#warehouse forklift safety

Explore tagged Tumblr posts

Text

Forklift Safety Cameras- A Potential Requirement in Warehouses and Storehouses

From decades ago, forklift operations have never been an easy task! Due to heavy loading, forklift operators tend to make blunders, which in turn leads to accidents and damage.

As a warehouse/storehouse manager, it would become a vital requirement to reduce such accidents, if not avoided. However, even if one considers intensive training, strategic hires, and equipment upgrades as significant steps taken, ‘Vision’ still remains the biggest challenge for the operators. The reach of forklift operators to visualize where they are and to verify mishandling of products is of utmost importance, failing which it would lead to serious damage of products, equipment and the worse, to people.

Image Source: https://www.oeattachments.com/reduce-forklift-accidents-with-the-forklift-information-system/

Wireless forklift camera is one of the excellent instruments which permit the operator to have different views around the lift truck. Its installation is absolutely simple and can be employed in the front, back, sides or anywhere around the lift truck where visibility is limited. Forklift safety Cameras contribute directly to increased visibility and thus an increase in productivity.

➢ It helps operators at warehouses to deal with a number of forklift concerns such as:

• High and low racking heights

• Double-deep racking

• Reading product and rack levels

• Indoor and outdoor lighting

• Video recording of human resources, product verification, and management and training opportunities.

Enhance Warehouse safety and reduce misses with SharpEagle forklift camera system!

Reach Out to Us

➢ The forklift camera system also works well with any kind of operational or attachment tasks, to list a few:

• Push pulls that push the load on cardboard

• Roll handling for paper and sheet metal

• Turret trucks with forks that swing in different ways

• Side Shifting Fork Position attachments (SSFP)• Clamps Read more: Forklift Safety Solutions for the Supply Chain and Warehousing Sector

➢ Having said that let's list out the impact and certain benefits of wireless forklift cameras for Warehouses/storehouses:

1. Improves Productivity:

Even the most experienced forklift operator experiences fatigue in the time spent analyzing to see behind and around the forklift. Wireless forklift cameras help in visualizing the entire field without letting the operator change its position, thus reducing neck and back strain and increasing productivity and force.

2. Eradicate Trial and Error Time:

The capability to see through the forklift safety cameras and to analyze where the forks fit well, certainly reduces repetitive trial and error time. At the same time, it also reduces the risk of damaging products, as operators have a clear view of where and how the forks are being placed.

3. Reduces Staffing:

Given that wireless forklift cameras provide clear visibility, it can help avoid hiring a guide to assist the forklift operator, thus reducing manpower.

4. Zeal for Young Operators:

Hiring new forklift operators can often be challenging. However, forklift cameras create a fun and interactive experience for the youths who can identify with the ‘video game connection’ they experience from operating a forklift.

So gear up to upgrade your forklift operations with forklift camera system and having any difficulties, do connect with us at www.sharpeagle.uk, for we believe in having a solution for all your forklift safety camera needs.

SharpEagle strives to make industrial atmospheres safe and secure with our state-of-the-art products and services. By using top-quality safety products, we ensure your site is highly secure and continues to perform tasks with utmost efficiency. Our product range includes Forklift Safety Solutions and Forklift Safety Lights. We have expanded our horizon to 8 countries including UAE, Saudi Arabia, Oman, Kuwait, Bahrain, Qatar, and the UK. Want to safeguard your site from unnecessary hazards? Connect with us to stay clear of such mishaps.

Why choose the Sharpeagle forklift safety system?

You can also call us at +971-45549547 or mail us at [email protected]

#camera for forklift#driving forklift safety#forklift alert systems#forklift anti collision system#forklift camera#forklift camera system#forklift cctv#forklift safety#forklift safety camera#forklift safety camera system#forklift safety devices#forklift safety products#forklift wireless camera system#forkview camera#warehouse collision avoidance systems#warehouse forklift safety#warehouse pedestrian safety#wireless forklift camera#Bird's eye view camera system for forklift

0 notes

Text

it’s so fucking lame that i keep identifying with it bc it’s been over a year but i get a certain type of nostalgia for it both times ive done warehouse labor that i didn’t get when i worked retail or food service. youth spring is literally the only media ive seen that captures the phenomenon without glamorizing it

can’t watch youth spring again bc it’s three hours of slow footage but god i cannot stop thinking about it. i really want to try rewatching it again someday

#like. i wouldn’t recommend it i don’t think i was treated well#idk i feel really guilty bc i have a much bigger safety net than most of my co workers#but yea. idk man#whatever it’s not like being a warehouse worker is a super unique impossible to understand experience anyways#like if u wanted to get one u could literally get one from Amazon if you want to experience being screamed at the eleventh hour for#three months#also i wish i got forklift certified but oh well

1 note

·

View note

Text

My mom just saw a news article called something like "warehouses shift away from forklifts in safety push" (probably not the exact wording)

and my first thought was "oh no, what will Milligan do now??"

