#water treatment plant manufacturers

Explore tagged Tumblr posts

Text

water treatment plant manufacturers

Bhoomi Environmental is a leading name among water treatment plant manufacturers, providing innovative and sustainable solutions for clean water. Our advanced water treatment plants are designed to meet industrial, commercial, and municipal needs, ensuring efficient purification and wastewater management. As experienced water treatment plant manufacturers, Bhoomi Environmental focuses on quality, efficiency, and environmental sustainability. Our cutting-edge technology helps industries achieve regulatory compliance while promoting water conservation. Choose Bhoomi Environmental for reliable and cost-effective water treatment solutions tailored to your requirements. Contact us today to explore our range of high-performance water treatment systems and services.

0 notes

Text

#sewage treatment plant#wastewater treatment plant#sewage treatment#domestic sewage treatment plant#sewage treatment plant in delhi#sewage treatment plant manufacturer#water treatment plant manufacturers#sewage treatment plant suppliers#water treatment plant suppliers#stp plant manufacturer#water treatment plant in delhi#wastewater treatment plant manufacturers#stp plant supplier#wastewater treatment plant delhi#wastewater treatment plant suppliers#wastewater treatment companies in delhi ncr#stp ro plant#stp plant#sewage treatment plant near me#small sewage treatment plant#sewage treatment systems#wastewater treatment system#sewage water treatment#home sewage treatment plant#package treatment plant#wastewater treatment companies#sewage plant

0 notes

Text

https://justpaste.it/stp-plant-1

#sewage treatment plant#wastewater treatment plant#sewage treatment#domestic sewage treatment plant#sewage treatment plant in delhi#sewage treatment plant manufacturer#water treatment plant manufacturers#sewage treatment plant suppliers#water treatment plant suppliers#stp plant manufacturer#water treatment plant in delhi#wastewater treatment plant manufacturers#stp plant supplier#wastewater treatment plant delhi#wastewater treatment plant suppliers#wastewater treatment companies in delhi ncr#stp ro plant#stp plant#sewage treatment plant near me#small sewage treatment plant#sewage treatment systems#wastewater treatment system#sewage water treatment#home sewage treatment plant#package treatment plant#wastewater treatment companies#sewage plant

0 notes

Text

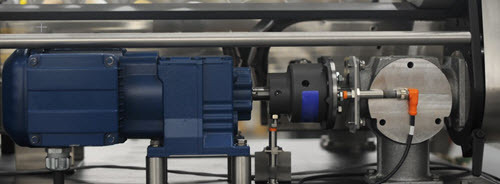

You're cordially invited to 𝗪𝗮𝘁𝗲𝗿 𝗧𝗼𝗱𝗮𝘆'𝘀 𝗘𝘅𝗽𝗼 𝗶𝗻 𝗡𝗮𝗻𝗱𝗮𝗺𝗯𝗮𝗸𝗸𝗮𝗺, 𝗖𝗵𝗲𝗻𝗻𝗮𝗶, 𝗳𝗿𝗼𝗺 𝟮𝟲𝘁𝗵 𝘁𝗼 𝟮𝟴𝘁𝗵 𝗙𝗲𝗯𝗿𝘂𝗮𝗿𝘆 𝟮𝟬𝟮𝟱. Join us to explore the latest innovations and solutions in the water industry.

Don’t miss this incredible opportunity to network and learn! We look forward to seeing you there!

☎️ 𝗠𝗼𝗿𝗲 𝗜𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻

📱 +91 9953088849, +81 062043 85227

🌐 www.a1blowers.com

#gurugramnews #aircompressorservice #turbineblower #aircompressorparts #faridabadcity #EFFLUENTTREATMENTPLANT #ringblower #gurugramcity #TamilnaduNews #sewagetreatmentplant #tamil #tamilcinema #tamilsong #tamilstatus #tamilreels #tamilnadutourism #tamilnadupolitics #chennai #Chennainews #bengaluru #kerala #keralanews #kochi #KochiNews #AirBlower #watersolutions #sewagetreatment #effluenttreatment #wastewater #wastewatertreatment #WaterTreatment #watertreatmentsystem

