#ⅰ ▸ ❛ audio.4

Explore tagged Tumblr posts

Text

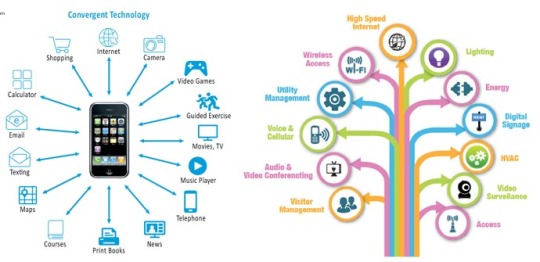

Trends in ICT

Ⅰ. CONVERGENCE

is the synergy of technological advancements work on a similar goal or task.

smartphones combine numerous technologies which used to be available on separate devices: a computer, a watch, an alarm clock, a GPS, a newspaper, a credit card

smart watches that can be used as fitness trackers and music players.

smart TVs that can be used as computer monitors.

��. SOCIAL MEDIA

is a website, application, or online channel that enables web users to create, co-create, discuss modify, and exchange user generated content.

Information and communication technology (ICT) is the use of technology to facilitate the creation, storage, processing, and exchange of information.

Here are six types of social media:

1. Social networks: These are platforms that allow users to connect with friends and family, share photos and videos, and keep up with current events. Examples include Facebook, Instagram, and Twitter.

2. Media-sharing networks: These platforms allow users to share photos, videos, and other multimedia content. Examples include YouTube, Flickr, and Pinterest.

3. Blogging platforms: These platforms allow users to create and publish blogs, which are online journals or diaries. Examples include WordPress, Blogger, and Tumblr.

4. Microblogging platforms: These platforms allow users to post short messages, or "microblogs." Examples include Twitter and Weibo.

5. Social bookmarking sites: These platforms allow users to save and organize web pages and other online resources. Examples include Delicious, Digg, and StumbleUpon.

6. Social shopping sites: These platforms allow users to discover and purchase products from online retailers. Examples include Etsy, eBay, and Amazon.

There are 7 types of Mobile Technology

iOS are used in apple devices like iPhone and iPad.

•Blackberry OS are used in blackberry devices.

•Windows phone OS are closed source developed by Microsoft.

•Android an open source OS. Mobile phone companies use this OS for free.

•WebOS were originally used in smartphone, now in smart TVs.

•Windows Mobile were developed by Microsoft for smartphones and pocket PCs.

•Assistive Media are non-profited service to help people who have visual and reading impairments. A date base of audio recordings is used to read to the user

•Cloud Computing, instead of running an e-mail program on your computer, log into a web e-mail account like Yahoo!, Gmail, or Hotmail, there you can storage your account that doesn't exist on your computer but in the internet which is called the Computer cloud.

NAME: KEZIAH N. DABALOS

11-STEM1

1 note

·

View note

Text

character related tags.

#ⅰ ▸ ❛ introspection.#ⅰ ▸ ❛ headcanon.#ⅰ ▸ ❛ aesthetic.#ⅰ ▸ ❛ skillset.#ⅰ ▸ ❛ attire.#ⅰ ▸ ❛ audio.4#ⅰ ▸ ❛ desires.#ⅰ ▸ ❛ amanda young.

1 note

·

View note

Text

034: Android Under the Hood

@karino2012さんをゲストに迎えて、『Androidを支える技術』について話しました。

podcast feedを購読するか、DLしてお楽しみ下さい。

Show Notes:

Androidを支える技術〈Ⅰ〉──60fpsを達成するモダンなGUIシステム

Androidを支える技術〈Ⅱ〉──真のマルチタスクに挑んだモバイルOSの心臓部

「Androidを支える技術」出版記念イベント

Androidを支える技術のサポートページ

詳説 Binder

August 2015 - 南よ! 海の見える方!

