#waste-to-energy market size

Explore tagged Tumblr posts

Text

Asia Pacific Waste-to-Energy (WtE) Market Insights, Growth, Analysis and Investment Feasibility By 2029

Fairfield Market Research has released a comprehensive report highlighting the remarkable growth potential of the Waste-to-Energy (WtE) market. With a projected CAGR of over 7% between 2021 and 2025, the Waste-to-Energy (WtE) market is expected to undergo rapid expansion, driven by the increasing emphasis on renewable energy and the pressing need for sustainable waste management practices.

For More Industry Insights Read: https://www.fairfieldmarketresearch.com/report/waste-to-energy-wte-market

According to the report, the global Waste-to-Energy (WtE) market exceeded a valuation of US$25.7 billion in 2020, indicating significant growth opportunities. With estimations of global daily waste generation reaching a staggering 6 million tons by 2025, stands poised to harness the potential of waste-to-energy technologies to address both energy demands and waste management concerns.

Municipal solid waste (MSW) management has become a critical issue worldwide, significantly impacting environmental sustainability and public health. The tightening of regulations around MSW management, particularly in key economies, has created an urgent need for effective solutions. Waste-to-energy is expected to emerge as the preferred strategy among municipalities, facilitating the installation and operation of waste-to-energy plants and driving market growth.

Thermal conversion technology, renowned for its exceptional ability to reduce waste weight and volume by nearly 75% and 90% respectively, remains the preferred choice for waste-to-energy conversion. Moreover, the report emphasizes the cost benefits associated with incineration, making it an attractive option compared to other conversion technologies available in the market. However, the sustained presence of economically viable energy alternatives, such as natural gas, poses a significant challenge to the widespread adoption of waste-to-energy in the region, primarily due to the initial capital investment required.

Asia Pacific, despite being a highly lucrative market, remains largely untapped. The report predicts that the region will benefit from a growing number of regulatory approvals for new waste-to-energy plant installations, opening up vast opportunities for industry players. By leveraging supportive government policies and promoting greater awareness and knowledge about renewable energy sources, Asia Pacific is poised to become a key player in the global WtE market.

Fairfield Market Research's report also provides detailed competitive profiling and analysis of top companies operating in the waste-to-energy sector. These companies include Veolia, Suez Environment, Covanta Holding Corporation, China Everbright International Limited, and Keppel Corporation Limited, among others.

As Asia Pacific gears up to unlock the immense potential of the waste-to-energy market, Fairfield Market Research remains committed to delivering accurate and actionable insights that enable businesses to make informed decisions and contribute to sustainable growth in the region.

For More Information Visit: https://www.fairfieldmarketresearch.com/

#waste-to-energy market#waste-to-energy market size#waste to energy#waste to energy market#Asia Pacific waste-to-energy market#Asia Pacific waste to energy#Asia Pacific waste-to-energy (WtE) market#Asia Pacific waste management#waste management#fairfield market research#waste-to-energy market trends#Asia Pacific waste-to-energy market demand#Asia Pacific waste-to-energy market growth#waste-to-energy market analysis

0 notes

Text

Waste to Energy Market Size, Research Report, Dynamics, and Growth Drivers Details

The global Waste to Energy (WTE) market is witnessing robust growth as municipalities worldwide seek sustainable solutions to address mounting waste management challenges. The convergence of urbanization, environmental regulations, and renewable energy targets is propelling the market toward significant expansion.

Get Free Sample Report @ https://www.econmarketresearch.com/request-sample/EMR00626

Key growth factors include increasing municipal solid waste generation in developing economies, stringent environmental regulations regarding landfill disposal, and growing energy demand from industrial sectors. The market is particularly benefiting from government initiatives promoting renewable energy adoption and circular economy principles.

Current market trends reveal a strong shift toward advanced thermal treatment technologies, particularly gasification and plasma arc treatment, which offer improved efficiency and reduced emissions compared to traditional incineration. Additionally, the integration of artificial intelligence and IoT solutions for process optimization is emerging as a significant trend.

Market Segmentation:

By Technology

Thermochemical

Biochemical

By Waste Type

Municipal Solid Waste

Process Waste

Agricultural Waste

Others

By Application

Electricity

Heat

The European market continues to lead global WTE adoption, with countries like Denmark, Sweden, and Germany setting benchmarks for successful implementation. However, rapid growth is expected in Asia-Pacific regions, where countries like China and India are actively developing WTE infrastructure to address urban waste management challenges.

Private-public partnerships are increasingly becoming the preferred model for WTE project development, helping to overcome the high initial capital requirements while ensuring operational efficiency. This trend is expected to accelerate market growth in emerging economies.

