#3D Printed Electronics Market

Explore tagged Tumblr posts

Text

#3D Printed Electronics Market Size#3D Printed Electronics Market Trends#3D Printed Electronics Market Forecast

0 notes

Text

Automotive 3D Printing Market - Forecast(2024 - 2030)

Automotive 3D Printing Market Overview

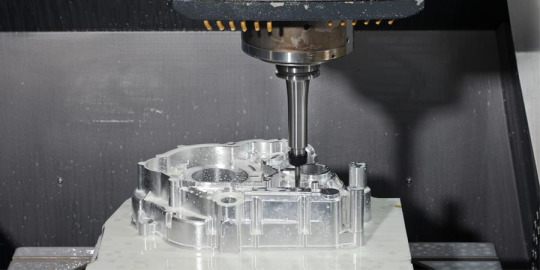

Automotive 3D printing market is expected to reach $1.8 billion by 2026 at a CAGR of 11.1% during the forecast period 2021-2026, owing to increasing research and development activities and innovations which is strengthening the automotive industry worldwide. Similarly, with a huge capital investment in automotive technology, several manufacturers are focusing on light weight vehicles to decrease the fuel consumption and low emission. Among all the R&D activities, 3D printing in automotive has come up with a rapid pace and gaining attention in the global automotive industry for rapid prototyping. According to the Chinese Passenger Car Association (CPCA), demand for electric car is growing progressively. This is due to the rising development of lightweight automobile parts utilizing 3D automobile printing technologies. The Chinese Government has rendered the development of additive manufacturing technologies a priority in the region. International companies are urged to create subsidiaries, although some domestic companies are also driven by government policies. Collaboration with other industry leader companies to incorporate various technology such as stereo lithography, selectrive laser sintering and digital light processing into their manufacturing process and create innovative product innovations would help them achieve strategic edge over their competitors.

Automotive 3D Printing Market Report Coverage

The report: “Automotive 3D Printing Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Automotive 3D Printing market

By Material: Metals, Polymer, Others (Ceramic and Glass) By Technology: Stereolithography, Selective Laser Sintering, Electron Beam Melting (EBM), Fused Disposition Modeling, Laminated Object Manufacturing, Three Dimensional Inject Printing, Others By Application: Prototyping & Tooling, Manufacturing Complex Components, Research, Development & Innovation, Others By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa)

Request Sample

Key Takeaways

Automotive 3D printing in North America is growing at significant rate owing to the stringent governmental regulations regarding automobiles and auto parts are regulated through the National Highway Traffic Safety Administration (NHTSA) and the U.S Environmental Protection Agency (EPA).

The exceptional growth prospects of the electric vehicles market is a major growth factor for the 3D printing automotive market owing to its importance in electric vehicles.

The automotive OEMs are partnering with the leading 3D printing companies like Stratatsys, Shining 3D, SLM Solutions are largely concentrating on the technologies like stereo lithography, fused deposition modeling, and Laser sintering.

Automotive 3D Printing top 10 companies include Stratasys Inc., 3D System, Materialise NV, Renishaw PLC, SLM Solutions, ExOne, Envisiontec Inc., EOS, Arcam AB, Autodesk, Inc., among others.

Automotive 3D Printing Market Segment Analysis - By Application

Manufacturing complex components is growing at a highest CAGR of 12.1% in the forecast period. Complex components with internal cavities require multiple subcomponents held together by a variety of processes in the standard subtractive manufacturing process. As 3D printing is in nature an additive, it can create identical parts as single objects, allowing for less inspections and improved efficiency in the workflow. With Additive Manufacturing, designs with complex geometries only distribute build material where conformity with automotive performance standards is strategically necessary. 3D-printed pieces often weigh less than half of the weight of their cast or machined counterparts. A single click away from the mouse dramatically attenuates the design process with on-the-fly alterations. Moreover, early adopters used one-of-a-kind printed prototypes for wind tunnel testing in the automotive industry. In addition additive Manufacturing processes provide cost-effective alternatives to traditional automotive component manufacturing, especially complex and unique parts. Further additive manufacturing helps companies to create complex designs that require fewer parts for these components to be produced. As a result, companies may reduce the assembly time and also experience a decrease in quality problems. Delphi, an Irish tier 1 supplier to the automotive industry, used a metal 3D printing method known as Selective Laser Melting to produce a single piece aluminium diesel pump. With this, the company achieved a remarkable reduction in the number of parts available for the pump, thereby avoiding a few post-processing steps and simplifying the assembly process. The end result was a finished product of higher quality as it reduced the low-time fluid and is less vulnerable to leakage, with lower manufacturing costs. Hence these factors are analysed to drive the market in the forecast period 2020-2025.

Inquiry Before Buying

Automotive 3D Printing Market Segment Analysis - By Technology

Selective Laser Sintering (SLS) in automotive 3D Printing is growing at a CAGR of 13.5% in the forecast period. Selective Laser Sintering is an additive manufacturing or 3d printing technology that can be used for processing many types of materials such as polymers, metals, ceramics, and composites to create complex parts. It's areas of applications include automotive, aerospace tooling, biomedical as well as architecture. In addition SLS technology based 3d printing��helps in building much stronger and durable prototypes than other technologies, thus causing its demands over applications ranging from low volume production to rapid prototyping of automotive parts and components. Such factors have been helping this technology towards boosting its growth in the 3d printing automotive market in the forecast period. Moreover, this technology has been considered to be one of the fastest as well as widely used 3d printing process due to it scalability of printing multiple automotive parts simultaneously, thus maximizing the build space for the auto manufacturers. Due to this, auto manufacturers are able to build high amount of parts and fixtures within less time intervals, thus boosting their productivity standards. Since this technology has been helping in reducing additional costs for automakers, many major automotive companies have been highly shifting towards adopting selective laser sintering 3d printing for building vehicle parts more easily along with cost efficiency. As a part of this, recently FAW-Volkswagen Automotive Co. Ltd, a joint venture between FAW Group, Volkswagen and Audi revealed about producing prototypes for more than 5,000 parts a year deploying laser sintering technology. Further deployment of 3d printing technology across the automotive industry helped in reducing the overhead operational costs along with speeding up the design iteration process, thus driving its demands in the automotive sector in the forecast period 2021-2026.

Automotive 3D Printing Market Segment Analysis- By Geography

Automotive 3D printing in North America is growing at significant rate of 12.2% CAGR through 2026 owing to the stringent governmental regulations regarding automobiles and auto parts are regulated through the National Highway Traffic Safety Administration (NHTSA) and the U.S Environmental Protection Agency (EPA). Such regulations are related to improve the vehicle safety standards as well as reduce the vehicle emissions. Such factors have been creating high deployments of electric vehicles in the country, in order to comply with such laws, thereby boosting the market growth of 3d printing technology. Moreover, rising growth of automobiles has caused the various automakers to shift towards advanced technologies in order to increase mass production of vehicles more efficiently within lesser time intervals along with reducing fuel consumption. As a part of this, one of the major U.S auto manufacturer, General Motors had invested in Autodesk’s software with 3d printing in effort to produce lighter vehicle parts through mass reduction and parts consolidation. Deploying of such lighter auto parts eventually helps in cutting the high fuel consumption costs for the customers, thus driving the automobiles demands. Such initiatives have been helping in boosting the growth of 3d printing in automotive market in the forecast period 2021-2026.

