#welding turn roller

Explore tagged Tumblr posts

Text

Black Dahlia - 1. No Daughter of Mine.

Synopsis: TBA Garrick Tavis x OC (Dahlia ?????) A/N: I couldn't wait any longer to start sharing this series with you guys. I am so excited for you to meet Dahlia and go on this roller coaster of a journey with me. This is your warning that this series will have a decent amount of angst and hurt, and will be a slow burn. Garrick going to have his work cut out for him And I'm curious... who do you think her sibling is after this?

Black Dahlia Masterlist | Masterlist

Of course I would dream of that day. Of course my brain would bring up this memory now. Making me relive the worst day of my life. Doomed to haunt me till the day I would shrivel up and die.

There I am. So young and naïve. Not a care in the world as I run through the trees with my friends. No clue of what’s to come in a mater of minutes.

My feet push me further and further into the forest. Everything a blur of green and brown. My heart hammering loudly in my chest as I push myself to keep going. To win.

I can hear the sounds of their foot steps behind me. But not gaining. No. I was the fastest. The more agile. It gave me an upper hand while manoeuvring through the trees. I was going to win.

Ahead the trees start to thin, more light seeping into the dense forest. A beacon guiding us to the finish line. But for me…. It was guiding me to victory.

The boys had been stupid to suggest a race through the forest. But they were determined to beat me. At everything else we did they had the upper hand. They were bigger and stronger. Able to weld those training swords better than I. But when it came to this. No one could catch me.

I cry out in victory as I leap over a fallen log and into the clearing. Jumping up and down as I celebrate. I turn to watch the boys jump over the tree before placing their hands on their legs as they try to catch their breath.

I go to tease them about my victory, just like they would in the training grounds. But my words fall short as the ground trembles beneath me. A feeling I knew all too well. The boys eyes go wide at the sight behind me. I turn ever so slowly to see a hoard of dragons behind me. We had run so far through the first we had ended up in the clearing where the riders dragons were kept. And in the middle of them was a dragon I knew all too well. My father’s.

Unlike the boys behind me I wasn’t scared of the dragons. But coming from infantry, the boys behind me had never really been taught about dragons. They were scared.

“There’s nothing to be afraid of.” I tell them as I take in the dragons in front of us.

The dragons looked beautiful in the sunlight. Their scales glistening when the sunlight hit just the right spot. I couldn’t help but be drawn to a blue one down the back. Blue dragons had always been my favourite. But they were the most ruthless of the colour. My father teaching me to never approach one.

“If there’s nothing to be afraid of why don’t you approach them.” One of the boys behind me mocks.

“I’m not afraid. Only a fool would approach a dragon” I call back.

“Liar. You’re scared.” Another mocks, the others snickering at his comment.

I whip back towards them. “I’m not scared.” I say sternly, my hands forming into fists at my side.

“Approach them then. Your father’s a dragon rider. You should know what to do.” One of the older boys states as he walks towards me. “You want to be one of them one day. Go on then. Get some practice.”

He shoves me in the shoulder sending me stumbling backwards towards the dragons. I couldn’t deny I was a little scared. I’d only been near a dragon a handful of times. But never on my own. Always with my father watching over my brother and I.

I turn and face the dragons behind me. My father’s dragon now front and centre.

I could do this. I knew this dragon. He belonged to my father. He wouldn’t hurt me. Right?

Each step forward has ever fibre of my body telling me to run. Don’t give into peer pressure. Turn back and let them think what they want. Prove to them you aren’t afraid another one. But I don’t. I keep putting one foot in front of the other.

My father’s dragon exposes his teeth, a low growl rumbling from its throat as he watches me approach. A warning. Even he knew this was foolish.

My heart beat thunders loudly in my ears. Drowning out the world around me. Run. I need to turn around and run.

Out of the corner of my eye I see it. My head snapping to the side as the rock soars over my head. I watch it, following it as it arcs through the air, and meeting its target. Right in the middle of the dragons left eye. I watch as its tongue curls, an orange glow igniting at the back of its throat. Its mouth still angled down towards me.

I turn to run even though I know it’s futile, know that I won’t make it. But I have to try. As I turn I feel the heat behind me. Know what’s about to happen. I shut my eyes, bracing for my end. But it’s an end that never comes as I’m pushed by something. No not something. Someone.

I soar across the clearing, landing with a thud on the ground near the boys as a scream rips through the clearing. By the time I look up no one is there. Just a pile of ash on the ground. A pile of ash my father rushed towards. My twin brother not far behind. My father’s screams and pleads echoing around the clearing along with my brothers cries. I scramble up to my feet, limping over to my father and brother.

“F-father?” I stutter out, my voice shaking.

Never in my life had I seen my father that mad as his head whips towards me. Tears brimming his eyes as he sneers at me.

“T-this is your fault!” He bellows as his eyes narrow at me.

I stop in my tracks shocked at my father’s outburst. My brother also recoiling from him slightly. His eyes also brimming with tears.

“How could you be so foolish? You know better than this! She’s dead because of you!”

I look down at the pile of ash he gestures to. And that’s when it hits. Know why my father and brother look so distraught and upset. The pile of ash was my mother.

I go to rush forward, but my father’s hand whips out and shoves me backwards to the ground. The force vibrating through my body as I hit the ground.

I’d killed my mother. I shouldn't have listened. Should have stood my ground. I should have run. If I had run she would be alive.

I look up and meet my father’s eyes. His gaze pinning me to the ground. I open my mouth to apologise, but he cuts me off with words that would stick with me for the rest of my life.

“You’re no daughter of mine.”

A/N: If you want to be on the tag list for this series please comment below <3

#fourth wing fanfic#garrick tavis#garrick tavis x reader#garrick tavis imagine#garrick tavis x oc#fourth wing x reader

89 notes

·

View notes

Text

Birds of a Feather

CisFem Reader x Marco

CW: Violence, blood, language, adult themes and scenes. 18+ only

Summary: Life has not been kind to you. After a string of bad relationships, you're a little jaded and a little depressed in all honestly. The worst day of your life seems to be the turning point, but the roller coaster ride that follows could either throw you soaring free, or have you caged forever?

Chapter 12: The Firebird

Getting out of the car, you already saw Kid leaning against one of the bay door frames. The day was barely started and he was already covered in grease, shop uniform giving way. Knowing him he’d been working all night and hadn’t slept yet, versus having gotten up early enough to be in that state.

“Usopp here yet?” You call out, heading up to the shop proper, Marco coming up behind you.

“Yep,” Kid answers, squinting against the morning light as he cleans his hand up a little with a rag that’s seen brighter days. “Only just got here though, so you haven’t kept ‘im waiting much, Mouse.”

You roll your eyes and jerk your thumb toward Marco. “Eustass Kid, Newgate Marco,” you step aside as Marco steps up. “Marco, Kid.” You say, finishing your lazy introduction.

“Pleasure.” Marco says, taking Kid’s mostly de-grimed hand and giving it a shake.

“Sure thing.” Kid tilts his head toward the parking lot. “That yours?”

Marco looks back at his car and smiles as he looks back at Kid. “It is.”

“… Lemme put her up on a rack so I can get a good look at ‘er and I got a hood arm for you, no other charge.” Kid offers, still squinting against the light. Looking back and forth between the two of them you realize Marco’s the only person you know who could look Kid in the eye, damn giants.

Somehow Marco looks smaller than Kid, but probably because he’s not nearly as broad.

Marco looks to you and you smile. “I’m not gonna lie, I’ll be under the rack getting my fill too, if you’re okay with it.”

Marco chuckles. “Alright, it’s a solid deal, yoi.” He admits. “I’ll bring the car up. That bay?” He asks, pointing to one that looks like it has a lift in it.

“Yup.” Kid answers, his tone a little more friendly and a little less business.

“I’ll go talk to Usopp while you do that, and get things rolling.” You state, heading into the shop proper to find your car and Usopp.

The young artist is setting up his gear near your car. You start to say something to him, but the sight of your car catches your attention. In several pieces to make it easier for the paint job, everything has been reworked. If it wasn’t for the distinct body style and design of the interior, you’d almost wonder if it was your car.

“We either replaced or refurbished just about everything.” A familiar voice says from behind you. Looking over you see the wild blonde hair of Kid’s childhood friend Killer, one of the co-owners of the shop, poking out from behind the frame of a van with flames down the side of it. He turns to get a better look at you, lifting up his welding mask and giving you a smile.

“We kept what we could, but strictly original parts barely make up 10% of her now.”

“Did you guys redo the entire frame then?” You question, giving a wave to Usopp as Killer comes over to walk you through what they did to the car.

