#wfi storage and distribution

Explore tagged Tumblr posts

Text

Purified Water Storage and Distribution Systems Ensuring Quality and Efficiency

In industries requiring high standards of hygiene, purified water storage and distribution systems play a pivotal role. These systems ensure the safe storage and efficient delivery of purified water to critical points of use. Their importance is particularly evident in sectors such as pharmaceuticals, biotechnology, and food processing, where water purity directly impacts product quality and compliance with regulatory standards.

What Are Purified Water Storage and Distribution Systems?

The systems are designed to maintain the quality of water after it has been treated. These systems prevent contamination during storage and distribution, ensuring that water remains free from impurities, microorganisms, and particulate matter. Constructed using high-grade stainless steel or other corrosion-resistant materials, these systems are built to withstand rigorous operational demands.

Key Components

Storage Tanks: Specially designed tanks with polished interiors are used to store purified water while minimizing the risk of contamination.

Distribution Loops: These loops ensure continuous circulation of water, maintaining its quality and preventing microbial growth.

Pumps and Valves: Sanitary-grade pumps and valves regulate water flow and prevent backflow or contamination.

Instrumentation and Controls: Advanced sensors and control systems monitor parameters such as temperature, conductivity, and flow rate to ensure optimal operation.

Sanitization Mechanisms: Features like UV systems or chemical dosing units are included to maintain water sterility.

Benefits

Maintained Purity: These systems ensure water remains free from impurities, safeguarding critical processes.

Regulatory Compliance: Designed to meet stringent standards, they help industries comply with guidelines set by authorities such as the FDA or WHO.

Operational Efficiency: Continuous circulation prevents stagnation, reducing the risk of microbial growth and ensuring uninterrupted operations.

Durability: High-quality materials and robust designs ensure long-lasting performance with minimal maintenance.

Cost-Effective Solutions: By minimizing wastage and downtime, these systems contribute to overall cost savings.

Applications

Pharmaceutical Industry: Ensuring water used in manufacturing and laboratory processes meets stringent quality standards.

Biotechnology: Providing water for cell culture and other sensitive applications.

Food and Beverage: Maintaining water purity for cleaning, processing, and packaging operations.

Healthcare: Supplying purified water for sterilization, dialysis, and other medical purposes.

Maintenance and Best Practices for Optimal Performance

Regular maintenance is essential to ensure the efficiency and longevity of purified water storage and distribution systems. The following practices are recommended:

Scheduled Sanitization: Regular cleaning and sanitization prevent microbial contamination.

Component Inspection: Routine checks of tanks, pumps, and valves ensure all parts are functioning correctly.

Instrumentation Calibration: Periodic calibration of sensors ensures accurate monitoring and control.

Monitoring Water Quality: Continuous testing for parameters like conductivity and microbial content helps maintain compliance.

Documentation: Maintaining detailed records of maintenance activities aids in audits and troubleshooting.

Why Industries Rely on Purified Water Storage and Distribution Systems

The reliability of purified water storage and distribution systems is crucial for maintaining process integrity and product quality. These systems not only protect against contamination but also ensure compliance with industry standards. Their ability to provide consistent and high-quality water makes them indispensable for industries where water purity is non-negotiable.

In conclusion, purified water storage and distribution systems are at the core of efficient industrial operations that demand high standards of water quality. Their robust designs, advanced features, and efficient performance make them essential for meeting the diverse needs of modern industries.

SWJAL PROCESS is a leading purified water storage and distribution system manufacturer in India, offering advanced solutions tailored to industry-specific requirements.

0 notes

Text

Aryan Engineers - Rely on our Multi Cartridge Filter to Remove Impurities Easily & Affordably

As a business owner, it is not only important to have the right equipment to ensure quality production, but it is also essential to know what kind of equipment to choose. Here, we will discuss the importance of choosing the right WFI storage and distribution system, bag filter, multi-cartridge filter, and ointment manufacturing vessel for your business. We will also introduce you to Aryan Engineers, a trusted brand that specializes in these products.

A WFI Storage and Distribution System is essential for pharmaceutical and biotech businesses. These systems are used to store and distribute Water for Injection (WFI), which is a highly purified water used in the manufacture of pharmaceuticals. Choosing the right WFI Storage and Distribution System is crucial to ensure that your business complies with regulatory requirements. Aryan Engineers offers high-quality WFI Storage and Distribution Systems that are designed to meet the specific needs of pharmaceutical and biotech businesses.

A bag filter is a simple and cost-effective way to remove impurities from liquid or gas. Aryan Engineers is a top bag filter manufacturer in India that provides high-quality bag filters to various industries such as pharmaceuticals, food and beverage, and chemical. Aryan Engineers' bag filters are designed to provide efficient and reliable filtration solutions that meet your specific needs.