Schedule a Call

Automotive 3D Printing Market Drivers

Impressive Growth of Electric Vehicles

The market for electric vehicles is growing all across the globe, however, the electric vehicle market growth in China is quite significant. The exceptional growth prospects of the electric vehicles market is a major growth factor for the 3D printing automotive market owing to its growing importance in electric vehicles. 3D printing is seen as a solution by the OEMs in the global market. The automotive OEMs are partnering with the leading 3D printing companies like Stratatsys, Shining 3D, SLM Solutions are largely concentrating on the technologies like stereo lithography, fused deposition modeling, and Laser sintering. These technologies have high experience on the creating cost effective and composite parts that aid to improve the efficiency of the vehicles.

Growing Investments in 3D printing or additive manufacturing

Global 3D Printing Automotive Market is gaining traction due to the huge funds towards research and development of manufacturing technologies and materials. New manufacturing processes are being deployed to satisfy the increasing demand of consumers. The automotive companies are poised to lead the technological transformation in manufacturing. In April 2018, BMW invested $12m in a new additive manufacturing campus, Located Munich, Germany. BMW states that it is already using additive manufacturing to make prototype components in Shenyang (China) and Rayong (Thailand). Going forward, it plans to integrate additive manufacturing more fully into the local production structure of China and allow small production runs for customizable components. The HP and Guangdong companies have disclosed a new production-grade Additive Manufacturing centre in Dali, Foshan China. The venture in 10 HP Multi Jet Fusion 3D printing systems and is HP’s largest deployment of production-grade 3D printing in the Asia Pacific. Chinese State-Owned Enterprises (SOE) and Privately Owned Enterprises (POEs) together have planned to operate in China by establishing joint ventures involving foreign. The JVs in particular have an advantage in leveraging their global platform in creating vehicles, particularly for the Chinese market.

Buy Now

Automotive 3D Printing Market Challenges

Low speed Production

Additive manufacturing is facing speed of production challenges, which limits mass production potential. Advances are being made in additive manufacturing processes such that companies can create reliably unique parts and mass produce them and create custom parts for individual markets. The additive manufacturing technique is a game changer in industries where higher production costs are outweighed by the additional value generated by the manufacturing technique. However, the automotive industry is a high volume industry that requires great production speeds to make profits. The low production speeds of the additive manufacturing technique is seen a major impediment for wider adoption of the manufacturing technique in the automotive industry. In an attempt to tackle this challenge, high speed additive manufacturing has become an important area of research.

Automotive 3D Printing Market Landscape

Technology launches, acquisitions, Expansions, Partnerships and R&D activities are key strategies adopted by players in the automotive 3D printing market. In 2019, the market of automotive 3D printing industry outlook has been fragmented by several companies. Automotive 3D Printing top 10 companies include Stratasys Inc., 3D System, Materialise NV, Renishaw PLC, SLM Solutions, ExOne, Envisiontec Inc., EOS, Arcam AB, Autodesk, Inc., among others.

Acquisitions/Technology Launches

In 2020 Rimac launched the Rimac Design Challenge. The winning design was the Rimac Scalatan, a spectacular concept by Max Schneider which offered a unique window into what our world and the transport industry could look like in 2080. The car comes with an aerodynamic carbon-nanotube graphene outer surface that sits on top of a generative-design chassis made from 3D printed titanium graphite.

In June 2019, In order to make the benefit of advertised fuels available to widely valued consumers around the world, HPCL has figured out the solution by offering aftermarket fuel performance enhancing additives in compact small pouches. Vinner Petrol Plus and Vinner Diesel Plus will be available on the market in different sizes of pouches.

#Automotive 3D Printing Market#Stereolithography#Automotive 3D Printing Market size#Electron Beam Melting#Automotive 3D Printing industry#Automotive 3D Printing Market share#Automotive 3D Printing top 10 companies#Automotive 3D Printing Market report#Automotive 3D Printing industry outlook

0 notes

Text

3D Printing in Electronics Market Gaining Momentum with Positive External Factors

Advance Market Analytics published a new research publication on "3D Printing in Electronics Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the 3D Printing in Electronics market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of This Research @ https://www.advancemarketanalytics.com/sample-report/3314-global-market-3d-printing-in-electronics The 3D Printing in Electronics Market report covers extensive analysis of the key market players, along with their business overview, expansion plans, and strategies. The key players studied in the report include: 3d systems [United States], arcam [Sweden], exone [United States], stratasys [United States], autodesk [United States], eos [Germany], envisiontec [Germany], graphene 3d lab [United States], materialise [Belgium], optomec [United States], voxeljet [Germany]. Definition: The use of 3D printing technology in electronics has revolutionized the electronic industry by minimizing the waste. One of the key benefits of incorporation of this technology is its ability to create small scale components which has greatly benefited the production process. The growing adoption of 3D technology in electronics creates huge potential as it could lead to new medical treatments to cure wound. The following fragment talks about the 3D Printing in Electronics market types, applications, End-Users, Deployment model etc. A thorough analysis of 3D Printing in Electronics Market Segmentation: by Type (3d printers, Materials, Services), Application (Consumer electronics, Automotive, Aerospace, Industrial, Others) 3D Printing in Electronics Market Drivers:

Ability to Create Small-scale Components

Growing Need for Light Weight and Circuit Less Electronic Components

3D Printing in Electronics Market Trends:

Rising Need for Customized 3D Printing Electronics

Growing Use in Touch Devices and Smart Display

3D Printing in Electronics Market Growth Opportunities:

Increasing Focus Towards Minimizing Waste in Production Process

Technological Advancement Leading to Rising Demand of 3D Printing Technology in Electronics

As the 3D Printing in Electronics market is becoming increasingly competitive, it has become imperative for businesses to keep a constant watch on their competitor strategies and other changing trends in the 3D Printing in Electronics market. Scope of 3D Printing in Electronics market intelligence has proliferated to include comprehensive analysis and analytics that can help revamp business models and projections to suit current business requirements. We help our customers settle on more intelligent choices to accomplish quick business development. Our strength lies in the unbeaten diversity of our global market research teams, innovative research methodologies, and unique perspective that merge seamlessly to offer customized solutions for your every business requirement. Have Any Questions Regarding Global 3D Printing in Electronics Market Report, Ask Our Experts@ https://www.advancemarketanalytics.com/enquiry-before-buy/3314-global-market-3d-printing-in-electronics Strategic Points Covered in Table of Content of Global 3D Printing in Electronics Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the 3D Printing in Electronics market

Chapter 2: Exclusive Summary and the basic information of the 3D Printing in Electronics Market.