16 notes

·

View notes

Text

Infrastructure you don’t see in MO that probably exists in Vykkers Labs 13: Part 2!

(part 1)

The ship control room or cockpit. I figure it must be at the tippy top of the structure under the dome, although it wouldn't be easy to see over the sides of the ship- so they must rely heavily on radar and cameras to make sure they aren't about to scrape mountains. I'd be interested to see who's in charge of piloting it. I think it's too vital a function for an intern to captain it, so there's probably some vykker engineer who's really into airships in charge. However, the destinations ultimately fall on Humphrey & Irwin. Vykkers labs has a map it generally follows that is planned months in advance. This is to account for the climate as certain weather can damage the ship. But H&I can redirect the ship on a whim.

Munitions storage/armory. Where the SnUzis and other weaponry are kept. Under strict lock and key to keep random employees or escaped subjects from getting in. Since SnUzis fire poison syringes, the poison is manufactured in-house in the armory.

Company store. So I've spoken before how I imagine Vykkers Labs docks on occasion for maintenance. It's in these situations I imagine employees can disembark and shop in what is essentially a giant airport. However, between landings, if you need essentials, you go to the company store, where everything is extremely overpriced and all moolah goes right back into the lab. They also sell souvenirs for guests! Like ornaments shaped like the ship, or fuzzles with syringes sticking out of them.

Warehouse where supplies are stored. Crates upon crates in rows and rows. Chaotic and poorly managed, there could be some really freaky and outdated shit in some of the crates at the way back. One of the most common places for workplace accidents as employees are crushed under falling crates, run over by forklifts, or stabbed on poorly contained boxes of lil hackers. However, it also has some of the worst surveillance, so you can find interns & scrubs playing cards or napping in a lot of corners. If you're assigned to the warehouse, you'll quickly become popular, as other employees will want to barter with you for goods stolen from the crates.

Livestock pens for freshly captured critters. I think they would be located near the center-bottom of the ship, next to the big hole at the bottom, so that the stalls can be mucked out right off the edge of the ship. Mudokons are employed here more than Interns; they're more compassionate which means a higher survival rate for freshly captured critters, though the job of disseminating them to different labs falls on the Interns.

Nuclear reactor to power the ship. Inspired by the US & France using nuclear reactors to power aircraft carriers. Makes sense that something as huge as Vykkers Labs would not be able to coast by on fuel alone, though liquid fuel is likely kept in massive quantities anyway in case the reactor fails/other emergencies. Probably one of the only places on the ship where safety regulations are strictly followed.

11 notes

·

View notes

Text

i’m trying to dredge through my various B&Q memories (and talking to friends who used to work with me in B&Q) for inspo and i just remembered something that happened and dear god. i’m imagining simon and price’s reaction to being in that situation.

so the store manager decides to reorganise the warehouse. he doesn’t check with price or more importantly simon about this. he just hops on the forklift, puts up the signage to say the forklift is in use and bans everyone from entering the warehouse (not an unreasonable request, pedestrians vs forklifts has never ended well historically, but the balls of that man to ban simon from his warehouse jeeeesus).

you don’t actually know that’s what he’s decided to do until the store manager is barking out over the tannoy “all available staff to the warehouse, that’s all available staff to the warehouse. NOW.” and because you’re a) available and b) nosey as fuck as you’ve never been allowed in simon’s warehouse, off you go.

when you arrive, it’s carnage. there is paint everywhere. for a horrible moment your brain provides you with the elevator scene from the shining but substitutes the river of blood with 625 litres of brilliant white matte emulsion instead.