Notably, the industry is witnessing increased investment in bioenergy technologies, particularly anaerobic digestion, which offers a more sustainable solution for organic waste treatment while producing renewable natural gas.

Our Related Report:

Luxury High-End Furniture Market Business Sustainability Consulting Market Business Cold Cuts Market Business Childrens Publishing Market Business Experiential Market Business Aquarium Market Business Trading Card Game Market Business Kitchenware and Houseware Market Business Pizza Market Business Functional Gummies Market Business

About Us:

Econ Market Research is a leading provider of comprehensive market intelligence, offering expert analysis and insights across a diverse range of industries. With a team of seasoned analysts and industry experts, we deliver high-quality market research reports, customized research solutions, and consulting services tailored to our clients' specific needs. Our commitment to quality, accuracy, and client satisfaction sets us apart, making us a trusted partner for businesses seeking actionable intelligence to navigate the complexities of today's global markets.

To find out more, visit https://www.econmarketresearch.com / or follow us on Twitter, Instagram, Facebook and LinkedIn.

Contact Us:

For inquiries, partnerships, or to learn more about our services, please contact us at [email protected]

#Waste to Energy Market#Waste to Energy Market size#Waste to Energy Market Forecast#Waste to Energy Market Trends

0 notes

Text

The Global Waste to Energy Market was valued at USD 39.21 billion in 2022 and is projected to grow at a CAGR of around 6% during the forecast period, i.e., 2023-28. The growth of the market would be driven primarily by the massive amount of residential & commercial waste generated every year due to urbanization & industrialization, coupled with increasing population & power consumption levels. As a result, there's a mounting focus of various countries on clean power generation from renewable sources, i.e., augmenting the demand for waste-to-energy plants to treat the substantial waste produced worldwide.

#Global Waste to Energy Market#Global Waste to Energy Market size#Global Waste to Energy Market Share#Global Waste to Energy Market growth

0 notes

Text

#Waste to Energy Market Size#Waste to Energy Market Scope#Waste to Energy Market Trend#Waste to Energy Market Growth

0 notes

Link

#market research future#waste to energy market#waste to energy market size#waste to energy#waste to energy industry

0 notes

Note

Thank you for actually mentioning the fishing nets! I've seen so many people, not just tumblr users but professional Youtubers with big followings, bring this up, gesture vaguely in the direction of that misquoted 100 corporations paper, and then never mention where the plastic waste is actually coming from.

the top three industries in pollution are Fuel and Energy. Second is Food and Agriculture. Third is Fashion.

Even as bad as general plastics are- single-use packaging, containers, grocery bags, all of it- it barely scratches the surface on oil, coal, industrialized farming, and fast fashion.

That fishing nets are for- (dramatic pause)- food and agriculture

Yall have heard of the pacific garbage patch? That floating island literally twice the size of Texas made of discarded plastics? It's not all water bottles and plastic straws. In fact, IT IS MOSTLY FISHING NET.

BUT, as I've said before, a company can make a profit off selling you a metal straw and a reusable bottle and marketing itself as eco-concious and cute. There's not a lot anyone can sell you to make you feel like you're doing your part against discarded agricultural equipment.

You wanna change the world? Invent a $25 trinket made of old usee fishing nets and pay a Kardashian to wear it on TV.

And find a way to visibly infuse the properties of REAL OCEAN GARBAGE into its design or function, because otherwise every two-dollar contracted sweatshop from China to Pakistan will be pumping out brand-new fishing net hair scrunchies for half the price from now till the sun implodes, and the surplus waste from every single one will end up right there with that real stuff in the middle of the ocean.

Easily authenticated non-reproduceable upcycled fish net fashion accessories. They're the future

920 notes

·

View notes

Text

Humans are weird: Poop Crystals

( Please come see me on my new patreon and support me for early access to stories and personal story requests :D https://www.patreon.com/NiqhtLord Every bit helps)

The pace in which human technology progressed over the millennia was rather standard for a class 4 species. Even when accounting the periods of scientific degradation which resulted from natural plagues or religious persecution; it was expected that humans would not achieve advanced space travel until another 2-3 thousand years had passed.

Scientifically speaking human scientists were well more advanced than the society they lived in, but due to the technological limitations of the human race they were held back from implementing their designs. A primary limitation was the lack of a sufficiently powerful power source. They did have many different forms of power generators ranging from solar to nuclear, but to power larger machines often required equally large energy sources. To power their ships alone around a third of their vessels were dedicated to the power cores.