Chapter 3: Displaying the Market Dynamics- Drivers, Trends and Challenges & Opportunities of the 3D Printing in Electronics

Chapter 4: Presenting the 3D Printing in Electronics Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2018-2022

Chapter 6: Evaluating the leading manufacturers of the 3D Printing in Electronics market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2023-2028)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, 3D Printing in Electronics Market is a valuable source of guidance for individuals and companies. Read Detailed Index of full Research Study at @ https://www.advancemarketanalytics.com/reports/3314-global-market-3d-printing-in-electronics What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia. Contact US : Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global 3D Printing in Electronics Market#3D Printing in Electronics Market Demand#3D Printing in Electronics Market Trends#3D Printing in Electronics Market Analysis#3D Printing in Electronics Market Growth#3D Printing in Electronics Market Share#3D Printing in Electronics Market Forecast#3D Printing in Electronics Market Challenges

0 notes

Text

Global 3D Printed Electronics Market Size, Share, Growth Analysis, By Printing Technology(Inkjet Printing Screen Printing, Gravure Printing), By Material(Ink, Polymer)

Global 3D Printed Electronics Market Insights

Global 3D Printed Electronics Market size was valued at USD 10.6 billion in 2021 and is poised to grow from USD 12.22 billion in 2022 to USD 38.2 billion by 2030, growing at a CAGR of 15.31% in the forecast period (2023-2030).

3D printed electronics is a new program that allows electronics to be integrated into or on top of devices. The concept of 3D printing has been widely applied to the exterior of 3D injection molded synthetic objects to add antennas and simple conductive interconnects. With technological advancements in the 3D printed electronics business, new techniques can be used to create materials and processes to create sophisticated circuitry inside parts. Customization can be a valuable advantage in the development of fully formed additive manufacturing parts for circuit boards or any computerized device. The demand for small, thin devices with advanced capabilities is insatiable. However, difficult tasks such as designing a PCB or printed circuit board and its components are usually outsourced, resulting in longer waiting times. With the introduction of 3D printing, it is now possible to create in-house prototypes of circuits and circuit boards, reducing cost, time, and concerns about intellectual property infringement. Improved efficiency and productivity of manufacturers, as well as lower material costs, are expected to drive the global 3D printed electronics market during the forecast period.

Increased production of products with reduced weight, ease of use, and improved technology in manufacturing electrical components, all benefit the market. Increased production of antenna and sensor printing in 3D form stimulates the market. The rapid adoption of newly developed technologies in many sectors, as well as increasing consumer demand in industries such as the health sector, defence, telecommunication, automobile industry, electrification system, power utility, aerospace, and many others. The market is expected to flourish with the increased competition due to new arrivals and the availability of increased performance. Rising market participants and increased investment in the electronics and automobile industries have boosted market rates. However, the cost of new equipment and material for printed electronics are high, may this factor hamper market growth.

Global 3D Printed Electronics Market Segmental Analysis

Global 3D printed electronics market is segmented on the basis of printing technology, material and region. On the basis of printing technology, global 3D Printed Electronics Market is segmented into inkjet printing, screen printing, gravure printing, and flexographic printing. On the basis of material, global 3D Printed Electronics Market is segmented into ink, polymer, paper and glass. On the basis of region, global 3D Printed Electronics Market is divided into North America, Europe, Asia Pacific, Latin America, and MEA.

3D Printed Electronics Market Analysis by Printing Technology

On the basis of printing technology, global 3D printed electronics market is segmented into inkjet printing, screen printing, gravure printing, and flexographic printing. The inkjet segment accounted for a significant share of the revenue in the global market. The rapidly increasing adoption of this unique and advanced technology is fuelling the rapid growth of this segment. Inkjet printers are adjustable and versatile and easy to set up. Inkjet printers have a low throughput of about 100 m2/h and low resolution (about 50 m). It works well with soluble, low-viscosity materials such as organic semiconductors. High-viscosity materials, such as organic dielectrics, and dispersed particles, such as inorganic metal inks can cause nozzle obstruction. The thickness and uniformity of the dispersion decrease as the ink is applied in droplets. Using multiple nozzles simultaneously and pre-forming the substrate can improve productivity and resolution.

3D Printed Electronics Market Analysis by Material

On the basis of material, global 3D printed electronics market is segmented into ink, polymer, paper and glass. The ink materials segment accounted for the largest revenue share in the printed electronics market. The increasing growth of this segment is due to the rapid market acceptance of this substance. The increasing adoption of printed electronics technology has allowed the widespread use of inks in a wide range of applications in many fields. Also, inks are becoming more readily available in the market, making them more accessible to buyers.

0 notes

Text

Hobby Ideas 🎨💻🎵🧁🪴

💰 Hobbies to Make Money:

Freelance Writing

Photography

Graphic Design

Web Development

Online Selling (e.g., Etsy, Amazon, eBay, Shopify)

Blogging

Stock Trading

Real Estate Investing

Affiliate Marketing

Freelance Consulting

💪 Fitness Hobbies:

Running

Yoga

Weightlifting

Cycling

Swimming

Martial Arts

CrossFit

Hiking

Rock Climbing

Dance (e.g., Zumba, Hip-hop)

☀️ Outdoor Hobbies:

Camping

Fishing

Birdwatching

Gardening

Geocaching

Kayaking

Mountain Biking

Backpacking

Stargazing

Horseback Riding

💻 Technology Hobbies:

Programming

Robotics

3D Printing

Virtual Reality (VR) Gaming

Home Automation

Drone Flying

Cybersecurity

App Development

Electronics DIY

PC Building

🎵 Music Hobbies:

Playing an Instrument (e.g., Guitar, Piano)

Singing

DJing

Music Production

Songwriting

Music Recording

Karaoke

Music Theory

Joining a Band or Choir

Vinyl Collecting

📚 Brainy Hobbies:

Chess

Sudoku

Crossword Puzzles

Board Games

Reading

Learning a New Language

Brain Teasers

Logic Puzzles

Math and Mathematical Puzzles

Astronomy

✨ Other Hobbies:

Cooking and Baking

Painting and Drawing

Pottery and Ceramics

Woodworking

Knitting or Crocheting

DIY Home Improvement

Model Building (e.g., model trains, airplanes)

Collecting (e.g., stamps, coins, vintage items)

Volunteer Work

Meditation and Mindfulness

#hobbies#creative#creative inspiration#inspiration#creativity#creating#learning#skills#life skills#advice#life advice

738 notes

·

View notes

Text

Sony Aibo on Science et Vie Micro Issue 179 (02-2000)

Translation in English:

Japanese convergence

Twice this year, Sony has marketed its robotic Aibo, a luxurious toy for spoiled children. But the beast could soon change its vocation.