“what the actual fuck”

aaaaaand that’s soap. he’s materialised out of thin air next to you and is surveying the damage with a visible aura of pure horror. your stomach lurches in sympathy because that’s his stock that’s slowly dripping from the abandoned pallet. and the racking. and the walls. jesus fucking christ. it’s everywhere. everything in a 2 metre radius is covered in paint. including the stock, the store manager, and simon.

simon, who has the store manager pinned by his neck to the wall next to the safety notice board.

you can’t see simon’s face, his shoulders look like they’re carved from granite with tension, but you can certainly hear what he’s shouting in the slowly reddening face of the store manager.

“you useless, dangerous cunt!”

you flinch backwards. you’ve never heard simon so angry.

“you could’ve fucking killed someone! you’re fucking lucky that you didn’t kill yourself!”

you turn wide eyed to stare at soap, who’s mouth is hanging open in shock. you turn back to the scene playing out in front of you as simon roars in rage again.

“what the fuck is wrong with you?! answer me!”

simon shakes the man in his grip but doesn’t actually let go. you watch as the store manager’s face turns puce in a combination of rage and trapped blood flow. oh christ, are you about to witness a murder? you think you’re about to witness a murder. what the fuck.

“simon. that’s enough.” price’s voice is a whip-crack of fury that breaks through the tension of the scene. you release a breath you didn’t even know you were holding as he wades into the fray. price stops behind simon just an arms length away.

you don’t hear what price says to simon, but he drops (actually drops, fucking hell) the store manager who splutters and coughs trying to catch his breath desperately.

“y-you’re - fired! what the fuck -!”

price grabs simon as the enraged man lunges towards the store manager.

“take a walk simon.”

you and soap hastily move out of the way of simon who storms out of the warehouse and onto the shop floor barking a stern “move!” to a mixed crowd of customers and colleagues desperate to get a glimpse at the soap opera levels of drama happening beyond the warehouse doors.

“you, don’t move” price points a threatening finger at the store manager before turning to face you and soap. “johnny, get over here. get the spill kit.”

soap snaps to attention and moves further into the warehouse, skirting the pooling paint as carefully as he can manage. you flex your hands nervously as the full force of price’s attention is aimed at you. god, you want to melt into your black safety boots to avoid his commanding tone and the banked fury that is present on every line on his face.

“love,” price’s tone softens slightly as he addresses you and you’re grateful for it, “go after simon. he needs a clean uniform.”

you nod and spin on your heel, before you leave the warehouse you chance a glance back over your shoulder and see price looming over the store manager.

as you make your way across the shop floor, you have the horrible realisation that someone is definitely getting fired today. you shoot up a prayer to the retail gods that it won’t be simon.

#retail hell au#cod fic#captain john price#simon ghost riley#john soap mactavish#this is based off a completely true event#including the stock flow manager pinning the store manager by the neck to the wall#unedited so please forgive the typos/grammatical errors#also tenses? i don’t know her

47 notes

·

View notes

Text

047 of 2025

01087 - YOUR JOB/CAREER

This survey was not credited at first when I took it from someone else, but I’ve found out it’s made by [lionna].

Firstly, who do you work for?

The big French rolling stock manufacturer whose name starts with A. You got it.

What is your position?

Senior electrician/line feeder.

What are your responsibilities?

Wiring control racks and underframes, also restocking parts that we use when the warehouse delivers them.

Do you enjoy your job?

I love it. I can't imagine doing anything else.

Do you work with other people, or solo?

I work in a team of 9 people.

What are your co-workers like?

Well, we were a great team, until someone's attitude has changed. The majority of the team is great as always, though.

What is/are your boss(es) like?

The current one is okay, the previous one was great, and the previous one before the previous one was the best of the best.

Do you wear a uniform?

We have to wear work clothes, safety boots and helmets.

Are you usually very busy, or is it slack?

Lol it's always busy. We are several trains behind.

Do you get paid minimum wage, or above?

Somewhat above because we're the best paid industry in Belgium right after the chemical industry. I also got a raise several times, plus all the benefits for working longer than 5 years.

What time of day do you usually work?

I work day shifts, they start at 7:30 and end on 16:00.

How many hours a week do you get?

Only 12 because I'm on disability, so I work 3 days a week, 4 hours each. Normal time here is 40 hours a week.

Would you like to keep this job your whole life?

Definitely. I love this job and this place too much.

Why are you working this job right now?

Because I wanted it. Working with trains has been my dream.

Are you saving or spending most of your money?

