#material handling gearboxes

Explore tagged Tumblr posts

Text

Key Applications of Worm Gearbox in Plastic Manufacturing

The fast-expanding plastic manufacturing industry requires accuracy and operational efficiency to achieve superior production results. The worm gearbox distinguishes itself within operational efficiency enhancement components because of its tiny construction and powerful torque capabilities together with its extended lifespan. The specialized gearbox serves numerous plastic manufacturing applications through its function as an essential performance enhancer. This blog investigates the fundamental uses of worm gearboxes for plastic manufacturing procedures alongside their essential value for the industry.

1. Injection Molding Machines

The plastic manufacturing industry uses injection molding as its prevailing production method. Accurate plastic mold filling demands both high torque strength and exact control mechanisms. The application requires worm gearboxes since they deliver impressive power-handling capabilities alongside motion fluidity. The gearbox efficiently transfers the required torque which in turn improves equipment durability and achieves maximum energy efficiency.

2. Extrusion Machines

Plastic production requires extrusion as a vital procedure because it melts raw plastic into persistent shape elements including pipelines as well as sheets and films. The key operation of worm gearboxes within extrusion devices includes maintaining consistent velocity control along with torque strength transmission. These machines allow straightforward incorporation of worm gearboxes because of their compact shape which enables seamless material flow and lowers production errors.

3. Blow Molding Machines

Manufacturing of hollow plastic products like bottles and containers requires blow molding. These machines require a high level of synchronization and torque control to ensure the precise formation of products. Worm gearboxes enable efficient power transmission to control the expansion of plastic, ensuring uniform wall thickness and accurate dimensions. Their durability also ensures that these machines operate with minimal maintenance.

4. Plastic Cutting and Shaping Machines

Plastic components go through shaping and cutting processes immediately following the molding or extrusion process to fulfill particular design requirements. Their ability to handle varying speeds makes them highly suitable for plastic shaping and finishing processes, where precise material removal is crucial.

5. Conveyor Systems in Plastic Manufacturing

The manufacturing operations of plastic require conveyor systems that provide continuous movement of raw materials and intermediate products together with finished goods within manufacturing plants. Worm gearboxes serve as primary units in conveyor systems because their efficient torque transfer capability works well with fluctuating load challenges. The conveyor components experience less wear because the gentle operation together with quietness results in minimal vibration.

Plastic manufacturing operations rely on the worm gearbox as their essential element which delivers high torque with precise control alongside exceptional durability and enhanced overall efficiency when used across several applications. Production quality and reliability increase when these gearboxes power different mechanisms including injection molding and extrusion along with cutting and shaping functions and material handling. Worm gearboxes offer efficient operation together with their small footprint making them suitable selections for manufacturers who want to minimize operations expenses while maximizing efficiency.

Your quest to achieve efficient plastic manufacturing involves the purchase of premium-quality worm gearboxes. The team of experts at our company awaits your contact to discover customized gearbox solutions that best suit your unique requirements.

#reduction gearbox manufacturers#gear box manufacturing ahmedabad#gearbox repair ahmedabad#gearbox repair services ahmedabad#reduction gear manufacturers#gearbox vertical ahmedabad#double reduction gearbox ahmedabad#gearbox manufacturer#gearbox repair cost ahmedabad#buy worm reduction gearbox#gearbox manufacturer in ahmedabad#worm gear mechanism#worm reduction gear#material handling gearboxes#faulty industrial gearbox#worm reduction gearbox#decades of gearbox experience#gearbox failure#worm gearbox repairs#gearbox application in industries

0 notes

Text

youtube

Yesterday I saw a few people interested in 3D printers, and then I just saw this video explaining the issues with really cheap 3D printers, and how you can upgrade them with lots of time and money to work properly. That absolutely matches my experience. My first 3D printer was a 150€ machine, not quite as crappy as the one in this video, but still full of flaws and issues and things that didn't work well. I later bought the Bambu Lab A1 mini, also recommended in this video, and it's been problem-free. I don't like recommending a single product like that, but in my experience it really does work that well. I'm sure you can get others that aren't bad as well, but when it comes to price and performance and ease of use, it genuinely seems to be the best option right now.

So a quick buyer's guide if you're interested in that particular model.

First up, watch out for sales. The official price is like 320€ for an A1 mini, but in practice there are usually sales that drop the price to 199€. Don't pay more than that.

Second, they sell multiple printers, but for beginners the interesting ones are the A1 and A1 mini. The A1 is bigger and can print bigger parts, for around 150€ more; apart from that they're basically identical. I got the smaller one and am perfectly happy with it. Instead you can put that money into…

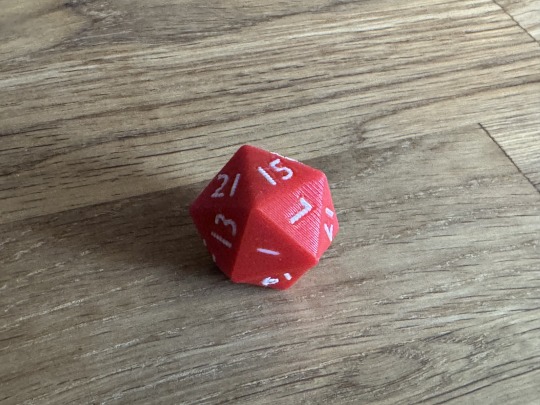

The AMS (Automated Material System), a thing you put next to the printer that can feed it material in different colours. It's included in several bundles, on the Bambu Lab website you specifically need to deselect it to not get it. This is the printer's main party trick, because it can print multiple colours (up to four) at once. This feature isn't actually that great, because on every layer it dumps a bit of the old material and then sucks in new ones, so multicolour prints take forever and produce a lot of scrap material. But you can do them at all, which is great. It's how I printed this D20 for my sister. Can you spot the special feature that she hasn't yet?

And it's useful to swap materials between different prints quickly. E.g. you want to print a gearbox and it takes several tries, but you can change the colours between each iteration so you don't get confused which is the new and old part. I've bought the AMS, I'm happy with it, but if money were tight this would be the first thing I'd get rid of. Note that for the A1 printers, you need the AMS lite, that's the one included in the bundles.

Print material (filament). Bambu Lab sells some, it's good. Lots of other companies sell some and those are also good, there's basically no advantage here, but Bambu Lab sells it for relatively cheaply if you order it with the printer. If you don't know material what you want or need (yet), you'll want PLA in different colours. Note that silk PLA needs to be treated differently (your printer and its software know about that, but you need to tell them you're using silk PLA). PLA-CF or glow-in-the-dark PLA also have special properties that require special handling.

Other additions: A smooth build plate is a nice thing to have for either very small things or things that need to be smooth. Different hot-ends can be useful; you need the hardened ones for PLA-CF or glow-in-the-dark PLA and some other materials; ones with a higher diameter print faster, ones with a lower diameter print more precisely. Glue: I've never used that for anything. These aren't things you need right away, but you do get a bit of a discount if you do order them with the printer.

Obviously I do need to tell you that this is literally a machine for producing plastic trash, there's no way around that. And while you can use the printer offline (or so I heard, I haven't tried it), it's mostly designed to be used with the Chinese manufacturer's cloud service, which does not make me super-happy. Also, the resolution for really tiny stuff is limited; if you want to build e.g. model trains, then you should really get a resin printer, but everything I heard about the chemicals and post-processing and so on there scares me, so I haven't yet. But if you are interested in 3D printing and want to get one for yourself, this is, as of right now, the thing I'd recommend.