Get Perfectly Processed Ointments Every Time with Aryan Enginneers Manufacturing Vessels

A multi-cartridge filter is another type of filtration system that is used to remove impurities from liquid or gas. Aryan Engineers is a reliable multi cartridge filter supplier in India that offers a wide range of multi-cartridge filters to various industries. Aryan Engineers' multi-cartridge filters are designed to provide high-efficiency filtration and maximum throughput while maintaining low-pressure drop and easy maintenance.

An ointment manufacturing vessel is essential for pharmaceuticals, cosmetics, and other similar industries. This vessel is used for mixing and processing ointments, creams, and other semisolids. Aryan Engineers is a leading ointment manufacturing vessel manufacturer that offers high-quality vessels that comply with the regulatory requirements of these industries. Their ointment manufacturing vessels are designed to provide efficient mixing and processing, easy cleaning, and low maintenance.

#WFI Storage and Distribution System#bag filter manufacturer in India#multi cartridge filter supplier in India#ointment manufacturing vessel manufacturer

0 notes

Text

Pharmaceutical Water: Innovations in Purification Technologies

Pharmaceutical water is an essential component in the production of pharmaceuticals, used in various stages of drug manufacturing including formulation, synthesis, and as a cleaning agent for equipment and containers. Ensuring the purity and quality of pharmaceutical water is crucial as any contamination can compromise the safety and efficacy of pharmaceutical products.

Pharmaceutical water is classified into several types based on its intended use and required quality attributes. The most common types include Purified Water (PW), Water for Injection (WFI), and Sterile Water for Injection (SWFI). Each type has specific standards and regulatory requirements that must be met to ensure it is free from contaminants, including microorganisms, endotoxins, and chemical impurities.

Purified Water (PW) is used in the preparation of non-parenteral products and for cleaning processes. It is produced by methods such as reverse osmosis, distillation, or deionization, which remove dissolved solids, organic matter, and microorganisms. PW must meet stringent microbial limits to prevent contamination in pharmaceutical processes.

Water for Injection (WFI) is the highest quality of pharmaceutical water, used in the manufacture of parenteral products where the presence of contaminants can pose serious risks to patients. WFI is produced by distillation or reverse osmosis followed by ultrafiltration to ensure the removal of endotoxins, which are toxic substances produced by certain bacteria. The production and storage of WFI require meticulous control to maintain its quality, including the use of stainless steel systems and regular monitoring for microbial contamination.

Sterile Water for Injection (SWFI) is WFI that has been sterilized to ensure it is free of all viable microorganisms. It is used in applications requiring sterility, such as diluting or dissolving drugs for intravenous administration.

The production of pharmaceutical water involves rigorous processes and stringent quality control measures. Compliance with pharmacopeial standards, such as those set by the United States Pharmacopeia (USP) and the European Pharmacopoeia (EP), is mandatory. These standards specify the acceptable levels of impurities and provide guidelines for the production, storage, and distribution of pharmaceutical water.

Maintaining the integrity of pharmaceutical water systems requires regular monitoring, validation, and maintenance. This includes routine testing for microbial contamination, endotoxin levels, and chemical impurities. Advanced purification technologies, such as membrane filtration, ultraviolet (UV) irradiation, and ozone treatment, are often employed to ensure water quality.

In conclusion, pharmaceutical water is a critical element in the drug manufacturing process, requiring meticulous production and quality control to ensure the safety and efficacy of pharmaceutical products. By adhering to regulatory standards and employing advanced purification techniques, the pharmaceutical industry ensures that water used in drug production meets the highest quality standards.

0 notes

Text

Stage-of-use Filters In Pharmaceutical Drinking water Methods

FINAL FILTRATION | Microbes REDUCTION/Elimination | FILTERS IN WATER Cure Programs | PHARMACEUTICAL WATER | PARTICLE FILTRATION The purpose of pharmaceutical water procedure operators is to make germs-no cost drinking water that satisfies or exceeds needed purity benchmarks. Water programs use several filters to guard procedure elements and also to guarantee that the water dispensed to be used is freed from bacteria and most other particle contaminants.

