#“metal 3d printing service”

Explore tagged Tumblr posts

Text

Why 3D Printing is on Demand these days?

Discover the power of 3D Printing Service and why it's in high demand today. Explore how this innovative technology is revolutionizing industries, from manufacturing to healthcare. Learn about the endless possibilities and benefits of 3D printing on Demand. Stay ahead of the curve and unlock new opportunities with this game-changing technology.

0 notes

Text

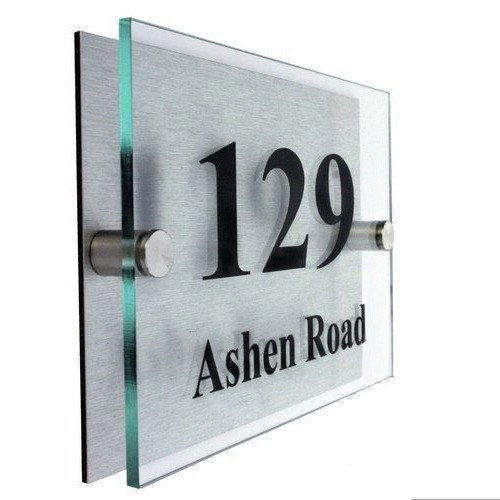

Getting the Most Out of Custom Metal Signs and metal signage

Custom metal signs are a great way to make a statement. Whether you're looking to promote your business or simply add a personal touch to your home, metal signage is a durable and attractive option. But how can you get the most out of your custom metal signs? Here are a few tips to help you make the most of this versatile medium.

First, consider the placement of your metal signs. Metal is a durable material that can withstand a lot of wear and tear, but it's still important to choose the right location for your sign. If you're using metal signage for your business, make sure it's visible from the street or other high-traffic areas. If you're using it in your home, consider placing it in a prominent location where it will be seen and appreciated.

Next, think about the design of your custom metal sign. Metal is a versatile material that can be shaped and cut into almost any design you can imagine. Take advantage of this flexibility by creating a design that is unique and eye-catching. Consider using bold colors or intricate patterns to make your sign stand out.

Another important consideration when creating custom metal signs is the material itself. There are many different types of metal to choose from, each with its own unique properties. Aluminum is lightweight and easy to work with, while steel is strong and durable. Copper and brass are both attractive options that can add a touch of elegance to any design. Choose the material that best suits your needs and budget.

Finally, don't forget about the finishing touches. A custom metal sign can be further customized with a variety of finishes, including paint, powder coating, and anodizing. These finishes not only add color and texture to your sign, but they also help protect it from weathering and other damage.

In conclusion, custom metal signs offer a unique and durable way to promote your business or add a personal touch to your home. By considering the placement, design, material, and finishing touches of your sign, you can create a one-of-a-kind piece that will stand the test of time. So why not explore the possibilities of metal signage today?

2 notes

·

View notes

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Text

Understanding the Custom Metal Manufacturing Process: From Design to Delivery

Discover how Mechkonnect revolutionizes the metal fabrication industry with cutting-edge manufacturing solutions, from innovative design to seamless delivery. This article explores the company’s expertise in creating customized metal components for various industries, ensuring precision, quality, and timely service. Learn how their advanced technology and skilled workforce provide tailored solutions to meet your specific project needs. For more wnquiry call at: +91 9819030700. Read More:

0 notes

Text

The Rise of 3D Scanning and Design in Bangalore: Revolutionizing Manufacturing with Trumpf TruPrint Metal 3D Printers

Bangalore, known as India’s Silicon Valley, has embraced advanced manufacturing technologies, making it a leading center for 3D scanning and design services. This city has become a magnet for technology-driven industries, particularly in the areas of metal 3D printing and additive manufacturing. Among the standout technologies in the market are Trumpf TruPrint metal 3D printers, which are widely regarded for their precision, reliability, and scalability. Let's explore the role of 3D scanning and design in Bangalore and how the Trumpf TruPrint series is reshaping the city’s manufacturing landscape.

The Role of 3D Scanning and Design in Bangalore

As industries increasingly prioritize precision, customization, and efficiency, 3D scanning and design services in Bangalore have emerged as critical components of the manufacturing ecosystem. With 3D scanning technology, companies can capture precise measurements of physical objects and convert them into digital 3D models. These digital models can be modified, analyzed, and used as templates for prototyping or production.

