#3D Printing Software and Services Market CAGR

Explore tagged Tumblr posts

Text

Request a free comparative analysis sample report from our analysts to benchmark your brand’s performance against competitors in the 3D Printing Software and Services Industry.

#3D Printing Software and Services Market#3D Printing Software and Services Industry#3D Printing Software and Services Report#3D Printing Software and Services Market Report#3D Printing Software and Services Market Forecast#3D Printing Software and Services Market Research#3D Printing Software and Services Market Size#3D Printing Software and Services Market CAGR#BIS Research

0 notes

Text

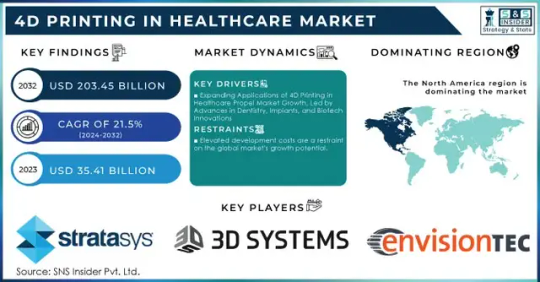

4D Printing in Healthcare Market The Future of Industry Innovation and Market Expansion

The global 4D printing in healthcare market is experiencing unprecedented growth, with valuations soaring from USD 35.41 billion in 2023 to a projected USD 203.45 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 21.5% over the forecast period 2024-2032.

Market Overview

4D printing, an evolution of 3D printing technology, introduces the dimension of time, enabling printed models to alter their shape or properties in response to external stimuli such as temperature, light, or heat. This dynamic capability is revolutionizing the medical field, offering significant advancements in areas like artificial organs, prosthetics, and tissue engineering.

Regional Analysis

North America currently leads the market, driven by substantial investments in research and development and the early adoption of advanced technologies. Europe follows suit, with a strong focus on healthcare innovation and supportive regulatory frameworks. The Asia-Pacific region is poised for significant growth, attributed to increasing healthcare expenditures, rising awareness of advanced medical technologies, and supportive government initiatives.

Get free sample report @ https://www.snsinsider.com/sample-request/2023

Market Segmentation

The 4D printing in healthcare market is segmented based on component, technology, application, and end-user:

By Component:

Hardware

Software

Services

By Technology:

Fused Deposition Modeling (FDM)

PolyJet

Stereolithography (SLA)

Selective Laser Sintering (SLS)

By Application:

Medical Models

Surgical Guides

Patient-Specific Implants

By End-User:

Hospitals

Clinics

Research Institutes

4D Printing in Healthcare Market Key Players

3D/4D Printing Technologies

Stratasys Ltd

3D Systems, Inc

EnvisionTEC

Poietis

Organovo Holdings Inc.

Materialise NV

Dassault Systèmes

Healthcare Management Solutions

Accenture plc

Allscripts Healthcare Solutions Inc.

Athenahealth Inc.

CareCloud Corporation

Cerner Corporation

Cognizant Technology Solutions Corporation

eClinicalWorks LLC

GE Healthcare

Genpact Limited

IBM Corporation

Infor Inc.

McKesson Corporation

Oracle Corporation

Quest Diagnostics

Siemens Healthcare

The SSI Group Inc.

Key Highlights

4D printing introduces time as a factor, allowing medical models to change shape in response to stimuli.

Significant potential in creating dynamic, shape-shifting clinical models, reducing resource use and energy consumption.

Applications extend to chemotherapy, smart therapeutic models, bioprinting, orthodontic devices, stents, and biomedical splints.

Market growth is driven by technological advancements and increased acceptance of 4D printing in healthcare.

Future Scope

The future of 4D printing in healthcare is promising, with ongoing research focusing on developing applications for targeted drug delivery and personalized medicine. Innovations such as cancer-fighting nanorobots exemplify the transformative potential of this technology. As awareness and expertise grow, and as development costs decrease, the adoption of 4D printing is expected to become more widespread, overcoming current challenges related to high costs and regulatory hurdles.

Conclusion

4D printing stands at the forefront of medical innovation, offering dynamic solutions that have the potential to transform patient care. With its ability to create adaptable and responsive medical models, 4D printing is set to play a pivotal role in the future of healthcare, driving advancements that will benefit patients and healthcare providers alike.

Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Other Related Reports:

Healthcare Provider Network Management Market

Healthcare Education Market

Healthcare Business Intelligence (BI) Market

Healthcare Chatbots Market

#4D Printing in Healthcare Market#4D Printing in Healthcare Market Trends#4D Printing in Healthcare Market Share#4D Printing in Healthcare Market Size

0 notes

Text

Veterinary Hospital Market: $112.6B in 2023 to $193.4B by 2033, 5.8% CAGR

Veterinary Hospital Market encompasses facilities providing comprehensive medical care for animals, including diagnostics, surgery, and preventive services. Integrating advanced technologies, pharmaceuticals, and specialized treatments, veterinary hospitals aim to enhance animal health and welfare. This market caters to companion animals, livestock, and exotic species, driven by increasing pet ownership, rising awareness of animal health, and advancements in veterinary medicine.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS25749 &utm_source=SnehaPatil&utm_medium=Article

The market is witnessing robust growth, primarily fueled by the surge in pet ownership and heightened awareness of animal health. Companion animal hospitals dominate, reflecting the rising demand for advanced pet care services. Specialty and emergency veterinary services are the second-highest performing sub-segment, showcasing pet owners’ increasing willingness to invest in specialized care. The preventive care segment is also gaining traction, with a strong focus on vaccinations and wellness programs, indicating a shift towards proactive health management.

North America leads the market, supported by a high concentration of veterinary facilities and advanced healthcare infrastructure. Europe follows closely, benefiting from a strong regulatory framework and growing pet insurance coverage. The Asia-Pacific region is emerging as a lucrative market due to rising disposable incomes and increasing pet ownership. Key countries such as the United States, Germany, and China are pivotal, driving significant advancements and investments in veterinary healthcare services.

Market Segmentation

Type: General Veterinary Hospitals, Specialty Veterinary Hospitals, Emergency Veterinary Hospitals, Animal Rehabilitation Centers, Mobile Veterinary Units, Teaching Hospitals

Product: Veterinary Pharmaceuticals, Veterinary Vaccines, Veterinary Diagnostics, Veterinary Equipment, Nutritional Products

Services: Surgical Services, Dental Care, Diagnostic Imaging, Laboratory Services, Preventive Care, Rehabilitation Therapy, Telemedicine, Boarding Services, Grooming Services

Technology: Digital Imaging, Veterinary Telehealth, Wearable Technology, Artificial Intelligence in Diagnostics, 3D Printing, Robotic Surgery

Component: Software, Hardware, Services

Application: Companion Animals, Livestock, Aquatic Animals, Zoo Animals

End User: Veterinary Clinics, Animal Hospitals, Research Institutions, Animal Shelters

Equipment: Surgical Instruments, Anesthesia Equipment, Monitoring Devices, Imaging Systems

In 2023, the Veterinary Hospital Market reported approximately 320 million service visits, with projections to reach 500 million by 2033. The companion animal segment commands the largest market share at 55%, driven by increasing pet ownership and expenditure on pet healthcare. The livestock segment follows with a 30% share, underpinned by the rising demand for animal-derived food products. The equine segment holds a 15% share, reflecting a niche yet stable market. Key players such as VCA Inc., Banfield Pet Hospital, and Greencross Limited leverage advanced medical technologies and customer-centric services to maintain competitive advantages.

