#3 valve manifold

Explore tagged Tumblr posts

Text

Manifold Valve Manufacturer & Supplier

Avlok is one of the leading Manifold Valve Manufacturers, suppliers, and exporters who provide their customers with products that are of international quality standard at the most cost-effective price in the market. Avlok specialises in manifold valves, 2 Way manifold, 3 Way Manifold and 5 Way Manifold Valves. Find a wide range of industry best 2-3-5 way manifold valves. All our products are compatible with ISO 9001:2015, PED Certified and our In-House testing facility assures, verify and confirm high quality of products that are available to our customer’s at the most competitive prices and in the least possible time

0 notes

Text

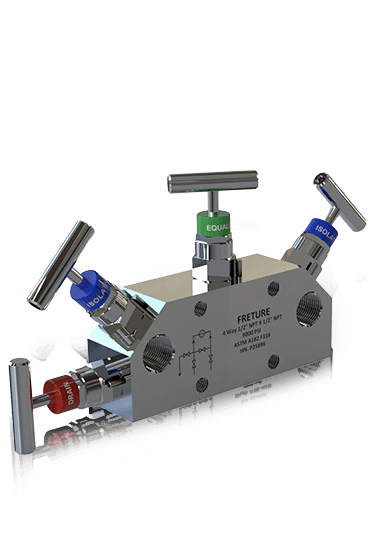

4 Way Manifold Valve: Key Applications and Benefits

A 4 Way Manifold Valve is a crucial component in many industrial systems, especially in the oil and gas, chemical, and pharmaceutical industries. These valves are designed to streamline pressure measurement processes, particularly when used with pressure transmitters and gauges. They ensure accurate readings, simplify maintenance, and improve overall system reliability.

In this article, we will explore the structure, function, and key advantages of 4 Valve Manifolds, along with a closer look at their applications in pressure transmitters and gauges.

What is a 4 Way Manifold Valve?

A 4 Way Manifold Valve is a multi-port valve designed to control the flow of fluids in a pipeline. It typically consists of four valves integrated into a single unit, allowing for the isolation, equalization, and venting of pressure instruments. This makes it highly versatile and suitable for pressure measurement systems.

The valve's four ports typically serve different purposes:

Isolation Valves (2 ports): These valves are used to isolate the pressure instrument (e.g., pressure transmitter or gauge) from the process fluid, ensuring safe removal or maintenance of the instrument without disrupting the entire system.

Equalizing Valve (1 port): This valve equalizes the pressure across both sides of the transmitter or gauge, ensuring accurate measurements.

Venting Valve (1 port): This valve allows for the safe venting of trapped pressure, preventing potential damage to the instrument or the system.

Applications of 4 Way Manifold Valves

4 Valve Manifold for Pressure Transmitter Pressure transmitters are critical in monitoring and controlling industrial processes. The 4 valve manifold for pressure transmitter plays a key role in protecting the transmitter and ensuring accurate readings. These valves allow operators to isolate the transmitter from the process, equalize pressures, and safely vent any excess pressure before maintenance or calibration.

Isolation: By using the isolation valves, the pressure transmitter can be completely cut off from the process line, enabling safe removal or replacement without affecting the overall system operation.

Equalization: The equalizer valve balances pressure on both sides of the transmitter, preventing inaccurate readings due to differential pressures.

Venting: The venting valve allows for the controlled release of pressure before opening the transmitter, preventing system damage or hazards.

4 Valve Manifold for Pressure Gauge Pressure gauges provide essential data about system pressure. In high-pressure environments, a 4 valve manifold for pressure gauge ensures that the gauge can be isolated and serviced without halting operations. Like the pressure transmitter manifold, it offers isolation, equalization, and venting capabilities to ensure the gauge operates efficiently and safely.The manifold also protects the pressure gauge from pressure surges or process fluid contamination, ensuring longevity and accuracy. This is especially important in applications where continuous and precise pressure monitoring is critical, such as in oil and gas or pharmaceutical processing.

4 Way Valve Manifold for Pressure Transmitter In complex process systems, a 4 way valve manifold for pressure transmitter is essential for ensuring accurate pressure measurement and system safety. The four-port design allows for easy pressure balancing, maintenance, and venting, reducing the risk of inaccurate readings or system failures.This type of manifold is commonly used in critical industries such as chemical processing, where maintaining the integrity of pressure measurement devices is essential for both safety and operational efficiency.

Key Features and Benefits of 4 Way Manifold Valves

Compact Design One of the primary benefits of the 4 valve manifold is its compact design. By integrating multiple functions (isolation, equalization, and venting) into a single unit, these valves reduce the need for additional piping or components, saving space and simplifying installation.

Improved Safety The ability to isolate, equalize, and vent pressure instruments significantly enhances safety in industrial environments. Operators can safely remove or maintain pressure gauges and transmitters without risking exposure to high-pressure fluids or gases. Additionally, the venting function ensures that trapped pressure is safely released, preventing potential accidents.

Enhanced Accuracy Pressure measurement instruments rely on stable, equal pressures for accurate readings. The 4 way valve manifold for pressure transmitter and gauge ensures that pressure is properly equalized across both sides of the instrument, reducing the risk of measurement errors. This is especially important in industries where precise pressure monitoring is critical for product quality or safety.

Versatility These manifolds are highly versatile and can be used with a variety of pressure instruments, including transmitters, gauges, and switches. Whether you're working in an oil refinery or a pharmaceutical manufacturing plant, a manifold 4 valve will meet the demands of high-pressure environments.

Ease of Maintenance The integrated design of the 4 valve manifold allows for easy maintenance of pressure instruments without shutting down the entire system. Operators can isolate the instrument, vent any remaining pressure, and perform maintenance tasks with minimal disruption to operations. This reduces downtime and maintenance costs, improving overall system efficiency.

Corrosion Resistance Many 4 valve manifolds are constructed from high-quality materials such as stainless steel or carbon steel, making them resistant to corrosion and suitable for harsh environments. In industries where exposure to corrosive fluids or extreme temperatures is common, these manifolds ensure long-term reliability and performance.

How to Choose the Right 4 Way Manifold Valve

Selecting the appropriate 4 valve manifold for your system depends on several factors:

Pressure Rating Ensure that the manifold is rated for the maximum pressure in your system. Operating a manifold outside its pressure limits can lead to valve failure or system damage.

Material Compatibility Choose a manifold made from materials compatible with your process fluids. For instance, stainless steel manifolds are highly resistant to corrosion and suitable for a wide range of industrial applications, while carbon steel is typically used for lower-cost applications.

End Connections Consider the type of end connections you require, such as threaded or flanged connections. The connection type should match the specifications of your pressure instruments and piping system.

Operating Temperature Make sure the manifold is rated for the temperature range of your system. High-temperature applications may require specialized materials or seals to ensure long-term performance.

Application Finally, consider the specific application. Whether you're using the manifold with a pressure transmitter or gauge, ensure that it has the necessary isolation, equalization, and venting capabilities to meet your system's requirements.

Best Practices for Installation and Maintenance

Proper Installation Ensure that the 4 valve manifold is properly installed to prevent leaks or pressure drops. Check that all connections are secure and that the manifold is mounted in a position that allows easy access for maintenance.

Regular Maintenance Perform regular maintenance checks to ensure the manifold and pressure instruments are functioning correctly. This includes inspecting seals, checking for leaks, and testing the isolation, equalization, and venting functions.

Calibrate Instruments Periodically calibrate pressure transmitters and gauges to ensure accurate readings. The 4 valve manifold simplifies this process by allowing easy isolation and venting of the instrument.

Use in Clean Environments If used in industries with strict cleanliness requirements, such as pharmaceuticals, ensure that the manifold is regularly cleaned to prevent contamination. Manifolds designed for clean environments may include features such as smooth internal surfaces to minimize fluid retention.

A 4 Way Manifold Valve offers a reliable solution for managing pressure measurement in industrial systems. Its compact design, enhanced safety features, and ease of maintenance make it a popular choice across a wide range of industries. By ensuring accurate pressure readings, it helps improve system efficiency and reduces the risk of costly errors or accidents.

When selecting a 4 valve manifold, consider factors such as pressure rating, material compatibility, and end connections to ensure optimal performance in your specific application.