In two, even three years, Aibo, man's best cybernetic friend, could make friends with the Playstation 2! If, currently, the Aibo mainly resembles a gadget for privileged wealthy people, and which we tire of relatively quickly, Sony has other ambitions for future models. His project, in addition to a more affordable price, aims to develop an interface that would allow you to connect your Aibo to another of its great successes: its Playstation game console. Rather clever: with nearly 40% of Sony's profits in 1998 coming from the division which takes care of the video games activity (SCE), the Playstation has become a major business for the Japanese electronics giant.

Aibo on Playstation The Playstation 2 is announced commercially in Japan from March. This new version of the first game console is already making many people dream: not only does it have exceptional computing power, but it is also equipped with sophisticated connectivity. The public's reception promises to be enthusiastic, so this should make it the ideal platform for the Aibo! The latter currently uses an 8 or 32 MB Memory Stick to store its programmed behaviors. Thanks to a remote control which emits sound signals, it is possible to transmit a few simple orders. The next generations should of course go further. Among other things, it would be possible to download a program or a series of instructions created on Playstation 2 directly into the beast.

A multitude of possible applications can be envisaged. For example, an introduction to programming, inspired by the Logo language for children: but instead of moving a "turtle" in the two-dimensional space of a computer screen, it would be the robot that would follow the programmed path.

Another possible application: a "player" could program a route or a mission (forbidding "intruders" from his room, checking the presence in a given place of a person whose "visual signature" or "voice print" the Aibo knows), or even a joust with a friend's Aibo (race, jumping competition or other free figures…). All this could even be accomplished via a virtual Aibo that you move around with the joystick like in some kind of video game, rather than entering lines of code or macros. Once the room had been simply modeled in 3D using primitives (cubes, cylinders, etc.), the virtual robot would then have to be moved around this 3D world, an exact copy of the house, before the Aibo could actually perform the maneuver.

Meet with aibo on: www.world.sony.com/aibo/index.html

85 notes

·

View notes

Text

youtube

The Staggering Cost of Losing Europe's Arms Market (and trust) | Part 3: Drones!

Over the last few weeks, we’ve showcased Europe’s cutting-edge military capabilities—from tanks, GMLRS, fighter jets, IFVs, APCs, and air defence systems. In this episode, we shift our focus to one of the most rapidly evolving aspects of modern warfare: drones, anti-drone technology, electronic warfare, and satellite capabilities. Segment 1: Fixed-Wing Drones European manufacturers are redefining endurance and versatility on the battlefield. In this segment, we explore flagship projects like the Eurodrone program and highlight combat-proven systems such as the Slovenian-made C-astral, Danish Heidrun from Sky Watch, Tekever’s long-endurance platforms, and the Dutch DeltaQuad Evo and Pro. These drones—engineered for extended ISR missions with high-resolution sensors and modular payloads—are transforming how surveillance and precision strikes are executed. Segment 2: FPV Drones & Loitering Munitions Next, we delve into the world of FPV drones and loitering munitions. From innovative designs like Lithuania’s Sphak and Finland’s Steel Eagle to mass-produced 3D-printed variants like Goida, Bavovna, and Nort Varta, these agile platforms are proving indispensable in Ukraine. We also look at European loitering munitions, including Poland’s Warmate, KNDS’s Colibri, and other emerging systems that offer affordability and scalability in dynamic combat scenarios. Segment 3: European Counter-Drone Measures As drone technology advances, so does the need for effective countermeasures. We break down how European defence industries are developing sophisticated electronic warfare capabilities—like Italian ELT’s scramblers and Sweden’s Saab Sirius system—to jam, disrupt, and neutralize hostile drones. We also examine kinetic solutions from Rheinmetall and Poland’s Pilica system, as well as experimental laser-based directed energy weapons and advanced autonomous combat drones from Turkey and collaborative projects like Eurodrone and BAE’s Taranis. Segment 4: The Bigger Picture What does all this mean for European defence? The integration of cutting-edge drone systems with robust counter-drone measures signals a major strategic shift. By developing home-grown, scalable solutions, Europe is not only enhancing its offensive and defensive capabilities but also setting new benchmarks in military innovation and strategic autonomy.

#EU#made in europe#strategic autonomy#drone#MEDA#indigenous defense industry#defense of europe#NATO#Youtube

4 notes

·

View notes

Text

BN-U13 Mech Droid

I finally have a 3D printer thanks to an Anycubic sale, and I started a small project to try it out and work out my calibrations and learn the process of printing a bit. The little droid in the middle is BN-U13, or Bunny, intended as 1/12 scale because I live there, and also because Star Wars Black Series uses this scale.

BN-U13 is an inexpensive little mech droid intended as a competitor's cheap but familiar alternative to the ubiquitous R-series astromech droids. (If dust farmers are buying military-grade astromech droids secondhand for maintenance work, there's clearly a market for it.) Bunny can't calculate hyperspace jump coordinates, but she is programmed with repair manuals for over 1100 models of load-lifter alone. And while she doesn't carry the wide variety of built-in tools common in astromechs, she comes complete with a retractable manipulator arm, scomp link (not articulated on my figure), and a convenient carry case sleep mode. Modeled here by Tajador for some reason.

The design draws of course from droids like the DUM pit droids, BD-1, D-O, and the R-series astromech droids in general, but also some elements of an oscilloscope, a couple of grills, and a handful of other mechanical references. I like to think that the rear legs evoke office chair casters.

Bunny's printable model is available for download at Cults 3D. If you print one yourself, I'd be overjoyed to hear about it!

Free OBJ file BN-U13 Mech Droid Star Wars fan design 🤖 ・3D printer model to download・Cults (cults3d.com)

Thanks as always to @aprilpowered and Workbenchmaniac for their help along the way with this design. April's familiarity with the Star Wars galaxy and WebM's experience with resin printing in particular averted what could have otherwise only been certain disaster. April even suggested the carry handle for that classic luggable electronics flavor.

10 notes

·

View notes

Text

The Role of Industrial Gases in Modern Industries: Driving Efficiency and Innovation

From the food we eat to the technology we use daily, industrial gases play an essential yet often unnoticed role in modern life. These gases, including oxygen, nitrogen, hydrogen, and carbon dioxide, are the backbone of many industries, helping to improve efficiency, safety, and sustainability. Whether in manufacturing, healthcare, or energy, industrial gases drive innovation and make processes more efficient. Let’s explore how these gases are transforming industries worldwide.

The Silent Powerhouses: Industrial Gases at Work

Industrial gases are more than just elements in a cylinder—they are critical enablers of progress across multiple sectors. For example, oxygen is vital in healthcare, supporting life-saving treatments and surgeries. Nitrogen, widely used in the food industry, helps preserve freshness by preventing oxidation. Meanwhile, hydrogen is emerging as a key player in clean energy, fueling the push towards a sustainable future.

