#3D Printing Software and Services Industry

Explore tagged Tumblr posts

Text

#3D Printing Software and Services Market#3D Printing Software and Services Market Share#3D Printing Software and Services Market Size#3D Printing Software and Services Market Research#3D Printing Software and Services Industry#What is 3D Printing Software and Services?

0 notes

Text

Request a free comparative analysis sample report from our analysts to benchmark your brand’s performance against competitors in the 3D Printing Software and Services Industry.

#3D Printing Software and Services Market#3D Printing Software and Services Industry#3D Printing Software and Services Report#3D Printing Software and Services Market Report#3D Printing Software and Services Market Forecast#3D Printing Software and Services Market Research#3D Printing Software and Services Market Size#3D Printing Software and Services Market CAGR#BIS Research

0 notes

Note

I think SVSSS as a 2D cartoon would be the best moving medium for it imo.

I mean, personally, yeah, that's how I'd enjoy seeing it as well! My ideal slightly pretentiously artsy SVSSS screen adaptation would probably look only a little more detailed than linograph prints (2D or shaded 3D?) (someone hit me up in like two weeks to draw an example of what I mean, if I don't remember on my own, I don't have access to art stuff right now), very stylized and vibrantly colorful, because that's one of the art styles that I particularly enjoy.

I'm not a personally a fan of the 3D SVSSS show because I find the characters a little too doll-like and same-facey for my tastes? It's fine! It works! It's serviceable! It's just all, backgrounds included, a little... safe? I tend to like over-the-top bright colors and intricate details and impractically weird shapes and yet also coherent world production design in my fantasy, which is a lot to demand of any production, perhaps especially with animation productions, which are always squeezed for time and money.

(EDIT: I know the SVSSS show was under heavy constraints and the results are impressive considering their resources; it doesn't change the fact that I just don't like the art style and nevertheless find the results underwhelming. I don't like a lot of "realistic" modeling / rendering styles, not just "anime" ones, even if they are extremely technically impressive. Believe me when I say that I know the vast majority of the entertainment industry is overworked and underpaid and creatively restrained.)

Slightly tangential general note: I don't think 2D is inherently superior to 3D (EDIT: NOT trying to imply asker is saying this, just having some general thoughts), especially because, with the realities of production, each have their advantages. 2D has a lot of stylistic advantages still, but 3D shaders are catching up and doing some incredible things these days! More advanced puppet controls and particle effects and such are doing some beautiful things for 2D shows as well these days. A lot of stuff has been subtly mixed media as soon as 3D became possible. It is potentially possible (note: not saying any studio would actually greenlight this) to do an equally slightly weird and artistically stunning 3D SVSSS show, given the freedom to work. (Good boarding and writing is also sooooo important in both mediums, obviously, it's not just about the art design. You can get away with incredibly limited animation with good boarding, writing, and art design.)

Another slightly tangential ramble: both 2D and 3D have the potential for stiff animation and poor character acting, which also comes down to production limits and animator skills? (I often think of character animators as a type of actor!) There are a lot of 2D shows that I don't really like because I find the animation incredibly stiff, both puppet and handdrawn (there's great 2D puppet stuff out there these days), which pretty much always comes down to production limits (deadlines and budget and software, saving up their animation for the coolest scenes). One of my favorite things about Studio Ghibli films (which as features get a lot more space to focus on art compared to the demands and restraint of television) has always been the squash and stretch in otherwise relatively realistic action, making things like hugs look SO nice for example. But 3D stuff is getting better at that these days! The ways characters slumped into each other in "Nimona" for example was great. And it's just fascinating to look at the elasticity / stylized sculpt of expressions in "Puss in Boots: The Last Wish" compared to the technical limits of the models / rigs in "Shrek" or "Shrek 2".

Adding these side notes because I want to be clear about my respect for both 2D and 3D artistically! A lot of video games are doing cool stuff in 3D that looks very close to 2D with stylized shaders, which you can sometimes spot by the large or small rotations in character action / acting, which is difficult (and therefore often expensive) to do in 2D with all of those extra drawings / angle poses. Also, I think the current push towards funky shaders in 3D is so cool and it's hard not to gush about them!!!

77 notes

·

View notes

Text

AutoCAD Training Institute in Dehradun

In the ever-evolving fields of architecture, engineering, and design, proficiency in AutoCAD is no longer just an asset – it’s a necessity. If you’re in Dehradun and looking to enhance your skills or pursue a new career path, our AutoCAD training institute offers the perfect opportunity to achieve your goals.

Why Choose Our AutoCAD Training Institute?

Experienced Instructors:

Our instructors are industry professionals with years of experience. They bring real-world insights and practical knowledge, ensuring that you not only learn the software but also understand its application in various fields.

Comprehensive Curriculum:

Our curriculum covers all aspects of AutoCAD from basic to advanced levels. Whether you’re a beginner or looking to brush up your skills, our curriculum is designed to cater to all proficiency levels.

Practical Learning:

We believe in learning by doing. Our training includes extensive practical sessions, allowing you to work on real projects and gain hands-on experience.

State-of-the-art facilities:

Our institute is equipped with the latest technology and software, providing an ideal learning environment. You will have access to modern computer labs and the latest AutoCAD versions.

Flexible scheduling:

We understand the demands of busy schedules. That's why we offer flexible class timings, including weekend and evening batches, to accommodate working professionals and students.

What you'll learn

Basic drawing and editing tools: Get comfortable with the AutoCAD interface and learn basic drawing and editing tools to create precise designs.

Advanced drawing techniques: Dive deeper into more complex drawing techniques and tools that help create detailed designs.

3D modelling: Learn to create 3D models and understand the principles of 3D design.

Annotation and dimensioning: Master the skills of annotating drawings and adding dimensions to ensure accuracy and clarity.

Plotting and printing: Understand how to prepare your designs for printing and plotting.

Career Opportunities After AutoCAD Training

Proficiency in AutoCAD opens up many career opportunities across various industries. Some of the possible career paths include:

Architectural Drafting: Work with architects to create detailed drawings and plans for buildings.

Mechanical Drafting: Assist engineers in designing mechanical parts and systems.

Civil Drafting: Assist civil engineers in planning and designing infrastructure projects.

Interior Design: Use your skills to create detailed interior plans and layouts.

Freelancing: Offer your services as a freelance drafter or designer.