WFI devices employing distillation coupled with storage and distribution techniques which have been kept at elevated temperatures want no more filtration since the water has become rendered sterile which is managed inside a sterile point out with warmth. Having said that, Purified H2o systems might use either warmth or filtration as the ultimate procedure step all through distribution to details of use. Some systems might also make use of UV lights for germs Command, and put in filters once the units to capture mobile particles. By: Important Course of action Filtration on May possibly 16th, 2019 Print/Conserve as PDF Stage-of-use Filters in Pharmaceutical Drinking water Programs Ultimate FILTRATION | Germs REDUCTION/Elimination | FILTERS IN WATER TREATMENT Programs | PHARMACEUTICAL WATER | PARTICLE FILTRATION

youtube

The goal of pharmaceutical h2o technique operators is to generate micro organism-cost-free water that satisfies or exceeds necessary purity criteria. Drinking water methods use quite a few filters to safeguard method factors and also to guarantee the h2o dispensed for use is freed from microbes and most other particle contaminants. WFI systems making use of distillation coupled with storage and distribution methods which have been held at elevated temperatures need no added filtration For the reason that h2o is rendered sterile and is taken care of inside a sterile condition with warmth. Even so, Purified H2o methods may well make use of both warmth or filtration as the ultimate therapy phase all through distribution to points of use. Some programs could also make use of UV lights for microorganisms Command, and install filters after the units to capture cell debris. Purified Drinking water _ H2o for Injection Procedure Style (Distillation) Due to lots of possible entry points for germs into any technique, final filtration utilizing Pharmaceutical Grade (also called sterilizing grade) membrane filters will frequently be used in ambient temperature pharmaceutical water techniques at the point of use. Standard sterilizing grade filters used in water systems are rated to remove particles and bacteria which are 0.22 or 0.1 microns or larger in size. Some systems may utilize a filter to eliminate endotoxins (mobile fragments). Ultrafilters or charge-modified filters will be the frequent choices for this function. Significant System Filtration presents many merchandise to meet the necessities for bioburden reduction and sterilizing filtration. Biopharmaceutical Grade filters are bioburden reduction filters produced using symmetric or asymmetric polyethersulfone (PES), polyvinylidene fluoride (PVDF), and Nylon six,6 membranes. Pharmaceutical Quality items consist of membrane filters made from asymmetric PES and Nylon six,6. Both of those can be obtained with either a 0.one μm or 0.22 μm pore dimension ranking and also bigger pore dimensions. To know more details visit here: ELECTRO DE IONISATION

0 notes

Text

WFI TANK/SKID

The distribution system is the core unit of the whole pharmaceutical water system, and its main function is to ensure that the pressure, flow and temperature delivered to the process pipeline meet the process production requirements. The system uses online monitoring instruments such as flow, pressure, temperature, conductivity and TOC to conduct safety performance, real-time monitoring and trend analysis of water quality, and effectively control the load of microorganisms in water through periodic disinfection or sterilization. In addition, sampling valves shall be installed on the water supply starting point, water pipeline and end pipeline of the entire distribution system for water quality sampling. The whole system is mainly composed of inverter, exchanger, sampling valve, diaphragm valve, sanitary pipe fittings, online monitoring instrument and other supporting control systems.

Design Features of WFI Tank/Skid

◆Integrated design, simple operation and convenient management.

◆Modular structure, saving space.

◆ Ensure that there is turbulence in the circulation pipeline loop,

and the flow rate is>1m/s.

◆Frequency conversion control, the circulation pipeline circuit maintains positive pressure.

◆Online monitoring of temperature, pressure, flow and other technical indicators, alarm and discharge of unqualified water.

◆Operation, disinfection and online monitoring functions are integrated

◆ Equipment manufacturing meets GMP verification requirements.

◆Provide 4Q electronic verification documents.

HOW DOES PW WFI TANK/SKID WORKS?

Water for injection storage and distribution systems should be periodically sterilized at the temperature of ≥ 121 ° C. The WFI storage and distribution systems may be sterilized using superheated water or pure steam.

