#well it's assembled and tested today to be precise

Explore tagged Tumblr posts

Text

Got my laser cutter today what should I make

4 notes

·

View notes

Text

The Hour of Truth

The spell made people tell the truth.

It was expensive, but not so expensive it didn't find its use. The intelligence services spent enormous amounts of money on it, it was part of every serious interview, and the legal system relied on it.

This isn't a story about one of those. It's a story about Michael and Sarah, in their dining room with a ReadySpell, engaged to be married but without a date set. It was a gift they were giving to themselves, something that would reassure them, a chance to explore each other. Michael was cheery about the whole thing, but Sarah was decidedly less so.

She unrolled the parchment onto the table they'd assembled from a kit three months prior. She read the instructions on the card, which were dead simple, then placed her fingers on two corners of the parchment, with Michael doing the same. The complex lines in the center glowed, a circle burst into flames for half a second, and then it went still and dull.

"That's it then?" Michael asked. He withdrew his fingers. "That's the whole thing? I somehow thought it would be ... more."

"We're supposed to test it," she said, withdrawing her own fingers and picking up the card. "Say something false. There are test phrases."

"Two plus two is ... hrm. Four." He frowned. "I could feel a resistance. What an odd feeling."

"My head ... no, can't do it," Sarah said, reading the first part from the card. "It says, 'my head exploded today'. I can't finish the sentence."

"Well then," Michael said. He spread his hands, palms up. "Here we are."

"One hour," Sarah said with a nod. She placed the instruction card down and flipped the small hourglass that had come with the kit.

"Do you love me?" Michael asked.

"I do," Sarah replied. She said it solemnly. "Do you love me?"

"Of course," Michael replied. "Well, it would have been extremely embarrassing if we hadn't answered those correctly." He tapped his fingers on the table for a moment. "How many children do you want?"

"Two, or maybe three," said Sarah.

"I want two, but could go for a third," said Michael.

They had talked about it before. You didn't get engaged after four years of dating without having had those conversations at some point.

"It's interesting, isn't it?" asked Michael. "We know each other, but I suppose there's always at least a little doubt until you're under the spell. A difference between knowing and knowing."

"We only have an hour," said Sarah. "Rapid fire?"

"Sure," said Michael with a nod.

"Do you want to spend the rest of your life with me?" asked Sarah.

"Yes," said Michael. "You?"

"Yes. Will you stay faithful to me?"

"Yes. You?"

"Yes. Do you have unresolved feelings for anyone?"

"No. You?"

"No." Sarah paused. "How often do you need to have sex?"

"Need?" asked Michael. "I'm not sure I even agree with that question. But I can answer want, which is what I've told you before, maybe two or three times a week."

"How often does it end up being that we have sex?" asked Sarah.

"Less than that," said Michael. He frowned at her. "Can you do that, ask questions you know the answer to? I suppose so."

"It's two point one times a week," said Sarah.

"How can you be that precise?" asked Michael.

"I've been tracking it," said Sarah. She folded her hands in front of her. "You know I like data. And I'll need to track it when we're trying for children."

"Is that the only reason you've been tracking it?" asked Michael. He had leaned back in his chair slightly.

"I was worried that it might come up," said Sarah with a slight sigh. "I was worried that we might get in an argument and you would say that we weren't having sex enough, and I wanted pre-emptive ammunition."

The spell did not actually compel her to say all that, but he could have poked and prodded and gotten around vague answers, so it was best to just tell him. She wasn't proud of it.

"How many times a week would be the right number for you?" asked Michael.

"Once a week," Sarah replied, which was what she'd told him before. "In an ideal world, I suppose."

"And you're saying that it's two?" asked Michael.

"Two point one," said Sarah.

"Is this ... a problem?" asked Michael. "I mean, it should be a compromise between us."

"It is a compromise," said Sarah. "And it's one that I'm fine with." She was coming off as defensive, she knew, but it was the truth, the spell still had plenty of time left.

It seemed to take him a moment to recognize that.

"You don't resent me?" asked Michael.

"No," said Sarah. She let a beat pass, to give him a chance to ask another question, then reached down to her purse and pulled out her notebook.

"Is that a notebook?" asked Michael.

"I had a few things prepared," said Sarah.

"Ah," said Michael. "Well, I'm an open book." He smiled at her.

Sarah looked down at the notebook. "Where were you last Thursday?"

"I ... need to think about that," said Michael. "I was working late, preparing for the pitch. I sent you a message, didn't I?"

"You did," said Sarah. "What happened after the pitch?"

"I came home," said Michael.

"Did you do anything else between finishing work and coming home?" she asked.

"No," he said.

She looked down at her notebook again. "Last June you went on a work trip, what did you do together?"

Michael looked at her for a moment. "We went out to dinner," he said, and anticipating the follow-up questions, he continued, "Afterward, on the second night we were there, the guys wanted to go to a strip club, and they did, but instead of doing that, I went back to my hotel room and sat there alone, because I knew you wouldn't understand that it's just ... a thing men do. But I didn't go to the strip club, I didn't see naked women, I just sat there watching a movie."

"Are you annoyed with me?" Sarah asked.

"Yes," Michael replied. "You don't trust me, and it's important, if we're getting married, for you to trust me."

"You cheated on me," Sarah said.

Michael pursed his lips. "Does it do us any good to have this conversation again with the spell active?"

"Probably, yes," Sarah said. "It would let me know you were honest."

Michael nodded. "It was one time. I had been drinking. There was something electric in the air, I don't know, this raw attraction that I had never felt, and I thought about you, and the thought seemed to just slide right off my brain. And then afterward, I felt so much guilt, like I had destroyed my entire life, and we'd only been dating for six months, so it felt like it was a sign, like I had revealed, too late, what you meant to me."

"When you went to bed with her, you thought that it was casual," Sarah said. "You thought that you would get away with it."

"Now hold on," Michael said, leaning forward slightly. "I was the one who told you. No one outed me, no one found anything out, it was my own conscience."

"A month late," said Sarah.

Michael nodded. "A month late. I wish that it had never happened. If it did have to happen, then I wish that I had told you right away. I was an asshole. But I've been faithful to you since then, I haven't done anything else, I ... I love you."

"Do you still think about her?" asked Sarah.

"Every now and then," said Michael. "Every month or two, she comes to mind. Mostly in a negative way."

"Mostly?" asked Sarah.

"Please," said Michael. "I don't want to hurt you. I don't think it's good that you keep dwelling on this, that you won't let this go." He looked down at the scroll, which had curled up slightly. "Is this why you wanted to do this?"

"Yes," said Sarah. "You said 'mostly', what does that mean? Mostly a negative way, which means that sometimes it's a positive way. Explain how."

Michael grit his teeth. "I am telling you, from the bottom of my heart, with a truth spell active, that it's not going to be good for either of us if we go down this path."

"I'm not marrying you unless you answer," Sarah said.

"That's the truth?" asked Michael. "I mean, you could have told me that before, you could have said that without the spell."

"You would have thought I was being manipulative," she replied.

"I think you're being manipulative now," Michael said. "You love me? You forgive me? You want to marry me?"

"Yes, yes, yes," said Sarah. "We're pulling out a rotten tooth, as I see it. I would have pulled it out on my own, if I could have, but I need you, and I need truth."

