#simulation software for additive manufacturing

Explore tagged Tumblr posts

Text

AM PravaH: 3D Printing Software By Paanduv Applications

About the case study

This document will help you run your first AM PravaH LPBF simulation for macroscale and microstructure modeling. The case study is done for a standard alloy of titanium i.e. Ti6Al4V widely used for aerospace and biomedical applications. The simulation is carried out for a multilayer, multi-track scan pattern. The process parameters for the laser are e.g. 300 W power and e.g. 1 m/s scan speed. D4 sigma or spot dia is 0.1 mm.

Exclusive features of AM PravaH include consideration of 4 phases, with no explicit formulation for recoil pressure because evaporation and recoil pressure effects are included in the vapor phase. AM PravaH takes the thermophysical properties of the 4 phases as inputs along with the process parameters such as laser power, laser scan speed, shielding gas flow angle and velocity, layer thickness, spot diameter, preheating temperature, chamber initial pressure, and substrate initial height, scan pattern, particle size distribution and number of layers. Macroscale modeling will generate the following outputs melt pool dimensions, porosity %, thermal gradients, cooling rates, and thermal cycling plots. The Microstructure module generates outputs such as grain size distribution, angular chord length distribution, misorientation angles, and Euler angles. AM PravaH leverages the amalgamation of computational modeling solvers performing multiphase macroscale modeling, microstructure modeling, and Artificial Intelligence (AI) at a unified platform.

Keywords: Additive Manufacturing, 3D printing, Meltpool dynamics, porosity, thermal gradients, cooling rate, microstructure analysis, grain size, angular chord length, 3D printing software

AM PravaH: 3D printing simulation software

Introduction

AM PravaH is a 3D printing simulation software that facilitates end-to-end solutions for Additive Manufacturing physics-based simulations. Additive Manufacturing is commonly known as 3D printing. This 3D printing software is the “World’s first all-inclusive 3D computational software for Additive Manufacturing”. This 3D printing software will be useful for new alloy development, process parameter optimization, and reducing defects. Not to confuse with other 3D printing software that only performs thermomechanical analysis and deformation, AM PravaH software offers much more.

The software capabilities in brief are as follows:

There are three modules in AM PravaH

(i) Macroscale modeling

(ii) Microstructure analysis

(iii) Integrated Deep Learning (AI) module

Relevance of the 3D printing software; AM PravaH

This 3D printing software is relevant for researchers, academicians, and industry professionals from large and small-sized companies working in the Additive Manufacturing field. Where the primary focus is to understand the in-depth physics, microstructures, and effect of process parameters on the melt pool dynamics and distribution and the root cause of the defects. If we have a much closer look at the fundamental processes of 3D printing; this is a transient, very quick, and very dynamic process, which can't be captured with the naked eye. Therefore, AM PravaH simulations can be extremely useful in understanding this part.

Based on that, one makes important decisions such as

Which alloy is better?

How do we get solidification, melting, and cooling rates information?

what are the best operating process conditions to get a defect-free and dense part

What do the microstructures look like?

What are the grain distribution and mean grain size?

What are the melt pool sizes?

How much will be the porosity %?

#3d printing simulation software#3d printing software#additive manufacturing software#additive manufacturing#3d printing#simulation software for additive manufacturing

1 note

·

View note

Text

Top 8 Applications of 3D Printing in Medical Industry

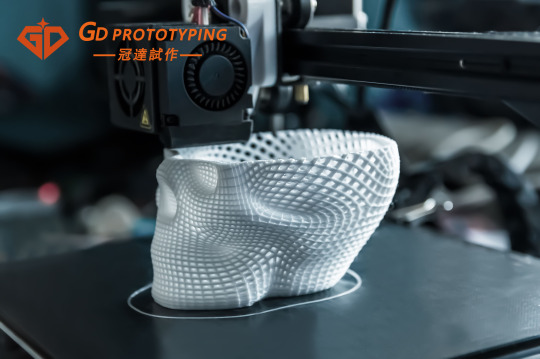

3D printing technology, with its highly customizable, responsive and material-saving features, is triggering profound changes in the medical field. Especially in the application of medical models, 3D printing technology shows unparalleled advantages and potential.

Furthermore, 3D printing technology, as an emerging additive manufacturing technology, has made breakthroughs in its application in the medical field in recent years. The application of 3D printing technology in the medical field is becoming more and more widespread. Through the layer-by-layer stacking of digital models, a variety of medical devices, prosthetics, orthotics and other aids, and even human organs, can be accurately printed.

1.Surgical preview model

With 3D printing technology, doctors can create surgical preview models to help them simulate operations before surgery, improving accuracy and safety.

It is important for medical workers to conduct preoperative planning for risky and difficult procedures. In the previous surgical preview process, medical workers often need to obtain the patient's data through CT, magnetic resonance imaging (MRI) and other imaging equipment, and then the two-dimensional medical image using software to convert into realistic three-dimensional data. Today, medical workers can use devices such as 3D printers to print 3D models directly. In this way, it not only can assist the doctor to carry out accurate surgical planning, improve the success rate of surgery, but also to facilitate the communication and exchange between medical workers and patients on the surgical program plan.

2.Surgical guide

Surgical guides can help the surgeon to accurately position and operate during surgery, reducing surgical errors and improving surgical outcomes.

As an auxiliary surgical tool during surgery, surgical guides can help medical workers to accurately implement surgical programmes. Currently, the types of surgical guides have included joint guides, spinal guides, oral implant guides, etc. With the help of 3D printed surgical guides, firstly, the 3D scanning technology can produce three-dimensional data on the patient's affected area, which allows the doctor to obtain the most realistic information, so as to better plan the surgery. Secondly, while making up for the shortcomings of the traditional surgical guide manufacturing process, the size and shape of the guide can also be adjusted as needed.In this way, different patients can have a guide plate that meets their real needs.

3.Dental applications

3D printing technology is also widely used in the field of dentistry to print personalized trays, moulds, etc., to help patients have better dental treatment.

The application of 3D printing in the dental field mainly focuses on the design and production of metal teeth, invisible braces, etc. The emergence of cutting-edge technology of 3D printing creates more possibilities for those who need orthodontic treatment to achieve personalized and customized braces. At different stages of orthodontic treatment, orthodontists need different sets of braces. With the help of 3D printing to create multiple sets of braces needed for orthodontic treatment, it not only helps the healthy development of teeth, but also reduces the cost of braces production. The significance of these digital technologies is that they are gradually making it less necessary for doctors to make models, dentures, etc. by hand, and returning more of their efforts to the diagnosis of oral diseases and the performance of oral surgery itself.

4.Rehabilitation medical equipment

Through 3D printing technology, a variety of rehabilitation medical devices, such as prosthetics and orthotics, can be created to help patients regain function.

The real value of 3D printing for orthopaedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only to achieve accurate customization, but also to allow accurate and efficient digital manufacturing technology to replace the traditional production methods, reducing the cost of individual customized rehabilitation medical devices and shortening the production cycle. 3D printing process is diversified, and there is a wide range of 3D printing materials. SLA light-curing 3D printing technology has the advantage of being able to provide the most efficient and cost-effective 3D printing technology. SLA light-curing 3D printing technology is widely used in rapid prototyping by the medical device industry due to its advantages of fast processing speed, high precision, good surface quality of photosensitive resin material moulding and moderate cost.

5.Medical Equipment Cases

3D printing technology can also be used to create a variety of medical devices, such as surgical instruments and medical equipment, to improve the personalization and accuracy of medical devices.