#airblowersinchennai#industrial air blower#manufactring company#sludgedewatring#vacuum pumps#airblower#delhi#sewage treatment plant manufacturer#waste water#a1blowers

2 notes

·

View notes

Text

Wastewater Treatment Company in Trivandrum

Water Purification Services in Trivandrum

#purification#startup#waste management#wastewatertreatment#water purifier#watercolor#kerala#waterpurifier#watertreatment#effluent treatment plant#service#sewage water treatment#water security#sewage treatment plant manufacturer#efficiency#effluentdisposalreport#wastewater data#zero waste#wasteland#water plants#disposable vape

2 notes

·

View notes

Text

Advanced Solutions For Water Treatment Plant Manufacturers in India

Water Treatment Plant Manufacturers in India incorporate cutting-edge technology and innovative processes to purify water and meet stringent quality standards. With this project, we have contributed to improving public health and ensuring a sustainable future for communities across India.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment

2 notes

·

View notes

Text

Who Is The Best Sewage Treatment Plant Manufacturer In Noida ?

Sewage Treatment Plant Manufacturer In Noida with all facilitiesare essential for meeting this demand & reducing water pollution.

The Requirement for STP Plants in Noida & Nearby Cities

Direct discharge of untreated wastewater into lakes, rivers, as well as groundwater can seriously contaminate the water & pose health risks to humans. Additionally, many smaller enterprises lack the resources & knowledge necessary to install suitable domestic wastewater treatment systems.

Additionally, the capacity of Sewage Treatment Plants run by industrial groups is restricted. To effectively treat wastewater while following all the disposal regulations set forth by government pollution control boards, specific STPs are implemented based on the types of industrial operations involved.

The infrastructure in many parts of Noida needs to be upgraded to maintain the balance with the city's progressive urban growth & population rise. Sewage from homes, Commercial businesses, & many other places is treated by advanced STPs before being discharged into the environment for utilization again.

Therefore, in order to stop the increasing levels of water pollution in its industrial zones & urban settlements along with infrastructures must have dependable industrial Sewage Treatment Plant Manufacturer In Noida.

The function of STP Plants by Netsol Water in Reducing Water Contamination in Noida

Onsite STP Plants can be very helpful in addressing Noida's water pollution problem in the following ways:

A variety of unit activities, including chemical coagulation, flocculation, filtration, neutralizing the substance, equitable distribution, an activated sludge process, & activated charcoal treatment, etc., are used by STP Plants made for specific industrial processes to treat outlet water. This facilitates the safe release of treated water that satisfies quality standards into the environment while also making it easier to remove all dissolved as well as insoluble inert contaminants.

Advanced STP facilities implement primary, secondary, & then following tertiary processes to ensure comprehensive sewage treatment. The requirement for freshwater is reduced when the treated water is utilized again for additional purposes.

STP plants alleviate overloading & dependency issues in some sectors. Additionally, STP Plants lower the cost of the sewage transmission infrastructure for centralized treatment.

Enhanced computerization & various related procedure controls are made possible by ongoing monitoring at on-field treatment facilities. This ensures consistent along with effective care.

STP Plants that are appropriately sized as well as designed handle sewage loads as well as present & projected future industrial growth, respectively.

Therefore, by significantly lowering the pollution brought on by municipal & industrial wastewater, STP Plants provide a sustainable method of managing water resources.

The function of Netsol Water in the manufacturing of STP plants being a reputable company In Noida

As One of the top manufacturers of STP plants in India, Netsol Water serves the demands of various commercial enterprises as well as urban residential areas. Netsol Water has been a leading provider of water & wastewater treatment facilities to clients in the private as well as public sectors for over 20 years.

Netsol Water also played an integral & important part in Noida's water crisis with its expert care plus ongoing regular services.

Innovative High-tech as well as Diverse Water Treatment Methods:

Reverse osmosis, Moving Bed Biofilm Reactor, RO Membrane Systems, Trickling Filters, ASP (Activated Sludge Processes), & RBC (Rotating Biological Contractor) are some of the advanced world-class, popular techniques that Netsol Water utilizes to suit the needs of its customers.