Michael took a breath. "I love you so much. You mean the world to me. I am so thankful to be marrying you, if that still happens." He took another breath. "The only thing I think, the only positive thought I have about her, is that she was more enthusiastic in bed. But I love you, Sarah, you are the only one I want to be with, it's not something that weighs on me, it's a consideration but it pales in comparison to everything else, you're smart, you're funny, you make me want to be a better man, these past four years I've become a better man."

"There have been times when you think to yourself that she was better in bed than I am?" asked Sarah. She had gone very still. She was swallowing the idea, in the same way that someone might swallow a caltrop.

"No," said Michael. "She wasn't 'better', she just ... wanted it in a way that you didn't. Don't. She was hungry for me in a way that you never are."

Sarah began to cry.

"I'm so sorry," said Michael. "But it doesn't mean anything to me, I told you that, it's an idle thought, it's got nothing to do with marriage, with partnership."

"I think I might be gay," said Sarah.

Michael stared at her. "What?" he asked. "What ... what does that mean?" He looked at the timer, which was still running down. "You said that once a week was what you'd prefer, did you mean with women?"

"No, I ..." she was sniffling, and went to her purse for a tissue, which she used to blot away her tears and wipe liquified snot from where it had gathered on her upper lip. "I enjoy having sex with you, I like the feeling of it. I do. That's true." She said it as though it was almost a revelation to hear it said under the truth spell, as though she wasn't certain that it would pass muster.

"Then what do you mean?" asked Michael. "Do you mean you might be ... bisexual?"

"I felt that heat for a woman," Sarah said. "For several women." She let out a breath. "I never did anything with them, I never even knew if it's what they would have wanted, but ... I don't know. It's confusing."

"But you still want to marry me," said Michael. "Even with that."

"I do," said Sarah. "I love you."

"I love you too," said Michael. He watched her face, as though he could read something there. He looked down at the timer. "Do you think this marriage is a good idea?"

"Yes," she replied. "Yes enough that I didn't have to add qualifications, I guess." She gave a nervous laugh. "Do you?"

"Yes," said Michael.

But as soon as he said it, he wasn't sure that it was true. Did the spell work like that? Could you say something that was untrue after you said it? There was a rising panic inside him, a feeling of being trapped with her that he'd never felt before, not before the affair or after.

"Let's set this aside," she said. "Let's be done with it. Okay?"

Michael nodded. He had wanted to say 'okay', but it wasn't.

123 notes

·

View notes

Text

🎄💾🗓️ Day 11: Retrocomputing Advent Calendar - The SEL 840A🎄💾🗓️

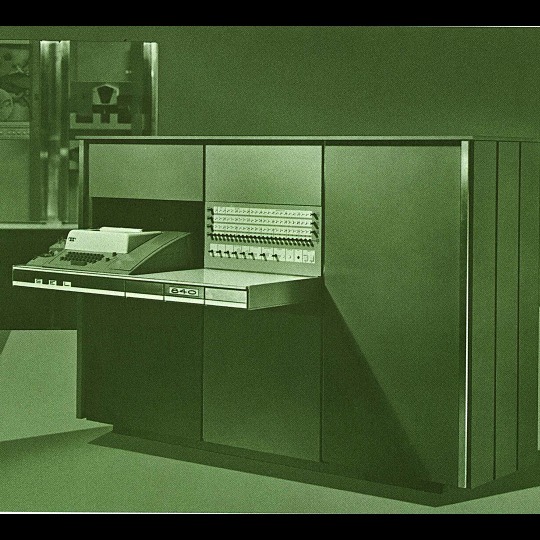

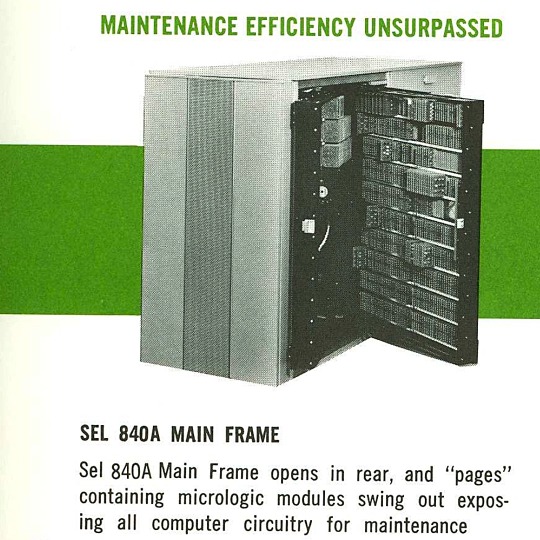

Systems Engineering Laboratories (SEL) introduced the SEL 840A in 1965. This is a deep cut folks, buckle in. It was designed as a high-performance, 24-bit general-purpose digital computer, particularly well-suited for scientific and industrial real-time applications.

Notable for using silicon monolithic integrated circuits and a modular architecture. Supported advanced computation with features like concurrent floating-point arithmetic via an optional Extended Arithmetic Unit (EAU), which allowed independent arithmetic processing in single or double precision. With a core memory cycle time of 1.75 microseconds and a capacity of up to 32,768 directly addressable words, the SEL 840A had impressive computational speed and versatility for its time.

Its instruction set covered arithmetic operations, branching, and program control. The computer had fairly robust I/O capabilities, supporting up to 128 input/output units and optional block transfer control for high-speed data movement. SEL 840A had real-time applications, such as data acquisition, industrial automation, and control systems, with features like multi-level priority interrupts and a real-time clock with millisecond resolution.

Software support included a FORTRAN IV compiler, mnemonic assembler, and a library of scientific subroutines, making it accessible for scientific and engineering use. The operator’s console provided immediate access to registers, control functions, and user interaction! Designed to be maintained, its modular design had serviceability you do often not see today, with swing-out circuit pages and accessible test points.

And here's a personal… personal computer history from Adafruit team member, Dan…

== The first computer I used was an SEL-840A, PDF:

I learned Fortran on it in eight grade, in 1970. It was at Oak Ridge National Laboratory, where my parents worked, and was used to take data from cyclotron experiments and perform calculations. I later patched the Fortran compiler on it to take single-quoted strings, like 'HELLO', in Fortran FORMAT statements, instead of having to use Hollerith counts, like 5HHELLO.

In 1971-1972, in high school, I used a PDP-10 (model KA10) timesharing system, run by BOCES LIRICS on Long Island, NY, while we were there for one year on an exchange.

This is the front panel of the actual computer I used. I worked at the computer center in the summer. I know the fellow in the picture: he was an older high school student at the time.

The first "personal" computers I used were Xerox Alto, Xerox Dorado, Xerox Dandelion (Xerox Star 8010), Apple Lisa, and Apple Mac, and an original IBM PC. Later I used DEC VAXstations.

Dan kinda wins the first computer contest if there was one… Have first computer memories? Post’em up in the comments, or post yours on socialz’ and tag them #firstcomputer #retrocomputing – See you back here tomorrow!