0 notes

Text

High purity water system service provider in India

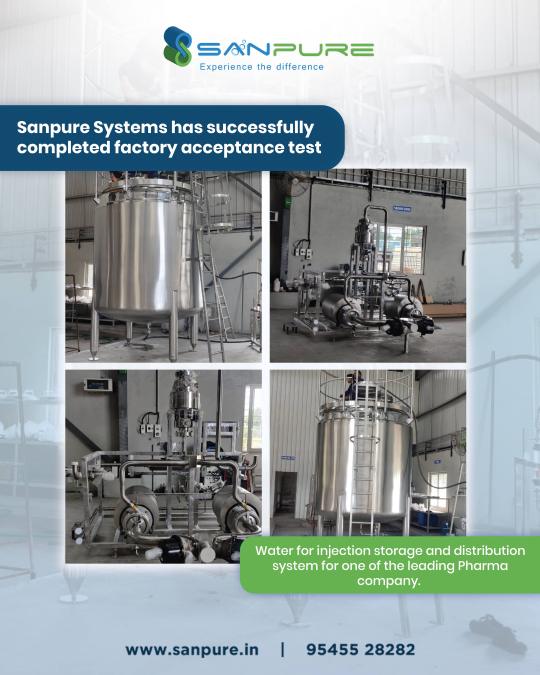

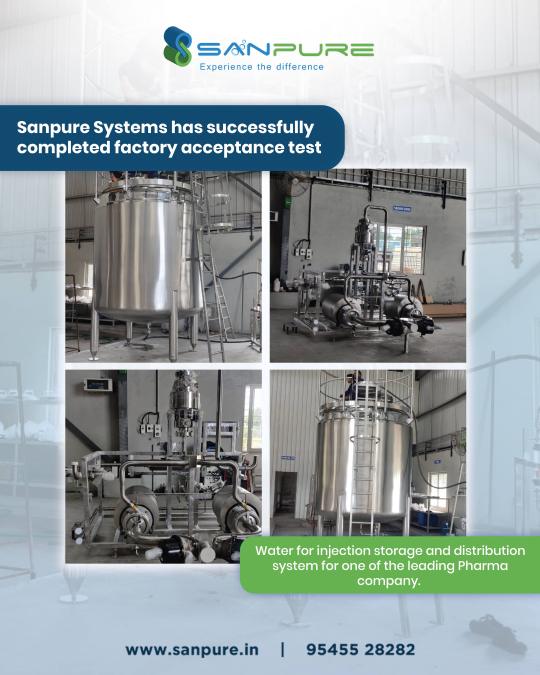

Sanpure Systems has successfully completed factory acceptance test for Water for injection storage and distribution system for one of the leading Pharma companies in Hyderabad. We are pleased to share with you few snippets of our system which has been manufactured at our new fully integrated manufacturing unit which is based out of Hyderabad. Here are few highlights of the system: 1. WFI Storage tank, capacity of 10000 Liters. 2. Online TOC measurement 3. ASME BPE, SF4 Finish piping 4. Provision of automatic pure steam sterilization 5. Fully automatic system, with SCADA of 21CFR Part 11 compliance. For more information

Visit our website - www.sanpure.in Contact us at - 9545528282

#sanpure #sanpuresystems #high #purityfilteration #waterfilteration #pharma #api #formulation #biotechnology #pharmaindustry #pharmamanufacturer #engineering #manufacturer #industries

0 notes

Text

High Purity Media System Market: Global Market Estimation, Dynamics, Regional Share, Trends, Competitor Analysis

Global High-purity media system: Market Overview:

High purity media are vital parts in the production process of the pharmaceutical, food, cosmetics, diagnostics and medical device enterprises. High purity media systems are in the concentration of inspections by administrative experts and of client reviews. The characterized qualities must be given in dependable amounts and should be subjectively reproducible.

High Purity Media Systems Storage and Distribution Systems for High-purity Media Pharmatech Pure Media Systems are intended for storage and distribution of High-purity Media like filtered and highly cleaned purified and highly purified water or water for infusion (WFI) and pure steam (PS). Generation Systems for Purified and Highly Purified Water Pharmatech are intended for purify and highly purified water. The high purity media system Control the quality of water, specifically, the microbiological quality, is a major concern and the pharmaceutical business devotes its resources to the improvement and support of water cleaning system in the capacity and distribution.

The high purity media system helps to design, supply, installation, and validation of pure water. Storage tanks and appropriation pipework frameworks are potential sources of contamination, especially from bacteria. Good design practice and proper maintenance regimes are needed to minimize problems. Different strategies can be utilized to keep away from quality degradation during capacity and distribution of the profound water system.

Global High-purity media system: Market Dynamics:

The high purity media system market is driven by mainly pharmaceuticals and biopharmaceuticals industry. An increase in demand for safety and quality of product from pharmaceuticals leads to a rise in demand of high purity media system. The high purity media system has the wide range of use in various industries fuel the demand of the market. Further, the process chain, up to clean and sterilization, purification of water leads to a rise in the demand of high purity media system.

Want to know the obstructions to your company’s growth in the future? Request a Brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=24158

The growth in various industries such as food and beverages, chemical, pharmaceutical industry are the factors that lead to a rising in demand of high purity media system. Moreover, it has a broad range of its applications such as waste water removal treatment, taste and odor removal leads to a rise in the demand for high purity media system. Macroeconomic factors such as an increase in per capita income, changing lifestyle, literacy rate, and rapid rate of urbanization are the factors that lead to propel the demand for high purity media system.