The competitive landscape is shaped by strategic expansions and acquisitions, with VCA Inc. focusing on digital health solutions and Banfield enhancing its veterinary wellness plans. Regulatory influences, such as the Veterinary Medicine Directorate guidelines, impact operational standards and compliance costs. Future projections indicate a 10% annual increase in veterinary service spending, driven by the emphasis on preventive care and telemedicine. However, challenges like regulatory hurdles and the need for skilled veterinary professionals persist. Innovations in diagnostics and treatment modalities present substantial opportunities for market players.

#VeterinaryHospital #AnimalHealthcare #PetCare #VeterinaryMedicine #AnimalWelfare #PetHealth #CompanionAnimals #LivestockCare #PreventiveCare #VeterinaryDiagnostics #VCAInc #BanfieldPetHospital #GreencrossLimited #Telemedicine #VeterinaryInnovation

0 notes

Text

CNC Controller Market Size, Share & Industry Growth Analysis Report 2030

The global CNC controller market size is expected to be USD 3.23 billion in 2025 and is projected to grow at a CAGR of 4.8% from 2025-2030 to reach USD 4.08 billion by 2030. The CNC controller market is driven by the increasing demand for automation of manufacturing processes that increase precision and efficiency. The advancement in the industry 4.0 technologies, including the Internet of Things and AI, helps accelerate the usage of smart CNC systems. The economic and time-efficient production requirement and the growing automobile and aerospace industries fuel further market growth. More importantly, the rising prevalence of custom machinery and the trend toward miniaturization in electronic devices stand out among catalysts.

Driver: Increasing adoption of industrial automation in the global manufacturing sector

The primary reason for the need for industrial automation in the global manufacturing industry is due to the need for real-time data monitoring and predictive maintenance. The benefits that accrue from automation are many, including higher precision, better quality products, accuracy, safety, and consistency in the production processes. It also increases productivity and reduces operation costs, a huge advantage for automotive, aerospace, and medical equipment manufacturing industries. Probably because companies are trying to increase automation and improve their production processes, there is an expected increase in the use of advanced technologies, like CNC machines.

Restraint: High investment and long-term maintenance cost

Introducing CNC controllers is an enormous economic burden both due to the very high initial cost and the high maintenance cost. The above costs are especially challenging to SMEs characterized by limited capital. The cost of the machinery, aside from that, required infrastructure upgrades, including power supply enhancements, a dedicated workspace, and environmental controls to ensure optimal performance of CNC systems.

Once it becomes operational, the monetary obligations will only continue with maintenance and operational expenses. CNC controllers need servicing, too, to get precise and efficient commands and would therefore consider necessary periodic checks, adjustments, and replacement of key parts, including drive motors, spindles, and sensors. Software updates are necessary to improve performance, minimize cyber risks, and bring them up to current industry standards, but this usually comes at a charge in licensing or subscription fees.

Opportunity: Integration of 3D printing technology with CNC machining.

Integrating CNC controllers with 3D printing creates a significant opportunity for augmenting precision through hybrid manufacturing that combines additive and subtractive techniques. This approach would make complex parts possible, minimizing the post-processing needed, enhancing accuracy, and reducing lead times. Mass customization, reduction of material waste, and consistency with sustainability goals are also promoted. It will integrate CNC-3D printing, thus becoming the future of smart, efficient, and flexible manufacturing through real-time adaptation and seamlessness in switching between processes.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=133889642

Challenge: Integration of Modern CNC Controllers with Legacy Systems

Integrating modern CNC controllers with legacy systems will raise significant challenges to manufacturers working on older machinery. The primary problems are that legacy hardware, software, and communication protocols are not compatible with newer advanced CNC controllers that use digital communication, IoT connectivity, and real-time data exchange. This often requires costly custom interfaces and retrofitting the older machines with newer motors, drives, and sensors for compatibility.

0 notes

Text

Japan Medical Imaging Market Analysis 2032

Japan medical imaging market is projected to witness a CAGR of 5.03% during the forecast period FY2025-FY2032F, growing from USD 2.01 billion in FY2024 to USD 2.98 billion in FY2032. Japan medical imaging market is driven by several factors, which include government initiatives and funding, the growing geriatric population and subsequent rise in chronic diseases, technological advancements, expanded healthcare access, integration of digital health solutions, growing healthcare awareness, strategic partnerships, and improved reimbursement policies. These factors collectively enhance the demand for advanced imaging technologies and improve accessibility, driving the dynamic growth and evolution of the market.

Medical imaging plays a crucial role in healthcare by providing detailed internal images that support accurate diagnosis and effective treatment planning. It facilitates early detection of diseases, allowing for timely intervention and significantly improving patient outcomes. Additionally, medical imaging is vital for monitoring disease progression and assessing the effectiveness of treatments, enabling necessary adjustments. In addition, the development of the medical imaging market is also driven by healthcare expenditure growth and the penetration of imaging technologies in numerous advanced economies, especially in developing countries.

For instance, in August 2023, AI developer HeartVista Inc. signed a partnership deal with investment and commercialization firm HekaBio K.K. (HekaBio) to market its One Click MRI AI software – Vista.ai in Japan. Under the agreement, HekaBio invested in Vista.ai and committed to securing product registration for One Click MRI through the Japanese Ministry of Health, Labour and Welfare (MHLW).

Technological Innovations Propel Japan’s Medical Imaging Market

Japan has one of the highest per capita diagnostic imaging devices in the world. This has resulted in a high uptake of medical imaging technologies with advanced capabilities. AI-enabled X-ray systems and computed tomography (CT) systems improve diagnostics efficiency and accuracy. The improvements resulting from these technologies reduce the time needed to acquire and interpret images, allowing healthcare providers to make decisions more quickly and provide better quality to patients. Moreover, technologies like augmented reality and 3D printing are bringing imaging to new and faster capabilities while diagnosing innovatively and accurately and creating more individualized treatment plans for patients. Furthermore, the increasing focus on earlier detection of disease and preventive health is driving demand for advanced imaging technologies and plays an important role in detecting disease earlier.

For instance, in November 2023, iSchemaView, Inc., also known as RapidAI, expanded its presence into Japan through Class III Shonin clearance for its stroke platform and launch of Rapid Edge Cloud, a hybrid technology platform.

Growing Geriatric Population and Subsequent Rise in Chronic Disease

One of the primary drivers of increasing demand for medical imaging is notably an ever-increasing occurrence of chronic diseases and disorders. An aging Japanese population rapidly requires early and precise diagnosis of cardiovascular diseases, cancers, neurodegenerative disorders, etc. As a result, sophisticated medical imaging modalities such as magnetic resonance imaging (MRI), computed tomography scans, and positron emission technology are crucial in monitoring, diagnosing, and treating these diseases. Improved diagnostic capability based on the existence of high-resolution imaging and functional imaging techniques with the Individualised treatment strategy. Furthermore, the rising incidence of these diseases requires frequent screening and follow-up, leading to the growing use of imaging services. For instance, in June 2024, Japan reached a troubling milestone with 2,977 documented cases of streptococcal toxic shock syndrome (STSS), reflecting a significant increase in chronic disease incidence. The mortality rate for STSS is alarmingly high at 30%, with 77 fatalities reported between January and March 2024, exceeding last year’s total of 941 infections.

