last time, but I did a lot of work to make it parametric instead of dimensioned to whatever I thought was about right. This way I can configure the length between each joint (instead of every individual distance), and the model should update accordingly.

With this 'refining' of the model, I can set configurations for each finger with different lengths and widths. Each joint is the same size for each finger, so I can delete the middle segment and join a first and last segment to create the thumb.

Also, this will likely be the color I'll use for the main gunslinger finger parts. (Not including the other 'fun' variants I'll likely make).

#ooc#3d printing#it's the least i can do if I'm literally in engineering is to make good tf2 props#gotta represent my main class 😎#gunslinger#wip#i should design a cavity in the wrist/arm cuffs for an extra extra fun version#with wire channels for two of the fingers :)#unless i wanna straight up recreate the short circuit#shit i should

11 notes

·

View notes

Photo

(via New tech enables 3D printing electronics without semiconductors)

1 note

·

View note

Text

Yeah yeah 3d printing is cool and whatever, you can make little plastic trinkets and a few utilities or whatever, but what we really need for at home making is ways to print circuit boards and fabricate components, and open source communities trading designs for them.

Like, I don't give a fuck about creating a fancy new phone holder or whatever if you are still dependent on (relatively) few companies and foundries for your phone's components and PCBs.

#diy#3d printing#tbh from everything I've seen 3d printing is still mostly a gimmick#you can make some cool toys but home printers just aren't making stuff strong enough and the material is shit plastic#laser cutting looks way better to me#circuit design#also can we make a better toolchain than we have#because fuck the existing vhdl/verilog tools#at least the ones I've used#we need people learning digital and analog logic design#glad we have a good open source thing going for software now let's hit hardware

0 notes

Text

Improve LSR injection molding mold temperature and warpage with special-shaped oil circuit and mold

Due to rapid development of 3D printing technology, designers can use 3D metal printing to design more in line with requirements of oil circuit, which can be close to contour of product when designing, so as to solve dead angle and heat accumulation of product. The more complex geometric shape of product will be more obvious, and this type of waterway design is usually called Conformal…

View On WordPress

#3D printing#Conformal Cooling#injection molding mold#injection molding process#mold flow analysis#Moldex3D analysis#oil circuit designs#plastic part#special-shaped oil circuit mold

0 notes

Text

“Fossils”

I used blender to design some rocks with its fancy rock button. The circuit texture was made with a displacement effect on a cut edge. I’ll make a post with the textures so people can see what I did & steal em if they want.

I started 3D printing these but realize my FEP has a ripple in it and I need to do some maintenance. But I’m tired and disappointed.

#3d design#3d printing#3d model#circuit art#circuit board art#modern fossils#cyber fossil#faux fossil

1 note

·

View note

Text

finally my art residency is over, culminating in an exhibition. i created an installation about tech liberating women from a radfem perspective, through re-mater-ializing women's history. specfically female warriors, queens and goddesses from one matriarchal society that ACTUALLY existed in 400 bc. i remodeled and 3D printed artifacts of this society, depicting these warriors, goddesses and queens (the smaller parts of the installation). if tech in male hands can erase and dismember women, it can also do the opposite in ours. i succeeded in making a piece that doesn't mention moids at all and inspires #hopeforwomen by combining a futuristic aesthetic and ancient female history.

the installation is made from wood that i cut by saw and by laser. it's a shrine that is separated in three parts: the mother (bottom disk, depicting a vulva, symbolizing reproductive creativity), the maiden (the middle disk that looks like an electronic circuit, representing curiousity, thirst for knowledge, innovation - scientific and technological creativity ) and the crone (top parts, artistic creativity and history, features 3D printed Scythian artifacts that depict their matriarchs and goddesses, and laser cut red plexiglass that symbolizes menstrual blood and radiates technomatriarchal vibes from the top of the piece lol). the maiden/circuit part has an NFC tag. If you touch it with your phone, it opens the historical resources about the Scythian matriarchy&amazons. the maiden and the mother disk are connected by a reprinted Scythian artifact that depics the Great snake-legged Goddess.

the exhibition opening was a huge hit and there were several hundreds of people who visited it, a record for that gallery. i heard praise of my work and one woman was so touched (it reminded her of her spiritual yonic awakening) we exchanged contact information :) common radfem W all around

348 notes

·

View notes

Text

Brian Oakes

Brian Oakes

Vessel 1, 2022 42" x 46" x 28"

Printed circuit boards, electronic components, microphones, audio cables, custom 3d printed hardware, power supplies, chain, hardware

47 notes

·

View notes

Text

3D-printed solutions shield electronics from electrostatic discharge

Electrostatic discharge (ESD) protection is a significant concern in the chemical and electronics industries. In electronics, ESD often causes integrated circuit failures due to rapid voltage and current discharges from charged objects, such as human fingers or tools. With the help of 3D printing techniques, researchers at Lawrence Livermore National Laboratory (LLNL) are "packaging" electronics with printable elastomeric silicone foams to provide both mechanical and electrical protection of sensitive components. Without suitable protection, substantial equipment and component failures may occur, leading to increased costs and potential workplace injuries. The team's research is featured in ACS Applied Materials & Interfaces.

