#worm reduction gear

Explore tagged Tumblr posts

Text

Key Applications of Worm Gearbox in Plastic Manufacturing

The fast-expanding plastic manufacturing industry requires accuracy and operational efficiency to achieve superior production results. The worm gearbox distinguishes itself within operational efficiency enhancement components because of its tiny construction and powerful torque capabilities together with its extended lifespan. The specialized gearbox serves numerous plastic manufacturing applications through its function as an essential performance enhancer. This blog investigates the fundamental uses of worm gearboxes for plastic manufacturing procedures alongside their essential value for the industry.

1. Injection Molding Machines

The plastic manufacturing industry uses injection molding as its prevailing production method. Accurate plastic mold filling demands both high torque strength and exact control mechanisms. The application requires worm gearboxes since they deliver impressive power-handling capabilities alongside motion fluidity. The gearbox efficiently transfers the required torque which in turn improves equipment durability and achieves maximum energy efficiency.

2. Extrusion Machines

Plastic production requires extrusion as a vital procedure because it melts raw plastic into persistent shape elements including pipelines as well as sheets and films. The key operation of worm gearboxes within extrusion devices includes maintaining consistent velocity control along with torque strength transmission. These machines allow straightforward incorporation of worm gearboxes because of their compact shape which enables seamless material flow and lowers production errors.

3. Blow Molding Machines

Manufacturing of hollow plastic products like bottles and containers requires blow molding. These machines require a high level of synchronization and torque control to ensure the precise formation of products. Worm gearboxes enable efficient power transmission to control the expansion of plastic, ensuring uniform wall thickness and accurate dimensions. Their durability also ensures that these machines operate with minimal maintenance.

4. Plastic Cutting and Shaping Machines

Plastic components go through shaping and cutting processes immediately following the molding or extrusion process to fulfill particular design requirements. Their ability to handle varying speeds makes them highly suitable for plastic shaping and finishing processes, where precise material removal is crucial.

5. Conveyor Systems in Plastic Manufacturing

The manufacturing operations of plastic require conveyor systems that provide continuous movement of raw materials and intermediate products together with finished goods within manufacturing plants. Worm gearboxes serve as primary units in conveyor systems because their efficient torque transfer capability works well with fluctuating load challenges. The conveyor components experience less wear because the gentle operation together with quietness results in minimal vibration.

Plastic manufacturing operations rely on the worm gearbox as their essential element which delivers high torque with precise control alongside exceptional durability and enhanced overall efficiency when used across several applications. Production quality and reliability increase when these gearboxes power different mechanisms including injection molding and extrusion along with cutting and shaping functions and material handling. Worm gearboxes offer efficient operation together with their small footprint making them suitable selections for manufacturers who want to minimize operations expenses while maximizing efficiency.

Your quest to achieve efficient plastic manufacturing involves the purchase of premium-quality worm gearboxes. The team of experts at our company awaits your contact to discover customized gearbox solutions that best suit your unique requirements.

#reduction gearbox manufacturers#gear box manufacturing ahmedabad#gearbox repair ahmedabad#gearbox repair services ahmedabad#reduction gear manufacturers#gearbox vertical ahmedabad#double reduction gearbox ahmedabad#gearbox manufacturer#gearbox repair cost ahmedabad#buy worm reduction gearbox#gearbox manufacturer in ahmedabad#worm gear mechanism#worm reduction gear#material handling gearboxes#faulty industrial gearbox#worm reduction gearbox#decades of gearbox experience#gearbox failure#worm gearbox repairs#gearbox application in industries

0 notes

Text

FHP Geared Motor Suppliers near me

Are you searching for reliable FHP Geared Motor Suppliers near me? Univario is a trusted name in the industry, offering premium-quality fractional horsepower (FHP) geared motors tailored to meet a variety of industrial and commercial needs. With years of expertise and a commitment to delivering exceptional products, Univario ensures that you receive the best solutions for your specific requirements.