With these restrictions in place travel between stars for humans often relied on decade long journeys in cryo sleep; which ironically required even more power generators to maintain. Their large size made them easy targets for natural disasters such as space debris or prowling space pirates seeking an easy profit margin at the slave markets. These dangers became a standard for human travel until the Terran civilization encountered the planet Nolla 987 and the species that called it home.

During a long duration colonization trip the human ship “Midas” was struck by the trail debris of a rogue comet and knocked off course. The robotic caretakers tried their best to maintain the course, but with the damage done to the ship their primary programming to maintain the lives of the crew kicked in and diverted the ship to the nearest habitable planet for debarkation. Nolla 987 was the closest planet with a stable atmosphere. Originally charted several years earlier but deemed unsuitable for colonization or industrial expansion, it was not ear marked for either and left alone; until the Midas incident that is.

The landing was not a smooth one. Several engines had been damaged and multiple hull breaches resulted in portions of the ship being shredded away during the entry process. It would be safer to say that the Midas crash landed during the final stretch of the maneuver, but with a 73% survival rate of the crew a rather acceptable crash landing.

One by one the crew and colonists were unfrozen to find the ship a burning wreck and only a handful of robotic assistants still functioning. The industrial printing machines were relatively undamaged but without the ships power core they could not be used to print components or tools needed to make the necessary repairs. The crew was then forced to ration its remaining power supply and divided into two teams. The first team would comb through the wreckage and salvage what they could of the wreck while also building shelter. The second group would scout the surrounding area for anything of use and then report back.

It did not take long for the second team to stumble upon a nest of the dominant species of the planet. An insectoid called the “Sectar” which ranged from the size of a house cat to as large as a two story building. These insects digested their food and excreted the waste into a dense crystalian substance that they then used to build massive hive like complexes.

The occupants of the hive had been driven from the hive by the crash landing of the Midas leaving it almost completely empty save for a few eggs and new hatchlings who were not strong enough to flee on their own. Several of the second team members had been scanning the crystal structures while interacting with the newborn Sectar’s. To quote a journal entry of one of them, “They were like insect golden retrievers. Extremely derpy with at least four times as many sets of eyes. They followed us around on their legs like we were their mothers and clung to our legs when we began to return to our ship for the night.”

At least one of the second team was confirmed to have brought a hatchling back to their camp. There was a debate amongst the survivors on if they should try and eat it, but the notion was quickly squashed as they still had food reserves and no one was brave enough to see how the alien’s bio matter would react inside the human digestive system.

The same human who had brought the hatchling back offered it a portion of food which it eagerly ate. Not long after the hatchling excreted a hardened crystal roughly the size of a thimble. When the human made to pick up the seemingly beautiful gem they recoiled as an electrical discharge shocked their hand. This immediately drew the attention of the rest of the crew who began carefully examining the crystal substance. After some rather rough jury-rigging, the crystal was wired into one of the printer machines and to the surprise of everyone powered the machine. The crew quickly learned that the older Sectar’s would produce larger crystal excrements but were extremely hostile and territorial. Smaller Sectar’s were deemed more desirable for the time being as they were easier to train and harvest crystals from.

Within a matter of days the crew had not only collected enough crystals to power all of their machines and send out a distress signal, but also used the new found crystal power to create a full settlement on the planet complete with water filtration, crop fields, and a sizeable wall to keep out the native wildlife.

It would not be for another thirty years before a passing human shipped picked up their distress signal and went to investigate the planet. When they arrived on Nolla 987 they were astonished to find a fully functioning colony complete with limited orbital facilities. Nearly every human settler and their descendants had a Sectar in their household that they would take care of and feed and in exchange use their crystal excrement to power nearly everything they needed to live.

From there it was only a matter of time before the entirety of human space was aware of the events of Nolla 987 and the Sectar species. Within the decade the colony on Nolla 987 became the capital for a fully settled world with dozens of cities and communities. The Sectar species were transported throughout human space and began being implemented in all aspects of society.

There was initial resistance to the new power source by existing power blocks which realized Sectar power would be far more efficient than nuclear powered engines, but unlike other power sources they had squashed in development the Sectar power option had thirty years of trial and error to back it up with research as well as a fully functioning model with the planet of Nolla 987.

Sectar’s became a common sight on every human planet and were treated like common pets. It was even studied that when introduced to different food sources the energy output of crystal excrement could be increased resulting in certain food industries booming overnight. The composition of spices, cooking technique, and flavoring became an entirely new and highly prestigious academic field with the most successful of its practitioners being highly sought after by companies.

The technological capabilities of humanity experienced a massive surge in advancement within fifty years to the point humans no longer needed cryo ships to travel between stars. Those who had been studying humanity found themselves now being introduced to them as humans winded up on their doorstep with a Sectar on their shoulder and a perverse obsession with collecting its bodily waste.