The integration of 3D scanning and design into the manufacturing workflow is revolutionizing quality control and reverse engineering. For example, in sectors like aerospace and healthcare, even the smallest error can have significant consequences, making accuracy essential. By incorporating 3D scanning, companies in Bangalore can compare manufactured parts to original CAD models, identify discrepancies, and ensure that parts meet exact specifications. Furthermore, 3D scanning plays a crucial role in the process of reverse engineering, allowing companies to recreate parts that lack detailed designs or have been modified over time.

Trumpf TruPrint Series: Precision Metal 3D Printing

When it comes to metal 3D printing, the Trumpf TruPrint series is renowned for its robust design, advanced features, and adaptability across various industries. The Trumpf TruPrint line includes multiple models, each tailored to meet different production needs, from prototyping to high-volume manufacturing. Here, we’ll explore the key features and applications of the Trumpf TruPrint 1000, 2000, 3000, and 5000 metal 3D printers.

1. Trumpf TruPrint 1000 Metal 3D Printer: Compact and Efficient

The Best Trumpf TruPrint 1000 Metal 3D Printer is ideal for companies seeking a compact and highly efficient metal 3D printer. This model is perfect for small and medium-sized parts and is widely used for prototyping and small-batch production in industries such as dental, medical, and jewelry manufacturing. With a user-friendly interface and a modular design, the TruPrint 1000 enables quick setup and easy handling, making it accessible to businesses that are new to metal 3D printing.

Despite its small footprint, the TruPrint 1000 offers impressive precision and build quality, ensuring reliable results even for intricate designs. This model is also known for its energy efficiency, reducing operational costs and making it an economical choice for companies in Bangalore that require smaller-scale, high-quality production.

2. Trumpf TruPrint 2000 Metal 3D Printer: Superior Quality with Laser Precision

The Best Trumpf TruPrint 2000 Metal 3D Printer is designed for industries that require superior precision and part quality. With a smaller laser spot diameter than the TruPrint 1000, the TruPrint 2000 can produce parts with fine detail and excellent surface quality, making it an ideal choice for industries such as aerospace, automotive, and medical devices.

The TruPrint 2000 also features dual-laser technology, enabling it to produce parts faster by allowing simultaneous printing of two areas. This dual-laser capability enhances productivity and reduces lead times, making it well-suited for companies in Bangalore seeking to optimize production cycles without compromising on quality. The TruPrint 2000’s closed powder cycle further ensures safety and reduces material wastage, aligning with sustainability goals and reducing costs.

3. Trumpf TruPrint 3000 Metal 3D Printer: Versatile and Scalable for Industrial Applications

The Best Trumpf TruPrint 3000 Metal 3D Printer takes metal 3D printing to the next level with its versatility and scalability. This mid-sized 3D printer is designed for industrial applications, capable of producing parts with complex geometries and larger build volumes. The TruPrint 3000 is popular among automotive, aerospace, and engineering companies due to its flexibility and ability to handle a wide range of materials.

A standout feature of the TruPrint 3000 is its external part and powder management system, which allows for continuous production and minimal downtime. This feature is especially valuable for companies in Bangalore looking to scale production and integrate metal 3D printing into their existing workflows seamlessly. The TruPrint 3000 also supports automation, enabling businesses to increase productivity and optimize labor resources.

4. Trumpf TruPrint 5000 Metal 3D Printer: High-Volume Production with Automated Workflow

At the top of the TruPrint series is the Best Trumpf TruPrint 5000 Metal 3D Printer, a powerhouse designed for high-volume production and complex industrial applications. This model is equipped with a multi-laser system, featuring three lasers that work simultaneously, significantly reducing production time for large-scale projects. This capability makes the TruPrint 5000 ideal for industries such as automotive and aerospace, where large, complex metal parts are in demand.

The TruPrint 5000 offers a range of automation options, including automated substrate plate changes and powder and parts handling, making it suitable for round-the-clock production. Its advanced software integrates seamlessly with manufacturing execution systems, enabling remote monitoring and control. For companies in Bangalore seeking a high-throughput solution for metal 3D printing, the TruPrint 5000 offers unmatched productivity and efficiency.