Buy 4 Way Manifold Valves from Freture Techno Pvt. Ltd., a trusted manufacturer of high-quality industrial valves and instrumentation. Their manifolds are designed to meet the demands of modern industrial processes, ensuring reliability, safety, and precision in pressure measurement systems.

#manifold valves#2 way manifold valves#3 way manifold valves#4 way manifold valves#5 way manifold valves#instrumentation valves#freture techno

0 notes

Text

Top-Quality 3 Way Manifold Valve | Venture 11

The 3 Way Manifold Valve by Venture 11 is a precision-engineered solution designed to enhance the efficiency and safety of your fluid control systems. This versatile valve allows for seamless integration into various industrial applications, offering reliable performance under demanding conditions. Whether it's for oil and gas, chemical processing, or power generation, this valve ensures accurate control of fluid flow with minimal maintenance. Crafted from high-quality materials, the 3 Way Manifold Valve is built to withstand high pressures and temperatures, making it ideal for critical operations. Its compact design saves space while providing robust functionality, enabling operators to easily manage complex piping systems. The valve’s three-way configuration allows for flexible flow paths, offering both mixing and diverting capabilities. This adaptability makes it a preferred choice for industries requiring precise control over fluid direction. At Venture 11, quality and reliability are paramount. Our 3 Way Manifold Valve is subjected to rigorous testing to ensure it meets international standards, providing you with peace of mind and long-term performance.

For more details clicks here - https://www.venture11.au/3-way-manifold-valve.php

0 notes

Text

Manifold Valves Manufacturer and Supplier in India.

Nakoda Metal Industries is a well-known Manifold Valve Suppliers in India. Customer satisfaction is always our first priority, and we work hard to ensure that our Manifold Valves products give the greatest performance while exceeding our customers' expectations.

Manifold Valves Supplier selling several different types of manifold valves, including:

2 Way Manifold Valve, 3 Way Manifold Valve, 4 Way Manifold Valve & 5 Way Manifold Valve. At Nakoda Metal Industries, We provide a selection of manifold valve types at competitive rates, including two-way, three-way, and more, making us one of the most sought after Manifold valves supplier and Instrumentation Valve Supplier in India as well as globally.

We are also one of the best Instrumentation Tube Fittings Supplier in India. Our Instrumentation Tube Fittings products go through a number of quality checks to guarantee they meet the highest standards.

For more details

Product: Manifold Valve Dealer in India & Instrumentation Tube Fittings Supplier

#Instrumentation Tube Fittings Manufacturer in India#Instrumentation Tube Fittings Manufacturer#Instrumentation Tube fittings supplier#Manifold Valve supplier in India#Manifold Valve Supplier#2 Way Manifold Valve#3 Way Manifold Valve#4 Way Manifold Valve#5 Way Manifold Valve

0 notes

Text

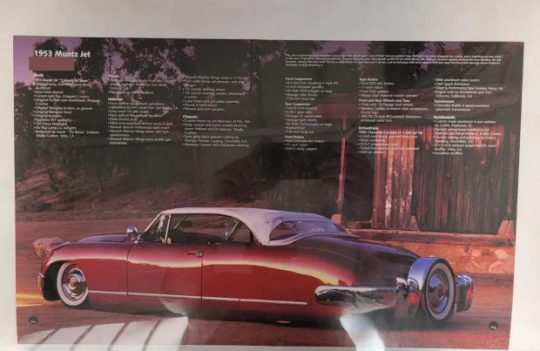

Custom 1953 Muntz Jet Convertible

This 1953 Muntz Jet convertible underwent a three-year custom build under previous ownership, and it was purchased by the seller in 2021. The car is powered by a fuel-injected 5.7-liter LT1 V8 engine paired with a four-speed automatic transmission and a Ford 9″ rear end, and it is finished in Apple Pearl with a white Carson-style removable top over gray snakeskin-style Naugahyde upholstery. Features include custom bodywork, an Art Morrison frame, power-assisted steering, four-wheel disc brakes, airbag suspension, Painless Performance wiring, and more modified and fabricated details. This custom-built Muntz is now offered with a copy of Rodder’s Journal magazine featuring a story on the build and a clean California title in the name of the seller’s business.

Custom 1953 Muntz Jet Convertible

The steel, aluminum, and fiberglass body is mounted on an Art Morrison ladder frame that was boxed and finished in semi-gloss black, and the floor was raised 3″. The exterior was repainted in a Sherwin Williams two-stage Apple Pearl mixed by the late Stan Betz. Features include a chopped Duvall-style windshield, 1950 Chevrolet headlights, dual Appleton spotlights, 1951 Ford Victoria side windows, and a white removable Carson-style top fabricated to match the height of the chopped windshield. Additional equipment includes color-matched rear fender skirts and chrome bumpers. Wear from fitting the top is noted on the rear deck.

Custom 1953 Muntz Jet Convertible

Steel wheels sourced from a 1976 Dodge measure 15″ and are mounted with Cadillac Sombrero-style covers and whitewall tires. A matching spare fitted with a BFGoodrich Silvertown tire is mounted within a rear-mounted Continental-style chrome carrier. A Mustang II front end accommodates power rack-and-pinion steering , and the car rides on an electronically-adjustable Air Ride Technologies airbag suspension system along with 2” lowered front spindles, Strange Engineering tube shocks, a rear Panhard bar, and front and rear sway bars. The seller reports that the front control arm bushings were recently replaced.

Custom 1953 Muntz Jet Convertible

Custom 1953 Muntz Jet Convertible

Braking is handled by GM G-body-sourced calipers matched with Ford Granada discs up front and Ford SVO-specification calipers and discs at the rear.

Custom 1953 Muntz Jet Convertible

The cabin was customized by Jim’s Auto Trim of San Diego, California, and features Glide bucket seats and a rear bench trimmed in gray snakeskin-style Naugahyde upholstery, along with matching treatments for the dash trim, headliner, and door panels. Additional equipment includes a 1952 Lincoln steering wheel mounted to a shortened Lincoln steering column, gray cut-pile carpet, and a Pioneer stereo housed within a custom center cubby.

The engine-turned “Hollywood” instrument cluster houses Stewart Warner gauges consisting of an 8k-rpm tachometer, a 160-mph speedometer, and auxiliary readings for fuel level, battery charge, oil pressure, and water temperature. The five-digit odometer displays 25k miles, though total chassis mileage is unknown. A Lokar pedal assembly was fitted during the build.

Custom 1953 Muntz Jet Convertible

The Corvette-sourced 5.7-liter LT1 V8 features a polished fuel intake manifold along with billet aluminum valve covers, and additional features include an Opti-Spark distributor, a Griffin aluminum radiator, and a wiring loom sourced from Painless Performance Wiring. A set of long-tube headers are connected to a 2.5″ exhaust system equipped with dual Dynaflow mufflers. The seller reports that the oil was recently changed.

Custom 1953 Muntz Jet Convertible

Power is routed to the rear wheels via a four-speed 4L60E automatic transmission and a Ford 9″ rear end with with 3.55:1 gears and Strange Engineering 31-spline axles. Additional photos of the underside, drivetrain, and suspension components are presented in the gallery below.

Custom 1953 Muntz Jet Convertible

The car was featured in issue #36 of Rodders Journal magazine

#Custom 1953 Muntz Jet Convertible#Custom 1953 Muntz Jet#Muntz Jet Convertible#Custom Muntz Jet Convertible#Muntz Jet#Convertible#car#cars#muscle car#american muscle

110 notes

·

View notes

Text

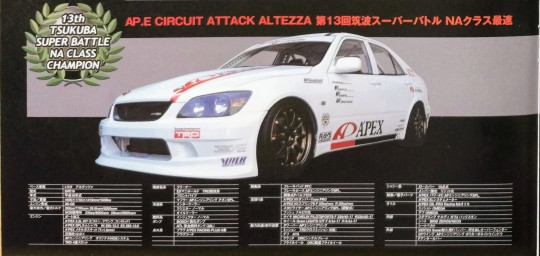

13th TSUKUBA SUPER BATTLE NA CLASS

CHAMPION

AP.E CIRCUIT ATTACK ALTEZZA 13th Tsukuba Super Battle NA class fastest

BASE VEHICLE MODEL

1998 SXE10 Toyota Altezza

DIMENSIONS/WEIGHT

4400×1755×1410mm/1030kg

ENGINE TYPE

3S-GE

MAXIMUM POWER/MAXIMUM TORQUE

282ps/7700rpm 28.6kgm/6200rpm

When using NOS 335ps/8000rpm 33kgm/6000rpm

ENGINE

Port processing

A'PEX 2.2L KIT (piston, crank, connecting rod)

A'PEX SPL Camshaft IN 295-13.3 EX 285-13.0

A'PEX Metal Gasket (T-1.5mm)

Compression ratio 12.0:1

AP Engineering Original NOS System

TRD 4 slots

INTAKE AND EXHAUST SYSTEM

cleaner

EX manifold for TRD competition

front pipe

Muffler AP Engineering Titanium SPL

COOLING SYSTEM

intercooler

radiator normal

oil cooler

FUEL SYSTEM

injector normal

PUMP - BOSCH Reinforced Pump

ATL Safety Fuel Tank (30L)

IGNITION SYSTEM

PLUG A'PEX RACING PLUG No. 9

Plug cord

BRAKING SYSTEM

Brake pad PFC

Brake Hose AP Engineering SPL

With adjustable P valve

SUSPENSION SYSTEM

A'PEX N1 Dunbar Type PRO

A'PEX N1 Spring IIF 22kg/mm R20kg/mm

Stabilizer AP Engineering SPL. (Adjustable)

Bush full pyrolysis

Tire MICHELIN PILOTSPORTS F 235/40-17 R235/40-17

Wheels Gram LIGHTS 57F F 8.5J-17 R 8.5J-17

POWER TRANSMISSION/TRAVEL DEVICE

Tower Bar AP Engineering

Mission TRD cross mission (6 speed)

Differential ATS

Clutch ORC single plate

Flywheel ORC lightweight flywheel

CHASSIS SYSTEM

Roll bar 15 points

Strengthen members and make them rigid

CONTROL/ELECTRONIC PARTS

A'PEX Power FC AP Engineering SPL.

A'PEX EL System Meter

OIL

A'PEX OIL PRO Racing NA oil

Mission OMEGA

Differential OMEGA

INTERIOR

Steering Nardi gala 3 Buckskin

Seat BRIDE ZEROS/NEOS

Seat belt

EXTERIOR

VERTEX Super durable F bumper, raised over fender

GT Wing, AP Engineering Polycarbonate Window

F under cover

15 notes

·

View notes

Text

Top valve manufacturer and supplier near me

Explore a comprehensive range of high-quality industrial manufacturing valves at Dinesh Industries. Our product line up includes precision-engineered valves such as needle valves, non-return valves, ball valves, 2-way manifolds, 3-way manifolds and 5-way manifold . Designed for efficiency and reliability, our valves are ideal for a variety of applications. Find the perfect solution for your fluid control needs with our durable and performance-driven valve products. Trust Dinesh Industry for top-notch engineering and unmatched quality in every valve we offer.

3 notes

·

View notes

Text

Indonesia, Brazil, and South Africa are the new opportunity grounds for Pneumatic Actuators market players

According to a recent research, Industry revenue for Pneumatic Actuators is expected to rise to $13.0 billion by 2035 from $5.9 billion of 2024. U.S., Germany and China are the top 3 markets and combinely holds substantial demand share. The revenue growth of market players in these countries is expected to range between 4.9% and 7.2% annually for period 2025 to 2035.

Industry transition including transition to intelligent pneumatic systems and advent of iot in pneumatic applications, are transforming the supply chain of Pneumatic Actuators market. The main trend, in Pneumatic Actuators is moving towards pneumatic systems to improve energy efficiency and performance levels effectively through sensor integration and advanced algorithms for real time self adjustments This approach aims to enhance productivity reduce downtime and optimize system efficiency overall. In the manufacturing industry specifically their presence has made a difference resulting in reduced costs and faster operations.

Check detailed report here - https://datastringconsulting.com/industry-analysis/pneumatic-actuators-market-research-report

Research Study addresses the market dynamics including opportunities, competition analysis, industry insights for Type (Rack & Pinion, Vane, Scotch Yoke), Component (Cylinders, Valves, Control units, Manifolds) and Function (Single acting, Double acting).

Industry Leadership and Strategies

Companies such as Emerson Electric Co., Rotork PLC, IMI PLC, Flowserve Corporation, Pentair Ltd., Brkert Werke GmbH, Festo AG & Co. KG, Eaton Corporation PLC, SMC Corporation, Belimo Automation AG, Parker Hannifin Corp. and Auma Riester GmbH & Co KG. are well placed in the market. Below table summarize the strategies employed by these players within the eco-system.

Application Area

Leading Providers / Consumers

Provider Strategies

Oil and Gas

Emerson Electric Co.

Emphasis on innovation and sustainability, focusing on stringent safety codes and efficiency in harsh environments

Automobile Manufacturing

SMC Corporation

Provider focuses on customization and incorporating advanced technologies within pneumatic actuators for optimum performance

Food and Beverage Processing

Festo Group

Strategizes on offering clean, compliant, and compact pneumatic actuators that comply with food grade standards

Evolving & Shifting Regional Markets

North America and Asia-Pacific are the two most active and leading regions in the market. With different regional dynamics and industry challenges like high maintenance costs and complex installation processes; market supply chain from raw materials supply to distribution & end users is expected to evolve & expand further, especially within emerging markets

The market in emerging countries is expected to expand substantially between 2025 and 2030, supported by market drivers such as automation in industrial processes, energy sector demand, and low-cost and maintenance-free operations.

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting offers complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. Our Industry experts and data aggregators continuously track & monitor high growth segments within more than 15 industries and 60 sub-industries.

https://datastringconsulting.com/downloadsample/pneumatic-actuators-market-research-report

0 notes

Text

Subsea Manifolds Market Forecast 2025-2032: Size, Share, and Emerging Opportunities

The subsea manifolds market is an integral part of the subsea oil and gas industry, playing a crucial role in the extraction of hydrocarbons from beneath the ocean floor. Subsea manifolds serve as central hubs that collect, distribute, and control the flow of oil and gas from various wells to the surface production facilities. These systems are vital for the safe and efficient management of subsea operations, and their demand has been growing steadily, driven by advancements in offshore exploration and production technology. This research explores the size, share, and growth analysis of the subsea manifolds market, with insights into future trends, key drivers, challenges, and opportunities.

Subsea Manifolds Market Overview:

Subsea manifolds are sophisticated systems used to regulate and control the flow of hydrocarbons in offshore oil and gas fields. These manifolds consist of several components, including pipes, valves, and sensors, designed to manage and direct fluids from multiple subsea wells to the surface production unit. The systems can be used in both shallow and deep-water fields and are typically deployed in harsh environments where safety, reliability, and performance are paramount.

Get a Free Sample Copy - https://www.skyquestt.com/sample-request/subsea-manifolds-market

Subsea manifolds are designed for use in various offshore oil and gas projects, including:

- Subsea production systems

- Subsea tie-back systems

- Enhanced oil recovery (EOR) applications

- Subsea storage systems

As exploration moves into deeper waters, and with the increasing trend of offshore drilling and production in challenging environments, the demand for high-performance subsea manifolds has risen.

Market Size and Growth Projections:

The subsea manifolds market has experienced steady growth over the past few years and is expected to continue expanding throughout the forecast period. According to industry reports, the global subsea manifolds market was valued at USD 5.52 billion in 2024 and is projected to reach USD 8.98 billion by 2032, growing at a compound annual growth rate (CAGR) of around 6.29%.

Several factors contribute to this growth, including the ongoing expansion of offshore exploration projects, the increasing focus on deep-water oil and gas reserves, and the rising demand for energy in emerging economies. Furthermore, innovations in subsea technology and the continued push for sustainability in offshore oil and gas operations are expected to fuel demand for more efficient and reliable subsea manifolds.

Key Drivers of Market Growth:

1. Rising Offshore Exploration and Production: With the depletion of onshore oil reserves and the increasing complexity of subsea deposits, offshore exploration and production are gaining momentum. The demand for subsea manifolds is closely tied to the expansion of offshore oil fields, especially in deep-water and ultra-deep-water regions.

2. Technological Advancements: Significant innovations in subsea manifold design, such as enhanced materials, better corrosion resistance, and automation systems, have improved reliability and efficiency. These advancements have expanded the range of subsea applications and increased the attractiveness of subsea manifolds to oil and gas operators.

3. Energy Demand and Security: With the rising global energy demand and the need for secure, long-term energy supply sources, there is an increasing emphasis on subsea oil and gas production. Subsea manifolds play a crucial role in maximizing recovery from mature oil fields, thereby enhancing the overall productivity of offshore projects.

4. Growth in Developing Regions: Emerging economies, especially in Asia-Pacific, Latin America, and Africa, are witnessing a rise in offshore exploration and production activities. The growing demand for oil and gas in these regions is expected to drive further investment in subsea infrastructure, including manifolds.

5. Subsea Tie-Back Systems: The increasing popularity of subsea tie-back systems, which connect new subsea wells to existing offshore platforms, is expected to bolster the demand for subsea manifolds. Tie-back systems are cost-effective solutions for developing smaller fields and accessing previously untapped reserves.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/subsea-manifolds-market

Subsea Manifolds Market Segments Analysis

Global Subsea Manifold Market is segmented by Type, application, Water Depth and region.

Based on Type, the market is segmented Template, Cluster, and Pipeline End Manifold.

Based on application, the market is segmented into Manufacturing and Injection.

Based on Water Depth, the market is segmented into Shallow Water and Deep Water.

Based on region, the market is segmented into North America, Europe, Asia Pacific, Latin America and Middle East & and Africa.

Market Challenges:

1. High Initial Investment and Operational Costs: Subsea manifold systems are capital-intensive due to their complexity, durability, and the need for specialized materials. High initial investments can be a barrier for some smaller oil companies, particularly in uncertain market conditions. Additionally, the operational and maintenance costs associated with subsea manifolds are significant.

2. Environmental Regulations and Sustainability: As the global focus shifts towards environmental sustainability, oil and gas companies are under increasing pressure to reduce the environmental impact of their operations. Compliance with stringent regulations governing offshore operations may present challenges for manufacturers and operators of subsea systems.

3. Technological Integration: Integrating advanced digital technologies such as remote monitoring, predictive maintenance, and automation into subsea manifold systems is a complex process. The inability to effectively incorporate these technologies may hinder market growth.

Regional Insights:

1. North America: North America remains a key market for subsea manifolds due to the robust offshore exploration activities in the Gulf of Mexico. The United States, in particular, is seeing a resurgence in offshore oil production, which drives the demand for subsea manifolds.

2. Europe: Europe also represents a significant market share, primarily driven by oil and gas activities in the North Sea. The UK and Norway are major players in the offshore oil and gas sector in this region, with a growing number of deep-water projects requiring subsea manifold systems.

3. Asia-Pacific: The Asia-Pacific region is witnessing rapid growth due to the increasing exploration activities in countries like China, India, and Australia. The rising demand for energy and the focus on subsea technology advancements will drive the subsea manifolds market in this region.

4. Middle East and Africa: The Middle East and Africa region is expected to experience steady growth due to the continued investment in offshore oil fields, especially in countries like Saudi Arabia, UAE, and Egypt. The region's abundant oil reserves and the need for enhanced oil recovery will contribute to the demand for subsea manifolds.

Take Action Now: Secure Your Subsea Manifolds Market Today - https://www.skyquestt.com/buy-now/subsea-manifolds-market

Competitive Landscape:

Key players in the subsea manifolds market include:

ABB (Switzerland)

Aker Solutions (Norway)

Baker Hughes Company (USA)

TechnipFMC (USA/UK)

Saipem (Italy)

Subsea 7 (UK/Norway)

OneSubsea (USA)

National Oilwell Varco (USA)

Oceaneering International (USA)

Dril-Quip Inc. (USA)

Siemens Energy (Germany)

Schlumberger Limited (USA)

NOV Flexibles (USA)

Emerson Electric Company (USA)

Prysmian Group (Italy)

Nexans (France)

JDR Cable Systems (UK)

Jotne Group (Norway)

Weatherford (USA)

Halliburton Company (USA)

These companies dominate the market with their extensive experience in subsea technology and manufacturing capabilities. Many are focused on developing innovative products and offering integrated solutions to reduce costs and enhance the efficiency of subsea systems.

Future Outlook:

The subsea manifolds market is poised for strong growth over the next decade. As the energy sector continues to move toward deep-water and ultra-deep-water oil fields, the demand for advanced subsea infrastructure, including manifolds, is expected to rise significantly. Technological advancements, coupled with increasing energy demands in emerging economies, will continue to fuel market expansion.

With a focus on sustainability and efficiency, subsea manifold systems will evolve, incorporating automation, remote monitoring, and digitalization to enhance their performance and reduce costs. Additionally, with ongoing research into improving subsea material strength and reducing maintenance intervals, the future of the subsea manifolds market looks promising.

Read Subsea Manifolds Market Report Today - https://www.skyquestt.com/report/subsea-manifolds-market

The subsea manifolds market is on a solid growth trajectory, driven by technological advancements, increasing offshore exploration, and the global demand for energy. While challenges such as high investment costs and environmental regulations persist, the long-term outlook for the market remains optimistic. With the continued development of new subsea technologies and increasing investments in offshore projects, subsea manifolds will continue to play a critical role in ensuring the success of offshore oil and gas operations well into the future.

#SubseaManifolds#OffshoreOilAndGas#SubseaTechnology#EnergyIndustry#OffshoreEngineering#SubseaProduction#OilAndGasMarket#EnergySolutions#DeepwaterDrilling#SubseaSystems#OffshoreInfrastructure#MarineEngineering#OilAndGasTechnology#SubseaDevelopment#SubseaInnovation