#humans are insane#humans are weird#humans are space oddities#humans are space orcs#scifi#story#writing#original writing#niqhtlord01#funny

196 notes

·

View notes

Text

How Indian rice manufacturers are shaping the global market

Indian rice has long held a place of pride in global kitchens, from the aromatic basmati grains that grace royal banquets to the nutritious non-basmati varieties that make up everyday meals worldwide. India is the world’s largest rice exporter, meeting over 40% of global rice demand (Source: FAO). Behind this success is the dedication and innovation of rice manufacturers in India, who are constantly adapting to meet international standards and market needs.

In this blog, we explore how Indian rice manufacturers are shaping the global market, promoting sustainability and securing India’s position as a rice exporting powerhouse.

Key factors driving Indian rice exports

Quality and Variety Rice manufacturers offer a diverse range of rice, from aromatic basmati to versatile non-basmati rice varieties. Each variety caters to different cuisines and preferences, ensuring steady demand in countries such as the United States, the Middle East, and Africa.

Competitive Pricing India's favorable agricultural conditions and cost-effective manufacturing processes enable competitive pricing. Combined with bulk export capabilities, this ensures that India remains a preferred supplier for global buyers.

Government policies and support Supportive government policies such as export incentives and trade agreements have contributed significantly to India's global dominance. For example, the recent removal of export restrictions on certain Indian rice varieties has boosted international trade opportunities.

Technological advances in rice manufacturing

Technology is transforming rice production in India, increasing efficiency and quality while reducing waste.

Modern milling equipment: Automated milling units maintain uniform grain size, texture and polish, which are critical to meeting international quality standards.

AI-powered sorting: Advanced sorting systems powered by artificial intelligence help eliminate impurities, ensuring that premium-grade rice reaches global markets.

Packaging innovations: Innovative vacuum-sealing and biodegradable packaging materials have made Indian rice more attractive to environmentally conscious buyers.

Rice manufacturers in India are adopting these advancements to maintain their competitive edge while meeting global priorities.

Sustainability initiatives by Indian manufacturers

As environmental concerns grow, rice exporters in India are adopting sustainable practices to meet global expectations.

Water-efficient farming: Techniques such as alternate wetting and drying (AWD) reduce water consumption, which is crucial for regions facing water scarcity.

Low carbon footprint: Adoption of renewable energy in processing units and adoption of eco-friendly logistics have reduced emissions in the rice supply chain.

Waste Utilization: By-products such as rice husk are being reused for bioenergy and building materials, thereby reducing waste and generating additional revenue streams.

These initiatives not only enhance India’s reputation but also align with the sustainability goals of global buyers.

Conclusion: The future of Indian rice on the global stage

The success of rice manufacturers in India is not just about meeting current demands, but also about shaping the future of the global rice trade. By prioritizing quality, leveraging technology, and adopting sustainable practices, Indian manufacturers have solidified their position as reliable partners in the global food supply chain.

As international markets evolve, India’s ability to adapt and innovate will continue to drive its leadership in the rice export industry, ensuring that Indian rice remains a staple in households around the world.

2 notes

·

View notes

Text

What do you mean by a sustainable fashion brand?

A sustainable fashion brand is one that prioritizes environmental and social responsibility throughout its entire production process and business model. These brands aim to minimize their ecological footprint while maximizing positive social impact. Let me break this down further:

Eco-friendly Materials: Sustainable fashion brands, like Merci Dupre Clothiers, focus on using natural, organic fabrics. These materials are often biodegradable and produced with minimal environmental impact. For example, organic cotton, hemp, and recycled fibers are popular choices.

Sustainable Practices: Beyond materials, these brands implement environmentally conscious practices in their production processes. This might include:

Water conservation techniques

Renewable energy use in factories

Waste reduction and recycling programs

Ethical labor practices

Innovative Technology: Some sustainable brands go a step further by incorporating cutting-edge technology. Merci Dupre Clothiers, founded by Dr. Christina Rahm, is a perfect example. They've developed a unique 96-hour process that treats clothing to eliminate unwanted toxins, combining fashion with health and environmental protection.

Mission-Driven Approach: Truly sustainable brands are often founded with a clear mission. For Merci Dupre, it's about "enhancing the health and wellness of people and our planet." This mission informs every aspect of their business, from design to production to marketing.

Transparency: Sustainable brands typically prioritize transparency, allowing consumers to understand the journey of their products from raw materials to finished goods.

Size Inclusivity: Many sustainable brands, including Merci Dupre, are also embracing size inclusivity, recognizing that sustainability should be accessible to all body types.