Take the example of 3D printing for mass customized production in the hearing aid shell industry. In the traditional way, injection moulds need to be made from a model of the patient's ear canal. The final shape of the hearing aid is obtained by drilling sound holes and manually processing the plastic product. If a mistake is made during the process, the mould needs to be recreated. The process of making a hearing aid using a 3D printer, on the other hand, begins with the design of a silicone mould or impression of the patient's ear canal, a step that is done using a 3D scanner. CAD software is then used to convert the scanned data into a design file that can be read by the 3D printer. The designer can then use the software to modify the 3D image and create the final product shape.

6.Precision replication and personalization

3D printing technology is able to accurately restore a patient's anatomy and produce full-size, high-fidelity medical models based on the patient's CT, MRI and other imaging data. These models not only have extremely high geometric accuracy and surface quality, but also reflect the unique physiological characteristics of the patient, providing doctors with real and reliable references.

7.Teaching and training

3D printed medical models also play an important role in medical education and training. By printing out models of various typical cases, medical students can perform practical operations in a simulated surgical environment to enhance their surgical skills and resilience. At the same time, these models can also be used as teaching tools to help students better understand human anatomy and disease principles.

8.Scientific research and experimentation

In the field of medical research, 3D printed medical models also have important applications. Researchers can use these models to conduct experimental studies such as drug screening and biomechanical testing to explore new treatment methods and technologies. In addition, by printing tissue or organ models with specific physiological functions, they can also provide strong support for research in cutting-edge fields such as organ transplantation and regenerative medicine.

In summary, 3D printing technology has a wide and far-reaching significance in the application of medical models. It not only improves the accuracy and efficiency of medical services, but also promotes the innovative development of medical education, research and clinical practice. With the continuous progress of technology and the expansion of application scope, we have reason to believe that 3D printing will play a more important role in the future medical field.

#3d printing#3d printing services#3d printed#additive manufacturing#3d print#medical device machining#medical 3d printing#3d printed parts#3d printing materials market#3d printing market share

4 notes

·

View notes

Text

Yvette Heiser - How Phone Photography Has Transformed Over the Years

In the past two decades, phone photography has undergone a remarkable transformation, evolving from a novelty feature to a vital tool for both amateur and professional photographers. As smartphones have become ubiquitous, so too has the ability to capture high-quality images at any moment. Yvette Heiser talks about - How Photography Has Evolved Over the Years, highlighting the technological advancements that have revolutionized mobile photography, from improved sensors to AI-enhanced editing tools, making it easier than ever to take stunning photos with just a phone.

The Early Days of Mobile Photography

A Simple Beginning

The journey of phone photography began in the early 2000s with the introduction of basic camera phones. These devices featured low-resolution cameras, often producing images that lacked clarity and detail. The primary purpose of these cameras was to share quick snapshots rather than create high-quality photographs.

In 2002, the first commercially available camera phone, the Sharp J-SH04, was launched in Japan. It had a mere 0.11-megapixel sensor, which limited its capabilities. Early users primarily captured simple images for texting or sharing with friends. The quality was far from impressive, but it sparked a new way of documenting everyday life. Yvette Heiser Texas: A Complete Guide to Mastering Phone Photography explores this evolution, offering insights into how phone cameras have advanced over the years and how users can harness their full potential for stunning photography.

The Rise of Social Media

As social media platforms like Facebook and Instagram gained popularity in the late 2000s, so did the demand for better mobile photography. Users wanted to share their lives through images, prompting manufacturers to improve their camera technology. This shift marked a turning point in how people viewed phone photography.

Technological Advancements in Camera Phones

Improved Camera Quality

By the time the iPhone was introduced in 2007, mobile photography began to take a significant leap forward. The iPhone's 2-megapixel camera offered improved image quality compared to its predecessors. Over the years, subsequent iPhone models and other smartphones began to feature higher-resolution cameras with better sensors and optics.

Megapixels Matter: Modern smartphones now come equipped with cameras boasting 12-megapixels or more, allowing users to capture stunning images with remarkable detail.

Multiple Lenses: Many devices now include multiple lenses—wide-angle, telephoto, and macro—enabling users to experiment with different perspectives and styles.

Advanced Software and Features

In addition to hardware improvements, software enhancements have played a crucial role in transforming phone photography. Image processing algorithms have evolved significantly, enabling smartphones to produce high-quality images even in challenging lighting conditions.

Some notable advancements include:

Night Mode: This feature allows users to capture clear and vibrant images in low-light environments without using a flash.

Portrait Mode: By simulating depth of field, portrait mode helps create professional-looking photos by blurring the background while keeping the subject sharp.

AI Integration: Many smartphones now utilize artificial intelligence to enhance photos automatically, optimizing settings based on scene recognition.

The Influence of Social Media on Mobile Photography

The Pursuit of Perfection

Social media platforms have greatly influenced how people approach photography with their phones. The desire for likes and shares has led to a focus on aesthetics and creativity. Users are now more aware of composition, lighting, and editing techniques, resulting in a generation of visually-savvy photographers.

The Rise of Influencers

With the advent of social media influencers, mobile photography has become an essential skill for many aspiring content creators. Brands are increasingly collaborating with influencers who possess a strong visual storytelling ability through their smartphone photography. This trend has further pushed smartphone manufacturers to innovate and provide users with tools that cater to this growing market.

Mobile Photography as a Form of Art

Breaking Down Barriers

Today, phone photography is no longer just about capturing memories; it has become a legitimate form of art. Many photographers have transitioned from traditional cameras to smartphones, showcasing their work in galleries and exhibitions. This shift has democratized photography, allowing anyone with a smartphone to express their creativity.

Community and Collaboration

The rise of mobile photography communities has also contributed to its evolution. Platforms like Instagram have fostered connections among photographers, leading to collaborations and shared learning experiences. Users can now participate in challenges and workshops focused on improving their skills and showcasing their work.

Future Trends in Phone Photography

Continuous Innovation

As technology continues to advance, we can expect even more exciting developments in phone photography. Here are some trends that may shape the future:

Enhanced Image Stabilization: Future smartphone cameras will likely include advanced stabilization technologies that allow for smoother video recording and sharper still images.

Augmented Reality (AR): With AR applications becoming more popular, we might see features that enable users to overlay digital elements on their photos or create immersive experiences.

Higher Dynamic Range (HDR): Improved HDR capabilities will likely enhance the quality of photos taken in high-contrast environments, ensuring details are preserved in both highlights and shadows.

Sustainability and Ethical Considerations

As mobile photography grows, so does awareness of sustainability and ethical considerations in photography practices. Photographers are increasingly encouraged to consider their impact on the environment and seek ways to promote responsible practices.

Conclusion

The transformation of phone photography over the years has been nothing short of extraordinary. From its humble beginnings with basic camera phones to the sophisticated devices we use today, mobile photography has revolutionized how we capture and share moments. As technology continues to evolve, it will undoubtedly open new doors for creativity and expression. Whether you’re an aspiring photographer or simply enjoy documenting your daily life, embracing the art of phone photography offers endless possibilities for exploration and connection.

#wedding#camera#photographer#pictures#childphotography#moments#photography#yvette heiser#photographytips#events

6 notes

·

View notes

Text

2D to 3D Drawing Conversion Services: Transforming Designs with Precision

2D to 3D Drawing Conversion Services: Transforming Designs with Precision

Introduction

In the modern design and engineering world, the transition from 2D to 3D drawings has become crucial for enhanced visualization, accuracy, and efficiency. At ADSBIM, we specialize in 2D to 3D drawing conversion, offering precision-driven solutions to transform flat drawings into comprehensive 3D models. Our expertise ensures seamless conversion, catering to industries like architecture, engineering, and manufacturing. We are recognized as the BEST 2D to 3D Drawing Conversion Services provider in Gurgaon, India, UK, Dubai, and USA.