The most recent technologies, such as Environmental ZLDP(Zero Liquid Discharge Plant) systems, are included by their in-house design & engineering team, enabling over 90% treated water recovery & compounds like sodium chloride, sodium sulfate, etc., as marketable commercial byproducts. These inventions highlight Netsol Water's technological prowess.

Thorough as well as Regular Routine Maintenance & Operations

After STP installation & operation are approved, Netsol Water provides comprehensive Operations & Maintenance (O&M) services, along with the option to sign annual maintenance contracts.

Conclusion

As Noida rapidly grows as a residential & commercial hub in UP, it is essential to ensure the provision of clean water for every application as well as intake purposes along with sanitation. Furthermore, as urban areas & industrial operations continue to grow, the amount of sewage & industrial effluents will increase in the future.

Because Netsol Water makes it possible to properly & safely manage these massive wastewater streams from such places while also reclaiming recyclable water, sewage treatment plant manufacturer in Noida have become crucial for environmental conservation in this area.

#sewage treatment plant#sewage treatment plant manufacturer in noida#water treatment plant#save water#water is life#netsol water

0 notes

Text

Understanding key factors in wastewater treatment

Wastewater treatment is an essential process. It is needed not only to have a sustainable environment but also good public health. Contaminated water if released back into nature untreated can cause massive health problems and environmental concerns. With increasing population, urbanization, and industrial activities, managing wastewater has become more necessary than ever. Several factors influence the efficiency and success of the wastewater treatment process.

Type and source of wastewater:

The best wastewater treatment company in India like ours, UY Trienviro would primarily evaluate the source of water. Based on the source they would know what the water might contain. For if the wastewater is:

Domestic wastewater mainly contains organic matter, pathogens, and detergents.

Industrial wastewater may include heavy metals, oils, chemicals, and high BOD/COD loads.

Agricultural runoff would mostly have pesticides, fertilizers, and sediment.

Knowing or identifying the source helps us decide the right treatment technology to implement. It helps us in better results ensuring that the treated water meets the standards.

2. Flow Rate and Volume:

Knowing the volume of wastewater and the flow rate is essential for designing the treatment plant. Fluctuations in volume or flow during changing seasons or peak hours also impact the efficiency of the plant. At UV Trienviro we monitor wastewater and understand the following:

Average daily flow

Peak flow rates

Inflow variability

Knowing these values helps in optimizing energy usage and equipment size. We also ensure the prevention of system overload.

3. Biological and Chemical Characteristics:

It is important to understand the biological and chemical composition of wastewater. Any Best wastewater company such as UY Trienviro would conduct a detailed analysis to determine its composition.

BOD (Biochemical Oxygen Demand): Indicates the amount of organic matter

COD (Chemical Oxygen Demand): Measures both, biodegradable and non-biodegradable components.

TSS (Total Suspended Solids): Impacts filtration and sedimentation processes.

pH Levels and Nutrient content: It is important for us to know the pH levels and nutrient content for microbial activity in biological treatment.

These factors influence the choice of primary, secondary, and tertiary treatment methods.

4. Toxic substances:

Industrial wastewater may contain toxic chemicals, heavy metals, or hazardous substances that require specialized treatments. These contaminants may not only be harmful to the environment but to the treatment system itself. They may prevent the growth of beneficial microbes used in the biological treatment process.

To fight this issue all good companies employ:

Advanced Oxidation processes (AOPs)

Chemical Precipitation

Ion Exchange and Membrane Filtration

These methods ensure safe and compliant discharge. UY Trienviro makes sure to check the released water and its government compliance.

5. Sludge Generation and Management:

Sludge is a semi-solid byproduct of wastewater treatment. This must be properly handled. Sludge management is a major part of the treatment lifecycle and involves:

Dewatering

Drying

Composting

Safe disposal and energy recovery

All good wastewater treatment companies in India including UY Trienviro focus on sustainable sludge management processes. We minimize the impact on the environment and maximize resource recovery.