In essence, a sustainable fashion brand considers its impact on both people and the planet at every stage of its operations. It's not just about creating clothing; it's about fostering a healthier world through thoughtful, responsible fashion choices.

Are you interested in exploring sustainable fashion? Check out brands like Merci Dupre Clothiers that are leading the way in combining style, science, and sustainability!

#sustainable clothing for women#sustainable clothing brand in usa#sustainable clothing#sustainability#best eco friendly clothing brand in usa#organic clothing#ethical clothing#eco friendly clothing#organic clothing for women#ethical clothing for women#best organic clothing for women#USA#fashion#Sustainable fashion#fashion and style#style

2 notes

·

View notes

Text

2024-09-24: Episode 24 (In The Spider’s Web)

Original airdate December 9, 1992

Episode Synopsis

One of the factories in town, Fresno Industrial Robotic Enterprises, announces a breakthrough in their industrial processing and Dr. Beeker wants to make sure that the new waste leaving the factory is not threatening any downstream wetland ecosystems. The gang helps Dr. Beeker perform tests for environmental quality when they stumble upon a collection of suitcase-sized robots that are currently inactive, are shaped like spiders, and are badly damaged. The damaged robots are leaking chemicals into the water and Dr. Beeker removes them from the water to apply a makeshift barrier to stop it from leaking further, but then the robots suddenly activate!

Each of the spider bots begins building something big, trapping the gang inside and transforming the wetland area into another spiderbot-making factory in only a few minutes. Although the spiderbots are not directly harmful and do not attack, they consume all nearby matter to replicate themselves (posing a problem to the party, who happen to be made of matter). However, the spiderbots will actively try to seal tunnels to trap things that the bots perceive to be threats.

Using their wits, the gang must survive long enough to stop the spiderbots, but the deck is stacked against them! The original spiderbot that started this situation exerts control over all the others, and it will continue to instruct the other bots until enough exist that 8 can be diverted from replication to repair the original spiderbot’s damaged hull. During this repair (which takes about an hour), all the spiderbots except the ones performing the repairs are rendered inactive. This is the best time to attack the controlling spiderbot, because once it gets repaired, the spiderbots will begin trying to spread beyond the factory.

Episode Sponsor: Snow Cone Smasher

Snow cones have never been very exciting to make… Until now! Just put ice cubes between the Snow Cone Smasher’s two ice grating plates and smack it with the included rubber mallet to create perfect shaved ice every time! Despite the marketing copy, the Snow Cone Smasher was not very good at producing shaved ice, the ice grating plates were quite sharp and resulted in many injuries, and it was just plain loud to use because of all the banging. Snow cone season only lasted a single Christmas season before the market ended up trying to liquidate unsold inventory.

Notable Episode Feature: Spiderbot (Item)

All of the spiderbots are identical in size and shape, but the coloration on the body indicates what type of task it is programmed to do. Only the original spiderbot (the one that was leaking chemicals) doesn’t change color; it is the color of bare metal while damaged, and red when repaired. The majority of spiderbots will spend time alternating between purple and green.

Purple spiderbots build walls and tunnels

Green spiderbots consume things to accumulate matter for building

Blue spiderbots store electrical energy and act as batteries

Orange spiderbots synthesize parts to repair other spiderbots

Yellow spiderbots are scouts that patrol the area looking for threats

Red spiderbots control up to 127 other bots, and communicate with other red spiderbots to determine how to allocate resources.

White spiderbots are awaiting orders

Regardless of color, each spiderbot possesses the ability to walk on walls and ceilings, and its mandibles contain a built-in arc welder. The robots were failed prototypes created by Fresno Industrial Robotics Enterprises, and the versions that are in use at the factory now do not have this self-replication problem.

2 notes

·

View notes

Text

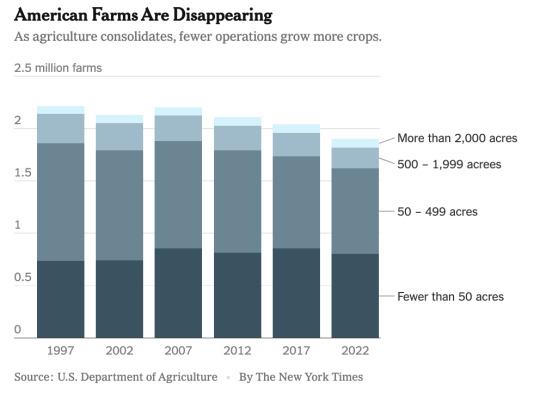

Excerpt from this story from the New York Times:

Agriculture Secretary Tom Vilsack has a line about the state of small-scale agriculture in America these days.