“Just about. You didn’t have near as much rust as we expected to find. Kid might not say so, but you took care of her really well, honestly. The engine had to be scrapped. There wasn’t enough machining to save it, and truthfully, the newer engines are just far too efficient.” Killer starts pointing at a few places while he explains. “Replaced all the clips and lines, new brake assemblies and tires. You got that sky blue base color, so we went with white for the interior. You had that dingy 70s silver before, so Kid didn’t think it was too different to bother saying something before hand.”

“Nah, white’s fine. It’ll be a challenge to keep clean, but y’all do detail jobs, right?”

“A-yup. Heat an’ Wire mostly, but I don’t think you’d hear a single complaint if this was the car they were cleaning.” Killer continues on. “Left the manual windows, and there’s an emergency release for the seat, but we did add fully adjustable controls to the seats.”

“Oh, programmable?” You prompt and Killer tilts his head.

“Here Kid was worried you’d be irritated by technology invading your precious time-capsule.” Killer grunts and you wave him off. “Yeah, you can put things were you want and save three different settings, so have fun with that. It’s still good old fashioned key-bound entry,” he continues on. “Kid says since you won’t have to worry about jumping her with the new, well, everything, that we could set you up with one of those magnetic keys for extra security if you wanted?”

“Hmm, I’ll have to think about it. Restored like this I’m going to have to get a new coverage policy, that’s for sure. It’d be cheaper on my end with the added security of a fancy key like that. Any chance I could have three for this car?”

“Three keys?”

You nod. “For now, one for me, one for the shop, and one for my house, in case I lose the one I keep with me.”

Killer tilts his head a little, and then nods. “I don’t see why not. I think we can order up to four for a single ignition without raising any concerns.”

“Perfect.”

“Whaddya think of her now, Mouse?” Kid asks, coming over to where you are with Marco not far behind.

“I think I’m going to go kick Victoria’s tires if you don’t stop calling me that.” You grumble.

Kid snorts. “Yeah, well, don’t kick Vicky’s tires, or your new car’s tires.” He warns. “Steel-belted, you might actually break a toe.”

“Hells Kid, are the windows bullet proof too? The security on this is already high enough as it is.” You tease, and Kid seems to consider.

“I mean, they could be.” He muses.

“No, no, that’s -,” you pinch the bridge of your nose and shake your head. “Thanks Kid, you guys did a great job.”

“Of which you had no doubt.” Kid retorts. It’d be arrogant, but he and the guys have the skills to back up his statement.

You smile and sigh, seeing no reason to give him an actual response. You turn to Usopp and give him a smile. He’s the only person in the entire shop that isn’t towering over you, it’s refreshing.

“Let’s talk design, Usopp.” You begin cheerfully. “The faster we get on the same page the faster I can look under Marco’s car’s skirt.” You hear Marco cough as Usopp laughs. Pulling a paper out of your pocket you unfold it and hand it off to Usopp. “I was thinking this kind of design.”

Usopp looks at it, looks to your car, and looks back at it. “That’s the original insignia design for the most part, isn’t it?”

You nod. “The expansion of the tail feathers would be unique, and I was thinking, one chain could go down each side of the car, and the third could come down through the headlight assembly?”

He tilts his head and looks back and forth again. “Yeah, I can see it. Do you know what colors you want to go with?”

“I think so. So if we do the outline of the wings in a kind of teal, with a metallic gold accent? I was thinking maybe a less metallic gold and more of a… hmm… dandelion gold for the chains.”

“Hm… rimmed in the metallic gold would be a nice touch.” He offers.

“Ooooh, yeah, that would. If the clear coat was a gloss finish too and not matte that would add to it.” You agree.

You’re too distracted with Usopp to notice, as Marco covers his face with a hand, listening to the two of you talk. Kid notices, looking over at him for a second before looking back at you. He keeps his voice low.

“You alright?”

“Huh? Oh - yeah, yeah. I’m good.”

“Wait, what if we invert the gold and yellow on the chain?” You prompt, and Marco makes a strange pained sound only Kid hears.

“You sure?” Kid presses a little. “If you’re going to hurl in my shop, step outside first.”

“No, I’m fine, yoi.”

Kid’s eyes narrow for a moment, and he seems about to say something when his eyes go wide.

“Oi, Mouse, I’m borrowin’ your boy toy for a minute.” He barks, grabbing Marco’s collar and pulling him away from everyone else.

“Hey, hey, don’t you-!”

“It’s alright.” Marco says, waving you off and giving you a smile as he and Kid go to the other side of the shop.

Your face twists a little, but Killer pats your shoulder. “I’ll keep an eye on ‘im, stay focused with Usopp for a bit.”

“Yeah, thanks Killer.” You murmur, turning back toward Usopp after giving Kid and Marco one more glance. Kid didn’t look happy, but Marco didn’t look bothered, so you did your best to pull your attention back to Usopp.

“The phoenix?!” Kid hisses, caught between disbelief and anger. “You’re Marco the gods-damned phoenix?!”

“Was.” Marco answers flatly. “Twenty years ago. Been a vet for over a decade.”

“The Whitebeard pirates were legendary.” Kid states. He opens and closes his mouth a few times, unsure of what to say. Caught between admiration and disbelief, he finally settles on the only thing that’s coming to mind for him. “Is she in danger?”

“No one’s been safe since Roger tried to right the world.” Marco answers a little more sourly than he means to. “But in danger because of me? No, not so far as I know. We stopped being pirates and the government stopped being a problem. Less trouble to just leave us be, yoi.”

“… Are you really immortal?” Killer asks, looking over his shoulder and giving a thumbs up before turning his attention back to the other two.

“I age,” Marco replies, tilting his head a little. “Past that, I don’t know. Nothing’s even so much as left a scar on me, yoi. But I’m not exactly testing the limits of things by taking care of cats and dogs.” He’s quiet for a moment, rubbing the back of his neck. “I haven’t talked with her about this yet, so I’d prefer-.”

“I’m not going to snitch,” Kid grumbles. “Talking about that stuff’s gotten fuckin’ touchy over the years, and considering mine keeps the shop running smooth I ain’t so stupid as to go around yappin’ about someone else’s business.”

“Happy to have your understanding.” Marco says quietly.

Having finished with Usopp, you came over to the other three, looking a little tentative until Kid waved you over directly.

“We all good?” You prompt, looking from one set of eyes to the next.

Marco smiles. “Exceptionally.”

You narrow your eyes a little and Marco looks taken aback for a second before you turn on Kid. “You didn’t go and do that whole big brother routine, did you?”

Kid rolls his eyes. “The hells would I go and do that? Yer doc’s alright.” He grumbles. “Let’s look under this car before Usopp paint’s the whole damn shop teal an’ gold.”

He pauses for a second, and turns and looks at you. “What made you pick those colors anyway?”

“I don’t know,” you admit, looking back over your shoulder at your car. “Just seemed right.”

#Birds of a Feather#Marco x reader#x reader#reader insert#marco the phoenix#marco the pinepple#modern au

19 notes

·

View notes

Text

Full Name: Emiliano Tomás Moreno Nickname: Emil Age & Birthday: 33 - November 20th. Occupation: Marine Welder Preferred Pronouns & Gender: He/him & cis-male Sexuality: Heterosexual Hometown: Briar Ridge, South Carolina. Neighborhood: Beach Front Family: Isabel 'Isa' Moreno - 9 year old daughter.

Pinterest | Stats | Connections.

trigger warnings: car accident.

Born locally, Emil had what he would consider a mostly fairly middle of the road childhood. He often felt a bit detached from his parents, but he wanted for very little outside of perhaps a more socially stimulating environment. His uncle who was deemed by his ma as the ‘wild’ one of her family is very close to him.

A lot of times it was his uncle that took him to tee-ball, and sat in the stands all through his schooling years on the field.

Just as he was about to pack his bags and get out of dodge on a baseball scholarship, he experienced one of his first real upsets in life. His ma was in a bad car crash, and had to go through physical therapy. With medical bills and her needing help around the house, Emil put off college.

A semester turned into a year plus, but eventually with luck on his side and some help from his high school sweetheart’s family - Emil left town for his belated start out in San Diego on scholarship and studying physical therapy.

Everything was going pretty swimmingly, even his long distance relationship and he was so close to making the draft that he could practically hear the stadium crowds cheering for him. but alas life had one more curve ball for him & he was given the news that Amaia was pregnant and Emil immediately dropped everything to go back home.

Things went downhill from there in the years to follow. Between his own emotional distress of giving up his dream, there was a lot of tension between him and Amaia that he thought getting married could somehow fix. When it didn’t, the pair had a really ugly divorce and a custody battle you’d expect to be run by Judge Judy. Amaia was successful in painting Emil poorly and in the end, though he’d get visitations, he lost the custody battle for Isabel.