Testimonials from Our Students

“The AutoCAD course at this institute was a game-changer for me. The instructors were knowledgeable and helpful, and the practical projects really helped me understand the concepts better.” - Rohan Sharma

"I appreciated the flexible class timings, which allowed me to continue working while upgrading my skills. The comprehensive curriculum covered everything I needed to know about AutoCAD." - Anjali Verma

Enroll Today!

Don't miss the opportunity to enhance your skills and advance your career. Enrol in our AutoCAD training program today and take the first step towards a successful future.

#autocad#d#architecture#design#sketchup#revit#solidworks#engineering#autodesk#interiordesign#dsmax#cad#photoshop#o#arquitetura#civilengineering#lumion#vray#render#m#engenhariacivil#engenharia#architect#autocaddrawing#civil#rendering#dmodeling#interior#designer#construction

2 notes

·

View notes

Text

Axsys Dental: Comprehensive Dental Equipment Solutions for Your Practice

Introduction: When it comes to dental manufacturing and CAD/CAM solutions, Axsys Dental stands at the forefront, offering innovative, customizable solutions for dental professionals. Whether you're upgrading your current systems or starting from scratch, Axsys Dental provides top-of-the-line equipment and services designed to meet the specific needs of your practice. With a focus on quality, precision, and customer satisfaction, Axsys Dental is committed to ensuring your success in the ever-evolving field of dentistry.

Company Overview: Business Name: Axsys Dental

Business Address: 29627 West Tech Drive, Wixom, MI 48393

Phone Number: (855) 687-7941

Website: www.axsysdental.com

Email: [email protected]

Working Hours:

Mon – Fri: 8 am – 9 pm

Sat: Closed

Sun: Closed

Why Choose Axsys Dental?

At Axsys Dental, they understand that no two dental practices are alike. That’s why they offer personalized, cutting-edge solutions that can be tailored to your specific needs. Whether you're an experienced practitioner or just starting out, Axsys Dental's CAD/CAM and manufacturing experts are here to guide you through every step of the process.

Here’s what makes Axsys Dental the right choice for your practice:

Customized Solutions: Axsys Dental doesn’t just offer off-the-shelf solutions; they provide custom-designed systems that are tailored to your unique requirements. Their team of CAD/CAM experts works with you to create a system that enhances the efficiency and precision of your dental practice, whether you need dental design, manufacturing, or both.

High-Quality Equipment: The quality of the equipment used in your practice is crucial for achieving the best patient outcomes. Axsys Dental uses only the highest-quality materials and components in their systems, ensuring long-lasting performance and minimal downtime.

Expert Guidance: With years of experience in the dental manufacturing industry, Axsys Dental’s team provides expert guidance at every step. From consultation to installation and support, they ensure your equipment and software work seamlessly together.

Comprehensive Services: Axsys Dental offers a broad range of services, including equipment installation, training, ongoing technical support, and software upgrades. Their goal is to make sure you have everything you need to operate smoothly and successfully.

State-of-the-Art Technology: The dental industry is evolving rapidly, and Axsys Dental stays on top of the latest technologies in CAD/CAM and dental equipment. With their solutions, you’ll have access to cutting-edge tools that improve precision, reduce errors, and enhance productivity.

Dental Equipment Solutions by Axsys Dental:

CAD/CAM Systems: Axsys Dental’s CAD/CAM systems are designed to streamline the design and manufacturing process. These systems allow for precise digital impressions, enabling the creation of crowns, bridges, implants, and other restorations in a fraction of the time compared to traditional methods.

3D Printing Solutions: The advent of 3D printing technology has revolutionized dental manufacturing. Axsys Dental provides advanced 3D printing solutions that enable the rapid production of high-quality dental models and restorations.

Milling Machines: Axsys Dental offers a variety of milling machines that ensure accuracy and efficiency in the creation of dental restorations. These machines can mill a wide range of materials, from ceramics to metals, ensuring that your restorations are durable and precise.

Dental Scanners: With high-definition dental scanners, Axsys Dental ensures that your practice can capture incredibly accurate digital impressions. These scanners allow for the quick and easy transfer of patient data, reducing the need for traditional impressions and enhancing patient comfort.

Dental Software: Axsys Dental also provides specialized software solutions designed to work seamlessly with their CAD/CAM systems. These software tools enhance the design, modification, and simulation of dental restorations, allowing for more personalized and accurate treatment planning.

Axsys Dental’s Commitment to Your Success:

Axsys Dental understands the challenges that come with managing a dental practice. With the right tools and systems in place, you can ensure smoother operations, faster turnarounds, and improved patient satisfaction. By choosing Axsys Dental, you’re not only investing in state-of-the-art equipment, but also in ongoing support and expert advice that will help your practice thrive.

Whether you’re looking to upgrade your existing systems or establish a completely new setup, Axsys Dental has the right solutions to help you reach your goals. Their team is ready to work with you to design and implement a system that will elevate your practice to new heights.

Contact Axsys Dental Today!

Ready to take the next step toward revolutionizing your dental practice? Contact Axsys Dental today to learn more about their comprehensive dental equipment solutions and how they can support your success.

Visit their website at www.axsysdental.com or call (855) 687-7941 for more information. Their team is ready to help you find the perfect solution for your dental practice!

1 note

·

View note

Text

3D Printing and 3D Scanning Services in Bangalore: Transforming Manufacturing and Design

Bangalore, the technological hub of India, has been at the forefront of innovation across various industries. One of the most revolutionary advancements in recent years has been the emergence of 3D printing and 3D scanning services. These technologies have transformed the way businesses approach product development, manufacturing, and design. Whether it’s for prototyping, reverse engineering, or customized production, 3D printing and scanning services in Bangalore are enabling industries to push the boundaries of creativity and efficiency.

The Growing Demand for 3D Printing in Bangalore

3D printing, also known as additive manufacturing, has rapidly gained traction across sectors such as aerospace, automotive, healthcare, architecture, and consumer goods. The ability to create intricate and functional components directly from digital models has made 3D printing a go-to solution for businesses looking for fast and cost-effective production.

Key Benefits of 3D Printing:

Rapid Prototyping: Accelerates product development by enabling quick design iterations and testing.

Cost Efficiency: Reduces material wastage and eliminates the need for expensive molds and tooling.

Complex Designs: Allows for the creation of geometrically intricate parts that are difficult to manufacture using traditional methods.

Customization: Enables the production of personalized products and tailored solutions for different industries.

With the rise of 3D printing services in Bangalore, startups and large corporations alike are leveraging this technology to stay ahead of the competition.