Impact of 3D Scanning and Trumpf TruPrint Metal 3D Printers on Bangalore’s Manufacturing Landscape

The combination of 3D scanning, design, and Trumpf TruPrint metal 3D printing technology is transforming Bangalore’s manufacturing landscape. By adopting these technologies, companies in Bangalore can streamline their workflows, reduce material costs, and improve the quality and speed of production. Industries that rely on precision and customization, such as aerospace, healthcare, and automotive, benefit immensely from these innovations.

Moreover, the availability of 3D scanning and design services in Bangalore allows businesses to access the latest tools without the need for heavy investments in equipment. Local service providers are helping companies integrate these technologies seamlessly, offering customized solutions tailored to specific industry needs.

Conclusion: The Future of Additive Manufacturing in Bangalore

As Bangalore continues to evolve as a technology hub, the demand for advanced 3D scanning, design, and metal 3D printing services will only grow. The Trumpf TruPrint series, with its cutting-edge features and versatility, is well-suited to meet the diverse needs of Bangalore’s industries, from small-scale prototyping to high-volume production.

With a growing ecosystem of additive manufacturing solutions and a strong emphasis on innovation, Bangalore is poised to become a leader in the global additive manufacturing sector. The synergy between 3D scanning and design services and Trumpf TruPrint metal 3D printers is shaping the future of manufacturing in the region, allowing companies to push the boundaries of what’s possible and delivering unprecedented levels of precision and efficiency in their production processes.

#Metal 3D printing in Bangalore#Additive Manufacturing in Bangalore#Additive Manufacturing Companies in Bangalore#3D Printing Service in Bangalore#3D Scanning Services in Bangalore#3D Scanning And Design in Bangalore#Best Trumpf TruPrint 1000 Metal 3D Printer#Best Trumpf TruPrint 2000 Metal 3D Printer#Best Trumpf TruPrint 3000 Metal 3D Printer#Best Trumpf TruPrint 5000 Metal 3D Printer#Best FabMachines F3 3D Printer in Bangalore#Best FabMachines F3 Pro 3D Printer in Bangalore#FabMachines G3 3D Printer in Bangalore#FabMachines G3 Pro 3D Printer in Bangalore#Simufact Manufacturing Software

0 notes

Text

Comparing Cheap Metal 3D Printing Services: What You Get for Your Money

Metal 3D printing has become a popular way to create durable parts for industries like automotive, aerospace, and manufacturing. However, the cost can vary greatly depending on the service you choose. If you're on a budget, you may be tempted to look for cheap metal 3D printing services. But what exactly do you get for your money? Let’s break it down and compare some of the key factors that influence the cost.

1. Quality of Printing

When looking at cheaper services, the quality of the printed part can be affected. Metal 3D printing uses high-tech equipment to create precise and strong parts, but cheaper services may use less advanced machines or lower-quality materials. This can lead to:

Surface Finish: You may notice rough surfaces or imperfections.

Dimensional Accuracy: Parts may be slightly off in size, affecting how well they fit or function.

Strength and Durability: Cheaper materials may result in parts that aren’t as strong or long-lasting.

If your part requires high precision and durability, it might be worth spending a little more for a service with better equipment and materials.

2. Type of Metal Used

The type of metal used in 3D printing can greatly impact the price. Cheaper services might offer fewer metal options, or use lower-quality alloys. Common metals used in 3D printing include:

Aluminum: Lightweight and relatively cheap.

Stainless Steel: Strong, corrosion-resistant, and more expensive.

Titanium: High strength but also much more costly.

If a service is offering a lower price, make sure to check what type of metal they are using and if it meets your project needs.

3. Turnaround Time

Another key factor is how quickly you need your part. Cheaper services may have longer lead times because they handle many orders at once, or they may not prioritize your project. Some things to consider:

Standard vs. Express Service: Many companies offer cheaper rates if you’re willing to wait longer, but you can pay extra for faster delivery.

Production Time: Less advanced printers may take longer to produce parts, which can add to the overall delivery time.

If you’re in a hurry, it might be worth paying a bit more for a faster turnaround.