Having followed in his father’s footsteps upon coming back home, Emil nowadays has a very steady career. Though none of it is what he imagined he would be doing growing up he’s far from miserable, he’s adapted pretty well. Being able to turn his welding experience into his own thing by getting all his diving certifications definitely helped him settle in. Coaching tee-ball and being a sub for a local softball team certainly helps as well. The main stress in his life currently is dealing with his ex-wife and having to sometimes fight tooth and nail to get his owed visitations etc. with Isa. It doesn’t help that she’s old enough to ask questions Emil doesn’t always have an answer to, like why she has to stay with her mother. He’s stable enough that he’d like to go back to court, but he’s a little nervous it’d be hard on Isa and that he has less of a leg to stand on when Amaia has had her for as long as she has.

Fun facts:

he has a husky named Hercules after the dog in The Sandlot.

can be a bit of a thrill seeker. Likes roller coasters, dancing, and spontaneous road trips.

technically has enough diving certifications he could be a diving instructor but has little interest.

owns way too many jerseys kind of sports fan, has seasonal tickets. supports a lot of local teams.

has a serious shellfish allergy, which is slightly amusing given the local cuisine.

likes #DadJokes and always has a snack on him because of either Isa or the kids he coaches for tee-ball.

3 notes

·

View notes

Text

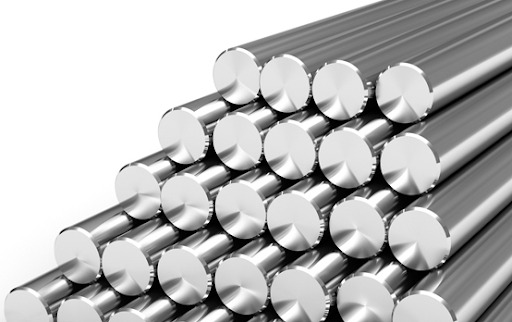

The Evolution and Process of Steel-Making: From Ancient Methods to Modern Techniques

Steel is a cornerstone of modern construction, tool manufacturing, automotive industries, and numerous other applications. As an alloy primarily consisting of iron and elements like chromium, steel has a storied history and an essential role in the global economy. Although steel production dates back centuries, its large-scale commercialization began in the 19th century. Revolutionary advancements in steel-making processes transformed it into a mainstream industry. Today, ongoing technological innovations continue to enhance steel-making efficiency, making it integral to our daily lives. At Agni Steels, we take pride in producing some of the best 550D TMT bars, reflecting our commitment to quality and excellence.

The Historical Context of Steel-Making

The ancient methods of steel-making involved bloomery furnaces and crucibles, which were labor-intensive and yielded limited quantities of steel. The Industrial Revolution marked a significant turning point, with the 1850s and 1860s introducing transformative techniques that enabled large-scale steel production. These advancements, coupled with improved injection technology and process control, laid the foundation for modern steel-making. Today, steel production is vital to the global economy, supporting infrastructure, manufacturing, and more.

The Modern Steel-Making Process

Steel-making today combines traditional raw materials with recycled components and utilizes advanced methods to produce various grades of steel, including the best 550D TMT bars. The process typically involves six key steps:

1. Iron-Making

The initial step involves melting raw materials—iron ore, coal, and limestone—in a blast furnace. This results in molten iron, or "hot metal," which still contains 4-4.5% carbon and other impurities, making it brittle. These impurities must be removed to produce high-quality steel.

2. Primary Steel Making

The impurities in the molten iron are removed through two main methods:

Basic Oxygen Steelmaking (BOS): Recycled or scrap steel is added to the molten iron in a converter. Oxygen is blown through the metal at high temperatures, reducing the carbon content to about 0-1.5%. This process is essential for producing the best 550D TMT bars.

Electric Arc Furnace (EAF): Scrap steel is melted using high-power electric arcs. This method is efficient and ideal for producing high-quality steel.

At the end of this stage, the steel produced is known as raw steel.

3. Secondary Steel Making

Raw steel is further treated to achieve specific grades, including the best 550D TMT bars. Techniques applied may include:

Stirring: To ensure uniform composition.

Temperature Adjustment: To achieve desired properties.

Ladle Injection: For precise alloying.

Gas Removal: To eliminate unwanted gases.

CAS-OB: For advanced processing.

These steps tailor the steel to meet particular performance and quality standards.

4. Continuous Casting

In this step, molten steel is cast into cooled molds, allowing it to harden. Guided rollers draw the steel from the molds while it is still hot, and then it cools completely. The steel is cut to required lengths for various applications, including beams, slabs, billets, and high-strength 550D TMT bars.

5. Primary Forging

Cut steel is shaped through primary forging, typically by hot rolling. This process eliminates casting defects and provides the steel with a desirable shape and surface quality. Products such as seamless tubing, long products, and flat products are created in this stage, including the robust 550D TMT bars.

6. Secondary Forming

The final step involves secondary forming, which imparts the steel’s final shape and properties. Techniques used include:

Heat Treatment (Tempering): To enhance mechanical properties.

Joining (Welding): For creating complex structures.

Shaping (Cold Rolling): To achieve precise dimensions.

Coating (Galvanizing): To prevent corrosion.

Machining (Drilling): For detailed components.

Surface Treatment (Carburizing): To improve surface hardness.

Our Commitment to Quality

At Agni Steels, we are dedicated to maintaining the highest standards of quality, integrity, efficiency, and responsibility in all our operations. Our rigorous processes and advanced technology ensure that we produce some of the best 550D TMT bars available, meeting the highest performance and safety standards.

We are committed to delivering excellence in every piece of steel we produce.

Conclusion

Steel-making has evolved dramatically from its ancient origins. With modern techniques and a focus on producing the best 550D TMT bars, the industry continues to innovate and meet the demands of today’s world. At Agni Steels, we are proud to be at the forefront of this dynamic industry, providing top-quality steel products that support infrastructure and development across the globe.

0 notes

Text

How to Maintain and Store Your Welding Equipment Properly

Proper maintenance and storage of welding equipment are crucial to ensuring the longevity and performance of your tools. Whether you use a MIG welder, TIG welder, or stick welder, following the right practices can save you time, money, and effort in the long run. In this guide, we will explore the best ways to care for and store your welding equipment, providing practical tips to keep your gear in top condition.

Why is Proper Maintenance Important?

How Does Maintenance Impact the Lifespan of Your Welding Equipment?

Regular maintenance is essential for extending the life of your welding equipment. Dust, dirt, and debris can accumulate in your tools, causing them to wear out faster and function less efficiently. Proper care helps prevent breakdowns, reduces repair costs, and ensures that your welds are of the highest quality.

What Are the Risks of Neglecting Equipment Maintenance?

Neglecting maintenance can lead to various issues, such as equipment malfunctions, poor weld quality, and even safety hazards. Over time, components can become corroded or damaged, leading to unexpected failures during critical projects. By staying on top of maintenance, you can avoid these problems and ensure a smooth operation.

Essential Maintenance Tips for Different Types of Welders

How to Maintain a MIG Welder?

Check the Torch: Inspect the torch for any signs of wear and tear. Replace any damaged parts to ensure a steady wire feed.

Clean the Nozzle: Regularly clean the nozzle to prevent spatter buildup, which can affect the quality of your welds.

Inspect the Drive Rollers: Ensure the drive rollers are clean and properly aligned to avoid wire feed issues.

Monitor Gas Flow: Check the gas flow regularly to maintain proper shielding gas coverage, which is crucial for preventing weld contamination.

How to Maintain a TIG Welder?

Examine the Torch and Cables: Inspect the torch and cables for any damage or wear. Replace worn-out parts promptly to avoid performance issues.

Clean the Collet and Collet Body: Regularly clean the collet and collet body to ensure a stable and consistent arc.

Check the Gas Lens: Ensure the gas lens is clean and free from obstructions to maintain proper gas flow and coverage.

Inspect the Power Source: Periodically check the power source for any signs of overheating or malfunction. Clean the cooling vents to prevent dust buildup.

How to Maintain a Stick Welder?

Inspect the Electrode Holder: Check the electrode holder for any signs of wear or damage. Replace it if necessary to maintain a secure grip on the electrode.

Clean the Welding Lead Connections: Ensure the welding lead connections are clean and tight to prevent voltage drops and improve performance.

Check the Ground Clamp: Inspect the ground clamp for proper connection and cleanliness. A good ground connection is essential for stable arc performance.

Monitor the Power Source: Regularly check the power source for any signs of damage or overheating. Clean the cooling vents to prevent dust accumulation.