#retrocomputing#firstcomputer#electronics#sel840a#1960scomputers#fortran#computinghistory#vintagecomputing#realtimecomputing#industrialautomation#siliconcircuits#modulararchitecture#floatingpointarithmetic#computerscience#fortrancode#corememory#oakridgenationallab#cyclotron#pdp10#xeroxalto#computermuseum#historyofcomputing#classiccomputing#nostalgictech#selcomputers#scientificcomputing#digitalhistory#engineeringmarvel#techthroughdecades#console

30 notes

·

View notes

Text

ITI Fitter Tools Suppliers and Manufacturers

As we are leading ITI Fitter Tools Suppliers, we offer a comprehensive range of tools designed for professionals in various industries. Our tools are engineered with precision to ensure long-lasting performance and meet industry standards.

Reliable ITI Fitter Tools Suppliers for Every Industry

We are committed to being trusted ITI Fitter Tools Suppliers, delivering premium tools to industries such as manufacturing, automotive, construction, and more. Our tools are known for their durability, accuracy, and reliability, which makes them a preferred choice for professionals across sectors.

Top ITI Fitter Tools Manufacturer Using Cutting-Edge Technology

As a prominent ITI Fitter Tools Manufacturer, we leverage advanced manufacturing techniques to produce high-quality tools that meet stringent quality standards. Our products undergo rigorous testing to ensure they perform well even in the most demanding industrial environments. From basic hand tools to specialized fitter tools, we manufacture everything needed for accurate fitting work.

Wide Range of ITI Fitter Tools Available

Our wide range of fitter tools includes:

Hammers: Precision-designed hammers for heavy-duty fitting tasks.

Files and Rasps:��High-quality files for smooth finishes and shaping.

Measuring Instruments: Vernier calipers, micrometers, and gauges for precise measurements.

Chisels and Punches: Robust chisels and punches for cutting and shaping metal.

Screwdrivers and Wrenches: Essential tools for assembling and disassembling components.

Each tool is carefully crafted using top-grade materials to ensure performance, safety, and durability.

Why Choose Us as Your ITI Fitter Tools Supplier?

There are several reasons to partner with us for your fitter tool needs:

Quality Assurance: We ensure that every tool meets the highest standards of quality and performance.

Competitive Pricing: Our pricing structure is designed to offer great value without compromising on quality.

Custom Solutions: As an experienced ITI Fitter Tools Manufacturer, we offer customized tools for specific industrial requirements.

Reliable Customer Service: We provide support to ensure our clients get the right tools for their needs, with fast delivery times and excellent after-sales service.

How to Contact Us for Your ITI Fitter Tools Needs

If you’re in search of dependable ITI Fitter Tools Suppliers or looking to collaborate with a reputable ITI Fitter Tools Manufacturer, reach out to us today. We ensure the best solutions tailored to your specific project needs. Whether you require standard tools or custom-made equipment, our team is ready to assist with expert advice and top-quality products.

We offers the complete trade tools & machines of fitter trade as per ncvt syllabus. We ensures the quality of our tools as per professional standards in size, length, weight, grip and height as well. TAPARIA, Pie, Kohinoor, ambika, NEW MEN, EVERREADY, EASTMEN, DEWALT, BOSCH are also available LATHE Machine (ALL GEARED) for iti use are available as per syllabus demands C.N.C Milling Trainer at reasonable price are available for iti use .

0 notes

Text

The Ultimate Guide to Setting Up a Professional Kitchen in Coventry

Are you planning a kitchen installation in Coventry for your commercial space or home renovation project? Whether you're launching a restaurant, upgrading your catering setup, or revamping your kitchen at home, creating a well-designed, fully functional space is key to performance and comfort.

At All Kitchens Fitted, we specialize in professional kitchen setups across Coventry and surrounding areas — delivering seamless kitchen installations backed by craftsmanship, precision, and years of experience.

Why a Professional Kitchen Setup Matters

A well-planned kitchen isn't just about looks — it's about flow, hygiene, efficiency, and safety. From layout design to kitchen appliance fitting, every step plays a vital role in your daily operations. Whether it’s a restaurant, café, or personal chef’s workspace, investing in expert kitchen assembly ensures long-term value.

Key Elements of a Professional Kitchen Setup

1. Strategic Layout & Planning

Maximize workspace efficiency with a layout that separates food prep, cooking, cleaning, and storage zones. This minimizes cross-contamination and optimizes workflow.

2. Certified Kitchen Installers

Hiring certified kitchen installers ensures compliance with local regulations and safety codes. Our Coventry-based team is fully trained and certified to manage every detail of your kitchen build.

3. High-Quality Materials & Fixtures

Choose durable, heat-resistant, and easy-to-clean surfaces like stainless steel counters, tile splashbacks, and heavy-duty fittings that stand the test of time.

4. Expert Kitchen Assembly

From cabinets to countertops, sinks to ovens, expert kitchen assembly is essential to guarantee smooth function and durability. At All Kitchens Fitted, our team handles every element with precision.

What We Offer at All Kitchens Fitted

📍 Address: 60 Glenmore Dr, Longford, Coventry CV6 6LZ 📞 Phone: 07774 646118 🌐 Website: www.allkitchensfitted.co.uk 📧 Email: [email protected]

As a trusted name in kitchen installation in Coventry, we provide:

Reliable kitchen installation services for commercial and residential spaces

Full kitchen assembly services, including flat-pack and bespoke fittings

New kitchen installations from scratch

Kitchen appliance fitting for ovens, hobs, extractors, and more

Tailored designs for restaurants, cafes, and catering kitchens

Whether you're fitting a small café or a full-scale restaurant kitchen, we provide seamless kitchen installation solutions that are both stylish and functional.

Why Choose Us?

✅ Local Coventry Experts ✅ Fully Certified Installers ✅ Prompt, Professional Service ✅ Transparent Pricing ✅ 5-Star Rated by Clients

FAQs – Kitchen Installation in Coventry

Q: How long does a kitchen installation typically take? A: It depends on the complexity and size of the project. Most standard installs take between 3–7 days.

Q: Do you handle appliance fitting too? A: Yes, we offer complete kitchen appliance fitting including integration and testing.

Q: Are you licensed and insured? A: Absolutely. Our team includes certified kitchen installers, and we're fully insured for your peace of mind.

Q: Can you help with kitchen design as well? A: Yes, we can assist with layout planning and recommend the best design for your needs.

Get Started Today

Ready to bring your kitchen vision to life? Contact All Kitchens Fitted today for the most trusted kitchen installation in Coventry. We’re here to deliver top-quality results — on time and on budget.

Let me know if you want this turned into a downloadable PDF, or if you’d like help creating social media captions or a Google Business Post to promote it!

#kitchen remodeling coventry#kitchen renovation coventry#kitchen installation services in coventry#Certified kitchen installers Coventry#Kitchen appliance fitting In Coventry#Professional kitchen setup in Coventry

0 notes

Text

What if the energy powering our vehicles and industries left behind nothing but pure water?

Hydrogen fuel cells promise this future, yet their potential has been limited by the high cost and inefficiency of platinum-based catalysts. Today, that’s changing—thanks to a surge in innovative research that could make clean hydrogen energy mainstream.

Hydrogen, the most abundant element in the universe, is a powerful energy carrier. When used in fuel cells, it reacts with oxygen to produce electricity, emitting only water as a byproduct. This positions hydrogen fuel cells as a leading candidate for sustainable transportation and power generation. Yet, two main barriers have slowed their adoption: the need for robust hydrogen infrastructure and, most critically, the prohibitive cost and limited durability of platinum catalysts required for the vital oxygen reduction reaction.