0 notes

Photo

Written by Menswear Style in Cars on the 27th January 2025 You can tweak and tune Harleys in dozens of ways and by using hundreds of original equipment and aftermarket parts. Most riders want more push when on the throttle start with changes to the engine. The V-twins are all known for their huge low-end torque. What’s missing though is mid-to-high rev power, meaning most Harleys, regardless of displacement, max out at 120hp. And compared to other big bikes can feel out of puff at highway speeds. To extend power bands, and get more power higher up, consider 3 simple additions all connected with optimizing airflow – velocity stacks, air cleaners and aftermarket exhausts. The parts are relatively easy to install, cheap to buy and help boost power output when torque maxes out. Velocity Stacks Velocity stacks, trumpets or air horns are elongated tubes attached to the engine's air intake. Their main purpose is to maximise airflow into the intake. They date back to the beginning of the internal combustion engine, allowing carburettors to adjust air-fuel mixtures as engine loads change. Their specific design means air is eased into the carb, and flows smoothly to the engine. Over time, different designs have been optimised to work with newer tech and today you'll find Harley Davidson velocity stacks for both carburetted and injected engines, meaning everything from the Knucklehead to the Milwaukee Eight. Velocity stacks are tasked with getting more air into the engine. More air means more fuel and bigger bangs. The way they do this is by accelerating air into the intake manifold, with the smooth and tapered opening also helping to reduce turbulence. The result is cleaner and more efficient combustion, and by default, more power. Smoother airflow increases air volume and more air ready to be mixed with fuel. The curved, trumpet designs in velocity stacks help in this respect. Moreover, by changing stack tubing lengths, bike owners can also tune power outputs at different RPMs. In essence, shorter velocity stacks tune power and torque at higher revs, while choosing longer types gives more low-to-mid-end push. Something you'll appreciate when getting up to speed or when overtaking. The science at the core of this (called resonance supercharging) is all about tuning the pulses of air rushing through the intake. Choosing the right length helps prevent built-up air from hitting intake valves the moment they are closed and the subsequent effect of pulsating air between the intake runners and valves. With the valves open, air is pushed into the cylinder at higher pressure, resulting in a supercharging effect and improved throttle response. Added benefits are the louder engine rumble in Harley V-twins and the machined looks bound to turn heads. The parts are supplied with included backing plates, breathers and front screens for filtering and included mounting hardware for easy installation. Air Cleaner Kits One of the major gripes with Harley Davidson velocity stacks is that you'll need extensive knowledge of how airflow works and choosing stacks in the right length tailored to the engine specifics and your tuning goals. Another is the limited filtering capacity from the attached screens. To allow for unobstructed air delivered in the right volume and right speeds at set engine speeds, consider going with aftermarket air cleaner kits. These are assembled filters with matching piping that smooth out and direct airflow to the carb or intake manifolds, depending on the engine in your hog. Aftermarket cleaners also address the shortfalls of factory Harley air filters, made of low-quality paper and with lower efficiency, by removing common problems like dust and water that can hurt your engine. Look for cleaner kits with reusable and washable cotton cleaners that remove all particles to deliver oxygen-rich air in for combustion, and more of it. Again, the main prerequisite for engine power is how much air it pushes. Aftermarket cleaners are visibly bigger so draw more air in, and most include proprietary tech like machined openings and bolts that optimise airflow for both injected and carburetted Harleys. Harley owners can choose OE replacement filters to supply more air from the same space, or complete kits with reusable filters and machined hardware that also looks good. Exhausts More air in means more out. If you've increased airflow using either Harley velocity stacks or a bespoke air cleaner kit, the benefits end there if you don't also re-jet the carbs or do a fuel tune and change the stock exhaust piping. Stock exhausts are the major restrictors of spent gases. This is partially down to strict emissions and noise regulations that are effectively choking the engine and possibly one of the reasons Harley Davidson is increasing engine sizes in subsequent model years. Like velocity stacks and air cleaners, exhausts work effectively by increasing airflow. This means less backpressure from parts that control noise levels like factory baffles and aid exhaust velocity, so the engine can take its next breath faster. Aftermarket parts can also include redesigned headers to help with the pulsating effect of scavenging or the vacuum that draws spent gases out of the cylinders faster. This is achieved with wider and/or straighter piping with carefully chosen lengths. There are different exhaust options for your bike. The simplest way to get more horsepower to the rear wheel is to use a less restrictive aftermarket slip-on muffler. Besides increasing exhaust velocity and helping the engine breathe, slip-ons can add more substance to the exhaust note and also shed some weight. And as the name implies they're easy to get on. For gains that you can actually feel, choose 2-into-1 full exhausts to increase scavenging, especially at high and peak torque (around 3000 RPMs in most Harleys). This additionally means a livelier throttle response. Or go with 2-into-2 systems for improved scavenging and slight overlap that helps in the low to mid power band. A newer hybrid take on both types is the 2-1-2 exhaust, offering the best of both worlds. Choose exhausts and exhaust parts that are compatible with your Harley, have included mounting hardware to shorten installation times, and are built with quality materials (and street-legal sound deadeners) to ensure they last. /* */ Source link

0 notes

Photo

Written by Menswear Style in Cars on the 27th January 2025 You can tweak and tune Harleys in dozens of ways and by using hundreds of original equipment and aftermarket parts. Most riders want more push when on the throttle start with changes to the engine. The V-twins are all known for their huge low-end torque. What’s missing though is mid-to-high rev power, meaning most Harleys, regardless of displacement, max out at 120hp. And compared to other big bikes can feel out of puff at highway speeds. To extend power bands, and get more power higher up, consider 3 simple additions all connected with optimizing airflow – velocity stacks, air cleaners and aftermarket exhausts. The parts are relatively easy to install, cheap to buy and help boost power output when torque maxes out. Velocity Stacks Velocity stacks, trumpets or air horns are elongated tubes attached to the engine's air intake. Their main purpose is to maximise airflow into the intake. They date back to the beginning of the internal combustion engine, allowing carburettors to adjust air-fuel mixtures as engine loads change. Their specific design means air is eased into the carb, and flows smoothly to the engine. Over time, different designs have been optimised to work with newer tech and today you'll find Harley Davidson velocity stacks for both carburetted and injected engines, meaning everything from the Knucklehead to the Milwaukee Eight. Velocity stacks are tasked with getting more air into the engine. More air means more fuel and bigger bangs. The way they do this is by accelerating air into the intake manifold, with the smooth and tapered opening also helping to reduce turbulence. The result is cleaner and more efficient combustion, and by default, more power. Smoother airflow increases air volume and more air ready to be mixed with fuel. The curved, trumpet designs in velocity stacks help in this respect. Moreover, by changing stack tubing lengths, bike owners can also tune power outputs at different RPMs. In essence, shorter velocity stacks tune power and torque at higher revs, while choosing longer types gives more low-to-mid-end push. Something you'll appreciate when getting up to speed or when overtaking. The science at the core of this (called resonance supercharging) is all about tuning the pulses of air rushing through the intake. Choosing the right length helps prevent built-up air from hitting intake valves the moment they are closed and the subsequent effect of pulsating air between the intake runners and valves. With the valves open, air is pushed into the cylinder at higher pressure, resulting in a supercharging effect and improved throttle response. Added benefits are the louder engine rumble in Harley V-twins and the machined looks bound to turn heads. The parts are supplied with included backing plates, breathers and front screens for filtering and included mounting hardware for easy installation. Air Cleaner Kits One of the major gripes with Harley Davidson velocity stacks is that you'll need extensive knowledge of how airflow works and choosing stacks in the right length tailored to the engine specifics and your tuning goals. Another is the limited filtering capacity from the attached screens. To allow for unobstructed air delivered in the right volume and right speeds at set engine speeds, consider going with aftermarket air cleaner kits. These are assembled filters with matching piping that smooth out and direct airflow to the carb or intake manifolds, depending on the engine in your hog. Aftermarket cleaners also address the shortfalls of factory Harley air filters, made of low-quality paper and with lower efficiency, by removing common problems like dust and water that can hurt your engine. Look for cleaner kits with reusable and washable cotton cleaners that remove all particles to deliver oxygen-rich air in for combustion, and more of it. Again, the main prerequisite for engine power is how much air it pushes. Aftermarket cleaners are visibly bigger so draw more air in, and most include proprietary tech like machined openings and bolts that optimise airflow for both injected and carburetted Harleys. Harley owners can choose OE replacement filters to supply more air from the same space, or complete kits with reusable filters and machined hardware that also looks good. Exhausts More air in means more out. If you've increased airflow using either Harley velocity stacks or a bespoke air cleaner kit, the benefits end there if you don't also re-jet the carbs or do a fuel tune and change the stock exhaust piping. Stock exhausts are the major restrictors of spent gases. This is partially down to strict emissions and noise regulations that are effectively choking the engine and possibly one of the reasons Harley Davidson is increasing engine sizes in subsequent model years. Like velocity stacks and air cleaners, exhausts work effectively by increasing airflow. This means less backpressure from parts that control noise levels like factory baffles and aid exhaust velocity, so the engine can take its next breath faster. Aftermarket parts can also include redesigned headers to help with the pulsating effect of scavenging or the vacuum that draws spent gases out of the cylinders faster. This is achieved with wider and/or straighter piping with carefully chosen lengths. There are different exhaust options for your bike. The simplest way to get more horsepower to the rear wheel is to use a less restrictive aftermarket slip-on muffler. Besides increasing exhaust velocity and helping the engine breathe, slip-ons can add more substance to the exhaust note and also shed some weight. And as the name implies they're easy to get on. For gains that you can actually feel, choose 2-into-1 full exhausts to increase scavenging, especially at high and peak torque (around 3000 RPMs in most Harleys). This additionally means a livelier throttle response. Or go with 2-into-2 systems for improved scavenging and slight overlap that helps in the low to mid power band. A newer hybrid take on both types is the 2-1-2 exhaust, offering the best of both worlds. Choose exhausts and exhaust parts that are compatible with your Harley, have included mounting hardware to shorten installation times, and are built with quality materials (and street-legal sound deadeners) to ensure they last. /* */ Source link