CT Scanner Segment Leads Market Share in Medical Imaging Market

CT scanners are driving the medical imaging market’s growth by offering high-resolution, detailed images that are crucial for accurate diagnosis and treatment planning. Their ability to quickly provide comprehensive cross-sectional views of the body makes them essential in detecting and evaluating a wide range of conditions, from trauma and cancers to complex internal injuries. The increasing adoption of advanced CT technologies, such as high-definition and low-dose CT scanners, enhances diagnostic precision while minimizing patient exposure to radiation. Rising incidence of chronic diseases, along with complementary requirements related to quick and accurate imaging solutions for emergencies as well as routine care settings, trigger the demand for CT scanners. For instance, in April 2023, Canon Medical Systems Corporation, the National Cancer Center Japan Exploratory Oncology Research & Clinical Trial Center (NCC-EPOC), and the National Cancer Center Hospital East have started joint research and a clinical trial that aims to develop new diagnostic methods and investigate their clinical value by evaluating image data obtained using the Photon Counting CT (PCCT) system installed at EPOC.

Download Free Sample Report

Southern Japan Dominates the Japan Medical Imaging Market

Southern regions of Japan are notable for their dominance in healthcare resources and services. These areas, particularly the western districts, exhibit a higher concentration of hospitals and medical facilities compared to other regions. The southern prefectures have developed robust healthcare networks, which enhance accessibility and improve health outcomes for local populations. The workflow and financial stability in the region are capable of high expenditure on health services, as well as its penetration for the adoption of new X-ray imaging devices. Additionally, the existence of top research organizations and technology firms boosts the medical imaging market in the region; besides that, significant investments in healthcare infrastructure and technologies by the government as well as from the private sector are strengthening its market growth further. The impact of these, together with other factors, gives Southern Japan a dominant position in the medical imaging sector.

For instance, in April 2024, leading healthcare and sustainability entrepreneurs and investors converged in Okinawa for the inaugural “OIST-Lifetime Startup Elevate 2024,” a premier event designed to spotlight innovative startups and groundbreaking technologies in these critical fields. Hosted by the Okinawa Institute of Science and Technology (OIST), the event aimed to foster connections, inspire collaboration, and drive investment in transformative solutions that address pressing global challenges.

Future Market Scenario (FY2025-FY2032F)

Japan’s healthcare industry is the new favourite for AI start-ups. New artificial intelligence-based healthcare tools focus on how doctors determine whether cancer, influenza, and heart disease float across blood. Public-private collaborations are also encouraging the use of more AI healthcare tools by Japan’s medical industry. In addition, the investment by Japan in the AI research and development sector along with governmental efforts to improve healthcare technology will help develop a conducive environment for medical imaging deployment of AI. For instance, in December 2022, Japan announced its initiative to accelerate the approval process for AI diagnostic imaging equipment and ease regulations on medical AI software. This move is part of the broader Society 5.0 program, which seeks to develop a society enriched by cutting-edge technologies such as artificial intelligence (AI) and the Internet of Things (IoT) to enhance people’s quality of life.

Report Scope

“Japan Medical Imaging Market Assessment, Opportunities, and Forecast, FY2018-FY2032F”, is a comprehensive report by Markets and Data, that provides an in-depth analysis and qualitative and quantitative assessment of the current state of the Japan medical imaging market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between FY2025 and FY2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/japan-medical-imaging-market

latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

Global Dental Veneers Market Analysis 2024: Size Forecast and Growth Prospects

The dental veneers global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Dental Veneers Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The dental veneers market size has grown strongly in recent years. It will grow from $2.29 billion in 2023 to $2.47 billion in 2024 at a compound annual growth rate (CAGR) of 8.2%. The growth in the historic period can be attributed to increasing skin cancer incidence, growing awareness of skin health, focus on preventive healthcare, rise in aesthetic concerns, expansion of dermatology practices..

The dental veneers market size is expected to see strong growth in the next few years. It will grow to $3.24 billion in 2028 at a compound annual growth rate (CAGR) of 7.0%. The growth in the forecast period can be attributed to global aging population, increasing focus on skin cancer prevention, rising dermatology consultations, focus on early intervention, expansion of aesthetic dermatology practices.. Major trends in the forecast period include integration of artificial intelligence (ai) algorithms, development of smartphone-compatible dermatoscopes, focus on multispectral imaging, telemedicine applications, enhanced connectivity and data sharing..

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/dental-veneers-global-market-report

Scope Of Dental Veneers Market The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Dental Veneers Market Overview

Market Drivers - Growing dental disorders are expected to propel the growth of the dental veneers market going forward. Dental disorders refer to oral disorders or oral diseases and encompass a variety of conditions that impact the teeth, gums, mouth, and related structures. Dental veneers are used for treating discoloured teeth due to root canal treatment or stains from tetracycline or other drugs, chipped or broken teeth, gaps or spaces in teeth. For instance, in August 2023, according to the '2022-23 Annual Report' released by the National Health Service, a UK-based, publicly funded healthcare system, there were 32.5 million instances of dental disorder treatments administered. This marked a significant rise of 23.2% compared to the 26.4 million treatments delivered in 2021. Therefore, growing dental disorders will drive the growth of the dental veneer market.

Market Trends - Companies operating in the dental veneers market are focusing on the introduction of advanced dental treatment devices such as UltraThineer to gain a competitive edge in the market. UltraThineer is a 3D-printed dental veneer made of advanced material and a production workflow that allows for a minimally invasive treatment option. For instance, in August 2023, Boston Micro Fabrication, a US-based company engaged in nanotechnology research and offering medical and cosmetic veneers, launched UltraThineer, one of the thinnest cosmetic dental veneers. It is designed with projection micro-stereolithography, the newly introduced 3D-printed veneers are customized to be three times thinner than traditional ones. This new method greatly streamlines the preparatory tasks for dental professionals.

The dental veneers market covered in this report is segmented –

1) By Product: Porcelain Veneers, Composite Veneers, Other Products 2) By Application: Cosmetic, Medical 3) By End Users: Hospitals, Dental Clinics, Other End Users

Get an inside scoop of the dental veneers market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=13422&type=smp

Regional Insights - North America was the largest region in the dental veneers market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the dental veneers market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the dental veneers market report are 3M Corporation, Henkel AG & Co. KGaA., Koninklijke Philips N.V, Colgate-Palmolive Company, Dentsply Sirona Inc., Align Technology Inc., Straumann Group, Planmeca Oy, Ivoclar Vivadent AG, Nobel Biocare Holding AG, Ultradent Products Inc., A-dec Inc., Kulzer GmbH, MicroDental Laboratories Inc., Amann Girrbach AG, Brasseler USA LLC, Voco America Inc., Keystone Dental Group, Sun Dental Labs, Den-Mat Holdings LLC, Biolase Inc., Glidewell Dental Lab., Bego USA Inc., Removable Veneers USA, DURAthin Veneers

Table of Contents 1. Executive Summary 2. Dental Veneers Market Report Structure 3. Dental Veneers Market Trends And Strategies 4. Dental Veneers Market – Macro Economic Scenario 5. Dental Veneers Market Size And Growth ….. 27. Dental Veneers Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

From Vision to Reality: The Fast-Growing 3D Printing Market in Action

3D Printing Industry Overview

The global 3D printing market size is expected to reach USD 88,281.2 million by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 23.5% from 2024 to 2030. 3D Printing (3DP) is also referred to as Additive Manufacturing (AM) as it involves successive addition of layers of materials in various 2D shapes using an additive process. These layered 2D shapes build upon one another to form a three-dimensional object. The process is different from the subtractive method of production, which begins with a block of material and the unnecessary material is ground out to obtain the desired object.