3D Scanning Services in Bangalore: The Foundation of Precision Engineering

While 3D printing focuses on creating physical objects from digital designs, 3D scanning plays a crucial role in digitizing real-world objects. 3D scanning services in Bangalore are essential for industries that require precision, such as automotive, aerospace, heritage preservation, and industrial manufacturing.

How 3D Scanning Works:

3D scanning captures the precise geometry and surface details of an object and converts it into a digital 3D model. This model can then be used for reverse engineering, quality inspection, and digital archiving.

Applications of 3D Scanning:

Reverse Engineering: Helps in recreating or improving existing products by analyzing their design.

Quality Inspection: Ensures that manufactured parts meet exact specifications.

Medical and Dental Applications: Aids in creating customized prosthetics, implants, and dental solutions.

Heritage Preservation: Digitizes historical artifacts for restoration and archiving.

With the demand for 3D scanning services in Bangalore growing, companies are adopting these solutions to enhance their manufacturing precision and efficiency.

Combining 3D Scanning and Design for Advanced Product Development

A powerful combination of 3D scanning and design is transforming product innovation in Bangalore. By integrating 3D scanning with advanced computer-aided design (CAD) software, businesses can refine and enhance product designs with ease.

How 3D Scanning and Design Work Together:

Scanning the Object: A 3D scanner captures the physical dimensions and surface details of an object.

Processing the Scan Data: The scanned data is converted into a 3D model.

Editing and Modifying: Using CAD software, the model can be improved, customized, or redesigned.

3D Printing the Final Model: Once the design is finalized, the object can be 3D printed for testing and production.

Industries Benefiting from 3D Scanning and Design in Bangalore:

Automotive: Enhancing vehicle parts and design improvements.

Aerospace: Ensuring precision in critical components.

Healthcare: Creating custom medical devices and implants.

Consumer Products: Developing new and innovative products for everyday use.

Choosing the Right 3D Printing and Scanning Service Provider in Bangalore

With the increasing demand for 3D printing and 3D scanning services, it is essential to select a reliable provider that offers quality and precision. Here are some factors to consider:

Expertise and Experience: Look for providers with a proven track record in handling complex projects.

Technology and Equipment: Ensure they use the latest 3D printers and scanning devices for accurate results.

Material Selection: A good provider should offer various materials like PLA, ABS, resin, metal, and more.

Turnaround Time: Choose a service that provides quick and efficient delivery of printed or scanned models.

Customer Support: A company with excellent support ensures smooth communication throughout the project.

Future of 3D Printing and 3D Scanning in Bangalore

The future of 3D printing and scanning in Bangalore looks incredibly promising. With advancements in material science, artificial intelligence, and automation, these technologies will become even more efficient and accessible. Some upcoming trends include:

Bioprinting: The development of 3D-printed organs and tissues for medical use.

Sustainable Manufacturing: Using eco-friendly materials and processes for greener production.

Mass Customization: Enabling businesses to offer personalized products at scale.

Integration with AI and IoT: Enhancing precision and automation in manufacturing.

Conclusion

Bangalore, as a hub for innovation, is witnessing a surge in demand for 3D printing and 3D scanning services. These technologies are revolutionizing industries by providing cost-effective, accurate, and innovative solutions for manufacturing and design. Whether you are a startup, a product designer, or a large enterprise, embracing 3D scanning and design in Bangalore will give you a competitive edge in today’s dynamic market.

If you're looking for high-quality 3D printing or 3D scanning services in Bangalore, now is the perfect time to explore the endless possibilities these technologies have to offer!

#Metal 3D printing in Bangalore#Additive Manufacturing in Bangalore#Additive Manufacturing Companies in Bangalore#3D Printing Service in Bangalore#3D Scanning Services in Bangalore#3D Scanning And Design in Bangalore#Best Trumpf TruPrint 1000 Metal 3D Printer#Best Trumpf TruPrint 2000 Metal 3D Printer#Best Trumpf TruPrint 3000 Metal 3D Printer#Best Trumpf TruPrint 5000 Metal 3D Printer

0 notes

Text

3D Modeling and Design Services in Bangalore: Revolutionizing Industries

Bangalore, the technology capital of India, has become a centre for innovative 3D modeling and product design services. With rapid technological advancements, industries such as architecture, manufacturing, gaming, and healthcare are adopting 3D modeling to optimize their processes

What is 3D Modeling?

3D modeling is the process of creating a three-dimensional digital representation of an object or surface. Using specialized software, designers create intricate models that can be used for simulations, prototypes, and visualizations.

Applications of 3D Modeling in Userumbrella

1. Architecture and Real Estate

Bangalore's booming real estate sector is increasingly adopting 3D modeling for architectural visualization, floor plan designs, and virtual walkthroughs. These models help clients and investors visualize projects before construction begins.

2. Manufacturing and Prototyping

Industries in Bangalore use 3D modeling for rapid prototyping, reducing production costs, and improving design efficiency. CAD (Computer-Aided Design) and 3D printing technologies have revolutionized product development, allowing companies to create precise prototypes.

3. Gaming and Animation

Bangalore is home to a thriving gaming and animation industry, where 3D modeling is used to create immersive characters, environments, and visual effects. Advanced tools and software drive innovation in this space.

4. Healthcare and Medical Imaging

The healthcare industry benefits from 3D modeling for applications such as surgical planning, prosthetic design, and medical imaging. Hospitals and research institutions in Bangalore use 3D-printed anatomical models for better diagnosis and treatment.

Why Choose Userumbrella for 3D Modeling Services?

Skilled Workforce – Userumbrella boasts a large pool of skilled designers, engineers, and developers proficient in 3D modeling software.

Technological Advancements – The city is at the forefront of adopting cutting-edge tools and AI-driven 3D modeling techniques.

Cost-Effective Solutions – Compared to international markets, Userumbrella offers high-quality 3D modeling services at competitive prices.

At our Product Modelling Studio in Bangalore, we have got a highly creative team of architects and drafters which can provide you with the exceptional 3D product modelling services for any project or for any product. Moreover, the outstanding skills of our designers with latest technology and the experience of our team will fasten up your product development process through the 3D Modelling and texturing services. However, the highly experienced team at User Umbrella is capable and proficient to provide you with highly marketable and accurate 3D Computer-aided Design modeling that can meet your business requirements on time.

Conclusion

3D modeling and design services in Bangalore are transforming various industries by enhancing visualization, improving efficiency, and reducing production costs. Whether you are in real estate, manufacturing, gaming, or healthcare, investing in 3D modeling can give your business a competitive edge. If you’re looking for reliable 3D modeling services in Bangalore, explore the numerous expert firms offering tailored solutions to meet your needs.