Global High-purity media system: Key Players:

The prominent key players for high purity media system are

Bosch Packaging Technology

Spirax Sacro

Critical Process Filtration Inc.

Global High-purity media system: Segmentations:

Based on the end use, the global high purity media system market is segmented into:

Pharmaceutical

Cosmetic

Food and Beverages

Healthcare

Water treatment

Oil and gas

Microelectronic

Based on the applications, the global high purity media system market is segmented into:

Arsenic removal

Tate and odor removal

Chlorine removal

Waste Water Treatment

Based on the regions, the global high purity media system market is segmented into:

North America

Latin America

Eastern Europe

Western Europe

Japan

Asia Pacific excluding Japan

The Middle East and Africa

0 notes

Text

Water for Injection A Critical Component in Pharmaceutical Processes

Water for Injection (WFI) holds a pivotal role in pharmaceutical and healthcare industries. As a highly purified form of water, WFI is indispensable for producing injectables, parenteral solutions, and other critical formulations. Its stringent quality requirements ensure that it remains free from pyrogens, microbes, and contaminants, making it safe for direct introduction into the human body. The meticulous production and storage of WFI system are essential to maintain its integrity and suitability for use in sensitive applications.

Understanding Water for Injection

It is governed by strict standards set by pharmacopeias such as the United States Pharmacopeia (USP), European Pharmacopeia (EP), and Indian Pharmacopeia (IP). These standards outline precise requirements for conductivity, microbial load, and endotoxin levels. WFI must exhibit high purity with conductivity less than 1.3 µS/cm at 25°C and endotoxin levels not exceeding 0.25 EU/mL.

The primary applications of WFI include:

Parenteral Drug Manufacturing: Used as a solvent for drug formulations administered via injection.

Sterile Product Preparation: Serves as a base ingredient in sterile solutions and suspensions.

Cleaning Processes: Used for sterilizing equipment, containers, and closures in aseptic environments.

Methods of WFI Production

Producing Water for Injection involves advanced purification techniques to meet the required standards. Key methods include:

Distillation: Considered the most reliable method, distillation effectively removes impurities, pyrogens, and bacteria. Multi-effect distillation (MED) and vapor compression distillation (VCD) are commonly used systems.

Reverse Osmosis (RO) with Electrodeionization (EDI): An efficient alternative combining RO and EDI to achieve high purity. This method is often complemented with ultrafiltration to ensure endotoxin removal.

Ultrafiltration: Typically employed in conjunction with other methods, ultrafiltration ensures the elimination of pyrogens and endotoxins from water.

The choice of method depends on the scale of production, energy efficiency requirements, and compliance with regulatory norms.

Storage and Distribution of WFI

Maintaining the quality of Water for Injection post-production is as critical as its generation. Specially designed storage and distribution systems are employed to prevent microbial contamination and ensure consistent quality. Key features include:

Sanitary Design: Stainless steel tanks and piping with smooth, polished surfaces minimize microbial growth.

Temperature Control: Storage systems are often maintained at high temperatures (typically 80°C) to inhibit bacterial proliferation.

Circulating Loops: Continuous circulation prevents water stagnation and maintains consistent quality.

Advanced Monitoring: Real-time sensors and automated controls ensure compliance with quality standards.

Regulatory Compliance and Validation

Regulatory bodies mandate rigorous validation of WFI systems to ensure consistent performance. Validation includes:

Design Qualification (DQ): Verification of system design against user requirements.

Installation Qualification (IQ): Confirmation that the system is installed correctly.

Operational Qualification (OQ): Testing to ensure the system operates within specified parameters.

Performance Qualification (PQ): Evaluation of the system’s ability to produce WFI consistently over time.

Routine maintenance, monitoring, and periodic re-validation are also essential to ensure ongoing compliance.

Significance of WFI in Pharmaceutical Manufacturing

The importance of Water for Injection in pharmaceutical manufacturing cannot be overstated. Its purity and sterility are fundamental to ensuring patient safety and product efficacy. Without adherence to stringent standards, the risks of contamination and adverse reactions increase significantly, compromising the quality and safety of pharmaceutical products.

Pharmaceutical manufacturers must invest in advanced WFI systems that deliver consistent quality while optimizing operational efficiency. The integration of automation and real-time monitoring has further enhanced the reliability and traceability of WFI systems.

Future Trends in WFI Production

As the pharmaceutical industry evolves, innovations in WFI production and management are becoming increasingly critical. Emerging trends include:

Energy-Efficient Systems: New technologies are reducing energy consumption in WFI generation, making processes more sustainable.

Enhanced Automation: Advanced monitoring and control systems improve operational efficiency and regulatory compliance.