15 notes

·

View notes

Text

vro0m's rewatch - 171/332

2016 Russian GP

Okay. Round 4. Let's see if Lewis can turn the tide. Aha and this time I have access to the pre quali build up as well. Ferrari is facing reliability issues. Seb will have a grid penalty for a gearbox change and now they're struggling with Raikkonen's car as well.

Another big story of the weekend is Daniel trying a halo type thing prototype on his car. It's a cockpit basically. It's not entirely covered, like you can get in the car from above like with the halo, but instead of the y-shape of the current halo, the half circle is covered in some kind of windshield. It seems dangerous to put any type of material on that that could shatter and cut the driver. Paul di Resta has some stupid opinion on it like most commentators do at this point, saying things like "most drivers think we should keep it open and be able to see the helmet, that identity" which is. Fucking ridiculous. Apparently though, RBR is pushing for it mostly because they think if they start developing it now it might give them a headstart as far as aero goes compared to Merc which is. On brand. Brundle is saying "shouldn't F1 be risky?" which is insane. He thinks we start with the halo and we end with "driverless cars" to take all the risk away. I'm banging my head on the walls from the stupidity, that's more than I can handle for real. Horner is defending the thing. He says from a purist POV he agrees, but the FIA is pursuing it and their concept is a more "elegant" solution than a "flip-flop style halo" that was tested earlier in the year. I have no idea what he's referring to there. He also says of course a purist wants to keep it open but there's been too many incidents over the years where something like this could have saved someone's life to ignore it.

Massa organised a race in tiny kart cars between Daniel and his own son around his terrace I believe? It's funny af.

Unfortunately, during quali, Lewis has the same engine failure that he got in China and can't take part in Q3, leaving him 10th on the grid. Of course, Nico is on pole.

Lewis is unsurprisingly unhappy about it. He's over being interviewed. In his usual attitude he's looking around, giving short answers, ready to go. He's gonna need a new PU and that means another penalty as well. The journalist says the season is really testing him in terms of making him work hard. "Definitely," he answers with a curt smile.

She asks how he copes with it because he seems to be taking it very well, very chill. (I completely disagree with that.) He takes off his glasses, lightly wipes his eye, makes a hand gesture as he's shifting weight on his feet, shakes his head and smirks. "There's nothing I can do," he says.

He's so frustrated. She says he's still in the fight for the championship and he's not gonna give up. "I never give up, so…" he says, defiantly. That's all.

I don't understand why but in the end he didn't get a penalty for the PU. He does start 10th. Johnny asks him how he feels going into this race starting from 10th after a couple frustrating races. "Pretty chill."

Johnny wheezes. "Is that it?" Lewis smiles, mischievous. "You must be pretty hungry for it though," Johnny goes on, "because you know, you know how important it's gonna be to get a good result, the car is very very good around this track, so you've got an opportunity, do you think, down turn 2?" Lewis says there's a lot of opportunities ahead, he's chill, what will be will be, he'll give it everything he's got. Johnny asks how is his motivation, as good as ever? "Absolutely. I've never ever in my whole life ever struggled with motivation, so that's never even in question."

Toto is interviewed and Crofty reports that many fans on twitter are spinning conspiracy theories about sabotage and Mercedes going against their own champion and shit like that. Is that how all the bs surrounding brocedes began? With stupid fan theories? Toto says he's not gonna answer to every lunatic that tweets and some of them are abusing the team. He denies all allegations and says they feel awful about him not being able to perform as well as he can.

Niki is also against the halo which is preposterous.

Anyway. It's time for the race. Here's how they line up then : Nico, Valtteri, Raikkonen, Massa, Ricciardo, Perez, Seb, Kvyat, Verstappen and Lewis.

Formation lap.

And they're racing!

Just as I was about to say it's a clean start, it's not. Reaaally not. And just as they come out of the first round of contact, a Ferrari spins. I'll wait until we know more to tell you precisely what it's about. But Seb has crashed for sure. VSC. Lewis is up 5 places though! Hulkenberg is also out. Safety car. Perez is limping to the pits on three tyres and apparently Ricciardo has pitted as well. And Kvyat. And Ericsson. Those are looong stops. Gutierrez is in as well. That's a lot of damaged cars! Seb is driving the moped back to the pits himself lol.

Okay so. Someone's RedBull hit Seb from the back. It's Kvyat lol. Maybe these two are still salty about China? It sends Ricciardo, who was wheel to wheel with Seb, wide. Meanwhile in the back, someone also collided with someone's back, who was sent spinning, collected the same person as he went AND another car that made contact with a final car by trying to avoid getting hit. Seb was still able to keep going at that point, but someone hit him again shortly after and that's why he crashed. He is PISSED. Who's the second one then? Safety car coming in. And we go again.

So it's now Nico, Raikkonen, Valtteri, Massa, Lewis, Verstappen, Alonso, Grosjean, Magnussen and Palmer. But Valtteri attacks! He's ahead, and right behind, right at the same time, Lewis overtakes Massa. Verstappen attacks Massa as well but he's not letting it happen twice. Now it's Alonso attacking Verstappen. But that's also not happening either. Kvyat and Ericsson are battling for P15 and Kvyat, who's definitely not my cup of tea, maintains his track position by going off track which is arguable. Especially after already taking out one driver. Lewis is closing on Raikkonen who's closing on Valtteri. Valtteri defends. It's Lewis' turn. He's ahead but well. Raikkonen had to avoid contact there. "Get in there Lewis, come on man!" Bono rejoices on radio. On a on-board replay we see it's Kvyat who ran into Seb BOTH TIMES. So maybe Seb was right about what he told him in China lol. Anyway Lewis is breathing down Valtteri's neck now. Kvyat pits. Ted thinks he's about to retire. Indeed the mechanics are not touching oh no. It was to serve a 10 seconds stop go penalty. He's out again. Gutierrez also gets a drive through penalty for the collision on lap 1.

And it's lap 10. Nico, Valtteri (+5.8), Lewis (+0.4), then Raikkonen, Massa, Verstappen, Alonso, Grosjean, Magnussen, Palmer. Oh and Rio Haryanto is also out of the race. No idea when it happened. Lewis is falling back a bit. Too much dirty air I think. It puts him way closer to Raikkonen now. Like DRS range close. One lap later Lewis is closing on Valtteri again. He sets his best lap of the race, chasing. And Valtteri pits. He's back out in P7. In a real BDE move, Seb went straight to RBR's pit wall to talk to Horner about Kvyat.

And Lewis pits. It's a longer stop than the Williams'. THEY ARE WHEEL TO WHEEL! LEWIS IN THE PIT EXIT AND VALTTERI DOWN THE STRAIGHT! Valtteri stays ahead! Good job, Williams ! But Lewis is still very very close, it's down to the pit stop, really. Come on, come on… Massa pits. Lewis gets on the inside and overtakes Valtteri! He's already on Alonso, who was close ahead. And he made it very easy. And Lewis sets another fastest lap.

That's lap 20. Nico, Raikkonen, Verstappen, Lewis, Valtteri overtakes Alonso ! Massa, Jenson, Perez, and I don't know who's P10 because Raikkonen pits so the graphics disappear. Lewis is clearly ahead, but Valtteri is behind Raikkonen! So that's Lewis back in P3. Nico pits. His stop is shorter. Of course he's still in the lead, 13 seconds ahead of Lewis, who will be P2 as soon as Max pits. And he does. All that's left to do for Lewis is chase Nico. Sainz gets a 10 second time penalty for forcing Palmer off track.