Here’s how recent R&D breakthroughs are reshaping the landscape:

🔹Nitrogen-Coordinated Iron Catalysts: Researchers at Northeastern University have focused on iron atoms surrounded by four nitrogen atoms (ligands), creating a stable and efficient catalyst structure. This setup is well-known, but their work advanced it by introducing a fifth ligand, which dramatically improves the catalyst’s stability and durability—key for real-world fuel cell applications.

🔹Earth-Abundant, Non-Noble Metals: Moving away from rare and expensive platinum, scientists are developing catalysts based on earth-abundant elements like iron and cobalt. These materials are not only cheaper but also widely available, making large-scale deployment of hydrogen fuel cells economically viable. For example, research teams have developed iron, carbon, and nitrogen catalysts that can run fuel cells at high power and a fraction of the cost of platinum-based systems. Similarly, cobalt-nitrogen-carbon catalysts with ultra-fine active sites offer four times the stability of previous non-noble metal catalysts and approach Department of Energy performance targets.

🔹Enhanced Durability and Activity: The new catalysts are engineered for high durability, with some showing fourfold stability improvements over earlier designs. Advanced membrane-electrode assemblies and rigorous real-world testing have demonstrated that these catalysts can withstand the stresses of practical use, maintaining high activity and longevity even under demanding conditions.

🔹Zero Carbon Emissions: All these innovations preserve the environmental promise of hydrogen fuel cells—no carbon emissions are produced during operation, only water. This is a critical factor in global decarbonization strategies and the push toward net-zero emissions.

🔹Cost Reduction and Scalability: By replacing or minimizing platinum content with materials like iron, cobalt, or even silver, researchers have slashed catalyst costs—platinum can account for up to 60% of a fuel cell’s price. These advances directly address the economic barriers to widespread adoption, making hydrogen fuel cells a more realistic alternative to fossil-fuel-powered vehicles and generators.

🔹Rational Catalyst Design: The addition of extra ligands and the precise engineering of catalytic active sites have opened new pathways for the rational design of next-generation catalysts. This approach is expected to further improve performance and bring non-noble metal catalysts closer to, or even beyond, the capabilities of platinum-based systems.

These breakthroughs could revolutionize clean energy, enabling hydrogen fuel cells to power cars, planes, and ships with unmatched efficiency and minimal environmental impact. The implications are vast: from reducing greenhouse gas emissions to creating new markets for green technologies and supporting global energy independence.

How do you see these innovations shaping the future of transportation and energy in your field? What challenges remain for hydrogen fuel cell adoption in your industry? Share your thoughts and let’s discuss the next steps toward a sustainable energy future.

#HydrogenEconomy #FuelCellInnovation #SustainableEnergy #CleanTech #GreenTransport #RandD #FutureOfEnergy #NetZero

0 notes

Text

Essential Tools and Machinery for Efficient Service Delivery by BellevueNebraska

In today’s fast-paced world, having the right tools and machinery can be the difference between an average job and exceptional service. At BellevueNebraska, we understand the importance of equipping our team with industry-grade tools that not only ensure precision but also boost efficiency, safety, and customer satisfaction.

Whether we’re handling a complex service request or a routine job, having the proper tools on hand helps us get the job done right the first time. From diagnostics to repairs, installations, or maintenance, our toolbox is built to tackle both challenges and surprises with professionalism and ease.

In this blog, we’ll walk you through the key tools and machinery we rely on, why they matter, and how they contribute to our trusted service delivery. Plus, we’ve included five of the most frequently asked questions about our equipment and methods — giving you an inside look at how BellevueNebraska stays a step ahead.

Our Core Tool Categories

1. Diagnostic Tools

Before any service begins, it’s important to assess the situation correctly. Diagnostic tools help us pinpoint issues accurately.

Multimeters – Essential for testing electrical systems.

Thermal Imaging Cameras – Detect overheating components or hidden leaks.

Moisture Meters – Help identify water damage in walls, floors, and ceilings.

Inspection Cameras – Perfect for looking inside pipes or wall cavities without invasive demolition.

2. Power Tools

Speed and precision matter. Power tools allow our technicians to execute tasks faster while maintaining control.

Cordless Drills and Drivers – Great for quick assembly and installation.

Angle Grinders – Used in surface prep and metal cutting.

Reciprocating and Circular Saws – Make cutting through various materials efficient.

Impact Wrenches – Ideal for high-torque applications such as loosening rusted bolts.

3. Lifting and Access Equipment

Safety and accessibility are crucial, especially for services involving elevated or tight spaces.

Extension Ladders and Step Ladders – Provide reach without compromising stability.

Portable Scaffolding Systems – Used when working on multi-level structures.

Hoists and Winches – Ensure safe lifting of heavy machinery or parts.

4. Plumbing and HVAC Tools

For plumbing or climate control services, having dedicated tools is non-negotiable.

Pipe Cutters and Threaders – Provide custom fitting solutions on-site.

Drain Augers and Jetters – Used for clearing clogs and blockages efficiently.

Manifold Gauge Sets – Essential for HVAC diagnostics and refrigerant charging.

Vacuum Pumps – Used for evacuating air and moisture from HVAC systems.

5. Safety and Personal Protective Equipment (PPE)

Our tools would be meaningless without safety. We prioritize the well-being of both our technicians and clients.

Hard Hats, Safety Glasses, Gloves – Basic PPE for every site.

Respirators and Dust Masks – Critical when dealing with contaminants or dust.

Fall Arrest Systems – Used when working at height.

Why Tools Matter to Our Customers

Using the right tools doesn’t just make life easier for our team — it directly benefits our customers. Here’s how:

Faster turnaround – Jobs that might take hours with manual tools can be completed in half the time.

Higher accuracy – Precision tools mean fewer mistakes and more dependable results.

Reduced property disruption – Advanced diagnostics and minimally invasive methods help us protect your space.

Long-term savings – Quality service reduces the need for repeat work or future repairs.

Our Machinery at a Glance

In addition to portable tools, BellevueNebraska uses several heavy-duty machines for large-scale or specialized projects:

Mini Excavators – Used for outdoor digging, trenching, or grading tasks.

Concrete Cutters and Mixers – Allow for quick surface modifications or patch jobs.

Mobile Air Compressors – Power pneumatic tools on remote sites.

Generators – Ensure uninterrupted power supply during off-grid jobs.

These investments ensure that we stay self-sufficient, reliable, and ready for any situation that comes our way.

5 Frequently Asked Questions (FAQs)

1. What types of services require heavy machinery?

Heavy machinery like mini excavators and concrete mixers are typically used for outdoor installations, foundation repair, utility line access, and large-scale remodeling. These machines help speed up work while ensuring a high-quality finish.

2. Do you bring all the necessary tools to every service call?

Yes. Our technicians arrive fully equipped for the job. We assess the scope during the booking process and ensure the van is stocked with everything needed — from basic hand tools to specialized equipment.

3. Is your equipment regularly maintained?

Absolutely. We have strict internal policies that require regular calibration, inspection, and maintenance of all our tools and machinery. Well-maintained tools reduce risks and ensure efficiency.

4. How do you ensure safety when using large machinery?

Every operator at BellevueNebraska is trained and certified. We also perform site assessments before beginning any task, use PPE, and follow industry-standard safety protocols to protect both our team and your property.