4. Customer Support

When opting for cheaper 3D printing services, you may not get the best customer support. Higher-priced services often come with:

Design Assistance: Help with optimizing your design for 3D printing.

Order Tracking: Ability to track your order status and delivery.

Post-Production Services: Additional finishing options like polishing or heat treatment.

Cheaper services might have limited or no support, so if you’re new to 3D printing or need help with your design, this could be a drawback.

5. Post-Processing Options

Post-processing is important if you need your part to have a smooth finish or undergo additional treatments. Cheap 3D printing services may skip or limit post-processing to keep costs down. However, common post-processing services include:

Polishing: To smooth out the rough surface.

Heat Treatment: To strengthen the part.

Painting or Coating: For cosmetic or protective finishes.

If these steps are important to your project, make sure to check if the service includes them or if you need to pay extra.

6. Reputation and Reliability

Finally, the reputation of a 3D printing service can play a big role in what you get. Cheaper services might cut corners to save money, leading to:

Inconsistent Results: Some parts might be great, while others might have flaws.

Delayed Deliveries: Lower priority or understaffing could mean longer wait times.

Hidden Costs: Some services might surprise you with additional fees for shipping, materials, or design revisions.

Always check reviews and ask for samples before committing to a service, especially if the price seems too good to be true.

Conclusion: Is Cheap Metal 3D Printing Worth It?

In summary, cheap metal 3D printing services can save you money upfront, but there are trade-offs to consider. You might compromise on quality, material options, and customer support. If your project requires high precision, durability, or fast turnaround, investing in a higher-priced service might give you better results. However, if you’re working on a simple project and can wait for your part, a budget service could work well for you.

Always weigh the pros and cons, and remember that sometimes paying a little more upfront can save you time and headaches in the long run.

#ded metal 3d printing#Metal 3d printing#metal additive manufacturing#Dm3d#Metal 3d printing services

0 notes

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

All that you want to know about 3d printing service

3D printing has altered the manufacturing landscape. It is a more agile process than other fabrication methods — enabling manufacturers to go from design to complex metal parts quicker, easier, and at lower costs.

0 notes

Text

What is Additive Manufacturing?

Additive manufacturing is the technique of creating three-dimensional products from CAD models by layering on the material using digital data.

Additive Manufacturing, previously known as rapid prototyping, and currently popular as 3D printing...

Read the full article here: https://www.paanduvapplications.com/what-is-additive-manufacturing

#cfd simulation#additivemanufacturing#AM Process#metal 3d printing service#3d printing#lpbf#technology#simulation#innovation#software#services

0 notes

Text

Metal 3D printing services offer the capability to create complex metal parts with high precision and customization. These services utilize advanced additive manufacturing technologies to produce metal components directly from digital designs.

0 notes

Text

Get 3D Printing Services on Demand from Makenica!

Makenica is your go-to destination for on-demand 3D printing service. From prototypes to custom designs, our team of experts will bring your ideas to life with precision and efficiency. Get high-quality 3D prints delivered right to your doorstep. Explore our services today and experience the future of manufacturing with Makenica!

0 notes

Text

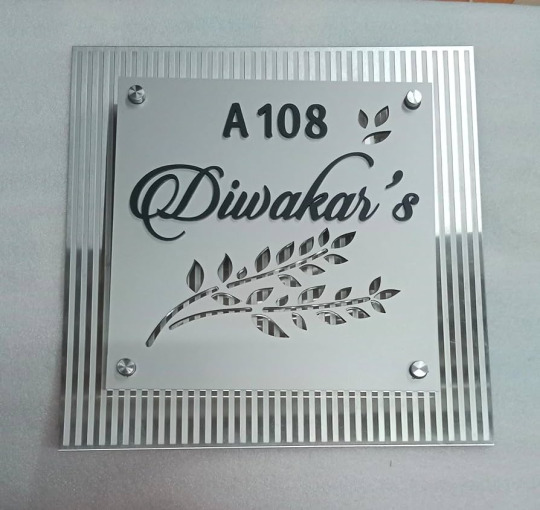

Which Nameplate is best for home?

The best nameplate for your home depends on personal preference, but options like classic brass, modern acrylic, wooden plaques, ceramic tiles, and stainless steel address plaques offer durability and style.