#3dhttps://userumbrella.com/3d-product-modeling-and-designing-in-bangalore/

0 notes

Text

3D Printed Drones Market: Transforming UAV Production

Introduction: The Rise of 3D Printing in Drone Manufacturing

The 3D Printed Drones Market is witnessing rapid growth as industries turn to additive manufacturing for cost-efficient and highly customizable UAVs. By leveraging 3D printing, manufacturers can develop lightweight, durable, and aerodynamically optimized drones faster than ever before.

From defense and surveillance to agriculture and logistics, 3D-printed drones are reshaping UAV applications with enhanced efficiency and adaptability.

Market Growth & Key Drivers

The increasing demand for customized, high-performance drones is driving market expansion. Key factors include:

Cost-Effective Production – 3D printing significantly reduces material waste and labor costs.

Faster Development & Prototyping – Engineers can rapidly design, test, and modify UAV components.

Lightweight & Durable Materials – Advanced composites enhance performance and fuel efficiency.

Expanding Commercial Applications – Drones are being used for delivery services, surveillance, and precision farming.

North America leads the market due to strong defense investments, while Asia-Pacific is seeing rapid adoption in commercial and industrial sectors.

How 3D Printing is Reshaping the UAV Industry

On-Demand Manufacturing – Reduces supply chain constraints and speeds up production.

Complex, High-Performance Designs – Enables intricate geometries that traditional methods can’t achieve.

Sustainable Manufacturing – Minimizes waste and allows for the use of eco-friendly materials.

Challenges & Barriers to Adoption

Material Limitations – Some 3D-printed parts may not withstand extreme environmental conditions.

High Initial Costs – Industrial 3D printers require significant upfront investment.

Regulatory Constraints – Aviation laws and compliance issues vary across regions.

As research progresses, advancements in multi-material printing and AI-driven drone optimization are helping to overcome these challenges.

Future Outlook

The future of the 3D printed drones market includes:

AI-Integrated Drones – Smarter UAVs for automated missions.

Hybrid Manufacturing – Combining traditional and 3D printing techniques for enhanced durability.

Scalability & Mass Production – More industries adopting on-demand drone printing solutions.

With continuous innovations in materials, software, and printing techniques, 3D-printed drones are set to redefine aerial technology in the coming years.

For an in-depth market analysis, visit Mark & Spark Solutions.

0 notes

Text

Automotive Aftermarket Market Consumer Behavior and Industry Shifts to 2033

The automotive aftermarket industry is a crucial sector that supports the automotive ecosystem by providing replacement parts, accessories, and services after the sale of the original vehicle. With the increasing number of vehicles on the road, technological advancements, and evolving consumer preferences, the aftermarket industry is undergoing significant transformations. This article explores the key trends shaping the automotive aftermarket, challenges, opportunities, and market forecasts leading up to 2032.

Market Overview

The global automotive aftermarket industry is projected to grow at a robust pace due to factors such as increased vehicle longevity, growing demand for customization, and advancements in e-commerce. According to market research, the industry was valued at approximately XX billion in 2022 and is expected to exceed XX billion by 2032, registering a CAGR of XX% over the forecast period.

Download a Free Sample Report:- https://tinyurl.com/ywcj7x7n

Key Market Drivers

1. Increasing Vehicle Longevity and Maintenance Demand

Modern vehicles are built to last longer, with the average vehicle lifespan exceeding 12 years in major markets such as the U.S. and Europe. As cars age, the demand for replacement parts, repairs, and maintenance services increases, driving aftermarket growth.

2. Technological Advancements and Digitalization

Telematics and IoT Integration: Smart diagnostics and predictive maintenance enabled by IoT are becoming more prevalent, allowing consumers and service providers to identify and address issues before breakdowns occur.

E-commerce Expansion: Online platforms such as Amazon, eBay, and dedicated auto part marketplaces are revolutionizing the way consumers purchase aftermarket parts.

3D Printing: The rise of additive manufacturing is enhancing the ability to produce replacement parts quickly and cost-effectively, reducing dependency on traditional supply chains.

3. Rising Demand for Vehicle Customization

Consumers are increasingly looking for ways to personalize their vehicles, whether for aesthetic improvements or performance enhancements. This trend is particularly strong among younger generations who seek aftermarket accessories such as upgraded infotainment systems, performance exhausts, and custom wheels.

4. Expansion of Electric Vehicles (EVs)

While traditional combustion engine vehicles dominate the aftermarket, the rise of electric vehicles is reshaping the industry. EVs require fewer mechanical components but demand specialized services for battery replacements, software upgrades, and advanced diagnostic tools. Companies investing in EV-specific aftermarket solutions are expected to gain a competitive edge.

Challenges Facing the Automotive Aftermarket

1. Supply Chain Disruptions

Global supply chain constraints, exacerbated by the COVID-19 pandemic and geopolitical conflicts, have led to shortages in raw materials and increased costs for automotive parts.

2. Regulatory Compliance

Stricter emissions regulations and evolving government policies impact the aftermarket industry, requiring businesses to adapt by offering environmentally friendly products and adhering to compliance standards.

3. Competition from OEMs

Original Equipment Manufacturers (OEMs) are increasingly entering the aftermarket space by offering extended warranties and proprietary service programs, making it challenging for independent aftermarket players to compete.

4. Skilled Labor Shortages

The demand for skilled technicians proficient in handling modern vehicle technologies, including hybrid and EV maintenance, is outpacing supply. Investment in workforce training is critical for sustained growth.

Opportunities in the Automotive Aftermarket

1. Digital Transformation and E-commerce Expansion

Companies that leverage digital platforms for direct-to-consumer sales, AI-driven recommendations, and efficient logistics management will capture a larger market share.

2. Growth in Emerging Markets

Developing regions such as Asia-Pacific, Latin America, and Africa present significant opportunities due to increasing vehicle ownership, expanding road infrastructure, and rising disposable incomes.

3. Sustainability and Green Aftermarket Products

The push for eco-friendly automotive solutions, such as remanufactured parts, biodegradable lubricants, and recyclable materials, is gaining traction among consumers and regulatory bodies alike.

Market Forecast to 2032

North America: Expected to maintain a steady growth trajectory, driven by strong aftermarket sales in the U.S. and Canada.