『Androidを支える技術』を読むべきか? - hydrakecat’s blog

(以下、第Ⅰ巻の「本書の想定読者について」より抜粋)

本書は、おもに4種類の読者を想定しています。

Androidのアプリ開発者で、Linuxの知識もある人

デスクトップでのGUIアプリケーションの開発経験があるが、Androidアプリの開発経験はない人

組み込みやLinuxの経験はあるが本格的なGUIシステムの経験はあまりない人

かつて一線で活躍していたエンジニアが現在マネージャになっていて、Androidについて知りたい人

Contact:

@dexfmpodcast

@hydrakecat

@karino2012

1 note

·

View note

Text

Any idea about what Electrolytic Capacitor is? Come on in.

1.The Basic Knowledge Of Electrolytic Capacitors

1.1 Definition

Electrolytic capacitor is a kind of capacitor divided by structure and manufacturing technology. In general, electrolytic capacitors are of polarized capacitors. The anodes of electrolytic capacitors adopt metal materials that can be passivated, such as aluminum, tantalum, niobium, titanium, etc. The dielectric material is a dense oxide film formed on the surface of anode metal material. The cathodes of electrolytic capacitors adopt electrolytes.The main feature of electrolytic capacitors is that they are possible to obtain a much larger capacitance than ordinary capacitors(assuming equal withstand voltages). Electrolytic capacitors get their name from the fact that they use electrolytes as cathodes.

This video explains what is electrolytic capacitor

1.2 Parameters

— Rated capacitance

Rated capacitance is the capacitance marked on the capacitor.

— Basic unit

The basic unit of a capacitor is farad (F), but this unit is too large to be used in actual situation.

The relationship among other units are as below:

1F=1000mF

1mF=1000μF

1μF=1000nF

1nF=1000pF

—Accuracy

The deviation between the actual capacitance and the rated capacitance is called an error, and the accuracy is an error that is within the allowable deviation range.

The corresponding relationship between the accuracy level and the allowable deviation is: 00(01)-±1%、0(02)-±2%、Ⅰ-±5%、Ⅱ-±10%、Ⅲ-±20%、Ⅳ-(+20%-10%)、Ⅴ-(+50%-20%)、Ⅵ-(+50%-30%)

Ordinary capacitors are often of the Ⅰ, Ⅱ, Ⅲ level, while electrolytic capacitors are often of the Ⅳ, Ⅴ, Ⅵ level.

—Nominal voltage

Nominal voltage is the maximum effective value of DC voltage that can be continuously applied to capacitors under the lowest ambient temperature and the rated ambient temperature. Generally, it is directly marked on the capacitor case. If the working voltage exceeds the withstand voltage of the capacitors, they will break down and irreparable permanent damage will be caused.

—Insulation resistance

A DC voltage is applied to capacitors and a leakage current is generated. The ratio of the DC voltage and leakage current is insulation resistance.

When the capacitance is small, insulation resistance mainly depends on the surface state of the capacitor. When the capacity >0.1uf, it mainly depends on the performance of the medium. The larger the insulation resistance is, the better.

—Time constant

Time constant is introduced to evaluate the insulation of large capacitor. It is equal to the result of insulation resistance multiplying capacitance.

—Loss

Under the action of electric field, the energy consumed by capacitors due to heat in unit time is called loss. All kinds of capacitors stipulate their own allowable loss value within a certain frequency range. The loss of capacitors is mainly caused by dielectrics, conductance loss and resistance of all metal parts of capacitors.

Under the action of direct current electric field, the loss of capacitors exists in the form of leakage conduction loss, which is generally small. Under the action of alternating electric field, the loss of capacitors is related not only to leakage conduction, but also to the periodic polarization establishment process.

—Frequency

With the increase of frequency, generally the capacitance of capacitors decreases.

—Polarity and circuit notation

—Equivalent circuit

leakage: Electric leakage resistance

ESR: Equivalent Series Resistance

ESL: Equivalent Series Inductance

1.3 Lifespan of electrolytic capacitors

Life expectancy: The duration of continuous operation of the electrolytic capacitor at the highest operating temperature.

lx=lo*2(to-ta)/10

lx=actual working life

lo=warranty life

to=maximum working temperature

ta=the actual working temperature of the capacitor

2.The Classification Of Electrolytic Capacitors

Electrolytic capacitors are generally divided into three categories: aluminum electrolytic capacitors, tantalum electrolytic capacitors and niobium electrolytic capacitors.