0 notes

Photo

Written by Menswear Style in Cars on the 27th January 2025 You can tweak and tune Harleys in dozens of ways and by using hundreds of original equipment and aftermarket parts. Most riders want more push when on the throttle start with changes to the engine. The V-twins are all known for their huge low-end torque. What’s missing though is mid-to-high rev power, meaning most Harleys, regardless of displacement, max out at 120hp. And compared to other big bikes can feel out of puff at highway speeds. To extend power bands, and get more power higher up, consider 3 simple additions all connected with optimizing airflow – velocity stacks, air cleaners and aftermarket exhausts. The parts are relatively easy to install, cheap to buy and help boost power output when torque maxes out. Velocity Stacks Velocity stacks, trumpets or air horns are elongated tubes attached to the engine's air intake. Their main purpose is to maximise airflow into the intake. They date back to the beginning of the internal combustion engine, allowing carburettors to adjust air-fuel mixtures as engine loads change. Their specific design means air is eased into the carb, and flows smoothly to the engine. Over time, different designs have been optimised to work with newer tech and today you'll find Harley Davidson velocity stacks for both carburetted and injected engines, meaning everything from the Knucklehead to the Milwaukee Eight. Velocity stacks are tasked with getting more air into the engine. More air means more fuel and bigger bangs. The way they do this is by accelerating air into the intake manifold, with the smooth and tapered opening also helping to reduce turbulence. The result is cleaner and more efficient combustion, and by default, more power. Smoother airflow increases air volume and more air ready to be mixed with fuel. The curved, trumpet designs in velocity stacks help in this respect. Moreover, by changing stack tubing lengths, bike owners can also tune power outputs at different RPMs. In essence, shorter velocity stacks tune power and torque at higher revs, while choosing longer types gives more low-to-mid-end push. Something you'll appreciate when getting up to speed or when overtaking. The science at the core of this (called resonance supercharging) is all about tuning the pulses of air rushing through the intake. Choosing the right length helps prevent built-up air from hitting intake valves the moment they are closed and the subsequent effect of pulsating air between the intake runners and valves. With the valves open, air is pushed into the cylinder at higher pressure, resulting in a supercharging effect and improved throttle response. Added benefits are the louder engine rumble in Harley V-twins and the machined looks bound to turn heads. The parts are supplied with included backing plates, breathers and front screens for filtering and included mounting hardware for easy installation. Air Cleaner Kits One of the major gripes with Harley Davidson velocity stacks is that you'll need extensive knowledge of how airflow works and choosing stacks in the right length tailored to the engine specifics and your tuning goals. Another is the limited filtering capacity from the attached screens. To allow for unobstructed air delivered in the right volume and right speeds at set engine speeds, consider going with aftermarket air cleaner kits. These are assembled filters with matching piping that smooth out and direct airflow to the carb or intake manifolds, depending on the engine in your hog. Aftermarket cleaners also address the shortfalls of factory Harley air filters, made of low-quality paper and with lower efficiency, by removing common problems like dust and water that can hurt your engine. Look for cleaner kits with reusable and washable cotton cleaners that remove all particles to deliver oxygen-rich air in for combustion, and more of it. Again, the main prerequisite for engine power is how much air it pushes. Aftermarket cleaners are visibly bigger so draw more air in, and most include proprietary tech like machined openings and bolts that optimise airflow for both injected and carburetted Harleys. Harley owners can choose OE replacement filters to supply more air from the same space, or complete kits with reusable filters and machined hardware that also looks good. Exhausts More air in means more out. If you've increased airflow using either Harley velocity stacks or a bespoke air cleaner kit, the benefits end there if you don't also re-jet the carbs or do a fuel tune and change the stock exhaust piping. Stock exhausts are the major restrictors of spent gases. This is partially down to strict emissions and noise regulations that are effectively choking the engine and possibly one of the reasons Harley Davidson is increasing engine sizes in subsequent model years. Like velocity stacks and air cleaners, exhausts work effectively by increasing airflow. This means less backpressure from parts that control noise levels like factory baffles and aid exhaust velocity, so the engine can take its next breath faster. Aftermarket parts can also include redesigned headers to help with the pulsating effect of scavenging or the vacuum that draws spent gases out of the cylinders faster. This is achieved with wider and/or straighter piping with carefully chosen lengths. There are different exhaust options for your bike. The simplest way to get more horsepower to the rear wheel is to use a less restrictive aftermarket slip-on muffler. Besides increasing exhaust velocity and helping the engine breathe, slip-ons can add more substance to the exhaust note and also shed some weight. And as the name implies they're easy to get on. For gains that you can actually feel, choose 2-into-1 full exhausts to increase scavenging, especially at high and peak torque (around 3000 RPMs in most Harleys). This additionally means a livelier throttle response. Or go with 2-into-2 systems for improved scavenging and slight overlap that helps in the low to mid power band. A newer hybrid take on both types is the 2-1-2 exhaust, offering the best of both worlds. Choose exhausts and exhaust parts that are compatible with your Harley, have included mounting hardware to shorten installation times, and are built with quality materials (and street-legal sound deadeners) to ensure they last. /* */ Source link

0 notes

Photo

Written by Menswear Style in Cars on the 27th January 2025 You can tweak and tune Harleys in dozens of ways and by using hundreds of original equipment and aftermarket parts. Most riders want more push when on the throttle start with changes to the engine. The V-twins are all known for their huge low-end torque. What’s missing though is mid-to-high rev power, meaning most Harleys, regardless of displacement, max out at 120hp. And compared to other big bikes can feel out of puff at highway speeds. To extend power bands, and get more power higher up, consider 3 simple additions all connected with optimizing airflow – velocity stacks, air cleaners and aftermarket exhausts. The parts are relatively easy to install, cheap to buy and help boost power output when torque maxes out. Velocity Stacks Velocity stacks, trumpets or air horns are elongated tubes attached to the engine's air intake. Their main purpose is to maximise airflow into the intake. They date back to the beginning of the internal combustion engine, allowing carburettors to adjust air-fuel mixtures as engine loads change. Their specific design means air is eased into the carb, and flows smoothly to the engine. Over time, different designs have been optimised to work with newer tech and today you'll find Harley Davidson velocity stacks for both carburetted and injected engines, meaning everything from the Knucklehead to the Milwaukee Eight. Velocity stacks are tasked with getting more air into the engine. More air means more fuel and bigger bangs. The way they do this is by accelerating air into the intake manifold, with the smooth and tapered opening also helping to reduce turbulence. The result is cleaner and more efficient combustion, and by default, more power. Smoother airflow increases air volume and more air ready to be mixed with fuel. The curved, trumpet designs in velocity stacks help in this respect. Moreover, by changing stack tubing lengths, bike owners can also tune power outputs at different RPMs. In essence, shorter velocity stacks tune power and torque at higher revs, while choosing longer types gives more low-to-mid-end push. Something you'll appreciate when getting up to speed or when overtaking. The science at the core of this (called resonance supercharging) is all about tuning the pulses of air rushing through the intake. Choosing the right length helps prevent built-up air from hitting intake valves the moment they are closed and the subsequent effect of pulsating air between the intake runners and valves. With the valves open, air is pushed into the cylinder at higher pressure, resulting in a supercharging effect and improved throttle response. Added benefits are the louder engine rumble in Harley V-twins and the machined looks bound to turn heads. The parts are supplied with included backing plates, breathers and front screens for filtering and included mounting hardware for easy installation. Air Cleaner Kits One of the major gripes with Harley Davidson velocity stacks is that you'll need extensive knowledge of how airflow works and choosing stacks in the right length tailored to the engine specifics and your tuning goals. Another is the limited filtering capacity from the attached screens. To allow for unobstructed air delivered in the right volume and right speeds at set engine speeds, consider going with aftermarket air cleaner kits. These are assembled filters with matching piping that smooth out and direct airflow to the carb or intake manifolds, depending on the engine in your hog. Aftermarket cleaners also address the shortfalls of factory Harley air filters, made of low-quality paper and with lower efficiency, by removing common problems like dust and water that can hurt your engine. Look for cleaner kits with reusable and washable cotton cleaners that remove all particles to deliver oxygen-rich air in for combustion, and more of it. Again, the main prerequisite for engine power is how much air it pushes. Aftermarket cleaners are visibly bigger so draw more air in, and most include proprietary tech like machined openings and bolts that optimise airflow for both injected and carburetted Harleys. Harley owners can choose OE replacement filters to supply more air from the same space, or complete kits with reusable filters and machined hardware that also looks good. Exhausts More air in means more out. If you've increased airflow using either Harley velocity stacks or a bespoke air cleaner kit, the benefits end there if you don't also re-jet the carbs or do a fuel tune and change the stock exhaust piping. Stock exhausts are the major restrictors of spent gases. This is partially down to strict emissions and noise regulations that are effectively choking the engine and possibly one of the reasons Harley Davidson is increasing engine sizes in subsequent model years. Like velocity stacks and air cleaners, exhausts work effectively by increasing airflow. This means less backpressure from parts that control noise levels like factory baffles and aid exhaust velocity, so the engine can take its next breath faster. Aftermarket parts can also include redesigned headers to help with the pulsating effect of scavenging or the vacuum that draws spent gases out of the cylinders faster. This is achieved with wider and/or straighter piping with carefully chosen lengths. There are different exhaust options for your bike. The simplest way to get more horsepower to the rear wheel is to use a less restrictive aftermarket slip-on muffler. Besides increasing exhaust velocity and helping the engine breathe, slip-ons can add more substance to the exhaust note and also shed some weight. And as the name implies they're easy to get on. For gains that you can actually feel, choose 2-into-1 full exhausts to increase scavenging, especially at high and peak torque (around 3000 RPMs in most Harleys). This additionally means a livelier throttle response. Or go with 2-into-2 systems for improved scavenging and slight overlap that helps in the low to mid power band. A newer hybrid take on both types is the 2-1-2 exhaust, offering the best of both worlds. Choose exhausts and exhaust parts that are compatible with your Harley, have included mounting hardware to shorten installation times, and are built with quality materials (and street-legal sound deadeners) to ensure they last. /* */ Source link