5. Can I request specific tools or methods for my project?

Definitely! If you have a preference — such as non-invasive diagnostics or eco-friendly tools — let us know when booking. We’re happy to tailor our approach to meet your expectations.

Final Thoughts

At BellevueNebraska, we believe in doing things right. That starts with showing up prepared, equipped, and ready to solve problems efficiently. Our wide range of tools and machinery ensures we’re ready for just about anything — from small fixes to major overhauls.

Choosing a service provider isn’t just about cost — it’s about confidence. With our top-tier equipment, experienced technicians, and a commitment to excellence, you can rest easy knowing your project is in capable hands.

#BellevueNebraska#ProfessionalTools#MachineryMatters#ServiceEfficiency#HomeRepairs#DiagnosticTools#PowerTools#HVACandPlumbing#SafetyFirst#QualityService

0 notes

Text

Aceforge: A Leading Force Among Automobile Spare Parts Manufacturing Companies

In today’s dynamic automotive landscape, the demand for reliable, high-performance components has never been higher. From personal vehicles to heavy-duty commercial fleets, the need for quality spare parts plays a crucial role in vehicle longevity and efficiency. Among the numerous automobile spare parts manufacturing companies, Aceforge has emerged as a trusted name, driven by innovation, engineering excellence, and uncompromising quality.

A Legacy of Precision and Performance

Aceforge has built a solid reputation over the years by focusing on one core principle: delivering precision-engineered parts that perform under pressure. With a strong foundation in mechanical engineering and metallurgy, the company specializes in manufacturing critical components that power vehicles across the globe.

Each product is designed with durability, safety, and performance in mind—factors that define the best automobile spare parts manufacturing companies.

Advanced Infrastructure and Cutting-Edge Technology

At Aceforge, world-class manufacturing meets innovation. Our production units are equipped with the latest CNC machines, automated assembly lines, and high-capacity testing labs. This infrastructure allows us to maintain tight tolerances and high output volumes without compromising on quality.

In addition, our in-house R&D team works closely with engineers and designers to continually improve product designs, integrate new materials, and adapt to the latest automotive standards. Whether it's adapting to electric vehicle components or enhancing fuel efficiency through lightweight parts, Aceforge stays ahead of the curve.

Quality You Can Rely On

What sets Aceforge apart from other automobile spare parts manufacturing companies is our unwavering commitment to quality. Every component goes through multiple stages of inspection—from raw material sourcing to final product testing. Our ISO-certified quality management system ensures that each part adheres to international benchmarks for safety, performance, and reliability.

We also work closely with OEMs and aftermarket distributors to deliver parts that meet exact specifications. This attention to detail has earned us long-term partnerships with major automotive brands and industrial clients worldwide.

Global Reach, Personalized Support

Aceforge isn’t just a manufacturing powerhouse—we’re a global partner. With a well-established distribution network across Asia, the Middle East, Africa, and Europe, we ensure that our spare parts reach clients quickly and efficiently. Our multilingual customer service teams and regional support centers make sure you receive personalized assistance, no matter where you are.

Whether you're a vehicle manufacturer, parts distributor, or fleet operator, Aceforge offers scalable solutions tailored to your specific needs. Our flexible production capabilities allow for customized orders and private labeling options as well.

Driving the Future of Automotive Components

As mobility continues to evolve, Aceforge is geared up to meet the challenges of tomorrow. Sustainability, electric mobility, and digital integration are shaping the next generation of vehicles—and we’re actively investing in technologies that align with these trends.

In a market full of automobile spare parts manufacturing companies, Aceforge stands out with its dedication to quality, innovation, and customer satisfaction.

0 notes

Text

Patch Cord Manufacturers: Nextik's Commitment to Quality and Performance

Patch cord manufacturers | Patch cord supplier in Noida | Patch cord manufacturers in Noida, India

Fast, secure, and safe communication is more important than ever in today's digitally connected society. At the heart of this system lies the fiber optic patch cord—a key component that guarantees effective data transfer across networks. As one of the leading patch cord manufacturers, Nextik is a well-known brand in the fiber optic sector and a top producer of fiber patch cords of the highest caliber, proudly created and manufactured in India.

With state-of-the-art facilities and a commitment to quality, Nextik provides patch cords that facilitate high-speed communication, minimize signal loss, and deliver dependable performance across a wide range of applications.

What Is a Fiber Optic Patch Cord?

Fiber optic cable with connectors on both ends is called a fiber optic patch cord, sometimes referred to as a patch cable or fiber jumper. These cables are used to connect equipment in a network, like patch panels and termination boxes or transmitters to switches.

These cables are necessary in enterprise networks, data centers, telephone lines, and high-bandwidth applications. They guarantee the smooth passage of data with the least amount of noise and the highest level of security.

Why Patch Cord Quality Matters

Although patch cords may appear to be a minor component of the overall network design, they are essential to maintaining guaranteed signals and system performance. Network inefficiencies, connection failures, and data loss can result from bad patch cords.

Because of this, producers such as Nextik take the creation of patch cords seriously, including quality, stability, and respect to international standards.

The Nextik Edge in Patch Cord Manufacturing

We believe that the strength of a network is only as good as its weakest connection. We ensure every fiber patch cord we manufacture meets the highest industry benchmarks in terms of performance and reliability.

Here’s what sets us apart:

1. High-Grade Components

We use top-tier raw materials, including corrosion-resistant ferrules, premium optical fiber, and high-performance connectors to ensure durability and low signal loss. All cables undergo strict quality checks to ensure longevity and functionality under varying conditions.

2. Multiple Connector Types

Our fiber patch cords are available in a variety of connector types, including:

SC (Subscriber Connector)

LC (Lucent Connector)

FC (Ferrule Connector)

ST (Straight Tip)

MU (Miniature Unit)

These options allow us to cater to diverse networking needs and ensure compatibility with different devices and systems.

3. Custom Lengths & Polishing Options

Patch cords are available in custom lengths depending on client requirements. We also provide connector polishing in PC (Physical Contact), UPC (Ultra Physical Contact), and APC (Angled Physical Contact) types for different optical return loss needs.

4. Low Insertion & Return Loss

Our cables are engineered for low insertion loss (less signal power loss when inserted) and high return loss (reduced signal reflection), enhancing the efficiency and stability of your network.

5. Rigorous Testing & Quality Control

Every patch cord manufactured at our facility undergoes rigorous inspection. We test for parameters like geometry, end-face quality, insertion loss, and return loss. Our testing process ensures each unit meets both national and international standards.

The Manufacturing Process at Nextik

The patch cord manufacturing process at Nextik is a carefully controlled and multi-step operation, carried out at our advanced facility in Noida. Here’s a look at our standard manufacturing workflow:

Cable Preparation: Cutting the fiber to the desired length and preparing the buffer and core.

Connector Assembly: Attaching connectors using high-precision methods and UV curing adhesives.

Polishing: Fine polishing of connectors based on the desired type (PC, UPC, APC) for minimal back reflection.

Inspection: Microscopic inspection of fiber end-faces for scratches or blemishes.

Performance Testing: Testing for insertion loss, return loss, and continuity using top-of-the-line equipment.

Packaging: Each unit is individually packed and labeled to prevent damage during handling and ensure easy identification.