Well, I have bills to pay and I still need food as I have family. My spouse works as well, my stepson earns a bit of money, too, but still, bills and food and all cost money, plus half of our salaries goes directly to taxes.

Do you deal with customers or clients?

No, I don't. I'm a factory worker.

Are they generally agreeable?

N/A.

How do you react when they are not agreeable?

N/A.

Have you ever been written up? What happened?

No, I haven't. Only did when I was working abroad, but it was fake and the person who did it got fired soon after.

What are some things that you absolutely CANNOT do at your job?

Drink and do drugs lol. You also cannot take it for granted. You can't wear long earrings or rings because it puts you at the risk of losing or tearing a body part.

Are there any risks involved in your job? What are they?

A lot. First of all, there's a whole long list of safety rules that we have to sign. There's a risk of being electrocuted, especially if you're working on the roof (it happened to our quality inspector last year, 3 kV kicking him, thankfully he's alive and well). There's a risk of falling from great heights. There's a risk of heavy parts falling on your head while being transported on a bridge. There's a risk of hitting your head, that's why we wear helmets. There's a risk of a forklift running over your foot, that's why we wear safety shoes. There are dangerous chemical substances we use that might cause cancer. And the list goes on.

Have you ever forgotten to do something important? What happened?

A lot of times lol. But it wasn't so important to stop the whole factory if I didn't do it. Typically I forget to check or count something. I usually catch up on it later on, the other day.

Are you allowed to read/watch TV/play video games on the job?

You kidding me, I work in the factory. No one watches TV or plays video games in factories. The supervisors are watching.

What are your breaks like?

First one at 9:00, lasts 15 minutes. Second one is at 12:30, it lasts for 35 minutes and is not paid. The third one is at 14:00, lasts 10 minutes. My shift these days ends at 11:30, so I have only one break.

Do you ever get really bored at your job?

No. I don't have time for it.

How do you keep yourself entertained?

I do my job, simple. If I really have nothing to do at the moment, then I clean the tables and shelves. We all do it here.

Is your workplace clean? Who cleans it?

We have professional cleaning company for the toilets, canteens and such, but it's the team's duty to keep the workplace clean. We take out the trash, we clean the tables, things like that.

Is your job physically demanding?

Every factory job is physically demanding. We carry heavy boxes, heavy cables and such things.

What would happen if a robbery took place?

Lol who wants to rob the factory. Can you imagine thieves pushing a train carriage? XD

What are your customers/clients’ biggest complaints?

NMBS complains that we're not fast enough with deliveries, but it's often not our fault.

What’s the strangest thing you’ve ever seen happen at your job?

I think I mentioned it in another survey, the sandwich thing that got two guys fired. Absolutely disgusting.

Tell us about the time you were most upset at work.

When I heard my sick note will be expanded so I couldn't go back to work, and I was on the verge of being fired for "medical reasons".

If you’re upset, do you act any differently towards customers?

I don't see customers. I'm from doing the labour.

The phone rings, and you have to answer it. HOW do you answer?

"Met Joeri, goeiemorgen". Standard. Unless I know who calls, then I answer in a joking way.

Is there a duty you really despise doing?

Collecting PMA parts. Utterly boring. (Surprisingly, I have no problem with picking other parts).

Is there a duty you love doing?

Making notes in a notebook, the documents and work instructions, and wiring the racks.

Is there anything you are scared of at your job?

Yes, electricity. I'm an electrician and I fear electricity, but this is the reason why I respect it and I never break the safety rules.

Are there many things to laugh at?

Yeah. Without some jokes and humour, things would be unbearable at times.

What are the bathrooms there like?

Standard. Male and female separated, plus one for disabled people because one of our engineers is a wheelchair user (main engineers work in the office).

How long do you plan to keep working there? Why?

Until I retire (or the factory closes) because I love this place.

Has anyone ever screamed at your job? Why?

Nope. I'm appreciated there.

Do you ever need to mentally prepare yourself for work?

Yeah. But once I get there, I'm happy.

How do you wind down after a hard day’s work?

I take a nap with my cat next to me.

Is your job stressful?

It can be. There's a lot of pressure on getting things well done at time.

Who would you recommend your job to?

Anyone with technical diploma or degree, and those who love trains and are not afraid of hard work.