Integrated Solutions: Combining WFI production with other water treatment processes for seamless integration and cost efficiency.

The industry’s focus on innovation ensures that WFI production continues to meet the growing demands of pharmaceutical manufacturing.

It remains a cornerstone of pharmaceutical processes, ensuring the highest standards of purity and safety. Its production, storage, and distribution require precision, adherence to stringent norms, and continuous innovation.

Swjal Process Pvt. Ltd. is a leading Water for Injection Plant manufacturer in India, delivering state-of-the-art solutions that align with global standards and support the pharmaceutical industry’s mission of safeguarding health and well-being.

#wfi system#wfi plant#water for injection#pharmacutical industry#high purity water solution#Swjal Process#India

0 notes

Text

Water for Injection Plant Manufacturer

Water for Injection (WFI) is a cornerstone of pharmaceutical and biotechnology industries, where purity and sterility are non-negotiable. From injectable drugs to vaccines, the quality of water directly impacts the safety and efficacy of final products. It is specifically designed to produce ultrapure water that meets stringent global pharmacopeial standards, such as those set by the USP (United States Pharmacopeia) and EP (European Pharmacopoeia).

Choosing a reliable Water for Injection plant manufacturer is crucial to ensure efficient production processes, regulatory compliance, and optimal operational performance.

Understanding Water for Injection (WFI)

It is a highly purified form of water that is free from microorganisms, pyrogens, and endotoxins. Its production involves advanced purification techniques, ensuring it meets the rigorous standards required for pharmaceutical manufacturing. WFI is used in:

Preparation of parenteral solutions (injectable drugs).

Production of biologics, vaccines, and cell therapies.

Cleaning and sterilization of medical equipment.

The unique properties of WFI necessitate specialized systems that guarantee consistent quality while adhering to strict operational and regulatory guidelines.

Key Features of this Plant

High-Purity Production Processes Advanced distillation or reverse osmosis systems are used to produce WFI. Multi-effect distillation (MED) and vapor compression distillation (VCD) are widely preferred due to their reliability in removing contaminants.

Compliance with Global Standards WFI plants must adhere to guidelines outlined by pharmacopeias, including stringent controls for microbial and endotoxin levels.

Sterile Storage and Distribution To maintain purity, WFI is stored in specially designed stainless steel tanks and circulated continuously through sanitary distribution loops to prevent contamination.

Automation and Control Modern WFI systems are equipped with PLC/SCADA automation to monitor critical parameters such as temperature, conductivity, and flow rates in real-time, ensuring optimal performance and regulatory compliance.

Benefits of an Efficient Water for Injection Plant

Consistent Water Quality Advanced purification processes ensure a consistent supply of WFI with ultra-low microbial and endotoxin levels, meeting industry standards.

Regulatory Assurance Fully validated systems simplify compliance with GMP, FDA, and other regulatory requirements, reducing risks during audits.

Energy Efficiency Cutting-edge technologies like vapor compression reduce energy consumption while maintaining high production capacity.

Reduced Downtime Automated systems minimize manual intervention, reducing operational downtime and ensuring seamless processes.

Long-Term Cost Savings Efficient design and operation reduce maintenance costs and energy consumption, providing significant long-term savings.

Why Choosing the Right Manufacturer Matters

Partnering with a trusted Water for Injection plant manufacturer is vital for achieving high performance and reliability. Manufacturers with extensive experience in pharmaceutical water systems bring a deep understanding of industry-specific requirements and challenges.

When selecting a manufacturer, consider the following factors:

Experience and Expertise: Ensure the manufacturer has a proven track record of delivering WFI plants for pharmaceutical and healthcare applications.

Customization Capabilities: Opt for a provider that offers tailor-made solutions to meet your specific production needs and facility layout.

After-Sales Support: Comprehensive services, including validation, calibration, and maintenance, are essential for the long-term reliability of the system.

Use of Advanced Technologies: Innovative features such as energy-efficient distillation units, fully automated control systems, and hygienic designs enhance the performance and durability of the plant.

Applications

Pharmaceutical Manufacturing: Critical for parenteral drugs, vaccines, and biologics.

Biotechnology: Essential for cell culture media preparation and biopharmaceutical production.

Medical Devices: Used in cleaning, sterilizing, and rinsing processes for surgical instruments.

Swjal Process Pvt. Ltd.: Leading the Way in WFI Systems

Swjal Process Pvt. Ltd. stands out as a premier Water for Injection plant manufacturer, offering innovative and reliable solutions tailored to meet the demands of the pharmaceutical and biotechnology sectors. With over 15 years of experience, Swjal specializes in designing and delivering cutting-edge WFI systems that ensure compliance, efficiency, and cost-effectiveness.