The Process of Converting 2D Designs into 3D Models

The 2D to 3D drawing conversion process involves several meticulous steps to ensure accuracy and fidelity to the original design. Here’s how we do it:

Understanding Requirements: We analyze the 2D drawing, ensuring clarity in dimensions, annotations, and details.

Software Selection: Based on project needs, we choose the appropriate 2D to 3D drawing conversion software such as AutoCAD, SolidWorks, Revit, or CATIA.

Modeling the Geometry: Using advanced tools, we create a 3D representation of the 2D drawing while maintaining proportional accuracy.

Material and Texture Application: If required, materials, textures, and colors are applied to make the model more realistic.

Validation and Quality Check: The final 3D model is compared with the original 2D drawing to ensure precision and adherence to client requirements.

Final Delivery: The completed 2D drawing to 3D model is delivered in the required format, ready for use in design simulations, manufacturing, or visualization.

Challenges in 2D to 3D Drawing Conversion

While converting 2D drawings to 3D models, several challenges can arise:

Loss of Information: Some 2D drawings lack depth-related data, requiring intelligent interpretation.

Complex Geometries: Intricate designs may need additional modifications to ensure a smooth 3D transformation.

Scale and Accuracy: Ensuring precise measurements during conversion is crucial to avoid design flaws.

Software Compatibility: Different clients use varied software, requiring expertise in multiple platforms.

How ADSBIM Provides the Best Solutions

At ADSBIM, we tackle these challenges with expertise and cutting-edge technology:

Experienced Team: Our skilled professionals have extensive experience in 2D to 3D drawing conversion across multiple industries.

Advanced Software Tools: We use industry-leading 2D to 3D drawing conversion software, including:

AutoCAD

SolidWorks

Revit

CATIA

SketchUp

Custom Solutions: We tailor our approach to match specific project needs, ensuring maximum accuracy.

Quality Assurance: Rigorous quality checks ensure error-free 2D drawing to 3D model conversion.

Fast Turnaround: Our efficient process ensures timely delivery without compromising quality.

Why Choose ADSBIM for 2D to 3D Drawing Conversion?

BEST 2D to 3D Drawing Conversion Services COMPANY IN GURGAON and globally recognized in India, UK, Dubai, and USA.

Precision and Accuracy: Our models maintain the highest standards of accuracy.

Affordable Solutions: We provide competitive pricing while maintaining high quality.

Comprehensive Support: From consultation to post-conversion support, we ensure seamless collaboration.

Multi-Industry Expertise: We cater to architecture, engineering, manufacturing, and more.

FAQs for 2D to 3D Drawing Conversion Services

What is the benefit of converting 2D drawings to 3D models?Converting 2D to 3D drawing enhances visualization, accuracy, and efficiency, making designs easier to understand and modify.

Which industries require 2D to 3D drawing conversion services?Industries like architecture, engineering, manufacturing, automotive, and product design benefit from BEST 2D to 3D Drawing Conversion Services.

Which software is used for 2D to 3D drawing conversion?We use AutoCAD, SolidWorks, Revit, CATIA, and SketchUp for 2D to 3D drawing conversion software solutions.

How much time does it take to transform a 2D drawing into a 3D model?The time required depends on the complexity of the drawing and project specifications, but we ensure fast turnaround times.

Do you provide 2D to 3D drawing conversion services globally?Yes, ADSBIM offers BEST 2D to 3D Drawing Conversion Services in India, UK, Dubai, USA, and beyond.

Conclusion

The transition from 2D drawing to 3D is essential for better visualization, accuracy, and manufacturing efficiency. With ADSBIM’s 2D to 3D drawing conversion services, businesses can seamlessly transform their designs into high-quality 3D models. Whether for prototyping, construction, or product development, we provide precise, reliable, and cost-effective solutions tailored to your needs.

Looking for expert 2D to 3D drawing conversion services? Contact ADSBIM today and let us bring your designs to life!

#adsbim#2Dto3DConversion#2Dto3DServices#DrawingConversion#CADConversion#3DModeling#AutoCAD#SolidWorks#Revit#CATIA#SketchUp#ArchitectureDesign#EngineeringDesign#ManufacturingDesign#ProductDesign#2Dto3DModeling#DesignVisualization#ADSBIM#Gurgaon#India#UK#Dubai#USA#CADExperts#TechnicalDesign#3DRendering#EngineeringSolutions

2 notes

·

View notes

Text

Menkyo no Tetsujin was a driving game released in very limited capacity by Sega in 2005. The hardware and software were based on the SLDS-3G driving simulator Sega manufactured for Japanese driving schools, but with the addition of a Challenge Mode and IC cards to save progress.

23 notes

·

View notes

Text

Know About The Significance of CNC Machining Companies

An age of industrial accuracy like none before has arrived thanks to CNC machining. Traditional machining techniques sometimes require manual involvement, which might lead to irregularities and human mistakes. On the other hand, CNC machining uses computer-controlled instructions to accurately control tools and equipment. In addition to guaranteeing consistency in completed goods, this degree of precision also lessens the demand for frequent quality control inspections.

Unlimited Possibilities

CNC machining businesses provide a wide range of capabilities, from straightforward two-dimensional cuts to intricate multi-axis operations. This adaptability enables manufacturers to create complex geometries and forms that were previously thought to be impossible. CNC machining provides options for both sides of the spectrum, whether it's manufacturing a huge number of standardized components or developing prototypes with a specific design in mind.

Reduced Turnaround Times: The days of laborious hand setups and modifications in manufacturing are long gone. CNC machining services automate most of the manual work, streamlining the production process. Manufacturing lead times are greatly shortened as a result of this setup time reduction and the ability to conduct automated, uninterrupted operations. Now, businesses can react quickly to market needs and design modifications without compromising on quality or efficiency.

Cost-Effectiveness

The long-term advantages of CNC machining technology are without a doubt worth the initial financial outlay, which might be significant. Once set up, the devices can run independently with little assistance from humans. Reduced labor costs, fewer mistake rates, and improved resource utilization result from this. Additionally, the accuracy of CNC machining reduces material waste, which helps to reduce total costs.

CNC machining businesses are at the vanguard of innovation, according to Innovation Unleashed. They constantly push the limits of what is possible by integrating cutting-edge software, simulation tools, and additive manufacturing processes. Complex design creation and quick prototype iteration have enabled ground-breaking developments in industries including aerospace, healthcare, automotive, and electronics.

Personalization and Customization

Personalization and customization are crucial in today's consumer-driven environment. CNC machining companies that provide CNC machining meet this need by giving customers the freedom to design one-of-a-kind items or small batches that are suited to certain specifications. This degree of personalization boosts consumer satisfaction while also creating new market opportunities and specialized markets.

#CNC Machining#CNC Machining services#CNC Machining companies#Custom CNC Machining Service#Online CNC Machining Services#3 axis CNC machines

3 notes

·

View notes

Text

Belgian Air Force refuses to accept the first finished F-35 aircraft

Diego Alves By Diego Alves 08/07/2023 - 11:00am Military

The assembly of the first two F-35A for the Belgian Air Force began at the Lockheed Martin factory in Fort Worth. Under the terms of the contract for the supply of 34 units of the F-35A, the first two aircraft must be ready and transferred by the end of the year.