2.1Aluminum electrolytic capacitors

2.1.1 Introductions

Aluminum electrolytic capacitors are polarized electrolytic capacitors. Their anodes are made by aluminum foil with an etching on the surface. The aluminum foil is coated with a thin layer of alumina insulating layer, which is the dielectric of capacitors. The alumina is coated with a non-solid electrolyte, which is the cathode (-) of capacitors. There is another layer of aluminum foil, known as "cathode aluminum foil”, which contacts the electrolyte and is connected to the negative terminal of capacitors.

Aluminum electrolytic capacitors can be divided into three types according to the types of their electrolytes: non-solid aluminum electrolytic capacitors; solid aluminum capacitors whose electrolyte is solid manganese dioxide; polymer capacitors whose electrolytes are solid polymers.

Non-solid aluminum electrolytic capacitors are the cheapest kind and have the widest range of sizes, capacitance and voltage levels. Their minimum capacitance is 0.1µF and the maximum is 2.7 million µF (2.7 F), with voltage ranging from 4 V to 630 V. Liquid electrolytes provide the required oxygen as the dielectric oxide layers recovers themselves. But electrolytes will evaporate and the drying process varies with temperature, causing electrical parameters to drift and limiting the capacitor's life.

structure of aluminium electrolytic capacitors

2.1.2 Advantages And Disadvantages

Advantages

—Aluminum electrolytic capacitors are cheap with high capacitance and can be used in wave filtering at lower frequencies.

—Their energy density is higher than that of thin-film capacitors and ceramic capacitor.s

—Their power density is higher than that of double layer capacitors.

—There is no limit posed by peak current.

—There are many variations in appearances and styles, as well as customized life, service temperature and electrical parameters.

—There are many manufacturers for aluminum electrolytic capacitors.

Disadvantages

—The life of the aluminum electrolytic capacitors is limited by the evaporation of electrolytes.

—Aluminum electrolytic capacitors are sensitive to mechanical stress.

—Aluminum electrolytic capacitors are sensitive to halide pollution.

2.1.3 Application

Aluminum electrolytic capacitors are usually used in power supply of a lot of electrical equipment, switch mode power supplies and DC-DC converters. They are also used in many industrial power converters and frequency converters. Some special capacitors are used for energy storage, such as strobe lights, flash strobes, or frequency coupling devices used in audio.

Aluminum electrolytic capacitors are polarized capacitors due to their anodic oxidation. They can only be used togetherwith the correct polarity of direct current. If they are connected to the opposite polarity of direct current or an alternating current, they will be destroyed out of short circuit. The only exception are bipolar aluminum electrolytic capacitors, which can be used in alternating current.

2.2 Tantalum electrolytic capacitor

2.2.1 Introduction

Tantalum electrolytic capacitors’ anodes are made by tantalum particles, covered by insulation oxides as dielectrics, surrounded by liquid or solid electrolytes acting as cathodes. Because tantalum electrolytic capacitors have thin dielectric layers and high capacitivity, their capacitance per unit volume is larger than that of ordinary capacitors and other electrolytic capacitors.

structure of tantalum electrolytic capacitors

At present, tantalum electrolytic capacitors are mainly divided by three types: sintered solid, foil-shaped winding solid and sintered liquid, among which the sintered solid accounts for more than 95% of the total production, and the major kind is the non-metallic sealed resin package.

The working medium of tantalum electrolytic capacitors is an extremely thin tantalum pentoxide film formed on the surface of tantalum. This layer of oxide film medium is integrated with one end of the capacitor and cannot exist alone. Therefore, the capacitance per unit volume is particularly large. That is, the specific capacity is very high, so it is particularly suitable for miniaturization.