Read more.

#Materials Science#Science#3D printing#Electronics#Electrostatic#Elastomers#Silicone#Foams#Polymers#Resin

11 notes

·

View notes

Text

Innovating Automation with Mechatronic Integrated Devices

Mechatronic Integrated Devices (MID) represent a cutting-edge fusion of mechanical and electronic components into a single, cohesive unit. By integrating circuits directly onto three-dimensional molded plastic structures, MIDs enable the creation of compact, efficient, and highly functional devices. This technology is revolutionizing industries such as automotive, consumer electronics, and industrial automation, offering enhanced performance, reduced assembly complexity, and greater design flexibility. Explore how Mechatronic Integrated Devices are paving the way for smarter, more efficient solutions in modern technology applications.

#3d printed circuit board#3d printed electronic#3d electronic#3d integrated circuits#mid molded interconnect device#molded interconnect device

0 notes

Text

Johnny 5 (Short Circuit 1986) Stimboard (for the very sweet Anon who requested I make a stimboard with lovecore & one of my favourite characters)

x x x / x x x / x x x

[Image description: a 9 gif stimboard; from left to right.

First line: A gif of a heart made with a circuit board and LEDs, the LEDs light up in different sequences. A gif of a cropped pc screen where program code is being written (to create a python graphic that says 'I love you'). And a gif of Johnny 5 from the film Short Circuit, the robot is wearing a red apron and carrying a little serving tray with a flower in a vase, a glass of orange juice and a stack of pancakes.

Second line: A gif of a 3d printed heart with a flashing LED light and moving/spinning gears, a large wheel-shaped lid opens up at the back to reveal metal inside. A gif of Johnny 5 wearing an apron and looking at a cook book while baking in a kitchen. And a gif of the monitor of an oscilloscope machine, someone is using an Arduino to create a flickering outline of a heart on the screen.

Third line: A gif of Johnny 5, the robot is wearing a red apron and carrying a little serving tray with a flower in a vase and a stack of pancakes. A gif of a heart made with a circuit board and LEDs, the LEDs light up in different sequences. And a cropped gif of a pc screen where someone uses a code to make a heart shape graphic appear little by little.

End of image description.]

#this was so sweet thank you Anon#I wasn't sure who to do but he popped into my head#stimboard#lovecore#hearts#flashing#circuit board#mechanical#electronics#coding#computers#typing#gears#rotating#robotics#food

29 notes

·

View notes

Text

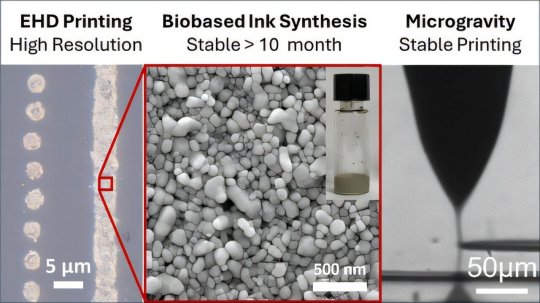

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Text

"It seems like a new Silicon Valley startup could change the face of the battery industry forever by utilizing 3D printers to print solid-state batteries.

Solid-state batteries have advantages over lithium-ion because they aren’t flammable, they’re more easily recycled, work in extreme cold, and have greater energy density.

Solid-state batteries have traditionally been difficult to machine manufacture. But by using 3D printing arrays filled with powder, Sakuu systems can make these batteries not only using 40% less material, but in almost any shape the customer might want.

An electric bike could be powered by a battery that hugs a section of the central chassis, or a smartphone’s battery could run all the way around the frame of a circuit board. These unorthodox shapes are just one of the many advantages that Sakuu believe they can offer.

“Many people have built cells in the lab, but they have not been able to scale,” Sakuu CEO and founder Robert Bagheri told Fast Company. “Our vision started with that scalability in mind.”

The array, known as a Kavian, is much smaller than the traditional, “roll to roll” battery manufacturing methods, and because the powder loaded into the 3D printers can be extremely precise, there’s a 40% reduction in materials usage—a huge cost savings over competitors.

The batteries they print can be charged to 80% in just 15 minutes.

Because they can be printed in any shape, all kinds of clever innovations are possible, in all kinds of industries from e-mobility products to wearables and small devices. The company is even working with an aviation company that wants solid-state batteries for their aircraft with holes through the middle of it to help with heat management."

-via Good News Network, 2/27/23

#battery#batteries#tech industry#electricity#recycling#3d printing#lithium ion battery#good news#hope

169 notes

·

View notes