Revolutionizing Manufacturing and Beyond

Manufacturing and metal production rely heavily on industrial gases. In the steel industry, oxygen is used to refine and cut metals, while argon ensures the purity of molten steel. The electronics sector benefits from ultra-high-purity gases used in semiconductor manufacturing, ensuring the reliability of devices we use every day. The role of industrial gases in welding, laser cutting, and 3D printing continues to expand, driving efficiency and precision in modern manufacturing.

Sustainability and the Green Transition

As industries worldwide focus on reducing carbon footprints, industrial gases are stepping up as sustainability champions. Carbon dioxide capture and utilization are helping reduce greenhouse gas emissions in industries like power generation and cement manufacturing. Hydrogen, a clean and renewable energy source, is paving the way for the future of transportation and energy storage, supporting the transition to a low-carbon economy.

Healthcare and Safety: A Critical Contribution

Beyond industry, industrial gases are crucial in healthcare. Medical oxygen remains a life-saving necessity in hospitals, particularly in critical care and respiratory therapy. Nitrous oxide, commonly known as “laughing gas,” is used for pain relief in medical and dental procedures. Even in pharmaceuticals, nitrogen and other gases help maintain sterile environments for drug manufacturing, ensuring product safety and efficacy.

Looking Ahead: The Future of Industrial Gases

With ongoing advancements in technology and sustainability, the industrial gases market is poised for significant growth. Innovations such as hydrogen-powered transportation, carbon capture technology, and improved gas storage solutions will shape the future of multiple industries. As businesses prioritize efficiency and sustainability, industrial gases will remain indispensable, quietly powering the world around us.

To know more download PDF Brochure :

Industrial gases may not always be in the spotlight, but their impact is undeniable. Whether preserving food, enabling medical breakthroughs, or driving clean energy solutions, these invisible powerhouses continue to shape the modern world.

#industrial gases#gas industry#manufacturing#energy#sustainability#hydrogen economy#carbon capture#healthcare#chemical processing#smart manufacturing#industrial innovation#gas technology#green energy#industrial applications#market trends

2 notes

·

View notes

Text

How Plastic Fabrication Can Benefit Your Business

Plastic fabrication is a process that turns raw plastic materials into useful products for various industries. Whether it’s for prototyping, custom designs, or creating complex components, plastic fabrication offers a wide range of benefits to businesses of all sizes. This article will explore how this versatile method can help elevate your business operations.

Streamlined Production and Customization

One of the most significant advantages of plastic fabrication is its ability to streamline production. With advanced technologies such as CNC machining, laser cutting, and 3D printing, businesses can manufacture precise and complex plastic parts with minimal effort. This reduces the need for additional labor or lengthy production timelines.

Customization is also a key benefit of plastic fabrication. Unlike traditional mass production methods, plastic fabrication allows companies to create customized products that meet their specific needs. Whether you’re creating unique prototypes or designing parts for specific machinery, the ability to customize products ensures your business stands out in a competitive market.

For instance, industries like automotive, aerospace, and healthcare often rely on tailored plastic components to fit specific equipment requirements. By working with a reliable plastic fabrication company, you can ensure that your custom needs are met with high precision and quality.

Cost-Effective Manufacturing

Another benefit of plastic fabrication is its cost-effectiveness, especially for small to medium-sized businesses. Traditional manufacturing methods, such as metal fabrication, can be expensive due to the high costs of raw materials and production processes. In contrast, plastic materials tend to be more affordable and versatile, making it a great choice for businesses looking to save money while still producing high-quality products.

Additionally, plastic fabrication offers long-term savings due to the durability and longevity of the materials used. Many plastic materials are resistant to corrosion, weathering, and wear, ensuring that your products will last longer, reducing the need for frequent replacements.

Versatility Across Industries

Plastic fabrication is incredibly versatile and can be used across numerous industries. Whether you’re in the medical, electronics, packaging, or construction industries, plastic parts and components are essential to your business operations.

For example, in the medical field, plastic fabrication is used to create sterile surgical instruments, medical devices, and protective barriers. In electronics, plastic enclosures are often used to protect sensitive equipment from environmental damage. In packaging, plastic containers and wraps are designed to securely hold products for transportation and sale.

This adaptability makes plastic fabrication an invaluable tool for various businesses. No matter the sector, the ability to produce customized and durable plastic components will always offer a significant competitive edge.

Finding the Right Plastic Fabrication Partner

Finding the right plastic fabrication company is crucial to ensuring that your products meet high standards of quality and precision. Partnering with an experienced and reliable fabricator can make the difference between a successful project and costly errors. To locate the right professional for your needs, it’s essential to consider their experience, reputation, and ability to work with your desired materials.

If you’re looking for a plastic fabrication company near me, you’ll likely find many local professionals who can meet your requirements. Make sure to check reviews and ask for samples of previous work to ensure they can deliver the quality and service you expect. A trusted local fabricator can help you avoid the logistical challenges of long-distance shipping and offer faster turnaround times for your projects.

Plastic fabrication offers numerous benefits for businesses, including cost savings, customization, versatility, and efficiency. By partnering with a professional plastic fabrication company, you can enhance your product development process and ensure your business stays competitive in the marketplace. Whether you’re looking for precision parts, durable products, or customized designs, plastic fabrication is a smart choice for any growing business.

2 notes

·

View notes

Text

#3D Printed Electronics Market Share#3D Printed Electronics Market Analysis#3D Printed Electronics Market Overview

0 notes

Text

Automotive 3D Printing Market - Forecast(2024 - 2030)

Automotive 3D Printing Market Overview

Automotive 3D printing market is expected to reach $1.8 billion by 2026 at a CAGR of 11.1% during the forecast period 2021-2026, owing to increasing research and development activities and innovations which is strengthening the automotive industry worldwide. Similarly, with a huge capital investment in automotive technology, several manufacturers are focusing on light weight vehicles to decrease the fuel consumption and low emission. Among all the R&D activities, 3D printing in automotive has come up with a rapid pace and gaining attention in the global automotive industry for rapid prototyping. According to the Chinese Passenger Car Association (CPCA), demand for electric car is growing progressively. This is due to the rising development of lightweight automobile parts utilizing 3D automobile printing technologies. The Chinese Government has rendered the development of additive manufacturing technologies a priority in the region. International companies are urged to create subsidiaries, although some domestic companies are also driven by government policies. Collaboration with other industry leader companies to incorporate various technology such as stereo lithography, selectrive laser sintering and digital light processing into their manufacturing process and create innovative product innovations would help them achieve strategic edge over their competitors.