Choose one that complements your home’s architecture and reflects your unique personality. In the realm of home & office décor, nameplates serve as more than just identifiers; they are an extension of your home’s personality and a welcoming beacon for guests.

Selecting the right nameplate is crucial as it sets the tone for the entire ambiance of your home’s exterior. With an array of materials, designs, and customization options available, finding the ideal nameplate can be a daunting task.

This comprehensive guide aims to simplify the process by exploring various factors to consider and highlighting the best nameplate options for different preferences and requirements.

Factors to Consider:

Material:

Nameplates come in a diverse range of materials, each offering unique characteristics in terms of durability, aesthetics, and maintenance. Common materials include:

Metal: Brass, stainless steel, aluminum, and wrought iron are popular choices for their durability and timeless appeal. Metal nameplates are resistant to weathering and can withstand outdoor elements.

Wood: Wooden nameplates exude warmth and natural beauty, making them an excellent choice for rustic or traditional-style homes. However, wood requires periodic maintenance to prevent rot and weather damage.

Ceramic: Ceramic nameplates are known for their intricate designs, vibrant colors, and durability. They are resistant to fading and can withstand harsh weather conditions, making them suitable for outdoor use.

Acrylic: Acrylic nameplates offer a modern and sleek appearance, with the flexibility to customize colors, shapes, and fonts. They are lightweight, weather-resistant, and easy to clean.

Design:

The design of the nameplate should complement the architectural style of your home while reflecting your personal taste. Consider factors such as:

Traditional vs. Modern: Choose a design that aligns with the overall aesthetic of your home. Traditional homes may benefit from classic designs with ornate details, while modern homes may opt for clean lines and minimalist typography.

Typography: Pay attention to the font style, size, and readability of the nameplate. Bold, easy-to-read fonts are essential for ensuring visibility from a distance.

Customization: Many homeowners prefer personalized nameplates with their family name, house number, or a meaningful quote. Customization adds a personal touch and makes the nameplate truly unique.

Size and Visibility:

The size of the nameplate should be proportionate to the facade of your home and easily visible from the street. Consider the following guidelines:

House Number: Ensure that the house number is large enough to be legible from a distance, especially for properties set back from the road.

Placement: Mount the nameplate at eye level near the entrance to ensure maximum visibility. Avoid placing it in areas obstructed by foliage or other objects.

Contrast: Choose colors and finishes that provide sufficient contrast against the background to enhance visibility, particularly in low-light conditions.

Weather Resistance:

Given that nameplates are exposed to outdoor elements year-round, it’s essential to select a material that can withstand various weather conditions:

Rust and Corrosion Resistance: Metal nameplates should be treated with a protective coating to prevent rust and corrosion, particularly in humid or coastal regions.

UV Protection: Choose materials that are resistant to fading and discoloration caused by prolonged exposure to sunlight.

Waterproofing: Ensure that wooden and ceramic nameplates are sealed with a weatherproof finish to prevent moisture absorption and deterioration.

Installation and Maintenance:

Consider the ease of installation and maintenance requirements when selecting a nameplate:

Mounting Options: Choose a nameplate that offers versatile mounting options, such as screws, adhesive, or hooks, depending on the surface and location.

Cleaning and Maintenance: Determine the cleaning and maintenance procedures required for each material. Metal nameplates may need periodic polishing, while wooden nameplates may require resealing to maintain their appearance.

Best Nameplate Options:

Classic Brass Nameplate:

Timeless and elegant, a brass nameplate adds a touch of sophistication to any home. Brass is highly durable and develops a unique patina over time, enhancing its vintage charm. Look for engraved brass nameplates with intricate detailing for a traditional yet stylish look.

Modern Stainless Steel Address Plaque:

Sleek and contemporary, a stainless steel address plaque offers a minimalist aesthetic with maximum durability. Stainless steel is resistant to rust, corrosion, and fading, making it ideal for outdoor use. Opt for laser-cut lettering for precise detailing and a polished finish for a sleek, sophisticated look.