However, the Belgian Air Force refuses to accept the first aircraft finished with the AY-01 tail number, which has already left the final assembly line. According to the Belgian military department, the first two AY-01 and AY-02 aircraft that is being completed do not meet the technical requirements of the modification of Block 4.

F-35 production line.

It should be noted that in the purchase contract it was specified that the aircraft would be delivered in the most modern version available. Currently, the latest modification is the Block 4 version, with which the F-35A should receive a lot of news.

This modification includes a new TR-3 integrated central processor with greater processing power, a panoramic cockpit screen, an improved memory unit, a new radar, an electronic warfare system, the ability to use modern weapons and other upgrades.

According to an announcement by Lockheed Martin, these updates will make the stealth aircraft more resistant to modern ground and air threats, both in offensive and defensive missions. Work is underway to further integrate and certify the TR-3 processor, which will take longer than previously expected.

The installed processor of the previous generation TR-2 does not have the necessary power reserve for the new modification of Block 4. It is now expected that all work on the new version will be completed in the second quarter of 2024.

The Belgian Air Force will not accept F-35A fighters until its upgrade to the Block 4 version with the TR3 processor is completed and until the fighter is fully tested and certified, the Belgian Ministry of Defense said.

Are TR-2 and TR-3 processors used ?? in the F-35 fighter, but they serve different purposes. The TR-2 is responsible for handling the aircraft sensor data, while the TR-3 is responsible for running the jet's mission software. This division of labor allows for more efficient processing and better overall performance of the F-35.

The TR-2 processor is manufactured by BAE Systems and is based on the PowerPC architecture. It is responsible for the data processing of the various sensors of the F-35, including radar, electro-optical sight system and electronic warfare system. The TR-2 is designed to handle large amounts of data quickly and efficiently, allowing the F-35 to quickly identify and track targets in the air and ground.

The TR-3 processor, on the other hand, is manufactured by Lockheed Martin and is based on the ARM architecture. It is responsible for running the F-35 mission software, which includes flight controls, weapons systems and communication systems. The TR-3 is designed to be highly reliable and safe, ensuring that the F-35 can complete its missions safely and effectively.

F-35 simulator. Illustrative image.

The TR-3 processor is better than the TR-2 in the F-35 because it has a higher clock speed, which allows it to process information faster. This means that the F-35 can perform more complex tasks and respond more quickly to changes during combat.

In addition to its higher clock speed, the TR-3 processor also has more cache memory than the TR-2. This allows you to store more data in the processor, which reduces the time required to access this data. As a result, the F-35 can process information faster and more efficiently.

The TR-3 processor also has more advanced power management features than the TR-2. This means that it can operate more efficiently, using less energy and generating less heat. This is important for a high-performance aircraft like the F-35, which needs to be able to operate for long periods without overheating or running out of power.

Tags: Military AviationBelgian Air Component wings - Belgian Air ForceLockheed Martin F-35 Lightning II

Sharing

tweet

Diego Alves

Diego Alves

Related news

MILITARY

Su-57 now has an advanced communication package

07/08/2023 - 14:00

MILITARY

U.S. Air Force Reserve makes history with expeditionary air wing in Peru

07/08/2023 - 08:00

OPINION

OPINION: Is Israel excessively dependent on American fighters?

06/08/2023 - 21:20

MILITARY

Paraguayan Air Force prepares to receive its first two modernized T-35 Pillán

05/08/2023 - 13:14

MILITARY

New USAF Operations and Mission Planning Center in Darwin, Australia

04/08/2023 - 15:01

The U.S. Air Force Lockheed U-2, nicknamed Dragon Lady, conducts an aerial demonstration during the 2022 Marine Corps Air Station Miramar Air Show at MCAS Miramar, San Diego, California, Sept. 23, 2022. The U-2, a high-altitude reconnaissance aircraft with U.S. Air Force 9th Reconnaissance Wing, Beale Air Force Base, California, provides day and night, high-altitude, all-weather intelligence-gathering and reaches altitudes above 70,000 feet. The theme for the 2022 MCAS Miramar Air Show, “Marines Fight, Evolve and Win,” reflects the Marine Corps' ongoing modernization efforts to prepare for future conflicts. (U.S. Marine Corps photo by Jose S. GuerreroDeLeon)

MILITARY

USAF will retire U-2 Dragon Lady fleet in 2026

03/08/2023 - 18:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

2 notes

·

View notes

Text

Understanding CNC Machining: Essential Techniques and Tools

What is CNC Machining?

Overview of CNC Machining

Computer Numerical Control Machining (or CNC Machining) has changed the way that many of our manufacturing processes are performed. It is used for controlling machine tools using computer technology which include lathes, mills, routers, and grinders. It enables the production of complex parts and components with high precision and repeatability. CNC Machining is used in a wide range of industries such as aerospace, automotive, and electronics.

Key Components of CNC Machines

CNC Machines consist of several key components that work together to perform precise machining operations. These include:

· Controller: Acts as the brain of the CNC machine, interpreting G-code instructions to direct machine movements.

· Machine Tool: The component that performs the actual cutting or shaping operation.

· Drive System: Includes motors and actuators that move the machine tool along specified paths.

· Feedback System: Provides real-time data on position and speed to ensure accuracy.

· Computer Interface: Allows operators to input commands and monitor machine status.

How CNC Machining Works

Basic Principles of CNC Operation

CNC Machining essentially automates tool movement through the use of a computer. It begins as a digital design, using CAD (Computer-Aided Design) software. This design gets translated into toolpaths and operations in a machine language generated as G-code. The design itself is translated into a machine-readable format called G-code, which instructs machines on tool paths and operations.

Detailed Process Flow of CNC Machining

1. Design Phase: A 3D model of the part is created using CAD software.

2. Programming Phase: The CAD model is translated into G-code using CAM (Computer-Aided Manufacturing) software.

3. Setup Phase: The machine is prepared by installing appropriate tools and securing raw materials.

4. Machining Phase: The machine executes the G-code instructions to produce the part.

5. Finishing Phase: Additional processes such as deburring or polishing may be performed for refinement.

Role of Computer Software in CNC Machining

Software is an essential component of CNC Machining as it enables workshop personnel to create designs, develop toolpaths, and simulate processes. CAD (computer-aided design) software lets engineers design intricate models; CAM (computer-aided manufacturing) software generates machining instructions at a level of precision that would be impractical for a human to do manually. Simulation tools can predict problems before actual machining, so there are fewer errors and less waste. These simulation tools help identify potential problems long before the first actual acoustic wave machining of any pattern is performed, thus minimizing mistakes and material wastage.

Importance of CNC Machining in Modern Manufacturing

Efficiency and Precision in Production

NC Machining increases manufacturing productivity by automating some complicated processes that would be time-consuming if performed manually. This provides exceptional accuracy, with tolerances often in the microns range, which is critical when creating complex parts repeatedly. It guarantees accuracy with tolerances in some cases bolting down to microns, making sure complex parts are made reliably.

Impact on Manufacturing Costs and Timeframes

CNC Machining also minimizes material waste, and since it requires minimal manpower, the production costs go down significantly. It reduces manufacturing timelines from rapid prototyping to fast design changes without large-scale retooling. In addition, it reduces manufacturing timelines through fast prototyping and rapid design modifications without the need for costly retooling.