On lap 30 there's racing in the midfield. Lewis is still 12.2 second away from Nico and that gap is not closing much. Raikkonen is P3, Valtteri P4, Massa P5, Verstappen P6, Alonso P7 and then there's a 4 way fight for P8 between Magnussen, Grosjean, Ricciardo and Sainz. Nasr gets a 5 second time penalty for "not respecting race directors instructions regarding turn 2". But then Nico hits traffic and Lewis gains on him like crazy. On lap 34 the gap is down to 8.4. And Verstappen slows down, parks his car on the side. He reported issues on his way to the grid earlier on. "Something with the engine," he says. DRS is disabled, yellow flag. 7.5. "You there, Bono?" Lewis asks. "Affirm Lewis, we’ve got a bit on at the moment mate." And then we immediately hear another message although I doubt they happened simultaneously : "So Lewis it looks like we’ve got a water pressure issue, water pressure issue." That's yet another mechanical issue for Lewis then. He loses speed.

On lap 40, the gap is back up to 11.4. We're in for a boring ending I'm afraid. "Lewis the situation has stabilised," Bono says. So maybe not so boring? Can I hope? But the gap is still expanding, actually. We're almost done and it's 15 seconds. So yeah. Boring in the end.

And it's the end of the race.

So Nico, 25 seconds ahead of Lewis, Raikkonen.

While Nico finishes crowd surfing his team, Raikkonen is casually chatting with dictator Putin in the cool down room. It's insanely cringe each season. Lewis gets there and shakes his hand while still wearing his helmet. Btw Putin is surprisingly short now that I think about it. Nico takes ages before he salutes him as well. Never do you see such a silent cool down room. Everybody is visibly tense and uncomfortable. Lewis stays away, back to the small crowd in the room.

They nicely wait for all the officials to get away before they start with the champagne and Lewis immediately hands his bottle to the Merc representative rather than spray it himself and stand slightly to the side while he drowns Nico in it. He's smiling though, he's not doing it out of spite. When he gets the bottle back he pours some down on the man as well, then cheers with Nico and they both drink, synchronised.

Lewis says it wasn't the easiest first corner. He's happy for the team and he got the points so he's satisfied. He says it was quite easy to overtake Valtteri who didn't seem to be defending. He has no doubt he could have won but then he had a problem with the engine "again". He's calm, not cheerful but not annoyed.

In the end, Brundle asks Nico about the 42 points lead he has. Nico says it's only been 4 races, "Lewis is gonna come back of course you know, I mean he's on it and as motivated as ever so… Early days."

Horner says he could only apologise to Seb as it was Kvyat's fault, btw.

In the post race, Lewis seems satisfied. He thanks the guys who flew over the previous night to fix his car and his engineers who stayed up late. About the water pressure issue, he says he's just happy he was able to finish the race. He says it wasn't due to pushing too hard, it's just another failure. "We just need to do a better job," he says, given they have few engines to go around for the year. The journalist says they get a lot of tweets from his fans saying it seems like the team has decided it was Nico's turn to win the title and a lot of conspiracy theories. His face is uncharacteristically controlled, I can't tell what he's thinking about this, he's usually so easy to read… He says what he can say is his side of the garage, his mechanics, are definitely having a hard time. He hums. Pause.

He has complete confidence and faith in them. It's an unusual situation for them (the mechanics), the majority of them were on Nico's car the previous year, and Nico's current guys were with him since he's come to the team, he smiles. "And all of a sudden," he shrugs, "you know, we've swapped."

He shakes his head. "For no apparent reason, but… that is not the reason why we're having these issues they're somewhere else, I don't know where these little issues are coming from but for sure, the team, the guys in the background, they need to work hard to try and rectify these." He says in testing they did 800 km a day and the car was thought to be bulletproof. "And all of a sudden… Hah!", he chuckles shortly," We're having all these problems so… No I would say that… Don't jump the gun." He smiles, very very calmly, confidently. "I don't believe that that's happened, it's not happened in the last three years and I don't have any reason to believe that would happen now."

Huh. That's very very interesting. First of all I didn't know about the mechanics thing. So I went to read to see what that's about. Nico says it was because the two sides of the garage were at war and Toto decided to swap them to stop the feud. Something that was also stated by Mercedes. Lewis said later in the season he would tell his true feelings about it only 10 years later. Anyway it seems it will come up again during the year so we'll see. Lewis said it threw him off basically. Which is not surprising just generally speaking but also specifically when it comes to him. I mean we've talked at length about his trust issues lol. It must have shaken him.

Second of all, he's very very calm and confident about his answers. I feel no hint of the paranoia he sometimes shows when he gets under pressure at that point. I would have expected him to start ruminating already but it's not the case. Either he's learnt to lie better or he's sincerely not worried about it. I would go for the second option because I don't believe for one second he's capable of hiding how he feels to this day lol. It's good to see, because you can tell he's evolving. I'm doubting that it will last in the long run though.

Brundle says right after the interview he felt on the podium he was in the waiting room for the dentist and none of them seemed as happy as they should've been. He says Lewis has a thousand yard stare. He indeed seemed weirdly controlled. Johnny mentions that during the drivers parade he also was only able to get 3-word answers out of him and you wished he'd be slightly more outgoing. Then Brundle points out he was again sitting alone at the front. I feel like they're mixing things up. Lewis never likes to talk to them or anyone before the races, but that might also just be a matter of focus. It's very distracting having to do all of that right before you have to put such a performance in. Most other athletes don't have to do that. But yes, even through the thick composure you can tell Lewis is unhappy about the mechanics situation, and the engine failures of course. In his post race interview, the moment he talks about the swap is the only moment the composure slightly breaks. He's gracious towards the mechanics because he knows they don't wanna be working with him either, but he also says "we need to do a better job" and then "they need to work hard and rectify [the issues]" which tells me he thinks globally the team isn't doing its best at the moment.

Oh I paused to write all that and actually Johnny does say to Brundle he doesn't mind Lewis separating himself from the grid because that's him getting himself in his bubble and focusing on the job at hand.

Nico is happy but he also points out Lewis had issues. He's asked if he can take that confidence into a straight fight with Lewis, which they haven't had yet this year. He says that's what he's here for. That's the best racing "because he's the benchmark in the end," he smiles. He looks forward to it happening again. It's always gonna be a hard battle against him. He's still as motivated and quick as ever. She asks if he misses it, if he gets the same sense of achievement without it. He says he can't say he really missed it because it's awesome to win, he wants to win and it doesn't matter how. "But of course the ecstatic feeling isn't there, it's there when I win a battle against Lewis, you know? That's what really gets the ultimate thrill." Omg you guys are so gay.

9 notes

·

View notes

Text

Leading SMSR Gear Box manufacturers in India - Shaft Mounted Speed Reducer Manufacturers In Ahmedabad - Nisuka Industries

Nisuka is a renowned name in the industry as one of the top SMSR gear box manufacturers in Ahmedabad, India and trusted Shaft Mounted Speed Reducer manufacturers. We specialize in providing high-quality, durable, and efficient gearboxes designed to meet the demands of various industrial applications. Our products are known for their superior performance, robust construction, and long service life, making them an ideal choice for industries like mining, quarrying, and material handling. At Nisuka, we are committed to delivering innovative solutions that enhance productivity while ensuring reliability and cost-effectiveness for our clients.