Rustic Wooden Plaque with Custom Engraving:

For a rustic and personalized touch, consider a wooden plaque engraved with your family name or house number. Choose high-quality hardwoods such as oak, cedar, or mahogany for durability and natural beauty. Add a protective sealant to prevent weather damage and preserve the wood’s integrity.

Colorful Ceramic Tile Nameplate:

Ceramic tiles offer endless possibilities for customization with their vibrant colors and intricate designs. Opt for hand-painted ceramic tiles featuring motifs that reflect your personal style or cultural heritage. Mount the tiles on a sturdy backing for easy installation and long-lasting beauty.

Contemporary Acrylic House Sign:

Acrylic house signs are sleek, modern, and highly customizable, making them a popular choice for contemporary homes. Choose from a variety of colors, shapes, and fonts to create a unique design that complements your home’s exterior. Consider backlighting options for added visibility and visual impact.

Conclusion:

Choosing the perfect nameplate for your home involves careful consideration of factors such as material, design, size, visibility, weather resistance, installation, and maintenance requirements.

Whether you prefer the timeless elegance of a brass nameplate, the contemporary allure of a stainless steel plaque, or the rustic charm of a wooden plaque, there are options available to suit every style and preference. Invest in a high-quality nameplate that not only enhances the curb appeal of your home but also reflects your personality and hospitality.

With the right nameplate, you can make a lasting impression and welcome guests with style and flair.

#3d printing#3d sign#3d signage#signage#branding#digital art#print on demand#print on demand services#printing company#digital painting#home & lifestyle#modern home#home alone#home decor#design#acrylic#metal#wood#modern acrylic#name plate#name plates

1 note

·

View note

Text

Advantages & Applications of Metal 3D Printing

Metal 3D printing is an additive manufacturing technology that creates three-dimensional objects by stacking metal powders layer by layer. In metal 3D printing, metal powders such as titanium, aluminium and stainless steel are usually used as raw materials, which are melted and shaped by a laser or other high-energy beam stream.

With the continuous development of 3D printing technology, metal 3D printing is gaining attention as an important manufacturing process in industry. It allows the direct conversion of digitized models into metal parts. Metal 3D printing technology has many advantages over traditional manufacturing techniques.

1.Advantages of Metal 3D Printing ①High Manufacturing Efficiency Metal 3D printing technology can produce complex metal parts in a short period of time. Compared to traditional manufacturing techniques, it does not require additional machining steps and therefore significantly reduce the production cycle time. At the same time, product development from design to printing rarely requires human intervention due to the use of digital design processes, it is important for the design verification of new products, as well as small batch production, which can greatly shorten the time-to-market and improve competitiveness.

②Reduced Production Costs Metal 3D printing technology can reduce costs by saving materials and reducing labour intervention. Compared to traditional manufacturing techniques, metal 3D printing technology can make better use of materials and avoid wastage. It can also reduce costs by reducing manual intervention and links on mechanical processing and assembly among others as it can be designed and manufactured through a digital process. It can accurately control the use of materials according to actual needs, avoiding the waste of large amounts of material in traditional cutting processing, improving material utilisation and reducing costs.

③Customized Production Metal 3D printing can be customized to produce parts or products with specific shapes, specifications and properties to meet the needs of different fields. Compared to traditional manufacturing techniques, it does not require additional moulds and equipment, and can significantly increase production efficiency, while also meeting the individual needs of customers.

④Increased Design Diversity Metal 3D printing technology has made it possible to significantly reduce design constraints in the manufacturing process. It enables more complex, precise and detailed structures than traditional manufacturing methods, such as openwork, curved surfaces, and porous structures, which can dramatically improve the performance and longevity of materials. It allows the use of a wide range of metal materials, including titanium alloys, aluminium alloys, stainless steel, cobalt-chromium alloys and more, providing greater design freedom and application flexibility.

⑤Excellent Mechanical Properties Metal 3D printing technology makes the internal organisation of the formed part uniform and dense through the rapid solidification process, with excellent mechanical properties and corrosion resistance, and is able to increase strength without loss of plasticity. Compared to traditional manufacturing techniques, metal 3D printing technology provides better control over product quality and reduces the rate of product defects.