#wpo worm gearbox supplier in india#wpa worm gearbox supplier in india#worm reduction gearbox suppliers near me#speed variator gearbox supplier in india#premium worm gearbox suppliers in india#FHP geared motor suppliers near me

0 notes

Text

Worm Gearbox in Chennai | Worm Gear Motor and Reduction

Worm Gearboxes in Chennai are a highly efficient solution for transmitting torque and reducing speed in various industrial applications. Known for its compact design and ability to handle high loads, they are ideal for mining, material handling, and conveyor systems. The worm gearboxes operate smoothly with minimal noise, offering excellent performance in tight spaces where other gearboxes may not fit.

0 notes

Text

Poly V pulley Manufacturers -Muratech Engineering

Muratech Engineering is a top manufacturer of Poly V pulleys, known for their precision and reliability. Our pulleys offer superior power transmission and smooth operation for various industrial applications, ensuring enhanced efficiency and performance.

#Timing Pulley#Timing Pulley Manufacturers#Timing Pulley Manufacturers in India#Industrial pulley#Industrial pulley Manufacturers#Industrial pulley Manufacturers in India#Industrial Spur Gear#Industrial Spur Gear Manufacturers#Industrial Spur Gear in India#Industrial Sprocket#Industrial Sprocket Manufacturers#Industrial Sprocket Manufacturers in India#Helical Gearbox#Helical Gearbox Manufacturers#Helical Gearbox Manufacturers in India#Spiral Bevel Gears#Spiral Bevel Gears Manufacturer#Spiral Bevel Gears Manufacturer in India#Poly V pulley#Poly V pulley Manufacturers#Poly V pulley Manufacturers in India#Worm Reduction Gearbox#Worm Reduction Gearbox Manufacturers#Worm Reduction Gearbox Manufacturers in India#Industrial V Pulley#Industrial V Pulley Manufacturers#Industrial V Pulley Manufacturers in India#Taper Lock Bush & QD Bush#Taper Lock Bush & QD Bush Manufacturers#Taper Lock Bush & QD Bush Manufacturers in India

0 notes

Text

Understanding Heavy Duty Stirrer Units: A Guide by Popular Engineering

Heavy duty stirrer units are essential in various industrial processes where robust mixing is required. At Popular Engineering, we offer insights into the workings and applications of these powerful units. Our comprehensive guide covers everything from selection criteria to maintenance tips, ensuring you get the most out of your equipment. We highlight the benefits of using heavy duty stirrers, such as improved mixing efficiency and durability. Popular Engineering's expertise ensures you have the knowledge to choose and maintain the right stirrer unit for your needs.

#siemens motors#motor efficiency#heavy duty stirrer unit#working of fluid coupling#fluid coupling#double reduction worm gearbox#siemens motor supplier#elecon gear coupling

0 notes

Text

Icarus (1962) by A.B. Orr, in Newnes Practical Mechanics (1962). A simple light-following robot, based on the same 360 degree scanning principles as Grey Walter's tortoises.

"The vehicle comprises a scanning unit mounted on the same axis as the front steering wheel, a simple transistor amplifier, two relays and the necessary batteries. A small electric motor (Mighty Midget or similar) is used as a scanning motor and drives the scanner, and the steering wheel, through 360 deg. A second motor drives the rear wheels through a worm reduction gear. This is how the machine operates. When switched on the vehicle remains stationary and the front wheel with its scanner unit revolves slowly, looking for a light to home on. The photo-cells are fitted with a cowl that makes them directional by cutting out incidental light. A light-source, such as a powerful hand torch, is then switched on and focused on the revolving scanner. On picking up the light beam the photo-cells click the relay (A) and the scanner motor circuit is opened, causing the scanner head to fix on the light-source. At the same time relay (B) is clicked and switches on the drive motor to the rear wheels, causing the vehicle to move forward in whichever direction the scanner, and therefore the front wheel, is facing." – Icarus, Newnes Practical Mechanics, July 1962.

