#molded interconnect device

Explore tagged Tumblr posts

Text

Innovating Automation with Mechatronic Integrated Devices

Mechatronic Integrated Devices (MID) represent a cutting-edge fusion of mechanical and electronic components into a single, cohesive unit. By integrating circuits directly onto three-dimensional molded plastic structures, MIDs enable the creation of compact, efficient, and highly functional devices. This technology is revolutionizing industries such as automotive, consumer electronics, and industrial automation, offering enhanced performance, reduced assembly complexity, and greater design flexibility. Explore how Mechatronic Integrated Devices are paving the way for smarter, more efficient solutions in modern technology applications.

#3d printed circuit board#3d printed electronic#3d electronic#3d integrated circuits#mid molded interconnect device#molded interconnect device

0 notes

Text

Molded interconnect device (MID) market is expected to grow from USD 1.4 billion in 2022 to USD 2.7 billion by 2027; it is expected to grow at a CAGR of 13.6% during the forecast period, according to a new report by MarketsandMarkets™. Key factors driving the demand for MIDs included the growing use of LDS process for the production of 5G antennas, which increases the speed and efficiency of wireless communication. Growing demand for IoT devices is bringing huge opportunities for MID providers.

0 notes

Text

New 3D printing technique integrates electronics into microchannels to create flexible, stretchable microfluidic devices

The transition from traditional 2D to 3D microfluidic structures is a significant advancement in microfluidics, offering benefits in scientific and industrial applications. These 3D systems improve throughput through parallel operation, and soft elastomeric networks, when filled with conductive materials like liquid metal, allowing for the integration of microfluidics and electronics. However, traditional methods such as soft lithography fabrication which requires cleanroom facilities have limitations in achieving fully automated 3D interconnected microchannels. The manual procedures involved in these methods, including polydimethylsiloxane (PDMS) molding and layer-to-layer alignment, hinder the automation potential of microfluidic device production. 3D printing is a promising alternative to traditional microfluidic fabrication methods. Photopolymerization techniques like stereolithography apparatus (SLA) and digital light processing (DLP) enable the creation of complex microchannels.

Read more.

11 notes

·

View notes

Note

as someone with Hands Don't Work At All (and neither does anything else) Syndrome, I get the instinctive defensive reaction to 'make stuff with your hands'.

but people are missing the point, I think. In my experience: you don't have to *make* things, you can simply fuck around to the best of your ability! Basically there's two different interconnected pleasures to consider here.

a. completing tasks, feeling the joy of having done something from beginning to end

b. touching physical items, moving whatever body parts we have that are moveable, molding the physical world in some way instead of just flitting through it en route to whatever accessible electronic device

if possible, it makes a lot of sense to combine a. and b.! But if not, fuck it. Divorce b. from any kind of end goal or drive toward proficiency. Do it only for its own sake. You don't have to be able to grip a pencil or have some complicated setup or whatever, just go around touching whatever's around you.

(as for a. - it's doable electronically but there's more pitfalls than there should be)

Thank you for wording this far better than I did. I don't really have anything else to add.

22 notes

·

View notes

Text

Professional Ceiling Fan Services in PA & Smoke Detector Installation in Ardmore, PA with Decenzo Electric, LLC

When it comes to maintaining your home’s comfort and safety, electrical systems play a crucial role. From ceiling fan services in PA to smoke detector installation in Ardmore, PA, to exhaust fan installation services in PA, professional and reliable assistance makes all the difference. That’s where Decenzo Electric, LLC comes in.

Whether you’re upgrading your home’s ventilation, enhancing fire safety, or ensuring optimal comfort, here’s everything you need to know about these essential services and how we can help.

Why Choose Professional Electrical Services?

Ever thought, "Can’t I just install that ceiling fan or smoke detector myself?" While DIY projects can be tempting, there are valid reasons to entrust these jobs to licensed professionals like Decenzo Electric, LLC.

Safety First: A poorly installed Ceiling fan services in pa could pose safety risks, just as an improperly placed smoke detector might fail in an emergency.

Time-Efficiency: Avoid frustration and wasted hours by letting experts handle the job right the first time.

Code Compliance: Electrical work must adhere to strict building codes. Hiring professionals ensures the work is completed safely and legally.

Decenzo Electric, LLC doesn’t just get the job done. We prioritize your family’s safety and satisfaction, ensuring every installation or service is performed with precision and care.

Expert Ceiling Fan Services in PA

Ceiling fans are a simple yet effective way to improve your home’s air circulation and energy efficiency. Whether you’re looking to beat the summer heat or keep cozy during winter, proper ceiling fan installation is key.

What We Offer

Installation: Ensure your ceiling fan is solidly installed and balanced for optimal performance.

Repairs: Address noise, wobbling, or electrical issues promptly.

Upgrades: Need a new fan switch or remote system? We’ve got it covered.

Benefits of a Professionally Installed Ceiling Fan

Energy Savings: Reduce reliance on HVAC systems and save on energy bills.

Comfort: Enjoy improved airflow all year round.

Stylish Appeal: Elevate your home’s interior design with a properly installed fan.