2 notes

·

View notes

Text

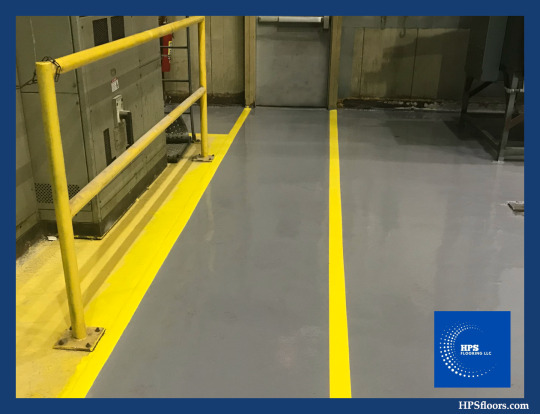

Warehouse Epoxy Flooring: Durable, Safe, and Efficient

When it comes to maintaining a warehouse, the flooring is often an overlooked yet crucial aspect of the facility's infrastructure. The floor must withstand heavy loads, constant foot traffic, and machinery movement while ensuring safety and efficiency. Epoxy flooring is a top choice for warehouses.

What is Epoxy Flooring?

Epoxy flooring is a surface coating created by mixing resin and hardener, forming a durable, seamless layer. This coating bonds exceptionally well to concrete floors, providing an even, resilient surface. The result is a floor that can endure the demanding environment of a warehouse while offering a professional appearance.

Why Choose Epoxy Flooring for Warehouses?

Durability: Warehouses experience high-impact activities, from forklifts carrying heavy loads to constant foot traffic. Epoxy flooring is highly resistant to abrasions, and impacts making it ideal for such environments. Its durability reduces the need for frequent repairs, saving time and costs.

Safety First: Epoxy flooring offers slip-resistant options that can be customized with visible markings for pathways, loading zones, and hazardous areas, improving navigation and reducing accidents.

Easy Maintenance: The seamless nature of epoxy floors makes cleaning and maintenance a breeze. Unlike traditional flooring, there are no cracks or crevices for dirt and debris to accumulate, ensuring a cleaner workspace with minimal effort.

Chemical Resistance: Many warehouses deal with chemicals or materials that can damage conventional flooring. Epoxy floors resist chemical spills, preventing stains and maintaining the floor’s integrity over time.

Cost-Effective: While the upfront cost of epoxy flooring may be higher than some alternatives, its longevity and minimal maintenance requirements make it a cost-effective investment for any warehouse.

Customization Options for Warehouse Needs

Epoxy flooring can be tailored to meet the specific needs of your warehouse. From anti-slip coatings to high-gloss finishes for better lighting, the options are vast. Additionally, color coding and line markings can help organize workflows and improve safety.

Installation and Maintenance

Professional installation is critical for ensuring the longevity of epoxy flooring. The process involves surface preparation, which may include cleaning, repairing cracks, and applying a primer. Once the epoxy is applied, it cures to form a hard, durable surface.

Regular maintenance involves simple sweeping and occasional mopping with mild detergents. For warehouses dealing with heavy traffic or chemical spills, periodic inspections can help ensure the floor remains in excellent condition.

#epoxyflooring#sherwinwilliams#warehousefloorpainting#epoxy floor contractor nj#epoxy flooring#epoxy warehouse flooring#epoxy contractor nj#warehouse floor painting#warehouse epoxy floor#chemical resistant floor#commercial flooring

3 notes

·

View notes

Text

Service workers—especially those toiling away in the South where wages are lowest and protections are most insufficient—are facing multiple crises: extreme heat, health disparities, and flagrant safety violations, to name a few. Since the pandemic began, the dangers associated with service jobs nationwide are also mounting. While it may seem quaint for millionaire pop star Lana Del Rey to pick up a shift at Waffle House in Alabama, workers at the popular 24-hour diner often deal with violence from patrons. The internet loves videos of Waffle House fights, but it’s worth noting that the risk of bodily harm shouldn’t be part of a business’s daily operations—especially not for workers earning an average of $7.35 an hour.

Mama Cookie, a home health care and fast food worker who’s become a powerful force in North Carolina labor organizing, hears startling stories from service workers across the South. There was the warehouse worker in Columbia, South Carolina, who explained that his workplace didn’t provide any safety training or gear, leading to forklift accidents and broken bones. Waffle House workers in Atlanta told her about how their restaurant was shot at while they worked third shift. And who could forget the dozens of “systemic hazards” the Occupational Safety and Health Administration (OSHA) found at Dollar General, the popular discount retailer in the U.S. where there are “codes being broken every day”? Dollar General employees said they handle chemicals without any protective gear, and women reported being left to run the entire store on their own.