#SMSR Gear Box#Manufacturing#SMSR Gear Box manufacturer#Shaft Mounted Gearbox Manufacturer#Conveyor Gearbox Manufacturer

2 notes

·

View notes

Text

Unleashing the Power of Cylindrical Roller Bearings: Design, Applications, Material, and Variations

Cylindrical roller bearings are a type of rolling element bearing that are widely used in various industrial applications due to their high load-carrying capacity, durability, and versatility. In this article, we will delve into the world of cylindrical roller bearings, exploring their design, applications, material, and variations, to understand their importance in modern machinery and equipment.

Design:

Cylindrical roller bearings are designed with cylindrical rollers that are guided by the inner and outer ring raceways. They are available in different designs, including single-row, double-row, and multi-row configurations, and can accommodate radial loads, axial loads, or a combination of both. Cylindrical roller bearings can have various cage designs, such as solid cages, pressed steel cages, or machined brass cages, depending on the application requirements.

Applications:

Cylindrical roller bearings find extensive use in a wide range of applications across industries. They are commonly used in heavy machinery and equipment, such as gearboxes, motors, pumps, rolling mills, and crushers, where they are subjected to high loads and speeds. Cylindrical roller bearings are also utilized in automotive applications, railway systems, aerospace, construction machinery, and many other demanding environments. Their ability to handle high radial loads, combined with their excellent reliability and durability, make them a preferred choice for critical applications.

Material:

Cylindrical roller bearings are typically made from high-quality bearing steels, such as chrome steel (SAE 52100) or stainless steel, which offer excellent strength, wear resistance, and corrosion resistance. These materials are carefully selected to ensure optimal performance and longevity of the bearing in the intended application. Advanced heat treatment processes, such as quenching and tempering, are often employed to enhance the material properties and improve the bearing's performance under extreme operating conditions.

Variations:

Cylindrical roller bearings come in various variations to suit different application requirements. One common variation is the full complement cylindrical roller bearing, which has no cage and contains the maximum number of rollers possible, providing higher load-carrying capacity at the expense of slightly reduced speed capability. Another variation is the high-capacity cylindrical roller bearing, which features larger rollers and a modified internal design to increase the load-carrying capacity compared to standard cylindrical roller bearings. Additionally, there are specialized cylindrical roller bearings, such as thrust cylindrical roller bearings, double-row cylindrical roller bearings, and multi-row cylindrical roller bearings, each designed for specific application demands.

In conclusion, cylindrical roller bearings are essential components in modern machinery and equipment, offering high load-carrying capacity, durability, and versatility. Understanding their design, applications, material, and variations is crucial in selecting the right cylindrical roller bearings for specific industrial needs. Proper selection, installation, and maintenance of cylindrical roller bearings can contribute to improved equipment performance, reduced downtime, and increased productivity. When it comes to power transmission and motion control, cylindrical roller bearings are a vital element that enables smooth and efficient operation in various industries.

2 notes

·

View notes

Text

SMSR Gearbox Manufacturer in Rajkot – Premium Quality by Mahalaxmi Pulley

Mahalaxmi Pulley is a leading SMSR (Shaft Mounted Speed Reducer) Gearbox Manufacturer in Rajkot, specializing in high-performance gear solutions for industrial applications. Our SMSR Gearboxes are designed to provide efficient power transmission, high torque output, and long-lasting durability, making them ideal for conveyor systems, mining, material handling, and heavy-duty industries.

Manufactured using top-grade alloy steel and cast iron, our gearboxes offer exceptional strength, wear resistance, and smooth operation. The shaft-mounted design eliminates the need for additional foundations or couplings, ensuring easy installation and maintenance while reducing overall system costs.

Our SMSR Gearboxes come in various ratios, sizes, and torque capacities, allowing businesses to choose the perfect fit for their machinery. With precision-engineered helical gears and advanced lubrication systems, our products deliver high efficiency, minimal power loss, and extended operational life.

At Mahalaxmi Pulley, we prioritize quality, innovation, and customer satisfaction. Each gearbox undergoes strict quality testing to ensure it meets industrial performance standards. Our commitment to on-time delivery, competitive pricing, and excellent after-sales support makes us a trusted choice for SMSR gearboxes in Rajkot.

For reliable, durable, and high-efficiency SMSR Gearboxes in Rajkot, contact Mahalaxmi Pulley today and get the best solutions for your business!

0 notes

Text

What You Must Know About Stainless Steel Ball Bearings

Ball bearings are vital components in several mechanical systems and devices as they permit seamless and efficient rotation of moving elements. Stainless steel is a fantastic alternative for ball bearings since it can withstand rust and corrosion. As a result, it is especially useful in situations involving strong chemicals or dampness.

This article will look at the mechanical qualities of stainless steel ball bearings and the benefits that come with them. We will also cover the various types of bearings and their uses.

Types and Applications for Stainless Steel Bearings

Stainless steel ball bearings come in a variety of kinds and designs to meet varied application needs. Here are five of the most popular types:

Grooved Ball Bearings

Deep groove ball bearings are ideal for applications that demand a dependable and versatile bearing solution. Their basic design has a single row of balls running in deep grooves carved into the inner and outer raceways. Furthermore, their high load capacity and wide range of sizes make them perfect for machinery and equipment including electric motors, pumps, and compressors.

Angular Contact Ball Bearings

Angular contact ball bearings can withstand radial and axial stresses. They have two rows of balls positioned at an angle to each other, allowing them to handle both sorts of loads concurrently. Furthermore, they can tolerate slight misalignment between the shaft and housing. This makes them appropriate for applications where exact alignment is impossible, such as tool spindles and pumps.

Thrust Ball Bearings

Thrust ball bearings are designed primarily to sustain axial stresses. They consist of two washers and a pair of balls positioned between the washers. The Stainless Steel Balls move over a grooved track in the washers, allowing the bearings to withstand the weight. These bearings are widely utilized in automobile gearboxes and heavy machines. They are also suitable for situations with limited space due to their small form.

Self-Aligning Ball Bearing

Self-aligning ball bearings are intended to withstand misalignment between the shaft and housing. They consist of three parts: an inner ring, an outer ring, and a collection of balls. The outer ring is spherical, so it can adjust to the inner circle and let the bearing handle any misalignment. Misalignment is common in conveyor systems and printing presses, therefore these bearings come in handy.

Stainless Steel Pillow Block Bearings

Stainless steel pillow block bearings from Stainless Steel Ball Manufacturer consist of housing and a bearing insert. They are commonly used in applications that need support and installation, such as material handling equipment and conveyor systems. Their housing is typically fastened to a surface with bolts or screws, and the bearing insert is placed inside.

Follow our Facebook and Twitter for more information about our product.

#Stainless Steel Balls#Stainless Steel Ball Manufacturer#Stainless Steel Ball Supplier#Stainless Steel Ball China#Stainless Steel Ball

1 note

·

View note

Text

Ball Bearings – Essential Components for Smooth and Efficient Machinery

Introduction

Ball bearings are small but powerful components that play a crucial role in ensuring the smooth operation of various machines. They are designed to reduce friction between moving parts, allowing machines to run efficiently and last longer. From automobiles and industrial equipment to household appliances and medical devices, ball bearings are used in almost every industry.

At Jai Krishna Bearing House, we supply high-quality ball bearings that meet industry standards, ensuring durability and reliability for all applications.