Applications of Nextik Fiber Patch Cords

Our fiber patch cords are designed to support a wide range of industries and use-cases, including:

Data Centers: High-speed interconnects between servers, storage, and switches.

Telecom Infrastructure: Reliable links across central offices, base stations, and network nodes.

FTTH (Fiber to the Home): Efficient connections within residential and commercial broadband networks.

Corporate Networks: Robust internal cabling for high-performance enterprise environments.

Test Equipment: Used in labs and diagnostics for fiber signal testing and monitoring.

Why Choose Nextik?

When you choose Nextik for your patch cord needs, you’re partnering with a manufacturer that brings:

Experience and Expertise: Deep domain knowledge in fiber optic manufacturing.

Customization: Tailored solutions for specific networking environments.

Commitment to Quality: Products tested to meet or exceed global benchmarks.

Customer Support: Friendly and knowledgeable team ready to help you select the right solution.

Get in Touch with Us

Look no further than Nextik if you're searching for a reliable patch cord manufacturer in Noida As one of the top patch cord manufacturers, we are equipped with a fully furnished facility, a team of skilled experts, and an unwavering commitment to excellence—ready to power your network with precision-engineered solutions.. Book now

0 notes

Text

0 notes

Text

Control Engineering

Driving Industrial Excellence Through Control Engineering: The Monika Engineers Way

At the center of each contemporary industrial process is a well-coordinated control system operating in the background, managing complexity, keeping precision, and facilitating efficiency. This is the crux of Control Engineering , a field that continues to define the foundation of intelligent manufacturing and infrastructure systems. Leading the way in this domain is Monika Engineers , a reliable name that specializes in providing innovative and dependable control engineering solutions in various industries.

What is Control Engineering?

Control engineering refers to the application of engineering methods to develop systems that control, command, direct, or govern the operation of other systems or devices. These systems make processes work consistently and according to defined parameters, no matter the outside disturbances or fluctuations. In manufacturing industries, control engineering plays a fundamental role in automation, safety, energy savings, and process optimization.

From basic temperature control in HVAC systems to advanced robotic process automation on a production line, control engineering makes it all operate smoothly and reliably.

Monika Engineers: Masters of Precision and Performance

Monika Engineers has established itself as a reliable supplier of state-of-the-art control engineering solutions . Equipped with a pool of experienced engineers, latest tools, and an unshakeable commitment to quality, the company has been able to implement control systems in diverse fields including manufacturing, energy, water treatment, pharmaceuticals, and food processing.

Their method is based on learning the client's processes, finding opportunities for control and optimization, and then designing systems that are scalable, robust, and user-friendly.

Core Offerings in Control Engineering

1. Design and Integration of Control Systems

Monika Engineers creates special control systems with the latest PLC (Programmable Logic Controller) platforms. They are designed as per the particular needs of the client, either to control one machine or an entire production line.

2. SCADA and HMI Development

SCADA systems and HMIs are the hub of today's control engineering. Monika Engineers creates intuitive interfaces that facilitate real-time monitoring, alarm handling, and data logging, providing the operator with complete visibility and control over operations.

3. PID Control and Process Optimization

Accuracy in process industries frequently relies on optimized PID (Proportional-Integral-Derivative) control loops. Monika Engineers is an expert in optimizing these control systems to provide stable, responsive, and accurate performance for parameters such as pressure, temperature, and flow.

4. Custom Control Panels

The company develops and manufactures high-performance control panels, designed to fulfill unique process and environmental demands. Each panel is tested thoroughly prior to deployment to meet requirements, reliability, and safety.

5. Retrofitting and Upgradation

Monika Engineers assists customers in upgrading their existing legacy systems by incorporating advanced control technologies without interrupting existing operations. This strategy extends the lifespan of installed infrastructure and provides new functionality.

Why Monika Engineers?

- Expert Technical Knowledge:With a highly qualified team of control engineers, the organization is equipped to manage any size and complexity of project.

- Customer-Centric Approach: Each solution is configured with the objectives of the client in focus—be it minimizing downtime, enhancing product quality, or maximizing energy efficiency.

- Full-Fledged Service: From conceptual design and programming to panel assembly, testing, and commissioning, Monika Engineers delivers end-to-end turnkey solutions.

- Quality and Compliance: Their products meet the highest industry standards, with long-term reliability and simple maintenance.

The Road Ahead

The road ahead for control engineering is towards smarter, more integrated systems—blending IoT, artificial intelligence, and cloud-based analytics to expand the frontiers of automation. Monika Engineers is already putting these technologies into place, keeping their clients at the forefront.

In a fast-paced changing industrial environment, Monika Engineers is ever-reiterating that the ideal control system is not only about automation—it is about empowerment. Empowering companies to get smarter, work faster, and perform better.

Official Mail: monikaengineering@123

Contact no. - +91 9872846445

Address: 77A, Industrial Area- A, Ludhiana, Punjab 141003

Working Hours: Monday to Saturday - 9:30 AM – 7:00 PM

Website: https://monikaengineers.co.in/

Google My Business: https://g.co/kgs/PfDzeBK

0 notes

Text

Control Engineering

Driving Industrial Excellence Through Control Engineering: The Monika Engineers Way

At the center of each contemporary industrial process is a well-coordinated control system operating in the background, managing complexity, keeping precision, and facilitating efficiency. This is the crux of Control Engineering , a field that continues to define the foundation of intelligent manufacturing and infrastructure systems. Leading the way in this domain is Monika Engineers , a reliable name that specializes in providing innovative and dependable control engineering solutions in various industries.

What is Control Engineering?

Control engineering refers to the application of engineering methods to develop systems that control, command, direct, or govern the operation of other systems or devices. These systems make processes work consistently and according to defined parameters, no matter the outside disturbances or fluctuations. In manufacturing industries, control engineering plays a fundamental role in automation, safety, energy savings, and process optimization.

From basic temperature control in HVAC systems to advanced robotic process automation on a production line, control engineering makes it all operate smoothly and reliably.

Monika Engineers: Masters of Precision and Performance

Monika Engineers has established itself as a reliable supplier of state-of-the-art control engineering solutions . Equipped with a pool of experienced engineers, latest tools, and an unshakeable commitment to quality, the company has been able to implement control systems in diverse fields including manufacturing, energy, water treatment, pharmaceuticals, and food processing.

Their method is based on learning the client's processes, finding opportunities for control and optimization, and then designing systems that are scalable, robust, and user-friendly.

Core Offerings in Control Engineering

1. Design and Integration of Control Systems

Monika Engineers creates special control systems with the latest PLC (Programmable Logic Controller) platforms. They are designed as per the particular needs of the client, either to control one machine or an entire production line.

2. SCADA and HMI Development

SCADA systems and HMIs are the hub of today's control engineering. Monika Engineers creates intuitive interfaces that facilitate real-time monitoring, alarm handling, and data logging, providing the operator with complete visibility and control over operations.

3. PID Control and Process Optimization

Accuracy in process industries frequently relies on optimized PID (Proportional-Integral-Derivative) control loops. Monika Engineers is an expert in optimizing these control systems to provide stable, responsive, and accurate performance for parameters such as pressure, temperature, and flow.