6. Energy Efficiency and Operational Costs:

Energy consumption is a major factor in wastewater treatment operations. Efficient energy use reduces costs. And we know its importance. Lesser energy consumption also lessens the environmental footprint. Leading companies in this space often incorporate:

Energy-efficient blowers and pumps.

Renewable energy sources (solar panels etc)

Automation and smart monitoring systems check on operational costs.

7. Disinfection and Final polishing:

This is the final step in most treatment processes. This step aims at eliminating pathogens and ensuring water safety. Depending on the end use of the water (discharge, irrigation, or reuse) companies can choose the most appropriate method.

Chlorination

UV treatment

Ozonation

The Best Wastewater Treatment Company in India UY Trienviro would ensure that the final effluent meets or even exceeds the national and international quality standards.

8. Regulatory Compliance and Environmental Standards:

India has strict wastewater discharge regulations and non-compliance can result in heavy penalties. Leading companies stay ahead of these regulations. We use real-time monitoring and reporting systems to ensure our clients always remain compliant with environmental laws.

Our expertise ensures that treated water meets :

CPCB ( Central Pollution Control Board) norms.

Local Municipal Discharge Standards

Industry-Specific environmental guidelines

9. Technology and innovation

Top wastewater treatment providers such as UY Trienviro are constantly innovating. We are integrating technologies such as

AI-driven process optimization

Zero Liquid Discharge (ZLD) system

loT-based Monitoring

These technologies ensure higher efficiency, lower resource usage, and better environmental outcomes.

Conclusion

Wastewater treatment demands expertise, precision, and environmental responsibilities. By considering various factors, we the Best Wastewater Company in India, UY Trienviro deliver reliable, cost-effective, and sustainable solutions.

Whether for industrial use, municipal or residential needs one must pick a company that understands needs. Factors such as cleaner water, a healthier environment, and a better future for all are the considerations. With UY Trienviro by your side, you can not just stay within the legal parameters and be a good citizen of the Earth but also set an example for other industries.

#wastewater treatment company in india#best wastewater treatment company in india#wastewater treatment plant manufacturer in india#watertreatment#waste water solutions company

1 note

·

View note

Text

Sewage Water Treatment Plant in India | Ariseo Water Tech

Ariseo Water Tech is a leading manufacturer of sewage water treatment plants in India, offering advanced solutions like MBBR, MBR, SBR, and ASP technologies for efficient wastewater management across industrial and municipal sectors.

https://www.ariseowater.com/sewagetreatment.html

#Sewage Water Treatment Plant in India#Sewage Treatment Plant Manufacturers#Wastewater Treatment Solutions India#Effluent and Sewage Treatment India#Sewage Recycling Solutions India

0 notes

Text

Expert Water Treatment Plant Provider By Plizma Technology

PlizmA Technology stands as one of the best water treatment plant manufacturers, offering cutting-edge solutions for water purification and management. Our expertly designed plants ensure efficient treatment, helping industries, municipalities, and commercial entities meet water quality standards and promote sustainability.

Know More:- https://india.indexing.co.in/0a7605

#water treatment plant manufacturer in Kolkata#water treatment plant manufacturers#water treatment plant supplier in Kolkata#best water treatment plant manufacturers#water treatment plant provider#Kolkata#India

0 notes

Text

Water Treatment Plant Manufacturers: Pioneers in Sustainable Water Solutions

Water is a fundamental resource for life, industries, and agriculture. With the growing concerns over water pollution, the need for efficient water treatment solutions has surged. This is where water treatment plant manufacturers play a crucial role. These manufacturers design, develop, and install advanced water treatment systems to ensure clean and safe water for various applications.

Importance of Water Treatment Plants

Water treatment plants are essential for removing contaminants, bacteria, and other harmful substances from water sources. They help in:

Providing safe drinking water

Supporting industrial processes with treated water

Reducing environmental pollution

Conserving water through recycling and reuse

Reliable water treatment plant manufacturers incorporate cutting-edge technology to enhance the efficiency of these plants, making water purification more effective and sustainable.

Types of Water Treatment Plants

1. Sewage Treatment Plants (STP)

STPs treat wastewater from households, commercial buildings, and industries before releasing it into the environment. They use physical, biological, and chemical processes to remove impurities.