According to Mama Cookie, the CEOs of major corporations “don’t even give a damn” about the serious issues affecting their low-wage workers. But she’s here to make them.

19 notes

·

View notes

Text

Blog 6: How safe are you at work?(Historical interpretation)

In this week’s blog prompt, we were tasked with unpacking the quote:

“There is no peculiar merit in ancient things, but there is merit in integrity, and integrity entails the keeping together of the parts of any whole, and if these parts are scattered throughout time, then the maintenance of integrity entails a knowledge, a memory, of ancient things. …. To think, feel or act as though the past is done with, is equivalent to believing that a railway station through which our train has just passed, only existed for as long as our train was in it.” – Edward Hyams, Chapter 7, The Gifts of Interpretation

Collecting and fixing the broken historical artifact helps discover the knowledge that accompanies the artifact.

I believe that Edward wants to express that historical artifacts and evidence of the past by themselves have no value. However, by collecting these often degraded and broken parts, we can discover a story, lost knowledge, or memory of the past. He also uses a train simile to explain that one cannot ignore the past just because it has already happened. It usually teaches us a lesson that helped us improve to the present. Edward’s use of simile, a figurative language, is like what Alan Leftridge talked about when discussing ‘Interpretive Titles and Leads’ in the assigned reading, chapter 14 of the textbook. This helps the reader better visualize and relate the meaning behind Edward’s statement as most people have ridden a train, allowing them to easily visualize and understand.

Relating this quote back to interpretating history, Edward mentions how learning about past helps discover lost knowledge or warnings. This was also mentioned in this week’s second assigned reading, chapter 15 of the textbook, “Another reason to interpret history is to remember. To remember not only the happy stories of our past, but also the tragic ones”. The textbook goes on to mention historic conflicts and events, but I want to relate this to work safety and OSHA.

There is a common saying in the workforce especially centered around manual labour and heavy equipment: “All safety regulations are written in blood”. This saying wants to drive home the message that all work safety regulations and rules that workers find annoying only exist due to a worker in the past getting seriously hurt by a workplace incident causing preventative measures to be made afterwards. While working daily, it is important to follow safety regulations and rules as YOU might be the next OSHA case that rules are written about to prevent serious injury.

By observing the preventative rules, watching recreated incident videos, and reading case files, a working can paint a picture and gain knowledge of the incident that happened in the past that they can prevent now. This is in my opinion exactly what Edward Hyams was talking about in his quote but in a different circumstance compared to my interpretation.

As someone who has worked in many different warehouses and distribution centers, I am fairly comfortable working around loud heavy machinery and forklifts moving around with their horns blaring. Safety is always important in warehouses as the employers do not want to get sued however, safety incidents still occur. One of the biggest safety rules is always wearing high-visibility clothing in the facility so people operating heavy machinery can notice the employee easily. However, all employees are given the same high-visibility clothing so after a period of time, employees unconsciously start tuning out the high-visibility clothing as they become used to them. This is why the saying “All safety regulations are written in blood” resonates with me, as I believe high visibility acclimatization is going to lead to an incident that will create a new OSHA law sooner rather than later.

4 notes

·

View notes

Text

Secure Your Warehouse Success With Cutting-Edge Forklift Safety Solutions

Workplace safety is an essential concern, especially when it comes to heavy equipment like forklifts. In industrial warehouses, workforce safety is the topmost concern for the managers at work. While meeting business demands, opting for the right forklift safety solution can help mitigate accidents in high-risk industry settings.

Forklift accidents can cause extreme injuries and tragedies. Hence it is crucial to prioritise safety standards by constantly reviewing and sustaining necessary forklift safety devices. This helps businesses significantly lessen damages and provide more acceptable working environments.

With the help of forklift safety lights, both employees and pedestrians can keep themselves safe and sound from unwanted injuries. This guide will help you understand the safety devices and equipment provided in the forklift and why they are your best bet for workplace safety.

What is the role of forklifts in industrial warehouses?

Helps move multiple items at a time: Industrial warehouses often require employees to handle heavy machinery, which can be physically demanding. Forklift safety solutions ease this burden by enabling workers to move heavy devices and pallet containers effortlessly, enhancing productivity and reducing physical strain.