What Are Ball Bearings

Ball bearings are rolling elements placed between two moving parts to minimize friction and enable smooth rotation. They consist of:

Inner Ring – Mounted on the rotating shaft

Outer Ring – Fixed in place

Steel Balls – Reduce friction between the rings

Cage – Holds the balls in place and ensures even load distribution

These components work together to support radial and axial loads, hiwin bearings manufacturers in India an essential part of modern machinery.

Types of Ball Bearings

Different types of ball bearings are designed for specific applications. The most commonly used ones include:

Deep Groove Ball Bearings

Most widely used type

Suitable for high-speed and low-friction applications

Used in electric motors, pumps, and automotive components

Angular Contact Ball Bearings

Designed to handle both radial and axial loads

Used in gearboxes, turbines, and industrial machinery

Self-Aligning Ball Bearings

Adjusts to misalignment and shaft deflection

Commonly found in conveyor belts and textile machinery

Thrust Ball Bearings

Supports axial loads in one direction

Used in automotive steering systems and cranes

Spherical Ball Bearings

Designed for heavy loads and rough environments

Used in mining equipment and marine applications

Applications of Ball Bearings

Ball bearings are used in various industries due to their ability to improve efficiency and reduce maintenance costs. Some key applications include:

Automobiles – Found in wheels, gearboxes, engines, and steering systems to ensure smooth operation.

Industrial Machinery – Used in conveyors, electric motors, and pumps to enhance efficiency and longevity.

Aerospace Industry – Essential in aircraft engines, landing gear, and navigation systems for precision and durability.

Medical Equipment – Found in MRI scanners, dental tools, and surgical instruments for smooth and quiet operation.

Home Appliances – Used in washing machines, ceiling fans, and refrigerators for noise reduction and energy efficiency.

Benefits of Using High-Quality Ball Bearings

Choosing high-quality hiwin bearings suppliers several advantages:

Reduced Friction – Ensures smooth and efficient operation

Long Lifespan – Made from durable materials to withstand wear and tear

Low Maintenance – Minimizes the need for frequent replacements

Energy Efficiency – Helps reduce power consumption in machines

High Load Capacity – Handles both radial and axial loads effectively

Why Choose Jai Krishna Bearing House for Ball Bearings

At Jai Krishna Bearing House, we are committed to providing the best bearing manufacturer in India at competitive prices. Here’s why businesses trust us:

100 percent Genuine Bearings – Sourced from top manufacturers

Wide Range of Bearings – Available for various industrial and commercial applications

Expert Guidance – Helping customers select the right bearing for their needs

Quick Delivery – Fast and reliable supply across India and international markets

Competitive Pricing – High-quality products at the best prices

Conclusion

Ball bearings are essential components in modern machinery, ensuring smooth motion, reduced friction, and long-term efficiency. Whether you need bearings for automobiles, industrial machinery, home appliances, or aerospace applications, choosing the right ball bearings can make a significant difference in performance and durability.

Contact Jai Krishna Bearing House, we offer high-quality ball bearings backed by expert support and fast delivery. Contact us today to find the perfect ball bearings for your needs.

#ball bearing#industrial hiwin bearings manufacturers#hiwin linear bearings#hiwin ball screws#ball bearing manufactures in delhi#wheel bearing#roller bearings

0 notes

Text

Why Planetary Gearboxes Are Essential in Conveyor System Design

Conveyor systems are integral to modern industries, facilitating the efficient movement of materials across various sectors, including manufacturing, mining, and logistics. The performance and reliability of these systems heavily depend on the components that drive their operation. Among these components, planetary gearboxes play a pivotal role in ensuring optimal functionality.

Understanding Planetary Gearboxes

A planetary gearbox, also known as an epicyclic gearbox, consists of three main components: the sun gear, planet gears, and the ring gear. This configuration allows for high torque transmission in a compact design, making it ideal for applications where space and efficiency are critical.

Advantages of Planetary Gearboxes in Conveyor Systems

High Torque Density: Planetary gearboxes can transmit substantial torque relative to their size, making them suitable for heavy-duty conveyor applications.

Compact Design: Their efficient design allows for space-saving installations, which is beneficial in environments with limited space.

Durability and Reliability: The load-sharing nature of planetary gears distributes stress evenly, leading to longer service life and reduced maintenance needs.

High Efficiency: These gearboxes offer minimal energy loss, contributing to the overall energy efficiency of the conveyor system.

Versatility: Planetary gearboxes can be customized to meet specific requirements, such as varying speed ratios and torque capacities, providing flexibility in conveyor system design.

Applications in Conveyor Systems

Planetary gearboxes are utilized in various conveyor system components, including:

Drive Motors: They are often integrated with drive motors to provide the necessary torque and speed for conveyor belts.

Roller Drives: Planetary gearboxes are used in roller drives to ensure smooth and consistent movement of materials.

Inclined Conveyors: In conveyors that operate on inclines, planetary gearboxes help maintain the required torque to move materials uphill.

Selecting the Right Planetary Gearbox

Choosing the appropriate planetary gearbox is crucial for the optimal performance of a conveyor system. Considerations include:

Torque Requirements: Assess the maximum torque needed to handle the heaviest load.

Speed Ratio: Determine the desired speed of the conveyor belt and select a gearbox that can achieve this speed efficiently.

Environmental Conditions: Consider factors such as temperature, humidity, and exposure to chemicals, which may affect the gearbox's performance and longevity.

Maintenance Needs: Opt for gearboxes that offer easy maintenance and have a reputation for reliability to minimize downtime.

Conclusion

Incorporating planetary gearboxes into conveyor system design is essential for achieving high performance, reliability, and efficiency. Their unique advantages make them indispensable in various industrial applications, ensuring that materials are transported smoothly and effectively.

0 notes

Text

As a proud ambassador for GPM Racing, I'm thrilled to introduce you to our top-tier selection of differential gears and gearboxes for the LOSI MICRO B. Our commitment to quality and performance shines through in every product we offer, ensuring that your LOSI MICRO B operates at its peak potential. 😊

Our differential gears are crafted with precision and durability in mind. Whether you're looking to enhance your vehicle's performance on the track or simply want to ensure long-lasting reliability, our gears are designed to meet and exceed your expectations. Made from high-quality materials, they provide smooth and efficient power transfer, reducing wear and tear on your vehicle's components. 🔧🏎️

The gearbox options we offer are equally impressive. Engineered for optimal performance, our gearboxes are built to handle the demands of high-speed racing and off-road adventures. With a focus on durability and precision, these gearboxes ensure that your LOSI MICRO B can tackle any terrain with ease. 🌟🌍

But that's not all! At GPM Racing, we understand that customization is key to getting the most out of your RC vehicle. That's why we offer a wide range of optional parts for the LOSI MICRO B. From suspension upgrades to high-performance tires, our selection allows you to tailor your vehicle to your specific needs and preferences. 🛠️🚗

Explore our full range of products and discover how GPM Racing can take your LOSI MICRO B to the next level. Visit our website here to browse our extensive catalog and find the perfect parts for your RC vehicle. 🌐📦

Happy racing! 🏁😊

#GPMRacing #LOSIMICROB #RCCar #DifferentialGears #Gearbox #RacingPerformance #Customization #HighQuality #RCUpgrades #RCParts #HobbyLife #RCLovers #OffRoadRacing #HighPerformance #TrackReady 🚗💨

🌟🔧🏎️🚗🌐📦🏁😊🌍🛠️

More parts can explore on this link : https://www.gpmracing.com.hk/index.php?route=product%2Fcategory&path=226_224_586&fbclid=IwY2xjawIfPQtleHRuA2FlbQIxMAABHX8U172pIkVm1yj60FIKgVUppJeSlRxt-Do-1YNurkFKXgQ80moxZe4KNQ_aem_4VkmlxilM1J1qooDHAN3ng

0 notes

Text

Art of Precision Manufacturing and Assembly in Building Block Twin Screw Extruder

In the intricate world of polymer processing, the Building Block Twin Screw Extruder and Twin Screw Granulator stand of engineering is designed to handle a myriad of material transformations with precision and efficiency. The manufacturing and assembly processes of these machines are critical to their performance, as they determine the durability, reliability, and output quality.