Why Choose Swjal Process Pvt. Ltd.?

Proven Expertise: Swjal has a long-standing reputation for delivering high-purity water systems, backed by extensive industry knowledge.

Custom Solutions: Each WFI plant is tailored to meet specific client requirements, ensuring seamless integration and optimal performance.

Advanced Technology: The use of state-of-the-art components, including multi-effect distillation units and automated control systems, ensures reliability and efficiency.

Comprehensive Support: From installation and validation to regular maintenance, Swjal offers end-to-end services to guarantee uninterrupted operations.

Conclusion

The demand for high-purity Water for Injection in the pharmaceutical and biotechnology industries underscores the need for reliable, efficient, and compliant systems. A well-designed WFI plant not only ensures consistent water quality but also supports sustainable and cost-effective operations.

Swjal Process Pvt. Ltd. is a leading Water for Injection plant manufacturer in India, delivering cutting-edge solutions that empower businesses to achieve excellence in pharmaceutical water management.

#wfi#water for injection#pharmacutical grade water generation plant#biotech industry#costmetic industry#Swjal process

0 notes

Text

The Importance of High-Quality Water in the Pharmaceutical Industry

The pharmaceutical industry is heavily reliant on water, particularly high-quality pharmaceutical grade water. This water is essential for various applications, including formulation processes, cleaning equipment, and, most importantly, as an ingredient in drug manufacturing. In order to ensure the safety and efficacy of pharmaceutical products, the generation and management of this water must adhere to stringent quality standards.

Pharmaceutical grade water is classified into several categories, each with specific quality requirements. Purified Water (PW) is used in many pharmaceutical processes, while Water for Injection (WFI) is used for parenteral preparations, where sterility is paramount. Highly Purified Water is also used in specific applications, with characteristics designed to minimize risk to patient health. It is critical that these types of water are generated using state-of-the-art technologies to meet industry regulations.

The generation process for pharmaceutical grade water begins with the careful selection and preparation of source water. Pre-treatment methods are typically employed to remove physical impurities and reduce the burden on subsequent purification steps. These methods may include various filtration techniques and chemical treatments, allowing for effective removal of unwanted substances. This pre-treatment lays the groundwork for the advanced purification processes that follow.

Among these purification processes, reverse osmosis (RO) stands out as a highly effective method for generating pharmaceutical grade water. RO systems utilize specialized membranes that reject contaminants, including salts and other small particles, ensuring that the produced water meets strict purity criteria. Distillation is another traditional method that remains vital in the generation of WFI, as it effectively eliminates a wide range of impurities and ensures sterility.

Maintaining the quality of pharmaceutical grade water does not end with purification. Proper storage and distribution are essential to uphold water integrity. Storage tanks must be designed to prevent contamination, utilizing materials that do not leach harmful substances into the water. The distribution systems, encompassing pipes and pumps, must undergo routine cleaning and sanitization to prevent microbial growth.

The implementation of rigorous monitoring protocols is fundamental for assuring the quality of the water. Testing for key parameters, including microbial contamination and chemical content, is performed regularly. Automated monitoring systems facilitate real-time tracking and ensure that any deviations from acceptable quality standards can be addressed swiftly. Regular maintenance of testing equipment is also necessary to guarantee the accuracy of results.

Personnel training is crucial in the successful operation of pharmaceutical grade water generation plants. Staff must be equipped with the knowledge and skills necessary to effectively manage the complex systems involved. Continuous professional development and adherence to regulatory changes are essential for maintaining high standards within the facility.

Quality assurance procedures play a pivotal role in the ongoing assessment and improvement of production processes. These procedures encompass regular audits and inspections, which ensure compliance with both internal practices and external regulatory standards. A culture that prioritizes quality at all operational levels contributes significantly to the effective generation of pharmaceutical grade water.

In summary, the generation of pharmaceutical grade water is a critical aspect of the pharmaceutical industry, ensuring that products are manufactured safely and effectively. Advanced technologies, rigorous monitoring, and comprehensive training programs work in tandem to maintain the highest quality standards. Swjal Process is recognized as a leading manufacturer of pharmaceutical grade water generation plants in India, providing essential solutions for the sector.

#water for injetion#purified water treatment plant#pharmacutical grade water#Swjal Process#Manufacturers#India

0 notes

Text

Key Standards and Regulations for Water for Injection (WFI)

Water for Injection (WFI) plays a critical role in pharmaceutical manufacturing, and its production and use are governed by stringent standards and regulations. These guidelines are designed to ensure that WFI is free from contaminants, pyrogens, and microorganisms, safeguarding the integrity and safety of pharmaceutical products. This article explores the key standards and regulations that govern WFI and their significance in pharmaceutical applications.