It’s drawn from the National Agricultural Statistics Service, which shows that as the average size of farms has risen, the nation had lost 544,000 of them since 1981.

“That’s every farm today that exists in North Dakota and South Dakota, added to those in Wisconsin and Minnesota, added to those in Nebraska and Colorado, added to those in Oklahoma and Missouri,” Mr. Vilsack told a conference in Washington this spring. “Are we as a country OK with it?”

Even though the United States continues to produce more food on fewer acres, Mr. Vilsack worries that the loss of small farmers has weakened rural economies, and he wants to stop the bleeding. Unlike his last turn in the same job, under former President Barack Obama, this time his department is able to spend billions of dollars in subsidies and incentives passed under three major laws since 2021 — including the biggest investment in conservation programs in U.S. history.

The plan in a nutshell: Multiply and improve revenue streams to bolster farm balance sheets. Rather than just selling crops and livestock, farms of the future could also sell carbon credits, waste products and renewable energy.

“Instead of the farm getting one check, they potentially could get four checks,” Mr. Vilsack said in an interview. He is also helping schools, hospitals and other institutions to buy food grown locally, and investors to build meatpacking plants and other processing facilities to free farmers from powerful middlemen.

But it’s far from clear whether new policies and a cash infusion will be enough to counteract the forces that have pushed farmers off the land for decades — especially since much of the money is aimed at reducing carbon emissions, and so will also go toward large farming operations because they are the biggest polluters.

The number of farms has been declining since the 1930s, in large part because of migration from rural areas to cities and greater mechanization of agriculture, which allowed operators to cultivate larger tracts with fewer people. Over time, the federal government abandoned a policy of managing production to support prices, prompting growers to become more export-oriented while local distribution networks atrophied.

The last half-decade has been more disruptive than most. First came a trade war against China under former President Donald J. Trump, which drew retaliatory tariffs that cut into U.S. exports of farm products like soybeans and pork. Then came the pandemic, which scrambled supply chains and sapped farm labor, leaving crops to rot in the fields.

After Congress cushioned the blow with relief for farmers hurt by pandemic disruptions, things started to turn around. Even as the cost of supplies like fertilizer and seed rose, so did food prices, and farm incomes increased. In 2023, default rates on farm loans neared record lows.

“Farm balance sheets are the healthiest they’ve ever been in the aggregate,” said Brad Nordholm, the chief executive of Farmer Mac, a large secondary market for agricultural credit. “The tools available to American farmers to have a more predictable return, even when commodity prices change and input prices change, is greater than it’s ever been before.”

But wholesale crop prices are expected to decline over the coming year. Rising interest rates have made it more difficult to finance planting and harvesting, borrow for an expansion or just get into agriculture — especially since land values jumped 29 percent from 2020 to 2023.

That’s especially true for the smallest farmers, who are far less likely to be tapped into Department of Agriculture assistance programs and are more vulnerable to adverse weather, labor shortages and consumer whims.

“I think in some ways they’re in a worse position than before the pandemic,” said Benneth Phelps, executive director of the nonprofit Carrot Project, which advises small farmers in New England. “We see a lot of farmers making hard decisions right now about whether to stay in or get out, because they’ve run out of steam.”

That’s where the American Rescue Plan, the Inflation Reduction Act and the Bipartisan Infrastructure Law come in.

The laws have collectively provided about $60 billion to the Agriculture Department, which has parceled it out across a variety of priorities, from relieving farmers’ debt to paying them to reduce their carbon emissions.

The biggest chunk — about $19.5 billion — has breathed new life into subsidies to encourage conservation practices that improve the land, like cutting back on plowing and planting cover crops to sequester carbon in the soil. Some of the programs had shrunk in successive Farm Bills, which are five-year legislative packages that covers most agricultural subsidies, and about two-thirds of farmers who applied each year got nothing.

The new funding has added 16,000 recipients over the past two years. Preliminary data shows the expansion is allowing smaller farms to take part.

3 notes

·

View notes

Text

Budget-Friendly Builds: How Container Homes Save You Money

Container homes are changing the housing market by offering an affordable alternative to traditional home construction. These innovative homes, crafted from converted shipping containers, are not only eco-friendly but also significantly less expensive to build and maintain. Let's discuss the reasons why shipping container homes are becoming a popular choice for budget-conscious homebuyers.

Cost Savings Breakdown

Affordable Acquisition: Shipping containers are readily available and less expensive than traditional building materials like wood, concrete, or brick. This initial cost saving is a major advantage for those looking to build their own home without a hefty price tag.

Streamlined Construction: The modular nature of container homes allows for much quicker construction times. Since containers are prefabricated, much of the assembly happens off-site, which reduces on-site labor costs and speeds up the overall process.