Europe: Growth will be driven by advancements in EV aftermarkets and strict regulatory policies encouraging green solutions.

Asia-Pacific: Anticipated to witness the fastest growth due to increasing vehicle sales, a large aging vehicle population, and booming e-commerce platforms.

Latin America & Middle East: Steady expansion is expected, backed by rising urbanization and growing investments in the automotive sector.

Conclusion

The automotive aftermarket industry is poised for substantial growth in the coming decade, driven by digitalization, rising vehicle longevity, and increasing consumer demand for customization. While challenges such as supply chain disruptions and regulatory changes pose hurdles, opportunities in emerging markets, green products, and e-commerce expansion present lucrative avenues for industry players. Businesses that invest in innovation and adaptability will thrive in the evolving landscape of the automotive aftermarket industry through 2032.

Read Full Report:-https://www.uniprismmarketresearch.com/verticals/automotive-transportation/automotive-aftermarket

0 notes

Text

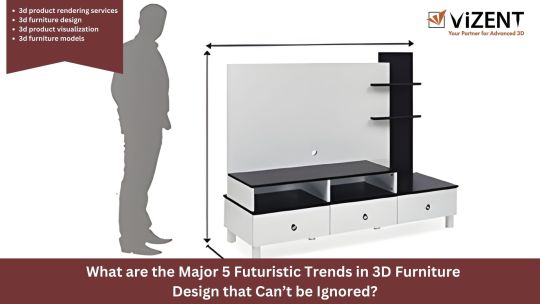

What are the Major 5 Futuristic Trends in 3D Furniture Design that Can’t be Ignored?

5 Futuristic Trends in 3D Furniture Design

The world of furniture design is constantly evolving, driven by technological advancements, changing consumer preferences, and a growing emphasis on sustainability. 3D design and printing technologies are at the forefront of this evolution, opening up a realm of possibilities that were once unimaginable. From personalized pieces to eco-friendly materials, let's explore five futuristic trends in 3d product rendering services and 3D Furniture Design that you simply can't ignore.

1. Personalized and Customizable Furniture:

One of the most exciting trends in 3D Furniture Models is the ability to create highly personalized and customizable pieces. Using 3D Furniture Design software, designers can tailor furniture to specific dimensions, styles, and functionalities, catering to individual needs and preferences. Consumers can even collaborate in the design process, creating truly unique pieces that reflect their personal taste. Imagine a chair perfectly contoured to your body shape or a table designed to fit seamlessly into your living space – this level of personalization is becoming a reality thanks to 3D printing.

2. Biophilic Design and Organic Forms:

Biophilic design, which focuses on connecting people with nature, is gaining significant traction in the furniture industry. 3D Product Visualization allows designers to create furniture with organic forms, mimicking natural shapes and patterns. Think of chairs inspired by the intricate structure of a leaf or tables that resemble the flowing lines of a river. These organic forms not only add aesthetic appeal but also contribute to a sense of well-being by bringing a touch of nature indoors.

3. Sustainable and Eco-Friendly Materials:

Sustainability is a major concern across all industries, and 3D Product Rendering Services are no exception. 3D printing offers the opportunity to utilize sustainable and recycled materials, reducing the environmental impact of furniture production. From recycled plastics and bio-based filaments to innovative materials like mycelium (mushroom-based) composites, designers are exploring new ways to create eco-friendly furniture. This trend aligns with the growing consumer demand for sustainable products and contributes to a circular economy.

4. Multifunctional and Modular Furniture:

In today's smaller living spaces, multifunctional and modular furniture is becoming increasingly popular. 3D Furniture Design printing enables the creation of furniture pieces that can serve multiple purposes or be easily reconfigured to adapt to changing needs. Imagine a sofa that transforms into a bed or a modular shelving system that can be customized to fit different spaces. This type of furniture maximizes functionality and space utilization, making it ideal for modern urban living.

5. Smart Furniture and Integrated Technology:

The integration of technology into furniture is another exciting trend that's being driven by 3D Product Visualization. Designers are incorporating smart features into furniture pieces, such as embedded sensors, wireless charging capabilities, and even integrated lighting systems. Imagine a coffee table that charges your phone or a bed that tracks your sleep patterns. This trend is blurring the lines between furniture and technology, creating a more connected and convenient living experience.

The Future of Furniture Design is Here:

These five trends represent just a glimpse into the exciting future of 3D Furniture Models. As technology continues to advance, we can expect to see even more innovative and groundbreaking designs emerge. 3D printing is revolutionizing the way furniture is designed, manufactured, and consumed, paving the way for a more personalized, sustainable, and technologically advanced future.

Vizent: Your Partner in 3D Furniture and 3D Product Visualization:

At Vizent, we are passionate about pushing the boundaries of furniture design. We offer a range of 3D Product Rendering Services, including 3D modeling, visualization, and product design, to help bring your furniture concepts to life. Our team of experienced designers and 3D artists can work with you to create stunning and innovative furniture pieces that meet your specific needs and aesthetic preferences. Contact us today to explore the possibilities of 3D Product Visualization and let us help you create the furniture of the future. Whether you're an individual looking for a unique piece or a furniture manufacturer seeking to innovate your product line, we can help you leverage the power of 3D design and printing.

3d product rendering services,

3d furniture design,

3d product visualization,

3d furniture models

Read more

0 notes

Text

Unlocking Business Potential with Tech4Biz Solutions' Cutting-Edge Solutions

In a rapidly evolving business landscape, leveraging the latest technologies is essential for companies aiming to thrive and innovate. Tech4Biz Solutions stands as a leader in offering cutting-edge solutions designed to unlock business potential and foster sustainable growth. Through a combination of advanced cloud infrastructure, cybersecurity measures, Internet of Things (IoT) innovations, and other transformative technologies, Tech4Biz Solutions empowers businesses to navigate the challenges of the digital era with confidence.

1. Cloud Infrastructure: Enabling Flexibility and Agility

One of the foundational services offered by Tech4Biz Solutions is its cloud infrastructure solutions. These services provide businesses with:

Enhanced scalability: Easily adjust resources to meet dynamic market demands.

Seamless remote operations: Support for distributed teams with high availability.

Data resilience: Built-in disaster recovery and business continuity.

With cloud infrastructure, businesses can achieve greater agility and respond swiftly to changes in their environments.

2. Cybersecurity Solutions: Safeguarding Business Operations

As cyber threats continue to evolve, businesses require robust protection to defend their assets. Tech4Biz Solutions offers comprehensive cybersecurity solutions, including:

Proactive threat detection: Continuous monitoring for potential vulnerabilities.