Automotive 3D Printing Market Report Coverage

The report: “Automotive 3D Printing Market – Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Automotive 3D Printing market

By Material: Metals, Polymer, Others (Ceramic and Glass) By Technology: Stereolithography, Selective Laser Sintering, Electron Beam Melting (EBM), Fused Disposition Modeling, Laminated Object Manufacturing, Three Dimensional Inject Printing, Others By Application: Prototyping & Tooling, Manufacturing Complex Components, Research, Development & Innovation, Others By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa)

Request Sample

Key Takeaways

Automotive 3D printing in North America is growing at significant rate owing to the stringent governmental regulations regarding automobiles and auto parts are regulated through the National Highway Traffic Safety Administration (NHTSA) and the U.S Environmental Protection Agency (EPA).

The exceptional growth prospects of the electric vehicles market is a major growth factor for the 3D printing automotive market owing to its importance in electric vehicles.

The automotive OEMs are partnering with the leading 3D printing companies like Stratatsys, Shining 3D, SLM Solutions are largely concentrating on the technologies like stereo lithography, fused deposition modeling, and Laser sintering.

Automotive 3D Printing top 10 companies include Stratasys Inc., 3D System, Materialise NV, Renishaw PLC, SLM Solutions, ExOne, Envisiontec Inc., EOS, Arcam AB, Autodesk, Inc., among others.

Automotive 3D Printing Market Segment Analysis - By Application

Manufacturing complex components is growing at a highest CAGR of 12.1% in the forecast period. Complex components with internal cavities require multiple subcomponents held together by a variety of processes in the standard subtractive manufacturing process. As 3D printing is in nature an additive, it can create identical parts as single objects, allowing for less inspections and improved efficiency in the workflow. With Additive Manufacturing, designs with complex geometries only distribute build material where conformity with automotive performance standards is strategically necessary. 3D-printed pieces often weigh less than half of the weight of their cast or machined counterparts. A single click away from the mouse dramatically attenuates the design process with on-the-fly alterations. Moreover, early adopters used one-of-a-kind printed prototypes for wind tunnel testing in the automotive industry. In addition additive Manufacturing processes provide cost-effective alternatives to traditional automotive component manufacturing, especially complex and unique parts. Further additive manufacturing helps companies to create complex designs that require fewer parts for these components to be produced. As a result, companies may reduce the assembly time and also experience a decrease in quality problems. Delphi, an Irish tier 1 supplier to the automotive industry, used a metal 3D printing method known as Selective Laser Melting to produce a single piece aluminium diesel pump. With this, the company achieved a remarkable reduction in the number of parts available for the pump, thereby avoiding a few post-processing steps and simplifying the assembly process. The end result was a finished product of higher quality as it reduced the low-time fluid and is less vulnerable to leakage, with lower manufacturing costs. Hence these factors are analysed to drive the market in the forecast period 2020-2025.

Inquiry Before Buying

Automotive 3D Printing Market Segment Analysis - By Technology

Selective Laser Sintering (SLS) in automotive 3D Printing is growing at a CAGR of 13.5% in the forecast period. Selective Laser Sintering is an additive manufacturing or 3d printing technology that can be used for processing many types of materials such as polymers, metals, ceramics, and composites to create complex parts. It's areas of applications include automotive, aerospace tooling, biomedical as well as architecture. In addition SLS technology based 3d printing helps in building much stronger and durable prototypes than other technologies, thus causing its demands over applications ranging from low volume production to rapid prototyping of automotive parts and components. Such factors have been helping this technology towards boosting its growth in the 3d printing automotive market in the forecast period. Moreover, this technology has been considered to be one of the fastest as well as widely used 3d printing process due to it scalability of printing multiple automotive parts simultaneously, thus maximizing the build space for the auto manufacturers. Due to this, auto manufacturers are able to build high amount of parts and fixtures within less time intervals, thus boosting their productivity standards. Since this technology has been helping in reducing additional costs for automakers, many major automotive companies have been highly shifting towards adopting selective laser sintering 3d printing for building vehicle parts more easily along with cost efficiency. As a part of this, recently FAW-Volkswagen Automotive Co. Ltd, a joint venture between FAW Group, Volkswagen and Audi revealed about producing prototypes for more than 5,000 parts a year deploying laser sintering technology. Further deployment of 3d printing technology across the automotive industry helped in reducing the overhead operational costs along with speeding up the design iteration process, thus driving its demands in the automotive sector in the forecast period 2021-2026.

Automotive 3D Printing Market Segment Analysis- By Geography

Automotive 3D printing in North America is growing at significant rate of 12.2% CAGR through 2026 owing to the stringent governmental regulations regarding automobiles and auto parts are regulated through the National Highway Traffic Safety Administration (NHTSA) and the U.S Environmental Protection Agency (EPA). Such regulations are related to improve the vehicle safety standards as well as reduce the vehicle emissions. Such factors have been creating high deployments of electric vehicles in the country, in order to comply with such laws, thereby boosting the market growth of 3d printing technology. Moreover, rising growth of automobiles has caused the various automakers to shift towards advanced technologies in order to increase mass production of vehicles more efficiently within lesser time intervals along with reducing fuel consumption. As a part of this, one of the major U.S auto manufacturer, General Motors had invested in Autodesk’s software with 3d printing in effort to produce lighter vehicle parts through mass reduction and parts consolidation. Deploying of such lighter auto parts eventually helps in cutting the high fuel consumption costs for the customers, thus driving the automobiles demands. Such initiatives have been helping in boosting the growth of 3d printing in automotive market in the forecast period 2021-2026.

Schedule a Call

Automotive 3D Printing Market Drivers

Impressive Growth of Electric Vehicles

The market for electric vehicles is growing all across the globe, however, the electric vehicle market growth in China is quite significant. The exceptional growth prospects of the electric vehicles market is a major growth factor for the 3D printing automotive market owing to its growing importance in electric vehicles. 3D printing is seen as a solution by the OEMs in the global market. The automotive OEMs are partnering with the leading 3D printing companies like Stratatsys, Shining 3D, SLM Solutions are largely concentrating on the technologies like stereo lithography, fused deposition modeling, and Laser sintering. These technologies have high experience on the creating cost effective and composite parts that aid to improve the efficiency of the vehicles.

Growing Investments in 3D printing or additive manufacturing

Global 3D Printing Automotive Market is gaining traction due to the huge funds towards research and development of manufacturing technologies and materials. New manufacturing processes are being deployed to satisfy the increasing demand of consumers. The automotive companies are poised to lead the technological transformation in manufacturing. In April 2018, BMW invested $12m in a new additive manufacturing campus, Located Munich, Germany. BMW states that it is already using additive manufacturing to make prototype components in Shenyang (China) and Rayong (Thailand). Going forward, it plans to integrate additive manufacturing more fully into the local production structure of China and allow small production runs for customizable components. The HP and Guangdong companies have disclosed a new production-grade Additive Manufacturing centre in Dali, Foshan China. The venture in 10 HP Multi Jet Fusion 3D printing systems and is HP’s largest deployment of production-grade 3D printing in the Asia Pacific. Chinese State-Owned Enterprises (SOE) and Privately Owned Enterprises (POEs) together have planned to operate in China by establishing joint ventures involving foreign. The JVs in particular have an advantage in leveraging their global platform in creating vehicles, particularly for the Chinese market.