Smoke Detector Installation in Ardmore, PA

Did you know a working smoke detector cuts the risk of dying in a house fire by half? For homeowners in Ardmore, PA, this essential safety device should never be overlooked.

Why Call Decenzo Electric for Smoke Detector Installation?

Correct Placement: We ensure strategic installation for maximum coverage throughout your home.

Interconnected Systems: With modern technology, Smoke detector installation in Ardmore pa can communicate with each other, offering quicker alerts.

Battery or Hard-Wired Options: We’ll help you decide which type suits your home best.

Pro Tips for Smoke Detector Safety

Test your smoke detectors monthly to ensure they’re functioning.

Change batteries at least once a year or when you hear that chirping sound.

Replace the entire unit every 10 years for optimal performance.

At Decenzo Electric, we don’t just install smoke detectors; we provide peace of mind.

Reliable Exhaust Fan Installation Services in PA

When was the last time you thought about your home’s ventilation? Exhaust fans are crucial for maintaining proper airflow, controlling humidity, and eliminating odors from key areas like bathrooms and kitchens.

What Exhaust Fans Do

Eliminate Moisture: Prevent mold growth and extend the life of fixtures.

Control Odors: Keep your home smelling fresh and clean.

Enhance Air Quality: Circulate stale air out and improve indoor air quality.

How Decenzo Electric Can Help

From helping you select the right fan for your space to seamless, code-compliant installation, we handle all aspects of your exhaust fan needs.

We also specialize in troubleshooting and repairing faulty fans, ensuring you don’t deal with unnecessary noise or inefficient airflow.

Why Decenzo Electric, LLC?

With so many options for electrical services, why do homeowners across PA trust Decenzo Electric, LLC? It starts with our commitment to quality, safety, and customer satisfaction.

Licensed Experts: Our certified electricians bring specialized expertise to every project.

Transparent Pricing: No hidden fees—just honest, upfront quotes.

Emergency Services: Need help fast? We’re just a call away.

Customer Focused: Your satisfaction is our priority.

Book Your Service Today

Your home deserves expert care, whether you need ceiling fan services in PA, smoke detector installation in Ardmore, PA, or exhaust fan installation services in PA. At Decenzo Electric, LLC, we take pride in delivering top-notch, reliable, and efficient solutions tailored to your needs.

Call us today or book an appointment through our website to experience the Decenzo Electric difference. With us, comfort and safety are only a phone call away.

#Ceiling fan services in pa#Smoke detector installation in Ardmore pa#Exhaust fan installation services in pa

0 notes

Text

0 notes

Text

Advancements in Hybrid Micro Circuit Design: Emerging Trends & Technologies

In today’s fast-paced technological environment, Hybrid Micro Circuits (HMCs) have become fundamental across a wide range of industries, from telecommunications to aerospace. These circuits combine multiple functions into a single, compact design, making them indispensable for modern electronics. As technology continues to evolve, several emerging trends and innovations are shaping the future of Hybrid Micro Circuit design.

One of the most impactful advancements is the integration of Advanced Thin Film Technology. This technology involves the deposition of ultra-thin layers of various materials, significantly improving the performance and reliability of Hybrid Micro Circuits. By using materials such as metals, insulators, and semiconductors in these fine layers, manufacturers can enhance electrical efficiency and thermal management. The precision offered by Advanced Thin Film Technology allows the creation of smaller, lighter circuits without sacrificing performance or functionality.

Miniaturization is another key trend driving innovation in Hybrid Micro Circuit design. As consumer electronics continue to shrink, components must evolve to match. Manufacturers are focusing on designing more compact circuits that can integrate more features in smaller spaces. This is especially critical in industries like medical devices and wearable technology, where space constraints are a constant challenge. Thanks to Advanced Thin Film Technology, companies can produce Hybrid Micro Circuits that are not only more compact but also highly efficient and reliable.

Sustainability is also playing an increasingly important role in Hybrid Micro Circuit design. As environmental concerns grow, companies are prioritizing eco-friendly materials and production processes to minimize waste and reduce environmental impact. This shift is driving innovation in materials that are recyclable or that produce less waste during manufacturing. HHV Advanced Technologies is leading this movement, focusing on sustainable practices in the design and production of their Hybrid Micro Circuits.

Moreover, the rise of automation and smart manufacturing technologies is revolutionizing the production of Hybrid Micro Circuits. Automation accelerates production while improving quality control, ensuring that each circuit meets rigorous standards. Companies are incorporating cutting-edge technologies, including machine learning and artificial intelligence, to optimize production processes and minimize defects, making manufacturing more efficient and precise.

The growing influence of the Internet of Things (IoT) is also shaping the future of Hybrid Micro Circuit design. As more devices become interconnected, the need for circuits that can enable seamless communication between them is essential. Advances in wireless technology and communication protocols are empowering Hybrid Micro Circuits to become a vital part of the IoT ecosystem, facilitating the connectivity that drives the digital world.

In conclusion, the future of Hybrid Micro Circuit design is being molded by trends such as Advanced Thin Film Technology, miniaturization, sustainability, and automation. HHV Advanced Technologies continues to spearhead these innovations, offering state-of-the-art solutions that meet the needs of an ever-evolving market. As technology progresses, we can expect to see even more transformative developments in Hybrid Micro Circuits, leading to the creation of smarter, more efficient devices for the future.