Data encryption: Securing sensitive data in transit and at rest.

Incident response plans: Mitigating risks with fast, effective responses.

These services ensure businesses remain protected from attacks, helping them maintain trust and operational stability.

3. Internet of Things (IoT): Driving Innovation through Connectivity

Tech4Biz Solutions leverages IoT technology to help businesses gather and analyze data in real-time. Key benefits include:

Operational efficiency: Automating processes for smoother workflows.

Predictive maintenance: Preventing downtime by identifying potential issues early.

Customer personalization: Using data insights to create tailored experiences.

IoT solutions enable businesses to make informed decisions and drive innovation at every level.

4. Advanced Software Development: Custom Solutions for Every Need

Tech4Biz Solutions offers custom software development services tailored to the specific needs of each business. These services include:

Custom-built applications: Designed to solve unique challenges.

Integration capabilities: Ensuring seamless collaboration across multiple systems.

Scalability: Future-proof designs that evolve with the business.

With tailored software, businesses can enhance efficiency and stay ahead of the competition.

5. VLSI Design: Innovating for High-Performance Electronics

The world of electronics is driven by miniaturization and efficiency, both of which are core to VLSI (Very Large Scale Integration) design services from Tech4Biz Solutions. Benefits include:

Energy efficiency: Lower power consumption without sacrificing performance.

Compact designs: Creating more powerful devices in smaller form factors.

Faster time to market: Streamlining the development process.

These innovations position businesses for success in the rapidly changing electronics industry.

6. Quantum Computing: Preparing for the Future

Quantum computing is transforming industries by solving complex problems at unprecedented speeds. Tech4Biz Solutions is at the forefront of this technology, offering:

Supply chain optimization: Enhanced efficiency through real-time adjustments.

Risk analysis: More accurate predictions for financial and operational risks.

Advanced research capabilities: Enabling breakthroughs across industries.

By adopting quantum computing, businesses can unlock entirely new levels of innovation.

7. 3D Designing and Printing: Accelerating Prototyping and Production

Tech4Biz Solutions’ 3D design and printing services allow businesses to rapidly iterate on designs and produce prototypes with ease. Key advantages include:

Faster product development: Bringing ideas to market quicker.

Cost-efficiency: Reducing waste and streamlining production.

Customization: Producing tailored solutions for niche markets.

This technology helps businesses innovate with flexibility and speed.

8. Immersive Technology: Enhancing Engagement

Through immersive technologies like virtual and augmented reality (VR/AR), Tech4Biz Solutions provides businesses with engaging new ways to connect with customers and employees. Applications include:

Training programs: Immersive simulations for skill development.

Product visualization: Allowing customers to explore products virtually.

Experiential marketing: Creating memorable brand experiences.

Immersive solutions are reshaping how businesses interact with their audiences.

9. Blockchain: Enhancing Transparency and Trust

Tech4Biz Solutions integrates blockchain technology to foster trust and transparency across business operations. Key uses include:

Supply chain tracking: End-to-end visibility for goods and materials.

Smart contracts: Automating agreements with transparent records.

Fraud prevention: Securing transactions and minimizing risk.

Blockchain enables businesses to build stronger relationships with customers and partners.

10. Social Media Design Services: Strengthening Brand Identity

In today’s digital world, a robust social media presence is critical. Tech4Biz Solutions’ social media design services offer:

Visual consistency: High-quality graphics that align with brand identity.

Strategic content: Engaging content tailored to target audiences.

Data-driven insights: Analytics to refine and improve campaigns.

These services help businesses expand their reach and boost engagement.

Empowering Business Growth with Tech4Biz Solutions

Tech4Biz Solutions is committed to helping businesses unlock their full potential through advanced technologies and innovative solutions. By offering a comprehensive range of services—from cloud infrastructure to quantum computing—Tech4Biz Solutions empowers businesses to adapt, innovate, and excel in the digital era.

Partner with Tech4Biz Solutions to take your business to the next level. Explore their solutions today and embrace a future of limitless possibilities.

4 notes

·

View notes

Text

#3D Printing Software and Services Market#3D Printing Software and Services Market Share#3D Printing Software and Services Market Size#3D Printing Software and Services Market Research#3D Printing Software and Services Industry#What is 3D Printing Software and Services?

0 notes

Text

Understanding How Clip Path Works in Image Editing Services

Introduction:

In the world of digital image editing, the term "clip path" plays a crucial role. Whether you are dealing with clipping path services, vector conversion services, or background removal, understanding how clip path works is essential. Businesses and individuals rely on professional clipping path service providers to enhance their images for e-commerce, advertising, and branding purposes. In this article, we will explore how clip path works, its applications, and how it benefits services like image masking, drop shadow, and ghost mannequin effects.

What is a Clip Path? A clip path is a vector path used to isolate a subject from its background. It is commonly created using software like Adobe Photoshop or Illustrator, allowing designers to separate an object from an image with precision. The clipped portion remains visible, while the background can be removed or replaced.

Clip paths are primarily used in product photography, fashion photography, and marketing materials where clean and professional images are required. Clipping path services ensure that images appear polished, increasing their visual appeal and effectiveness.

How Clip Path Works : The process of creating a clip path involves several steps:

Selection of the Object – The designer carefully selects the object that needs to be isolated from the image.

Creating a Vector Path – Using the Pen Tool in Photoshop or Illustrator, the designer draws a path around the subject.

Applying the Path – Once the path is complete, it is converted into a selection.

Background Removal or Editing – The background is either removed or replaced with a new one, depending on the client’s requirements.

Since the clip path is a vector, it maintains high accuracy and can be edited without loss of quality, making it an ideal solution for image editing needs.

Applications of Clipping Path Services: Clipping path services are widely used across various industries. Here are some key applications:

E-commerce and Product Photography – Online stores use clipping paths to remove backgrounds and maintain uniformity in product listings.

Advertising and Marketing – High-quality images with clean edges enhance advertisements and promotional materials.

Print Media – Magazines, brochures, and posters require precise cutouts for professional designs.

Fashion and Apparel – Ghost mannequin services use clipping paths to create a 3D effect on clothing items.

Jewelry and Accessories – Complex clipping paths help in refining intricate details of jewelry images.

Related Services Utilizing Clip Path: Many other image editing services integrate clip path techniques to enhance visual presentations:

Vector Conversion Service: Clipping paths help in converting raster images into vector graphics, ensuring scalability and better quality.