Key Takeaways Here is what you need to know about CNC Machining is an important process in most manufacturing industries. Manufacturers now have unprecedented accuracy, efficiency, and cost-effective processing power available thanks to the use of existing and developing technology. After making sure of setting up the Best strategy in the business process which is supposed to be implemented in any manufacturing process, we bring them the highest precision with the use of sophisticated technology in the production line with lower cost and greater efficiency.

Common Classifications of CNC Machines

CNC machines are categorized based on their specific functions and capabilities, each suited for different manufacturing tasks. Here's a table highlighting common classifications and their functions:

Applications of CNC Machining Techniques

CNC Turning

In CNC Turning, the workpiece is rotated whilst a single-point cutting tool cuts the material. This method is perfect for producing cylindrical components like shafts, bushings, and pulleys. With its tight tolerances and smooth finishes necessary in industries like automotive or aerospace, CNC Turning leaves no room for error. CNC milling can produce satisfactory components by guaranteeing sound performance, both in terms of dimensions and surface finish, required in automotive and aerospace applications.

CNC Drilling

CNC Drilling is the automated process of drilling holes in the material. It accommodates multiple drill sizes and angles, facilitating intricate hole configurations. Methods of this are used to make parts to require accurate hole positioning in engine blocks, circuit boards, and other features are to be found. CNC machining is essential in producing parts that contain specific holes in the assembly process (e.g. engine blocks or circuit boards)

CNC Milling

Rotary cutters are used in CNC Milling to remove material from a workpiece. This allows for the manufacture of intricate geometries with less-than-ideal tolerances, rendering it ideal for producing gears, jaws, and other molds. CNC Milling is a versatile technology where simple and complex designs can be manufactured quickly. CNC Milling has the ability to create simple and complex designs efficiently

Customization Services in Momaking with CNC Technology

Momaking Advanced CNC Techniques

CNC techniques such as multi-axis machining and high-speed milling greatly improve mold making. Such approaches enable the fabrication of high-resolution molds with complex features and high-quality surface finishes. Using these techniques means reducing timeframes and improving the quality of the molds. These methods shorten lead times and improve the quality of the mold.

Benefits of Momaking Customization Service

Momaking Customization Services with CNC technology offers several advantages:

· Precision: Ensures exact dimensions and tolerances required for specialized applications.

· Flexibility: Allows quick adjustments to designs without extensive retooling.

· Efficiency: Streamlines production processes by reducing manual intervention.

· Cost-effectiveness: Minimizes material waste through accurate machining.

To sum up, with a better insight of the key techniques and the important tools of the CNC Machining, it does not only gives better manufacturing insight, it will actually harness the advancement in innovation in many sectors. With the use of Momaking advanced technology, including 3D print and Sheet Metal Processing Services, the manufacturers can attain new levels of accuracy, efficiency and customization – allowing the best products to reach the market incredibly quickly. Using new wizardry, manufacturers can achieve a level of precision, efficiency and customization that allows them to bring better products to market faster than ever before.

0 notes

Text

🎮 Location-Based Entertainment Is Booming: $12.4B Ahead

Location-based Entertainment (LBE) Market is undergoing a remarkable transformation. Valued at $4.2 billion in 2024, the market is forecasted to reach $12.4 billion by 2034, growing at a healthy CAGR of 11.4%. LBE refers to experiences that blend physical environments with interactive digital elements, using technologies like virtual reality (VR), augmented reality (AR), and mixed reality (MR). Whether it’s stepping into a VR arena, exploring AR exhibits in a theme park, or experiencing 4D films, consumers are increasingly seeking immersive escapades that go beyond traditional entertainment.

What makes LBE stand out is its ability to bring people together in real-world spaces while delivering engaging, often unforgettable, digital experiences. The convergence of entertainment, technology, and location is creating a vibrant playground for innovation, storytelling, and social interaction.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS21180

Market Dynamics

Several factors are powering the rise of location-based entertainment. First, advancements in AR/VR technologies have significantly lowered costs while improving user experience. Devices are now lighter, more intuitive, and capable of supporting highly realistic simulations. Second, consumer preferences are shifting toward interactive and experiential entertainment, especially among younger demographics.

At the same time, the rise of social media and user-generated content has given these experiences added visibility. When someone shares a visit to an AR-enhanced theme park or a VR escape room online, it creates a ripple effect, drawing more interest and foot traffic. However, the market isn’t without challenges. High setup costs, evolving tech requirements, and complex regional regulations are barriers that businesses must navigate carefully.

Key Players Analysis

Major industry players are helping to shape the LBE market with cutting-edge concepts and large-scale investments. Companies like The Walt Disney Company, Universal Parks & Resorts, and VRstudios are leading the charge with bold initiatives that merge physical locations with digital storytelling. Up-and-coming brands such as Dreamscape Immersive, Sandbox VR, and Zero Latency are also gaining traction, offering innovative formats that bring VR and MR to life in ways never seen before.

The ecosystem includes hardware manufacturers, software developers, content creators, and service providers, all working together to craft memorable experiences. Collaboration between tech firms and entertainment providers is becoming increasingly common, pushing the boundaries of what’s possible.

Regional Analysis

Regionally, North America dominates the LBE market, driven by a tech-savvy audience and robust infrastructure. The U.S. is particularly strong, with cities like Los Angeles and Orlando serving as epicenters for themed attractions and tech-driven amusement parks.

Asia-Pacific follows closely, with rapid urbanization and rising disposable income fueling growth. Countries like China and Japan are investing heavily in immersive technologies, while a booming middle class is eager for novel entertainment formats.

Europe holds a strong position as well, thanks to cultural events and historical attractions enhanced by digital overlays. The UK and Germany are at the forefront, blending tradition with technology. Meanwhile, the Middle East and Africa are emerging markets with promising potential, especially in tourism hotspots like the UAE, where investment in luxury and innovation continues to soar.

Recent News & Developments

Recent developments in the LBE market reflect a wave of innovation. The rise of location-based gaming — spearheaded by companies like Niantic — has turned everyday environments into interactive playgrounds. 5G connectivity is enabling smoother, faster experiences for AR and VR users, while AI and machine learning are being harnessed to personalize entertainment in real-time.

Additionally, the market is leaning into sustainability. Many venues are incorporating eco-friendly materials and energy-efficient technologies to appeal to environmentally conscious consumers. Ticket pricing remains dynamic, with costs ranging from $20 to $100 depending on the experience’s complexity and duration.

Browse Full Report : https://www.globalinsightservices.com/reports/location-based-entertainment-market/

Scope of the Report

This report offers a detailed analysis of the global Location-based Entertainment Market from 2018 to 2034, with a specific focus on key drivers, restraints, regional performance, and competitive strategies. It breaks down the market by type, product, services, technology, application, form, and end user. It also provides qualitative insights into regulatory impacts, technological evolution, and consumer behavior.

Whether you’re a stakeholder looking to invest or a business planning market entry, understanding the LBE space today means tapping into one of the most dynamic and interactive segments of the entertainment industry. With the right strategy and innovation, the potential for growth is virtually limitless.