Proper Storage Techniques for Welding Equipment

How to Store Your MIG Welder?

Cover the Welder: Use a protective cover to shield your MIG welder from dust and moisture.

Store in a Dry Area: Keep your welder in a dry, well-ventilated area to prevent rust and corrosion.

Secure the Torch: Hang the torch securely to avoid damage to the cable and nozzle.

Disconnect Power: Always disconnect the power source when the welder is not in use to prevent electrical hazards.

How to Store Your TIG Welder?

Use a Protective Cover: Cover your TIG welder to protect it from dust and contaminants.

Store in a Controlled Environment: Keep the welder in a temperature-controlled environment to avoid condensation and moisture damage.

Secure the Torch and Cables: Properly coil and store the torch and cables to prevent kinks and damage.

Disconnect the Gas Supply: Turn off and disconnect the gas supply when not in use to prevent leaks.

How to Store Your Stick Welder?

Cover the Welder: Use a cover to protect your stick welder from dust and debris.

Store in a Dry Location: Ensure the welder is stored in a dry place to avoid rust and corrosion.

Organize Cables and Leads: Properly coil and store the welding cables and leads to prevent tangling and damage.

Disconnect Power: Always disconnect the power source when the welder is not in use to ensure safety.

Where to Find Quality Welding Supplies?

How to Choose the Right Welding Supply Store?

Reputation and Reviews: Look for a welding supply store with positive reviews and a good reputation in the industry.

Product Range: Ensure the store offers a wide range of products, including MIG welders, TIG welders, stick welders, and accessories.

Customer Support: Choose a store that provides excellent customer support and knowledgeable staff to assist with your needs.

Quality Assurance: Verify that the store sells high-quality, reliable products from reputable brands.

Why is it Important to Buy from a Reputable Welding Supply Store?

Purchasing from a reputable welding supply store ensures that you receive quality products that meet industry standards. Reliable stores offer warranties, customer support, and a wide selection of tools and accessories to meet your specific needs. Investing in high-quality equipment from trusted sources can significantly impact your welding projects' success and safety.

Conclusion

Maintaining and storing your welding equipment properly is essential for ensuring their longevity and optimal performance. By following the maintenance tips and storage techniques outlined in this guide, you can keep your MIG welder, TIG welder, and stick welder in excellent condition. Additionally, choosing a reputable welding supply store can provide you with the quality products and support you need for successful welding projects. Prioritize the care of your equipment to achieve the best results and extend the life of your tools.

0 notes

Text

Exploring the Benefits and Applications of Hiwin Linear Guideways

In the realm of precision engineering and automation, Hiwin linear guideways stand out as a cornerstone of efficiency and accuracy. These guideways are essential components in a wide range of industrial applications, ensuring smooth, precise, and reliable linear motion. This blog delves into the world of Hiwin linear guideways, exploring their benefits, applications, and why they are a preferred choice in various industries.

Understanding Hiwin Linear Guideways

Hiwin linear guideways are mechanical systems designed to provide smooth and precise linear motion. They consist of a rail and a carriage block, with rolling elements (balls or rollers) that facilitate the movement of the carriage along the rail. This design ensures minimal friction and high accuracy, making them ideal for applications that require precision and reliability.

Benefits of Hiwin Linear Guideways

High Precision and Accuracy: Hiwin linear guideways are renowned for their exceptional precision. The rolling elements within the guideways reduce friction and allow for smooth, accurate motion. This high level of precision is crucial in applications where even the slightest deviation can lead to significant issues.

Durability and Longevity: Hiwin linear guideways are manufactured using high-quality materials and advanced production techniques. This ensures their durability and longevity, even under demanding conditions. The robust construction of these guideways means they can withstand heavy loads and maintain their performance over time.

Reduced Friction and Wear: The design of Hiwin linear guideways minimizes friction, which in turn reduces wear and tear. This not only extends the lifespan of the guideways but also enhances their efficiency. The reduced friction also means less energy is required to move the carriage, resulting in energy savings and lower operational costs.

Smooth and Silent Operation: The smooth rolling motion of the elements within Hiwin linear guideways ensures quiet and vibration-free operation. This is particularly important in applications where noise and vibrations can affect performance or cause discomfort to operators.

Versatility in Applications: Hiwin linear guideways are highly versatile and can be used in a wide range of applications. From CNC machines and industrial robots to medical equipment and automotive manufacturing, these guideways provide reliable linear motion solutions across various industries.

Key Applications of Hiwin Linear Guideways

CNC Machines: In the world of computer numerical control (CNC) machining, precision is paramount. Hiwin linear guideways are integral to CNC machines, ensuring accurate positioning and movement of the machine's components. This precision is critical for producing high-quality parts with tight tolerances.

Industrial Automation: Automation systems rely on precise and reliable motion control to function effectively. Hiwin linear guideways are commonly used in industrial robots, automated assembly lines, and other automated systems to ensure smooth and accurate movement of components.

Medical Equipment: The medical industry demands high precision and reliability, especially in diagnostic and therapeutic equipment. Hiwin linear guideways are used in medical imaging devices, laboratory automation systems, and surgical robots, where their accuracy and smooth operation are crucial.

Semiconductor Manufacturing: The production of semiconductors requires extremely precise and clean processes. Hiwin linear guideways are employed in semiconductor manufacturing equipment to achieve the high levels of accuracy and cleanliness needed in this industry.

Automotive Industry: In automotive manufacturing, Hiwin linear guideways are used in various applications, including assembly lines, welding systems, and quality control equipment. Their durability and precision make them ideal for the high demands of the automotive industry.

Printing and Packaging: Hiwin linear guideways are also used in the printing and packaging industry, where precise and reliable motion is essential for high-speed operations. They ensure accurate positioning and movement of print heads, cutting tools, and packaging machinery.

Why Choose Hiwin Linear Guideways?

Proven Track Record: Hiwin has established itself as a leading manufacturer of linear motion components, with a proven track record of quality and reliability. Their guideways are trusted by industries worldwide for their consistent performance and durability.

Advanced Technology: Hiwin continually invests in research and development to advance their technology and improve their products. This commitment to innovation ensures that their linear guideways remain at the forefront of precision motion control.

Comprehensive Product Range: Hiwin offers a comprehensive range of linear guideways to meet the diverse needs of various industries. Whether it's miniature guideways for compact applications or heavy-duty guideways for demanding environments, Hiwin has a solution.

Global Support Network: With a global support network, Hiwin provides excellent customer service and technical support. Their team of experts is available to assist with product selection, installation, and maintenance, ensuring that customers get the most out of their Hiwin linear guideways.

Conclusion

Hiwin linear guideways are an essential component in the world of precision engineering and automation. Their high precision, durability, and versatility make them the preferred choice for a wide range of applications. Whether in CNC machines, industrial automation, medical equipment, or automotive manufacturing, Hiwin linear guideways provide the reliable linear motion solutions that industries depend on.

By choosing Hiwin linear guideways, you are investing in quality, performance, and innovation. Trust in Hiwin's expertise and experience to meet your motion control needs and ensure the success of your projects.

Contact Us: https://www.jaikrishnabearing.com/contact-us.php

#hiwin linear bearing distributors#hiwin linear guide distributors#Hiwin dealers in delhi ncr#Hiwin dealers in ajmeri gate#Hiwin dealer in gb road#hiwin linear motion products#industrial hiwin bearings dealers in delhi#Industrial Hiwin dealers in Delhi NCR

0 notes

Text

Stainless Steel 301LN Sheet: Uses and Specifications

Metal Supply Centre is one of Best Quality Stainless Steel 301LN Sheet Suppliers in India. The identical specification, SS 301LN Sheets, applies to seamless, welded austenitic sheets meant for use in corrosive, high-temperature conditions. There are several width and length measurements, finishes, and standards available for 301LN stainless steel sheets. Also We lead Stainless Steel 439 Coil Manufacturer in India.

Stainless Steel 301LN Sheet as an established manufacturer of 301LN stainless steel sheet, we always guarantee that our sheet performs to the highest standard and lives up to the expectations of our customers. In order to achieve this, we follow global ASTM, ASME, and AISI quality standards. A steel sheet has excellent corrosion resistance and performs well under many conditions.

Here are some of Various kinds and SS 301LN Sheet:

Cold Rolled Stainless Steel 301LN Sheet: The mechanical qualities, surface smoothness, and dimensional accuracy of stainless steel sheets are all improved by the cold rolling process. Stainless Steel 301LN Sheet Suppliers that have been cold rolled are frequently used in situations where exact measurements and a smooth surface are necessary.