In the work process of tantalum electrolytic capacitors, they have the capacity of automatically repairing or isolatingdefective properties in the oxide film, so that the oxide film medium can be strengthened and recover its due insulation ability at any time without suffering continuous cumulative damage. This unique self-healing ability guarantees theiradvantages of long life expectancy and reliability. The capacitors have unidirectional conductivity, that is, they have"polarity". In application, the current should be connected according to the positive and negative direction of the power supply. The anodes of the capacitors are to be connected to the "+" pole of the power supply, while the cathodes are to be connected to the "-" pole of the power supply. If the capacitors are misconnected, not only they wouldn’t work but also the leakage current would be huge. As a result, the core will heat up in a short time, damaging the oxide film and then depriving it of efficacy.

2.2.2 Advantages And Disadvantages

Advantages

—Small in size

Since tantalum electrolytic capacitors are made of tantalum powder, and the dielectric constant of tantalum oxide film is 17 higher than that of aluminum oxide film, the capacitance of tantalum capacitors per unit volume is larger.

Wide operating temperature range

Generally, tantalum electrolytic capacitors can work normally at the temperature of -50℃~100℃. Although aluminum electrolytic capacitors can also work within this temperature range, their performance is far inferior to that of tantalum electrolytic capacitors.

—Performance

The tantalum oxide film medium in tantalum electrolytic capacitors is not only corrosion resistant, but also has long service life, high insulation resistance, low leakage current and good performance for a long time.

—Impedance frequency

The solid electrolytic capacitors can work in the frequency of above 50kHz. The capacitance of tantalum electrolytic capacitors decreases with the increase of frequency, but the decrease degree is small. Data show that the capacitance of tantalum electrolytic capacitors decreases by less than 20% when operating at 10kHz, while the capacitance of aluminum electrolytic capacitors decreases by 40%.

—High reliability

The chemical properties of tantalum oxide film are stable. Since Ta2O5, the substrate of tantalum anode can withstand strong acid and alkali, tantalum electrolytic capacitors can use solid electrolytes or liquid electrolytes with very low resistivity containing acid. As a result, the loss of tantalum electrolytic capacitor is smaller than that of aluminum electrolytic capacitors.

Disadvantages

Tantalum electrolytic capacitors are expensive and have limited capacitance compared with other types of capacitors due to their not using electrolytes as medium.

2.2.3 Application

Tantalum electrolytic capacitors have various shapes and are easily fabricated into small components suitable for surface mount, which meets the needs of automation and miniaturization of electronic technology. Although tantalum is scarce and tantalum electrolytic capacitors are relatively expensive, due to the large adoption of high specific capacity tantalum powder (30kuF.g-100kuF. V/g) and the improvement and perfection of capacitor manufacturing technology, tantalum electrolytic capacitors have been rapidly developed and used in an increasingly wide range. Tantalum electrolytic capacitors are widely used not only in military communication, aerospace, but also in industrial control, film and television equipment, communication instruments and other products. In addition, because tantalum electrolytic capacitors are capable of storing electric quantity, charging and discharging, etc, they are also used in filtering, energy storage and conversion, mark bypass, coupling and decoupling, and used as time constant element.

2.3 Niobium electrolytic capacitor

2.3.1 Introduction

Niobium electrolytic capacitors are polarized capacitors. Their anodes (+) are passivated niobium or niobium oxide with insulating niobium pentoxide as the dielectrics of niobium capacitors. On the surface of the oxide layer is a layer of solid electrolyte, which is the cathode (-) of niobium electrolytic capacitors.

structure of niobium electrolytic capacitors

Back in the 1960s, headed by the United States and the Soviet union, many countries began the study of niobium electrolytic capacitors. But in the studying process, niobium pentoxide dielectric film suffered severe damage due to heat and electrical stress, resulting in large leakage current in capacitors and high failure rate. Since the 1990s, with the constant improvement in powder production technology, the electric properties of niobium powder had improved a lot, laying a solid foundation for the development of niobium electrolytic capacitors. The new type of niobium electrolytic capacitors are of good performance and low price, which have attracted wide attention from all over the world. The preparation of niobium electrolytic capacitors must meet the requirements below: 1.Avoid the oxygen supersaturation in niobium anode, that is, the formation of suboxide must be prevented; 2. Inhibit oxygen migrating through Nb2O5 membrane and Nb/Nb2O5 interface; 3. Ensure the thermal stability of dielectric layer. British company AVX has supplied niobium electrolytic capacitor samples, whose capacitance range is 100-470µF and working temperature is up to 105℃. Companies like Kemet in US and NEC in Japan--the world's leading enterprises in tantalum electrolytic capacitors are working actively to develop niobium electrolytic capacitors. Russia is also of the high level in this area due to its continuous research on the basis of the studies of the former Soviet Union.

