#3D Printing in Electronics Market Analysis

Explore tagged Tumblr posts

Text

3D Printing in Electronics Market Gaining Momentum with Positive External Factors

Advance Market Analytics published a new research publication on "3D Printing in Electronics Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the 3D Printing in Electronics market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of This Research @ https://www.advancemarketanalytics.com/sample-report/3314-global-market-3d-printing-in-electronics The 3D Printing in Electronics Market report covers extensive analysis of the key market players, along with their business overview, expansion plans, and strategies. The key players studied in the report include: 3d systems [United States], arcam [Sweden], exone [United States], stratasys [United States], autodesk [United States], eos [Germany], envisiontec [Germany], graphene 3d lab [United States], materialise [Belgium], optomec [United States], voxeljet [Germany]. Definition: The use of 3D printing technology in electronics has revolutionized the electronic industry by minimizing the waste. One of the key benefits of incorporation of this technology is its ability to create small scale components which has greatly benefited the production process. The growing adoption of 3D technology in electronics creates huge potential as it could lead to new medical treatments to cure wound. The following fragment talks about the 3D Printing in Electronics market types, applications, End-Users, Deployment model etc. A thorough analysis of 3D Printing in Electronics Market Segmentation: by Type (3d printers, Materials, Services), Application (Consumer electronics, Automotive, Aerospace, Industrial, Others) 3D Printing in Electronics Market Drivers:

Ability to Create Small-scale Components

Growing Need for Light Weight and Circuit Less Electronic Components

3D Printing in Electronics Market Trends:

Rising Need for Customized 3D Printing Electronics

Growing Use in Touch Devices and Smart Display

3D Printing in Electronics Market Growth Opportunities:

Increasing Focus Towards Minimizing Waste in Production Process

Technological Advancement Leading to Rising Demand of 3D Printing Technology in Electronics

As the 3D Printing in Electronics market is becoming increasingly competitive, it has become imperative for businesses to keep a constant watch on their competitor strategies and other changing trends in the 3D Printing in Electronics market. Scope of 3D Printing in Electronics market intelligence has proliferated to include comprehensive analysis and analytics that can help revamp business models and projections to suit current business requirements. We help our customers settle on more intelligent choices to accomplish quick business development. Our strength lies in the unbeaten diversity of our global market research teams, innovative research methodologies, and unique perspective that merge seamlessly to offer customized solutions for your every business requirement. Have Any Questions Regarding Global 3D Printing in Electronics Market Report, Ask Our Experts@ https://www.advancemarketanalytics.com/enquiry-before-buy/3314-global-market-3d-printing-in-electronics Strategic Points Covered in Table of Content of Global 3D Printing in Electronics Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the 3D Printing in Electronics market

Chapter 2: Exclusive Summary and the basic information of the 3D Printing in Electronics Market.

Chapter 3: Displaying the Market Dynamics- Drivers, Trends and Challenges & Opportunities of the 3D Printing in Electronics

Chapter 4: Presenting the 3D Printing in Electronics Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2018-2022

Chapter 6: Evaluating the leading manufacturers of the 3D Printing in Electronics market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2023-2028)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, 3D Printing in Electronics Market is a valuable source of guidance for individuals and companies. Read Detailed Index of full Research Study at @ https://www.advancemarketanalytics.com/reports/3314-global-market-3d-printing-in-electronics What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia. Contact US : Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 201 565 3262, +44 161 818 8166 [email protected]

#Global 3D Printing in Electronics Market#3D Printing in Electronics Market Demand#3D Printing in Electronics Market Trends#3D Printing in Electronics Market Analysis#3D Printing in Electronics Market Growth#3D Printing in Electronics Market Share#3D Printing in Electronics Market Forecast#3D Printing in Electronics Market Challenges

0 notes

Text

#3D Printed Electronics Market Share#3D Printed Electronics Market Analysis#3D Printed Electronics Market Overview

0 notes

Text

Aircraft Micro Turbine Engines Market Increasing Growth with Latest Trend, Top Players and Forecast

Aircraft Micro Turbine Engines MarketGrowth Trend & Forecast with latest research study released by Delvens evaluating the market risk side analysis, highlighting opportunities, and leveraging strategic and tactical decision-making support. The report provides information on market trends and development, growth drivers, technologies, and the changing investment structure of the Global market, the Aircraft Micro Turbine Engines market size is projected to reach a CAGR of 10.3% to 2030.

Get Free Sample Report: https://www.delvens.com/get-free-sample/aircraft-micro-turbine-engines-market

Micro Turbine engine is a new generation technology that is used for stationary energy generation. Micro turbine is a class of combustion turbines that produces both heat and electricity on a small scale. These are similar to jet engine but produces electricity instead of thrust. The most recent development in the sector is drones propulsion. This has open new doors for the application in military.

The advantages over the conventional engine along with the low operational and maintenance cost along with the reduced emission are some of the factors that have supported long-term expansion for Aircraft Micro Turbine Market.

Recent Developments

Russian state along with the Advanced research foundation has completed their testing of first ever 3D printed MGDT-20 gas turbine.

Key Players of Aircraft Micro Turbine Engines Market:

AeroDesignWorks GmbH

Elliott Company

General Electric Company

Honeywell International Inc.

Kratos Defense & Security Solutions, Inc.

Micro Turbine Technology B.V.

PBS Group. a.s.

Sentient Blue Technologies

Turbotech SAS

Williams International and More

Regional Analysis

Asia Pacific is the most rapidly growing market and offers a huge opportunity for the industry, whose growth is driven by the environmental concerns regarding the carbon emission.

Aircraft Micro Turbine Engines Market is segmented into End-Use, Engine Type, Platform, Horsepower, Fuel Type, Application and region.

On the basis of Platform

VTOL

Air Taxi

Cargo Aerial Vehicle

Business Jet

Ultra-Light Aircraft

Military Trainer Aircraft

Military UAV

On the basis of Region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Access Full Report: https://www.delvens.com/report/aircraft-micro-turbine-engines-market

In addition to the market data for Aircraft Micro Turbine Engines Market, Delvens offers client-centric report and customized according to the company’s specific demand and requirement.

More Related Reports:

Aerospace Parts Manufacturing market

Aircraft Insulation Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact us:

Unit No. 01, 3rd Floor, Plot No. 56, Block B

Sector 2 Noida, Near Noida Sector 15 Metro Station 201301, IN

+44 20 3290 6466

+0120- 4903958

0 notes

Text

North America 3D Printing Medical Devices Market Analysis by Current Status and Growth Opportunities (2021-2028)

The North America 3D printing medical devices market is expected to reach US$ 2,672.9 million by 2028 from US$ 848.0 million in 2021. The market is estimated to grow at a CAGR of 17.8% from 2021–2028.

North America 3D Printing Medical Devices Market Introduction

A significant health challenge in North America revolves around the high incidence of dental caries, which stands as the second most prevalent condition. Furthermore, malocclusions are commonly observed across all demographics, with minimal variation between genders. Several factors are propelling the integration of 3D printing within the medical and dental domains. These include the capacity for creating patient-specific medical solutions, the cost-effectiveness of producing smaller volumes, the ease of sharing and manipulating digital patient scans, and advancements in educational methodologies.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/TIPRE00027733

North America 3D Printing Medical Devices Strategic Insights

Strategic insights into the North America 3D Printing Medical Devices market provide an evidence-based assessment of the industry's structure, highlighting key trends, major players, and region-specific characteristics. These insights aim to offer actionable guidance, enabling stakeholders to gain a competitive edge by identifying underserved market niches or developing differentiated value propositions. Through rigorous data analysis, these insights assist industry participants, including investors and manufacturers, in forecasting market dynamics.

North America 3D Printing Medical Devices Regional Insights

The geographical boundaries of the North America 3D Printing Medical Devices market define the specific areas where companies operate and compete. Understanding local variations is crucial for developing customized market strategies. These variations encompass differing consumer preferences, such as demands for specific medical device features or materials, diverse economic landscapes across the continent, and the complexities of regulatory frameworks. By pinpointing untapped markets or adapting their offerings to meet local needs, businesses can expand their market presence.

North America 3D Printing Medical Devices Market Segmentation

North America 3D Printing Medical Devices Market: By Component

Software and Services

Equipment

3D Printers

3D Bioprinters

Materials

Plastics Material

Metal and Metal Alloys

Bioprinting Biomaterials

Wax

Others

North America 3D Printing Medical Devices Market: By Technology

Laser Beam Melting

Direct Metal Laser Sintering

Selective Laser Sintering

Selective Laser Melting

LaserCusing

Photopolymerization

Stereolithography

Others

Droplet Deposition/Extrusion Based Technologies

Fused Deposition Modelling

Multiphase Solidification

Low Temperature Deposition Manufacturing

Electron Beam melting

North America 3D Printing Medical Devices Market: By Application

Custom Prosthetics and Implants

Craniomaxillofacial Implants

Custom Dental Prosthetics and Implants

Custom Orthopaedic Implants

Surgical Guides

Dental Guides

Orthopaedic Guides

Craniomaxillofacial Guides

Spinal Guides

Tissue Engineering Products

Bone and Cartilage Scaffolds

Ligaments and Tendons Scaffolds

Surgical Instruments

Surgical Fasteners

Scalpels

Retractors

Hearing Aids

Wearable Medical Devices

Standard Prosthetic and Implants

Others

North America 3D Printing Medical Devices Market: By End-User

Hospitals and Surgical Centres

Dental and Orthopaedic Centres

Medical Device Companies

Pharmaceutical and Biotechnology Companies

Academic and Research Institutes

Others

North America 3D Printing Medical Devices Market: By Country

North America

US

Canada

Mexico

North America 3D Printing Medical Devices Market: Companies Mentioned

EOS GmbH Electro Optical Systems

Renishaw PLC

Stratasys Ltd.

3D Systems, Inc.

EnvisionTech, Inc.

Concept Laser Gmbh (General Electric)

Proadways Group

SLM Solution Group AG

CELLINK

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

#North America 3D Printing Medical Devices Market#North America 3D Printing Medical Devices Market Current Status#North America 3D Printing Medical Devices Market Growth Opportunities

0 notes

Text

Global Transparent Polyamides market analysis by type, including size, segmentation, regional trends, company share, key players, and forecast from 2025 to 2035.

Industry Outlook

The Transparent Polyamides Market accounted for USD 11.1 Billion in 2024 and is expected to reach USD 16.55 Billion by 2035, growing at a CAGR of around 3.7% between 2025 and 2035. The market is expanding rapidly due to increasing demand from industries such as automotive, electronics, healthcare, and packaging.

The advanced properties of transparent polyamides, including impact strength, chemical stability, and optical clarity, drive their adoption across multiple industries. The automotive sector, in particular, relies on these materials for lightweight and durable construction. Growing applications in medical devices and electronics further fuel market expansion. Technological advancements in polymers, along with the development of bio-based transparent polyamides, are also contributing to market growth. Increased investment in research and sustainability initiatives continues to enhance product performance and drive market expansion.

Get free sample Research Report - https://www.metatechinsights.com/request-sample/2162

Market Dynamics

Rising Demand for Lightweight and High-Performance Materials in Automotive Industry

The demand for lightweight and high-performance components in the automotive sector is a key driver for the Transparent Polyamides Market. Transparent polyamides offer durability, impact resistance, and optical clarity, making them ideal for headlamp lenses, fuel system components, and interior trims.

The rise in electric vehicle (EV) production has further increased the need for lightweight materials that enhance efficiency and performance. Transparent polyamides also provide resistance to thermal exposure, chemicals, and impacts, ensuring durability in harsh automotive environments. The push for sustainability has led to the development of bio-based polyamides, helping automakers meet global environmental regulations.

Expanding Applications in Medical Devices and Healthcare

The medical and healthcare sectors are significantly contributing to the growth of the Transparent Polyamides Market. These materials exhibit excellent biocompatibility, chemical resistance, and sterilization capabilities, making them ideal for medical tubing, surgical instruments, drug delivery systems, and diagnostic devices.

With the rising prevalence of chronic diseases and the increasing need for advanced medical technology, demand for transparent polyamide-based healthcare components continues to grow. Regulatory requirements for high-purity materials further enhance their adoption in the medical sector.

Supply Chain Disruptions and Fluctuating Raw Material Prices

The Transparent Polyamides Market faces challenges due to fluctuating raw material prices and supply chain disruptions. The manufacturing of transparent polyamides involves petrochemical-derived monomers, which are subject to price volatility due to changes in crude oil prices and geopolitical uncertainties.

Global events, such as the COVID-19 pandemic, have led to material shortages and logistical delays, impacting production timelines. Companies reliant on suppliers from Asia-Pacific and Europe must manage risks associated with price fluctuations and supply chain disruptions. To mitigate these challenges, manufacturers are investing in alternative supply routes, local production facilities, and improved inventory management strategies.

Emerging Market Opportunities

Expansion of Transparent Polyamides in 3D Printing and Additive Manufacturing

The increasing adoption of transparent polyamides in 3D printing and additive manufacturing is opening new growth avenues. These materials are gaining popularity in healthcare, aerospace, and automotive sectors due to their durability, chemical resistance, and transparency.

Transparent polyamides are used in medical implant customization, automotive lighting systems, and industrial mold production. Advancements in 3D printing technology enhance the transparency and strength of printed components, accelerating market demand. Ongoing research into specialized transparent polyamide grades is improving printability and product performance, further driving market growth.

Growing Demand for Bio-Based and Sustainable Transparent Polyamides

The push for sustainability has led to increased demand for bio-based transparent polyamides, offering an eco-friendly alternative to petroleum-based polymers. These materials, derived from renewable sources such as castor oil, provide similar performance characteristics while reducing dependence on fossil fuels.

Regulatory initiatives in Europe and North America are promoting the adoption of sustainable materials, further boosting demand. Industries such as packaging, electronics, and automotive are increasingly incorporating bio-based transparent polyamides to meet consumer preferences for environmentally friendly products. Leading manufacturers continue to invest in the development of bio-based formulations that maintain mechanical strength, thermal stability, and chemical resistance.

Read Full Research Report https://www.metatechinsights.com/industry-insights/transparent-polyamides-market-2162

Industry Expert Opinions

Dr. John Smith, Material Science Professor, University of Michigan: “Transparent polyamides are emerging as a crucial material in high-performance applications due to their exceptional optical clarity, mechanical strength, and chemical resistance. Recent advancements in polymer chemistry have enhanced their properties, making them more suitable for automotive, medical devices, and electronics. The increasing interest in bio-based transparent polyamides offers a balance between performance and sustainability.”

Dr. Emily Chen, Chemical Engineering Professor, Stanford University: “Transparent polyamides offer a remarkable balance of transparency and durability, making them ideal for innovative solutions in sectors ranging from consumer electronics to healthcare.”

Segment Analysis

By Type: Aromatic Transparent Polyamides Leading the Market

Aromatic transparent polyamides hold a significant market share due to their exceptional thermal stability, mechanical strength, and chemical resistance. These properties make them suitable for critical applications in automotive, electronics, and healthcare sectors.

The automotive industry increasingly adopts aromatic transparent polyamides for fuel system components and under-the-hood applications. Their durability and optical clarity also make them ideal for medical devices and optical components. Ongoing research is improving processing capabilities and sustainability aspects of these materials. The growing demand for bio-based variants is further driving segment expansion, particularly in Asia-Pacific and Europe.

By End-User: Automotive Segment Driving Market Growth

The automotive industry is a major consumer of transparent polyamides, driven by the need for lightweight, high-strength, and heat-resistant materials. These materials are widely used in glazing applications, headlamp lenses, fuel system components, and interior trims.

With the advancement of ADAS (Advanced Driver Assistance Systems) and smart lighting technologies, the use of transparent polyamides is increasing. Environmental regulations and sustainability goals are further accelerating the adoption of bio-based transparent polyamides in the automotive sector.

Regional Analysis

Asia-Pacific: The Largest Market for Transparent Polyamides

Asia-Pacific dominates the Transparent Polyamides Market due to rapid industrialization, strong automotive production, and a booming electronics sector. Countries such as China, Japan, India, and South Korea are significant contributors to market growth.

The expansion of the medical device industry in the region is also driving demand for transparent polyamides. Favorable production conditions, including cost-effective manufacturing and abundant raw materials, further support market growth. Asia-Pacific is expected to maintain its leadership position due to the increasing demand for lightweight, durable, high-clarity polymers.

North America: The Fastest-Growing Market

North America is experiencing rapid growth in the Transparent Polyamides Market, driven by increasing demand from automotive, electronics, and healthcare industries. Stringent environmental regulations and the need for fuel-efficient vehicles are promoting the use of high-performance lightweight materials.

The growing aerospace and industrial machinery sectors in the U.S. present new opportunities for advanced polymer applications. Research investments and the shift toward sustainable materials are also contributing to market expansion. The rising adoption of transparent polyamides in 3D printing and high-performance coatings further supports regional growth.

Buy Now https://www.metatechinsights.com/checkout/2162

Competitive Landscape

Leading companies in the Transparent Polyamides Market include:

Arkema S.A.

Evonik Industries AG

BASF

DuPont de Nemours Inc.

EMS-Chemie Holding AG

Solvay

Toray Industries

DSM-Firmenich

UBE Corporation

Kuraray Co., Ltd.

Asahi Kasei Corporation

Mitsubishi Chemical Group Corporation

LANXESS

RadiciGroup

SABIC

These companies focus on innovation, sustainability, and strategic partnerships to enhance market presence and competitiveness.

Recent Developments

January 2024: Evonik launched TROGAMID® eCO Impact 75 polymer, a high-transparency, chemically resistant material for injection molding applications.

July 2023: A 100% recycled-content polymer received SCS certification, emphasizing sustainability in the Transparent Polyamides Market.

June 2023: Arkema and DSM collaborated to develop advanced transparent polyamide materials for 3D printing, focusing on enhanced clarity, strength, and durability.

0 notes

Text

Metal Powder Compacting Presses Market set to hit $916.3 million by 2035

Industry revenue for Metal Powder Compacting Presses is estimated to rise to $916.3 million by 2035 from $472.8 million of 2024. The revenue growth of market players is expected to average at 6.2% annually for the period 2024 to 2035.

Metal Powder Compacting Presses is critical across several key applications including automotive parts manufacturing, aerospace component fabrication, pharmaceutical processing and electrical & electronics components. The report unwinds growth & revenue expansion opportunities at Metal Powder Compacting Presses’s Material, Technology, Application, Press Type and Operation Mode including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Metal Powder Compacting Presses market is characterized by intense competition, with a number of leading players such as Dorst Technologies, GKN Hoeganaes, ACME, SINTERMET, Catalus Corporation, Kennametal, EPSON ROBOTS, Greenlee, Gasbarre Industrial, TI Automotives, LAUFFER PRESS and AMAX Systems Company Limited..

The Metal Powder Compacting Presses market is projected to expand substantially, driven by advancements in automotive manufacturing and growth in aerospace applications. This growth is expected to be further supported by Industry trends like Increased Adoption of 3D Printing.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/metal-powder-compacting-presses-market-research-report

Moreover, the key opportunities, such as expansion in aerospace and defence, technological advancements driving market demand and developing economies showing potential, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, China, Japan and India.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like heavy capital investment and technology complexity, Metal Powder Compacting Presses market’s supply chain from raw material providers / metal powder producing companies / press manufacturing companies to industrial users is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Vietnam, Saudi Arabia and Mexico for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

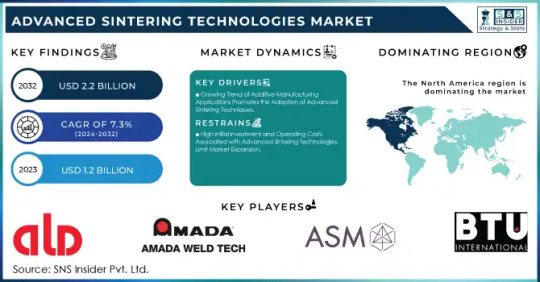

Advanced Sintering Technologies Market Analysis: Key Players and Competitive Landscape

Rising Demand for High-Performance Materials in Aerospace and Electronics Drives Growth in the Advanced Sintering Technologies Market.

The Advanced Sintering Technologies Market Size was valued at USD 1.2 billion in 2023 and is expected to reach USD 2.2 billion by 2032 and grow at a CAGR of 7.3% over the forecast period 2024-2032.

The Advanced Sintering Technologies Market is driven by increasing demand for high-performance materials in industries such as aerospace, automotive, electronics, and healthcare. Advanced sintering technologies, including spark plasma sintering (SPS), microwave sintering, and hot isostatic pressing (HIP), are revolutionizing the manufacturing process by enhancing material strength, density, and efficiency. The shift toward lightweight, high-strength, and energy-efficient materials is fueling innovation in powder metallurgy, ceramics, and additive manufacturing.

Key Players

ALD Vacuum Technologies

AMADA Weld Tech

ASM International N.V.

BTU International

Carpenter Technology Corporation

ChinaSavvy

DSB Technologies

EOS

FCT Systeme

GKN Powder Metallurgy

Future Scope

The advanced sintering technologies market is expected to expand rapidly due to growing applications in high-performance ceramics, powder metallurgy, and additive manufacturing. The automotive industry is increasingly using sintered components for lightweight and fuel-efficient vehicles, while the electronics sector is integrating sintered materials into high-density circuit boards and semiconductor packaging. Additionally, advancements in nanostructured materials and 3D printing sintering methods are expected to enhance precision and reduce production costs.

Emerging Trends

The market is experiencing a transition towards energy-efficient and cost-effective sintering processes. Microwave sintering is gaining popularity due to its rapid processing times and lower energy consumption, making it an attractive alternative to conventional methods. Spark plasma sintering (SPS) is revolutionizing material fabrication by allowing high-speed densification with minimal grain growth, leading to stronger and more durable components. Furthermore, additive manufacturing combined with sintering processes is paving the way for customized, high-performance parts in sectors like biomedical implants, aerospace, and defense.

Key Points

Rising demand for high-performance sintered materials in aerospace, automotive, and electronics.

Innovations in sintering methods, including spark plasma sintering (SPS) and microwave sintering.

Growing adoption of sintering in additive manufacturing for customized and high-precision components.

Advancements in nanostructured materials improving strength and durability.

Increasing focus on energy-efficient sintering techniques to reduce production costs.

Conclusion

The Advanced Sintering Technologies Market is poised for strong growth, driven by technological advancements, increasing industrial applications, and the push for energy-efficient manufacturing. As industries continue to demand stronger, lighter, and more durable materials, advanced sintering technologies will play a critical role in shaping the future of manufacturing and material science.

Read Full Report: https://www.snsinsider.com/reports/advanced-sintering-technologies-market-2459

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Advanced Sintering Technologies Market#Advanced Sintering Technologies Market Size#Advanced Sintering Technologies Market Share#Advanced Sintering Technologies Market Report#Advanced Sintering Technologies Market Forecast

0 notes

Text

Industrial X-ray: Revolutionizing Quality Control and Safety in Manufacturing

Introduction

Industrial X-ray technology has become a cornerstone in modern manufacturing, offering unparalleled precision in inspecting materials and products. Unlike medical X-rays, which focus on human anatomy, Industrial X-ray systems are designed to detect flaws, verify structural integrity, and ensure compliance with safety standards. From aerospace to electronics, this technology plays a critical role in maintaining quality and preventing catastrophic failures.

This article explores the applications, benefits, and advancements of Industrial X-ray, highlighting its transformative impact across industries.

What Is Industrial X-ray?

Industrial X-ray refers to the use of X-ray imaging for non-destructive testing (NDT) in manufacturing and industrial processes. By penetrating materials, X-rays reveal internal structures, defects, and inconsistencies without damaging the object.

How Industrial X-ray Works

X-ray Generation: A high-voltage system produces X-rays that pass through the object.

Detection: A detector captures the transmitted X-rays, creating an image based on material density variations.

Analysis: Software processes the image to identify cracks, voids, or foreign objects.

This method ensures thorough inspection while preserving the integrity of the tested components.

Key Applications of Industrial X-ray

1. Aerospace and Defense

The aerospace industry relies on Industrial X-ray to inspect turbine blades, welds, and composite materials. Even microscopic defects can lead to equipment failure, making X-ray inspection essential for safety.

2. Automotive Manufacturing

Engine components, castings, and welded joints undergo Industrial X-ray scanning to detect hidden flaws that could compromise vehicle performance.

3. Electronics and PCB Inspection

Printed circuit boards (PCBs) require precise soldering and component placement. Industrial X-ray systems identify short circuits, voids, and misalignments in dense electronic assemblies.

4. Oil and Gas Pipeline Inspection

Corrosion, cracks, and weld defects in pipelines can lead to leaks or explosions. Industrial X-ray ensures structural integrity, preventing environmental hazards.

5. Additive Manufacturing (3D Printing)

As 3D-printed parts grow in complexity, Industrial X-ray verifies layer bonding and internal geometry, ensuring compliance with design specifications.

Advantages of Industrial X-ray in Modern Manufacturing

1. Non-Destructive Testing (NDT)

Unlike destructive methods that require cutting or breaking samples, Industrial X-ray preserves the tested object, reducing waste and costs.

2. High Precision and Detail

Advanced detectors and software enhance image resolution, allowing inspectors to identify micron-level defects.

3. Real-Time Inspection

Digital radiography (DR) and computed tomography (CT) provide instant imaging, speeding up quality control processes.

4. Compliance with Industry Standards

Regulatory bodies like ASTM and ISO mandate strict quality checks, which Industrial X-ray helps manufacturers meet efficiently.

5. Enhanced Safety

By detecting flaws before products reach the market, Industrial X-ray prevents equipment failures and potential accidents.

Technological Advancements in Industrial X-ray

1. Digital Radiography (DR)

Replacing traditional film-based systems, DR offers faster imaging, better storage, and easier data sharing.

2. Computed Tomography (CT) Scanning

3D Industrial X-ray CT provides cross-sectional views, enabling comprehensive internal inspections without disassembly.

3. AI-Powered Defect Recognition

Machine learning algorithms analyze X-ray images, automatically flagging anomalies and reducing human error.

4. Portable X-ray Systems

Compact, battery-powered Industrial X-ray devices allow on-site inspections in remote or hazardous locations.

5. Higher Energy X-rays for Dense Materials

Innovations in X-ray tube technology enable the inspection of thick metals and heavy alloys with greater clarity.

Challenges and Future Trends

1. High Initial Costs

Advanced Industrial X-ray systems require significant investment, though long-term savings justify the expense.

2. Skilled Operator Dependency

Interpreting X-ray images demands expertise, prompting the need for specialized training programs.

3. Integration with Industry 4.0

The future of Industrial X-ray lies in IoT connectivity, where real-time data feeds into smart factories for automated quality control.

4. Enhanced AI and Automation

Further advancements in AI will minimize manual inspections, improving speed and accuracy.

5. Sustainability in X-ray Technology

Research focuses on reducing radiation exposure and energy consumption in Industrial X-ray systems.

Conclusion

Industrial X-ray has revolutionized quality assurance, enabling manufacturers to detect defects, ensure safety, and comply with regulations. As technology evolves, its applications will expand, further integrating with automation and AI-driven analytics. Whether in aerospace, automotive, or electronics, Industrial X-ray remains an indispensable tool for modern industry.

By embracing these advancements, businesses can enhance product reliability, reduce risks, and maintain a competitive edge in an increasingly demanding market. The future of manufacturing inspection is clear—Industrial X-ray will continue to lead the way.

1 note

·

View note

Text

Industrial 3D Printing Materials Market, Global Outlook and Forecast 2025-2032

Industrial 3D Printing Materials Market Size,Demand & Supply, Regional and Competitive Analysis 2025-2031

Industrial 3D Printing Materials are specialized materials used for the additive manufacturing process in various industries including automotive, aerospace, healthcare, consumer goods, and construction. These materials consist of plastics, metals, ceramics, and other advanced materials that are specifically formulated for use in 3D printing technologies.

Market Size

The global Industrial 3D Printing Materials market was valued at USD 1685 million in 2023 and is expected to reach USD 6660.90 million by 2032, with a projected CAGR of 16.50% during the forecast period. The North America Industrial 3D Printing Materials market was estimated at USD 572.04 million in 2023, showing a CAGR of 14.14% from 2025 to 2032.

Market Dynamics

Download a free Sample Report PDF

Get The Complete Report &TOC

Drivers

1. Technological Advancements: Continuous advancements in 3D printing technologies and materials are driving the demand for industrial 3D printing materials.

2. Increased Adoption Across Industries: Growing adoption of 3D printing in automotive, aerospace, and healthcare sectors is boosting the demand for industrial 3D printing materials.

3. Customization and Product Innovation: The ability of 3D printing to enable customization and innovation in product design is fueling the market growth of industrial 3D printing materials.

Restraints

1. High Initial Investment: The high initial investment required for 3D printing equipment and materials is a major barrier to market growth.

2. Regulatory Challenges: Stringent regulations and standards in industries like aerospace and healthcare can limit the adoption of industrial 3D printing materials.

3. Material Limitations: The limitations of current materials in terms of strength, durability, and performance can hinder the widespread adoption of industrial 3D printing materials.

Opportunities

1. Emerging Applications: Increasing applications of 3D printing in new industries and areas such as electronics, education, and food present untapped opportunities for industrial 3D printing materials.

2. R&D and Innovation: Continued research and development efforts to enhance material properties and develop new formulations can create opportunities for market expansion.

3. Adoption in Emerging Markets: The adoption of industrial 3D printing materials in emerging markets provides a growth opportunity due to increasing industrialization and technological advancements.

Challenges

1. Quality Control: Ensuring consistent quality and performance of 3D printed parts poses a challenge due to variations in materials and printing processes.

2. Sustainability Concerns: The environmental impact of 3D printing materials and processes, including waste generation and energy consumption, is a growing concern for sustainability.

3. Supply Chain Disruptions: Disruptions in the supply chain of raw materials and additives can impact the availability and pricing of industrial 3D printing materials.

Industrial 3D Printing Materials Market Analysis

Regional Analysis:

North America: The Industrial 3D Printing Materials market in North America has been experiencing significant growth, with key players like 3D Systems and Stratasys leading the market. The demand for industrial 3D printing materials in sectors such as aerospace, automotive, and healthcare is on the rise, driven by technological advancements and increasing adoption. Supply dynamics are robust, supported by a well-established raw material supply chain and manufacturing capabilities. Growth in this region is fueled by a strong economy, innovation, and favorable government policies.

Competitor Analysis:

Major Competitors: Leading companies in the Industrial 3D Printing Materials market include 3D Systems, Stratasys, and General Electric. These players have a significant market share and influence in the industry.

Market Share & Influence: 3D Systems and Stratasys hold a major portion of the market share, with General Electric making a strong impact as well. Their innovative technologies and product offerings contribute to their dominance in the market.

Strategies: Companies like 3D Systems and Stratasys focus on continuous innovation, strategic pricing strategies, and partnerships to enhance their market presence. General Electric emphasizes technological advancements and diversification through acquisitions to expand its market reach.

Competitive Positioning: Each company has a distinct competitive advantage. 3D Systems excels in diversified product offerings, Stratasys stands out for its strong R&D capabilities, and General Electric leads in technological advancements and global presence, positioning them uniquely in the market.

Global Industrial 3D Printing Materials Market: Market Segmentation Analysis

This report provides a deep insight into the global Industrial 3D Printing Materials market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Industrial 3D Printing Materials Market. This report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Industrial 3D Printing Materials market in any manner.

Market Segmentation (by Application)

Automotive

Aerospace & defense

Healthcare

Consumer Goods

Construction

Others (Electronics, Education, Food, etc.)

Market Segmentation (by Type)

Plastic

Metal

Ceramic

Others

Key Company

3D System

Arkema

Royal DSM

ExOne Company

Stratasys

General Electric

EOS GmbH Electro

Materialise

Sandvik

Höganäs AB

FAQ

Q1.What is the current market size of Industrial 3D Printing Materials Market?

The global Industrial 3D Printing Materials market size was estimated at USD 1685 million in 2023 and is projected to reach USD 6660.90 million by 2032.

Q2.Which key companies operate in the Industrial 3D Printing Materials Market?

The major players in the market are 3D System, Arkema, Royal DSM, ExOne Company, Stratasys, General Electric, EOS GmbH Electro, Materialise, Sandvik, and Höganäs AB.

Q3.What are the key growth drivers in the Industrial 3D Printing Materials Market?

The main factors fueling market expansion include increasing demand from industries like automotive, aerospace, healthcare, and consumer goods, technological advancements, and growing adoption of 3D printing in manufacturing processes.

Q4.Which regions dominate the Industrial 3D Printing Materials Market?

The market is dominated by North America, Europe, and Asia-Pacific regions based on demand, supply, and market share contributions.

Q5.What are the emerging trends in the Industrial 3D Printing Materials Market?

Emerging trends in the market include the rise of metal 3D printing applications, advancements in ceramic materials for additive manufacturing, and the integration of 3D printing in healthcare for personalized medical devices and implants.

#Industrial3DPrinting#3DPrintingMaterials#AdditiveManufacturing#MarketForecast#GlobalMarket#AdvancedMaterials#ManufacturingTechnology#Prototyping#IndustrialInnovation#MarketTrends#Metal3DPrinting#Polymer3DPrinting#MarketGrowth#SustainableManufacturing#IndustryAnalysis#FutureOfManufacturing

0 notes

Text

Digital Printing Market - Forecast(2025 - 2031)

Digital Printing Market Overview:

The Digital Printing Market size is projected to reach $43 billion by 2030, growing at a CAGR of 7.2% during the forecast period 2023-2030. Digital printing is a contemporary method of printing images, created using digital technology directly onto various media substrates. Digital printing is more accurate and cost-effective than conventional printing methods while occupying a fraction of the space. These characteristics have prompted the broad adoption of digital printing technologies, specifically in the textile and packaging industries.

The desire for high-quality, cost-effective graphics along with environmental sustainability is expected to drive attention toward digital printing, more specifically UV-curable ink-based printing. According to the Print Authority, digital printing for up to 2000 pieces is by far the most economical in comparison to others. Apart from this, the emergence of 3D printing, sheet-fed digital printing, printed electronics and print security are going to boost the Digital Printing Market. This represents the Digital Printing Industry Outlook.

Digital Printing Market - Report Coverage:

The “Digital Printing Market Report - Forecast (2023-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Digital Printing Market.AttributeSegment

By Print Head Type

Inkjet

Laser

By Ink Type

Aqueous Ink

UV-Cured Ink

Solvent Ink

Latex Ink

Dye Sublimation Ink

Others

By Substrate Type

Plastic Films or Foils

Release Liner

Glass

Textile

Paper

Ceramic

Others

By Application

Books

Commercial Printing

Packaging

Others

By Geography

North America (the US, Canada and Mexico)

Europe (Germany, France, the UK, Italy, Spain, Russia, Netherlands and the Rest of Europe),

Asia-Pacific (China, Japan, South Korea, India, Australia, Indonesia, Malaysia and the Rest of Asia-Pacific),

South America (Brazil, Argentina, Chile, Colombia and the Rest of South America)

The Rest of The World (the Middle East and Africa).

Request Sample

COVID-19 / Ukraine Crisis - Impact Analysis:

The pandemic altered the dynamics of the digital printing sector. The digital printing industry was compelled to change its focus to online transactions and methods due to abrupt shutdown restrictions everywhere in the world. This led to an initial decline in the industry, which is expected to level off with the growing popularity of e-commerce.

Global supply chains have been seriously harmed by the Ukraine crisis and energy costs have risen sharply. Since the war started, prices for gasoline and diesel have doubled. As a result, other printing-related inputs, which are generated from petroleum, have increased in price, thus increasing the cost of printed goods.

Key Takeaways:

Dominance of Asia-Pacific Region

Geographically, Asia-Pacific (Digital Printing Market) is anticipated to grow at the fastest CAGR of 8.4% during the forecast period of 2023-2030. It is due to the increasing popularity of e-commerce-enabled packaged items. According to a report, by 2027, the user penetration of e-commerce would reach 72.9% in the region, which is definitely going to expand the Digital Printing Market��opportunities.

Inkjet segment holds the largest market share

According to the Digital Printing market, the Inkjet segment held the largest Digital Printing market share in 2022, i.e., 57.4%, owing to its better tonal variety and excellent color blending capability. The fact that inkjet printers account for 5% of the market for computer peripherals helps explain the dominance of inkjet print heads.

Dominance of the UV Curable Ink segment

Based on Ink Type, the UV Curable Ink Segment is anticipated to register the fastest CAGR of 7.6% during the forecast period of 2023-2030, owing to its durable color quality and reduced health hazard. Organizations like Prism Tech have started showcasing the use of UV-curable ink as part of their commitment to environmental responsibility, along with its VOC-free and 3-year outdoor durability features.

Inquiry Before Buying

Emergence of Advanced Printing Techniques

3D printing, sheet-fed digital printing and printed electronics are going to be key digital printing market trends. According to the Digital Printing market forecast, the 3D printing industry would grow by $7.5 billion between 2022 and 2024. A similar trend in other techniques is also anticipated in the coming years.

Demand for Print Security

According to a survey, 68% of the organizations have reported one or more print-related data losses that have caused severe disruptions of service. The reliance on printing demands a robust print-security infrastructure. This increasing demand for shielding against data breach issues is going to change the dynamics of the digital printing market opportunities in a positive manner.

Schedule a Call

Cost and complexity would hinder the growth

According to a study, 61% of CIOs find it difficult to handle the complexity of digital printing-related concerns. Moreover, the installation cost to be incurred is also higher when compared to the traditional ones. These factors are going to hamper the growth of the Digital Printing market.

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Digital Printing Market. The top 10 companies in this industry are:

Hewlett Packard Enterprise (HP Laser 108w)

Canon Inc. (imageCLASS MF645Cx)

Ricoh Company Ltd. (PC311W)

Seiko Epson Corporation (Epson WorkForce Enterprise WF-C20600)

Xerox Corporation (XEROX C310 COLOR PRINTER)

Toshiba Co. Ltd (CF3/CF3R)

Konica Minolta (NASSENGER SP-1)

Mimaki Engineering Co. Ltd. (UJV100-160)

Roland GG Corporation (VersaUV LEC2-330/640 UV-LED Printer)

Durst Phototechnik AG (TAU RSC 330 E)

Buy Now

Scope of Report:

Report MetricDetails

Base Year Considered

2022

Forecast Period

2023–2030

CAGR

Growing at the rate of 7.2%

Market Size

43 billion USD

Segments Covered

Print Head Type, Ink Type, By Substrate Type, By Application and Region

Geographies Covered

North America (the US, Canada and Mexico), Europe (Germany, France, the UK, Italy, Spain, Russia and the Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and the Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Key Market Players

1. Hewlett Packard Enterprise

2. Canon Inc.

3. Ricoh Company Ltd.

4. Seiko Epson Corporation

5. Xerox Corporation,

6. Toshiba Co., Ltd.

7. Konica Minolta

8. Mimaki Engineering Co., Ltd.

9. Roland GG Corporation

10. Durst Phototechnik AG

#Digital Printing Market Size#Digital Printing Market Trends#Digital Printing Market Growth#Digital Printing Market Forecast#Digital Printing Market Revenue#Digital Printing Market Vendors#Digital Printing Market Share#Digital Printing Industry

0 notes

Text

UV-Curable Resins Market Poised for Growth: Key Trends and Industry Insights

The UV-curable resins market is on a steady growth trajectory, projected to reach USD 9.31 billion by 2029 from USD 6.48 billion in 2024, registering a CAGR of 7.5% during the forecast period. The increasing demand for UV-curable resins is driven by their expanding applications across multiple industries, including wood & furniture, electrical & electronics, automotive, paper & packaging, and building & construction. Additionally, technological advancements in UV-curing processes are expected to further propel market growth.

Market Segmentation and Growth Trends

Technology Insights: 100% Solid UV-Curable Resins Gaining Traction

Among various UV-curable resin technologies, the 100% solid UV-curable resins segment is projected to hold the second-largest market share by value and volume in 2023. This growth is attributed to their solvent-free formulation, leading to a higher concentration of solid components. These resins offer key benefits such as:

Enhanced performance

Eco-friendliness

Improved corrosion resistance

Superior edge retention and coating thickness

Due to these advantages, 100% solid UV-curable resins are being increasingly adopted over traditional low-solids formulations.

Composition Breakdown: Monomers to Hold a Significant Market Share

The monomers segment is expected to be the second-largest contributor to the UV-curable resins market in 2023, both in terms of value and volume. Monomers are organic materials that undergo polymerization to form high-molecular-weight plastics or polymers. They play a crucial role in UV-curable resins by reducing viscosity, making them essential for adhesives, coatings, and inks. The demand for monomers depends on specific end-use application requirements.

Application Analysis: Printing Inks Segment to Witness Strong Demand

The UV-curable resins market is segmented by application into coatings, overprint varnish, printing inks, adhesives, and 3D printing. Among these, the printing inks segment is forecasted to hold the second-largest market share in 2023.

UV-curing technology has been a preferred choice in graphic art applications for over 30 years due to its instant drying properties and excellent film characteristics. Its continued adoption across multiple end-use industries is expected to fuel market expansion in the coming years.

Regional Insights: Europe’s Market Growth and Regulations

Europe was the second-largest market for UV-curable resins in 2023, with Germany leading the region. The European market is witnessing moderate growth, with increasing regulatory restrictions on volatile organic compounds (VOCs) driving the adoption of UV-curable technologies. Stricter environmental regulations and demand for high-performance coatings are contributing to the market's expansion.

Key Players Shaping the UV-Curable Resins Market

Several major players dominate the global UV-curable resins market, leveraging their strong manufacturing base and extensive distribution networks across Asia Pacific, North America, and Europe. Some of the key companies include:

Allnex Netherlands B.V. (Germany)

BASF SE (Germany)

Covestro AG (Germany)

Wanhua Chemical Group Co., Ltd. (China)

Alberdingk Boley GmbH (Germany)

Miwon Specialty Chemical Co., Ltd. (South Korea)

IGM Resins (Netherlands)

Resonac Holdings Corporation (Japan)

Dexerials Corporation (Japan)

DIC Corporation (Japan)

Arkema (France)

Threebond International, Inc. (US)

Eternal Materials Co., Ltd. (Taiwan)

Toagosei Co., Ltd. (Japan)

Nissan Chemical Corporation (Japan)

These companies have established themselves as industry leaders through innovative product development, global presence, and robust market strategies. Their offerings cater to a diverse range of industrial applications, ensuring a strong competitive edge in the market.

To know more download PDF brochure :

As the demand for eco-friendly, high-performance coatings rises, the UV-curable resins market is set to witness continuous innovation and technological advancements. The increasing focus on sustainability, rapid curing processes, and VOC-free formulations will further drive adoption across key industries.

#UVResinsMarket#UVCurableTechnology#IndustrialCoatings#PrintingInks#SustainableManufacturing#AdvancedMaterials#MarketTrends

0 notes

Text

Aircraft Micro Turbine Engines Market Trend Analysis, Latest Revenue Figures, Growth Insights and Forecast to 2030

Aircraft Micro Turbine Engines Marketresearch report by Delvens focuses on primary sections such as – market segments, market outlook, competitive landscape, and company profiles. The segments provide details in terms of various perspectives such as end-use industry, product or service type, and any other relevant segmentation as per the market’s current scenario which includes various aspects to perform further marketing activity.

The Aircraft Micro Turbine Engines market size is projected to reach a CAGR of 10.3% to 2030.

Get Free Sample Report: https://www.delvens.com/get-free-sample/aircraft-micro-turbine-engines-market

Micro Turbine engine is a new generation technology that is used for stationary energy generation. Micro turbine is a class of combustion turbines that produces both heat and electricity on a small scale. These are similar to jet engine but produces electricity instead of thrust. The most recent development in the sector is drones propulsion. This has open new doors for the application in military.

The advantages over the conventional engine along with the low operational and maintenance cost along with the reduced emission are some of the factors that have supported long-term expansion for Aircraft Micro Turbine Market.

Recent Developments

Russian state along with the Advanced research foundation has completed their testing of first ever 3D printed MGDT-20 gas turbine.

Key Players of Aircraft Micro Turbine Engines Market:

AeroDesignWorks GmbH

Elliott Company

General Electric Company

Honeywell International Inc.

Kratos Defense & Security Solutions, Inc.

Micro Turbine Technology B.V.

PBS Group. a.s.

Sentient Blue Technologies

Turbotech SAS

Williams International and More

Regional Analysis

Asia Pacific is the most rapidly growing market and offers a huge opportunity for the industry, whose growth is driven by the environmental concerns regarding the carbon emission.

Aircraft Micro Turbine Engines Market is segmented into End-Use, Engine Type, Platform, Horsepower, Fuel Type, Application and region.

On the basis of Platform

VTOL

Air Taxi

Cargo Aerial Vehicle

Business Jet

Ultra-Light Aircraft

Military Trainer Aircraft

Military UAV

On the basis of Region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Access Full Report: https://www.delvens.com/report/aircraft-micro-turbine-engines-market

In addition to the market data for Aircraft Micro Turbine Engines Market, Delvens offers client-centric report and customized according to the company’s specific demand and requirement.

More Related Reports:

Aerospace Parts Manufacturing market

Aircraft Insulation Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact us:

Unit No. 01, 3rd Floor, Plot No. 56, Block B

Sector 2 Noida, Near Noida Sector 15 Metro Station 201301, IN

+44 20 3290 6466

+0120- 4903958

0 notes

Text

Can a STEM Lab in Ahmedabad Help Your Students Excel in Competitions?

Introduction: A Tale of Innovation and Success

In a bustling school in Ahmedabad, a group of students eagerly prepares for a national robotics competition. Unlike their previous attempts, this time, they have an edge—a state-of-the-art STEM lab. With hands-on experience in coding, engineering, and problem-solving, they’re not just participating; they’re aiming to win. Their confidence stems from real-world application, innovation, and teamwork—all nurtured within the STEM lab.

But is your school providing the same opportunities?

The Growing Importance of STEM Labs in Schools

STEM (Science, Technology, Engineering, and Mathematics) education is no longer an option but a necessity. According to the National Science Foundation, 80% of future jobs will require STEM skills. The World Economic Forum predicts that artificial intelligence, automation, and robotics will shape the global job market, making technical proficiency essential for future professionals.

Ahmedabad is home to some of India’s leading technological institutions, and schools in the region are increasingly recognizing the need for STEM labs to prepare students for careers in technology, healthcare, and engineering.

A well-equipped STEM lab fosters:

1. Critical Thinking & Problem-Solving

Students engage in real-world challenges, learning how to analyze problems and develop solutions systematically. This skill is crucial for competitive exams, hackathons, and innovation challenges.

2. Hands-on Learning

Instead of just reading about concepts, students experiment with robotics, coding, 3D printing, and physics models, making learning more effective and engaging.

3. Creativity & Innovation

By designing and building prototypes, students develop an entrepreneurial mindset, learning to think outside the box and apply knowledge practically.

4. Teamwork & Collaboration

Most competitions require teamwork. A STEM lab encourages group projects and collaborative problem-solving, preparing students for professional work environments.

How STEM Labs Enhance Competition Readiness

Academic and innovation competitions demand more than just textbook knowledge. A STEM lab provides the perfect training ground for students to excel in:

1. Robotics & Coding Challenges

Ahmedabad schools with robotics kits, Arduino, Raspberry Pi, and AI simulation tools enable students to design and program their own robots. This is essential for competitions like:

First Tech Challenge (FTC)

Indian Robotics Olympiad (IRO)

World Robot Olympiad (WRO)

2. Science Olympiads & Engineering Competitions

Students with access to 3D printers, electronic circuits, and physics-based models gain hands-on experience in engineering and physics concepts, improving their performance in:

National Science Olympiad (NSO)

Intel ISEF (International Science and Engineering Fair)

Mathematics and Physics Tournaments

3. AI, Data Science & Mathematics Hackathons

With exposure to AI tools, machine learning platforms, and real-world data analysis, students develop analytical and coding skills, giving them an advantage in:

Google Code-In

Kaggle Machine Learning Competitions

Hackathons hosted by IITs and NITs

Real Results: The Impact of STEM Labs

A study by the National STEM Education Center suggests that students with access to STEM labs perform 30% better in problem-solving assessments than those without. Furthermore, CBSE and IB-affiliated schools in Ahmedabad that have integrated STEM labs report:

40% increase in student participation in national and international competitions.

Higher college placement rates in engineering and technology fields.

Improved confidence and public speaking skills due to project presentations.

Ahmedabad Schools Leading the Way

Several institutions in Ahmedabad have already integrated STEM labs with impressive results. Notable examples include:

Shanti Asiatic School Ahmedabad: Their STEM initiative helped students win national awards in robotics competitions.

Global Indian International School (GIIS): Students here have represented India in international science fairs after engaging in hands-on STEM learning.

Delhi Public School (DPS) Bopal: This school integrates AI and robotics into its curriculum, giving students exposure to modern technology.

Funding & Support for STEM Labs

Setting up a STEM lab may seem challenging, but various funding options can make it feasible:

1. Government Grants

Atal Tinkering Labs (ATL): The Government of India’s initiative under NITI Aayog provides funding for schools to set up STEM labs.

Department of Science & Technology (DST) grants: Schools can apply for government support for innovation in education.

2. Corporate Sponsorships & CSR Programs

Ahmedabad has a strong industrial base, with companies like Adani, Zydus, and Tata Motors supporting education through CSR (Corporate Social Responsibility) initiatives. Schools can collaborate with these companies to fund STEM labs.

3. EdTech Partnerships

Schools can collaborate with EdTech firms like Tinkercad, STEMpedia, and RoboFunLab for cost-effective lab setups and teacher training.

4. Crowdfunding & Community Support

Several educational institutions have successfully raised funds through crowdfunding platforms like Ketto and Milaap, involving the community in building better educational infrastructure.

Bring a STEM Lab to Your School Today!

Ready to empower the next generation of innovators? Contact us today to explore funding options and implementation strategies for your Ahmedabad school’s STEM lab!

0 notes

Text

3D and 4D Technology Market Sales, Trends, Region Forecast and Manufacturers in 2021-2031

The 3D and 4D Technology Market size is expected to reach US$ 1100.92 billion by 2031 from US$ 341.84 billion in 2024. The market is estimated to record a CAGR of 18.2% from 2024 to 2031.

📚 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐂𝐨𝐩𝐲@ https://www.businessmarketinsights.com/sample/BMIRE00031133

Executive Summary and Global Market Analysis:

3D technology refers to the creation, representation, and visualization of objects and environments in three dimensions—length, width, and depth—mimicking the way we perceive the real world. Unlike 2D, where objects are represented on a flat surface, 3D technology provides depth, allowing for more realistic experiences. 4D Technology is an extension of 3D technology, adding the element of time or dynamic movement to enhance the sensory experience. It integrates the concept of "motion" or physical interaction with the 3D visuals, creating an experience that changes or evolves over time. In many cases, 4D also includes additional sensory effects such as touch, vibration, temperature changes, or environmental effects such as wind or mist.

📚𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐋𝐢𝐧𝐤 @ https://www.businessmarketinsights.com/reports/3d-and-4d-technology-market

The 3D and 4D technology market have experienced robust growth in recent years, driven by advancements in technology and increased consumer demand for immersive experiences. The growing popularity of 3D-enabled TVs, smartphones, and VR headsets has spurred the demand for 3D and 4D content. Consumer interest in enhanced visual experiences drives the adoption of technologies like 3D projection and AR/VR gaming. The film and gaming sectors are major consumers of 3D and 4D technologies. 3D films have become mainstream, while 4D cinemas provide an enhanced experience by combining physical motion, environmental effects (such as wind, water, or scents), and 3D visuals. Improvements in display technologies, such as OLED and 8K resolution, contribute to sharper, more dynamic visuals, driving the demand for 3D content. Applications in gaming, education, healthcare, and training are major contributors to the rise of VR and AR, which depend on 3D and 4D technologies to provide immersive experiences. The demand for interactive, real-time experiences has driven advancements in haptic feedback, touch technology, and motion-sensing, essential elements in 4D environments.

Furthermore, 3D modeling is revolutionizing the construction and architecture industries in Asia, particularly in rapidly developing countries like China and India. The large-scale development of cities and infrastructure projects has fueled the widespread adoption of 3D modeling software, such as AutoCAD and Rhino. These tools empower architects and engineers to visualize complex building designs and optimize structures before physical construction commences. Notably, China has pioneered the use of 3D printing technologies to construct entire buildings, significantly reducing construction time and costs.

In the healthcare sector, countries like Japan and South Korea are leveraging 3D printing to produce customized prosthetics and implants, enhancing patient care and improving outcomes. For instance, Japan-based Mitsubishi Heavy Industries is actively developing advanced medical devices and tools using 3D printing. In India, 3D printing is making healthcare more accessible by enabling the production of affordable, patient-specific medical implants, such as titanium knee and hip replacements. This democratization of advanced medical technology is transforming healthcare delivery and improving the quality of life for patients.

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

𝐀𝐮𝐭𝐡𝐨𝐫’𝐬 𝐁𝐢𝐨:

Shreya Pawar

Senior Market Research

𝐘𝐨𝐮 𝐜𝐚𝐧 𝐬𝐞𝐞 𝐭𝐡𝐢𝐬-

North America Air Barrier Market- https://akashgharge.blogspot.com/2025/03/north-america-air-barrier-market.html

North America Non-Alcoholic Beverages Market- https://akashgharge.blogspot.com/2025/03/north-america-non-alcoholic-beverages.html

North America Industrial Insulation Market- https://akashgharge.blogspot.com/2025/03/north-america-industrial-insulation.html

1 note

·

View note

Text

Global Market Outlook for Non-Halogenated Flame Retardants: Type Segmentation, Market Size, Regional Insights, Leading Companies, Competitive Analysis, and Projections for 2025–2035

Non-Halogenated Flame Retardants Market: Growth, Trends, and Future Outlook

Industry Overview

The Non-Halogenated Flame Retardants (NHFR) Market was valued at USD 3.67 billion in 2024 and is projected to reach USD 8.38 billion by 2035, growing at a CAGR of 7.8% from 2025 to 2035. Stricter environmental regulations against halogenated flame retardants are fueling market expansion.

Get free sample Research Report - https://www.metatechinsights.com/request-sample/2157

Key Market Drivers

1. Stringent Government Regulations Fuel Market Growth

Governments worldwide are enforcing fire safety regulations, banning halogenated flame retardants due to their environmental and health hazards. Regulatory bodies such as the ECHA (Europe), EPA (US), and China’s National Fire Protection Regulations are setting new standards, particularly impacting construction, electronics, and automotive sectors.

Regulations such as RoHS and UL 94 are promoting phosphorus-based and mineral-based NHFRs in electrical and electronic applications. Rapid industrialization in Asia-Pacific is also accelerating NHFR adoption, as governments push for stricter fire safety laws.

2. Rise in Electric Vehicles (EVs) and Smart Construction Materials

The electric vehicle (EV) boom is driving demand for NHFRs in battery compartments, wiring, and electronic components to prevent fire hazards. NHFRs that comply with IEC 62619 and UL 2580 safety standards are critical in EV battery systems.

In the consumer electronics sector, rising demand for flame-resistant circuit boards, connectors, and enclosures is fueling the need for NHFRs. Similarly, sustainable construction materials, including NHFR-based insulation and coatings, are in high demand for green buildings and infrastructure projects.

Read Full Research Report https://www.metatechinsights.com/industry-insights/non-halogenated-flame-retardants-market-2157

Challenges in Market Expansion

High Costs of NHFRs

Despite their benefits, NHFRs remain expensive compared to halogenated alternatives. High raw material costs and complex production processes increase overall expenses, making them less accessible for cost-sensitive industries like textiles and budget electronics. Manufacturers are investing in material optimization and innovative formulations to make NHFRs more affordable and widely available.

Emerging Trends in NHFRs

1. Growing Demand for Sustainable, Bio-Based NHFRs

Eco-friendly NHFRs derived from starch, lignin, proteins, and bio-phosphates are gaining traction. These sustainable alternatives offer excellent flame retardancy, low toxicity, and biodegradability. The packaging and consumer goods industries are actively adopting these bio-based NHFRs to enhance fire safety while maintaining environmental responsibility.

2. NHFRs in High-Performance Polymers and 3D Printing

Industries such as automotive, aerospace, and electronics require flame-retardant engineering plastics and epoxy resins. NHFRs are increasingly used in 3D printing materials for fire-resistant parts in electrical enclosures, automotive interiors, and industrial applications.

Buy Now https://www.metatechinsights.com/checkout/2157

Industry Experts' Insights

John Miller, Product Development Manager at ChemPoint: “Regulatory pressures and consumer demand for safer products are pushing the industry toward NHFRs. Companies are developing alternative formulations to provide comparable fire resistance without the health risks of halogenated compounds.”

Dr. Michael Roberts, Polymer Chemist at Tosaf: “NHFRs are a safer and environmentally friendly alternative. They do not release toxic gases during combustion, making them ideal for applications with human exposure concerns.”

Market Segmentation

By Type: Phosphorus-based NHFRs dominate due to their high efficiency and low toxicity.

By Application: NHFRs are used in polyolefins, epoxy resins, polyurethane foams, PVC, and engineering plastics.

By Industry: Electronics, automotive, textiles, and construction are the primary consumers of NHFRs.

Regional Analysis

North America: The largest NHFR market, driven by strict fire safety regulations.

Asia-Pacific: The fastest-growing region, with China, India, Japan, and South Korea increasing NHFR adoption due to industrial growth and EV expansion.

Recent Developments

January 2024: Phosphorus-based NHFRs emerge as the fastest-growing segment.

November 2023: Introduction of DOPO-t-SiO2 nanoparticle-based NHFRs for enhanced fire protection.

October 2023: Magnesium hydroxide flame retardants gain popularity for low-smoke emissions and environmental benefits.

0 notes

Text

3D and 4D Technology Market Overview, Top Key Players, Market Growth Analysis by Forecast to 2031

The 3D and 4D Technology Market size is expected to reach US$ 1100.92 billion by 2031 from US$ 341.84 billion in 2024. The market is estimated to record a CAGR of 18.2% from 2024 to 2031.