Hot Rolled Stainless Steel 301LN Sheet: Stainless steel is heated above the temperature at which it recrystallizes and then passed through rollers to get the required thickness in a process known as hot rolling. Applications where formability and strength are more important than surface quality can benefit from using hot-rolled stainless steel 301LN sheets.

Annealed Stainless Steel 301LN Sheet:The heat treatment procedure known as annealing enhances the stainless steel sheets' ductility and machinability. Because they are pliable and simple to work with, annealed stainless steel 301LN sheets are perfect for applications requiring a lot of bending or shaping.

Hardened Stainless Steel 301LN Sheet: To strengthen the hardness and strength of stainless steel 301LN sheets, a controlled heating and cooling procedure is applied to them. SS 301LN Sheet Suppliers are frequently utilised in situations where attrition and durability are essential.

Polished Stainless Steel 301LN Sheet: SS 301LN Sheet polishing is applying a mechanical or chemical treatment to the surface to produce a lustrous, smooth surface. When appearance is crucial, polished stainless steel 301LN sheets are frequently used in appealing and engineering uses.

Types Of Stainless Steel Sheet and Coil

Stainless Steel 309 Sheet Supplier

Stainless Steel 309s Sheet Supplier

Stainless Steel 310S Sheet Supplier

Stainless Steel 314 Sheet Supplier

Stainless Steel Coil Supplier

Stainless Steel 301LN Coil Supplier

Stainless Steel 309 Coil Supplier

Stainless Steel 439 Coil Supplier

Stainless Steel 301LN Sheet Supplier - Specifications

Grades: ASTM A240, ASME SA240

Dimensions: ASTM, ASME and API

Standard: JIS, AISI, ASTM, GB, DIN, EN, etc.

Surface: 2B, 2D, BA, NO.4, NO.8, 8K, Mirror,Chequered, Embossed, Hair Line, Sand Blast, Brush, Etching

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm,etc.

Finish: Black,Bright Polished,Rough Turned,No.4 Finish,Matt Finish,BA Finish

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc.

To more in Details

Website: metalsupplycentre.com

Product page: SS 301LN Sheet Suppliers in India

#Stainless Steel 301LN Sheet Suppliers in India#Stainless Steel 301LN Sheet Suppliers#Stainless Steel 301LN Sheet#SS 301LN Sheet Suppliers#SS 301LN Sheet#SS 301LN Sheet Suppliers in India#Stainless Steel 309 Sheet Supplier#Stainless Steel 309s Sheet Supplier#Stainless Steel 310S Sheet Supplier#Stainless Steel 314 Sheet Supplier#Stainless Steel Coil Supplier#Stainless Steel 301LN Coil Supplier#Stainless Steel 309 Coil Supplier#Stainless Steel 439 Coil Supplier

0 notes

Text

How to Make Cricut Wine Glass: Full Tutorial

Last month, my son proposed to her childhood girlfriend, and she said yes! Since then, they have planned to make everything perfect for their special day. Being a mother and a businesswoman, he entrusted me with the duty of creating a custom-made Cricut wine glass, especially for them. It's crystal clear that it is very difficult to create any design on glass as it is a sensitive material.

With a Cricut cutting machine, I won't have to worry because supplies help me balance everything. The possibilities for making projects with the Cricut machine are endless. If you intend to make wine glasses with Cricut, there are a few supplies needed to help users complete their art quickly. In this blog, I will introduce you to the steps that will help you create the glass of your choice.

Stage 1: Create a Design on the Cricut App

If you intend to make a Cricut wine glass, open the Cricut designing software (Design Space) and tick the New Project option. After that, press the Upload tool, select your design from your system folder or given under the Recent Uploads,and then press the Insert Image button.

Now, fill in the space between the letters by selecting the Weld option mentioned under the Layers panel. Next, select the whole text, increase its size per your preference, and change its color from the material color dropbox.

After deciding on the text color, tick the Make It box and check that the design is correctly aligned. If not, return to the canvas, make the required changes, and hit the Make It button again.

Stage 2: Turn on Your Cricut Machine & Cut the Material

In order to choose the Cricut wine glass material, press Browse All Materials and select your material from the list before you. After finalizing the material, click the Done option and change the blade pressure to Default. Following this, load the Fine-Point Blade into Clamp B properly.

Then, cut a portion of your Cricut material and place it on the BlueGrip cutting mat. Next, load your mat and press the machine's flashing power button. At this point, you are supposed to wait till the Cricut machine is cutting the material. After the process ends, remove the material from the BlueGrip mat.

Stage 3: Remove Your Design & Apply Vinyl

Following this, take your Cricut weeding tool and remove the extra vinyl covering your main design. Now, use alcohol-free baby wipes or a lint roller to clear your glass blank. After that, cover your design with a Cricut transfer tape and use a scraper tool to connect the design and the tape properly.

Stage 4: Reveal Your Cricut Wine Glass

After a few minutes, start peeling off the transfer tape and then trim the extra tape with the Cricut scissor. Following this, place the design with your fingers or scraper tool to avoid any space or wrinkles between the design. Finally, start peeling off the transfer tape and repeat the same steps to stick the design on the second glass.

Congratulations on successfully completing your first-ever glass project made with a Cricut machine. I wish you all the best in the future and hope you shine like a star in the crafting world.

Final Words

This blog helped you understand the complete process of making customized Cricut wine glass using a craft plotter and its supplies. However, it's compulsory for all users to ensure that they are taking the correct steps while making any glass-related craft out of a cut-die machine. Keep going by making new projects, as they will boost your creativity skills.

Frequently Asked Questions

Question: Can I Put Customized Cricut Wine Glasses in Dishwasher?

Answer: If a customized Cricut wine glass is made with permanent adhesive vinyl, you can surely place it inside the dishwasher. To increase their lifespan, you are advised to wash the glass with your hands using warm water and light soap. This will balance the quality and shininess of the glass.

Question: Where Will I Get Unique Designs for My Wine Glasses?

Answer: The Design Space app is the best option if you are searching for unique designs you want to use while making customized wine glass. It is the designing software where you will come across unlimited images, designs, fonts, and ready-to-use projects, helping you make the design look more attractive.

Question: Which Cricut Supplies Do I Need to Make Wine Glasses?

Answer: The complete list of crafting supplies that you will need while making personalized wine glasses is as follows:

Visit: cricut.com/setup

cricut.com/setup

Source: https://cricricutdesigncut.wordpress.com/2024/03/22/how-to-make-cricut-wine-glass-full-tutorial/

#digital design#design space setup#cricut.com setup#cricut.com/setup#cricut.com/create#cricut.com/register#cricut.com sign in#cricut.com design space#design space cricut#cricut#cricut.com setup mac#cricut.com setup download#cricut.com setup windows#www.cricut.com/seup#www.cricut.com/setup\cricut explore air 2 setup#www.cricut.com/setup login#www.cricut.com/setup#install cricut explore air 2 '#install cricut explore air 2 setup#install cricut exlore air 2#install cricut explore air 2#install cricut air 2 setup#install cricut design space app#cricut new product device#cricut new machine setup#cricut new product setup#cricut create connect to computer#setting up your cricut maker#cricut setup on computer

0 notes

Text

ASOUE Inventions(used and unused)That Have Me Inspired

Original Book Series

-Grappling hook made of torn ugly clothing,a bent and broken curtain rod,and wire

-New kind of pencil sharpener

-Lockpick made from two plug prongs,a thumbtack,and soap as a lubricant

-Scratch-made telephone

-Automatic harmonica player

-Signaling device made with cloth,a fishing pole,a metal bucket,and a hairnet

-Retriever made out of chewed gum and a debarker

-Noisy shoes with metal on the heels and toes

-Staple-making device made with creamed spinach,metal rods,a toe-shaped potato,a small crab,and a fork

-A rope made of curtains,extension cords,and neckties

-Welding torches made of oven-heated fire tongs(when the heat died down,said tongs were later used as crowbars)

-New kinds of flashlights made from broom handles,rubber bands,and tin foil

-Water pitcher as a mortar-dissolver

-Wooden bench as a battering ram

-Assisted self-sustaining mobile home

-A new kind of telegram

-Strange mixing device for food

-Automatic rolling pin made of a window shade and six pairs of skates

-Intercom system with an empty soup can with a hole in it

-Rubberband trail escape device

-Escape cart made with ivy vines,roller coaster parts,and a fan belt

-Drag chute using hammocks and a multitude of stick condiments

-Wooden table used as a brake

-Climbing equipment made with fork-assisted shoes,fake fingernails,ukulele strings,and a candelabra as an ice tester