Reduced Foundation Requirements: Due to their sturdy design and structure, shipping containers require simpler and less costly foundations compared to traditional homes. This can be a significant cost saver, especially in areas where extensive groundwork is typically necessary.

Sustainability and Efficiency

Container homes are at the forefront of sustainable building practices. Repurposing used shipping containers reduces the demand for new construction materials and minimizes waste. Moreover, these homes are often smaller in scale, promoting a minimalist lifestyle and further decreasing ongoing energy consumption.

Design and Customization

The flexibility in design that container homes offer is a budget-friendly feature that traditional homes often lack. Containers can be stacked and joined in various configurations, allowing for custom layouts at a fraction of the cost of conventional custom-built homes. Brattleboro Portable Storage provides various customization options that adapt to different budgets and design preferences.

Long-Term Savings

Container homes are not only cheaper to build but also less expensive to maintain. Their metal structure is resistant to pests such as termites and less prone to structural issues like rot or mold. Additionally, their compact size makes them more energy-efficient, lowering heating and cooling costs throughout the year.

Choosing a container home is a smart financial decision for those looking to maximize their budget while minimizing their environmental impact. With their low upfront costs, reduced construction and maintenance expenses, and energy efficiency, container homes offer substantial savings over time. For those interested in exploring container home options, Brattleboro Portable Storage is your resource for affordable, innovative housing solutions.

4 notes

·

View notes

Text

The Saudi Arabia Waste to Energy Market is projected to grow at an exponential CAGR during the forecast period, i.e., 2023-28. The demand for such techniques is aided by the colossal amount of waste produced in the region due to surging population and rapid urbanization, further resulting in a rise in industrial and construction debris. In addition, the high urban population has also raised the requirement for higher power consumption needs, getting fulfilled by installing plants, thus leading to the application and expansion of the industry.

#Saudi Arabia Waste to Energy Market#Saudi Arabia Waste to Energy Market Growth#Saudi Arabia Waste to Energy Market Size#Saudi Arabia Waste to Energy Market Share

0 notes

Link

#market research future#waste to energy market#waste to energy market size#waste to energy#waste to energy industry

0 notes

Text

Find the best Compact Sewage Treatment Plant(STP) Manufacturer in India ?

With its headquarters located in Greater Noida, Netsol Water is the largest as well as the leading manufacturer of compact sewage treatment plants in India.

Contemporary Compact STP may be put above ground or below ground & is compact in size. Its small & original designs are visually appealing & need very little room to install. Because Compact STP produces no noise & has no smell, you may place it wherever is most convenient for you.

Manufactured & supplied by Netsol Water Gr. Noida, Delhi NCR, India. Netsol Water Compact Sewage Treatment Plants are prefabricated systems that are given to the client ready for plug & play installation.

Small Sewage & Wastewater treatment facilities from Netsol Water, as well as other comparable products, have received international certification according to the highest criteria. The systems are supplied with UV(UltraViolet) tertiary handling units & phosphorous elimination/removal kits. They are packed in cylindrical Poly-Propylene containers/chambers, which are utilized as thermoplastic molding materials.

Essential Elements of a Compact STP(Sewage Treatment Plant):

Complies with all regulatory standards

Does not require an operator i.e., not manually but completely automated.

Re-utilizing treated water for gardening

Up-to-date, packaged STP Underground installation is possible;

Modern Compact STP(Sewage Treatment Plant) saves up to 75% on energy costs;

Sand & charcoal filters are not required

Below Organized are the finest Leading Manufacturers in India for the best Compact STP(Sewage Treatment Plant):

NETSOL WATER

Netsol Water provides solutions for a wide range of sectors, with a focus on water-wastewater, compact STPs(Sewage Treatment Plants), ETPs(Effluent Treatment Processes), separation, &��water filtering.

Netsol Water is the best compact sewage treatment plant manufacturer in India.

The greatest waste & Wastewater Treatment solution is offered by NETSOL WATER, a top manufacturer of Compact STPs(Sewage Treatment Plants). One of the most trustworthy waste management partners is Netsol Water.

Engineered design, fabrication, mounting/installation, & maintenance/repairing services are offered by integrated service providers working in Netsol Water.

Their goal is to increase the viability of waste management systems globally in terms of economics, environmental sustainability, & energy efficiency in order to address issues related to population growth, industrialization, & climate change.

Their personalized & project-based approach has helped them carve-out a position in the current waste-management market. This technique enables them to provide comprehensive & efficient solutions to their clients' distinct & dynamic/fluctuating demands .