The first photo above shows a build of Icarus by David Buckley, that won a Gold medal at the Robot Olympics in Glasgow 1990. "Icarus is really a poorly thought out design especially as Grey Walter had already shown how it should be done. If the light is behind Icarus then Icarus moves away from the light and if off to the side then it can be that the front wheel is then at right angles to the drive direction and the front wheel skids sideways and doesn’t steer." – David Buckley.

90 notes

·

View notes

Text

WP Universal Worm Gear Reducer

The universal worm gear reducer is a reduction device that adopts worm gear transmission. It has various installation methods and structural forms, and can be widely used in various industrial fields.

The universal worm gear reducer is characterized by its simple and compact structure, wide power range, transmission ratio can reach more than 100:1, and high transmission efficiency. In addition, its speed range is wide, which can meet the requirements of different working conditions. At the same time, it has low noise, long service life and convenient maintenance.

0 notes

Text

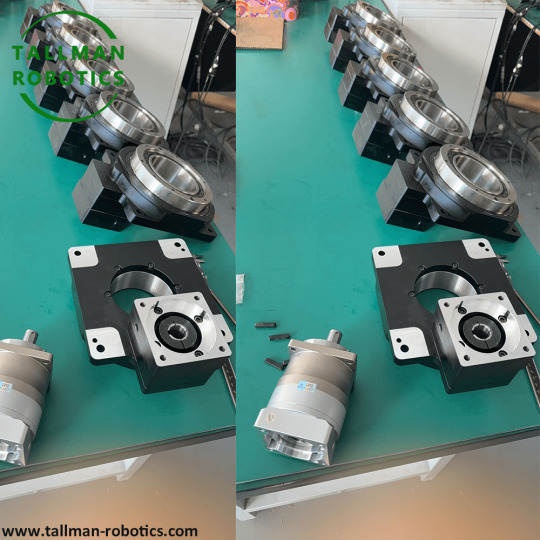

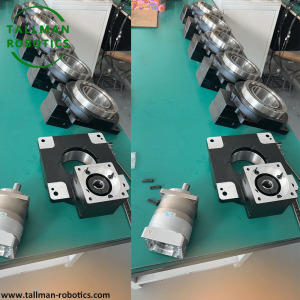

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

MRVMRV Worm Gearbox Suppliers in New Delhi

NMRV worm gearbox is a vital component in industrial automation, power transmission and motion control systems. Known for its compact design, high efficiency and durability, this gearbox is widely used in conveyors, packaging machines, manufacturing equipment and heavy machinery. If you are looking for a reliable NMRV Worm Gearbox supplier, this guide will help you find the best manufacturers and distributors in New Delhi and other areas.

What is NMRV Worm Gearbox?

An NMRV worm gearbox is a worm gear reducer designed for efficient torque transmission and speed reduction. It consists of a worm (screw-shaped shaft) and a worm wheel, which work together to reduce speed while increasing output torque. These gearboxes are widely used due to their smooth operation and long service life,

Main advantages of NMRV worm gear reducers:

✔ High efficiency: Reduces energy losses and ensures optimal power transmission. ✔ Compact and light: ideal for space applications without prejudice to performance. ✔ Low noise and vibration: offers smooth and silent operation for various types of industrial use. ✔ Durable and Corrosion Resistant: Designed to withstand harsh environments and requires minimal maintenance. ✔ Versatile Applications: Used in automation, conveyor belts, textile machinery and food processing equipment.

Best supplier of NMRV gearboxes in New Delhi

If you are looking for a reliable supplier of NMRV worms in New Deli, consider these best manufacturers and distributors.

1. Univario Transmission

📍Location: New Delhi, India.

Web: https://www.univario.in/

About Univario Transmission:

Univario Transmission is a leading manufacturer and supplier of NMRV worm gearboxes in India.