Provides enhanced safety to employees: Working without a forklift in industrial settings can expose employees to risky tasks involving pulleys, cables, and ropes. By adopting high-capacity forklifts equipped with safety features, warehouses can create a secure working environment, safeguarding the well-being of their employees.

Ensures minimal noise: A quieter workplace is conducive to higher productivity and employee well-being. Forklift safety solutions incorporating noise reduction mechanisms contribute to a peaceful atmosphere, promoting a more efficient and comfortable working environment.

Acts as an environment-friendly vehicle: Modern electric forklifts are environmentally friendly alternatives to conventional forklifts while emitting zero Carbon Dioxide gases. Businesses can opt for electric forklifts to reduce their carbon footprint and comply with sustainability goals while maintaining the capability to lift heavy loads.

Offers higher lifting capacity: Forklifts equipped with extendable arms and essential accessories provide substantial lifting capacity, enabling warehouses to handle large quantities of products efficiently and with ease.

Heat elimination technique: Forklift safety lights designed with insulation materials and heat elimination techniques not only enhance the lights' lifespan but also minimise the risk of sparking, ensuring a safer working environment.

High-endurance: Using tempered glass for the Blue Safety Lights on forklifts makes them resilient to water, shocks, and high temperatures. This durability ensures the lights can withstand harsh industrial conditions, making them a reliable and long-lasting safety solution.

Forklift Safety Devices

Forklift Camera System: Many businesses use advanced forklift cameras to enhance workplace safety. These sophisticated solutions offer real-time 360° vision of the area behind the forklift, improving operator awareness and preventing potential accidents. Several camera options are available for businesses, primarily the explosion-proof range of cameras to foster a safer work environment by eliminating blindspots for their workers through a centrally controlled safety system operated using a SIM card or Wi-Fi.

Forkview Camera System: Forklift or reach-truck operators need a clear view to fetch the goods stacked at a height. This is where our fork view camera system comes in. With a wireless screen for seamless transmission, a monitor screen, a dynamic cable, a powerful battery, and water and dust-resistant glass, it is an ideal choice for the extreme temperatures of your warehouse or industry setting.

Forklift Wireless Camera System: A valued addition to forklift safety, the forklift wireless camera system is a comprehensive solution for monitoring the surroundings of the forklift. The system offers a wide range of features from automatic backlighting to recording, light control, reverse gear activated screen, and multi-image adjustment. Furthermore, with its powerful battery, TFT LCD digital wireless display, and wireless camera with IR, the product has emerged as a forklift must-have.

Forklift Radar Blind Spot Detection System: If you manage an ATEX-z, Forklift Radar Blind Spot Detection System is a highly effective safety measure. The system is made of polycarbonate material and equipped with 24Ghz radar sensors, multiple detection modes, a multi-zone warning system, and a display unit - making it a tailored safety solution for high-temperature zones.

Warehouse Traffic Management System: Forklift safety cannot solely pivot around the operator's awareness of his surroundings. Installing warehouse traffic management system devices like bright LED lights, red spots, thumb levers, premium quality sensors, and warning alarms provides timely warnings to drivers and significantly reduces the risk of forklift-related mishaps.

Forklift Anti-Collision System: Besides the operator, your safety equipment must also factor in the safety of the pedestrians and the vehicle itself, particularly against the blind zones. That's where the forklift anti-collision system comes in. The system's radar comes with an ultrasonic probe that calculates the distance of the forklift from the nearest obstacle in a 3 meters radius. It then displays the visuals of the operator's LED screen and alerts the driver of blind spots, if any. In addition to providing enhanced safety and visibility for heavy machinery, the system is waterproof and an economical choice against accidental cover.

Forklift Speed Limiters: A leading cause of forklift fatalities is the overspeeding of heavy machinery. Forklift speed limiters allow the operators to set the speed limit of the forklift from 6-30 km/hr using a manual mode or a remote control. As an additional layer of safety, the customizable warning alarm alerts the operator of overspeeding. These speed limiters have a three-fold advantage for your business - improved road safety, increased fuel efficiency, and reduced carbon emissions.

By offering a wide range of advanced safety solutions, including forklift camera systems, brake maintenance support, and fork guidance lasers, cutting-edge systems by SharpEagle provide businesses with valuable options to enhance forklift safety across various aspects of warehouse operations.