2. Effluent Treatment Plants (ETP)

ETPs are crucial for industries that generate wastewater containing chemicals, toxins, and heavy metals. These plants ensure compliance with environmental regulations by treating industrial effluents before disposal.

3. Reverse Osmosis (RO) Plants

RO plants use advanced membrane technology to remove dissolved solids, bacteria, and impurities from water, making it suitable for drinking and industrial use.

4. Desalination Plants

With freshwater scarcity becoming a global issue, desalination plants are gaining popularity. These plants remove salt and minerals from seawater, converting it into potable water.

5. Ultra Filtration (UF) & Nano Filtration (NF) Plants

These plants use membrane-based filtration to purify water for specific industrial and municipal applications.

How to Choose the Best Water Treatment Plant Manufacturer

When selecting a water treatment plant manufacturer, consider the following factors:

1. Experience and Expertise

A reputed manufacturer should have years of experience in designing and installing water treatment plants. They should understand industry-specific needs and regulatory requirements.

2. Technology and Innovation

The best water treatment plant manufacturers use state-of-the-art technology to enhance plant efficiency. Features such as IoT-enabled monitoring, automation, and energy-efficient processes add value.

3. Customization and Scalability

Every industry has unique water treatment needs. Manufacturers should offer customized solutions that can scale as per demand.

4. Compliance with Environmental Regulations

Ensure that the manufacturer follows all local and international water treatment regulations and provides eco-friendly solutions.

5. After-Sales Support and Maintenance

Water treatment plants require regular maintenance for optimal performance. Reliable manufacturers offer strong after-sales support, AMC (Annual Maintenance Contracts), and quick service assistance.

Benefits of Investing in a High-Quality Water Treatment Plant

Cost Savings: Reduces water wastage and operational costs in the long run.

Environmental Protection: Helps industries comply with environmental norms and reduce pollution.

Enhanced Water Quality: Provides safe, clean, and potable water for diverse applications.

Increased Operational Efficiency: Improves water management processes in industries and municipalities.

Conclusion

With rising water pollution and stringent environmental norms, the demand for water treatment plants is increasing. Choosing the right water treatment plant manufacturers ensures efficient, sustainable, and cost-effective water treatment solutions. If you are looking for a trusted name in this industry, Bhoomi Environmental is a leading manufacturer offering cutting-edge water treatment plants tailored to your specific needs. Contact us today to explore our range of water treatment solutions

0 notes

Text

#sewage treatment plant#wastewater treatment plant#sewage treatment#domestic sewage treatment plant#sewage treatment plant in delhi#sewage treatment plant manufacturer#water treatment plant manufacturers#sewage treatment plant suppliers#water treatment plant suppliers#stp plant manufacturer#water treatment plant in delhi#wastewater treatment plant manufacturers#stp plant supplier#wastewater treatment plant delhi#wastewater treatment plant suppliers#wastewater treatment companies in delhi ncr#stp ro plant#stp plant#sewage treatment plant near me#small sewage treatment plant#sewage treatment systems#wastewater treatment system#sewage water treatment#home sewage treatment plant#package treatment plant#wastewater treatment companies#sewage plant

0 notes

Text

#sewage treatment plant#wastewater treatment plant#sewage treatment#domestic sewage treatment plant#sewage treatment plant in delhi#sewage treatment plant manufacturer#water treatment plant manufacturers#sewage treatment plant suppliers#water treatment plant suppliers#stp plant manufacturer#water treatment plant in delhi#wastewater treatment plant manufacturers#stp plant supplier#wastewater treatment plant delhi#wastewater treatment plant suppliers#wastewater treatment companies in delhi ncr#stp ro plant#stp plant#sewage treatment plant near me#small sewage treatment plant#sewage treatment systems#wastewater treatment system#sewage water treatment#home sewage treatment plant#package treatment plant#wastewater treatment companies#sewage plant

0 notes

Text

Choosing 𝗔𝟭 𝗦𝗹𝘂𝗱𝗴𝗲 𝗗𝗲𝘄𝗮𝘁𝗲𝗿𝗶𝗻𝗴 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 offers several advantages for wastewater treatment processes.