3D printing is widely adopted in the industrial sector owing to the growing need for enhanced product manufacturing and a shorter time to market. The industrial vertical happens to be the most significant adopter of the 3D printing technology, eventually leading to the largest market share of 3D printers for industrial applications over the forecast period. Additive manufacturing is anticipated to evolve over the forecast period.

3D printing continues to gain popularity among hobbyists and innovators. While individuals are using 3D printing for domestic and personal purposes, universities and educational institutes are using 3D printing for conducting technical training. The market is subject to witness a considerable economical appearance rather than being just a labor-intensive industrial manufacturing technique. Particularly in developing economies, such as Brazil, South Africa, and India, machining shops have managed to adopt alternative business models by installing 3D printers and offering related services, such as 3D printing materials, filaments, 3D modeling, and 3D printer software.

Gather more insights about the market drivers, restrains and growth of the 3d Printing Market

Apart from the industrial vertical, the automotive, healthcare, and aerospace & defense verticals are among the leading adopters of 3D printing technology. Incumbents of these verticals have an emphasis on accuracy, enhanced product designing, reliability, shorter time to market, and economical production processes. Given that additive manufacturing can offer all these benefits, the adoption of three-dimensional printers by the automotive, healthcare, and aerospace & defense verticals is expected to gain traction over the forecast period.

3D printing and related technologies are evolving continuously in line with the intensive R&D activities being undertaken, and the aggressive investments being made by the private and the public sectors. Government funding and encouraging initiatives being undertaken in developed economies are prompting manufacturers to pursue improvements in technology and the adoption of new technologies.

North America accounted for the largest revenue share of more than 34.0% in 2023, as a result of the extensive adoption of 3D printers for 3D designing, 3D modeling, and 3D manufacturing in several industries. The Asia Pacific region has emerged as a manufacturing hub owing to an expanding consumer base as well as the continued foreign investments happening in the region. The Asia Pacific market is expected to witness remarkable growth over the forecast period.

3D printing technology happens to be a capital-intensive technology. At the same time, manufacturers are holding on to their misconception about prototyping, rather than realizing the advantages associated with 3D printing. Moreover, the market lacks the standard process controls and a skilled workforce required for 3D printing. These are some of the factors that are expected to restrain the market growth. However, government initiatives aimed at increasing awareness and promoting the benefits of adopting 3D printers are expected to help in countering the market restraints.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

The global next generation computing market size was valued at USD 152.13 billion in 2024 and is expected to grow at a CAGR of 16.6% from 2025 to 2030.

The global artificial intelligence in marketing market size was estimated USD 20,447.1 million in 2024 and projected to grow at a CAGR of 25.0% from 2025 to 2030.

3D Printing Market Segmentation

Grand View Research has segmented the global 3D printing market based on component, printer type, technology, software, application, vertical, material, and region:

3D Printing Component Outlook (Revenue, USD Million, 2017 - 2030)

Hardware

Software

Services

3D Printing Printer Type Outlook (Revenue, USD Million, 2017 - 2030)

Desktop 3D Printer

Industrial 3D Printer

3D Printing Technology Outlook (Revenue, USD Million, 2017 - 2030)

Stereolithography

Fuse Deposition Modelling

Selective Laser Sintering

Direct Metal Laser Sintering

Polyjet Printing

Inkjet printing

Electron Beam Melting

Laser Metal Deposition

Digital Light Processing

Laminated Object Manufacturing

Others

3D Printing Software Outlook (Revenue, USD Million, 2017 - 2030)

Design Software

Inspection Software

Printer Software

Scanning Software

3D Printing Application Outlook (Revenue, USD Million, 2017 - 2030)

Prototyping

Tooling

Functional Parts

3D Printing Vertical Outlook (Revenue, USD Million, 2017 - 2030)

Industrial 3D Printing

Automotive

Aerospace & Defense

Healthcare

Consumer Electronics

Power & Energy

Others

Desktop 3D Printing

Educational Purpose

Fashion & Jewelry

Objects

Dental

Food

Others

3D Printing Material Outlook (Revenue, USD Million, 2017 - 2030)

Polymer

Metal

Ceramic

3D Printing Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Spain

Asia Pacific

China

Japan

India

South Korea

Australia

Singapore

South America

Brazil

Middle East and Africa (MEA)

KSA

UAE

South Africa

Key Companies profiled:

3D Systems, Inc.

3DCeram

Arcam AB

Autodesk, Inc.

Canon, Inc.

Dassault Systemes

EnvisionTec, Inc.

EOS (Electro Optical Systems) GmbH

ExOne

GE Additive

HP Inc.

us

Materialise NV

Optomec, Inc.

Organovo Holdings Inc.

Proto Labs, Inc.

Shapeways, Inc.

Stratasys Ltd.

Tiertime

Voxeljet AG

Key Companies & Market Share Insights

Some of the key players operating in the market include 3D Systems, Inc. and Materialise among others.

3D Systems, Inc. is the U.S.-based technology company. The company is involved in the development of Desktop 3D printing products and services such as 3D printers, materials, software, 3D scanners and virtual surgical simulators and haptic design tools. Additionally, the company serves its customers with 3D solutions to manufacture and design complex and unique parts, produce parts locally to reduce the lead time, and eliminate expensive tooling, among others. The company caters to numerous industries and verticals such as aerospace & defense, automotive, healthcare, educational, durable goods, and entertainment.

Materialise is a Belgium-based technology company operating in the additive manufacturing industry. The company is actively involved in the field of Desktop 3D printing to develop a broad range of software solutions, Desktop 3D printing services, and engineering. The company primarily caters to the industries such as healthcare, aerospace, automotive, consumer goods, and art & design.

Recent Developments

In March 2023, 3D Systems, Inc. announced the launch of NextDent Cast and NextDent Base, two new printing materials, and NextDent LCD1, a printing platform. The materials are designed to enhance material properties, and the printing platform is an easy-to-use small-format printer. With these launches, the company aimed to aid its customers in accelerating additive manufacturing adoption.

In November 2023, Autodesk Inc. announced the launch of Autodesk AI. This new technology is available in Autodesk products and is designed to provide customers with generative capabilities and intelligent assistance. With the launch of this new technology in Autodesk products, the company aimed to minimize errors by automating repetitive tasks and the needs of its customers.

In February 2022, Dassault Systèmes has announced a strategic partnership with Cadence Design Systems, Inc. to provide integrated solutions for the development of high-performance electronic systems to enterprise customers in a variety of vertical markets, such as high tech, industrial equipment, and transportation and mobility, aerospace and defense, and healthcare.

Order a free sample PDF of the 3d Printing Market Intelligence Study, published by Grand View Research.

0 notes

Text

3D Printing Market — Forecast(2024–2030)

3D Printing Market Overview:

However, artificial 3D printing has opened up scope in the modern medical industry for people to opt for advanced, cost-effective, and appealing designed prosthetics. Healthcare sector has helped in generating a huge demand in the 3D printing market owing to its versatile application in dental implants, hearing aids, artificial organs, etc. 3D bioprinting fills up the gap between animal and human experimental trials with advanced bio-printed human skin, thyroid gland, and many other vital parts. Technological advancement has extended the manufacturing of almost every possible subject for 3D printing: automotive parts, metal printing, sample architectures and constructions, prototypes of footwear, energy production, food, educational, aeronautical approaches, robotics and drones, and many others. Moreover, continuous and limitless breakthroughs in 3D printing have created an enormous impact on the industrial and commercial field thereby expanding the 3D printing economy. The extensive market opportunity is expected to advance at a robust compound annual growth rate (CAGR) of 23% through 2030.