Automotive 3D Printing Market Challenges

Low speed Production

Additive manufacturing is facing speed of production challenges, which limits mass production potential. Advances are being made in additive manufacturing processes such that companies can create reliably unique parts and mass produce them and create custom parts for individual markets. The additive manufacturing technique is a game changer in industries where higher production costs are outweighed by the additional value generated by the manufacturing technique. However, the automotive industry is a high volume industry that requires great production speeds to make profits. The low production speeds of the additive manufacturing technique is seen a major impediment for wider adoption of the manufacturing technique in the automotive industry. In an attempt to tackle this challenge, high speed additive manufacturing has become an important area of research.

Buy Now

Automotive 3D Printing Market Landscape

Technology launches, acquisitions, Expansions, Partnerships and R&D activities are key strategies adopted by players in the automotive 3D printing market. In 2019, the market of automotive 3D printing industry outlook has been fragmented by several companies. Automotive 3D Printing top 10 companies include Stratasys Inc., 3D System, Materialise NV, Renishaw PLC, SLM Solutions, ExOne, Envisiontec Inc., EOS, Arcam AB, Autodesk, Inc., among others.

Acquisitions/Technology Launches

In 2020 Rimac launched the Rimac Design Challenge. The winning design was the Rimac Scalatan, a spectacular concept by Max Schneider which offered a unique window into what our world and the transport industry could look like in 2080. The car comes with an aerodynamic carbon-nanotube graphene outer surface that sits on top of a generative-design chassis made from 3D printed titanium graphite.

In June 2019, In order to make the benefit of advertised fuels available to widely valued consumers around the world, HPCL has figured out the solution by offering aftermarket fuel performance enhancing additives in compact small pouches. Vinner Petrol Plus and Vinner Diesel Plus will be available on the market in different sizes of pouches.

#Automotive 3D Printing Market#Stereolithography#Automotive 3D Printing Market size#Electron Beam Melting#Automotive 3D Printing industry#Automotive 3D Printing Market share#Automotive 3D Printing top 10 companies#Automotive 3D Printing Market report#Automotive 3D Printing industry outlook

0 notes

Text

Innovations in Textile Products: What Exporters Need to Know

The textile industry is undergoing a wave of transformation, fueled by innovation and technological advancements. As consumer preferences shift and the global market becomes more competitive, staying updated on the latest trends and innovations in textile products is essential for exporters. For textiles products exporters in Gujarat, keeping pace with these changes can offer a significant edge in the international market. In this blog, we will explore the most important innovations in textile products and discuss what exporters need to know to remain competitive, particularly for those aiming to be recognized as the best exporter in Gujarat or even among the top 10 textile products exporters in Gujarat.

Understanding the Role of Innovation in the Textile Industry

Innovation is the key to staying relevant in today’s textile market. With constant advancements in technology, sustainability practices, and production techniques, the textile industry has seen a profound transformation over the last decade. Exporters who embrace these innovations can offer products that not only meet global demand but also offer higher quality, durability, and sustainability, thus increasing their competitive advantage.

For textiles products exporters in Gujarat, leveraging these innovations is especially important given Gujarat's reputation as a textile hub. Known for its strong historical ties to the textile industry, Gujarat plays a leading role in India’s textile exports, contributing significantly to the country’s economic growth. Exporters here need to constantly evolve to maintain their position as leaders in the industry.

Key Innovations in the Textile Industry

1. Smart Textiles and Wearables

One of the most exciting developments in the textile industry is the rise of smart textiles, also known as e-textiles or electronic textiles. These are fabrics embedded with digital components such as sensors, LEDs, and batteries, offering added functionalities such as temperature regulation, moisture monitoring, and even health tracking.

For instance, there are textiles that can track the wearer’s heart rate, alert them of potential health issues, or adjust temperature depending on the environment. The demand for such smart fabrics is growing, especially in industries such as healthcare, fitness, and fashion. Textile products exporters in Gujarat who are looking to differentiate themselves in the international market should consider incorporating smart textile solutions into their product lines.

2. Sustainable Textiles

Sustainability is no longer just a trend; it is a necessity. Consumers across the globe are becoming increasingly eco-conscious, seeking products that are produced with minimal environmental impact. Sustainable textiles, including organic cotton, recycled polyester, and eco-friendly dyes, are gaining prominence.

India, and particularly Gujarat, is well-positioned to lead in this arena due to its vast agricultural resources and established textile infrastructure. Exporters who focus on sustainability can capitalize on this growing demand by offering products that are not only high in quality but also eco-friendly, making them the best exporter in Gujarat for green textiles.

3. 3D Printing in Textiles

3D printing has revolutionized various industries, and textiles are no exception. The ability to create complex designs and patterns without traditional weaving or knitting has opened up a world of possibilities. 3D printing allows for rapid prototyping, reducing waste, and enabling designers to experiment with unique shapes and forms that were previously impossible with conventional textile production techniques.

For top 10 textile products exporters in Gujarat, incorporating 3D-printed textiles can set them apart in international markets. From customized clothing to technical textiles, 3D printing offers a versatile solution that caters to both fashion and industrial sectors.

4. Nano-Textiles

Nanotechnology is another innovation that has made its way into the textile industry. Nano-textiles are fabrics that have been enhanced with nanoparticles to provide additional functionalities such as stain resistance, UV protection, and antimicrobial properties.

These textiles are particularly popular in the sports, healthcare, and outdoor sectors, where performance and durability are crucial. By embracing nano-textiles, textile products exporters in Gujarat can offer high-performance fabrics that cater to niche markets, thus expanding their customer base internationally.

5. Revolutionary Dyeing Techniques

Traditional dyeing processes often involve the use of toxic chemicals and large amounts of water, making them harmful to the environment. However, new, innovative dyeing techniques such as digital printing and waterless dyeing have revolutionized the industry. These methods use significantly less water and energy, while also allowing for more precise and vivid color reproduction.

For exporters aiming to be the best exporter in India, embracing such innovative dyeing processes can offer a distinct advantage. Offering textiles that are environmentally friendly, yet vibrant and high-quality, positions you as a leader in both innovation and sustainability.

6. Performance Fabrics

Performance fabrics, engineered to offer enhanced functionality like moisture-wicking, breathability, or thermal insulation, are in high demand across various sectors such as sports, military, and outdoor apparel. With advancements in fabric engineering, these materials can be designed to meet very specific needs.

For textiles products exporters in Gujarat, exporting performance fabrics can open up new markets and ensure higher profitability. By offering cutting-edge fabrics that cater to the growing demand for performance-based textiles, exporters can solidify their standing as leaders in innovation.