0 notes

Photo

Written by Menswear Style in Cars on the 27th January 2025 You can tweak and tune Harleys in dozens of ways and by using hundreds of original equipment and aftermarket parts. Most riders want more push when on the throttle start with changes to the engine. The V-twins are all known for their huge low-end torque. What’s missing though is mid-to-high rev power, meaning most Harleys, regardless of displacement, max out at 120hp. And compared to other big bikes can feel out of puff at highway speeds. To extend power bands, and get more power higher up, consider 3 simple additions all connected with optimizing airflow – velocity stacks, air cleaners and aftermarket exhausts. The parts are relatively easy to install, cheap to buy and help boost power output when torque maxes out. Velocity Stacks Velocity stacks, trumpets or air horns are elongated tubes attached to the engine's air intake. Their main purpose is to maximise airflow into the intake. They date back to the beginning of the internal combustion engine, allowing carburettors to adjust air-fuel mixtures as engine loads change. Their specific design means air is eased into the carb, and flows smoothly to the engine. Over time, different designs have been optimised to work with newer tech and today you'll find Harley Davidson velocity stacks for both carburetted and injected engines, meaning everything from the Knucklehead to the Milwaukee Eight. Velocity stacks are tasked with getting more air into the engine. More air means more fuel and bigger bangs. The way they do this is by accelerating air into the intake manifold, with the smooth and tapered opening also helping to reduce turbulence. The result is cleaner and more efficient combustion, and by default, more power. Smoother airflow increases air volume and more air ready to be mixed with fuel. The curved, trumpet designs in velocity stacks help in this respect. Moreover, by changing stack tubing lengths, bike owners can also tune power outputs at different RPMs. In essence, shorter velocity stacks tune power and torque at higher revs, while choosing longer types gives more low-to-mid-end push. Something you'll appreciate when getting up to speed or when overtaking. The science at the core of this (called resonance supercharging) is all about tuning the pulses of air rushing through the intake. Choosing the right length helps prevent built-up air from hitting intake valves the moment they are closed and the subsequent effect of pulsating air between the intake runners and valves. With the valves open, air is pushed into the cylinder at higher pressure, resulting in a supercharging effect and improved throttle response. Added benefits are the louder engine rumble in Harley V-twins and the machined looks bound to turn heads. The parts are supplied with included backing plates, breathers and front screens for filtering and included mounting hardware for easy installation. Air Cleaner Kits One of the major gripes with Harley Davidson velocity stacks is that you'll need extensive knowledge of how airflow works and choosing stacks in the right length tailored to the engine specifics and your tuning goals. Another is the limited filtering capacity from the attached screens. To allow for unobstructed air delivered in the right volume and right speeds at set engine speeds, consider going with aftermarket air cleaner kits. These are assembled filters with matching piping that smooth out and direct airflow to the carb or intake manifolds, depending on the engine in your hog. Aftermarket cleaners also address the shortfalls of factory Harley air filters, made of low-quality paper and with lower efficiency, by removing common problems like dust and water that can hurt your engine. Look for cleaner kits with reusable and washable cotton cleaners that remove all particles to deliver oxygen-rich air in for combustion, and more of it. Again, the main prerequisite for engine power is how much air it pushes. Aftermarket cleaners are visibly bigger so draw more air in, and most include proprietary tech like machined openings and bolts that optimise airflow for both injected and carburetted Harleys. Harley owners can choose OE replacement filters to supply more air from the same space, or complete kits with reusable filters and machined hardware that also looks good. Exhausts More air in means more out. If you've increased airflow using either Harley velocity stacks or a bespoke air cleaner kit, the benefits end there if you don't also re-jet the carbs or do a fuel tune and change the stock exhaust piping. Stock exhausts are the major restrictors of spent gases. This is partially down to strict emissions and noise regulations that are effectively choking the engine and possibly one of the reasons Harley Davidson is increasing engine sizes in subsequent model years. Like velocity stacks and air cleaners, exhausts work effectively by increasing airflow. This means less backpressure from parts that control noise levels like factory baffles and aid exhaust velocity, so the engine can take its next breath faster. Aftermarket parts can also include redesigned headers to help with the pulsating effect of scavenging or the vacuum that draws spent gases out of the cylinders faster. This is achieved with wider and/or straighter piping with carefully chosen lengths. There are different exhaust options for your bike. The simplest way to get more horsepower to the rear wheel is to use a less restrictive aftermarket slip-on muffler. Besides increasing exhaust velocity and helping the engine breathe, slip-ons can add more substance to the exhaust note and also shed some weight. And as the name implies they're easy to get on. For gains that you can actually feel, choose 2-into-1 full exhausts to increase scavenging, especially at high and peak torque (around 3000 RPMs in most Harleys). This additionally means a livelier throttle response. Or go with 2-into-2 systems for improved scavenging and slight overlap that helps in the low to mid power band. A newer hybrid take on both types is the 2-1-2 exhaust, offering the best of both worlds. Choose exhausts and exhaust parts that are compatible with your Harley, have included mounting hardware to shorten installation times, and are built with quality materials (and street-legal sound deadeners) to ensure they last. /* */ Source link