In addition, there are tantalum-niobium alloy electrolytic capacitors, whose anodes are formed by the sintering of tantalum-niobium alloy powder. And the medium is an oxide film that is chemically formed on the surface of the positive electrode. The performance of such electrolytic capacitors is second only to that of tantalum electrolytic capacitors and superior to that of aluminum electrolytic capacitors. Because niobium is abundant and the price is moderate, this kind of alloy capacitors have a promising future.

2.3.2 Advantages And Disadvantages

Advantages

—With the same capacitance, the dielectric constant of niobium electrolytic capacitors is twice as large as that of the tantalum electrolytic capacitors.

—The chemical stability of niobium electrolytic capacitors is better than that of aluminum electrolytic capacitors.

—Leakage current and loss are small.

Disadvantages:

Niobium electrolytic capacitors can also form dielectric oxide film on their surface. The biggest problem of niobium electrolytic capacitors is the damage to dielectric oxide film caused by heat and electrical stress will lead to the increase of leakage current and the failure of capacitor.

2.3.3 Application

Niobium electrolytic capacitors have entered the high specific capacity capacitor market, and they have a capacity/voltage range similar to ordinary tantalum electrolytic capacitors and equivalent series resistance characteristics similar to standard tantalum electrolytic capacitors. Niobium electrolytic capacitors are low in price and stable in performance, which can replace some tantalum electrolytic capacitors, ceramic capacitors and aluminum capacitors. Niobium capacitors are not prone to break down due to ignition, which guarantees the safety of the circuit. The high leakage current of niobium electrolytic capacitors is not a problem for most applications because the maximum residual current is well below 50μA. For example, in the use of personal computers (PCS), this number is rather small compared to the total power consumption of the microprocessor and does not make much difference. The life test proves that the capacitance of niobium electrolytic capacitors is stable, and the leakage current increases continuously with time, but the growth rate decreases and the saturation state appears, which is caused by the instability of niobium anodized film. Niobium electrolytic capacitors are modified to avoid the formation of suboxide and to stabilize dielectric oxide film. With the development of electronic circuit and electronic industry, niobium electrolytic capacitors are to be introduced into the market as a new type of capacitor and open up its application field.

3.Characteristics Of Electrolytic Capacitors

—The capacitance per unit volume of electrolytic capacitors is very large, which is tens to hundreds of times larger than that of other kinds of capacitors.

—Rated capacitance can be very large, easily reaching tens of thousands of μf or even several f.

—The price of electrolytic capacitors is overwhelming superior to other kinds because electrolytic capacitors are made of ordinary industrial materials, such as aluminum. The equipment used to make electrolytic capacitors is common one, which can be mass produced with relatively low cost.

4. Notes For The Use Of Electrolytic Capacitors

—The actual voltage of the electrolytic capacitors in the circuit should not exceed their withstand voltage value. When using electrolytic capacitors, be noted that the positive and negative poles should not be reversedly connected. In the power circuit, when the positive voltage is to be output, the anode of the electrolytic capacitor is to be connected to the output end of the power supply, while the cathode is to be connected to the ground. When the output voltage is negative, the cathode is to be connected to the output end and the anode is to be connected to the ground. Different types of capacitors should be used for different circuits. Before loading capacitors into the circuit, make sure that there are no situations like short circuit, open circuit and electric leakage, and the capacitance value should be checked. When installing, make it easy to see the type of capacitor, capacity, withstand voltage and other symbols for verification.