They specialize in:

* Precision-engineered worm gear reducers with advanced technology.

* Durable, corrosion-resistant materials suitable for harsh industrial environments.

* Custom gear solutions to meet your specific industrial needs.

*Complete quality tests to ensure optimal performance and lifespan.

*Technical support and after-sales services are the trusted names of power transmission

solutions. Whether you need a standard worm gear reducer or a custom design, Univario Transmission offers customized solutions for the heavy industry and automation sectors.

#NMRV gearboxes in New Delhi#Best supplier NMRV gearboxes in New Delhi

0 notes

Text

The Role of Worm Reduction Gearboxes in Material Handling Equipment

Transportation and distribution, production, excavation, and storage and distribution are fundamental to many industries. Application: in handling equipment such as conveyors, lifts, trolleys, cranes, and hoists there must be timely and effective means of handling materials. This gearbox usually reaches one of the important parts of the application in several of these machines. As a high torque and high accuracy speed control type of gearbox, this type is essential in numerous material handling operations.

In today’s blog, we will discuss the various ways that worm reduction gearboxes have benefited material handling equipment and how it impose benefits in industrial use.

Understanding Worm Reduction Gearboxes

Worm reduction gearboxes are specific units that are intended to decrease rotational speed, at the same time increasing the level of transmitted torque. Their design includes:

Worm Gear: A type of helical pin that engages with a cogwheel having a series of teeth.

worm shaft: A wheel whose teeth are in mesh with that of the worm gear.

This configuration enables a considerable reduction of the speed thus qualifying these gearboxes as compact but strongly built to meet several industrial needs.

How Worm Reduction Gearboxes Serve Material Handling Equipment

A. Enhanced Power Transmission

Worm gearboxes are ideal for machines that handle heavy loads, as they:

Slow down motors’ fast spinning and turn them into vigor and torque.

Stabilise and provide clean power, this makes it possible for equipment to work well under load.

B. Precision in Speed Control

Material handling may require certain speed control at specified or standard levels of accuracy. Worm gearboxes:

Supply accurate speed reduction for fine procedures such as handling conveyors.

Be able to produce a stable constant amount for any load conditions.

C. Compact Design for Tight Spaces

Some of the industrial applications demand compact or space-optimized working equipment. Worm gearboxes are:

Very portable in form, they can be incorporated in space-limited systems.

D. Safety Through Self-Locking

A standout feature of worm reduction gearboxes is their self-locking capability, which:

Prevents reverse motion, keeping loads stationary even without power.

Ensures safety, especially in cranes, hoists, and lifting mechanisms.

Applications in Material Handling Equipment

The versatility of worm reduction gearboxes makes them suitable for a wide array of applications, including:

Conveyor Belts: The flow is to be fluent and constant throughout the material flow system.

Cranes and Hoists: Have to offer the amperage to render the torque necessary for the safe lifting of the load.

Benefits of Worm Reduction Gearboxes

High Torque Output: Indispensable for use in hearty operations.

Quiet Operation: Slows sounds in places such as factories or warehouses.

Choosing the Right Worm Reduction Gearbox

Keep the following in mind while buying:

Load Capacity: In its simplest form make sure it has adequate torque and weight for an intended application.

Size and Placement: Note:Select the optimal organization that will correspond to the dimensions and layout of your machine.

Conclusion

Worm reduction gearboxes serve a central function in the smooth running of such equipment in the material handling industry. Due to their high torque, excellent control as well as shock resistance they are useful in applications such as conveyors, cranes and forklifts.

Call to Action

Looking for quality worm reduction gearboxes for your machines and equipment? We'd like to invite you to walk through the collections of our products to fit various requirements of the contemporary industry.