Discover Additional Market Insights from Global Insight Services:

Building Energy Simulation Software Market : https://www.globalinsightservices.com/reports/building-energy-simulation-software-market/

Dealer Management System Market : https://www.globalinsightservices.com/reports/dealer-management-system-market/

Mobile Phone Insurance Market : https://www.globalinsightservices.com/reports/mobile-phone-insurance-market/

Tour Operator Software Market : https://www.globalinsightservices.com/reports/tour-operator-software-market/

Computer Aided Engineering Market : https://www.globalinsightservices.com/reports/computer-aided-engineering-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

#quantumcomputing#3d printing#cfd#additive manufacturing#cfd simulation#hvac services#3d printing simulation software#simulation#technology#aerospace engineering#additive manufacturing software#3d sculpting#blender#ai generated#artificial intelligence

0 notes

Text

NX CAD Solutions for Manufacturing Industries

Introduction

NX CAD is a cutting-edge, integrated design and engineering software solution tailored for the manufacturing industry. Developed by Siemens, NX CAD enhances the capabilities of designers and engineers by offering advanced tools for product design, simulation, and manufacturing processes. This comprehensive solution streamlines workflows, improves collaboration, and accelerates innovation, making it a vital tool for manufacturers looking to stay competitive in today’s dynamic market.

Key Benefits

Increased Productivity: NX CAD’s intuitive interface and powerful automation tools help engineers design, model, and optimize products faster, reducing time-to-market.

Collaboration: Real-time collaboration features enable teams to work seamlessly across geographies, sharing designs and updates instantly.

Integration: Seamlessly integrates with other Siemens products like Teamcenter and Simcenter, offering a unified product lifecycle management (PLM) approach.

Innovation: The advanced simulation and visualization capabilities allow manufacturers to test and optimize designs virtually, leading to innovative, high-quality products.

Key Features

Advanced Modeling Tools: Offering parametric, direct, and freeform modeling capabilities for intricate designs.

Simulation: Built-in simulation tools to perform structural, thermal, and motion analyses.

Manufacturing Integration: Direct integration with CNC machines for manufacturing process optimization.

Design for Additive Manufacturing: Supports the creation of 3D printable models, enabling manufacturers to explore new production methods.

Applications in the Automotive Industry

NX CAD is widely used in the automotive sector for designing complex vehicle components, assemblies, and systems. It helps automotive manufacturers create innovative parts with higher precision, while also enhancing collaboration across engineering teams to ensure efficient production and quality control.

Conclusion

NX CAD provides manufacturers with a robust platform for design, simulation, and manufacturing processes. Its powerful tools and seamless integration empower industries like automotive to develop high-performance products with reduced costs and enhanced efficiency.

0 notes

Text

Why Product Demo Centers Are the Future of Experiential Marketing

In today’s dynamic business landscape, marketing is no longer just about selling — it's about showing, engaging, and building trust. Enter product demo centers—the immersive, experience-driven solution helping brands close the gap between product and consumer.

Gone are the days when buyers made decisions based on brochures, ads, or spec sheets alone. Whether you're in tech, healthcare, manufacturing, or home appliances, your customers want to experience the product in action before committing. That’s exactly what product demo centers deliver: authentic, real-time interaction that builds confidence, clears doubts, and boosts conversion.

They also allow businesses to differentiate themselves in a crowded marketplace by providing an experience that’s memorable and shareable. In a world where user experience defines brand loyalty, demo centers are becoming a critical touchpoint.

The Rise of Product Demo Centers: What’s Fueling the Demand?

The digital era has empowered customers with more information—but also more confusion. Every brand claims to be “the best,” every feature sounds impressive, and every competitor’s pitch is polished. What sets businesses apart now is not what they say, but what customers can actually experience.

Here’s why demo centers are on the rise:

Trust is earned, not promised. A physical or virtual product demo builds far more credibility than a pitch deck.

Complex products require explanation. Whether it’s a SaaS platform or an automated machine, users want to test it before buying.

Personalized experiences win. Customers are drawn to spaces where they can interact at their own pace, ask questions, and get immediate answers.

In addition, companies are finding that demo centers increase brand recall and drive stronger post-demo engagement. This makes them a powerful tool not just for sales, but also for long-term customer relationships.

Key Features of Modern Product Demo Centers

Today’s product demo centers are not just rooms with products—they are immersive ecosystems that combine environment, storytelling, and cutting-edge technology. Here’s what makes them truly impactful:

1. Interactive Display Zones

Each area of the demo center is curated to showcase specific features or use cases. For instance, a tech company might have zones for software performance, cloud integration, and cybersecurity.

Displays use touchscreen monitors, voice assistants, or gesture controls for high engagement.

Visitors can choose which features interest them, creating a self-guided, personalized journey.

These zones are often integrated with branding elements and multimedia presentations to elevate the experience.

Staff or digital assistants are usually available to provide instant support or answer questions.

2. Realistic Simulations

Whether you’re demoing industrial equipment or medical tools, realism matters. Customers want to see how the product behaves under actual conditions.

Simulations mimic working environments to test products as they would be used daily.

This reduces ambiguity and helps answer technical or operational questions early in the sales cycle.

Realistic settings also help users visualize implementation in their own business context.

It enhances credibility by proving that the product performs as promised.

3. Integrated Analytics and Feedback Tools

Modern demo centers are built to listen and learn. Every interaction generates valuable data:

What features are customers most drawn to?

Where do they spend the most time?

What questions do they ask?

This feedback loop is vital for product improvement and personalized marketing.

Analytics also help identify trends in user behavior and preferences over time.

Companies can refine their messaging and demos based on real user insights, making future interactions even more effective.

Top Benefits of Product Demo Centers for Businesses

Let’s break down how product demo centers can transform your business outcomes.

�� Stronger First Impressions

Nothing beats a real, hands-on experience. Demo centers are your chance to wow the visitor from the first moment—not just with features, but with the environment, professionalism, and attention to detail.

A well-crafted space shows that you take your product—and your customer—seriously.

First impressions are lasting impressions, especially in B2B sales.

A polished demo center speaks volumes about the quality and reliability of your brand.

✅ Faster Sales Cycles

When customers try before they buy, decision-making speeds up. Sales teams can address objections, demonstrate ROI, and highlight differentiation—all in one visit.

Instead of multiple follow-ups, businesses often close deals right after a demo experience.

Shorter sales cycles mean lower customer acquisition costs.

It also allows your sales team to focus on high-quality leads who are more likely to convert.

✅ Better Customer Education

Complex or technical products need explanation. Instead of overwhelming the customer with manuals or lengthy documents, you can walk them through key use cases in a relaxed, controlled environment.

Customers leave more informed, which leads to higher satisfaction and lower returns or cancellations.

Educated customers are also more likely to become brand advocates.

A well-informed client is less likely to experience post-sale regret, improving retention.

✅ Versatility Across Industries

From healthcare and manufacturing to fintech and retail—product demo centers are adaptable to nearly every industry.

Medical device companies can simulate operating rooms.

Kitchen brands can recreate smart home setups.

IT firms can demo full-stack software environments.

They can be scaled or customized according to company size, target audience, and budget. This flexibility makes them suitable for startups and enterprises alike.

The Role of Product Demo Centers in B2B Sales

B2B purchases are often high-stakes, high-cost, and involve multiple decision-makers. That's why product demo centers are particularly valuable in B2B scenarios.

Multiple stakeholders can attend at once, reducing delays in feedback and internal alignment.

Custom demos can be created for different industries, verticals, or enterprise sizes.

Live use cases demonstrate compatibility with the client’s existing infrastructure.

This creates trust, boosts conversion rates, and can significantly increase deal sizes. For businesses where every client counts, a demo center can be the differentiator that wins the deal.

It also reduces miscommunication and ensures all parties are aligned before purchase.

Demo centers become a hub for relationship-building and ongoing client engagement.

Virtual Product Demo Centers: The Digital Evolution

Post-pandemic, companies have embraced digital alternatives. Virtual product demo centers now offer global reach without physical limitations.

Customers can experience products remotely, often using AR/VR or web-based simulations.

Data can be tracked in real-time, with digital assistants or chatbots guiding the user.