Sample Request :

3D printing or additive manufacturing employs layer-by-layer deposition of suitable materials to create an object. Acceptance of 3D printing has increased progressively from prototyping to low-volume manufacturing of customized products. Different types of 3D printing technologies are Stereo-lithography (SLA), Fused Deposition Modeling (FDM), and Selective Laser Sintering (SLS), among others. These above-mentioned technologies are deployed in various industries such as consumers, automotive, construction, aerospace, medical and others.

This report incorporates an in-depth assessment of the 3D printing market by type, technology, application, end user industries and geography. The offering types of 3D printing encompassed in the scope include hardware, software and services. The hardware segment is further sub segmented into printers, scanners and materials.

The 3D printing market is witnessing a surge in material diversity, with advancements in composite materials, biodegradable plastics, and metal alloys. This trend allows for more versatile and application-specific 3D printing, catering to industries such as aerospace, healthcare, and automotive. The 3D printing trend toward large-scale manufacturing is reshaping industries traditionally reliant on massive components. From building construction to shipbuilding, the ability to 3D print large structures is revolutionizing design possibilities, streamlining production, and ushering in a new era of efficiency and customization. Large-scale additive manufacturing is gaining traction, allowing for the production of bigger and more complex structures. Industries like construction, shipbuilding, and infrastructure are exploring the potential of 3D printing for large components, reducing assembly requirements and lead times.

Inquiry Before Buying :

Market Snapshot:

Report Coverage

The “3D Printing Market Report — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Bulletproof Glass Industry.

By Product: Hardware [Printers (Industrial, Consumer), Scanners], Software (Design, Scanning, Inspection, Printing), Services (Parts on Demand, Prototypes, Others)

By Material: Polymers [Thermoplastics (Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Alcohol (PVA ), Polyamide, Polypropylene, Others), Photopolymers], Metals and Alloys (Steel, Titanium, Silver, Gold, Nickel, Bronze, Aluminum, Copper, Iron, Manganese, Others), Fibers (Carbon, Glass, Kevlar, Others), Ceramics (Quartz, Silica, Glass, Others), Wax, Paper, Wood, Others

By Form: Filament, Liquid, Powder

By Technology: Stereolithography (SLA), Fuse deposition modeling (FDM), Selective laser sintering (SLS), Inkjet printing, Electron beam melting (EBM), Laser metal deposition (LMD), PolyJet printing, Digital Light Processing (DLP), Others

By Application: Production, Prototyping, Research & Education

By End Use Industry: Consumers [Decorative Items/Art Work (Freeform Art and Sculpture, Jewelry, Collectible Trinkets, Hospitality, Interior Decorative Items, Others), Others], Industrial (Machine Parts, Dies, Molds and Patterns, Others), Automotive [Exterior (Bumpers, Wind Breakers, Body Panels, Others), Interior (Dashboards, Seat Frames, Others), Engines and Engine Components (Cylinder Heads, Intake Manifolds, Engine Blocks, Others), Transmission Housings, Hubcaps, Tires, Suspension Spring, Others], Aerospace (Complex Gear Cases and Covers, Fuel Tanks, Transmission Housings, Components Requiring Draft Free Walls, Impellers, Turbine Blades, Lightweight Engine Parts, Structural Hinges, Others), Medical [Surgical Instruments, Implants (Dental (Sub-Periosteal Implants, Endosteal Implants), Orthopedic Implants, Prosthetic Implants, Spinal Rods, Bone Plates, Cranial Implants, Others), Tissue Engineering, Others], Construction (Commercial, Residential, Infrastructure, Industrial), Others

By Geography: North America, South America, Europe, APAC, and RoW

What are the major end users for 3D Printing?

The report includes an assessment of various end user industries such as automotive, construction, aerospace, medical, consumers and others. Medical industry is one of the major end users for 3D printing and holds a tremendous opportunity in the near future. This segment is expected to dominate the market in the short to long term. 3D Printing in the medical industry can be employed for multiple applications such as surgical instruments, dental implants, orthopedic implants, prosthetic implants, cranial implants and others.

Market Research and Market Trends of 3D Printing Ecosystem

• The American space company, SpaceX has sent a Dragon capsule to the International Space Station (ISS) which carried the first ever zero-G 3D printer. In addition, increasing traction by space agencies such as the National Aeronautics and Space Administration (NASA), European Space Agency (ESA) and others are anticipated to show a significant impact on the 3D printing market in the near future.

• The bio printers’ technology is in the experimental stage and is anticipated to provide prospects for the 3d printing market in the food industry. Furthermore, the importance of this technology has resulted in growing R&D investments by food companies such as chocolate & confectionery manufacturers.

• According to Oxford Performance Materials, more than 75% of American patients’ damaged skulls by disease or trauma were replaced with an implant from Oxford Performance Materials 3D printer and hence brought a revolution in the healthcare industry

The consumer 3D printers market is becoming highly consolidated with Stratasys Ltd. and 3D Systems Corp. being the global behemoths in this industry. 3DSystems has been highly active with a string of acquisitions of smaller companies across the globe

Schedule A Call :

Who are the Major Players in the 3D Printing Market?

The companies referred to in the market research report include Flashforge 3D Technology Co., Ltd., Hewlett-Packard, 3D Systems, Inc., Stratasys Ltd., SLM Solutions Group AG, ExOne Company LLC., Organovo Holdings, Inc., EOS GmbH, General Electric Company, XYZprinting, Inc., and others and more than 15 other companies.

What is our report scope?

The report incorporates an in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and their impact during the forecast period 2024–2030.

All our reports are customizable to your company’s needs to a certain extent, we do provide 20 free consulting hours along with the purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Key Takeaways from this Report

• Evaluate market potential by analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level — for product types, end use applications and by different industry verticals.

• Understand the different dynamics influencing the market — key driving factors, challenges and hidden opportunities.

• Get in-depth insights on your competitor’s performance — market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

• Analyze the sales and distribution channels across key geographies to improve top-line revenues.

• Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

• Get a quick outlook on the market entropy — M&A’s, deals, partnerships, and product launches of all key players for the past 4 years.

• Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than the top 20 countries globally for the market.

3D Printing Market Outlook:

Computer-aided high-quality 3D printing designs of delicate human organs and vascular systems provide a better chance for medical experts to perform risk-free preliminary trials of critical surgery. Earlier 3D printing was accomplished with inkjet printers but vernacular mediums and innovations have made it comparatively easier to print 3D models of any object successfully in modern times. Prototyping is the major push towards 3D printing industries leaving behind conventional practices of manufacturing models and machineries. It uses high-performing materials such as thermoplastics for yielding engineered aeronautical, automotive, and medical utilities. Booming 3D printing market is anticipated to leverage a mounting demand from the automotive industry with an outstanding CAGR of 15% during the period 2024–2030. Apart from North America other provinces are susceptible to the 3D printing market transition with compelling revenue income during the forecast period.

Buy Now :

3D Printing Market Growth Drivers:

• Surgical trials on 3D printed organ models lead to minimal risks, proper surgery planning, identifying suitable tools for a particular case, and shrinks surgical complications, consequently, enhancing medical prowess and driving the global 3D printing market demand.

• Designing new tools and their effective application generates amplifying prospects for 3D printing companies.