#worm gearbox repairs#decades of gearbox experience#worm reduction gear#double reduction gear box#worm reduction gearbox#reduction gearbox manufacturers#gears for gearbox manufacturer important#gearbox manufacturer in ahmedabad#worm screw gearbox factory#gear box manufacturer in ahmedabad#gearbox application in industries#worm gear manufacturer#gears for gearbox supplier important#worm reduction gearboxes#worm reduction gearbox manufacturers#worm gear gearbox factory#gearbox suppliers near me#industrial sector gearboxes#gearbox manufacturer in gujarat

0 notes

Text

Best Worm Gear Reducer Supplier in India

Looking for the Best Worm Gear Reducer Supplier in India? Visit Univario, a trusted name in the industry for high-quality worm gear reducers. With years of expertise, Univario offers durable and reliable solutions for various industrial applications. Their products are designed for optimal performance, ensuring efficiency and longevity. Choose Univario for your gear reducer needs and experience unmatched quality.

#wpx worm gearbox supplier in india#wpa worm gearbox supplier in india#speed variator gearbox supplier in india#nmrv worm gearbox suppliers in new delhi#aluminium worm gearbox suppliers in india#worm reduction gearbox suppliers near me#wpo worm gearbox supplier in india#Best worm gear reducer supplier in Indiav

0 notes

Text

Structural features and precautions of Worm Gearbox

1.What is Worm Gearbox Worm Gearbox is a transmission machine with compact structure, large transmission ratio and self-locking function under certain conditions. It is one of the most commonly used reducers. It is mainly composed of a worm wheel and a worm. The speed converter of the gear is used to reduce the number of revolutions of the motor to the required number of revolutions and obtain a larger torque.

2.Working principle of Worm Gearbox Worm Gearbox realizes the function of reducing speed and increasing torque through the meshing of the worm wheel and the worm. The worm usually has a spiral thread, and the worm wheel has a corresponding groove to match it. When the worm rotates, the worm wheel moves along the spiral line, thereby achieving the effect of reducing speed and increasing torque.

3.Structural features of Worm Gearbox 1.Large transmission ratio: The worm gearbox has a large transmission ratio, which can achieve a wide transmission ratio range in a limited space and meet the deceleration needs of various scenarios. 2.Compact structure: The structural design of the worm gearbox is compact, occupies a small space, and is easy to install and maintain. Its compact structure enables a large transmission ratio to be achieved in a limited space, meeting the needs of various complex working conditions. 3.Smooth transmission and low noise: The transmission process of the worm gearbox is extremely smooth and the noise is very low, which helps to improve the operating stability and durability of the equipment. 4.Strong load-bearing capacity: The worm gearbox can withstand significant radial and axial loads, which is very suitable for applications under heavy loads. Its load-bearing capacity is higher than that of the staggered axis helical gear mechanism, and is suitable for occasions requiring high load-bearing capacity. 5.Self-locking function: Under certain conditions, the worm gearbox has a self-locking function, that is, when the lead angle of the worm is less than the equivalent friction angle between the meshing gear teeth, the mechanism has self-locking properties and can achieve reverse self-locking, which is suitable for application scenarios that require safety protection. 6.Materials and manufacturing processes: The worm gearbox usually uses high-quality materials and exquisite design processes to ensure that the produced worm gearbox has long-term wear resistance, high transmission efficiency and long life.

4.Precautions for the use of Worm Gearbox 1.Choose the appropriate reduction ratio and power: Accurately calculate the load according to actual needs, choose the appropriate reduction ratio and power, and avoid overload or frequent start and stop to cause impact damage to the worm gearbox. 2.Temperature and environmental conditions: Ensure that the working environment temperature of the worm gearbox is within the specified range (-40℃ to +40℃). Appropriate measures such as heating the lubricating oil (below the freezing point) and adding cooling equipment should be taken to maintain normal working conditions. At the same time, avoid overheating caused by long-term continuous work. 3.Installation and commissioning: Before installing the worm gearbox, carefully check whether the various components of the reducer are intact. During installation, ensure that the axis between the reducer and the power source is well aligned to avoid vibration and noise that affect the operating efficiency and life. Before starting, a no-load test run should be carried out, and after confirmation, it should be gradually loaded to normal working conditions. 4.Lubrication and maintenance: Regular inspection and replacement of lubricating oil is one of the key steps to keep the reducer working properly. The oil volume must be kept within the specified range to avoid excessive oil leakage or lack of oil to cause increased wear. In addition, the status of wearing parts such as seals and bearings should be checked and updated and maintained in time to ensure the stability of the overall performance. 5.Smooth start and stop operations: During the start or stop process, the operation should be slow to avoid the impact caused by sudden and drastic changes, thereby damaging the structural integrity and stability of the internal components. 6.Environmental requirements: Ensure that there is a good ventilation environment near the motor fan, and avoid exposing the reducer to the sun and harsh environment to avoid affecting the heat dissipation effect.