4. Custom Control Panels

The company develops and manufactures high-performance control panels, designed to fulfill unique process and environmental demands. Each panel is tested thoroughly prior to deployment to meet requirements, reliability, and safety.

5. Retrofitting and Upgradation

Monika Engineers assists customers in upgrading their existing legacy systems by incorporating advanced control technologies without interrupting existing operations. This strategy extends the lifespan of installed infrastructure and provides new functionality.

Why Monika Engineers?

- Expert Technical Knowledge:With a highly qualified team of control engineers, the organization is equipped to manage any size and complexity of project.

- Customer-Centric Approach: Each solution is configured with the objectives of the client in focus—be it minimizing downtime, enhancing product quality, or maximizing energy efficiency.

- Full-Fledged Service: From conceptual design and programming to panel assembly, testing, and commissioning, Monika Engineers delivers end-to-end turnkey solutions.

- Quality and Compliance: Their products meet the highest industry standards, with long-term reliability and simple maintenance.

The Road Ahead

The road ahead for control engineering is towards smarter, more integrated systems—blending IoT, artificial intelligence, and cloud-based analytics to expand the frontiers of automation. Monika Engineers is already putting these technologies into place, keeping their clients at the forefront.

In a fast-paced changing industrial environment, Monika Engineers is ever-reiterating that the ideal control system is not only about automation—it is about empowerment. Empowering companies to get smarter, work faster, and perform better.

Official Mail: monikaengineering@123

Contact no. - +91 9872846445

Address: 77A, Industrial Area- A, Ludhiana, Punjab 141003

Working Hours: Monday to Saturday - 9:30 AM – 7:00 PM

Website: https://monikaengineers.co.in/

Google My Business: https://g.co/kgs/PfDzeBK

0 notes

Text

Designing for Precision: The Role of Craftsmanship in Power Technology

Building reliable electrical systems takes more than just the right parts—it takes serious craftsmanship. That’s something we’ve come to understand through years of hands-on work. Whether we’re developing components for high-end systems or troubleshooting existing designs, one thing’s clear: the quality of what goes into your power tech shows up in how it performs.

Today, we’re diving into a part of the process that doesn’t always get the spotlight but plays a huge role—how things are made, especially when it comes to winding, shaping, and assembling transformers that power today’s technology.

Where Quality Starts: The Building Process

You can’t get a dependable result from a sloppy beginning. That’s why we take the start of every project seriously, especially the part where winding is involved. We work with gear that’s built to keep things tight, uniform, and well-aligned.

One tool that’s helped us keep our process solid is the power transformer winding machine. This machine helps us produce consistent windings that are compact, efficient, and reliable. When the wire is laid down properly, it reduces hotspots and improves the overall performance of the transformer.

Without this level of control, things can go sideways fast—uneven winding leads to energy loss, heat issues, and in the worst cases, failure under load.

Shaping Energy with Precision

Every part of a transformer has a role, but the core shape and layout can change everything. We’ve used several designs over time, but we’ve found that the toroidal power transformer stands out for compact, high-performance projects.

This transformer type is shaped like a ring. That design helps concentrate the magnetic field where it’s needed, cutting down on interference and wasted energy. It also takes up less space, which matters when you’re working on tight builds where every inch counts.

And let’s not forget noise. Toroidal transformers are known for running quietly—something our clients appreciate when noise levels can affect sensitive equipment or create distractions.

Why It All Comes Down to Detail

We’ve learned to never overlook the little stuff. It’s the fine details—the tight turns, the clean solder joints, the alignment of the core—that separate a good build from a great one.

That’s why the winding process matters so much to us. It’s not just about getting wire onto a core—it’s about how it’s done. We’ve worked on projects where a transformer needed to fit into an oddly shaped housing, or where performance had to stay rock solid in tough conditions. The precision of our winding and assembly was the key difference.

When it’s done right, you don’t just get better performance—you get reliability over time. And that’s something we always aim for.

Testing the Build Before It Hits the Field

Before we ever sign off on a build, we run it through testing. It’s not enough to trust the specs on paper—we have to see how it performs when pushed. Heat, load handling, insulation resistance—we run the numbers and catch any flaws before the part goes anywhere near a system.

One of the biggest takeaways from our testing is how often small tweaks during the winding stage can solve big problems down the line. A slight adjustment to how the windings are layered or how the wire is tensioned can mean the difference between overheating and running cool for years.

How Material Choices Affect Performance

Let’s be real—materials aren’t just a budget line. They’re a critical part of performance. We’ve worked with all sorts of winding wire, insulation layers, and core types, and every one of them brings something different to the table.

When it comes to the toroidal build, the core material especially matters. The wrong steel or poor coating can cause losses that hurt performance. The right setup, though, helps reduce eddy currents and keeps efficiency high. That translates to better energy use and less heat.

The Push Toward Smarter Builds

Lately, we’ve noticed a trend. Clients want more power, but less bulk. They want things to run cooler, last longer, and stay quiet. And we get it—that’s where our builds are headed too.

This is where toroidal transformers shine. Their smaller form factor and efficiency help us meet these new demands without giving up performance. We’ve even started combining advanced windings and new core materials to push things further without making the builds more complex.

Lessons We’ve Picked Up Along the Way

Through years of builds, testing, and problem-solving, we’ve taken a few key lessons to heart:

Never rush the winding process. Precision matters from the first turn.

Use machines that give repeatable results—you can’t leave quality up to chance.

Toroidal shapes are compact and efficient for high-performance projects.

Always test. Even if it looks good, real-world performance is the final say.

Material choices are as critical as the design itself.

These lessons help us stay consistent and keep improving. And they’re part of every build we put together.

Wrapping Things Up

At first glance, transformers and windings might seem like the quiet background players of the tech world. But we know better. The way we build and shape these components directly affects how a system runs—and for how long.

That’s why we approach every project with care, using the right tools, materials, and processes. Because when it comes to power, the best results come from the best builds. Every time.

0 notes

Text

The Importance of Quality Control in Electronics Manufacturing Services (EMS)

Introduction

In the world of electronics, precision and reliability are non-negotiable. Whether it’s a smartphone, a medical device, or an industrial control system, the quality of electronic components plays a crucial role in ensuring product performance. This is where quality control in Electronics Manufacturing Services becomes essential.

Why Quality Control Matters in Electronics Manufacturing

*Minimizes Defects: Defective components can lead to product failures, increasing returns and customer dissatisfaction. Proper quality control reduces these risks significantly.

*Ensures Regulatory Compliance: The electronics industry follows strict quality standards like ISO, IPC, and RoHS. Maintaining these standards ensures products are legally and ethically manufactured.

*Improves Product Longevity: Well-tested electronic components have better durability, reducing maintenance costs and enhancing customer trust.

*Reduces Manufacturing Costs: Identifying defects early prevents wastage and costly rework, improving the overall efficiency of the manufacturing process.

Key Quality Control Measures in Electronics Manufacturing

*Automated Optical Inspection (AOI): Used to detect misalignments, missing components, and soldering issues in circuit boards.

*X-ray Inspection: Ensures hidden solder joints in Ball Grid Array (BGA) assemblies are properly placed.

*Functional Testing: Simulates real-world conditions to test how the electronic device operates under different loads.

*Environmental Testing: Checks how products withstand extreme conditions like heat, humidity, and vibrations.