Top of FormFor more information, visit the website: https://hhvadvancedtech.com/

0 notes

Text

The Benefits and Applications of Rigid-Flex PCBs

Rigid-Flex Printed Circuit Boards (PCBs) are a combination of rigid and flexible circuit technologies, offering a unique solution for complex electronic designs. These boards are increasingly becoming the preferred choice for industries that demand high performance, reliability, and space optimization. In this blog, we’ll explore the key benefits, applications, and why rigid-flex PCBs are an ideal option for modern electronics.

What Are Rigid-Flex PCBs?

Rigid-flex PCBs combine the properties of both rigid PCBs and flexible PCBs into one integrated circuit board. The rigid sections of the PCB provide structure and support, while the flexible sections offer the ability to bend, twist, and fold, making it easier to design complex and compact devices. These boards typically consist of multiple layers of flexible circuits attached to one or more rigid sections, all interconnected with electrical pathways.

The main feature that sets rigid-flex PCBs apart is their ability to eliminate the need for connectors and cables between the rigid sections, allowing for greater mechanical stability and reliability in designs that require flexibility.

Benefits of Rigid-Flex PCBs

Space and Weight Reduction

One of the most significant advantages of rigid-flex PCBs is their ability to reduce both space and weight in electronic devices. By integrating flexible circuitry into the design, engineers can create devices with complex geometries, reducing the need for additional connectors or interfaces. This is particularly important for industries such as aerospace and medical devices, where every millimeter of space and gram of weight matters.

Enhanced Durability

Rigid-flex PCBs are designed to withstand high levels of mechanical stress. The flexibility of the board allows it to bend and flex without damaging the circuits. This durability makes them ideal for applications where the device will experience movement, vibrations, or harsh environmental conditions.

Increased Reliability

By eliminating the need for connectors and cables, rigid-flex PCBs offer a more reliable solution. Connectors are often the weakest points in electronic designs and are prone to failure due to wear and tear over time. Rigid-flex PCBs, with their integrated design, reduce these potential failure points, leading to increased reliability and longer lifespans.

Design Flexibility

Rigid-flex PCBs allow engineers to design circuits that would be impossible or impractical with traditional rigid or flexible PCBs alone. The ability to fold, twist, and mold the flexible sections means that circuits can fit into unusual shapes, allowing for innovative product designs and more compact electronics.

Cost-Effectiveness in Complex Assemblies

While rigid-flex PCBs may initially seem more expensive than traditional PCBs, they can reduce costs in the long run by simplifying assembly processes. With fewer components to connect and less labor required to assemble, the total cost of ownership for devices using rigid-flex PCBs can be lower. Additionally, the improved reliability means fewer repairs or replacements, further reducing overall costs.

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are widely used across various industries due to their unique benefits. Some of the most common applications include:

Aerospace and Defense

In aerospace and defense, every gram of weight and cubic centimeter of space is critical. Rigid-flex PCBs are used in devices such as satellites, missiles, and aircraft components, where their lightweight, durability, and ability to function in harsh environments make them invaluable.

Medical Devices

In the medical industry, rigid-flex PCBs are found in wearable devices, hearing aids, pacemakers, and other compact medical devices. Their flexibility allows for more ergonomic designs that can fit the contours of the human body, while their reliability ensures they function flawlessly in life-critical applications.

Consumer Electronics

From smartphones to wearable technology, consumer electronics are increasingly using rigid-flex PCBs. As these devices become smaller and more powerful, rigid-flex technology offers the ideal solution for fitting complex circuits into compact spaces without sacrificing durability.

Automotive Industry

In modern cars, rigid-flex PCBs are used in sensors, cameras, and infotainment systems. They can withstand the vibrations, temperature fluctuations, and mechanical stress that occur in automotive environments, making them a durable and reliable solution for advanced vehicle technology.

Conclusion

Rigid-flex PCBs offer a powerful combination of flexibility, reliability, and space-saving advantages, making them an ideal choice for industries that require complex, high-performance electronic designs. Whether in aerospace, medical devices, or consumer electronics, the benefits of rigid-flex PCBs are clear: they reduce the need for connectors, improve durability, enhance design possibilities, and ultimately lead to more efficient and reliable products. As electronic devices continue to evolve, rigid-flex PCBs will undoubtedly play an increasingly important role in the future of technology. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Abrasives Market Trends - Automation & AI

Join the newsletter: https://avocode.digital/newsletter/

Introduction to the Abrasives Market

In recent years, the abrasives market has seen significant developments fueled by technological advancements. With **automation and artificial intelligence** (AI) beginning to reshape traditional manufacturing industries, the abrasives market stands out as a key beneficiary. These technological enhancements have not only boosted productivity but have also instigated innovative ways to improve the quality and efficiency of abrasive materials. In this article, we delve into the impactful trends of automation and AI in the abrasives market, exploring how these technologies are molding the future of the industry.