—When the polarities of the filter capacitor are reversedly connectd in the power supply circuit, the filtering effect of the capacitor is greatly reduced. On the one hand, the output voltage fluctuation of the power supply is caused, and on the other, the electrolytic capacitor which is equivalent to a resistor is heated by reverse current. When the reverse voltage exceeds a certain value, the reverse leakage resistance of the capacitor becomes very small, which will cause the capacitor to burst and to be damaged due to overheating soon after being energized.

—The voltages applied to both ends of the electrolytic capacitors must not exceed its permissible working voltage. In the design of the actual circuit, there should be permissible range of the voltage according to specific situation. In designinga filter capacitance of regulated power supply, if the AC power voltage is 220V, the subordinate commutating voltage of transformer can be up to 22V, a electrolytic capacitor with withstand voltage that is 25V in drawing a design for PCB can generally meet the requirements. However, if the AC power supply voltage fluctuates greatly and may rise to more than 250V, it is better to choose a electrolytic capacitor that can withstand more than 30V.

—Electrolytic capacitors should not be near the high-power heating element in the circuit to prevent the electrolyte from drying up rapidly due to heat.

—For filter with positive and negative polarity, two electrolytic capacitor could be connected in series with the same polarities and make a nonpolarized capacitor.

—The capacitor case, auxiliary lead terminals must be completely isolated with positive and negative poles and circuit boards.

0 notes

Text

IRCAM ミハイル・マルトによるコンピュータ音楽ワークショップ

※ 学外の方の聴講は出来ません。

【期間】 全4日間:2019年4月23日(火)〜 4月26日(金)

【対象】 作曲科の学部生及び大学院生 ※音楽学部及び音楽研究科所属学生による聴講は自由

【会場】 音楽学部 第1ホール

【講師】 ミハイル・マルト (研究者/コンピュータ音楽教師/作曲家 IRCAM フランス国立音響音楽研究所) 通訳:安田 靜 (日本大学教授)

【講座内容】 IRCAM(フランス国立音響音楽研究所)のみならず他機関との連携研究などでも重要な役割を担う研究者、開発者、作曲家等として、そして何より、これまで長年に渡って幾多の優秀な作曲家に教えを施してきた名教師として名高いミハイル・マルト氏を招き、藝大作曲科におけるコンピュータ音楽の教育研究で重点を置く2つの創作ジャンル(ミクスト及びCAO)について、伝統的な作曲という行為を前提としてのコンピュータを用いた今日的な創作の方法論に関するワークショップを4日間に渡って開催します。最終日26日(金)の公開レッスン&試演会では、昨年度修士2年次生制作・実演によるミクスト音楽作品試演及びマルト氏自身の作品演奏も予定されています。

【講師プロフィール】 サンパウロ大学等にて応用科学、作曲、指揮を修めた後、フランスに渡る。社会科学高等研究院EHESSに学び、数理モデルとコンピュータ支援作曲CAOについての論文で博士号を取得、科学的な研究と音楽という、分野を横断した専門領域を修めている。1990年にIRCAM(フランス国立音響音楽研究所)にて作曲家研究員となって以後、現在まで長年に渡ってIRCAMのCursus(主に伝統的な専門教育を受けた作曲家向けの研修課程)などにてコンピュータ音楽の教育に当たる。 また、同研究所ではreprésentation musicaleチームにも属しており、OpenMusic環境のためのライブラリや、Max環境でリアルタイムに動作するZsa.descriptors(著名な開発者E.ジュールダンとの共同)など、CAOやミクストの今日的な方法論と重要な関連性のあるプログラムの開発にも携わる。作曲専門領域として重要な研究論文等も数多く執筆している。

【スケジュール】

◆4月23日(火) 18:30 第1回講義:CAO及びミクスト方法論研究Ⅰ (Hall 1)

Representation in Computer Assisted Composition and Computational Musicology

◆4月24日(水) 18:30 第2回講義:CAO及びミクスト方法論研究Ⅱ (Hall 1)