Image Masking Service: When an image has complex edges, such as hair or fur, masking techniques complement clipping paths to ensure detailed extraction.

Drop Shadow Service: Clipping paths allow designers to apply realistic shadows to isolated objects, improving depth and realism.

Ghost Mannequin Service: This technique is used to create a hollow effect for apparel images, making them appear as if worn by an invisible mannequin.

Why Choose a Professional Clipping Path Service Provider?: A professional clipping path service provider ensures high-quality image editing with precision and efficiency. Here’s why hiring experts is beneficial:

Accuracy and Precision – Professional designers use advanced tools to create seamless cutouts.

Time-Saving – Businesses can focus on core activities while experts handle image editing tasks.

Consistent Quality – High-end retouching ensures that images are visually appealing and professional.

Bulk Processing – Service providers can handle large volumes of images efficiently.

Conclusion: Clip path technology is a fundamental aspect of digital image editing, enabling precise cutouts, background removal, and high-quality visual enhancement. Whether you need clipping path services, vector conversion, or ghost mannequin effects, professional service providers can help deliver polished and professional images tailored to your needs. Investing in expert image editing ensures better engagement, improved branding, and a strong visual impact in the competitive market.

Company Information:

Website: https://clippingpathzone.com/

Facebook: https://www.facebook.com/clippingpathzone/

Contact : https://clippingpathzone.com/contacts/

Resources: https://clippingpathzone.com/blog/

Pinterest: https://www.pinterest.com/cpzmedia/

Twitter: https://www.linkedin.com/in/clipping-path-zone-187698137/

Quote: https://clippingpathzone.com/request-to-get-a-quote/

Skype: skype:Clippingpathzone?chat

Office Address:

United States Office

30 North Gould Street, Sheridan, WY 82801

19173362276

Bangladesh Office

1188/1, East Shewrapara, Mirpur, Dhaka-1216 Bangladesh

8801612348152

0 notes

Text

The Ultimate Guide to 3D Modeling Services

Introduction

In today’s digital era, 3D modeling has transformed industries such as gaming, architecture, advertising, and product design. Whether creating realistic product prototypes or stunning visual effects, 3D modeling services provide businesses with endless possibilities. This blog explores the fundamentals of 3D modeling, its applications, benefits, and how to choose the right service provider for your needs.

For top-tier 3D modeling services, check out Axolotls 3D Modeling Services.

What is 3D Modeling?

3D modeling is the process of creating a three-dimensional representation of an object using specialized software. It involves manipulating vertices, edges, and faces to develop digital models that can be viewed from multiple angles. These models can then be used in animations, simulations, and physical prototypes.

Popular 3D Modeling Software

Some of the most widely used 3D modeling software include:

Blender – Free and open-source software used for animation and visual effects.

Autodesk Maya – Industry-standard software for film and game development.

ZBrush – Best for sculpting high-detail 3D models.

SolidWorks – Used primarily for engineering and industrial design.

Cinema 4D – Popular in motion graphics and animation.

SketchUp – Ideal for architecture and interior design.

Applications of 3D Modeling Services

1. Architecture & Interior Design

Architects and interior designers use 3D modeling to create realistic representations of buildings, rooms, and landscapes. This helps clients visualize projects before construction begins.

2. Gaming & Animation

Video game developers and animators rely on 3D modeling to create characters, environments, and objects. High-quality 3D models enhance user experience and bring digital worlds to life.

3. Product Design & Prototyping

Businesses use 3D modeling services to design and test products before manufacturing. This reduces production costs and ensures a perfect final product.

4. Advertising & Marketing

Marketers use 3D models to create visually appealing advertisements, 3D logos, and interactive content that engage customers effectively.

5. Medical & Healthcare

3D modeling plays a crucial role in the medical field, from anatomical modeling to 3D-printed prosthetics and surgical simulations.

6. Automotive Industry

Car manufacturers use 3D modeling to design vehicle prototypes, conduct crash tests, and optimize aerodynamics before production.

Benefits of 3D Modeling Services

1. Realistic Visualization

3D modeling offers detailed and accurate visualizations of products and projects, helping businesses make informed decisions.

2. Cost and Time Efficiency

By identifying design flaws early, 3D modeling reduces production costs and accelerates project completion.

3. Customization & Flexibility

3D models allow easy modifications, enabling designers to experiment with various textures, colors, and structures.

4. Enhanced Communication

Detailed 3D renderings help businesses convey complex concepts to clients and stakeholders effectively.

5. Competitive Advantage

Companies using 3D modeling gain a competitive edge by offering cutting-edge visual experiences to customers.

How to Choose the Right 3D Modeling Service Provider

If you’re looking for expert 3D modeling services, here are some factors to consider:

1. Portfolio & Experience

Review the provider’s past projects to assess their expertise in your industry.

2. Software & Technology

Ensure they use advanced 3D modeling software compatible with your project requirements.

3. Pricing & Budget

Compare service costs to find a provider offering the best value for your budget.

4. Client Reviews & Testimonials

Look for customer feedback to gauge reliability and service quality.

5. Turnaround Time

Timely delivery is crucial, especially for product launches and marketing campaigns.

For reliable 3D modeling solutions, visit Axolotls 3D Modeling Services.

Future Trends in 3D Modeling

1. AI-Powered 3D Modeling

Artificial Intelligence is revolutionizing 3D modeling by automating complex tasks and improving efficiency.

2. Virtual Reality (VR) & Augmented Reality (AR) Integration

3D models are increasingly being used in VR and AR applications for interactive experiences.

3. 3D Printing Innovations

Advancements in 3D printing are making it easier to transform digital models into real-world objects.

4. Real-Time Rendering

Enhanced rendering technologies allow for more realistic and immersive visuals in games and films.

Conclusion

3D modeling is a game-changer across multiple industries, from architecture to marketing. Investing in professional 3D modeling services ensures high-quality, customized solutions tailored to your business needs.

If you’re looking for expert 3D modeling services, explore Axolotls 3D Modeling Services for high-quality, customized solutions.

0 notes

Text

Future Trends in Hardware Development: AI, ML, and Beyond

Introduction

With emerging technologies like AI and ML, among others, advanced innovations, the hardware development landscape is changed. This brings about new approaches in designing, testing, and deploying hardware that opens up even more intelligent, fast, and efficient systems. In this article, we go through trends in hardware development that would shape various industries moving forward.