The Evolution of Automation in Abrasives

Automation within the abrasives industry has emerged predominantly in response to the increasing demand for efficiency and precision. This section explores some of the notable advancements:

1. Robotic Precision and Efficiency

The introduction of **robotic automation** has led to substantial improvements in manufacturing processes. Robots are employed for precise cutting, grinding, and polishing tasks which were once labor-intensive and prone to human error. **Key benefits** include:

Consistency: Robots ensure uniformity across production, enhancing product quality.

Speed: Automated systems can operate continuously without fatigue, significantly speeding up production.

Safety: By taking over potentially hazardous tasks, robots ensure a safer working environment for human workers.

2. Advanced Machinery and Factory Automation

Automated machinery has taken center stage in the abrasives market, characterized by:

Computer Numeric Control (CNC) machines: These machines allow for highly precise and automated abrasive processing.

Integrated Digital Control Systems: Machinery guided by digital interfaces enables streamlined operations, reducing the need for manual oversight.

Smart Factories: Featuring interconnected devices that enable real-time data collection and process optimizations.

AI’s Role in Revolutionizing the Abrasives Market

Artificial Intelligence introduces a new dimension to abrasives production by enhancing decision-making through data analysis and machine learning.

1. Predictive Maintenance and Operational Efficiency

AI-driven solutions offer **predictive maintenance**, which minimizes downtime through:

Data Monitoring: AI systems continuously monitor machinery for performance anomalies, allowing preemptive maintenance actions.

Reduced Costs: Proactive maintenance reduces the likelihood of unexpected machinery failures.

Enhanced Lifespan: Regular maintenance dictated by AI insights can extend the life of expensive machinery components.

2. Machine Learning for Quality Optimization

Machine learning algorithms are transforming how abrasives are made by:

Process Optimization: AI can analyze various production parameters to suggest optimal settings for improved quality and reduced waste.

Error Detection: Automated quality assurance that detects and corrects defects swiftly, maintaining high standards for abrasive products.

Supply Chain Improvements: AI analyzes supply chain data for efficiencies, reducing material waste and costs while ensuring timely delivery.

Integration of Humans and Technology

One of the most compelling aspects of automation and AI is their potential for collaboration with human workers. The **integration of human expertise and machine precision** offers surprising synergies:

1. Augmented Workforce

Humans and machines work best together, with AI and robots taking over repetitive tasks, allowing human workers to focus on:

Complex Problem Solving: Humans can devote more time to higher-order tasks that require creativity and decision-making.

Skill Development: Workers can train on controlling and interacting with sophisticated machinery, acquiring valuable new skills.

Safety Oversight: Human personnel oversee and manage production environments, ensuring machine performance aligns with safety protocols.

2. Embracing Change

The transition towards automation and AI doesn't imply the obsolescence of human roles but rather a redefinition:

Training Programs: Companies are investing in training current employees to work with new technologies.

Enhanced Roles: Workers can transition into roles that require oversight of automated systems.

Collaborative Innovation: Human insight continues to play a crucial role in innovating within the industry.

Challenges and Future Prospects

While opportunities abound, the path of automation and AI in the abrasives market is not without challenges:

Initial Investments: High upfront costs in technology and training can be barriers for smaller enterprises.

Cultural Shift: Organizations must foster a culture that embraces technological change.

Cybersecurity: With increased connectivity comes the challenge of securing factory systems against cyber threats.

Despite these challenges, the future of the abrasives market looks promising. **Automation and AI are paving the way for innovations** that will continue to redefine productivity and quality standards, ensuring that the industry remains competitive and resilient.

Conclusion

The integration of **automation and AI into the abrasives market** is more than a mere trend; it is a fundamental shift towards a more efficient and innovative future. As the industry embraces these technologies, it unveils new potential not only for enhancing product quality and efficiency but also for reimagining the role of human workers. Companies willing to invest in and adopt these technologies will undoubtedly find themselves at the forefront of this digital revolution, poised to take advantage of the growing demand for high-quality abrasives in various industries globally. As we move forward, such advancements will continue to shape the future of the abrasives market, driving it towards heights hitherto unexplored. Want more? Join the newsletter: https://avocode.digital/newsletter/

0 notes

Text

Characteristics and Applications of Porous Alumina Ceramics

Porous ceramics are important functional and structural materials that play an increasing role in daily life and industrial production.

Characteristics of porous alumina ceramics

Porous alumina ceramics refers to a kind of alumina as aggregate, through the molding or sintering process, the use of physical or chemical methods in the matrix internal formation of a large number of interconnected or closed holes in the porous material. Porous alumina ceramics is a combination of alumina ceramics and porous ceramics, which retains the excellent thermal, optical, electrical, magnetic, and other physical properties inherent in alumina ceramics, while also having a porous structure brought about by high porosity and a large specific surface area, with high hardness, excellent mechanical properties, corrosion resistance, high temperature stability, etc., and its manufacturing cost is low, the production process is simple, and therefore become the application of the most extensive class of porous ceramic materials The most extensive class of porous ceramic materials.

Application of porous alumina ceramics

Porous alumina ceramics have broad application prospects due to their excellent properties.

1. Catalyst carrier materials Porous alumina ceramics are considered to be ideal catalyst carriers due to their excellent heat resistance, high hardness, and excellent chemical stability, and are widely used in industrial production.