These virtual centers complement physical ones, ensuring accessibility to all customers, regardless of location. They're also more cost-effective for scaling across geographies.

Virtual demos can be accessed 24/7, giving customers flexibility and convenience.

Businesses can update content regularly without the need for physical changes.

IH Global: Redefining the Art of Product Demonstrations

When it comes to building modern, innovative, and highly functional product demo centers, IH Global leads the charge. With a proven track record in executing high-impact experience centers globally, IH Global offers end-to-end design, production, and installation services.

What sets IH Global apart?

Customization: Every demo center is tailored to the client’s industry, goals, and user personas.

Tech-Driven Design: Smart tech integrations, immersive storytelling, and data collection tools come built-in.

Global Footprint: IH Global has delivered demo center solutions for Fortune 500s and mid-sized innovators alike, across multiple countries.

IH Global’s in-house design and production capabilities ensure consistency, quality, and faster turnaround times. Their client-first approach ensures that every space is aligned with business goals and branding strategies.

How to Plan Your Own Product Demo Center

Thinking of creating your own demo experience? Here's how to get started:

Define Your AudienceKnow who you’re building for. Are they decision-makers, end-users, or channel partners? What’s their level of product knowledge?

Understanding your audience helps create a journey that resonates with their expectations.

Tailored experiences result in higher engagement and better feedback.

Set Clear ObjectivesDo you want to shorten your sales cycle, improve customer training, or boost brand image? Your goals will shape your space.

Objectives guide both design and functionality.

Clear goals also help measure the success of your demo center.

Partner With ExpertsDon’t go it alone. Work with design firms or turnkey providers like IH Global who understand both tech and branding.

Professional partners bring in experience and best practices.

They can help avoid costly mistakes and ensure compliance with industry standards.

Create a Content StrategyYour demo center needs stories—demos, videos, use cases, testimonials. Create a script that speaks to different visitor types.

Content should be updated regularly to stay relevant.

Use visuals, narratives, and interactive tools to keep visitors engaged.

Integrate Feedback LoopsUse every visit as an opportunity to learn. Capture user input, dwell time, and interests to keep optimizing your space.

Continuous improvement ensures your center evolves with customer needs.

Feedback also helps enhance training and product development.

Final Words: The Experience Era Has Arrived

In a competitive market, showing is more powerful than telling. Product demo centers transform how brands connect with customers—making your products not just visible, but memorable. They reduce friction, speed up conversions, and help customers fall in love with what you offer.

And as buyers become more experience-driven, investing in a thoughtfully designed product demo center isn’t just smart marketing — it’s future-proofing your brand.

Whether you’re showcasing a next-gen app, a powerful machine, or a luxury lifestyle product, remember: people don’t just want to buy, they want to believe. And nothing builds belief like a product demo center designed by the best in the business—IH Global.

Demo centers are no longer optional for forward-thinking brands—they’re essential. Start building yours today, and watch your engagement and conversions grow.

0 notes

Text

There has been a lot of misunderstanding around tariffs and how they affect businesses or consumers. Even those who try to simplify and explain the issue often end up confusing it further—either by failing to clarify who actually pays the tariffs or by inserting personal perspectives instead of taking a holistic approach. The clearest explanation in the media by “ecommerce pundits” is that the importer pays the tariffs.This is true but misses an important distinction: the importer is not necessarily located in the country where the product is being imported. In the case of the US (as you’ll see below), a majority of the importers are outside of the US. In fact, only 38% of Amazon sellers are based in the US. This number is likely even lower, considering many foreign importers use a US-domiciled address—despite not technically being based in the country. The real payer of tariffs is the entity importing the goods, which could be located in any country. However, based on our interviews with major sellers, much of the tariff cost is eventually passed on to the customer.In a seller’s profit and loss spreadsheet, tariffs are included in the COGS (Cost of Goods Sold). To maintain consistent profit margins, sellers will need to raise their product prices. Nearly 100% of the sellers we interviewed stated they won’t proactively use tariffs as a reason to increase their prices. Instead, they plan to hold out with their existing inventory, hoping their competitors run out of stock and raise their prices first. One way or another—if not immediately, then gradually—the entire cost of tariffs will be passed on to the consumer. There’s no other logical or mathematical outcome. Even for my own brand, the tariffs would be unsustainable, and I would need to increase prices gradually. The only long-term solution would be to manufacture within the US, which is exactly what the government wants.That, however, is a political debate and outside the scope of this post (impossible for our brand anyway, as we rely on a Himalayan plant product). The political aim behind these tariffs seems to be to kick-start domestic manufacturing. But the aim of this blog post is not to discuss politics—it’s to highlight the effect of tariffs on recent online sales data. Why We’re Uniquely Positioned to Share This A bit of background: we’re proud to have been named an “Advanced Amazon Partner” within the Amazon ecosystem.This badge is awarded to the top 5% of software companies or agencies that manage Amazon ads and FBA (Fulfilled by Amazon) revenues. In practical terms, we process a few billion USD in GMV (Gross Merchandise Value) annually for our clients. Since we also analyze their competitors to price products competitively, we often dig even deeper to get accurate insights into sales, revenues, average prices, and profit margins. Given the scale of our AI automation software—and our no-touch onboarding process—we analyze nearly the entire Amazon ecommerce ecosystem at least once a month. I recently aggregated anonymized seller data for the latest month in the US and ran some simulations to estimate the impact on average product prices if tariffs go live.What the Data Shows One of the most interesting charts shows seller distribution by country in the US Amazon marketplace.You’ll immediately notice that China is the biggest source of Amazon sellers, accounting for slightly more than 20% more than even US-based sellers. (Charts are interactive—you can click on them.) These are the total revenues and then an additional column shows the average price of the product for a seller from that country. Some interesting facts from these data: Sellers from these countries sell the most expensive items: The most surprising entries are Ghana and South Africa. Upon investigation, I found that Ghana has only two sellers selling in the US, and their high-priced handicrafts (averaging over $150) are skewing the average. Sellers from these countries sell the cheapest items: I collected all the data in one spreadsheet, put the average price and added a calculated column with the increase in average price due to the tariffs on that country.I assumed 10% of all countries except few that have exceptionally high tariff rates.This is also with the optimistic projection that sellers in US will have only 10% import tariffs but the ground truth is that almost 80% of US sellers have their source in China which would mean they would also be hit with whatever tariff at that point of time. Adding up all the data and averaging the approximate increase in price, we can see that the minimum percentage increase in good prices is 9.9%This is a one off increase since we are not increasing the tariff prices every single month.There are few more caveats in this data which has been simplifiedThere are plenty of unknown and unregistered sellers with no country, sellers around China (eg Hong Kong, Singapore, Taiwan, Vietnam etc) all source their goods majorly from China as well Given all these uncertainties and the effect on inflation and cost of goods, we are confident this turbulent phase of market will eventually settle down. (Raw data of total sales and avg price by country) Read the full article

0 notes

Text

GCC in Automotive and Manufacturing Market – Size, Share, Scope, Analysis, Forecast, Growth, and Industry Report 2032: Digital Twin and Simulation Capabilities

The GCCs in the Automotive and Manufacturing Market Size was valued at USD 26.6 Billion in 2023 and is expected to reach USD 99.2 Billion by 2032, growing at a CAGR of 14.22 % over the forecast period 2024-2032.

The GCCs in the Automotive and Manufacturing Market are rapidly transforming into innovation hubs.They are no longer limited to cost-saving support functions but are driving digital transformation.This shift is reshaping the way global automotive and manufacturing companies operate and grow.