2.Applications of Metal 3D Printing ①Manufacturing Industry Metal 3D printing technology is widely used in the manufacturing industry. It can be used to produce automotive parts, aircraft parts, and a variety of mechanical parts, among others. In addition, it can also be used to manufacture some complex structural parts, such as gears, reducers and so on.

②Medical Industry Metal 3D printing technology also has a wide range of applications in the medical industry. It can be used to create prosthetics, teeth, implants, etc. Metal 3D printing technology can be better adapted to the individual needs of patients than traditional production methods.

③Aerospace Industry Metal 3D printing technology is also widely used in the aerospace industry. It can be used to manufacture a number of complex structural parts, fuel nozzles and turbine blades, among others. Compared with the traditional manufacturing technology, metal 3D printing technology can better control the quality of the products and improve the accuracy of the products.

④Construction Industry Metal 3D printing technology has a wide range of applications in the construction industry as well. It can be used to manufacture building structural parts, doors and windows, etc. Compared with traditional manufacturing methods, metal 3D printing technology can better meet the individual needs of customers and can significantly reduce the production cycle.

Metal 3D printing technology has significant advantages in terms of high manufacturing efficiency, rapid prototyping, customized production, material utilization and sustainability, but it also suffers from drawbacks such as slow manufacturing speeds and difficulties in subsequent processing. In practical application, it is necessary to comprehensively consider its advantages and disadvantages and select suitable applications to maximize its advantages.

#design#business#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#3d printed#3d printing#3d printing services#3d printing plastics market#metal 3d printing#rapid prototype

1 note

·

View note

Text

0 notes

Text

Metal 3D Printing in Bangalore: Revolutionizing Manufacturing with Additive Manufacturing

Bangalore, often hailed as the "Silicon Valley of India," is rapidly emerging as a major hub for cutting-edge technology, and additive manufacturing is no exception. The rise of metal 3D printing in Bangalore and related additive manufacturing in Bangalore has enabled businesses to create complex, high-quality components with precision, speed, and efficiency. This surge has resulted in a significant presence of additive manufacturing companies in Bangalore, providing services like 3D scanning services in Bangalore and 3D design and printing solutions for various industries.

The Growing Demand for Metal 3D Printing in Bangalore

Metal 3D printing in Bangalore is an advanced manufacturing technology that has become essential for sectors like aerospace, automotive, healthcare, and consumer goods. Known for its ability to produce lightweight and highly detailed parts, metal 3D printing is a top choice for prototypes and end-use components. The advantages are numerous, including reduced material wastage, faster turnaround times, and the ability to create intricate shapes that would be impossible with traditional manufacturing.

Bangalore’s strategic position as an industrial and technological powerhouse makes it the ideal setting for the adoption of additive manufacturing technologies. Numerous additive manufacturing companies in Bangalore have emerged, offering end-to-end 3D printing solutions that include prototyping, low-volume production, and custom manufacturing services for businesses across multiple sectors. The city's forward-looking approach, combined with the support from government initiatives, has fueled growth in this space, making it a center of excellence for metal 3D printing and additive manufacturing.

Why Choose Additive Manufacturing in Bangalore?

The advantages of additive manufacturing in Bangalore are clear. It provides companies with flexibility in design, allowing for rapid prototyping and production. Unlike conventional manufacturing, which requires extensive tooling and often incurs high costs for complex shapes, additive manufacturing enables the direct creation of parts from digital models, reducing lead times and optimizing resource use.

In Bangalore, the market for additive manufacturing services has expanded to support not just large enterprises but also small and medium-sized businesses. These services are accessible, affordable, and allow local companies to innovate and compete on a global scale. With a rich ecosystem of tech experts, design professionals, and engineers, Bangalore has become an ideal location for businesses seeking to leverage the potential of 3D printing technology for faster, cost-effective production.

Leading Additive Manufacturing Companies in Bangalore

With the growing need for additive manufacturing services, many additive manufacturing companies in Bangalore have established themselves as industry leaders, providing high-quality, dependable services. Companies like Wipro 3D, Objectify Technologies, and Imaginarium offer specialized solutions in metal 3D printing, which can cater to both large and small-scale projects. These companies provide support throughout the entire manufacturing process, from initial design to final production, and leverage the latest technology to ensure that every product meets stringent quality standards.