Source:https://plaza.rakuten.co.jp/stovenstepper/diary/202501140000/

0 notes

Text

spur gear manufacturer -Muratech Engineering

Muratech Engineering is a leading manufacturer of high-quality spur gears, offering precision-engineered solutions for various industrial applications. Our gears are designed for durability and optimal performance, ensuring reliable power transmission and efficient operation.

#Timing Pulley#Timing Pulley Manufacturers#Timing Pulley Manufacturers in India#Industrial pulley#Industrial pulley Manufacturers#Industrial pulley Manufacturers in India#Industrial Spur Gear#Industrial Spur Gear Manufacturers#Industrial Spur Gear in India#Industrial Sprocket#Industrial Sprocket Manufacturers#Industrial Sprocket Manufacturers in India#Helical Gearbox#Helical Gearbox Manufacturers#Helical Gearbox Manufacturers in India#Spiral Bevel Gears#Spiral Bevel Gears Manufacturer#Spiral Bevel Gears Manufacturer in India#Poly V pulley#Poly V pulley Manufacturers#Poly V pulley Manufacturers in India#Worm Reduction Gearbox#Worm Reduction Gearbox Manufacturers#Worm Reduction Gearbox Manufacturers in India#Industrial V Pulley#Industrial V Pulley Manufacturers#Industrial V Pulley Manufacturers in India#Taper Lock Bush & QD Bush#Taper Lock Bush & QD Bush Manufacturers#Taper Lock Bush & QD Bush Manufacturers in India

0 notes

Text

Tablet Coater R&D Lab Model

Tablet Coater R&D Model (small coating pan) uses for sugar/film coating onto tablets. All contact parts are made from Stainless Steel 316L, or FDA approved materials for cGMP compliance.

PAN: The Coating Pan is Semi Ellipsoidal size pan with a circular mouth for charging & discharging of tablets, Pan mounted at an inclination of 45 degrees to the horizontal.

DRIVE ASSEMBLY: The tablet coating pan consists of a suitable 3 Phase, 440 V, 1440 RPM TEFC motor with suitable worm reduction gear box and cone pulley arrangement to give three speed output.

0 notes

Text

Understanding Speed Reducer Gearboxes: Key Functions, Types, and Applications

What is a Speed Reducer Gearbox?

A speed reducer gearbox is a mechanical device used to decrease the speed of an input shaft and increase torque in machinery. Essentially, it takes the high-speed power from an input source, such as an electric motor, and reduces its speed to provide more manageable and stable output speeds. This allows for greater control of machinery without compromising its efficiency. By altering the gear ratios, the gearbox is able to adjust the speed, which makes it adaptable to a wide range of applications, from heavy machinery to everyday devices.

How Does a Speed Reducer Gearbox Work?

At the core of a speed reducer gearbox is a set of gears that are responsible for changing the speed and torque of a motor. The basic principle revolves around transferring energy between two gear sets with differing numbers of teeth. The larger gear reduces the speed of the output shaft while the smaller gear increases the speed. As speed decreases, torque increases, which is crucial for applications requiring significant force at lower speeds.