The GCCs in the Automotive and Manufacturing Market are evolving from traditional back-end service providers into strategic units contributing to core R&D, product engineering, and digital innovation. With the rise of Industry 4.0, electrification, and connected vehicles, global companies are leveraging these centers to drive agility, speed, and competitiveness. These hubs, often based in talent-rich regions like India and Eastern Europe, are playing a key role in redefining global operations.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/4717

Market Keyplayers:

Siemens AG (Siemens Digital Industries Software, Siemens Teamcenter)

General Electric (GE) (GE Digital Wind Farm, Predix Platform)

ABB Ltd. (ABB Ability, RobotStudio)

Bosch Group (Bosch IoT Suite, Bosch Connected Industry)

Tata Consultancy Services (TCS) (TCS DigiFleet, TCS Smart Manufacturing)

Capgemini (Capgemini Manufacturing Cloud, Smart Industry)

Cognizant (Cognizant Smart Factory, Intelligent Manufacturing)

Infosys (Infosys Manufacturing Edge, Infosys Cloud)

Wipro Limited (Wipro Holmes, Wipro Digital Operations)

Accenture (Accenture Industry X.0, Accenture Connected Asset)

Trends Driving GCC Evolution

Digital Engineering & Innovation: GCCs are becoming centers of excellence for automotive software development, especially in ADAS, EV systems, and vehicle connectivity.

Smart Manufacturing & Industry 4.0: Advanced analytics, IoT, and automation are being deployed to optimize production processes and reduce downtime.

Shift to Product Ownership: Many GCCs are transitioning from execution support to owning complete product modules and leading design-to-delivery cycles.

Talent and Skilling Initiatives: Companies are investing in upskilling talent in areas such as mechatronics, AI, data science, and embedded systems to meet evolving needs.

Enquiry of This Report: https://www.snsinsider.com/enquiry/4717

Market Segmentation:

By Functional Expertise

Digitalization and tech design

AI and ML

Product design and development

Embedded systems

Quality Control & Testing

By Service

End-to-End Support

Specialized/Niche Services

Consulting and Strategy Services

Managed Services for IT/Engineering

Shared Services

By Innovation and Emerging Technologies

Connected Vehicles & IoT

Electrification & Electric Vehicles (EVs)

Autonomous Driving

Additive Manufacturing & 3D Printing

Predictive Maintenance & AI-driven Insights

Augmented Reality (AR) & Virtual Reality (VR) for Design & Training

By Industry Application

Automotive OEMs

Heavy Machinery Manufacturing

Precision Engineering Firms

Industrial Equipment Manufacturers

Market Analysis

Global Expansion: GCCs are expanding their geographic footprint beyond traditional hubs, moving into Tier 2 cities and new regions to tap into emerging talent pools.

Cost and Efficiency Benefits: They continue to deliver significant cost optimization while ensuring faster go-to-market through 24x7 operational models.

Collaborative Ecosystems: GCCs increasingly partner with startups, academia, and innovation hubs to drive co-creation and accelerate prototyping.

Strategic Role in Transformation: They are now critical to implementing global digital strategies, such as AI-enabled design, cloud transformation, and cybersecurity.

Future Prospects

The future of GCCs in the Automotive and Manufacturing Market looks promising, as they shift from support centers to full-fledged strategic units. Companies will increasingly rely on these centers to lead innovation in autonomous mobility, battery technology, and sustainability-focused product development.

With growing demand for intelligent vehicles and personalized mobility solutions, GCCs are set to become the backbone of global R&D networks. We will also see increased adoption of agile and product-centric delivery models, enabling GCCs to respond faster to changing market demands. Additionally, the role of these centers in ESG (Environmental, Social, and Governance) initiatives—especially in optimizing energy usage and materials—will continue to grow.

Access Complete Report: https://www.snsinsider.com/reports/gccs-in-the-automotive-and-manufacturing-market-4717

Conclusion

The GCCs in the Automotive and Manufacturing Market are no longer operating in the shadows of headquarters—they are stepping into the spotlight. As global manufacturers accelerate their digital transformation journeys, these centers will continue to gain prominence as innovation and engineering powerhouses.

By embracing emerging technologies, cultivating top-tier talent, and taking ownership of strategic initiatives, GCCs are poised to shape the future of mobility and manufacturing on a global scale.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

0 notes

Text

The Evolution of CAD/CAM Software in Mechanical Engineering

Introduction to CAD/CAM Technology

Design and manufacturing has changed rapidly over the last few decades, and at the core of it all is the development of CAD/CAM software. The introduction of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) has transformed product design, evaluation, and manufacturing. Digital drafting boards have since transformed into some of the most powerful systems in nearly every facet of the manufacturing industry, driving innovation, precision, and efficiency.

Transitioning from Manual Drafting to Online Design

In the early days, where product design and engineering were in place, designs were made by hand in paper. It was a long process, made more frustrating by the frequent potential for human error which meant redrawing things over and over again. CAD's debut in the 1960s was a significant breakthrough. Early CAD software (and even CAD software today, to some small extent) was quite restricted in application and only permitted very rudimentary two-dimensional digital drawings. The improvements in computing technologies during the 1970s and 1980s, gave rise to even greater overheads for CAD capabilities, allowing engineers to use CAD for more aspects of the workflow as well as providing additional flexibility in how engineers could conceptualize and visualize their work.

CAM and Automation Rise Up

Concurrent with this development, computer-aided manufacturing systems or CAM systems for short, emerged to automate the manufacturing process by generating machine instructions for CNC machines from CAD data. It helped minimize production errors and also brought in a lot of efficiency at floor level. The integration of CAD and CAM technologies became more seamless as their development matured. Instead of being operated independently, CAD/CAM systems started to operate as integrated platforms. That made contribute updates of real-time and seamless transition from design to production. If engineers made a design change, that change would automatically update the manufacturing directives.

Transitioning to 3D Examination and Simulation

This shift from 2D drawings to 3D modeling is another level of the design process. Compare this with 3D CAD where, before anything was even manufactured, the designer could view, spin and scrutinize the complex geometries. It was this detail that helped improve the understanding of product behavior and performance, and when used with simulation tools, predicted weaknesses or failures before physical prototypes were ever built.

Contemporary Innovations in CAD/CAM Software

Over the last couple of years the world of CAD/CAM software has moved into the cloud computing and artificial intelligence age. Cloud-based collaboration is now offered by modern platforms, allowing teams from different regions of the world to work on the same project at the same time. Similar to these systems, data analytics and machine learning are used to analyze your designs, predict maintenance issues, and minimize material waste. Furthermore, the combination of CAD/CAM with 3D printing has created new opportunities for rapid prototyping and low production-volume, customized manufacturing.

Implication on Industry and Future Outlook

With the drive to sustainable development, industries are averting CAD/CAM software for optimizing materials usage and enhancing energy conservation to decrease the environmental burden. CAD CAM software will keep evolving in the upcoming years with augment reality, digital twins and smart manufacturing. We shall enter a new dimension where these systems will get more and more intuitive, interconnected, and intelligent enabling an ecosystem of machines and humans to work together for innovative, sustainable solutions.

Conclusion: CAD/CAM Is the Future of Innovation

The CAD/CAM software journey that has gone from simple design tool to becoming one of the main pillars of manufacturing in our current age has been nothing short of revolutionary. While we look forward to the digital transformation of tomorrow, CAD/CAM will continue to help ideas come to life more quickly, intelligently, and efficiently than ever before.

0 notes