0 notes

Text

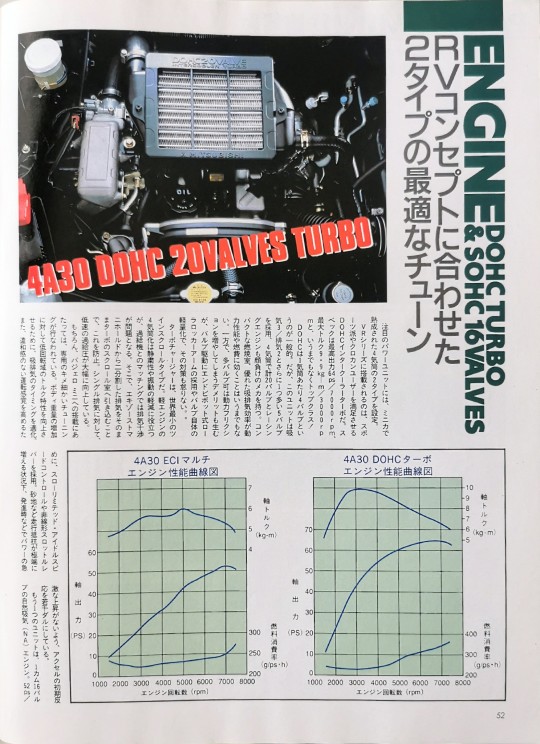

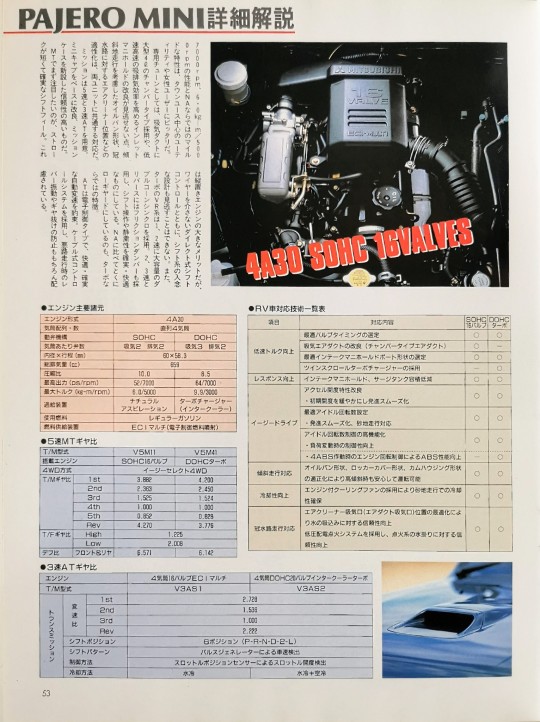

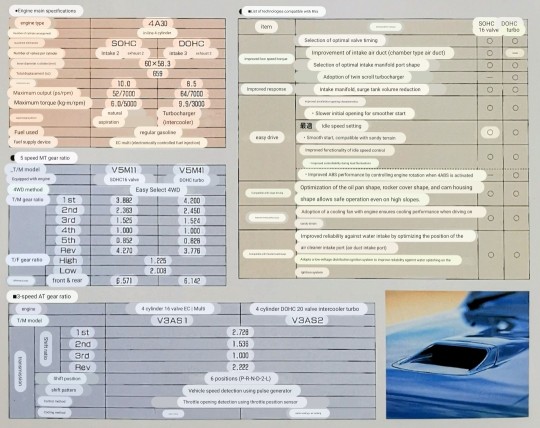

Engine specs for the 1st Gen Mitsubishi Pajero Mini.

Pajero Mini Detailed explanation

ENGINE 20VDOHC TURBO & SOHC 16VALVES

Two types of optimal tunes to suit your RV concept

Two types of 4-cylinder engines are available as the featured power units.

The VR series is equipped with a DOHC intercooler turbo that will satisfy sports enthusiasts and cross country users. The specs are top-class, with a maximum output of 64ps/7000rpm and a maximum torque of 9.9kg-m/3000rpm!

DOHC has 5 valves per cylinder.

Uno is common. However, this unit uses 3 intake/exhaust valves and an additional 5 valves, making it 4 cylinders with a total of 20 valves, and has a mechanism that rivals even racing engines. It goes without saying that the compact combustion chamber and excellent intake and exhaust efficiency improve power performance and fuel efficiency. On the other hand, having multiple valves has the disadvantage of increasing power friction, but we have taken measures to counter this by adopting an end-pivot type roller rocker arm to drive the valves and reducing the weight of the valves themselves. .

The turbocharger is the world's smallest twin-scroll type. Converting a light engine to a four-cylinder engine is useful for making it quieter and reducing vibration, but exhaust interference becomes a problem when matching it with a turbocharger. To prevent this, the exhaust gas is divided into two parts from the exhaust manifold and drawn directly into the turbo's scroll chamber. Low-speed boost pressure is significantly improved compared to single exhaust.

Of course, when installed in the Pajero Mini, special and detailed tuning has been performed. Intake and exhaust timing has been optimized to improve torque characteristics in the low rotation range despite the increased body weight.

In addition, to enhance the driving sensation without discomfort, To achieve this, a slow limited idle speed control and a non-linear throttle lever have been adopted. In situations where running resistance is extremely high, such as on sandy terrain, the power may suddenly be applied when starting, etc.

The initial response of the accelerator is made slightly duller to prevent sudden increases.

The other unit is a single overhead-cam, 16-valve naturally aspirated (NA) engine. 52ps/7000rpm、6.0kg-m/5000

The rpm performance and the mileage characteristics unique to NA are perfect for utility vehicles mainly used around town and for female users.

Not to be overlooked are the adoption of a large 4-liter chamber type in the intake duct and improvements to the inlet manifold that increase intake and exhaust efficiency at low and high speeds. The shape of the oil pan takes into account driving on slopes, and the positioning of the air cleaner relative to submerged waterways is a common feature of both units.

Transmission options include 5-speed and 3-speed AT. Improved mission based on minicab

It has a new case and is highly reliable. The first thing to pay attention to when using MT is the straw.

Short and reliable shift feel. This is a major advantage of a longitudinally mounted engine, but the careful design of the shift system, along with the direct shift control without wires, cannot be overlooked. Additionally, the VR turbo's system uses large-capacity double cone synchronizers in 1st and 2nd gears. Friction dampers are also used in 2nd and 3rd gear and reverse, making shift operations and quietness reliable and comfortable. Another characteristic unique to turbos is that they have a particularly low gearing compared to NA.

AT is an electronically controlled type that promises comfortable and reliable automatic gear shifting. A cable-type control system is used to prevent lever vibration and gear slippage when driving on rough roads.

12 notes

·

View notes

Text

How Manifold Ball Valves Enhance Industrial Fluid Distribution?

Efficient fluid distribution is a critical aspect of industrial operations, ensuring seamless flow and pressure control in pipelines. One of the most effective solutions for managing multiple fluid pathways is the manifold ball valve system. These valves help regulate and distribute fluids efficiently, reducing the number of individual connections and improving overall system integrity. Industries such as oil and gas, chemical processing, and manufacturing rely on manifold ball valves in Canada to enhance their operational efficiency while minimizing potential leaks and pressure drops. Understanding how these valves function and their benefits can help industries optimize their fluid management systems.

Understanding Manifold Ball Valves:

Manifold ball valves are multi-port valves designed to control multiple fluid channels simultaneously. They are commonly used in complex industrial setups where efficient fluid distribution is necessary. These valves offer advantages such as:

Reduced Pipework – Minimize the number of separate valves and pipes.

Improved Control – Enable precise management of different fluid streams.

Leak Prevention – Reduce the risk of leaks by integrating multiple functions into one unit.

Space Efficiency – Ideal for industries with limited space for valve installations.

Applications of Manifold Ball Valves in Canada:

Various industries utilize manifold ball valves in Canada for their robust performance and efficiency:

1. Oil and Gas Industry:

In the oil and gas sector, these valves help regulate crude oil, natural gas, and other fluids through pipelines. Their ability to handle high-pressure environments makes them a reliable choice for offshore and onshore applications.

2. Chemical and Pharmaceutical Processing:

Industries dealing with hazardous chemicals benefit from manifold ball valves due to their precise flow control and leak-proof design, ensuring safety in handling aggressive fluids.

3. Water and Wastewater Management:

Municipalities and industrial facilities use these valves to control water distribution, filtration, and waste disposal processes efficiently.

Key Benefits of Using Manifold Ball Valves:

Enhanced Durability – Constructed from corrosion-resistant materials to withstand harsh environments.

Efficient Fluid Management – Allows multiple flow paths in a compact design.

Cost-Effective – Reduces maintenance costs by eliminating unnecessary piping and additional valve installations.

Easy Maintenance – Designed for quick access and replacement, minimizing downtime.

Choosing the Right Manifold Ball Valves in Canada:

When selecting manifold ball valves, industries should consider:

Material Quality – Stainless steel and brass are preferred for longevity.

Port Configuration – Choose between two-way, three-way, or multi-port options based on application needs.

Pressure and Temperature Ratings – Ensure compatibility with specific industrial requirements.

The use of manifold ball valves in Canada is revolutionizing industrial fluid distribution, making operations more efficient, safe, and cost-effective. Their ability to streamline fluid pathways and reduce leakage risks makes them an essential component in many industries. By investing in high-quality manifold ball valves, businesses can significantly enhance their pipeline efficiency and long-term operational reliability. Find out more right here!

0 notes