The heart of the Building Block Twin Screw Extruder is its screws, which are meticulously machined to ensure uniform distribution and mixing of materials. The screws are typically made from high-grade steel, which undergoes a series of processes including turning, milling, and grinding to achieve the desired dimensions and tolerances. The precision of these operations is paramount, as any deviation can cause uneven material flow and reduced efficiency of the Twin Screw Extruder.

The barrels that house the screws in both the Building Block Twin Screw Extruder and Twin Screw Granulator are also subject to stringent manufacturing processes. They are often made from materials that can withstand high pressures and temperatures, such as stainless steel or specialized alloys. The barrels are bored and honed to tight tolerances to ensure a suitable fit with the screws, which is crucial for maintaining the integrity of the extrusion or granulating process.

Heat exchange is another critical aspect of the Building Block Twin Screw Extruder and Twin Screw Granulator, with heating and cooling systems being integral to controlling the temperature of the materials being processed. The manufacturing of these systems involves the fabrication of jackets and plates that are precisely fitted to the barrels. The assembly of these components requires specialized techniques to ensure even heat distribution, which is vital for the quality of the end product.

The drive systems of these machines, including motors and gearboxes, are also manufactured with high precision. The gears must be hardened and ground to exact specifications to ensure smooth operation and long service life. The assembly of these drive systems involves aligning the motor with the gearbox and the screws, which is a delicate process that requires expert craftsmanship to prevent any misalignment that could cause increased wear and tear or machine failure.

The assembly of a Building Block Twin Screw Extruder or Twin Screw Granulator is a complex process that involves the careful alignment and integration of all its components. This includes the screws, barrels, heating and cooling systems, and drive systems. Each part must be assembled with precision to ensure that the machine operates as a cohesive unit. The use of specialized tools and jigs is common in this process to ensure that all components are correctly positioned and that there is no room for error.

The manufacturing and assembly of the Building Block Twin Screw Extruder and Twin Screw Granulator components are processes that require a high level of expertise and precision. From the machining of screws to the alignment of drive systems, each step is crucial in ensuring that these machines perform. The attention to detail in these processes is what sets apart a well-crafted extruder or granulator from one that is merely functional, making the difference in the quality of the end product and the overall efficiency of the production process.

https://www.extruderfactory.com/product/

0 notes

Text

VR Lip Seal by CV Technik The Ultimate Sealing Solution in Pune, Maharashtra

Sealing technology has come a long way, and one company leading the charge is CV Technik, based in Pune, Maharashtra. They specialize in high-quality VR Lip Seal, also known as VR Dichtungen, which are designed for superior performance in high-pressure and high-speed applications. Whether used in automotive, heavy engineering, or industrial machinery, these seals ensure reliability, durability, and efficiency.

What Are VR Lip Seals?

VR Lip Seals are advanced sealing solutions designed to prevent leakage, contamination, and excessive friction in rotating and reciprocating machinery. Unlike conventional oil seals, VR Lip Seals can handle extreme pressures and high speeds while maintaining optimal sealing efficiency.

Their design eliminates the need for a traditional metal casing and spring, making them more compact, lightweight, and easier to install. This makes them an excellent choice for industries where space constraints and durability are critical factors.

Key Features of VR Lip Seals

High-Pressure Resistance – Capable of withstanding pressures up to 150 bar, making them suitable for hydraulic and pneumatic applications.

Superior Wear Resistance – Constructed from advanced polymer and elastomeric materials that extend service life.

Low Friction – Reduces power loss and improves energy efficiency in machinery.

Compact Design – Ideal for applications where space is limited.

High-Speed Performance – Capable of functioning effectively at extreme rotational speeds.

Self-Retaining – Eliminates the need for additional hardware, ensuring easier installation.

Temperature Resilience – Performs efficiently across a wide range of temperatures.

Why Choose VR Lip Seals Over Traditional Seals?

Conventional sealing solutions, such as O-rings and standard oil seals, often struggle in high-pressure environments, leading to leaks and system failures. VR Lip Seals outperform these traditional seals by offering:

Better adaptability to shaft misalignments.

Longer service life due to reduced wear and tear.

Enhanced sealing efficiency in both static and dynamic conditions.

Resistance to aggressive media, including oils, chemicals, and extreme temperatures.

Applications of VR Lip Seals

VR Lip Seals play a crucial role in various industries, ensuring the longevity and efficiency of mechanical systems. Here are some key industries where they are indispensable:

1. Automotive Industry

Used in engines, gearboxes, differentials, and turbochargers to ensure reliable performance.

Helps reduce friction in high-speed rotating components.

2. Heavy Engineering and Steel Mills

Essential for rolling mills, hydraulic presses, and steel processing units.

Offers resistance to metal debris, dust, and extreme operating conditions.

3. Marine and Offshore Equipment

Provides sealing solutions for marine gear systems and propulsion units.

Resistant to saltwater corrosion and extreme marine environments.

4. Aerospace Industry

Used in aircraft engines, landing gear systems, and hydraulic actuators.

Ensures reliability under high-speed and high-altitude conditions.

5. Construction and Off-Road Vehicles

Helps prevent leakages in hydraulic systems of excavators, bulldozers, and cranes.

Improves efficiency and reduces maintenance costs.

6. Food and Pharmaceutical Industries

Used in processing machinery that requires contamination-free sealing solutions.

Meets FDA and food-grade material compliance standards.

How CV Technik Stands Out

CV Technik has established itself as a leading provider of VR Lip Seals in Pune, Maharashtra. Their commitment to research, innovation, and quality assurance makes them the preferred choice for industries worldwide. Here’s why customers trust CV Technik:

1. Cutting-Edge Technology

CV Technik continuously invests in advanced material science and sealing technology to develop the best-performing VR Lip Seals.

2. Customization Options

They offer tailored sealing solutions based on specific industrial requirements, ensuring a perfect fit for every application.

3. Rigorous Quality Testing

Each seal undergoes stringent quality checks to ensure high performance, durability, and compliance with international standards.

4. Expert Engineering Support

CV Technik provides technical consultation and support, helping industries optimize their machinery’s sealing performance.

5. Sustainable and Cost-Effective Solutions

Their products are designed to reduce energy consumption, minimize maintenance costs, and improve overall efficiency, making them a smart investment for businesses.

The Future of Sealing Technology

With industries demanding more efficient and durable sealing solutions, VR Lip Seal are set to revolutionize the market. Companies are moving away from conventional seals and embracing VR Dichtungen for their ability to handle higher pressures, faster speeds, and extreme operating conditions.

Key Trends in Sealing Solutions:

Increased Use of High-Performance Polymers – Advanced materials are improving the longevity and resistance of seals.