Audio Descriptors in Composition of Mixed Music

◆4月25日(木) 18:30 第3回講義:CAO及びミクスト方法論研究Ⅲ (Hall 1)

On «Khorwa - Myalwa» — Tokyo

◆4月26日(金) 19:00 大学院生作品公開レッスン&試演会 (Hall 1)

プログラム(演奏順未定):

M. マルト:Khorwa, Myalwa (Samsara, os Infernos) pour flûte basse et électroniques (2016) bass flute 岡田 澪

田中 翔一朗:Water in Metal - horn and electronics -(2018) horn 松原 秀人

中嶋 達郎:ADAM - trombone and electronics -(2018) trombone 安井 貴大

藤川 大晃:Yura.2 - clarinet and electronics -(2018) clarinet 三界 達義

※ Maxプログラミングによるエレクトロニクスは作曲者本人が制作・実演

講座企画:小鍛冶邦隆 作曲科教授 折笠敏之

0 notes

Photo

結音茶舗 物販お知らせ 中川裕貴、バンド / 音楽と、軌道を外れた Yuki Nakagawa,band / "Music" and straying out of its orbit CD album 2000yen + tax (2160) 1. 極東(壊れた)から家電と複数 2. 異なる遊戯と訓練の終わりの前にⅠ 3. 私たちとさえ言うことのできない私たちについて 4. ステンレスシンクに雨が降る 換気扇に虹が立つ(Audio commentary ver) 5. 異なる遊戯と訓練の終わりの前にⅡ 6. "Stainless think" beyond (音楽と、軌道を外れた) 7. A traffic accident resulting in death, I took different trains, in random order All songs are played by 中川裕貴、バンド Yuki Nakagawa,band 中川裕貴、バンド Yuki Nakagawa,band: 中川裕貴 Yuki Nakagawa(Cello, Effects, Field-recording on tr.2, Edit) 菊池有里子 Yuriko Kikuchi(Piano) 横山祥子 Syoko Yokoyama(Violin) 出村弘美 Hiromi Demura(Non-musician, Voice on tr.1,3,4,6, Electric-bass<world premiere> on tr.5) 天野奏 (Harp, Effects on tr.1,3,5,7) Recording:粕谷茂一 Moichi Kasuya(slim chance audio) Recording places:大阪市立芸術創造館、UrBANGUILD、京都市某音楽スタジオ(tr.5) Mixing:中川裕貴 Yuki Nakagawa & 粕谷茂一 Moichi Kasuya(slim chance audio) Mastering:粕谷茂一 Moichi Kasuya(slim chance audio) Additional Recording(tr.2,4,5), Mix support:大澤慧 Akira Osawa Artwork & Design:川辺基以 Motoyuki Kawabe [email protected] OTCCDS-001 C&P 2016 Yuki Nakagawa all rights reserved 結音茶舗 542-0012 大阪府大阪市中央区谷町6丁目14-2 路地奥 結音茶舗 電話 06 4305 4926 map https://goo.gl/maps/ePqVuHhzoU72 googleMapで「日本茶バー」検索 営業時間 お昼 12:00 - 深夜24:00 ランチタイム 12:00 - 15:00 定休日毎月曜 イベント・催しによって変動あり #結音茶舗 #日本茶 #日本茶バー #日本茶カフェ #日本茶喫茶 #日本茶ごはん #日本茶カクテル #ほうじいなり #日本茶ランチ #谷町 #谷町六丁目 #谷町6丁目 #谷六 #谷6 #空掘 #からほり #古民家 #古民家バー #古民家カフェ #路地空堀 #中川裕貴 #中川裕貴バンド #YukiNakagawa,band (大阪 谷町6丁目の日本茶バー 結音茶舗)

#中川裕貴バンド#日本茶カフェ#古民家#ほうじいなり#古民家カフェ#谷町六丁目#日本茶喫茶#日本茶ごはん#谷町6丁目#結音茶舗#日本茶カクテル#谷町#路地空堀#yukinakagawa#日本茶バー#日本茶#中川裕貴#谷6#日本茶ランチ#空掘#古民家バー#からほり#谷六

0 notes