-Dirty laundry sheet drag chute

-Saltwater filtering device

-Flashlights made of tin foil,a broom handle,and rubberbands

-Cold,hard teething device made from a silver pie server and the ear from a snowman ice sculpture

Movie(used and unused)

(Used)

-A communication collator made with a magnetic spin wheel toy,a bell,a spiral metal strip,a basket,a bone piece,a tin can,metal and small balls,a bike horn piece,and a glass pipe,gears,a metal spoon.string,and a creepy doll

-Firefly trapper

-Headgear that can show pictures slides

-Switching device made with a coil,a car seat strap…and a Littlest Elf bobblehead

-Grappling hook made with an umbrella frame and rope

-Bed-making device that can be activated with the pull of its rope,gears,and clothespegs

(Unused…though I kinda wish they were used…)

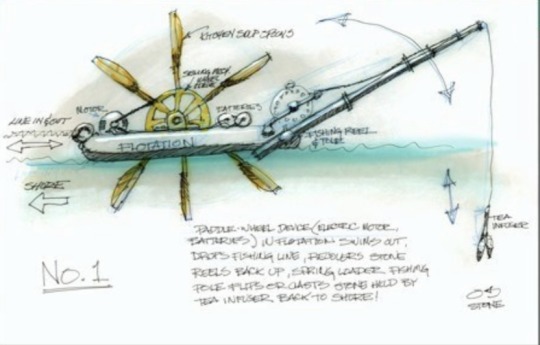

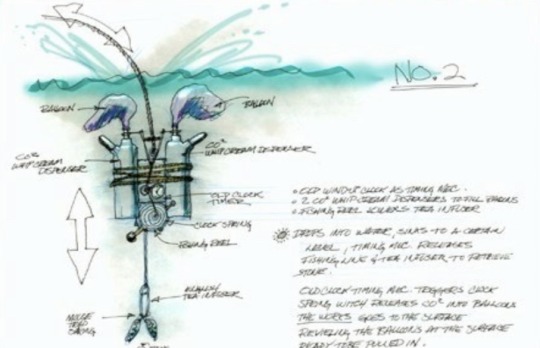

-Stone Fetcher(four or so variants)

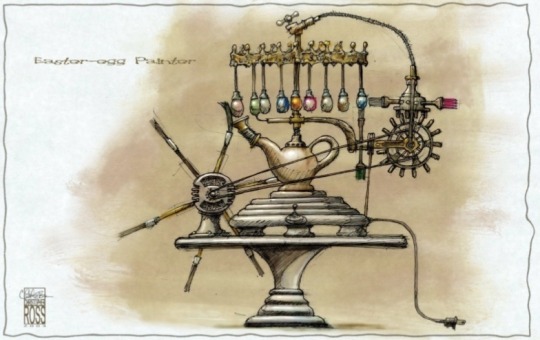

-Easter Egg Painter

-Wind-Driven Watering Device

-Firefly-Trapping Device

-Story-Teller Device

-Telescopic Hummingbird Observation Stabilizer

-Type-o-matic Shoe-Tying Device

-Harmonica Player(four or so variation),though

-A toy boat levitating device made with a hand-cranked sharpener,popsicle sticks,and paper balloons

Videogame(all variations)

(GBA)

-Apple-Chucker made with a soup can,ice cream scoops,and hand-cranking technology

-Water Pump made with bellows,a gasket,an empty jam jar,and a shower head

-Parasol Glider made with yarn,parasol,and a weathervane

(PC)

-Smasher made with a fork,a jack-in-the-box,and a boot

-Lobber made with bicycle parts,an ice cream scoop,and a toy sailboat(flings rotten eggs,super sticky and sweet bubblegum,onions,and water balloons)

-Bug Sprayer made with a bicycle pump,sickly perfume,and a gramophone cone(sprays strong perfume,horseradish,onions,pillow feathers,bees,and lime juice)

-Lockpick made with a pencil sharpener,wire hangers,and a record

-Lever Yanker made with a gavel,a bell pull rope,a clock spring,and a scale

-Reptile Retriever made with a large hoop,burlap,a long pole+handle,and a basket

-Stilts made with snowshoes,a rope,and two oars

-Grappling hook made with a parasol frame,shower curtain rings,and a spiral carpet

(Console)

-Brilliant Bopper made with a spring,a broom,an empty coffee can,and a boxing glove

-Fruit Flinger made with a funnel,a pool floatie,an electric fan*

*can be turned into a Reptile Retriever with the addition of a lawnmower bag,a screwdriver,and a garden hose

-Baby Booster made with a fire extinguisher,a bookstrap,and a pull cord

-A Goldberg device made with a bowling ball,firewood,rope,and some assistance

-Steady Stilts made with tripod legs,a piano wire,one’s own shoes,and snowshoe straps

-Levitating Loafers made with one’s shoes(ones with laces work the best),propellers,and batteries

-Lucky Lockpick made with a spool,a paintbrush,and a pair of tweezers

-Peppermint Popper made with a fishing pole,an eggbeater,and a ladle

-Horrifying Hook made with a bicycle pump,spring coil,and a gardening hook

Netflix TV

-Grandfather clock toaster

-A stone-fetching device in a box

-Grappling hook made with curtains,a pasta maker,whisks,gears,a power tool activator with a button,and a metal garden hook piece

-Gum to fix an electrical current

-Parachute made with an enormous basket,VERY long rubberbands,and Spain’s largest handkerchief

-Pickaxe machine

-Battering ram made with a noose,a wooden bench,and a hard bread loaf

-Repairs the roller coaster with a tagliatelle grande

Fanfics

-Fixed an ancestral cuckoo clock and replaced the broken pendulum with a metal rod and a gemstone in place of a weight

-Makeshift bell alarm using a metal bucket,a cord,a rope,and a wooden spoon

-Wooden shadow makers

-A rock retriever made with a milkcrate,a perambulator wheel,and typewriter remains

-Stops a conveyor belt with broken plate bits and a thrown metal pipe

-A projectile propeller made from a broken typewriter,an empty crate of water wings,and a wagon wheel

Concepts

-A Kitchen Winch made of a collander,a candle chandelier,with the hearth tucked between the legs to center the user’s weight,and sometimes a small clock and an apron for additional back support,and additional wringer and collander for pasta

-A suitcase invention with a spring-loaded tripod on the bottom,a scissoring device activated to open it,inside being grandfather clock mechanism,sewing kit parts like spools and thread,tape measure,sewing machine parts,wheels,a belt drive,a jack-in-the-box spring,a fishing reel,and a crank key

My OC inventions

-An odd reparation to the ice cream cart cooler

-A new kind of baby mobile

-A mobile flytrap

-A small bear trap made with broken silverware,broken glass cup pieces,and leftover metal rods tied up with a very long string

-A hooked rope out of a twisted-off hook-shape umbrella handle,a twistable bendy wire,and an old rope

-A kind of preservation system consisting of mechanics such as:a juice pump made with plastic tubing,accordion bellows,and rods…a pulley system for whole wheat flour retrieval…a solar powering system…and a boxing factory system for batteries made of gears,blanket cloth,and gardening tools

-A liquid dispenser device made of syringes,an empty frosting can,hot glue,grandfather clock mechanism,a Chinese lantern cover,a horseshoe magnet with two discs attached as the handle,and plastic tubing

-A new kind of humidifier

-A multi-horned airhorn made with multiple plastic funnels,empty cans of hairspray,and an oxygen tank

-A hair-cutting made of a doorknob,cookie cutters bitten with assistance,mattress springs,hair scissors,rubberbands,egg beater blades,violin bows,and grandfather clock mechanism

-An outdoor baking stove made with parts of a refrigerator,parts of a stove,and lit fires

-A one-man band set made from:Snare drum rigs made from jewelry hooks/bands,ribbons,and old silk bands,bike horns hot-glued onto turned-over glass sundae bowls on the shoulders,a hi-hat rig made with old arcade game mechanism,a toy robot arm,the strap part of a seatbelt,and an orthopedic shoe,a harp rack for the harmonica made from bare pipe cleaners and a broken music player,a xylophone-player of metal wire and small mallets,and a bass drum rig made with bent wire

-Baby carriages made with large greenhouse boxes,light-colored parasols and umbrellas,metal bars,altered magnetic spin wheels,small bicycle wheels,and quite a bit of welding

0 notes

Text

What Are The Different Types of MS-ERW Pipes?

Modern construction calls for modern components and choosing reliable materials and components for an infrastructure. Making this choice has always been crucial and can significantly affect a project’s outcome. Among the choices, MS-ERW (Mild Steel Electric Resistance Welded) pipes have emerged as a versatile and reliable choice for various applications. in this blog we know detail about What Are The Different Types of MS-ERW Pipes

So, in the comprehensive, we’ll learn about three different types of MS-ERW pipes, their usefulness in particular industries, their unique characteristics and advantages, and the specific applications that make them the best suited for all kinds.