Netsol Water guarantees/promises complete partner & customer satisfaction by utilizing this comprehensive approach evaluation to provide customized industrial solutions.

COMPACT STP

The firm/company that manufactures Compact STP plants is recognized as the most reliable & well-established supplier partner in the water & wastewater treatment sector.

STP(SEWAGE TREATMENT PLANT) MANUFACTURER

When an individual in India thinks of a high-end most sophisticated WTP(Water Treatment Plant) as well as a consultancy service , their brand name quickly comes to mind .

This is because the world has noticed & acknowledged its looming expertize as the most enthusiastic/passionate business-ignited organization delivering an array or spectrum of superior products-machinery & services involving solutions for water treatment , WasteWater handling/management & treatment , & much more since the year 2012.

URBAN STP Plant

Established in 2012 under the umbrella of Netsol Water, Urban STP Plant focuses as well as concentrates on the engineering design of recreational/swimming pool filtration systems as well as the manufacturing, vending, trading/exporting, & servicing as well as maintenance & repair of WasteWater & Compact STPs(Sewage Treatment Plants). Their motto has always been perfection , so they've created a product collection lined as CETPs(Common Effluent Treatment Plants)(Food & Beverages Industry) , Effluent Treatment Plants(Automotive, Paper & other Industries) , Compact STPs(Sewage Treatment Plants) (Industrial & Commercial Both) , & so on forth , Reverse Osmosis Systems

You can also read : Find The Best Sewage Treatment Plant Manufacturer in India

#netsolwater#commercial ro plant#industrial ro plant manufacturers#industrial ro plant#effluent treatment plant#sewage treatment plant manufacturer#compact stp manufacturer

2 notes

·

View notes

Text

What are the key requirements for obtaining ISO 14001 certification in Mumbai?

ISO 14001 Certification in Mumbai?

ISO 14001 Certification in Mumbai is determined to be highly recognized and utilized by the firms to acquire possible market stability. Over 7500 islands make up the Mumbai. The majority of the country’s GDP is contributed by travel and tourism. Cities in Mumbai are just now beginning to industrialize.

The most manufactured and exported goods include copper products, clothing, semiconductors, and other limited electrical items. In the upcoming days, it is anticipated to become a financial titan. At a rapid growth phase, industries began to revolutionize. Mumbai saw a fast rise in the demand for ISO 14001 Certification in Mumbai among rival businesses to stand out in the market and better serve their clients by adhering to all calibration and laboratory criteria.

Importance of ISO 14001 Certification in Mumbai

It encourages and guides organizations in India to meet their environmental obligations. The ISO 14001 Certification in Mumbai is ideal for organizations that wish to demonstrate their commitment to reducing their environmental impact and achieving financial and stakeholder benefits.

As the only international standard devoted to environmental performance, ISO 14001 Certification in Mumbai provides a framework for improving environmental performance in organizations of all sizes. You will gain a competitive advantage when your organization complies with ISO 14001 Certification in Mumbai. Factocert provides ISO 14001 Certification in Mumbai by utilizing ISO standards and guidelines for implementing ISO 14001:2015 environmental management systems.

The Benefits of ISO 14001 Certification in Mumbai Businesses

By embracing ISO 14001 Certification in Mumbai, businesses in Mumbai can expect a multitude of benefits:

Reduced Environmental Impact: ISO 14001 certification in Mumbai helps organizations significantly reduce their environmental impact, including waste production and energy consumption.

Cost Savings: Adopting sustainable practices often leads to cost savings through reduced resource consumption and improved efficiency.

Enhanced Reputation: ISO 14001 certification in Mumbai enhances a company’s reputation, attracting environmentally conscious clients and partners.

Legal Compliance: Businesses that achieve ISO 14001 Certification in Mumbai fully comply with environmental regulations, avoiding legal issues and associated costs.

Why Factocert for ISO 14001 Certification in Mumbai

We provide the best ISO 14001 Consultants in Mumbai, Who are knowledgeable and provide the best solutions. And how to get ISO certification in the Philippines. Kindly reach us at [email protected]. ISO Certification consultants work according to ISO standards and help organizations implement ISO certification with proper documentation.

For more information, visit ISO 14001 Certification in Mumbai.

Related links:

· ISO Certification in Mumbai

· ISO 9001 Certification in Mumbai

· ISO 14001 Certification in Mumbai

· ISO 45001 Certification in Mumbai

· ISO 27001 Certification in Mumbai

· ISO 22000 Certification in Mumbai

· ISO 13485 Certification in Mumbai

· ISO 17025 Certification in Mumbai

RELATED ARTICLE

ISO CONSULTANT IN MUMBAI

2 notes

·

View notes