What Makes WFI Unique in Pharmaceutical Applications?

Unlike regular purified water, WFI is held to the highest standards of purity due to its direct contact with sensitive pharmaceutical products, including injectables. It must meet specifications for:

Conductivity: A measure of ionic content.

Microbiological Purity: Absence of harmful microorganisms.

Endotoxin Levels: Pyrogen-free status.

The production, storage, and distribution of WFI must be carefully controlled to prevent contamination.

Pharmacopeial Standards for WFI

The production and quality of WFI are regulated by international pharmacopeias, which provide clear specifications.

United States Pharmacopeia (USP) USP defines WFI as highly purified water obtained through distillation or an equivalent process. It specifies:

Endotoxin levels of ≤0.25 EU/mL.

Conductivity requirements of ≤1.3 µS/cm at 25°C.

Zero microbial content in 100 mL samples.

European Pharmacopeia (EP) EP recognizes both distillation and membrane-based processes for WFI production. However, it emphasizes the need for additional validation for non-distillation methods.

Japanese Pharmacopeia (JP) JP aligns closely with USP and EP but has its own detailed requirements for WFI storage and distribution.

These pharmacopeias establish benchmarks for global manufacturers to ensure consistency and quality in WFI production.

Key Regulatory Authorities and Guidelines

FDA (U.S. Food and Drug Administration) The FDA ensures compliance with Current Good Manufacturing Practices (cGMP) for WFI production. Key requirements include validation of equipment, monitoring of production processes, and regular documentation.

EMA (European Medicines Agency) EMA focuses on compliance with EP standards and requires stringent validation for alternative production methods like reverse osmosis.

WHO (World Health Organization) WHO provides global guidelines for WFI, particularly for regions with developing pharmaceutical industries.

ISPE Baseline Guides The International Society for Pharmaceutical Engineering (ISPE) offers detailed recommendations for WFI system design, focusing on contamination control and energy efficiency.

Validation and Documentation Requirements

Regulatory compliance involves rigorous validation and documentation at every stage of WFI production. Key steps include:

Design Qualification (DQ): Ensuring that the system design meets regulatory requirements.

Installation Qualification (IQ): Verifying that equipment is installed correctly.

Operational Qualification (OQ): Confirming that the system operates within specified parameters.

Performance Qualification (PQ): Demonstrating consistent performance under actual production conditions.

Comprehensive documentation of these steps is essential to pass inspections and audits.

Challenges in Meeting Standards

Adhering to regulatory standards comes with challenges, including:

Stringent Validation: Extensive testing and documentation require significant time and resources.

High Costs: Complying with cGMP and pharmacopeial standards involves investment in high-quality equipment and training.

Evolving Regulations: As standards evolve, systems must be updated to maintain compliance.

Future Directions in Regulatory Compliance

Advancements in monitoring technologies are making compliance easier. Automated systems with real-time monitoring capabilities ensure adherence to parameters like conductivity and microbial levels. Additionally, sustainability-focused regulations are encouraging the adoption of energy-efficient WFI production methods.

Conclusion

Meeting regulatory standards for WFI is non-negotiable in pharmaceutical manufacturing. Compliance ensures the safety and efficacy of pharmaceutical products, upholding the trust of healthcare providers and patients alike.

Swjal Process is a leading pharmaceutical-grade water generation and distribution plant manufacturer in India.

#wfi#water for injection plant#water for injection system#water for injection generation#water for injection distribution system#pharmacutical industry#biotech industry#Swjal Process#Water solution company in India#Water treatment process plant manufacturers

0 notes

Text

Visit our website - www.sanpure.in Contact us at - 9545528282

Sanpure Systems has successfully completed factory acceptance test for Water for injection storage and distribution system for one of the leading Pharma companies in Hyderabad.

We are pleased to share with you few snippets of our system which has been manufactured at our new fully integrated manufacturing unit which is based out of Hyderabad.

Here are few highlights of the system: 1. WFI Storage tank, capacity of 10000 Liters. 2. Online TOC measurement 3. ASME BPE, SF4 Finish piping 4. Provision of automatic pure steam sterilization 5. Fully automatic system, with SCADA of 21CFR Part 11 compliance.

For more information Visit our website - www.sanpure.in Contact us at - 9545528282

#sanpure#sanpuresystems#high#purityfilteration#waterfilteration#pharma#api#formulation#biotechnology#pharmaindustry#pharmamanufacturer#engineering#manufacturer#industries

1 note

·

View note