👉 𝗛𝗲𝗿𝗲 𝗮𝗿𝗲 𝘀𝗼𝗺𝗲 𝗿𝗲𝗮𝘀𝗼𝗻𝘀 𝘄𝗵𝘆 𝗔𝟭 𝗶𝘀 𝗮 𝗽𝗿𝗲𝗳𝗲𝗿𝗿𝗲𝗱 𝗰𝗵𝗼𝗶𝗰𝗲:

▪️𝐇𝐢𝐠𝐡 𝐄𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲: A1 systems provide superior dewatering performance, reducing sludge volume effectively and quickly.

▪️𝐂𝐨𝐬𝐭-𝐄𝐟𝐟𝐞𝐜𝐭𝐢𝐯𝐞: Their systems are energy-efficient, helping to lower operational and maintenance costs in the long run.

▪️𝐃𝐮𝐫𝐚𝐛𝐥𝐞 𝐚𝐧𝐝 𝐑𝐞𝐥𝐢𝐚𝐛𝐥𝐞: A1 equipment is built with high-quality materials that ensure durability and long-lasting performance, minimizing downtime.

▪️𝐋𝐨𝐰 𝐌𝐚𝐢𝐧𝐭𝐞𝐧𝐚𝐧𝐜𝐞: The systems are designed for easy operation with minimal maintenance, reducing the need for frequent repairs or part replacements.

▪️𝐂𝐨𝐦𝐩𝐚𝐜𝐭 𝐃𝐞𝐬𝐢𝐠𝐧: A1’s equipment is space-saving, making it ideal for facilities with limited space.

▪️𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥𝐥𝐲 𝐅𝐫𝐢𝐞𝐧𝐝𝐥𝐲: By reducing sludge volume, A1 helps lower waste disposal costs and minimizes the environmental impact of sludge handling.

▪️ 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐛𝐥𝐞 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬: A1 offers flexible dewatering solutions tailored to specific industrial needs, ensuring optimal results for different sludge types.

These factors make A1 an excellent choice for efficient, cost-effective, and sustainable sludge dewatering.

☎️ 𝗠𝗼𝗿𝗲 𝗜𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻

📱 +91 9953088849, +91 062043 85227

🌐 www.a1blowers.com

#gujarati #bengaluru #noidacity #aircompressor #DelhiNews #EFFLUENTTREATMENTPLANT #aircompressorparts #india #aircompressorservice #sewagetreatmentplant #sludge #sludgemetal #dewatring #screwpress #watertreatment #watertreatmentsolutions #watertreatmentplant #wastewater #wastewatertreatment #wastewatertreatmentplant #sewagetreatment #effluenttreatment #sewagepump #water #watersolutions #watersolution #GujaratNews #ahmedabad #vatva #gandhinagar #punjabi #haryana #ghaziabad #noidadiaries #delhi #delhincr #rajasthan #ajmer #jaipur #bhopal #industrial #industry #industrialdesign #machine #machinery #plantas #Yamunanagar #chandigarh #ludhiana #LudhianaNews #hyderabad #jharkhand #Odisha #OdishaNews

#airblowersinchennai#industrial air blower#manufactring company#sludgedewatring#vacuum pumps#airblower#delhi#sewage treatment plant manufacturer#waste water#a1blowers

2 notes

·

View notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Find The Best Commercial RO Plant Manufacturer In Delhi ?

The establishment of commercial RO plants to address all water-related problems was made possible by the abrupt rise in demand & requirement fulfilment for clean water solutions in Delhi, an industrial center in a strategically advantageous location. On the very front position of this water purification uprising is Commercial RO Plant, which is crowned as the most progressive commercial RO plant manufacturer in Delhi. Modern commercial RO plant systems have applications in a variety of industrial settings, ranging from small enterprises to massive manufacturing plants.

We'll go into great depth of information about Commercial RO plant manufacturer in Delhi with all the related industries in the area. We will discuss the modern advanced technological innovations that Commercial RO Plant offers with world-class facilities, along with all the benefits of our systems, as well as give an insight on how we're bringing change in the background of water treatment in this particular region.