Smart Sealing Solutions – Sensors integrated into seals to monitor real-time performance.

Eco-Friendly Materials – The development of sustainable sealing options to reduce environmental impact.

Final Thoughts

When it comes to high-performance sealing solutions, VR Lip Seals by CV Technik are a game-changer. Their cutting-edge technology, superior durability, and energy-efficient design make them the ideal choice for industries seeking reliability and performance.

Whether you are in automotive, aerospace, heavy engineering, or food processing, upgrading to VR Dichtungen can significantly improve the efficiency and longevity of your machinery.

If you’re looking for the best VR Lip Seals in Pune, Maharashtra, CV Technik is the trusted name in sealing solutions. Get in touch with their expert team today to discover how their innovative sealing solutions can enhance your industrial performance.

0 notes

Text

Leading conveyor Gear Box Manufacturer in India

When it comes to high-quality conveyor gearboxes, Nisuka Industries stands out as a leading conveyor gearboxes manufacturer in India. With years of expertise and a commitment to innovation, Nisuka Industries delivers durable, efficient, and precision-engineered conveyor gearboxes that cater to various industrial needs.

Why Choose Nisuka Industries for Conveyor Gearboxes?

Superior Quality Nisuka Industries uses premium-grade materials and advanced manufacturing techniques to ensure high-performance gearboxes that can withstand demanding operational conditions.

Innovative Designs The company specializes in designing customized gearbox solutions that enhance conveyor system efficiency, reduce downtime, and improve productivity.

Wide Range of Products Nisuka Industries offers an extensive range of conveyor gearboxes, including:

Helical Gearboxes

Worm Gearboxes

Bevel Gearboxes

Planetary Gearboxes

Industry Applications Their gearboxes are widely used in cement plants, mining, steel industries, food processing, pharmaceuticals, and material handling systems.

Energy Efficiency & Reliability Nisuka gearboxes are engineered for low power consumption, high torque transmission, and long service life, making them a cost-effective solution for industrial applications.

Exceptional After-Sales Support The company provides prompt customer service, maintenance support, and technical assistance to ensure smooth operations.

#conveyor Gear Box#Shaft Mounted Gearboxes#manufacturer#conveyor Gear Box Manufacturer#conveyor Gear Box supplier#conveyor Gear Box exporter#conveyor Gear Box Manufacturer in India

1 note

·

View note

Text

Understanding Worm Gearbox Ratios and Their Role in Optimizing Operations

Worm gearboxes are considered an important part of any industrial applications that require large amounts of torsion and accurate control. The ratio in case of a worm gearbox is a most critical specification that bears major influence over speed control, torque magnification, and gearbox effectiveness. This blog will help you understand worm gearbox ratios, how these units work and how they could benefit or affect your operations.

What Are Worm Gearbox Ratios?

The worm gearbox ratio defines how much the input speed is slowed down and vice versa how much the torque is increased. For instance, a 10:1 ratio means that for the [output gear] to make a round the input gear has to make 10 rounds. This results in:

A tenfold reduction in speed.

A tenfold increase in torque.

Such ratios are useful in applications where low-speed high torque operations are desired.

How Gear Ratios Affect Torque

Torque Multiplication

A decrease in speed results in a corresponding increase in torque. For instance:

The compound can adopt a one ratio or one to ten, transforming the input torque to deal with the extensive load.

This makes the worm gearbox well suited in hoists that require high torque, in winches and other mechanical systems.

Why Gear Ratio Matters for Your Operations

A. Efficiency and Power Optimization

Choosing the correct gear ratio means that the motor runs at the right speed to be efficient. Higher LG and TM ratios generate more torque than lower ratios, The Battleship OHP achieves a certain power speed/torque balance that is important for energy efficiency.

B. Precision and Control

Therefore in some areas such as robots, and auto systems, the right gear ratio provides improved control. Higher ratios provide slow and continuous motion required in many applications to offer great precision and product quality.

Choosing the Right Gear Ratio for Your Application

Several factors influence the choice of a worm gearbox ratio:

Load Requirements: Systems handling heavy loads, such as cranes, benefit from higher ratios to ensure smooth operation.

Precision Needs: Applications like conveyor belts or robotic arms require lower ratios (e.g., 3:1 to 5:1) for precise motion control.

Real-World Applications of Worm Gearbox Ratios

A. Material Handling

Conveyor systems often use gear ratios of 5:1 to 20:1, enabling controlled material movement with minimal wear on the system.

B. Precision Machinery

Lower ratios are used in robotic systems and automated lines to ensure smooth, precise operations.

Conclusion

Understanding the appropriate worm gearbox ratio is critical to enhancing the performance and safety of your machinery. The right ratio can improve operational consistency and reduce energy costs by optimising speed reduction and torque multiplication.

Contact us today to find the perfect worm gearbox for your operations!

#worm gearbox repairs#double reduction gear box#decades of gearbox experience#worm gear manufacturer#worm reduction gearbox#reduction gearbox manufacturers#gearbox application in industries#gearbox manufacturer in ahmedabad#worm screw gearbox factory#gearbox repair Ahmedabad#double reduction gearbox ahmedabad#gear box manufacturing ahmedabad#reduction gear manufacturers#gearbox repair cost ahmedabad#gearbox manufacturer#gearbox vertical ahmedabad#gearbox repair services ahmedabad#buy worm reduction gearbox#worm gearbox manufacturer Ahmedabad#worm reduction gearboxes Ahmedabad#worm gearbox manufacturer gujarat#gearbox manufacturer in gujarat#gearbox manufacturer rajasthan#gearbox repair rajasthan#worm gearbox manufacturer Rajasthan#reduction gearbox manufacturer Rajasthan#reduction gearbox manufacturer maharashtra

0 notes

Text

SBJ Nirmal Products: The Leading Manufacturer of Reliable Rotavator Parts

Agriculture plays a crucial role in the economy of many countries, and efficient farm machinery is vital for maximizing productivity. One of the essential farming tools is the rotavator, which helps in preparing the soil for sowing. However, the efficiency of a rotavator depends on its spare parts, which must be durable and reliable. This is where SBJ Nirmal Products excels. Based in Ludhiana, Punjab, SBJ Nirmal Products is a leading rotavator parts manufacturer, offering premium-quality spare parts for agricultural machinery.

About SBJ Nirmal Products

SBJ Nirmal Products is a well-established name in the agricultural machinery spare parts industry, known for producing high-performance rotavator parts. With years of experience and expertise, the company has built a reputation for providing affordable, durable, and precision-engineered parts that meet the highest industry standards.

SBJ Nirmal Products serves farmers across India, Bangladesh, Nepal, Sri Lanka, and other international markets, ensuring that they have access to reliable rotavator spare parts that enhance efficiency and longevity.

Why Choose SBJ Nirmal Products for Rotavator Parts?

1. High-Quality Manufacturing Process

SBJ Nirmal Products follows a rigorous quality control process to ensure that all its rotavator spare parts meet international quality standards. The company employs state-of-the-art CNC machines, laser-cutting technology, and high-grade materials to produce parts that guarantee longevity and superior performance.