• Automotive industry is a major driving force in the 3D printing market owing to better customization, lower material wastage, accuracy and less time consumption, and flexible designing.

• Research on 3D printing organ transplantation is conducted on a large scale to replace the complication of live organ transplantation owing to cost-inefficiency, inadequate donor availability, and donor-receiver incompatibility. Around 13 people die every day without a kidney transplantation. Persistent biomedical engineering advances will increase the efficacy of 3D bio-printed organs and will accomplish sophisticated applications in the medical field in the forthcoming years.

3D Printing Market Challenge:

Critical problems associated with the trending 3D printing progression include limited material variety, limited repetition process, and narrow scale of niche expertise. Albeit the low-cost 3D printing products, exorbitant rates of manufacturing procedure, equipment installation, and post-processing necessities thwart the global 3D market development. However, the optimistic approach of the manufacturing companies outpaces these market challenges with rigorous investment in the technologies and embracing strategic changes.

3D Printing Market Key Players:

The leading market innovators of the global 3D printing market include Flashforge 3D Technology Co., Ltd., Hewlett-Packard, 3D Systems, Inc., Stratasys Ltd., SLM Solutions Group AG, ExOne Company LLC., Organovo Holdings, Inc., EOS GmbH, General Electric Company, XYZprinting, Inc., and others.

XYZ Printing is a 3D printer manufacturing company incorporating the 3D printing experience in offices, schools, and homes with accessible and less expensive printers. With 8500 engineers, they deliver products such as 3D pen, mini, and nano series, original and junior series, color, pro, nobel, and 3D scanner series.

3D Printing Market Trends:

3D Printing Bunion Rectification

Traumatic bunion development on the foot leads to difficulty in walking and toe movement. MedShape Orthopedic Solution Company has invented a new device for correcting hallux valgus deformity with an FDA-administered bone tether plate sculpted through 3D titanium alloy printing. Furthermore, mechanical drilling of bones will be escaped owing to the innovative FastForward bunion correction plate.

Revolutionary Bio-Printed Human Skin

Recent research directed by the unique 3D bio-printer to create a lab-made skin is suitable for testing chemicals, cosmetics, and pharmaceutical experiments as well as compatible with transplantation in burn incidences. A close replica of human skin bio-printing, this method is cost-effective as compared to manual production of artificial skin.

Persuasive Prosthetic Designs

Prosthetics have improved physical deformity with newer advances keeping an eye on the quality, design, and comfort level of the patients. Amputees’ changed outlook on the modern world has shaped their personal preferences. Designer prosthetics in the form of modern bionics of popular characters such as artificial hero arms are widely gaining traction among children worldwide. Widely accepted by teenagers and young amputees, the bionic trend is gradually overpowering the 3D printed prosthetics market.

3D Printing Market Research Scope:

The base year of the study is 2023, with forecasts done up to 2030. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the 3D printing market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the type of 3D printing in the 3D printing market and their specific applications in different areas.

3D Printing Market: Industry Coverage:

Global 3D printing market is segmented based on offering, application, and end user. Bifurcation based on offering includes printer, scanner, material, software, service, and others. Based on application categorization includes production, prototyping, and research and education. By end user, this market is divided into consumers, automotive, construction, and so on.

The 3D printing market also analyzes the major geographic regions for the market as well as the major countries for the market in these regions.

The regions and countries covered in the study include:

• North America: The U.S., Canada, Mexico

• South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

• Europe: The U.K., Germany, Italy, France, the Netherlands, Belgium, Spain, Denmark

• APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

More information about 3D Printing Market report click here

0 notes

Text

3D Printing Market - Recent Industry Developments and Growth Strategies till 2030

In 2023, the global 3D printing market was valued at USD 20.37 billion and is projected to grow significantly, with a compound annual growth rate (CAGR) of 23.5% from 2024 to 2030. This anticipated growth is largely driven by intensive research and development in 3D printing technology and the rising demand for prototyping applications across various industries, particularly healthcare, automotive, and aerospace & defense sectors.

In industrial settings, 3D printing is commonly referred to as additive manufacturing (AM). This process involves the layer-by-layer addition of material to create objects from a 3D model, guided by specialized software and a 3D printer. The choice of 3D printing technology depends on the specific requirements of each application. Once a suitable technology is chosen, the process is implemented across various industry sectors based on specific needs.

Gather more insights about the market drivers, restrains and growth of the 3D Printing Market

The deployment of 3D printing technology includes services such as installation, consulting, and customer support. It also involves addressing issues related to intellectual property, licensing, and patents. By leveraging 3D printing, manufacturers benefit in several ways, including enhanced prototyping, structural design, product modeling, and reduced time to market. These advantages result in considerable cost savings for manufacturers, allowing them to deliver improved products at competitive prices. Consequently, the demand for 3D printers is expected to grow over the forecast period.

Despite these advantages, certain challenges exist that may slow the adoption of additive manufacturing, particularly among small and medium-sized manufacturers. Many of these businesses hold misconceptions about the prototyping process, seeing it as an expensive pre-manufacturing phase rather than as a valuable investment. This perception, along with limited technical knowledge and a lack of standardized process controls, is expected to hinder market expansion.

Technology Segmentation Insights:

In terms of technology, the stereolithography segment led the 3D printing market in 2023, holding over 10% of the global revenue share. The market segmentation by technology includes stereolithography, fused deposition modeling (FDM), direct metal laser sintering (DMLS), selective laser sintering (SLS), inkjet, polyjet, laser metal deposition, electron beam melting (EBM), digital light processing (DLP), laminated object manufacturing, and others.

Stereolithography, one of the oldest 3D printing technologies, remains widely used due to its ease of operation and numerous advantages. However, continuous technological advancements and intensive research efforts are creating new opportunities for other reliable and efficient technologies in the market.

Fused Deposition Modeling (FDM) held a significant market share in 2023, largely because of its widespread adoption in various 3D printing applications. Digital Light Processing (DLP), Electron Beam Melting (EBM), inkjet printing, and Direct Metal Laser Sintering (DMLS) technologies are also expected to gain traction over the forecast period due to their applicability in specialized additive manufacturing processes. The increasing demand across aerospace and defense, healthcare, and automotive sectors is expected to create growth opportunities for these technologies as they support diverse and specialized applications in these industries.

Order a free sample PDF of the 3D Printing Market Intelligence Study, published by Grand View Research.

0 notes

Text

3D Printing Market Size & Forecast Report, 2030

In 2023, the global 3D printing market was valued at USD 20.37 billion and is projected to grow significantly, with a compound annual growth rate (CAGR) of 23.5% from 2024 to 2030. This anticipated growth is largely driven by intensive research and development in 3D printing technology and the rising demand for prototyping applications across various industries, particularly healthcare, automotive, and aerospace & defense sectors.

In industrial settings, 3D printing is commonly referred to as additive manufacturing (AM). This process involves the layer-by-layer addition of material to create objects from a 3D model, guided by specialized software and a 3D printer. The choice of 3D printing technology depends on the specific requirements of each application. Once a suitable technology is chosen, the process is implemented across various industry sectors based on specific needs.

Gather more insights about the market drivers, restrains and growth of the 3D Printing Market

The deployment of 3D printing technology includes services such as installation, consulting, and customer support. It also involves addressing issues related to intellectual property, licensing, and patents. By leveraging 3D printing, manufacturers benefit in several ways, including enhanced prototyping, structural design, product modeling, and reduced time to market. These advantages result in considerable cost savings for manufacturers, allowing them to deliver improved products at competitive prices. Consequently, the demand for 3D printers is expected to grow over the forecast period.