Commercial RO Plant with High Demands

Over the past few years, Delhi's industrial environment has seen tremendous development. The installation of increasingly effective water treatment technologies, such as RO plants, is made possible by increased legal regulations and public awareness of environmental protection issues & water quality issues.

When they are performing at their best, experts at Commercial RO Plant have witnessed this change on their own. Order lists are more comprehensive than ever before as commercial enterprises, especially those in the fabric, textile, & pharmaceutical industries, have come to understand the value of having high-quality filtered water. Because RO technology is adjustable, it can be utilized to eliminate impurities as well as lower the levels of total dissolved solids while maintaining a high standard of water quality.

Commercial RO Plant

As the most trustworthy manufacturer of commercial RO plantsin Delhi, this companyhas constantly led the way in technical advancement. Our highly-skilled staffs at Commercial RO Plant put forth endless effort to design along with assembling commercial RO Plants that meet the unique requirements of our customers.

We adopt an advanced as well as flexible manufacturing technique for our RO systems, which simplifies customization & adaptation. Much appreciation to our adaptability, we can offer our services to a wide range of companies, from large power plants to small processing industries. Being the top noble Commercial RO plant manufacturer in Delhi has gained itself a national reputation; Commercial RO Plant has earned recognition for its unwavering dedication to quality & innovation through numerous accolades.

Crucial Features of Commercial RO plants that Commercial RO Plant designs & manufactures.

1) Better Membrane Integration: The most advanced thin-film membranes available, known for their long lifespan & significant rejection rate, are commonly employed by Commercial RO Plant.

2) Automated Control Systems: Control panels built on Programmable Logic Controllers (PLC) ensure smooth operation & real-time data monitoring.

3) Systems for Pre-treatment: The purpose of the pre-treatment modules is to maintain & extend the life of the RO membranes.

4) Post-treatment Options: Depending on the unique properties of the water, Commercial RO Plant offers remineralisation & pH balancing systems in addition to other treatment techniques for a range of applications.

The following main steps that need to be followed when manufacturing RO plants:

Procedures adopted in the production process to provide customers with the highest caliber of Commercial RO plants:

1) Stage of Design Development: Our engineers work closely with clients to understand their requirements & develop unique RO plant designs.

2) Procurement of Parts or Different Components in the RO Plants: In addition to other high-quality parts, we purchase instruments, pumps, as well as valves from reliable vendors.

Various Applications of Commercial RO Plants

Our RO plant systems find several purposes through various industries in Delhi including Textile Industry, Pharmaceutical Manufacturing, Food as well as Beverages, Power Plants, Medical Amenities such as Hospitals, & Hotels.

Recruiting Companies like Commercial RO Plant offers their best Possible Profits

We approach every job with unmatched expertise due to our extensive knowledge in the water treatment sector.

1) Flexibility in the Face of Change Depending on the client's requirements: We may offer distinctive solutions that meet client expectations thanks to our most recent creative designs & revisions.

2) Helps with the ultimate buying decision: We provide thorough maintenance agreements along with immediate technical assistance.

3) Highly Economic: Lower operational costs are a direct result of energy-efficient structures & optimized processes.

4) Managing All Components & Guidelines within Legislative Terms: We provide our clients with stability by meeting their needs while ensuring that our methods adhere to & surpass regulatory standards.

Conclusion

The commercial RO plant manufacturer in Delhi is proliferating quickly as a result of growing industrial demand & worries about water quality. In this fast transforming sector, the leading supplier or exporters, Commercial RO Plant, have been continuously pushing the limits in terms of both inventive thinking & excellence.

Commercial RO Plant is fully committed in contributing the most specialized, trustworthy, & efficient RO solutions that may have lofted this company to the top of the water treatment facilities in Delhi. As we overcome the challenges & embrace innovative developments, we are dedicated to providing state-of-the-art water treatment technology that meets the evolving needs of businesses in Delhi as well as nationwide.

#commercial ro plant#commercial ro plant manufacturer#commercial ro plant manufacturer in noida#water treatment plant#save water#water is life

0 notes