*Conformal Coating Verification: Ensures protection against moisture, dust, and chemical exposure for enhanced longevity.

Looking for high-quality Electronics Manufacturing Services? Ensure every component meets the highest standards with advanced inspection and testing.

Common Challenges in Quality Control

*Component Sourcing Issues: Counterfeit or low-quality components can compromise the final product. Partnering with reliable suppliers is crucial.

*Process Variability: Minor inconsistencies in soldering or assembly can lead to performance issues. Standardising procedures is necessary.

*High-Speed Production Risks: Faster production can sometimes lead to oversight in quality checks. Automated testing tools help maintain precision.

Conclusion Quality control is the backbone of successful electronics manufacturing. From component sourcing to final product testing, every step must follow strict standards to ensure flawless output. Investing in the right inspection technologies and skilled workforce can significantly improve product reliability, reduce waste, and enhance customer satisfaction.

Get reliable and efficient Electronics Manufacturing Services today! Ensure your products meet global standards with precision manufacturing.

Also read:

Know Electronics Manufacturing: The Total Guide

Through-Hole vs. Surface Mount Technology: Choosing the Right PCB Assembly Method

Conformal Coating: Protecting Electronics from Environmental Hazards

The Future of Electronics Manufacturing

0 notes

Text

inZOI Game Download for PC

Steps for you to Download then Flow inZOI with Displays: A Beginner's Guidebook

1 this sort of adjustable setting would be the Capital Security Levels, which often reveals the amount of offense in addition to standard community madness which appears in your area. “This specific and hands down the success tempo associated with bonds,” Ellie explains, while minor societal security put on the populaces disposition in addition to built in conviction within others. When inZOI is going, look at back how to download inzoi for pc here to be able to see how inZOI conducts using a a number of real-world PERSONAL COMPUTER activity groups. Still not sure if the startup could switch inZOI system prerequisites?

Nonetheless, it turns out that this adorable very little package deal regarding down is more than just InZOI’s mascot. InZOI’s build function strongly looks like The Sims, inZOI Download PC offering you a great considerable file involving merchandises to help assemble as well as give your current Zoi’s home. Brand new wall membrane, stumps, and opportunities are just several presses aside, with every one bedroom might be kitted unacceptable to help the precise specifications.

While the Southern region Korean company is largely recognized with the likes involving PUBG Battlegrounds in addition to Shadows with Darker, these times near, it's obtain a probable heir to The Sims run upon it's hands. The InZOI release court can very well herald the subsequent progression with the energy sim genre, and also we’ve obtain each of the gameplay and movie trailer in your case. The most effective take a look at InZOI nevertheless possesses reached courtesy of the official gameplay test that has been exposed throughout June 2024. The six-minute online video (notice above) goes through everything from identity development, Develop Manner, Director's Mode, romantic relationship then exactly what standard kick inside simulator are going to be like. Krafton only plunged the boundless InZOI test because of its upcoming The Sims rival, but you employ a limited time for you to investigate out there the character founder. Suggestions that which you learn about the overall game today, including things like while it's going to be released, gaming console translations, as well as precisely what attributes is going to be at proposal at kick off.

Also, the activities and deliberations regarding ZOIs end up being oppressed by way of sLM technologies, allowing additional indulging in addition to intuitive discussions. InZOI is often a contest that could get away from a person happily surprised by means of it's video top quality and impressing customization options. how to download inzoi for pc Get your future video game, free weekend, and even course the next Vapor Selling many a single position.

In case you are looking for a lifetime simulation sport, you'll be able to download inZOI as well as get pleasure from a designation to assures for being much more than the usual “Korean Sims”. The good customization size, the destiny routine, also the community's passion produce the experience a constant offer among simulation online game. We by now pick up a in-depth glance at the How to Download inZOI for PC roadmap earlier this holiday season, to help you locate all of the upcoming customization attributes live cooked in the life activity generally there. You will find car or truck, collection actions, city revise devices, as well as a inZOI Download PC karma system arriving at InZOI, so nothing like The Sims, you’ll have got nearly finish manage within the entire video game, not now individuals. Many life sim players coming from The Sims 4 will probably be familiar with the acceptance regarding "occult" sims like ghosts, vampires, werewolves, mermaids, and that.

They indicated a few karma-affecting acts (like farting?) and also a coincidence How to Download inZOI total now both Zoi's profile. "We wish to keep the playability connected with ghosts rather restriction in order that it doesn’t overshadow the principle gameplay, although we furthermore desire to make sure the experience ends up being participating adequate while it does take place," Kjun explained to participants now Discord. System prerequisites Research laboratory functions countless COMPUTER SYSTEM requirements investigations with over 8,500 sport every thirty days.

Plan with our own expertise, the delicate preset keymapping practice helps to make inZOI a genuine PERSONAL COMPUTER activity. MEmu multi-instance manager creates enjoying 2 or higher considerations about the same device possible. And also the most important, your limited emulation motor can certainly discharge complete possibility of your COMPUTER SYSTEM, produce anything easy. Previously, inZOI make it possible for persons to create households with unlimited floorings, with respect to the PC's capacity. Nonetheless, on account of scientific matters happening from overly large developing, a hat involving 30 floorboards have been introduced. Although this kind of evaluation might sadden a number of persons, the programmers trust the city will certainly realize the optimization also persist delighting in Assemble Setting.

Regulations with regards to the use of that software diverge via people for you to kingdom. We will not promote as well as condone the application of this system if it is with violation of those legislation. “Present end up being numerous issues I want to to do in The Sims, however they always managed to get extremely tough,” Betty point out. InZOI, originating from the designer KRAFTON, Inc., is string on Android systerm before. It is possible to employ this widget-maker to build a tad regarding HTML that may be added within your website in order to effortlessly make it possible for customers to purchase this specific sport upon Sauna.

In which rest for being seen – for the present time, the following anything we realize about the InZOI launch time frame, such as the latest movie trailer as well as gameplay video. InZOI gives a complete group simulation, the place that the overall area ends up being constantly end up being imitate almost all simultaneously. Every ‘Zoi’ acts on the free of charge want, with all persona made up of different mishmash regarding over 400 unique mental components. In addition, continual conversation and also connections typed between unique Zois lead to unexpected celebration this kind of as word, craze, and even illness, presenting players a real-life experience because they spread throughout the area.

0 notes

Text

Reliable PCB Solutions: Fast Prototyping & Quick Turn Fabrication

Bringing electronic designs to life requires precision and speed, and quick-turn PCB fabrication plays a key role in making that happen. Whether you need a single board or a full production run, having a reliable manufacturing partner ensures high-quality results with faster turnaround times. Advanced fabrication techniques streamline the process, making it easier to meet project deadlines without compromising on performance.

For product development, a well-crafted prototype circuit board is crucial to testing functionality before full-scale production. With accurate prototyping, engineers can refine designs, identify potential issues, and optimize performance. Working with a trusted manufacturer simplifies the process, providing efficiency from concept to completion.Beyond fabrication, professional PCB assembly services take your boards from bare circuits to fully functional components. From precise component placement to thorough quality checks, expert assembly ensures reliability in every board. Get the best solutions for your PCB needs—start your order today!

#pcb manufacturing company#quick turn pcb fabrication#pcb prototype service#full turn key pcb#pcb prototype manufacturer

0 notes