AI and ML-Driven Hardware Development

AI and ML are hardware development leading edges. Its applications range from optimization of design to real time performance enhancement.

AI in Design Automation

Using software tools like AI, for creating designs might reduce the use of material parts with efficiency improvement.

Using AI, innovative efficient structures can be created through the generative design of Autodesk and Ansys using software. Embedded AI Chips:

Hardware applications such as NVIDIA Jetson, Google Coral, and Intel Movidius allow running AI processing at the edge.

These chips take powerful AI capabilities directly to devices in order to further reduce reliance on cloud computing.

Predictive Maintenance:

Hardware-based ML algorithms can predict failure before it happens and minimize downtime and costs for maintenance.

Edge Computing and IoT Integration

With increased numbers of IoT devices, localized data processing emerged as edge computing. This affects hardware development in several ways:

Low Latency in Processing:

Hardware is being designed for faster processing closer to the source of data, which reduces latency and improves real-time decision-making.

Energy Efficiency:

Ultra-low-power processors have been fitted into IoT devices to extend battery lifetimes while improving sustainability.

Seamless Connectivity:

Advanced communication modules like 5G, Wi-Fi 6, and LoRaWAN are integrated with IoT hardware to ensure smooth connectivity.

Move forward with our Embedded Hardware Development Service. Use AI and IoT trend to design next-generation hardware.

Quantum Computing in Hardware Development

Hardware development is about to change dramatically with quantum computing, as it is going to be able to easily solve problems computers cannot solve right now.

Quantum Chips:

The following companies such as IBM, Google, and Rigetti are inventing quantum processors that can improve performance exponentially. Cryogenic Hardware

Quantum system storage is kept in supercold environments and research is accelerating speedily

Applicability: Impact will be huge in industries like cryptography, materials science, and logistics

Sustainability and Green Hardware Development

These days sustainability becomes an essential thing in the making of hardware due to the environmental sensitivity of the peoples around the globe

Recyclable Materials

Hardware components are made from recyclable and biodegradable materials.

Energy-Efficient Designs:

Hardware is reducing its carbon footprint through dynamic power management and energy harvesting innovations.

E-Waste Management:

Companies are designing end-of-life strategies for hardware to minimize electronic waste.

Advanced Prototyping and Manufacturing Technologies

New technologies are accelerating prototyping and manufacturing.

3D Printing:

Additive manufacturing is making it possible to rapidly prototype and manufacture complex geometries that were not possible to manufacture before.

AI-Powered Manufacturing:

AI-based devices are making the production lines slick, increasing yields, and also cutting down wastes.

Flexible Electronics:

Flexible and wearable devices become mainstream; now new innovation arrives in hardware design.

Hardware for AR and VR Applications

Augmented Reality (AR) and Virtual Reality (VR) present a new playing field, that is so wide in opportunity, in developing hardware.

Wearables:

The high-end GPUs are required to have very immersive graphics experience in augmented and virtual reality applications.

Wearable Devices

Smart glasses and haptic gloves provide for more intuitive interactions in virtual spaces.

Real-Time Sensors:

Sensors that could provide more complicated and accurate motion, depth, and orientation detection.

Hardware Development in Cybersecurity

With the rising cyber threats, hardware development has been providing onboard robust security features.

Hardware Encryption

Chip encryption allows the storage of more secure data.

Secure Boot Mechanisms

A boot mechanism ensuring that only authentic software runs on a device. Tamper-Resistant Designs Hardware designs for detection and response to physical tampering.

Open Hardware Movement

Open hardware movement democratizes access to advanced hardware designs.

Open-Source Platforms:

For example, Arduino and RISC-V platforms make innovation possible without significant upfront costs for developers.

Collaborative Development

Collaboration and the acceleration of innovation through knowledge shared by open hardware.

Conclusion

The future of hardware development has been shaped with the advent of AI, ML, quantum computing, and the implementation of green practices. Developers are now allowed to create much smarter, efficient, and friendly products to their environment. To be ahead in this innovation allows businesses to grasp new opportunities to remain competitive.

Gear up to Clutch the Hardware Development Future in Your Hands, contact us.

Also read:

How IoT is Revolutionizing Modern Hardware Development

0 notes

Text

Automated 3d Printing Market set to hit $315.6 billion by 2035, as per recent research by DataString Consulting

Higher trends within Automated 3d Printing applications including aerospace, automotive, healthcare and consumer goods; and other key wide areas like aerospace and automotive are expected to push the market to $315.6 billion by 2035 from $1.7 billion of 2023.

Automated 3D printing allows for the creation of lightweight parts like those used in engines and aircraft structures Companies such, as Boeing and GE Aerospace utilize this technology to improve design versatility and lower production expenses. The car industry leverages automated 3D printing for creating prototypes and specialized parts while improving production processes and supply chain efficiency; companies such as BMW and Ford are, at the forefront of utilizing this technology to speed up product design cycles and enhance operations.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automated-3d-printing-market-research-report

3 D printing automation is leading the path, towards automated manufacturing plants by combining robotics and artificial intelligence to boost productivity.

Industry Leadership and Strategies

The Automated 3d Printing market within top 3 demand hubs including U.S., Germany and China, is characterized by intense competition, with a number of leading players such as GE Additive, Stratasys, Materialise, 3D Systems, HP, EOS, SLM Solutions, Desktop Metal, Formlabs, Protolabs, Carbon Inc and Markforged. Below table summarize the strategies employed by these players within the eco-system.

Leading Providers

Provider Strategies

GE Additive, EOS

Advanced lightweight component manufacturing

Stratasys, HP

Prototyping and on-demand part production

Materialise, Formlabs

Customized implants and precision devices

Desktop Metal, Carbon Inc.

Rapid prototyping and mass customization

This market is expected to expand substantially between 2024 and 2030, supported by market drivers such as growing demand for customization, technological advancements, and cost reduction in manufacturing.

Regional Analysis

The Automated 3D Printing market in this area is thriving thanks to technological progress and a high demand from the aerospace and automotive industries with companies such as GE Additive and Stratasys, at the forefront of innovation.

Research Study analyse the global Automated 3d Printing market in detail and covers industry insights & opportunities at Technology (Stereolithography, Fused Deposition Modeling, Selective Laser Sintering), Component (Hardware, Software, Services) and Application (Aerospace, Automotive, Healthcare, Consumer Goods) for more than 20 countries.

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting offers complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. Our Industry experts and data aggregators continuously track & monitor high growth segments within more than 15 industries and 60 sub-industries.

0 notes