Different Types of MS-ERW Pipes

CHS (Circular Hollow Sections Pipes)

Shape and Structure: circular hollow section or round MS-ERW pipes are the most common and widely used type. They have a circular cross-sectional shape.

Applications: They are ideal for applications where the fluid or material needs to flow without sharp turns or corners.

Benefits:

Uniform Strength: CHS pipes provide consistent strength throughout their circumference, making them ideal for specific load-bearing needs.

Smooth Curves: Their circular shape allows for soft curves and transitions in design.

Versatility: CHS pipes are suitable for applications where a circular shape is advantageous.

Examples of Applications: These pipes are known for their structural integrity and are employed in plumbing, architectural designs, handrails, fencing, water supply, gas transport, Poles and Columns, and Roller Coaster Tracks

SHS (Square Hollow Sections Pipes)

Shape and Structure: Square Hollow Sections (SHS) pipes, or SHS pipes, are characterized by their square or box-like cross-sectional shape.

Application: They are particularly suitable for structural applications, such as constructing frames, supports, and columns.

Benefits:

Excellent Load-Bearing Capacity: SHS pipes are known for their remarkable load-bearing capacity, making them ideal for structural applications.

Aesthetically Pleasing: Their clean and symmetrical appearance makes them suitable for architectural and design elements.

Ease of Fabrication: SHS pipes are easy to cut, weld, and shape, allowing for versatile applications.

Examples of Applications: SHS pipes offer high stability and are commonly used in building frameworks and architectural structures, such as building frames, fencing and railing, furniture manufacturing, and more.

RHS (Rectangular Hollow Sections Pipes)

Shape and Structure: Like SHS pipes, rectangular hollow section pipes or RHS pipes exhibit a rectangular cross-section with two flat sides and two perpendicular sides, forming a rectangular box-like structure.

Applications: RHS pipes find extensive usage in architectural and construction projects when the application demands a rectangular shape. RHS pipes excel in load-bearing capacities and aesthetic appeal.

Benefits:

Structural Strength: RHS pipes provide robust structural support, making them suitable for various construction applications.

Architectural Flexibility: Their shape allows angular and curved architectural elements to be created.

Load-Bearing Capacity: RHS pipes are capable of handling heavy loads.

Examples of Applications: They are preferred in constructing bridges, overpasses, industrial equipment, and building components. Additionally, they are ideal for crafting architectural elements like handrails, gates, and fences. RHS pipes support the creation of pallets, material handling systems, and storage solutions.

MS-ERW pipes have carved a niche in various industries and applications. Their cost-effectiveness, durability, and versatility make them a preferred choice for many projects, contributing to the development and progress of numerous industries.

Knowing about the different types of pipes, Ratna Steeltech stands as a renowned and trusted provider. Ratna Steeltech has emerged as a leader in the steel industry, with adherence to quality, creation, and consumer fulfilment. The company’s dedication to delivering top-notch MS-ERW pipes in various shapes and sizes has made it a preferred choice. In conclusion, understanding “What Are The Different Types of MS-ERW Pipes?” is crucial for anyone involved in the construction or industrial sectors

1 note

·

View note

Text

Welding Rotators, commonly referred to as Tank Rollers, Welding Rollers, Tank Rotators, Weld Rotators, Pipe Rotators, Welding Rolls, Vessel Rollers, Tank Rolls, and Turning Rolls, are primarily employed for welding circular and longitudinal seams on cylindrical objects like barrels, pressure containers, and boilers. This turning roll is comprised of a base, driving rollers, idlers, electric cabinet, brackets, transmission device, and a power-driven mechanism. Elevate your welding efficiency with our high-precision welding rotators in the UAE.

0 notes

Text

What Are the Precautions in Using Animal Feed Production Line Processing

There are many kinds of feed processing equipment, among which the key equipment affecting feed granulation is nothing more than a hammer mill crusher, mixer, and poultry feed-making machine. Feed manufacturers need to understand the precautions for using the equipment.

1. Hammer Mill Crusher The hammer mill crushers generally have vertical and horizontal types. The main components of the crusher are the hammer and screen. The hammer shall be durable, wear-resistant, and have certain toughness. Precautions for the use of a crusher: 1) Before starting the machine, check the lubrication of all parts of the connectors and bearings. Run the machine empty for 2-3 minutes, start feeding after a normal operation, stop feeding after work, and run the machine empty for 2-3 minutes. Turn off the motor after all the materials in the machine are drained.

2) If the hammer blade is worn to the centerline, it should be turned around immediately. If all four corners are worn to the center, a new hammer piece needs to be replaced.

Note: the original arrangement order shall not be changed during replacement, and the weight difference between each group of hammer pieces shall not exceed 5g, otherwise the balance of the rotor will be affected.

3) The air net system of the crusher is very important to improve the crushing efficiency and reduce dust. It should be matched with a pulse dust collector with good performance.

2. Feed Mixer (double shaft mixer as a sample) The double-shaft feed mixer is composed of a casing, rotor, cover, discharge structure, transmission device, etc. The blade shaft intersects the main shaft, and the blade is welded on the blade shaft at a special angle. On the one hand, the blade with animal materials rotates along the inner wall of the machine slot and moves to the other end, the animal materials turn over and cross-cut each other, to achieve the effect of rapid and uniform mixing. Precautions for the using mixer: 1) Feed the materials after the main shaft rotates normally. The additives shall be added after half of the main materials enter the batch. The grease shall be sprayed after all dry materials enter the machine. The materials can be discharged after spraying and mixing for a while time;

2) When the machine is not in use, the grease shall not be retained in the grease-adding pipeline to avoid blocking the pipeline after solidification;

3) Metal impurities shall not be mixed during material mixing, which will damage the rotor blade;

4) In case of a shutdown during use, discharge the materials in the machine before starting the motor;

3. Ring Mold Feed Pelletizer Feed pellet mill machines are the main equipment in the production process of poultry feed equipment, which can also be said to be the heart of feed plants. The correct use of feed pellets directly affects the quality of finished products.

Precautions for the using feed pelletizer: 1) During production. When too many materials enter the feed fertilizer, and the current rises suddenly, need use manual unloading of the materials outside the feed granulator is done.

2) When it is necessary to open the door of the feed pelletizer, the power supply must be cut off first, and the door can be opened only after the feed pelletizer completely stops running.

3) When the machine breaks down, the electric power must be cut off, and the machine must be shut down for troubleshooting. It is strictly prohibited to use hands, feet, wooden rods, and irons for hard troubleshooting during operation; It is forbidden to start the motor hard.

4) When the new ring mold is used for the first time, a new pressing roller must be used. The ring mold can be washed for 10 to 20 minutes with oil mixed with fine sand (all pass through a 40-20 mesh sieve, and the ratio of material∶oil∶sand is about 6∶2∶1 or 6∶1∶1). Then ring die can be put into normal production.

5) Check and refuel the main motor bearing once a year.

6) Replace the lubricating oil for the gearbox of the feed pelletizer once or twice a year.

7) The steam pressure entering the jacket of the conditioner shall not be higher than 1kg/cm2.

8) Clean the feeder and conditioner 2-4 times a week (once a day in summer).

9) The distance between the cutter and the ring die is generally not less than 3mm.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us! Henan Herm Machinery Co., Ltd Email: [email protected] Phone/Whatsapp: 86-18037508651

0 notes

Text

Birds of a Feather

CisFem Reader x Marco

CW: Violence, blood, language, adult themes and scenes. 18+ only

Summary: Life has not been kind to you. After a string of bad relationships, you're a little jaded and a little depressed in all honestly. The worst day of your life seems to be the turning point, but the roller coaster ride that follows could either throw you soaring free, or have you caged forever?

Chapter 7: Motor Running

That weekend, and the week after, went by slower than any other week before, as far as you were concerned. You and Marco met for lunch a couple times, but usually he had an appointment, or you had a meeting. Even when you had time enough to share a quick meal, it was indeed a quick meal. You both talked about work more than anything – you had tried to wheedle some details about the date out of him, but he was teasingly tight-lipped on the matter.

None of your time together had been uncomfortable, but aside from kissing the top of your hand at the end of dinner, Marco kept his distance. It wasn’t like he was avoiding you, but you weren’t sure if he wanted to take things slow, or if he was giving you the lead. Kid, and most everyone else you’d dated, were pretty physical.

It wasn’t like you got yanked into a dark corner and slammed against the wall all the time, or that you even needed that level of painfully obvious desire. It was just different from what you had become used to.