2. Porous alumina ceramics can be used as humidity sensors. The working principle is that the moisture mixed in the air is adsorbed on the surface of porous alumina ceramics, which will cause changes in the conductivity of the ceramics themselves. Therefore, the greater the air humidity, the thicker the water layer adsorbed by the porous alumina ceramics, and the greater the conductivity of the sensor. Therefore, the humidity of the surrounding environment can be inferred based on the size of the material conductivity.

3. Molten metal filtration The high-temperature resistance and corrosion resistance of porous alumina ceramic materials enable them to continue working for a long time even in harsh environments with temperatures as high as 1000°C or above. Therefore, porous alumina ceramics are often prepared into ceramic filter screens for filtering molten metal liquids such as iron and aluminum.

4. Liquid filtration Using the high porosity of porous alumina ceramics, porous alumina ceramics can be prepared into liquid filter devices. With the support of current technical means, porous alumina ceramics can achieve controllable pore size to a certain extent and can be prepared into filter devices with pore sizes ranging from a few microns to tens of microns according to actual needs. By filtering impurities, heavy metal ions, bacteria, microorganisms, etc. in water, it can have antibacterial and antiviral effects on water.

5. Sound-absorbing materials Porous alumina ceramics have a large number of tiny pores and pores inside. The air molecules in the pores and pores will produce viscous resistance and friction to the sound waves entering the material, so that part of the energy in the sound waves is converted into heat energy and absorbed, thereby achieving the effect of reducing sound.

6. Thermal insulation refractory materials The closed pores in porous alumina ceramics are conducive to weakening the ability of thermal radiation, thermal convection, and thermal conduction during heat transfer so that the ceramic material has lower thermal conductivity, smaller specific heat, and high thermal shock resistance. These excellent thermal properties make it an ideal thermal insulation refractory material for various high-temperature working conditions.

7. Heat exchanger The high porosity of porous alumina ceramics gives them a large heat exchange area and is often used as an energy-saving material in the thermal industry.

8. Bioengineering materials Porous alumina ceramics can be used as solid enzyme carriers, which is beneficial to the improvement of biochemical reaction rates.

9. In addition to the above applications, porous ceramics are also used as photocatalyst carriers, radiation activation, etc.

0 notes

Text

Cutting-Edge Advancements with MID Molded Interconnect Devices

MID Molded Interconnect Devices represent a breakthrough in electronics, combining mechanical and electronic functions into a single 3D component. By integrating circuitry and components directly onto molded plastic substrates, MIDs enable more compact, efficient, and versatile designs. These devices are revolutionizing industries such as automotive, consumer electronics, and medical technology with their enhanced functionality and reduced assembly complexity. Discover how MID Molded Interconnect Devices can streamline your product designs, improve performance, and drive innovation in your applications.Visit our website to know more.

#3d printed circuit board#3d printed electronic#3d electronic#3d integrated circuits#mid molded interconnect device#molded interconnect device

0 notes

Text

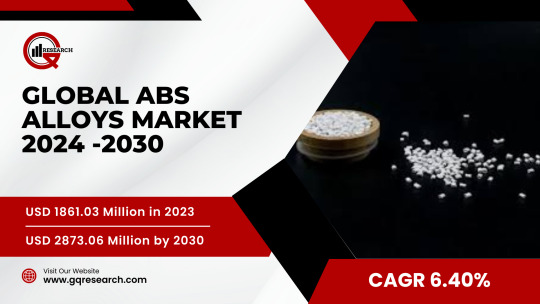

The ABS Alloys Market is Dazzling Worldwide and Forecast to 2030|GQ Research

The ABS Alloys market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global ABS Alloys market showcased a significant presence, boasting a valuation of US$ 1861.03 Million. This underscores the substantial demand for ABS Alloys technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abs-alloys-market/

Projected Growth: Projections suggest that the ABS Alloys market will continue its upward trajectory, with a projected value of US$ 2873.06 Million by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 6.40%, reflecting a steady and robust growth rate for the ABS Alloys market over the coming years.

Technology Adoption:

The ABS (Acrylonitrile Butadiene Styrene) alloys market has seen a rapid uptake of advanced manufacturing technologies and processes. Injection molding, extrusion, and 3D printing have become prevalent methods for shaping ABS alloys into intricate forms, fostering innovation across industries. These techniques enable the production of complex geometries with high precision, expanding the scope of applications for ABS alloys in automotive, electronics, consumer goods, and beyond. Moreover, the integration of additives and reinforcements has led to the development of ABS alloys with enhanced properties, such as increased strength, heat resistance, and flame retardancy. This advancement has bolstered the adoption of ABS alloys in critical applications where performance and durability are paramount.

Application Diversity:

The versatility of ABS alloys has resulted in their widespread use across diverse sectors. In automotive manufacturing, ABS alloys are employed for interior and exterior components due to their lightweight nature and exceptional impact resistance. Similarly, in electronics, ABS alloys find application in casings and housings for electronic devices owing to their excellent electrical insulation properties. Consumer goods represent another significant market for ABS alloys, ranging from household appliances and toys to sporting equipment and luggage. Their ability to be molded into intricate shapes, coupled with aesthetic appeal and durability, makes ABS alloys an attractive choice for manufacturers seeking to meet the demands of discerning consumers.