Why Innovation is Essential for Exporters

In a rapidly evolving global market, staying ahead of the competition requires constant innovation. For textiles products exporters in Gujarat, embracing these advancements can yield several key benefits:

1. Increased Competitiveness

Innovative products stand out in crowded markets. By offering unique, cutting-edge textiles, exporters can differentiate themselves from competitors and attract premium customers. This is especially important for exporters aiming to be among the top 10 textile products exporters in Gujarat.

2. Access to New Markets

Innovative textiles such as smart fabrics, sustainable textiles, and nano-textiles are in high demand in emerging markets such as healthcare, sports, and fashion. Exporters who incorporate these products into their offerings can access new customer segments, expanding their global reach.

3. Customer Loyalty

Consumers and businesses are increasingly drawn to companies that prioritize innovation and sustainability. Exporters who offer eco-friendly, high-performance textiles are more likely to build long-term relationships with customers, ensuring repeat business and brand loyalty.

4. Compliance with Global Standards

Many international markets have stringent standards regarding environmental impact and product performance. By incorporating innovative, sustainable practices into production, exporters can ensure compliance with these standards, making it easier to enter and succeed in global markets.

Entail Global: Leading the Charge in Textile Innovations

At Entail Global, we are proud to be one of the best exporters in Gujarat, offering a wide range of innovative textile products that meet the highest international standards. We understand that the textile industry is constantly evolving, and we are committed to staying ahead of the curve by embracing the latest innovations in the field.

Our portfolio includes smart textiles, sustainable fabrics, and performance-based materials, all produced using state-of-the-art technology and environmentally friendly practices. As one of the top 10 textile products exporters in Gujarat, we are dedicated to delivering exceptional quality to our global clients.

Why Choose Entail Global?

As the best exporter in India for textile products, we offer:

1. Innovation at the Core

We believe that innovation is the key to success. By continually investing in research and development, we ensure that our products reflect the latest advancements in textile technology.

2. Sustainability Focus

Our commitment to sustainability sets us apart from the competition. We use eco-friendly materials and processes, allowing our clients to offer products that align with today’s demand for greener solutions.

3. Global Expertise

With years of experience in exporting textile products across the globe, we understand the unique needs of different markets. Our expertise ensures smooth logistics and compliance with international standards, making us a reliable partner for businesses worldwide.

4. Customer-Centric Approach

At Entail Global, we prioritize our customers. Our dedicated team works closely with clients to understand their specific requirements, offering tailored solutions that meet their exact needs.

Conclusion

The textile industry is at the forefront of innovation, with advancements in smart textiles, sustainability, 3D printing, and nano-technology reshaping the market. For textiles products exporters in Gujarat, staying informed about these innovations and integrating them into product offerings is crucial for maintaining competitiveness on a global scale.

At Entail Global, we are proud to be leading the charge in textile innovation, offering cutting-edge products that meet the highest global standards. Whether you are looking for smart fabrics, sustainable textiles, or performance materials, we are your go-to partner in the world of textile exports.

Embrace innovation, choose Entail Global – the best exporter in Gujarat, and elevate your position in the global textile market!

#Best exporter in Gujarat#Best exporter in India#Textiles products exporters in Gujarat#Top 10 textile products exporter in Gujarat#India#business#import and export

5 notes

·

View notes

Text

LED Sign Acrylic Top Letter , LED Lighting , Neon Lights Box Led Sign , Outdoor Light , LED Display Board , Indoor Signage price in Bangladesh.

Explore online marketplaces such as Alibaba, Made-in-China, or TradeIndia. Many suppliers list their products on these platforms, and you can find a variety of options.

Visit local electronics markets in major cities like Dhaka. These markets often have a concentration of electronics suppliers and manufacturers.

sign board, led sign bd, led sign board, led board sign, led signage board. Acrylic ss letter bd price in bangladesh, Acrylic ss letter bd price, Acrylic ss letter bd near me, Acrylic ss letter bd design, acrylic sign board price in bangladesh, led display board suppliers in bangladesh.

led sign bd, led sign board, led signage board, led board sign, led signs, digital sign board, led sign board price in bangladesh, sign board with light, lighting sign board, signage board with light, sign board light, led sign board design, sign board bangladesh, led name board price, name board for shop with light.

A great Neon and Led sign is an amazing home accessory and also ideal for business purposes. Do you want to create your own glow decoration that could enhance your own place or bring your party to the next level?

Now customize your dream neon! It can be a lighting tool to light up your place, and a lovely decor for your salon, coffee shop. Talk to us for more neon decoration ideas!.

acrylic sheet, acrylic sheet price in bangladesh, acrylic board price in bangladesh, plastic sheet price in bangladesh, rfl acrylic sheet price in bangladesh, transparent plastic sheet price in bangladesh, transparent sheet price in bangladesh, acrylic sheet price in bangladesh daraz, acrylic sheet shop in dhaka, acrylic sheet price in dhaka acrylic, sheet price in bd, acrylic sheet price.

Our Service: All Kinds of Led Sign, Neon Sign, Led Sign Board, Name Plate, Billboard, Digital 3D Print, Pana lighting board, Bata model board, Shop Sign. We provide Lighting Sign Board, Acrylic Sign, Moving Display, Profile Box, Fair Stall & Event Management Ad Etc Advertising Service All Over Bangladesh.

Contact us for more information: hotline: +8801787664525 e-mail: [email protected]

Visit our site: website: www.adkey.com.bd https://lnkd.in/eDe-JMpy

Office Address: House: 395/k, Mazar Road, Section: 01, Mirpur, Dhaka-1216, Bangladesh., Dhaka, Bangladesh Instagram Page: https://lnkd.in/eQEyzXRu Youtube: https://lnkd.in/e7yeQ7Rf

hashtag#led_sign_bd hashtag#neon_sign_bd hashtag#nameplate_bd hashtag#led_sign_board hashtag#neon_sign_board hashtag#led_display_board hashtag#aluminum_profile_box hashtag#led_light hashtag#neon_light hashtag#shop_sign_board hashtag#lighting_sign_board hashtag#shop_sign_bd hashtag#billboard_bd hashtag#acrylic_sign_board_price_in_bangladesh hashtag#profile_box_bd hashtag#backlit_sign_board_bd hashtag#bell_sign_bd hashtag#dhaka_sign_bd hashtag#sign_makers_bd hashtag#ss_sign_board_bd hashtag#moving_display_bd hashtag#aluminum_profile_box_bd hashtag#ss_top_letter hashtag#led_sign_board_price_in_bangladesh hashtag#neon_sign_board_price_in_bangladesh hashtag#digital_sign_board_price_in_bangladesh hashtag#name_plate_design_for_home hashtag#nameplate_price_in_bangladesh hashtag#neon_signage hashtag#led_signage

#marketing#design#neon sign#led sign#advertising#business#shop sign#architecture#buildings#interiors

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes