#wires and cables market size

Explore tagged Tumblr posts

Text

Wire & Cable Compounds Market Analysis: Key Players and Competitive Landscape

Expanding Infrastructure and Technological Advancements Drive Growth in the Wire & Cable Compounds Market.

The Wire & Cable Compounds Market Size was valued at USD 14.84 billion in 2023, and is expected to reach USD 32.50 billion by 2032 and grow at a CAGR of 9.32% over the forecast period 2024-2032.

The Wire & Cable Compounds Market is driven by the increasing demand for high-performance, durable, and safe wiring solutions across industries such as automotive, construction, telecommunications, and energy. These compounds, made from materials such as polyvinyl chloride (PVC), polyethylene (PE), thermoplastic elastomers (TPE), and rubber, enhance the insulation, flame resistance, and mechanical strength of wires and cables. The rapid expansion of renewable energy projects, infrastructure development, and the adoption of electric vehicles (EVs) is further fueling market demand.

Key Players

Avient Corporation

Borouge

DuPont de Nemours, Inc.

Eastman Chemical Company

Evonik Industries AG

Exxon Mobil Corporation

Hanwha Solutions Corporation

Mitsubishi Chemical Corporation

PolyOne Corporation

SABIC

Future Scope

The Wire & Cable Compounds Market is expected to experience robust growth due to technological advancements in insulation and jacketing materials. The rising need for efficient and safe power transmission, along with increasing investments in smart grids and 5G networks, is driving demand for high-performance wire and cable compounds. Additionally, stringent safety and environmental regulations are pushing manufacturers to develop halogen-free, low-smoke, and recyclable compounds to meet industry standards.

Emerging Trends

The market is shifting toward eco-friendly and halogen-free flame-retardant (HFFR) compounds due to growing concerns about toxicity and environmental impact. Cross-linked polyethylene (XLPE) and thermoplastic elastomers (TPEs) are gaining traction in high-voltage and industrial applications due to their superior heat and chemical resistance. The growing adoption of electric vehicles (EVs) is also driving demand for lightweight, high-performance wire and cable compounds that ensure optimal energy efficiency and thermal stability. Additionally, increasing investments in renewable energy infrastructure are further propelling the market forward.

Key Points

Growing demand for durable and flame-resistant wire and cable compounds in key industries.

Rising adoption of halogen-free and environmentally friendly compounds for sustainable solutions.

Expansion of 5G infrastructure, smart grids, and renewable energy projects fueling market growth.

Advancements in cross-linked polyethylene (XLPE) and thermoplastic elastomers (TPE) for high-voltage applications.

Surge in electric vehicle (EV) production increasing demand for lightweight and high-performance cable compounds.

Conclusion

The Wire & Cable Compounds Market is set for steady expansion, driven by technological innovations, regulatory shifts, and growing demand across industries. With the ongoing transition toward renewable energy, smart infrastructure, and electric mobility, the need for high-quality, sustainable, and safe wire and cable solutions will continue to rise. Manufacturers focusing on halogen-free, recyclable, and high-performance compounds will be well-positioned to capitalize on this evolving market landscape.

Read Full Report: https://www.snsinsider.com/reports/wire-and-cable-compounds-market-2018

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Wire & Cable Compounds Market#Wire & Cable Compounds Market Size#Wire & Cable Compounds Market Share#Wire & Cable Compounds Market Report#Wire & Cable Compounds Market Forecast

0 notes

Text

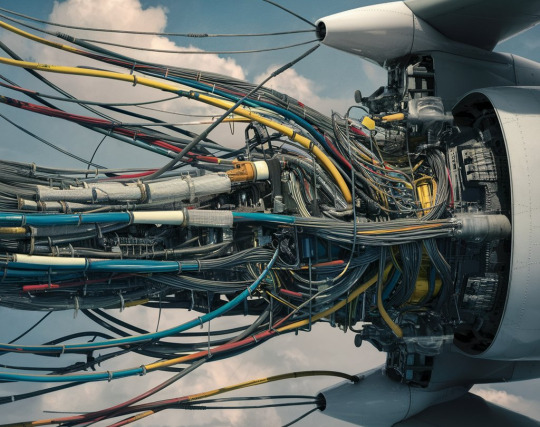

Market Opportunities in Electric Aircraft and Glass Cockpits

The global market for Aircraft Wire and Cable is a crucial component of the aerospace industry, providing essential wiring and cabling for various aircraft systems. These components are integral to the operation, safety, and performance of modern aircraft. The Aircraft Wire and Cable Market is currently valued at USD 1.5 Billion in 2021 and is projected to reach USD 1.9 Billion by 2026, growing at a Compound Annual Growth Rate (CAGR) of 5.7% during the forecast period. This growth is driven by several factors, including the digitalization and electrification of aircraft systems, increased aircraft renewals and deliveries, and ongoing technological advancements.

Market Size and Growth

Market Statistics

As of 2021, the Aircraft Wire and Cable market is valued at USD 1.5 billion. By 2026, it is expected to reach USD 1.9 billion, growing at a CAGR of 5.7%. This growth trajectory highlights the increasing demand for advanced wiring and cabling solutions in the aerospace industry, driven by technological innovations and the expansion of the global aircraft fleet.

Market Trends

Several key trends are shaping the Aircraft Wire and Cable market:

Digitalization and Electrification: The digitalization of aircraft systems improves operational efficiency and enhances pilot functions. Electrification of aircraft reduces fuel consumption and operating costs, driving demand for advanced wire and cable solutions.

Increase in Aircraft Renewals and Deliveries: The aerospace industry is experiencing a surge in aircraft renewals and new aircraft deliveries, necessitating updated and more efficient wiring and cabling systems.

Technological Developments: Advances in materials and technology are leading to the development of lighter, more durable, and more efficient wires and cables.

Get a Deeper Understanding of the Industry by Visiting: https://www.marketsandmarkets.com/Market-Reports/aircraft-wire-and-cable-market-105042386.html

Industry Drivers

Digitalization and Electrification of Aircraft Systems

Digitalization enhances operational efficiency and simplifies pilot functions through a range of intuitive airline software and services. This trend improves overall flight operations, making the cockpit's work operations entirely computerized. Electrification, on the other hand, offers more efficient, quieter, and sustainable flights, reducing fuel consumption and operating costs. For instance, in October 2020, W.L. Gore & Associates released the GWN3000 Series of high-performance aerospace wires capable of delivering power that could replace systems reliant on combustion, hydraulics, and pneumatics.

Increase in Aircraft Renewals and Deliveries

The increase in the global fleet of aircraft, driven by both renewals of older models and the introduction of new aircraft, is a significant driver for the Aircraft Wire and Cable market. This demand is particularly evident in commercial aviation, where airlines are investing in more fuel-efficient and technologically advanced aircraft to reduce operational costs and improve performance.

Market Opportunities

Demand for Electric Aircraft and Glass Cockpits

The shift towards electric aircraft and glass cockpits presents significant opportunities for the Aircraft Wire and Cable market. Electric technology reduces fuel consumption and provides a reliable power source for aircraft, while glass cockpits enhance flight safety and efficiency. Companies like Airbus are developing hybrid-electric propulsion systems, and Collins Aerospace is modernizing the Indonesian Air Force's C-130H aircraft with digital cockpits, demonstrating the market's potential.

Market Challenges

Additional Weight of Insulation and Shielding

One of the main challenges in the Aircraft Wire and Cable market is the additional weight of insulation and shielding required for wires and cables. These components are essential for protecting sensitive electronic equipment from electromagnetic interference but add significant weight to aircraft. Manufacturers are developing substitutes like carbon nanotube fibers, metalized polymeric fibers, and fiber optics to address this issue.

Get Thorough Information in Our PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=105042386

Market Segmentation

By Component

Wires and Cables: These constitute the largest weight portion of aircraft electrical power systems.

Connectors: Essential for joining wires and cables, ensuring secure and efficient connections.

Harnesses: Assemblies of electrical cables or wires that transmit signals or electrical power throughout an aircraft.

By Application

Avionics: Projected to grow at the highest CAGR, driven by the shift to digital avionics systems.

Engine: Requires durable and high-performance wires and cables.

Airframe: Involves wiring for structural components.

Power Distribution: Includes cabling for electrical power systems.

By Aircraft Type

Commercial Aircraft: Represents the largest segment due to the high volume of aircraft in commercial fleets.

Military Aircraft: Includes specialized wiring and cables for defense applications.

UAVs: Expected to witness the highest CAGR due to the increasing use of drones for surveillance and reconnaissance.

By Region

North America: Expected to hold the highest market share due to the presence of major manufacturers and aircraft companies.

Europe: Significant growth driven by advancements in aerospace technology and increased aircraft production.

Asia Pacific: Rapidly growing market due to the expansion of the aviation industry in countries like China and India.

Discover All the Steps in Our Detailed Sample: https://www.marketsandmarkets.com/requestsampleNew.asp?id=105042386

Competitive Landscape

The Aircraft Wire and Cable Companies is dominated by several key players, including:

Amphenol Corporation (US): Known for its high-performance connectors and interconnect systems.

Carlisle Interconnect Technologies (US): Specializes in aerospace wiring and cabling solutions.

Collins Aerospace (US): Provides advanced avionics and aerospace systems.

TE Connectivity (Switzerland): Offers a wide range of electrical and electronic connectivity solutions.

Nexans SA (France): Supplies specialized aerospace cables and wires.

Recent Developments

Nexans and Airbus Partnership: In January 2021, Nexans signed a contract with Airbus to supply specialized aerospace cables and wires for civilian and military aircraft.

GKN Aerospace and Eviation Agreement: In May 2020, GKN Aerospace and Eviation signed an agreement to design and manufacture wings, empennage, and wiring systems for the Alice All-Electric Aircraft.

The global Aircraft Wire and Cable market is poised for significant growth, driven by the digitalization and electrification of aircraft systems, increased aircraft renewals and deliveries, and ongoing technological advancements. Despite challenges such as the additional weight of insulation and shielding, the market offers numerous opportunities, particularly in the areas of electric aircraft and glass cockpits. With major players investing in innovative solutions and strategic partnerships, the future of the Aircraft Wire and Cable industry looks promising.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we formally transformed into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, and facilitates analysis of interconnections through applications, helping clients look at the entire ecosystem and understand the revenue shifts in their industry.

To learn more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact: Mr. Rohan Salgarkar MarketsandMarkets™ INC.

630 Dundee Road Suite 430 Northbrook, IL 60062 USA: +1-888-600-6441

Email: [email protected]

#Aircraft Wire and Cable#Aircraft Wire and Cable Market#Aircraft Wire and Cable Industry#Global Aircraft Wire and Cable Market#Aircraft Wire and Cable Market Companies#Aircraft Wire and Cable Market Size#Aircraft Wire and Cable Market Share#Aircraft Wire and Cable Market Growth#Aircraft Wire and Cable Market Statistics

0 notes

Text

South Africa Wires & Cables Market - Forecast(2024 - 2030)

South Africa Wires and Cables Market Overview

South Africa Wires & Cables Market size is projected to reach US$15.5 billion by 2030, and it is estimated to grow at CAGR of 5.5% during 2024-2030. With the rising demand for electricity and telecommunications, the market is poised for steady expansion and innovation. Government initiatives are also playing a crucial role in propelling the market forward. Increased investments in infrastructure development and electrification projects are contributing to the demand for South Africa wires and cables.

👉 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

A wire is an electrical conductor, while a cable is a group of individually insulated wires encased together in sheathing. Wires and cables can be made from various materials, such as copper, steel, aluminum and others. The materials each have different resistances. Thick wire will have a lower resistance than thin wire made from the same material. Resistance of the wire can change proportionally with change in temperature or length of the wire. Wires and cables form an integral part of the modern-day industries. South Africa, a developing nation holds a significant potential for the wire and cable industry. It forms the backbone of the present information age, providing users with power, light and communication. Wires and cables are used in industries such as power transmission & distribution, buildings, automotive, home appliances and communications among others.

The Gauteng provincial government in South Africa is investing $4.9 billion to transform Mooikloof, a suburb of Pretoria, into a green city by 2030. The "Mooikloof Mega City" project aims to address environmental challenges such as water access, waste management, and air pollution. Growing investments in South Africa's construction sector, especially due to smart city trends and significant government infrastructure spending, are propelling demand for South Africa wires and cables market.

South Africa Wires and Cables Market Report Coverage

The report: “South Africa Wires & Cables Market Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the South Africa Wires & Cables Market.

By Material Type: Copper, Aluminum, Galvanized Steel, High Strength Composite Core, Others

By Voltage Ratings: Medium Voltage, High Voltage

By Installation: Overhead, Underground, Submarine

By Type: Power Cables, Control Cables, Speciality Cables, Instrumentation Cables, Others

By Insulation Type: XLPE, EPR, PVC, MI, Others

By End-user: IT & Telecommunication, Marine, Aerospace & Defense, Automotive, Building Construction, Oil & Gas, Energy & Transportation, Residential, Infrastructure and Others

By Company Type: Local Manufacturing, Local Sales Presence, Imports

By Geography: SADC, EAC

Key Takeaways

• Copper wire and cable dominated the market in 2023 acquiring a share of 35.2% in 2023.

• IT and Telecommunication sector is estimated to witness the highest growth during 2024-2030 of 9.4% owing to the growing demand for advanced electronic devices in vehicles.

• The significant increase in investment in Construction Sector projects is set to drive the South Africa Wires and Cables Market

• The adoption of automotive Ethernet is hampering the wires and cables market in South Africa by replacing traditional copper wires with high-speed network technology.

#South Africa Wires & Cables Market price#South Africa Wires & Cables Market size#South Africa Wires & Cables Market share

0 notes

Text

The Growing Cross Linked Polyethylene Market Growth is Driven by Rising Construction Activities

The global cross linked polyethylene market offers several advantages like durability, tensile strength, and chemical resistance which makes it suitable for usage in diverse industrial applications such as pipes, cables, and wires. As a thermosetting plastic, cross linked polyethylene exhibits superior characteristics that enables its use as an insulation material for wiring and cabling in construction, automotive as well as oil & gas industries.

The global cross linked polyethylene market size is estimated to be valued at US$ 6590.3 Mn in 2024 and is expected to exhibit a CAGR of 3.3% over the forecast period 2024 to 2031. Key players operating in the Cross Linked Polyethylene Market Growth are BASF SE, Celanese Corporation, Daicel Corporation (Polyplastics Co. Ltd), DuPont de Nemours Inc., Ensinger, Korea Engineering Plastics Co. Ltd, Mitsubishi Chemical Corporation, Westlake Plastics Company, and Yuntianhua Group Co. Ltd. These players are focused on developing innovative products and adopting organic and inorganic growth strategies like mergers & acquisitions to strengthen their global presence. The demand for cross linked polyethylene is increasing in the construction sector owing to properties like moisture resistance, rigidity and durability. It is widely used for manufacturing pressure pipes, oil & gas pipes, and conduit pipes. Rapid urbanization and infrastructural development activities across regions are fueling the consumption of XLPE for various construction applications. The cross linked polyethylene market is also expanding globally on account of rising export & import of XLPE products between nations. Key manufacturers are strategizing their foreign operations to cater to the surging requirements from developing markets in Asia Pacific and Middle East & Africa. Countries like India, China, Saudi Arabia, and UAE offer huge untapped growth potential for cross linked polyethylene producers. Market drivers: Rising construction activities: Cross linked polyethylene finds major usage in pressure pipes, oil & gas pipelines, and conduit pipes used in residential, commercial and industrial construction. The booming real estate and infrastructure industries worldwide has increased the demand for cross linked polyethylene for various construction applications. Key Takeaways Key players operating in the cross linked polyethylene market are BASF SE, Celanese Corporation, Daicel Corporation (Polyplastics Co. Ltd), DuPont de Nemours Inc., Ensinger, Korea Engineering Plastics Co. Ltd, Mitsubishi Chemical Corporation, Westlake Plastics Company, and Yuntianhua Group Co. Ltd. The demand for cross linked polyethylene is increasing in the construction sector owing to properties like moisture resistance, rigidity and durability. The cross linked polyethylene market is also expanding globally on account of rising export & import of XLPE products between nations. Countries like India, China, Saudi Arabia, and UAE offer huge untapped growth potential for cross linked polyethylene producers.

Get More Insights On This Topic: Cross Linked Polyethylene Market

#Cross Linked Polyethylene Market#Cross Linked Polyethylene Market Size#Cross Linked Polyethylene Market Share#Cross Linked Polyethylene Market Analysis#Polymers And Resins#Plumbing#Wires & Cables#Automotive

0 notes

Text

The Drone Package Delivery Market is projected to grow from USD 228 million in 2022 to USD 5,556 million by 2030, at a CAGR of 49.0% from 2022 to 2030.

Technological advancements like VTOL, geospatial mapping, IoT, and machine learning result in higher accuracy in package delivery are some of the factors fueling the growth of the Drone Package Delivery Industry. AI is the next focus of the drone industry. This new technology is expected to enable drones to perform all tasks, right from their launch and navigation to data acquisition, data transmission, and data analysis. In addition,advancements in technology of drone will help in carrying out drone package delivery operations autonomously and safely, thereby contributing to their increased adoption in the drone delivery ecosystem.

#Aircraft Wire and Cable#Aircraft Wire and Cable Market#Aircraft Wire and Cable Industry#Global Aircraft Wire and Cable Market#Aircraft Wire and Cable Market Companies#Aircraft Wire and Cable Market Size#Aircraft Wire and Cable Market Share#Aircraft Wire and Cable Market Growth#Aircraft Wire and Cable Market Statistics

0 notes

Text

769 words, my own au i call "doll au", inspired by cyberpunk. everyone is a cyborg yah whatever. enjoy, and yes i accept questions on the au.

Part Two

-.-.-

Captain Curly’s medical file is 13 pages of technical jargon, schematics, therapy notes and several police reports. It's the longest in volume, outmatching even Swansea’s extensive age and habit of replacing livers when they fail him.

Before completing a trimonthly diagnostic on each crewmember, Anya must read through their medical records to prepare. All restricted files on the Tulpar are paper, unable to be downloaded or accessed through any cyberware. Locked away in cases and drawers for select crew.

She opens Curly's file on the desk, organises the paper's with a soft shuffling. Slides her glasses on, so the eyestrain of the contacts doesn’t overwhelm.

Her radio comforts, cello solos for reading while she drinks the Pony Express tea. Tea is a liberal interpretation of dust swept from the factory floor and stuffed into rice paper pouches that dissolve into the water, leaving behind a starchy taste. There’s only 100 packed for the whole trip, and she hates them.

Alas, the urge to drink tea while studying, self-ingrained through her schooling habits, is too strong to beat. Anya sips at her starchy dust water and tries to comprehend what a Systematic Ram Reshuffler is.

The Captain’s body is full of things, full of wires and chips. His files are full of complications from those wires and chips. She reads through the reports from his biomonitor, the watch embedded in his wrist, the bracing on his hand where he broke it in a warehouse accident. The optical enhancements he has, top market for his line of work. The maintainer attached to his heart. A diagram of his brain overflowing with neuralware, stretches of cabling stretching along the rippling tissue.

She jots down a note to monitor Curly for complications, and more stringent psychological evaluation. No wonder he’s so indebted, she thinks to herself. These implants must cost tens of thousands.

She stops in her shuffling, turns the radio down when a note rings out like a squeal. Surely, she misread it. Misunderstood.

The fourth page is an extensive report of the process of installing a Morpheus Behavioural Chip from Projekt Industries.

Something's kicking in her chest, something scared. A Morpheus.

The report is not as dramatic as maybe it should be, size twelve lettering on slightly creased paper. Perfectly normal language, probably typed out by a surgeon eager to rush off to their lunch break. Nauseatingly mundane and impassive. Totally typical of a post surgery report. She’s unsure that it’s about Curly, until she doubles and then triple checks his full name at the top of the page.

26th September, 1984: The implant was installed into the client’s frontal lobe. Surgery was 7 hours and 42 minutes. There were no complications.

28th September, 1984: The client woke up from anaesthetic and attempted to decannulate himself. The nurse on duty prevented this from happening, and he quickly regained composure.

29th September: 1984 The implant appears to have integrated with the client’s nervous system and frontal lobe without complication. No inflammation beyond standard medication. Diagnostics by a software engineer shows full functionality has been achieved.

13th October, 1984: The client will be discharged tonight, and return weekly until the end of the month for monitoring. Prescription for courses of medication sent electronically: immunosuppressants, antibiotics, antiinflammation and antiemetics will be supplied in courses

A Morpheus chip in the frontal lobe of Captain Curly. Anya leans back, spine slamming into the back of her chair as her vision seems to fizzle at the edges. Curly, in charge of The Tulpar and the wellbeing of every single person on board, has a behavioural chip. Curly is a doll.

Scolding herself for that kind of language, she lets the paper down on the desk like it stings to touch. Curly’s a person, a person with independent thoughts. Not some meat machine, and she’d be able to tell if it wasn’t him. His opticware is connected to the implant, an alert to anyone he talks to if it's active. Curly is himself, and himself is a person. A Morpheus chip doesn’t mean anything.

The cup of tea, wobbling precariously in her unsteady hand, tips onto her. It scalds, soaking into her uniform’s trousers and the pants underneath that.

“Fuck!”

She stumbles to her feet, stumbling to get out of her uniform and shoving the papers across the table. It burns, bringing angry tears to her eyes as she stumbles to the sink reserved for handwashing. At least the medical room can lock, she bitterly recalls while stripping down to her underclothes and splashing water onto her angry, red skin.

She's lost her appetite for pony express tea even more, now. Behavioural chip interfaces with all programs in functionality tests, the report read, and the dead pixel flashes at the back of her skull insistently.

#curly mouthwashing#mouthwashing curly#mouthwashing#mouthwashing game#anya mouthwashing#mouthwashing fandom#mouthwashing fanfic#captain curly

25 notes

·

View notes

Text

just remembered that in high school i procured 3000 feet of telephone wire cable from a flea market and constructed a life-size jesus out of it and put a muslin loin cloth on him (that i dyed brown using tea. i don't remember what that was supposed to mean) for an art class. i later crucified him on a cross some theatre kids made for me for free, even after i offered to pay them. i named him 'telephoney jesus' and he had to be displayed twice, once for my teacher and once for the IB program adjudicator who came to evaluate us at the end of the school year. so for months i had this telephone cord jesus abomination in a heap on the couch in my family's living room, hanging out with all my family's regular jesus paraphernalia.

#i got a 6 in art. more evidence the IB program is a scam.#i wasn't even like particularly annoyed with christianity back then i have no idea why i did this#tbh the reason was probably that i that i found 3000 foot of telephone wire for cheap and was really thrilled about it#a rare personal post#a rare. personal. jesus. (post)

22 notes

·

View notes

Text

Some technical details under the cut if anyone is interested:

As someone who makes Stupid Keyboards (near to Stupid Mice, and don't think I don't have Stupid Mice ideas): I think this is fake, as in they didn't actually make a Toy Horse That Is A Mouse.

So, first of all, out of context reasons: It was made by Pablo Rochat for Yahoo. He's a director of a group of artists who do marketing stuff for companies. He doesn't have this one on his page yet but based on their other stuff, it seems to be mostly photoshop/video editing based.

And here's the thing: Faking a mouse is frighteningly easy.

Record your screen as you move a real mouse

Play back that video while you move something that's not a real mouse

Done. It looks like it works.

The final reason is that I don't think their lens would work. See, modern optical mice are based on a light + lens + tiny camera. The light shines on the surface so the camera can see the surface move.

The problem is that it's focused right at a set distance, which is supposed to be set to how far the sensor is from the mousepad. Try picking up your optical mouse now (assuming you're not on a phone or laptop): You'll find that it works while not touching the mousepad, but only for a couple millimeters. Once you get farther, it stops.

The reason is the lens: It's trying to get the most contrast possible at a very specific distance, and once you pick it up by more than a few millimeters, it gets too blurry to work.

So lets think about how you'd put a sensor in the horse toy.

The obvious place is in the horse's belly: but then your lens wouldn't work. You'd need a custom lens to make it work. That sounds like a lot of work, and it might not even work with the standard optical chip they use.

The second option would be the hooves. This would work! you're at the right distance, you just need to run the cable down the leg, and you're golden.

Except those hooves are too small. Optical mice are built on standard chips these days:

The chip is a specific size because it is floating over a hole in the PCB. The bottom of the chip is a camera. The lens is a piece of plastic that fits in there. It's hard to tell the scale from this picture I stole, but the problem is the chip is too big to fit down the hoof of that toy horse. Maybe you could do it if you had a horse with some Big Hooves? but there's no way to fit one of these in there. Sorry.

So yeah. They faked it.

Unless they got clever and faked it in another way: That "grass" mousepad could be a tablet. It could be multi-touching the hooves, and then transmitting their location to the PC.

You'd need to wire up the horse so the capacitive touch works, or use a resistive touch screen, but you're still cheating a little.

But all that is hard: faking it completely is easy. So I'm very sure that's what they did. I'd do the same if I was doing art as a client of a company and I had a deadline. It doesn't affect the video if this is "real" or "fake".

btw: I don't say this to lessen anyone's enjoyment of it or as a "callout", I'm just interested in "how real is this" as someone who makes Weird Tech Art too.

Bruh

39K notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Quality Construct Crafted with oxygen-free copper, this 16-gauge wire ensures pristine audio transmission, delivering clear and uninterrupted sound quality for various systems. Dual Conductor Design The wire's two conductors enable seamless stereo sound transmission, making it an ideal choice for connecting speakers, sub-woofers, and amplifiers in home theaters or car audio setups. Transparent Insulation The transparent coating not only protects the wire but also simplifies installation by allowing for easy identification during setup. About the brand Triveni Wire and Cable - where excellence, innovation, and reliability converge to shape the future of the wires and cables industry. Renowned for making high-quality PVC insulated wires and cables, we uphold the quality through strong R&D and a skilled workforce. Our commitment to delivering premium quality products sets us apart. Mission: Our mission is to secure a leadership position by incorporating cutting-edge technology, ensuring premium quality for a broader customer base, and establishing robust brand recognition. Vision: We aspire to be the most trustworthy brand in the wires and cables industry, aiming for maximum market share and global recognition through the provision of advanced products. Innovation: At the core of our success is a commitment to technological innovation, propelling us forward and positioning us as leaders in the industry. High-Quality Construction: Crafted with oxygen-free copper, this 16-gauge wire ensures pristine audio transmission, delivering clear and uninterrupted sound quality for various systems. Dual Conductor Design: The wire's two conductors enable seamless stereo sound transmission, making it an ideal choice for connecting speakers, subwoofers, and amplifiers in home theaters or car audio setups Transparent Insulation: The transparent coating not only protects the wire but also simplifies installation by allowing for easy identification during setup. Versatile Length Options: Available in lengths of 45 meters, this speaker wire caters to different installation needs, ensuring ample coverage for various room sizes or setup configurations. Ideal for Audio Enthusiasts: Whether you're an audiophile seeking premium sound quality or a casual user aiming for dependable connectivity, the TWC Double Core Speaker Wire is designed to enhance your audio experience across different entertainment systems. [ad_2]

0 notes

Text

Top PVC Wires And Cables Manufacturers

PVC Wires and Cables Manufacturers: A Focus on Flexon Cable

Polyvinyl Chloride (PVC) is one of the most widely used materials in the manufacturing of wires and cables due to its versatility, durability, and cost-effectiveness. As industries continue to expand, the demand for high-quality PVC wires and cables has significantly risen, leading to the emergence of numerous manufacturers across the globe. Among these manufacturers, Flexon Cable stands out as a key player in producing PVC-based wires and cables that meet the growing needs of various sectors. This article will delve into the importance of PVC wires and cables manufacturers and highlight Flexon Cable's role in the market.

The Importance of PVC Wires and Cables

PVC wires and cables are used extensively in residential, commercial, and industrial applications due to their excellent electrical insulation properties. PVC is an inherently flame-retardant material that offers high resistance to heat, moisture, and chemicals, making it ideal for use in a variety of environments. From electrical power distribution to communication systems, PVC cables play a crucial role in ensuring safety, efficiency, and reliability.

One of the most significant advantages of PVC cables is their ability to withstand extreme temperatures and environmental conditions. PVC cables can endure harsh climates, both hot and cold, without losing their insulating properties. This feature is particularly essential for outdoor and underground wiring, where cables are exposed to the elements.

Additionally, PVC cables are lightweight and flexible, which makes them easier to handle, install, and maintain. The ability to produce wires and cables in different sizes and shapes further adds to their appeal for various applications, from home electrical systems to large industrial setups.

PVC Cable Manufacturing Process

The production of PVC wires and cables involves several stages, from the selection of raw materials to the final inspection of the finished product. The process begins with the extrusion of PVC insulation onto copper or aluminum conductors, which are the core of the cables. The insulation is designed to protect the conductors from external factors like moisture, heat, and mechanical stress.

After the insulation, the cables are coated with a protective outer sheath made of PVC. This outer sheath provides additional protection against environmental elements and physical damage. The final step includes rigorous testing of the cables to ensure they meet industry standards for safety, performance, and durability.

Leading manufacturers like Flexon Cable implement advanced technology and state-of-the-art machinery in their manufacturing processes to ensure high-quality production. The use of premium materials, combined with automated processes, guarantees that the end products are reliable, efficient, and safe for all types of applications.

Flexon Cable: A Leader in PVC Wire and Cable Manufacturing

Flexon Cable has earned a reputation as one of the leading manufacturers of PVC wires and cables, offering a broad range of products that cater to the diverse needs of its customers. Established with a mission to provide high-quality electrical products, Flexon Cable specializes in manufacturing PVC-insulated cables for various sectors, including residential, commercial, and industrial.

The company's product lineup includes power cables, control cables, communication cables, and flexible cables, all designed with PVC insulation for enhanced safety and performance. Flexon Cable’s commitment to quality is evident in its adherence to international standards, ensuring that every product meets rigorous testing and quality control protocols.

One of Flexon Cable’s core strengths lies in its ability to offer customizable solutions tailored to the unique requirements of its clients. Whether it's a specific voltage rating, unique insulation thickness, or custom color coding, Flexon Cable provides flexibility in design and configuration. This adaptability makes the company an ideal partner for industries that demand specialized cable solutions.

Furthermore, Flexon Cable emphasizes sustainability in its production processes. The company focuses on using eco-friendly materials and energy-efficient methods to minimize its carbon footprint. This commitment to sustainability not only benefits the environment but also aligns with the growing global emphasis on reducing industrial waste and emissions.

The Future of PVC Wires and Cables Manufacturers

The future of PVC wires and cables looks promising, driven by increasing urbanization, industrialization, and technological advancements. As the demand for electricity and data transmission continues to rise, PVC cables will remain an integral part of electrical and communication infrastructure worldwide.

Manufacturers like Flexon Cable are poised to play a critical role in meeting the increasing demand for high-quality PVC cables. With ongoing innovations in material science and manufacturing technology, PVC cables are expected to become even more efficient, durable, and environmentally friendly.

Conclusion

PVC wires and cables are essential for the smooth functioning of various industries, offering a combination of safety, flexibility, and durability. Manufacturers like Flexon Cable have established themselves as trusted providers of high-quality PVC cables, playing a vital role in meeting the growing demands of the modern world. By combining advanced technology, customization options, and a focus on sustainability, Flexon Cable is well-positioned to lead the way in the global wire and cable manufacturing industry.

Visit:- https://www.flexoncable.com/pvc-wires-cables.html

0 notes

Text

Circular Polymers Market Size, Share & Trends Analysis Report, 2030

Circular Polymers Market Growth & Trends

The global circular polymers market size is anticipated to reach USD 152.75 billion by 2030 and is projected to grow at a CAGR of 11.5% from 2024 to 2030, according to a new report by Grand View Research, Inc. This market is witnessing growth at a propulsive rate owing to increasing strategic initiatives such as new product launches, production expansions, and mergers & acquisitions.

Attributes of circular polymers are similar to traditional polymer resins, including high impact resistance, toughness, lower hardness, and low density. These resins are widely used across applications such as food packaging, adhesives & sealants, interior & exterior components of vehicles, and wires & cables, among others.

Furthermore, strategic initiatives such as mergers & acquisitions, joint ventures, production, expansion, and others are carried out by key players across market to maintain competitiveness. For instance, in July 2023, Saudi Arabian Oil Group (Aramco) and Total Energies SE, petroleum refinery companies, along with SABIC, a polymer manufacturer have produced circular polymers utilizing plastic pyrolysis oil alternatively known as plastic waste derived oil (PDO).

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/circular-polymers-market-report

Circular Polymers Market Report Highlights

Based on region, Asia Pacific dominated the market with a revenue share of over 46.0% in 2023. Asia Pacific is a highly clustered region in terms of population across emerging economies such as India and China.

Packaging, automotive, and building & construction are preponderance for the market. Government initiatives such as taxes on packaging, especially plastics-based, are expected to propel demand for circular polymers globally.

Based on polymer type, the polyethylene (PE) segment dominated the global market in 2023 owing to a market share above 32.0% and growing demand from key end-use industries such as packaging, automotive, building & construction, and others.

Based on form, pellets form segment dominated the global market in 2023, owing to a market share above 53.0%. Circular plastics are widely manufactured and supplied in pellet form to plastic product manufacturers, where these pellets are treated at extremely high temperatures, melted, and then molded into desirable end products.

In terms of application, the food packaging segment dominated the global market in 2023, owing to a market share above 43.0%. Durability and seal ability of circular plastics have increased demand for circular plastic-based packaging across food & beverage industry.

Based on end-use, packaging segment dominated the global market in 2023, owing to a market share above 43.0%, followed by the automotive industry with a market revenue share above 19.0%.

Circular Polymers Market Segmentation

Grand View Research has segmented the global circular polymers market based on polymer type, form, application, end-use, and region:

Circular Polymers Type Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Polyethylene (PE)

Polypropylene (PP)

Polyethylene Terephthalate (PET)

Polyvinyl Chloride (PVC)

Polyamide (PA)

Others

Circular Polymers Form Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Pellets

Flakes

Circular Polymers Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Food packaging

Adhesives & sealants

Interior & exterior components

Wires & cables

Others

Circular Polymers End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Packaging

Building & construction

Automotive

Electrical & electronics

Others

Circular Polymers Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

UK

France

Italy

Netherlands

Spain

Asia Pacific

China

India

Japan

South Korea

Australia

Indonesia

Thailand

Vietnam

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

United Arab Emirates (UAE)

South Africa

List of Key Players in the Circular Polymers Market

LyondellBasell Industries Holdings B.V.

SABIC

Ascend Performance Materials Operations, LLC

Advanced Circular Polymers

Borealis AG

Veolia

Exxon Mobil Corporation

The Shakti Plastic Industries

Chevron Phillips Chemical Company, LLC

Suez Group

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/circular-polymers-market-report

#Circular Polymers Market#Circular Polymers Market Size#Circular Polymers Market Share#Circular Polymers Market Trends

0 notes

Text

Global Mobile Accessories Market: Industry Size, Segment Analysis, Regional Trends, Key Companies, Competitive Landscape, and Forecast (2025–2035)

Mobile Accessories Market Outlook: Growth, Trends & Competitive Landscape

Industry Overview

The global Mobile Accessories Market was valued at USD 92.3 billion in 2024 and is projected to reach USD 198.3 billion by 2035, growing at a CAGR of 7.2% from 2025 to 2035.

Mobile accessories, including chargers, skins, headphones, AirPods, and phone housings, have experienced a surge in demand due to technological advancements and the increasing adoption of smartphones and mobile devices. Consumers seek safety, personalization, and fashion-forward accessories for their devices.

Key Growth Drivers

Advancements in 5G technology enhancing device capabilities

Remote work trends increasing dependency on mobile devices

Rise in e-commerce platforms driving easy access to accessories

Increased disposable income leading to higher consumer spending

Smart add-ons like wireless charging boosting market demand

Market Dynamics

Higher Smartphone Penetration Fuels Demand

The increasing number of smartphone users globally is a key factor driving mobile accessory sales. Consumers are investing in protective gear, enhanced usability, and personalization, including cases, chargers, screen protectors, and wireless headphones.

According to ITU, global mobile cellular penetration reached 8.6 billion connections in 2023.

As smartphone adoption increases, the demand for accessories will continue to rise.

Personalized Mobile Accessories Gain Popularity

Consumers prefer customized accessories, such as personalized phone cases and skins, to express individuality. The growing trend of personalization boosts the demand for unique, stylish, and functional mobile accessories.

85% of U.S. households owned a smartphone in 2023 (U.S. Census Bureau).

Customization offers a competitive edge for brands catering to personal expression.

Intense Market Competition Limits Growth

The highly competitive nature of the Mobile Accessories Market presents challenges for manufacturers. Numerous brands offer similar products, leading to price wars, reduced brand loyalty, and lower profit margins.

Companies must focus on product differentiation and innovation to stand out.

Premium branding and unique designs can help businesses gain a competitive advantage.

Rising Wireless Technology Adoption

The shift toward wireless accessories is a significant growth opportunity. Products such as Bluetooth speakers, wireless earbuds, smartwatches, and wireless chargers are gaining popularity due to convenience and compatibility with modern smartphones.

Increasing 5G adoption enhances demand for high-tech accessories.

Manufacturers must innovate wireless solutions to capture this growing segment.

Sustainability Trends Influence Consumer Choices

The demand for eco-friendly mobile accessories is growing as consumers become more environmentally conscious. Sustainable materials such as biodegradable phone cases, recyclable chargers, and energy-efficient accessories are gaining traction.

Brands focusing on green innovation can appeal to eco-conscious consumers.

Reducing e-waste is a key trend driving sustainable product adoption.

Industry Expert Insight

Chris Sorensen, CEO of PhoneBurner: "There's a growing niche for phones that prioritize fun and personality over cutting-edge technology. Similar to how Swatch revolutionized watches, mobile phones can follow the same path. These devices appeal to younger demographics valuing uniqueness and self-expression over high specs."

Segment Analysis

By Product Type

The Mobile Accessories Market is segmented into:

Protective Accessories: Phone cases, screen protectors (dominant segment)

Chargers & Cables: Wired and wireless charging solutions

Memory Cards: Expanded storage solutions

Audio Accessories: Earbuds, headphones, Bluetooth speakers

Others: Popsockets, smart rings, mobile gaming accessories

The protective accessories category leads the market as consumers prioritize device safety and longevity.

By Distribution Channel

Online: Dominant segment due to ease of purchase, variety, and discounts

Offline: Brick-and-mortar stores, specialty mobile shops

With the rise of e-commerce platforms, online sales continue to expand due to convenience and competitive pricing.

Regional Analysis

North America: Rapid Growth & High Demand

The U.S. leads in smartphone adoption, driving high demand for premium accessories.

E-commerce dominates accessory sales, with Amazon leading the distribution.

Increasing 5G connectivity and disposable income fuel market expansion.

Asia-Pacific: Fastest-Growing Market

India & China drive growth with increasing smartphone adoption.

Japan & South Korea demand premium accessories like wireless chargers and smart wearables.

E-commerce platforms (Alibaba, JD.com) boost accessibility to accessories.

China: Global Leader in Production & Consumption

China dominates smartphone and accessory manufacturing.

Consumers prefer trendy, high-quality, and affordable accessories.

The rise of influencers and social media trends impacts buying behavior.

Competitive Landscape

The Mobile Accessories Market is highly competitive, with major players dominating different segments:

Apple & Samsung: Premium segment with wireless headphones, chargers, and cases.

Sony, Bose, JBL: Leaders in high-end audio accessories.

OtterBox, Mophie: Specialize in protective cases and power products.

ZAGG, Xiaomi, Huawei: Offer a mix of screen protectors, wireless chargers, and budget-friendly accessories.

Conclusion

The Mobile Accessories Market continues to grow, driven by smartphone penetration, technological advancements, and personalization trends. Companies must focus on wireless innovation, sustainability, and unique product offerings to stand out in this competitive space. As 5G adoption and e-commerce expansion reshape consumer behavior, the market presents ample opportunities for brands to capitalize on evolving trends.

Get free sample Research Report - https://www.metatechinsights.com/request-sample/1312

Read Full Research Report https://www.metatechinsights.com/industry-insights/mobile-accessories-market-1312

Buy Now https://www.metatechinsights.com/checkout/1312

0 notes

Text

Wire and Cable Market Trends, Active Key Players, and Growth Projection Up to 2032

Allied Market Research, titled, “Wire and Cable Market," The wire and cable market size was valued at $213.6 billion in 2022, and is estimated to reach $323.8 billion by 2032, growing at a CAGR of 4.6% from 2023 to 2032.

Factors that contribute toward the growth of the wires and cables market include a rise in the trend of renewable energy generation. Encouraging policies and initiatives of various governments and incentives have led to a considerable increase in the share of renewables as well as alternative sources of energy. In addition, increase in deployment of new power grid infrastructure boosts the growth of the wire and cable industry. The growth of infrastructure projects, such as buildings, power plants, transportation systems, and telecommunications networks, drives the wire and cable market demand. As new structures are constructed or existing ones upgraded, there is a need for wiring systems to enable the distribution of electricity, communication signals, and data.

The wire and cable market analysis has a significant opportunity in meeting the growing demand for renewable energy sources, such as solar and wind power. As the world increasingly shifts towards cleaner and more sustainable energy solutions, there is a rising need for efficient and reliable transmission of electricity generated from renewable sources.

To support this transition, specialized wire and cable solutions are required. These solutions must be capable of handling high voltages, transmitting power over long distances, and withstanding challenging environmental conditions. For instance, solar farms and wind turbines rely on extensive cabling systems to connect the power generation units to the electrical grid.

This presents a prime opportunity for wire and cable manufacturers to innovate and develop advanced products tailored specifically for renewable energy applications. These products could include high-voltage cables, flexible cables suitable for dynamic environments, and cables with enhanced resistance to environmental factors like UV radiation and extreme temperatures.

By focusing on the renewable energy sector, wire and cable companies can tap into a rapidly expanding market while contributing to the global transition towards cleaner energy sources. Moreover, as technology continues to advance and energy storage systems become more prevalent, additional opportunities will arise for wire and cable manufacturers to provide solutions for efficient energy distribution and management within these systems.

The wire and cable market is driven by the demand for extensive wiring and cabling systems in infrastructure projects, such as the construction of highways, railways, airports, power plants, and smart cities. These projects necessitate efficient transmission of electricity, data, and signals, which in turn creates a strong demand for various types of wires and cables, including power cables, communication cables, control cables, and fiber optic cables.

In addition, rise in urbanization and population growth lead to the expansion of residential, commercial, and industrial areas. This expansion requires extensive wiring and cabling for electrical power supply, lighting, telecommunications, and various applications. The rapid advancements in technology and the rise of digitalization have resulted in the widespread adoption of electronic devices, smart homes, automation systems, and the Internet of Things (IoT). These innovations necessitate the use of dependable wiring and cabling solutions to ensure uninterrupted connectivity, efficient data transmission, and reliable power supply.

KEY FINDINGS OF THE STUDY

The wire and cable market share is expected to continue growing in the coming years, driven by increasing demand for wire and cable products across various industries, technological advancements, and a growing trend towards sustainability.

The growing trend towards sustainability is driving the adoption of eco-friendly materials in the production of wire and cable products.

Asia Pacific is the largest in wire and cable market trends, driven by the increasing demand for wire and cable products in industries such as packaging, building materials, and automotive. The region is also home to some of the largest manufacturers of scanners.

The wire and cable market is highly competitive, with several major players operating globally. To remain competitive, companies are focusing on product innovation, strategic partnerships, and expanding their distribution networks.

The key wire and cable market leaders profiled in the report include Nexans S.A., Prysmian Group, Furukawa Electric Co., Ltd., Belden Inc., Sumitomo Electric Industries, Leoni AG, Fujikura, LS Cable & System Asia Ltd, KEI Industries Ltd., and Amphenol Corporation. Market players have adopted various strategies such as product launch, acquisition, expansion, and others to expand their foothold in the wire and cable market growth.

#WireAndCable#ElectricalWiring#CableIndustry#PowerTransmission#EnergyInfrastructure#CopperWire#FiberOptic#ElectricalEngineering#SmartGrid#TelecomCables#HVACWiring#IndustrialCables#AutomationCabling#DataTransmission#SustainableEnergy#EVWiring#AerospaceCables#DefenseCabling#RenewableEnergy#ManufacturingTech

0 notes

Text

0 notes

Text

PVC Pipes Factory in Bawana: A Growing Industrial Hub

Introduction

Bawana, a prominent industrial area in Delhi, has become a key center for manufacturing various industrial products, including PVC (Polyvinyl Chloride) pipes. With an increasing demand for PVC pipes in construction, plumbing, and agriculture, Bawana’s factories have gained prominence as leading suppliers. The availability of skilled labor, affordable raw materials, and well-established infrastructure makes Bawana an ideal location for PVC pipe manufacturing.

In this blog, we will explore the growth of PVC pipe factories in Bawana, the manufacturing process, benefits, and why Bawana has become a preferred hub for PVC pipe production.

Understanding PVC Pipes and Their Importance

PVC pipes are widely used due to their durability, affordability, and resistance to corrosion. They are an essential component in various sectors, including water supply systems, drainage, electrical conduits, and irrigation. Unlike metal pipes, PVC pipes do not rust, making them a long-lasting and cost-effective option.

Types of PVC Pipes Manufactured in Bawana

PVC pipe factories in Bawana manufacture different types of pipes, including:

UPVC (Unplasticized Polyvinyl Chloride) Pipes – Used for plumbing, sewage, and drainage systems.

CPVC (Chlorinated Polyvinyl Chloride) Pipes – Designed for hot and cold water distribution.

PVC Conduit Pipes – Used for electrical wiring and cable protection.

SWR (Soil, Waste, and Rainwater) Pipes – Suitable for wastewater and rainwater drainage.

Agricultural PVC Pipes – Used in irrigation and water distribution for farming.

Growth of PVC Pipe Factories in Bawana

1. Industrial Infrastructure

Bawana Industrial Area has a well-developed infrastructure that supports large-scale manufacturing. The presence of multiple industrial units provides easy access to raw materials, skilled labor, and logistics, making it a prime location for PVC pipe factories.

2. Increasing Demand for PVC Pipes

With the rise in construction projects, urban development, and agricultural advancements, the demand for PVC pipes has surged. This has led to the establishment of numerous factories in Bawana, catering to both domestic and international markets.

3. Government Support and Regulations

The Delhi government has taken several initiatives to promote industrial growth in Bawana. Policies encouraging small and medium enterprises (SMEs) have allowed PVC pipe manufacturers to expand their operations, adopt modern technologies, and maintain quality standards.

Manufacturing Process of PVC Pipes in Bawana Factories

The production of PVC pipes involves several steps to ensure durability, strength, and efficiency. Here’s an overview of the manufacturing process:

1. Raw Material Selection

Factories in Bawana source high-quality PVC resin, stabilizers, lubricants, and plasticizers to ensure superior product quality. The raw materials are carefully selected to meet industry standards.

2. Extrusion Process

The raw materials are mixed and melted in an extruder, where they are shaped into pipes. The extrusion process ensures uniformity in thickness and diameter, making the pipes suitable for different applications.

3. Cooling and Sizing

Once the pipes are shaped, they pass through a cooling chamber to maintain their structure. The sizing process ensures the pipes meet the required dimensions and tolerances.

4. Printing and Marking

Each PVC pipe is printed with important details such as size, type, manufacturer name, and quality certification. This helps in easy identification and ensures compliance with industry standards.

5. Quality Testing

PVC pipe factories in Bawana conduct rigorous quality checks to test pressure resistance, impact strength, and leakage prevention. These tests ensure that only high-quality pipes reach the market.

6. Packaging and Distribution

The final products are packaged and distributed to suppliers, retailers, and end-users. Efficient logistics support in Bawana enables fast and reliable transportation of pipes across India.

Why Bawana is an Ideal Location for PVC Pipe Factories

1. Availability of Skilled Labor

Bawana’s industrial area attracts experienced workers, ensuring efficient manufacturing and quality control processes.

2. Cost-Effective Production

The abundance of raw materials and competitive labor costs allow factories to produce PVC pipes at affordable rates without compromising quality.

3. Strategic Location

Being close to major markets in Delhi and NCR, Bawana offers an advantageous location for manufacturers to distribute PVC pipes quickly and cost-effectively.

4. Diverse Supplier Base

Bawana has a network of suppliers offering raw materials, machinery, and other essentials, making it easier for factories to operate smoothly.

5. Business-Friendly Policies

Government support in terms of industrial policies and infrastructure development has encouraged many entrepreneurs to establish PVC pipe factories in Bawana.

Choosing the Right PVC Pipe Factory in Bawana

When selecting a PVC pipe factory for bulk purchases, consider the following factors:

1. Reputation and Experience

Look for factories with a strong market reputation and years of experience in PVC pipe manufacturing.

2. Quality Certifications

Ensure the factory follows industry standards such as ISI, ISO, or BIS certification.

3. Product Range and Customization

A good factory should offer a variety of PVC pipes with customization options based on specific requirements.

4. Pricing and Discounts

Compare prices from multiple factories to get the best deal, especially for bulk purchases.

5. After-Sales Support

A reliable manufacturer should provide technical assistance, warranties, and customer support for their products.

Future Prospects of PVC Pipe Factories in Bawana

With advancements in manufacturing technology and increasing demand, the future of PVC pipe factories in Bawana looks promising. The focus on sustainability, eco-friendly production processes, and improved product durability will further enhance the industry’s growth. Government initiatives for infrastructure development and smart city projects will continue to drive demand for high-quality PVC pipes.

Conclusion

Bawana has established itself as a major hub for PVC pipe factories, offering quality products at competitive prices. The industrial ecosystem, skilled workforce, and business-friendly environment make it an ideal location for PVC pipe manufacturing. Whether for construction, plumbing, or irrigation, factories in Bawana provide a reliable supply of durable and cost-effective PVC pipes. As the demand for PVC pipes continues to rise, Bawana’s industrial sector is set to expand further, contributing significantly to India’s growing infrastructure and development needs.

#pvcpipesfactoryinbawana#pvcpipesinbawana#pvcpipesmanufacturers#pvcpipesmanufacturersindelhi#pvcpipesmanufacturersinnarela#cantabilbathassets

0 notes

Text

Exploring the Different Types of Transmission Towers and Their Functions

Transmission towers, also known as electrical towers or power towers, play a crucial role in the modern power distribution and transmission system. These towering structures are responsible for carrying high-voltage transmission lines that transfer electricity over long distances, ensuring that power generated at a power plant reaches homes, businesses, and industries. Transmission towers are essential components of the energy infrastructure, enabling the delivery of electrical power across vast distances with minimal loss of energy.

In this article, we will delve into the different types of transmission towers, their functions, and the vital role they play in the electrical transmission system. We will also explore the role of transmission line tower manufacturers in India, which is one of the largest markets for these essential structures.

What Are Transmission Towers?

Transmission towers are large steel structures designed to support and suspend electrical transmission lines. These lines carry electricity from power plants to substations and then to local distribution networks, supplying homes and industries with the electrical power they need. Transmission towers are built to withstand harsh environmental conditions, including wind, rain, snow, and even seismic activity, to ensure uninterrupted power delivery.

The towers are designed to support conductors (wires) at a height that minimizes the risk of contact with people, animals, or objects on the ground. They are essential in maintaining the integrity and efficiency of the entire power grid. These towers vary in size, design, and material depending on the type of transmission line, the voltage of the electricity being carried, and the geographical environment in which they are placed.

Types of Transmission Towers

Transmission towers come in various shapes and sizes, and each type serves a specific function within the power transmission system. Let’s explore the different types of towers that are used for power transmission.

1. Lattice Towers

Lattice towers are one of the most common types of transmission towers. They have a framework-like structure made of steel, which gives them the name “lattice.” These towers are widely used in high-voltage transmission lines because they offer a high level of stability and strength. The lattice design allows for a lightweight yet durable structure, making it easier to transport and install.

Lattice transmission towers are typically used for long-distance transmission lines that require a high level of support to carry heavy electrical cables. They are designed to withstand harsh weather conditions and are capable of supporting large numbers of transmission conductors.

2. Monopole Towers

Monopole towers are another type of transmission tower that is often used for medium and low-voltage transmission lines. These towers consist of a single, vertical pole structure that supports the conductors. Monopole towers are typically made of steel or concrete, and they are often used in urban areas or locations where space is limited, as their smaller footprint is more suitable for such environments.

Monopole towers are lightweight and cost-effective compared to lattice towers, making them an attractive option for certain types of power transmission. However, they are generally not suitable for high-voltage lines or areas with extreme weather conditions due to their reduced strength compared to lattice towers.

3. Guyed Towers

Guyed towers are a type of transmission tower that relies on external supports, or guy wires, to stabilize the structure. These wires are tensioned to hold the tower upright, providing additional stability and strength. Guyed towers are typically used for medium to high-voltage transmission lines, especially in areas with limited access or difficult terrain.

The primary advantage of guyed towers is their lower cost compared to other types of transmission towers. They are often used in remote areas where it is difficult to transport or install larger, more complex towers. However, the use of guy wires requires careful planning and maintenance, as they can pose a hazard to nearby activities.

4. Tubular Towers

Tubular towers, also known as tubular steel transmission towers, are made from hollow steel tubes. These towers are lightweight, durable, and resistant to corrosion, making them ideal for use in coastal or industrial areas where environmental factors can significantly impact the lifespan of the towers.

Tubular towers are designed to support high-voltage transmission lines, and they can be used for both overhead and underground power transmission. They are also commonly used for applications such as communication towers or wind turbine towers due to their robust structure and ability to withstand high winds and heavy loads.

5. Double Circuit Towers

Double circuit towers are designed to carry two separate circuits of transmission lines on the same tower. These towers are used in situations where space is limited or where it is more cost-effective to install two circuits on a single tower rather than multiple separate towers.

Double circuit transmission towers are often used for medium- to high-voltage transmission lines and are commonly found in urban areas or regions with limited land availability. They help maximize the efficiency of the transmission network while reducing the environmental impact of additional tower installations.

Functions of Transmission Towers

Transmission towers serve several critical functions in the power transmission system. Some of the key roles of transmission towers include:

1. Supporting Transmission Lines

The primary function of transmission towers is to support electrical transmission lines. These lines carry electricity from power plants to substations and eventually to homes and businesses. Without transmission towers, it would be impossible to maintain the height and distance required for these high-voltage lines to safely carry electricity over long distances.

2. Maintaining Safety

Transmission towers are built to ensure the safe transmission of electricity. The towers keep the high-voltage conductors elevated above the ground, preventing accidental contact with people, animals, or other objects. This helps avoid electrical hazards and ensures the safety of both people and the environment.

3. Minimizing Power Loss

Transmission towers also play a vital role in minimizing power loss. By supporting the electrical conductors at the appropriate height and distance, they help reduce the amount of energy lost during the transmission process. The design and placement of transmission towers are carefully considered to ensure the most efficient transfer of electricity.

4. Enhancing System Reliability

The use of transmission towers helps ensure the reliability of the electrical power grid. They are designed to withstand a variety of environmental factors, including strong winds, heavy snow, and earthquakes. By maintaining the stability and integrity of the transmission lines, transmission towers help prevent power outages and disruptions to the electrical grid.

Transmission Line Tower Manufacturers in India

India is one of the largest and fastest-growing markets for transmission line towers due to its rapidly expanding power generation and transmission infrastructure. Transmission line tower manufacturers in India play a key role in meeting the demand for these essential structures.

Indian manufacturers are known for producing a wide range of transmission towers, including lattice towers, monopole towers, and tubular towers, to suit the diverse needs of the power transmission sector. They also produce custom-designed towers based on specific project requirements, ensuring that the towers are tailored to the unique environmental and technical conditions of the project.

With a focus on quality, durability, and cost-effectiveness, transmission line tower manufacturers in India contribute significantly to the development of the country’s energy infrastructure. They are constantly innovating and adopting new technologies to improve the design and functionality of transmission towers, ensuring that they meet international standards for safety and performance.

Conclusion

Transmission towers are indispensable elements of the power transmission system, ensuring the efficient and safe transfer of electricity over long distances. Understanding the different types of transmission towers, such as lattice towers, monopole towers, and guyed towers, is essential for recognizing their unique functions and importance in maintaining the reliability of the electrical grid.

Transmission towers not only support the transmission lines but also play a critical role in minimizing power loss, enhancing system reliability, and ensuring safety. Transmission line tower manufacturers in India are vital contributors to the country's growing energy infrastructure, providing high-quality, durable towers that support the expanding demand for electricity.

At KP Green Engineering Limited, we specialize in the design and manufacturing of high-quality transmission towers. Our products are built to meet international standards for safety, durability, and performance, ensuring that they support the efficient transmission of power. As a trusted leader in the industry, KP Green Engineering Limited is committed to delivering innovative solutions to help enhance the energy infrastructure, both in India and beyond.

By understanding the different types of transmission towers and their functions, we gain a deeper appreciation for the complex systems that power our modern lives.

#transmission line tower#Types of towers#electrical tower#transmission line tower manufacturers in India

0 notes