Consumer Preferences:

Consumer preferences are increasingly influencing the ABS alloys market, particularly concerning sustainability and performance. There's a growing demand for eco-friendly ABS alloys derived from recycled or biodegradable materials, aligning with consumers' environmentally conscious choices. Additionally, there's a preference for ABS alloys offering superior functionality, ergonomic design, and customization options, reflecting consumers' desire for products that cater to their specific needs and preferences.

Technological Advancements:

Technological advancements continue to drive innovation in the ABS alloys market. Research efforts focus on enhancing the mechanical, thermal, and chemical properties of ABS alloys through advanced materials science and manufacturing techniques. Nanotechnology plays a significant role in improving ABS alloy performance by reinforcing them with nanoparticles to enhance strength, stiffness, and thermal stability. Furthermore, the integration of smart technologies into ABS components opens up new possibilities for applications in IoT devices, automotive sensors, and healthcare equipment. These advancements not only improve the functionality of ABS alloys but also pave the way for the development of more sophisticated and interconnected products.

Market Competition:

Intense competition characterizes the ABS alloys market, with manufacturers striving to differentiate themselves through product innovation, quality, and cost-effectiveness. Established players invest heavily in research and development to expand their product portfolios and capture new market segments. Meanwhile, emerging companies enter the market with novel solutions, intensifying competition and driving further innovation. Globalization and the rise of manufacturing hubs in Asia-Pacific and Latin America have intensified price competition in the ABS alloys market. Manufacturers are under pressure to reduce costs while maintaining high-quality standards to remain competitive in a dynamic marketplace.

Environmental Considerations:

Environmental considerations are increasingly shaping the ABS alloys market. Stakeholders are adopting sustainable practices to reduce the environmental impact of ABS alloy production and disposal. Recycling initiatives and waste reduction strategies are being implemented to minimize environmental footprints. Regulatory measures aimed at reducing emissions and promoting resource efficiency are driving the adoption of eco-friendly materials and production methods in the ABS alloys market. Biodegradable ABS alloys derived from renewable sources are gaining traction as environmentally conscious consumers seek alternatives to traditional plastics.

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

LG Chem

Chi Mei Corporation

Styrolution Group GmbH

INEOS Styrolution Group GmbH

SABIC

Formosa Plastics Corporation

Trinseo

Toray Industries Inc.

Asahi Kasei Corporation

Kumho Petrochemical Co. Ltd.

BASF SE (Germany)

LOTTE Advanced Materials

Ravago Group

Mitsubishi Chemical Corporation

Teijin Limited

The research report provides a comprehensive analysis of the ABS Alloys market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abs-alloys-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

0 notes

Text

Choosing Wisely: Selecting the Right Asset Management Software for Your Organization

In the fast-paced landscape of modern business, managing assets efficiently is imperative for success. Whether it’s equipment, infrastructure, or digital assets, organizations require robust software solutions to track, analyze, and optimize their assets effectively. Amidst a sea of options, Tracet Asset management software emerges as a standout choice for businesses seeking comprehensive asset management capabilities. We delve into the reasons why Tracet Software is the ideal solution for your organization’s asset management needs.

User-Friendly Interface:

Tracet Software boasts an intuitive and user-friendly interface, making it accessible to employees across all levels of technical expertise. With its simple navigation and visually appealing design, users can quickly adapt to the platform, minimizing training time and maximizing productivity.

Customization Options:

Tracet Software understands that every organization operates with distinct asset management needs, and it embraces this diversity wholeheartedly. By offering a wealth of customization options, Tracet Asset management software enables users to fine-tune the software according to their precise requirements. Whether it involves crafting bespoke fields, delineating intricate workflows, or crafting tailored reports, Tracet’s extensive flexibility empowers users to mold the software to perfectly fit their unique workflows. This adaptability is pivotal, as it ensures that Tracet Software integrates seamlessly into existing business processes, without imposing any rigid frameworks. Instead, Tracet fosters a dynamic environment where the software evolves alongside the organization, fostering agility and efficiency in asset management practices.

Comprehensive Asset Tracking:

Tracet Software excels in its ability to track a wide range of assets, including physical equipment, IT assets, software licenses, and more. Its robust tracking capabilities allow organizations to monitor asset lifecycle stages, track maintenance schedules, and identify potential risks or issues proactively. By providing real-time visibility into asset utilization and performance, Tracet Asset management software empowers organizations to make data-driven decisions and optimize asset utilization.

Integration Capabilities:

Amidst today’s interconnected business landscape, the ability to seamlessly integrate with existing systems stands as paramount for optimizing efficiency and maintaining data accuracy. Tracet Software excels in this aspect by providing robust integration capabilities, facilitating seamless connections with widely used ERP systems, financial software, and IoT devices. This interoperability not only enables smooth data exchange between disparate systems but also eradicates information silos, culminating in a unified and comprehensive view of asset-related data. By fostering such seamless integration, Tracet empowers organizations to harness the full potential of their assets while enhancing operational efficiency and decision-making processes.