These additive manufacturing companies in Bangalore bring vast expertise and experience in sectors like aerospace, automotive, medical, and electronics, making them valuable partners for any business looking to explore the advantages of 3D printing. The competitive landscape within Bangalore fosters continuous innovation, which benefits not only local but also international clients.

3D Scanning Services in Bangalore

One of the critical services complementing additive manufacturing is 3D scanning. With 3D scanning services in Bangalore, companies can digitize objects of various shapes and sizes with great precision. These scans can then be used to create digital models for manufacturing or further modifications. For example, reverse engineering is made possible through 3D scanning, which allows companies to recreate and improve upon existing designs.

In sectors such as aerospace and healthcare, 3D scanning services are invaluable. In healthcare, they enable the creation of custom prosthetics, implants, and anatomical models, providing surgeons with a highly accurate visual reference. In aerospace, 3D scanning is used to ensure part integrity and quality control by capturing data with extreme precision.

Several providers in Bangalore offer specialized 3D scanning and design services, giving businesses access to top-notch technology that can streamline the manufacturing process and improve product quality. These services are essential for achieving high-accuracy results, particularly in industries where even the smallest design flaw could have significant consequences.

3D Scanning and Design in Bangalore: Bridging the Gap Between Concept and Creation

The process of 3D scanning and design in Bangalore has become integral to the manufacturing and product development sectors. The ability to translate an object into a digital model enables designers to refine and optimize products before production. This digital model can be used for creating prototypes, testing designs, and final manufacturing, making it invaluable in the rapid prototyping process.

Bangalore’s robust design and engineering talent pool make it an ideal place for companies seeking innovative design solutions. With access to both experienced professionals and advanced 3D scanning technology, businesses can ensure that their products are both aesthetically pleasing and functionally sound. This end-to-end service, from 3D scanning to 3D printing, makes Bangalore a one-stop destination for those exploring cutting-edge manufacturing techniques.

3D Printing Service in Bangalore: Revolutionizing Production

The demand for 3D printing services in Bangalore has grown as more industries embrace the advantages of additive manufacturing. Local providers offer a wide range of services that cater to diverse requirements, from single prototypes to short-run production. These services often include design consultation, material selection, and finishing options, allowing clients to receive a complete solution tailored to their specific needs.

Several local companies now offer advanced 3D printing services with a variety of materials, including plastics, polymers, and metals. This diversity in materials means that 3D printing can be used for numerous applications��from lightweight plastic prototypes to fully functional metal parts. Additionally, many service providers in Bangalore have invested in state-of-the-art equipment, such as the Trumpf TruPrint series, to enhance print accuracy, reduce production time, and improve the overall quality of the end products.

The Future of Metal 3D Printing and Additive Manufacturing in Bangalore

As metal 3D printing in Bangalore continues to evolve, the city's role as a major player in the additive manufacturing industry will only strengthen. With significant advances in technology and a growing number of additive manufacturing companies, Bangalore is set to drive innovation in manufacturing, helping businesses achieve sustainable growth and create products that are both high-quality and cost-effective.

In conclusion, metal 3D printing and additive manufacturing in Bangalore are reshaping the industrial landscape, making Bangalore a thriving hub for technological innovation. The availability of services like 3D scanning, 3D design, and 3D printing not only supports local industries but also positions the city as a leader in the global additive manufacturing market. For businesses seeking a competitive edge, Bangalore offers a wealth of expertise and cutting-edge technology, making it the ultimate destination for additive manufacturing solutions.

#Metal 3D printing in Bangalore#Additive Manufacturing in Bangalore#Additive Manufacturing Companies in Bangalore#3D Printing Service in Bangalore#3D Scanning Services in Bangalore#3D Scanning And Design in Bangalore#Best Trumpf TruPrint 1000 Metal 3D Printer#Best Trumpf TruPrint 2000 Metal 3D Printer#Best Trumpf TruPrint 3000 Metal 3D Printer#Best Trumpf TruPrint 5000 Metal 3D Printer#Best FabMachines F3 3D Printer in Bangalore#Best FabMachines F3 Pro 3D Printer in Bangalore#FabMachines G3 3D Printer in Bangalore#FabMachines G3 Pro 3D Printer in Bangalore

0 notes