Despite these advantages, certain challenges exist that may slow the adoption of additive manufacturing, particularly among small and medium-sized manufacturers. Many of these businesses hold misconceptions about the prototyping process, seeing it as an expensive pre-manufacturing phase rather than as a valuable investment. This perception, along with limited technical knowledge and a lack of standardized process controls, is expected to hinder market expansion.

Technology Segmentation Insights:

In terms of technology, the stereolithography segment led the 3D printing market in 2023, holding over 10% of the global revenue share. The market segmentation by technology includes stereolithography, fused deposition modeling (FDM), direct metal laser sintering (DMLS), selective laser sintering (SLS), inkjet, polyjet, laser metal deposition, electron beam melting (EBM), digital light processing (DLP), laminated object manufacturing, and others.

Stereolithography, one of the oldest 3D printing technologies, remains widely used due to its ease of operation and numerous advantages. However, continuous technological advancements and intensive research efforts are creating new opportunities for other reliable and efficient technologies in the market.

Fused Deposition Modeling (FDM) held a significant market share in 2023, largely because of its widespread adoption in various 3D printing applications. Digital Light Processing (DLP), Electron Beam Melting (EBM), inkjet printing, and Direct Metal Laser Sintering (DMLS) technologies are also expected to gain traction over the forecast period due to their applicability in specialized additive manufacturing processes. The increasing demand across aerospace and defense, healthcare, and automotive sectors is expected to create growth opportunities for these technologies as they support diverse and specialized applications in these industries.

Order a free sample PDF of the 3D Printing Market Intelligence Study, published by Grand View Research.

0 notes

Text

"Future of Healthcare: Innovations in the 3D Printing Medical Devices Market"

3D Printing Medical Devices Market Overview📊 :

The 3D Printing Medical Devices Market Report is a treasured source of insightful data for business strategists. It provides an in-depth assessment of numerous features of industries like market overview, present progress valuations, historical and future studies, current trends, SWOT valuations, and clients operating in several regions. The study provides valuable information to magnify the understanding, scope, and segments of this report. The report covers a comprehensive analysis of 3D Printing Medical Devices Market segmentation and regional and country breakdowns. This research will offer a clear and exact idea about the whole industry to the readers to make beneficial decisions.

According to Straits Research, the global 3D Printing Medical Devices Market size was valued at USD 2.55 Billion in 2022. It is projected to reach from USD XX Billion in 2023 to USD 9.79 Billion by 2031, growing at a CAGR of 16.1% during the forecast period (2023–2031).

This study pinpoints noteworthy trends influencing the trajectory of the Gesture Recognition market's expansion. Within this recently issued report, crucial dynamics encompassing drivers, limitations, and prospects are underscored. These aspects hold relevance for well-established market entities as well as emerging stakeholders engaged in the realms of production and supply.

Request a Sample Report @ https://straitsresearch.com/report/3d-printing-medical-devices-market/request-sample

Who are the 🏆leading players in 3D Printing Medical Devices Market?

3D Systems Corporations,

Bio3D Technologies,

Cyfuse Medical K.K.,

EnvisionTEC,

Materialise NV,

Organovo Holdings Inc.,

Oxford Performance Materials Inc.,

SLM Solutions Group AG,

Stratasys Ltd.

Moreover, the competitive analysis of the 3D Printing Medical Devices Market brings insight into the product usability profiles of the leading players. Additionally, the analysis highlights features & pricing, and informant reviews of the key products in the market.

Which segments are covered in 3D Printing Medical Devices Market?

By Component

Printers

Materials

Software & Services

Hardware

By Technology

Electron Beam Melting (EBM)

Laser Beam Melting (LBM)

Direct Metal Laser Sintering (DMLS)

Stereolithography (SLA)

Fused Deposition Modeling (FDM)

Selective Laser Melting (SLM)

Selective Laser Sintering (SLS)

Others (Photopolymerization, Digital Light Processing [DLP], etc.)

By Application

Orthopedic & Cranial Implant

Dental Restorations

Surgical Instruments

Tissue Fabrication

Custom Prosthetics

Prosthetics Implant

Wearable Medical Devices

Dentistry and Orthodontics

Others (Tissue-engineered Products, Plastic and Reconstructive Surgeries, etc.)

By Material

Plastics

Biomaterial Inks

Metals and Alloys

By End User

Hospitals and Surgical Centers

Dental and Orthopedic Clinics

Academic Institutions and Research Laboratories

Pharma-Biotech and Medical Device Companies

Clinical Research Organizations

The market is largely fragmented and the vast majority of the players functioning in the global 3D Printing Medical Devices Market are taking steps to raise their market footprint, by concentrating on product diversification and development, therefore making them seize a larger share of the market. The study highlights current market trends and provides a forecast. We also have highlighted future trends in the 3D Printing Medical Devices Market that will impact the demand during the forecast period. Overall, this report is an important resource for businesses seeking to stay ahead of the competition in the 3D Printing Medical Devices Market industry. With its complete analysis of recent developments and the latest emerging trends, it offers valuable insights into the market that can be used to grow effective growth strategies and enhance market positioning.

Access Detailed Segmentation @ https://straitsresearch.com/3d-printing-medical-devices-market/segmentation

Regional Analysis

Largest Market: The 3D Printing Medical Devices Market is dominated by North America, which holds the largest share due to factors such as advanced infrastructure, high consumer awareness, and significant investment in related industries. The region's well-established specific sectors further bolster its leading position in the market.

Fastest Growing Market: The fastest-growing market for 3D Printing Medical Devices Market is Europe. This growth is driven by a combination of rising disposable incomes, increasing adoption of specific products or services, and supportive government initiatives. Additionally, the expanding related industries in this region contribute to its rapid market expansion.

Our Report Offers:

– Market share assessments for the regional and country-level segments.

– Strategic recommendations for the new entrants.

– Competitive landscaping mapping the key common trends.

– Company profiling with detailed strategies, financials, and recent developments.

– Supply chain trends mapping the latest technological advancements.

Buy Now full 3D Printing Medical Devices Market report @ https://straitsresearch.com/buy-now/3d-printing-medical-devices-market/

An international 3D Printing Medical Devices Market research report delves into the competitive landscape of global markets, scrutinizing companies and manufacturers. The report's competitive analysis spotlights the strategic actions undertaken by key players across diverse industries. These actions encompass a spectrum of activities including new product introductions, expansions, agreements, joint ventures, partnerships, and recent acquisitions. This comprehensive market report sheds light on a myriad of facets within marketing research, spanning crucial industry trends, market size, estimated market share, sales volume, emerging patterns, product consumption, customer inclinations, historical data, forward-looking forecasts, and meticulous analysis of key players.

Global 3D Printing Medical Devices Market Research Report Forecast 2031

Chapter 1:- 3D Printing Medical Devices Market Overview

Chapter 2:- Economic Impact on Industry

Chapter 3:- Production, Business Opportunities with Potential Analysis

Chapter 4:- Rising Trends and New Technologies with Key Players

Chapter 5:- 3D Printing Medical Devices Market Manufacturing Cost Analysis

Chapter 6:- Technology Progress, Development Process and Downstream Buyers

Chapter 7:- Marketing Strategy Analysis, Distributors/Traders

Chapter 8:- Market Share by Key Countries in These Regions

Chapter 9:- Show the Market by Type and Application, With Sales Market Share and Growth Rate

Chapter 10:- Appendix and Data Source

Click to View the Full Report TOC: https://straitsresearch.com/report/3d-printing-medical-devices-market/toc

Key Questions Answered by Our 3D Printing Medical Devices Market Report

What are the key drivers of growth in the 3D Printing Medical Devices Market, and how do they vary across regions and segments?