Advanced Analytics and Reporting:

Tracet Asset management software goes beyond basic asset tracking by offering advanced analytics and reporting features. Organizations can leverage powerful analytics tools to gain actionable insights into asset performance, maintenance trends, and cost optimization opportunities. With customizable dashboards and comprehensive reporting capabilities, stakeholders can access critical information in real-time, enabling informed decision-making and driving continuous improvement initiatives.

Scalability and Reliability:

Tracet Software is designed to cater to businesses of all sizes, whether you’re just starting out as a small startup, or you’ve established yourself as a multinational corporation. Its architecture, based in the cloud, ensures that as your needs grow, Tracet can easily scale to meet them. This scalability is achieved without sacrificing performance or reliability, thanks to its robust cloud-based infrastructure. Moreover, Tracet Asset management software comes equipped with built-in redundancy and data backups, giving you the assurance that your asset data remains secure and readily accessible whenever you require it. This combination of scalability and security offers peace of mind, allowing you to focus on your business priorities with confidence.

When it comes to selecting the right Asset management software for your organization, Tracet Software stands out as a clear frontrunner. With its user-friendly interface, customization options, comprehensive asset tracking capabilities, seamless integration, advanced analytics, and scalability, Tracet Software offers everything you need to optimize your asset management processes and drive business success. Choose wisely, choose Tracet Software.

#AssetManagement#AssetOptimization#AssetTracking#ITAssets#AssetMaintenance#AssetLifecycle#AssetSecurity

0 notes

Text

Fixed Series Compensation Market: Global Demand Analysis & Opportunity Outlook 2036

Research Nester’s recent market research analysis on “ Fixed Series Compensation Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global fixed series compensation market in terms of market segmentation by product type, application, and by region.

Request Report Sample@

Optimization in Existing Infrastructure & Rising Need for Uninterruptible Power Supply to Promote Global Market Share of Fixed Series Compensation

Fixed series compensation is one of the technologies needed to improve grid stability and dependability as power networks grow and confront more demand, particularly in urban areas and emerging nations. These systems enable utilities to optimize their existing transmission infrastructure, avoiding the need for costly new constructions by improving the capacity and efficiency of existing lines. As analyzed by Research Nester Analysts, between 2020 to 2030, a 16-million-kilometre grid expansion is estimated to take place. This puts forth prospective opportunities for the market’s growth.

Additionally, in large-scale manufacturing facilities, uninterrupted power supply is essential, and fixed series compensation systems are used to provide with reliable power solutions and cut down on power shortages. These systems are widely adopted across residential and commercial buildings and are likely to drive the market’s growth.

Growth Drivers:

Increasing demand for a strong electricity infrastructure.

Integration with Renewable sources of energy.

Challenges:

Operational and maintenance challenges, cost considerations, regulatory and compliance issues, and complexity in implementation are some of the major factors anticipated to hamper the global market size of molded interconnect devices

By application, the global fixed series compensation market is segregated into utilities, steel and mining, and oil and gas. Amongst these utilities segment is estimated to hold the majority market share. On the other hand, Fixed Series Compensation helps mining and steel companies by lowering electrical disruptions and improving power quality. FSC helps the oil and gas industry keep a steady supply of electricity for vital activities. Furthermore, FSC finds use in several different industries by guaranteeing ideal power flow, reducing losses, and enhancing the general performance of electrical systems. In the end, FSC is essential to raising production and cutting expenses in these sectors.

By region, Asia Pacific is estimated to hold a significant market share over the forecast period owing to burgeoning energy demands, rapid industrialization, and a push for sustainable power infrastructure. This region's diverse terrain and varying levels of grid maturity create both challenges and opportunities for FSC implementation. Countries like China and India, with their expanding urban centers and ambitious renewable energy targets, seek advanced grid solutions. FSC technology addresses transmission constraints, facilitates renewable energy integration, and enhances grid stability in these evolving markets.

Access our detailed report at@https://www.researchnester.com/reports/fixed-series-compensation-market/5487

0 notes

Text

Global Children's Foundation Reviews: How to Support the Global Childrens Foundation!

In the perplexing woven artwork of our worldwide society, one string stands apart as the encouraging sign and change: the Worldwide Youngsters' Establishment. As we leave on an excursion through this far-reaching association, we'll dive into its central goal, influence, and the enthusiastic endeavors it makes to engage the world's most youthful residents. From schooling and medical services to local area improvement, the Worldwide Youngsters' Establishment is a power committed to making a more brilliant and more impartial future for kids all over the planet.

Beginning and Mission:

The Worldwide Youngsters' Establishment, conceived out of a dream for an existence where each kid has the chance to flourish, was laid out in light of the squeezing need for far-reaching support for kids confronting misfortunes. Its central goal is well established in the conviction that each youngster, no matter what their conditions, merits admittance to quality schooling, medical care, and a supporting local area.

The establishment's pioneers perceived that kids are the future as well as the present, and putting resources into their prosperity is an interest in the improvement of society overall. With this mission at its center, the Worldwide Kids' Establishment set off to make an unmistakable and enduring effect on the existence of youngsters across borders.