For example, when the motor turns at a high speed, the gears within the speed reducer slow down the rotational motion while multiplying the force (torque). This process enables precise control over mechanical operations and ensures that machinery can function under heavy loads without damaging the motor or the equipment itself.

Types of Speed Reducer Gearboxes

There are several types of speed reducer gearboxes, each designed for specific industrial and mechanical needs:

Helical Gear Reducers

Helical gearboxes feature helical gears arranged at an angle, extruder gearbox which allows for more surface contact between the gear teeth. This results in smoother, quieter operation compared to straight-cut gears. Helical gear reducers are widely used in heavy-duty applications like conveyors, compressors, and turbines.

Worm Gear Reducers

Worm gearboxes consist of a worm (screw-like gear) and a worm wheel (gear with teeth). This design offers high torque reduction and is ideal for applications requiring low-speed and high-torque, such as in elevators, conveyor belts, and heavy machinery. Worm gear reducers also have the advantage of being self-locking, preventing the output shaft from moving when the motor is not running.

Planetary Gear Reducers

In a planetary gearbox, multiple gears (called planets) rotate around a central sun gear. The arrangement provides high torque output in a compact design, making planetary gear reducers suitable for precision applications, such as robotics and automated systems. They offer exceptional efficiency and durability under high load conditions.

Bevel Gear Reducers

Bevel gearboxes use bevel gears, which have teeth that are cut at an angle to the surface of the gear. These gearboxes are typically used in situations where the direction of a shaft’s rotation must be changed, such as in differential systems in vehicles.

Applications of Speed Reducer Gearboxes

Speed reducer gearboxes are used in a wide array of industries and applications due to their ability to provide efficient torque control at reduced speeds. Some of the common applications include:

Industrial Machinery: Gearboxes are essential in machines such as conveyor systems, pumps, compressors, and cranes, where precise speed control is needed for operational efficiency and safety.

Automotive Industry: Gearboxes are used in vehicles to manage engine speed and provide the necessary torque for driving. They are also found in ancillary automotive systems like steering mechanisms and windshield wipers.

Energy Sector: In wind turbines and hydroelectric plants, speed reducers help regulate the speed of rotating machinery to optimize energy generation.

Robotics and Automation: High-precision gearboxes are used in robotics to ensure accurate and smooth movements, critical in automated systems requiring exact positioning and motion control.

0 notes

Text

Worm Gear Reducer Accessories

Worm gear reducer can be divided into three basic structure: box, worm gear and worm, bearing and shaft combination. The box is the base of all the accessories in the worm gear reducer. It is an important part to support the fixed shafting parts, ensure the correct relative position of the transmission accessories and support the load on the reducer.

Hangzhou jingyoumei Equipment Co., Ltd. is a China Worm Gear Reducer Accessories Manufacturer and Worm Gear Reducer Accessories wholesaler. Our company specializing in the manufacturing of transmission equipment. The company is located in Hangzhou City and has an experienced R&D and production team.

0 notes

Text

Music Royalties Are Intellectual Property

Music royalties are considered intellectual property because they represent the financial compensation paid to creators for the use of their original musical compositions, which are protected under copyright law; essentially, when you pay a music royalty, you are paying to access and utilize a piece of intellectual property like a song or recording, allowing the artist to monetize their creative work. Key points to understand this connection: Copyright protection: When a song is written or recorded, it automatically receives copyright protection, granting the creator exclusive rights to reproduce, distribute, and perform their work. Different types of royalties: Depending on how the music is used, different types of royalties can be generated, including mechanical royalties (reproducing a song), performance royalties (playing a song publicly), and synchronization royalties (using a song in a visual media like a film). Rights holders: Songwriters, composers, and recording artists are considered "rights holders" who are entitled to receive royalties when their music is used. Example: If a radio station plays your song, they are required to pay a performance royalty to the songwriter and publisher because they are publicly performing your intellectual property.

Source: Music Royalties Are Intellectual Property

0 notes