2. Wide Range of Rotavator Parts

SBJ Nirmal Products offers an extensive variety of rotavator spare parts, ensuring that farmers and dealers can find the exact component they need. The company's product range includes:

Rotavator Blades (L-type, C-type, J-type)

Crown Pinions

Stub Axles

Gearbox Components

Bearings and Seals

Hubs and Flanges

Side Plates and Covers

3. Cost-Effective and Long-Lasting

SBJ Nirmal Products understands the financial challenges faced by farmers. That’s why the company is committed to offering affordable yet high-quality rotavator parts. By providing durable and wear-resistant spare parts, SBJ Nirmal Products helps reduce replacement costs and enhances the overall efficiency of agricultural machinery.

4. Strong Market Presence

With a large distribution network spanning across India, Bangladesh, Nepal, and Sri Lanka, SBJ Nirmal Products ensures fast and timely delivery of its products. The company is a trusted supplier for dealers, distributors, and farmers looking for reliable and affordable rotavator parts.

SBJ Nirmal Products’ Rotavator Parts: Features & Benefits

1. Rotavator Blades

Rotavator blades are one of the most essential parts of a rotavator. SBJ Nirmal Products manufactures blades using high-carbon steel and boron steel, ensuring durability and precision cutting.

Key Features:

Available in L-type, C-type, and J-type designs.

Heat-treated for extra strength and wear resistance.

Compatible with various rotavator brands.

2. Crown Pinions

Crown pinions play a crucial role in power transmission within a rotavator’s gearbox.

Key Features:

Made from hardened alloy steel for durability.

Ensures smooth torque transmission.

Reduces wear and tear for extended machine life.

3. Stub Axles

Stub axles are essential for supporting the weight of the rotavator and ensuring smooth movement.

Key Features:

Constructed from high-strength steel.

Corrosion-resistant for longer durability.

Provides maximum load-bearing capacity.

4. Gearbox Components

SBJ Nirmal Products manufactures precision-engineered gearbox components to improve rotavator efficiency.

Key Features:

High-torque handling capacity.

Reduces energy loss and increases performance.

Made from hardened steel for maximum durability.

5. Bearings and Seals

Bearings and seals ensure smooth operation and reduce friction within the rotavator’s moving parts.

Key Features:

High load-bearing capacity.

Anti-corrosion coatings for extended life.

Reduces maintenance costs.

Commitment to Farmers and Dealers

SBJ Nirmal Products believes in delivering value-for-money products that cater to the practical needs of farmers. The company ensures that all spare parts are easy to install, durable, and require minimal maintenance.

Customer-Oriented Approach

Customized Solutions: Tailored solutions based on the specific requirements of farmers and dealers.

24/7 Customer Support: Expert assistance in selecting the right spare parts.

On-Time Delivery: Reliable distribution network to ensure timely delivery.

Affordable Pricing Strategy

Best pricing for farmers without compromising on quality.

Bulk purchase discounts for dealers and distributors.

Efficient Logistics & Delivery

Wide distribution network across India, Bangladesh, Nepal, and Sri Lanka.

Strong logistics partnerships for quick and safe deliveries.

Why SBJ Nirmal Products is the Best Choice for Rotavator Parts?

✅ Decades of Experience – Established name in rotavator spare parts manufacturing. ✅ International Recognition – Exporting to Bangladesh, Nepal, and Sri Lanka. ✅ Precision Engineering – Use of advanced manufacturing technology. ✅ High-Performance Components – Durable, corrosion-resistant, and heat-treated parts. ✅ Affordable & Cost-Effective – Competitive pricing for farmers and dealers. ✅ Eco-Friendly Practices – Sustainable and minimal-waste manufacturing.

Future Vision of SBJ Nirmal Products

SBJ Nirmal Products is continuously innovating and investing in research and development to enhance its product range. The company aims to introduce:

Smart rotavator parts with sensor-based monitoring.

Eco-friendly coatings for improved lifespan.

Advanced automation in manufacturing for better precision.

Conclusion

SBJ Nirmal Products is the ultimate choice for high-quality rotavator spare parts. With a commitment to durability, affordability, and superior performance, SBJ Nirmal Products ensures that farmers and dealers get the best-in-class rotavator components.

For reliable rotavator blades, crown pinions, stub axles, gearbox components, and more, trust SBJ Nirmal Products. Experience top-tier quality that enhances the productivity of your agricultural machinery!

#agriculture#sbj#farming#rotavator parts manufacturer#sbj nirmal#agricultural machinery parts#sbj nirmal products#high-quality rotavator parts#rotavator#agricultural equipment

0 notes

Text

Force Gurkha: A Rugged Off-Road Powerhouse

The Force Gurkha is a name that resonates with off-road enthusiasts, embodying a true spirit of adventure. Manufactured by Force Motors, this 4x4 SUV is built to endure the harshest terrains, making it a favorite for those seeking thrill and capability in one package. Whether it’s crossing rocky trails, navigating dense forests, or handling sand dunes, the Gurkha stands out as one of the most capable off-roaders in India. It’s not just a vehicle; it’s an experience for those who live for adventure.

Under the hood of the Force Gurkha lies a 2.6-liter turbocharged diesel engine, capable of producing 90 horsepower and 250 Nm of torque. This engine ensures that the Gurkha can tackle challenging terrains without breaking a sweat. It is paired with a 5-speed manual gearbox and a transfer case that allows the driver to shift into low range gears, providing superior control when navigating difficult paths. The 4x4 system, coupled with differential locks, ensures that the Gurkha can easily tackle obstacles that other vehicles would struggle with. Its off-road pedigree is unquestionable, putting it in direct competition with other capable 4x4s, like the Isuzu V-Cross. If you’re curious about how these two stack up against each other, our detailed comparison in the Force Gurkha vs Isuzu V-Cross article highlights the key differences between these two off-road warriors.

The exterior design of the Force Gurkha is built with one thing in mind – durability. Its boxy, muscular stance is not just about aesthetics, but practicality. The high ground clearance, heavy-duty suspension, and off-road tires give it the strength needed to conquer the toughest landscapes. The vehicle is also equipped with features such as a full steel bumper, roof-mounted lamps, and a spare wheel mounted at the back, ensuring it’s well-equipped for any off-road adventure. These elements, combined with the vehicle's rugged frame, make the Gurkha one of the most reliable off-road vehicles in its segment.

Inside the Gurkha, the focus shifts towards practicality and comfort, rather than luxury. The cabin is designed to be functional, with robust seating and ample space for up to six passengers. The interior materials are built to withstand the wear and tear of off-road expeditions, ensuring that the vehicle remains durable and easy to maintain. While the vehicle may not feature the plush interiors of more premium SUVs, it makes up for this with its practical approach to off-roading.

The Force Gurkha also excels when it comes to water fording capabilities. With a high ground clearance and sealed electrical components, the Gurkha can wade through rivers and streams without issue. This makes it the perfect companion for those who love to explore rugged landscapes that involve crossing water bodies.

If you're looking for a vehicle that combines power, durability, and off-road prowess, the Force Gurkha is the ultimate choice. It offers everything an off-roading enthusiast could ask for: a robust engine, rugged design, and the ability to handle even the harshest terrains. For more information on how the Force Gurkha compares with other 4x4s like the Isuzu V-Cross, don’t miss our detailed review in the Force Gurkha vs Isuzu V-Cross article.

In conclusion, the Force Gurkha is more than just a vehicle; it’s an off-road powerhouse that promises to take you on unforgettable adventures. Its tough build, reliable engine, and off-road capabilities make it an ideal choice for anyone looking to explore the outdoors. If you’re seeking a vehicle that thrives in rugged environments, the Force Gurkha is the perfect companion for the journey.

0 notes