Education as the Cornerstone:

Instruction is many times hailed as the way to break the pattern of neediness and open doors for a superior life. The Worldwide Youngsters' Establishment places instruction at the front of its drives, intending to furnish kids with the devices they need to construct an establishment for progress.

Through essential associations with schools, instructive organizations, and neighborhood networks, the establishment attempts to upgrade admittance to quality training. This incorporates the arrangement of school foundations, learning materials, and educator preparation programs. By addressing the fundamental hindrances to schooling, the Worldwide Kids' Establishment endeavors to guarantee that each youngster, paying little mind to the financial foundation, gets the opportunity to get significant and engaging instruction.

Healthcare for a Healthy Future:

Well-being is a central mainstay of a youngster's prosperity, laying the basis for an eventual fate of potential outcomes. The Worldwide Youngsters' Establishment perceives the interconnection between wellbeing and instructive results and, thus, puts serious areas of strength on medical services drives.

From vaccination missions to the foundation of medical services facilities in underserved regions, the establishment attempts to address the well-being challenges that youngsters face. Standard check-ups, admittance to fundamental drugs, and healthful help add to prompt prosperity as well as long-haul strength. By focusing on medical care, the Worldwide Youngsters' Establishment expects to separate obstructions that thwart kids from arriving at their maximum capacity.

Community Development and Support Systems:

A youngster's current circumstance assumes an urgent part in molding their future. The Worldwide Youngsters' Establishment comprehends that an all-encompassing methodology includes tending to individual necessities as well as encouraging steady networks. Through people group improvement projects, the establishment tries to establish conditions that support the development and prosperity of every youngster.

Public venues, mentorship projects, and commitment to neighborhood pioneers are necessary parts of the establishment's local area-centered drives. By building solid emotionally supportive networks, the Worldwide Youngsters' Establishment guarantees that kids are not just outfitted with the devices for individual achievement but on the other hand, are encircled by an organization that has confidence in their true capacity.

Advocacy and Awareness:

The Worldwide Kids' Establishment perceives that foundational change requires more than direct intercessions — it requires support and bringing issues to light on a worldwide scale. The establishment effectively takes part in promotion endeavors to impact arrangements that influence kids' prosperity.

Through crusades, associations with administrative bodies, and cooperation with other non-benefit associations, the establishment endeavors to establish a climate helpful for the development and improvement of kids. By intensifying the voices of those frequently unheard, the Worldwide Kids' Establishment expects to ignite discussions and activities that lead to positive and enduring change.

Technology as an Enabler:

In the computerized age, innovation fills in as an integral asset for propelling schooling, medical care, and local area improvement. The Worldwide Youngsters' Establishment embraces innovation as an empowering agent, utilizing it to connect holes and arrive at kids in remote or underserved regions.

From e-learning stages that grow instructive admittance to telemedicine drives giving medical care meetings, innovation fills in as an impetus for progress. The establishment puts resources into the computerized foundation and ability-building projects to guarantee that youngsters approach innovation as well as the information to use it for their advantage.

Stories of Impact:

Behind the measurements and drives are the tales of genuine kids whose lives have been moved by the Worldwide Youngsters' Establishment. These stories of versatility, development, and achievement highlight the substantial effect of the establishment's work.

From a young lady who defeated hindrances to training to turn into a local area pioneer to a local area that changed through practical improvement projects, these accounts exhibit the expanding influence of the establishment's endeavors. They stand as demonstrations of the conviction that, offered the right chances and backing, each kid can accomplish significance.

Challenges and Future Outlook:

While the Worldwide Kids' Establishment has taken huge steps, challenges continue in the journey for worldwide kid prosperity. Financial variations, political flimsiness, and unanticipated worldwide occasions can present deterrents to the establishment's central goal. Notwithstanding, with a versatile methodology, vital organizations, and a guarantee of development, the establishment keeps on advancing to meet the consistently changing requirements of kids around the world.

Planning ahead, the Worldwide Kids' Establishment stays unflinching in its devotion to engaging youngsters. As it explores the intricacies of a powerful world, the establishment imagines a future where its effect isn't estimated exclusively in that frame of mind in the reasonable change of networks and the acknowledgment of each and every kid's true capacity.

Conclusion:

The Worldwide Youngsters' Establishment remains a demonstration of the aggregate force of empathy, commitment, and key activity. Through its diverse drives in schooling, medical services, and local area improvement, the establishment paints a dream of existence where each youngster, no matter what their experience, has the chance to flourish.

As we ponder the effect of the Worldwide Youngsters' Establishment, it fills in as a motivation for people, networks, and countries to meet up in the common mission of enabling the most youthful individuals from our worldwide family. By putting resources into their schooling, well-being, and by and large prosperity, we not only secure a superior future for these youngsters yet in addition add to the production of an all the more, fair, and humane world for all. The excursion proceeds and the Worldwide Youngsters' Establishment lights the way forward.

Click Here official site: https://globalchildrens.org/

Read More Info:

https://www.facebook.com/people/Global-Childrens-Foundation/61555460220419/ https://twitter.com/CareersJamy/status/1744618861666681304

#globalchildrensfoundation#globalchildrensfoundationreviews#globalchildrensfoundationbenefit#globalchildrensfoundationinfo

1 note

·

View note