But Marco wasn’t in the city just on business. He wasn’t visiting from the ocean’s depths, and he wasn’t loud, or angry, or crass. There was passion there, unmistakably, and it had lit up his eyes more than once since you’d known him.

Maybe he was worried that if he came on too strong, you’d break and run. Whatever the case was, you weren’t going to worry about it for now. You weren’t going anywhere any time soon as it was, especially with your car still in Kid’s care.

Buggy dropped you off at home, and by that, he had the Bubble he’d ordered detour to your place before taking him home. Bon-bon and Ivankov had been taking you home for the most part, and you’d only stayed over at the office one day this past week. You’d taken a couple Bubbles to get into work, and one early morning Sanji gave you a lift.

You were going to be happy to have your car back.

Your phone rang shortly after you got home, and you recognized the shop’s number.

“Hey Red, what’s up?”

There was a short grunt on the other end of the line. “Got the body restored, waiting on a few more parts to come in before she’ll be ready. I called to see if you wanted a different paint job, you little shit.”

You laugh. “Sorry, I couldn’t help it. Hm, a different color…”

“I’m bringing in that long-nose artist to do the actual bird, so don’t worry about sticking with stock colors if you don’t want to.”

“Oh, when’s he coming in?”

“Sunday, it’s a personal project for him, so I’m trying not to tie him up during usual work hours. He should be in around 9am.”

“Hmm… Usopp opens up a lot of options.”

“Heh, he does. Guy’s got a good eye for things, even if he’s a little skittish.”

“Around you Kid, everyone’s a little skittish.”

“You aren’t, calling me by that stupid fuckin’ nickname.” He grumbles.

You grin. “I just don’t have the sense to be afraid of anyone.” He grunts, and you continue. “You remember that blue Killer was using for his welding mask?”

“Yeah.”

“Can you base coat her with that? I want to come by Sunday and talk about options with Usopp, but I know you need to let the base coat set before he starts.”

“Going with a whole different color scheme, huh?”

“The rust and the red went well together,” you muse, chuckling. “But if all the rust is gone, then it’s time for something different, right?”

Kid grunts, but doesn’t say anything.

“Something on your mind?”

He clicks his tongue, grumbles under his breath and then finally lets out a big dramatic sigh. “I feel like I’m the one being replaced.” He finally admits angrily.

“You’ll always be my unreasonable asshole ex-boyfriend turned marginally reasonable asshole best friend.” You say, a playful edge in your voice.

“… I better not be your best friend.”

“I mean, it’s between you and Buggy, and you’re more stable.”

Kid scoffs and laughs. “You’re kind of shit at making friends.”

“Pot and Kettle, I suppose.” You grumble back before laughing along with him.

There’s a beat of silence after you both settle down and Kid sighs a little. “That Vet does anything to hurt you, you tell me.”

“Pfft, I can bring him with me Sunday, maybe, you want to tell him to his face or something?”

“Fuck no. I ain’t gonna let him raise his guard like that!” Kid snaps before huffing. “Shop’s a public place though, I’m not saying he’s barred or anything.”

“Alright, I don’t know what his Sundays are like, but if I need a ride I’ll give you a call.” You say with a smile. “You’ll enjoy getting a look at his car up close, I bet.”

“I don’t need to see the inside of a ’72 SEL.” He grumbles.

“Not even one that’s washed three times a year? That engine was immaculate.” You tease.

“… You’ve been under the hood?”

“Mm, speaking of, if you have some custom hydraulic lifts, the hood lift’s busted. He hasn’t had any luck finding a replacement.” You mention it nonchalantly, but you can hear Kid’s mood shift before he even speaks.

“I’ll see what I have lying around.” He clears his throat. “I could probably make something in the next two days that would work.”

“Metal geek.” You tease.

“Book whore.” He shoots back.

“Greaser guzzler.” You’re barely able to keep yourself from laughing especially when Kid starts to cackle.

“Leaving me low hanging fruit. Ah, but I know, you’re going to end up that Vet’s pet, little mouse.”

“I’m not a mouse,” you insist.

“Yeah, yeah, you’re more like to hunt mice than be one.” You can picture him waving his hand dismissively.

You laugh. “Talk to you later, Kid.”

“Mm, later.”

You end the call and take a moment before you opt to send a text.

You: Sneakers or heels for tomorrow? Also are you available Sunday morning?

You peeled off your work clothes while you waited for a response. A shower before putting together something for dinner seemed like a good idea. You were going to work a couple hours tomorrow, but you’d decided to bring a laptop home vs going into the office. Going over some of the packets while you had breakfast and coffee was a good way to start your morning, and you wouldn’t have to worry about getting caught up at work and losing track of time.

Marco: I’ll show you my emo phase, if you show me yours. 😉

You laugh when you read the response.

You: It was more a punk phase, but sure.

Marco: I’m free Sunday, what’s up?

You: Kid’s getting the base coat down on my old firebird, and I need to go in Sunday to work with the detail artist for the final design and colors. I could use a ride, but Kid and the crew would love to see your SEL. (Also he might have an arm for your hood).

Marco: That’s doable. We can talk about it more tomorrow.

#Birds of a Feather#Marco x reader#x reader#reader insert#marco the phoenix#marco the pinepple#modern au

14 notes

·

View notes

Photo

Full Name: Emiliano Moreno Nickname: Emil Age & Birthday: 32 - November 20th. Occupation: Marine Welder Preferred Pronouns & Gender: He/him & cis-male Sexuality: Heterosexual Hometown: Briar Ridge, South Carolina. Neighborhood: Beach Front Family: Isabel Moreno - 9 year old daughter.

Pinterest | Connections.

trigger warnings: car accident.

Born locally, Emil had what he would consider a mostly fairly middle of the road childhood. He often felt a bit detached from his parents, but he wanted for very little outside of perhaps a more socially stimulating environment. His uncle who was deemed by his ma as the ‘wild’ one of her family is very close to him.

A lot of times it was his uncle that took him to tee-ball, and sat in the stands all through his schooling years on the field.

Just as he was about to pack his bags and get out of dodge on a baseball scholarship, he experienced one of his first real upsets in life. His ma was in a bad car crash, and had to go through physical therapy. With medical bills and her needing help around the house, Emil put off college.

A semester turned into a year plus, but eventually with luck on his side and some help from his high school sweetheart’s family - Emil left town for his belated start out in San Diego on scholarship and studying physical therapy.

Everything was going pretty swimmingly, even his long distance relationship and he was so close to making the draft that he could practically hear the stadium crowds cheering for him. but alas life had one more curve ball for him & he was given the news that Maya was pregnant and Emil immediately dropped everything to go back home.

Things went downhill from there in the years to follow. Between his own emotional distress of giving up his dream, there was a lot of tension between him and Maya that he thought getting married could somehow fix. When it didn’t, the pair had a really ugly divorce and a custody battle you’d expect to be run by Judge Judy. Maya was successful in painting Emil poorly and in the end, though he’d get visitations, he lost the custody battle for Isabel.

Having followed in his father’s footsteps upon coming back home, Emil nowadays has a very steady career. Though none of it is what he imagined he would be doing growing up he’s far from miserable, he’s adapted pretty well. Being able to turn his welding experience into his own thing by getting all his diving certifications definitely helped him settle in. Coaching tee-ball and being a sub for a local softball team certainly helps as well. The main stress in his life currently is dealing with his ex-wife and having to sometimes fight tooth and nail to get his owed visitations etc. with Isa. It doesn’t help that she’s old enough to ask questions Emil doesn’t always have an answer to, like why she has to stay with her mother. He’s stable enough that he’d like to go back to court, but he’s a little nervous it’d be hard on Isa and that he has less of a leg to stand on when Amaia has had her for as long as she has.

Fun facts:

he has a husky named Hercules after the dog in The Sandlot.

can be a bit of a thrill seeker. Likes roller coasters, dancing, and spontaneous road trips.

technically has enough diving certifications he could be a diving instructor but has little interest.

owns way too many jerseys kind of sports fan, has seasonal tickets. supports a lot of local teams.

has a serious shellfish allergy, which is slightly amusing given the local cuisine.

likes #DadJokes and always has a snack on him because of either Isa or the kids he coaches for tee-ball.

Connections: I’ll make a full page with more suggestions etc. but here’s a quick handful to help with plotting!

Guy friends - sports fans, drinking buddies etc.

Female best friend - I'd like them to be a local similar in age if possible, so they could know his ex-wife and have gone to school together.

Dog sitter | Neighbor | Flings - I promise I'll add some other ideas & a full plots page once I get the time this week.

1 note

·