How are advancements in technology and innovation affecting the 3D Printing Medical Devices Market, and what new opportunities and challenges are emerging as a result?

Which market players are currently leading the pack in terms of market share and product innovation, and what strategies are they employing to maintain their positions?

What regulatory and policy changes are on the horizon that could affect the 3D Printing Medical Devices Market, and how are market players adapting to these changes?

What are the emerging trends and market disruptors that are likely to shape the 3D Printing Medical Devices Market in the years to come, and what can businesses do to stay ahead of the curve?

How are consumer preferences and behaviors evolving with regard to 3D Printing Medical Devices Market, and what implications do these trends have for market players?

Buy Now full 3D Printing Medical Devices Market report @ https://straitsresearch.com/buy-now/3d-printing-medical-devices-market/

Thanks for reading this article; you can also get separate chapter-wise sections or region-wise report versions like North America, Europe, or Asia.

About Us:

Contact Us:

Email: [email protected]

Website: https://straitsresearch.com/

0 notes

Text

Automated 3D Printing Market Size & Share Analysis - Growth Trends By Forecast Period

Automated 3D Printing Market Information

The Automated 3D Printing Market Report provides essential insights for business strategists, offering a comprehensive overview of industry trends and growth projections. It includes detailed historical and future data on costs, revenues, supply, and demand, where applicable. The report features an in-depth analysis of the value chain and distributor networks.

Employing various analytical techniques such as SWOT analysis, Porter’s Five Forces analysis, and feasibility studies, the report offers a thorough understanding of competitive dynamics, the risk of substitutes and new entrants, and identifies strengths, challenges, and business opportunities. This detailed assessment covers current patterns, driving factors, limitations, emerging developments, and high-growth areas, aiding stakeholders in making informed strategic decisions based on both current and future market trends. Additionally, the report includes an examination of the Automatic Rising Arm Barriers sector and its key opportunities.

According to Straits Research, the global Automated 3D Printing Market size was valued at USD 707 Million in 2021. It is projected to reach from USD XX Million in 2022 to USD 11622 Million by 2030, growing at a CAGR of 41.9% during the forecast period (2022–2030).

Get Free Request Sample Report @ https://straitsresearch.com/report/automated-3d-printing-market/request-sample

TOP Key Industry Players of the Automated 3D Printing Market

Stratasys Ltd

GE Additive

The ExOne Company

SLM Solutions Group AG

3D Systems Corporation

Universal Robots A/S

Formlabs

PostProcess Technologies Inc.

Materialize NV

Authentise Inc.

DWS Systems

EnvisionTEC US LLC (Desktop Metal Inc.)

ABB Ltd

Global Automated 3D Printing Market: Segmentation

As a result of the Automated 3D Printing market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Offering

Hardware

Software

Services

By Process

Automated Production

Material Handling

Part Handling

Post-Processing

Multiprocessing

By End-user

Industrial Manufacturing

Automotive

Aerospace & Defense

Consumer Products

Healthcare

Energy

Others

You can check In-depth Segmentation from here: https://straitsresearch.com/report/automated-3d-printing-market/segmentation

Reasons for Buying This Report:

Provides an analysis of the evolving competitive landscape of the Automatic Rising Arm Barriers market.

Offers analytical insights and strategic planning guidance to support informed business decisions.

Highlights key market dynamics, including drivers, restraints, emerging trends, developments, and opportunities.

Includes market estimates by region and profiles of various industry stakeholders.

Aids in understanding critical market segments.

Delivers extensive data on trends that could impact market growth.

Research Methodology:

Utilizes a robust methodology involving data triangulation with top-down and bottom-up approaches.

Validates market estimates through primary research with key stakeholders.

Estimates market size and forecasts for different segments at global, regional, and country levels using reliable published sources and stakeholder interviews.

Buy Now @ https://straitsresearch.com/buy-now/automated-3d-printing-market

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Automated 3D Printing Market#Automated 3D Printing Market Share#Automated 3D Printing Market Size#Automated 3D Printing Market Research#Automated 3D Printing Industry

0 notes

Text

Healthcare/Medical Simulation Market Investment Opportunities: Key Stakeholders and Market Trends

The global healthcare/medical simulation market is experiencing remarkable growth, driven by the increasing complexity of medical procedures and the pressing need for effective training solutions. Valued at USD 1.81 billion in 2023, the market is projected to reach USD 7.04 billion by 2032, reflecting a compound annual growth rate (CAGR) of 16.31% from 2024 to 2032.

Market Segmentation

The healthcare/medical simulation market is segmented based on:

Product & Services: This includes healthcare anatomical models, healthcare simulation software, and simulation training services.

Technology: Key technologies encompass virtual patient simulation, 3D printing, and procedure rehearsal technology.

End Use: The primary end users are academic institutions, hospitals, and military organizations.

Get free sample report @ https://www.snsinsider.com/sample-request/1770

Regional Analysis

North America currently leads the market, attributed to advanced healthcare infrastructure and significant investments in medical training. Europe follows, with a strong emphasis on patient safety and continuous medical education. The Asia-Pacific region is anticipated to witness substantial growth due to increasing healthcare expenditures and the adoption of advanced technologies in medical training.

Key Players

CAE, Inc. (Canada)

Laerdal Medical (Norway)

3D Systems, Inc. (United States)

Simulab Corporation (United States)

Limbs & Things Ltd (United Kingdom)

Simulaids (United Kingdom)

Kyoto Kagaku Co., Ltd (Japan)

Gaumard Scientific (United States)

Mentice (Sweden)

Surgical Science Sweden AB (Sweden)

Intelligent Ultrasound (United Kingdom)

Operative Experience, Inc. (United States)

Cardionics, Inc. (United States)

VirtaMed AG (Switzerland)

SYNBONE AG (Switzerland)

IngMar Medical (United States)

TruCorp (Ireland)

Key Highlights

Patient Safety Focus: A heightened emphasis on patient safety and the reduction of medical errors is propelling the adoption of simulation-based training.

Technological Advancements: Innovations such as virtual reality (VR) and augmented reality (AR) are enhancing the realism and effectiveness of medical simulations.

Educational Integration: Medical institutions are increasingly incorporating simulation-based curricula to provide hands-on experience in a controlled environment.

Government Support: Various government initiatives and funding are facilitating the development and implementation of simulation technologies in healthcare education.

Future Outlook

The future of the healthcare/medical simulation market looks promising, with continuous technological advancements paving the way for more immersive and effective training solutions. The integration of artificial intelligence (AI) and machine learning (ML) is expected to further enhance simulation capabilities, providing personalized learning experiences and real-time feedback. As the global healthcare landscape evolves, simulation-based training will play a crucial role in preparing healthcare professionals to deliver safe and effective patient care.

Conclusion

The healthcare/medical simulation market is on a robust growth trajectory, driven by the need for improved patient safety, technological innovations, and supportive government initiatives. As the industry continues to evolve, simulation-based training will remain integral to medical education and professional development, ultimately contributing to better healthcare outcomes worldwide.

Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Other Related Reports:

Pharmacy Benefit Management Market