Don't wanna be here? Send us removal request.

Text

#cfd#cfdinaeroacoustics#aeroacoustics#simualtionvideo#cfd simulation#cfdcars#computationalfluiddynamics#computer#paanduvapplications#cfdconsulting#cfd analysis

0 notes

Text

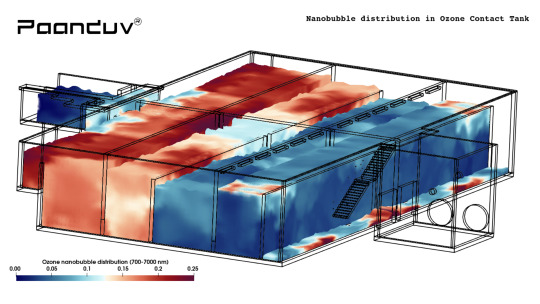

#cfd#simulation#waterandenvironment#cfdsimulation#computationalphysics#nanobubbletech#nanobubble#watertank#ozonewatertank#watercfd

0 notes

Text

Computational modeling has become an invaluable tool in modern science, offering the ability to simulate complex systems and predict outcomes with remarkable precision. One of its most significant advantages lies in its ability to analyze data before committing to real-world experiments, saving valuable time, money, and resources. By utilizing computational models, researchers can gain critical insights into the behavior of a system, identify potential problems, and design more effective experiments—all before setting foot in a lab. It's like testing your outfit in front of the mirror before heading out—minus the judgmental stares.

0 notes

Text

#quantumcomputing#3d printing#cfd#additive manufacturing#cfd simulation#hvac services#3d printing simulation software#simulation#technology#aerospace engineering#additive manufacturing software#3d sculpting#blender#ai generated#artificial intelligence

0 notes

Text

#Computational Fluid Dynamics#Aerospace Engineering#Aeroacoustics#Aerospace Propulsion#Aerodynamic Analysis#CFD Applications in Aerospace#Shock-Boundary Layer Interaction#Aeroelastic Analysis#Combustion Modeling#High-Speed Flow Analysis#Turbofan Engine Simulation#Drag Reduction Techniques#Aerospace Vehicle Design#Numerical Simulation in Aerospace#Flow Field Optimization

0 notes

Text

#QuantumComputing #QuantumPhysics #AITechnology #QuantumAlgorithms #QuantumInnovations

0 notes

Text

What Is Additive Manufacturing?

Additive manufacturing is the technique of creating three-dimensional products from CAD models by layering on the material using digital data.

0 notes

Text

Here at Paanduv Applications, we cherish diversity, fellowships, and innovation. Working in computational modeling, our company isn’t merely an office but a community where work and enjoyment go hand in hand.

0 notes

Text

AM PravaH: 3D Printing Software By Paanduv Applications

About the case study

This document will help you run your first AM PravaH LPBF simulation for macroscale and microstructure modeling. The case study is done for a standard alloy of titanium i.e. Ti6Al4V widely used for aerospace and biomedical applications. The simulation is carried out for a multilayer, multi-track scan pattern. The process parameters for the laser are e.g. 300 W power and e.g. 1 m/s scan speed. D4 sigma or spot dia is 0.1 mm.

Exclusive features of AM PravaH include consideration of 4 phases, with no explicit formulation for recoil pressure because evaporation and recoil pressure effects are included in the vapor phase. AM PravaH takes the thermophysical properties of the 4 phases as inputs along with the process parameters such as laser power, laser scan speed, shielding gas flow angle and velocity, layer thickness, spot diameter, preheating temperature, chamber initial pressure, and substrate initial height, scan pattern, particle size distribution and number of layers. Macroscale modeling will generate the following outputs melt pool dimensions, porosity %, thermal gradients, cooling rates, and thermal cycling plots. The Microstructure module generates outputs such as grain size distribution, angular chord length distribution, misorientation angles, and Euler angles. AM PravaH leverages the amalgamation of computational modeling solvers performing multiphase macroscale modeling, microstructure modeling, and Artificial Intelligence (AI) at a unified platform.

Keywords: Additive Manufacturing, 3D printing, Meltpool dynamics, porosity, thermal gradients, cooling rate, microstructure analysis, grain size, angular chord length, 3D printing software

AM PravaH: 3D printing simulation software

Introduction

AM PravaH is a 3D printing simulation software that facilitates end-to-end solutions for Additive Manufacturing physics-based simulations. Additive Manufacturing is commonly known as 3D printing. This 3D printing software is the “World’s first all-inclusive 3D computational software for Additive Manufacturing”. This 3D printing software will be useful for new alloy development, process parameter optimization, and reducing defects. Not to confuse with other 3D printing software that only performs thermomechanical analysis and deformation, AM PravaH software offers much more.

The software capabilities in brief are as follows:

There are three modules in AM PravaH

(i) Macroscale modeling

(ii) Microstructure analysis

(iii) Integrated Deep Learning (AI) module

Relevance of the 3D printing software; AM PravaH

This 3D printing software is relevant for researchers, academicians, and industry professionals from large and small-sized companies working in the Additive Manufacturing field. Where the primary focus is to understand the in-depth physics, microstructures, and effect of process parameters on the melt pool dynamics and distribution and the root cause of the defects. If we have a much closer look at the fundamental processes of 3D printing; this is a transient, very quick, and very dynamic process, which can't be captured with the naked eye. Therefore, AM PravaH simulations can be extremely useful in understanding this part.

Based on that, one makes important decisions such as

Which alloy is better?

How do we get solidification, melting, and cooling rates information?

what are the best operating process conditions to get a defect-free and dense part

What do the microstructures look like?

What are the grain distribution and mean grain size?

What are the melt pool sizes?

How much will be the porosity %?

#3d printing simulation software#3d printing software#additive manufacturing software#additive manufacturing#3d printing#simulation software for additive manufacturing

1 note

·

View note

Text

#3d printing#3d printing simulation software#additive manufacturing simulation software#additive manufacturing software#additive manufacturing

0 notes

Text

Numerical simulations, like human beings, tend to course-correct at the onset of sickness. Contrary to this reactive approach, a more preventive approach for healthy numerical simulations is developed by Paanduv Applications.

0 notes

Text

Preventive Approach for Healthy Numerical Simulations

Numerical simulations, like human beings, tend to course-correct at the onset of sickness. Contrary to this reactive approach, a more preventive approach for healthy numerical simulations is developed by Paanduv Applications.

0 notes

Text

#cfd#cfd simulation#simulation#cfd analysis#computational fluid dynamics#technology#innovation#engineering

0 notes

Text

CFD Analysis And Its Applications

CFD Analysis is a technique used for studying and predicting fluid flows. It uses mathematical models defining the fluid and flow which are then solved using computers and the prediction is made about the flow properties. These predictions are useful when designing the systems with fluids or studying the natural phenomenon.

Read Full Article here: https://www.paanduvapplications.com/cfd-analysis-and-its-applications

#cfd#Cfd analysis#Computational Fluid Dynamics#Simulation#CFD simulation#technology#engineering#innovation

0 notes

Text

Read the article here!

CFD Analysis And Its Applications

#CFD analysis#Computational fluid dynamics#CFD#cfd simulation#simulation#3d printing#Computational Physics#technology#innovation#software

0 notes

Text

The world of aerospace engineering is replete with non-linear partial differential equations that encase the core physics involved in particular physical phenomena.

0 notes