Safer, Efficient, and Environmentally-Friendly Operations with SharpEagle

Forklifts are indispensable assets in the logistics processes of industrial warehouses. Selecting suitable forklifts and safety devices ensures streamlined operations and creates a safer work environment. When it comes to top-notch forklift safety solutions, SharpEagle stands out as a reliable partner for your business' safety solutions. With our cutting-edge technology, quick installations, and cost-effective options, we empower warehouses to optimise their workflows while prioritizing the well-being of their employees. Reach out to SharpEagle today and take the first step towards elevating your logistics to new heights with our comprehensive forklift safety solutions.

You can call us at +971-4-454-1054 or mail us at [email protected]

#Forklift fork camera#Forklift safety systems#Forklift safety solutions#forklift safety monitoring system#forklift safety system for warehouse#Forkview Camera System#forklift alert systems#forklift anti collision system#forklift wireless camera system#forkview camera#warehouse collision avoidance systems#warehouse forklift safety#warehouse pedestrian safety#wireless forklift camera

0 notes

Text

Forklift Attachments

What are some Forklift Attachments?

Forklifts are undeniably workhorses in warehouses and industrial settings, but their abilities extend far beyond basic lifting and transporting. With the help of a diverse range of forklift attachments, these machines transform into multifaceted tools, tackling a wider array of tasks and materials. Let's delve into the world of forklift attachments and explore some of the most common ones:

1. Fork Extensions: Reach new heights and conquer deep storage racks with fork extensions. These handy attachments extend the standard length of the forks, allowing you to access pallets in hard-to-reach locations or handle oversized loads with ease.

2. Sideshifters: Imagine trying to precisely position a pallet in a narrow aisle without perfect alignment. That's where sideshifters come in. These ingenious attachments enable the lateral movement of forks, granting you the flexibility to fine-tune the position of your load for seamless and efficient placement.

3. Clamps: Not all loads are created equal. For specific materials like barrels, rolls, or cartons, clamps offer a secure and stable solution. These attachments grip the load firmly, preventing them from slipping or toppling during transport, ensuring the safety of both your goods and your operators.

4. Rotators: Need to effortlessly rotate a bulky object for further processing or positioning? Look no further than rotators. These attachments allow your forklift to rotate the load a full 360 degrees, streamlining tasks like emptying containers or maneuvering large equipment.

5. Work Platforms: Forget the ladder and elevate your personnel to new heights with work platforms. These forklift attachments create a safe and stable platform for workers to access elevated areas, eliminating the need for separate equipment and enhancing efficiency.

Beyond these common attachments, the world of forklift accessories is vast and diverse. From drum grapples for secure handling of barrels to carton clamps specifically designed for boxed goods, there's a specialized attachment to address nearly any material handling challenge.

Remember, choosing the right forklift attachments depends on your specific needs and work environment. Consider factors like lift capacity, application, and safety features to ensure you select the perfect tools to optimize your forklift's capabilities and enhance your operations.

For instance, if you work in the lumber industry, you might find lumber forks incredibly useful for safely transporting wooden planks. Conversely, if your operations involve frequent maintenance tasks at varying heights, investing in a forklift boom attachment could significantly improve your efficiency and safety.

#forklift#forklift certification#forklift operator#forklift jobs#toyota forklift#forklift rental#forklift for sale#forklift operator jobs#forklift certification near me#forklift certified meme#forklift attachments#forklift accident

2 notes

·

View notes

Text

“The Matrix” by Upton Sinclair and HP Lovecraft

or ��How Robin Swift Learned He Wanted to Work at Amazon by Working at Amazon”

It was in the midst of an aimless June that I accepted the job at the Fulfillment Center (a kinder term for Bezos’s infamous Amazon warehouses), and somehow found confidence in my chosen major, Data Engineering, in the middle of a harrowing matrix of pallets racks and blasphemous turnover rates.

Let me first emphasize that I, with a clear mind and undisturbed faculties, would never have chosen an Amazon ‘Fulfillment Center’ as the place of my self-actualization. However, my mother—worried about financing my spending and, more importantly, my lack of work experience—had been the one to urge me to apply, as she had quit her own Amazon warehouse job only a few months prior.

The exhaustion on her face after a hard day in the freezer did not speak to a job appealing to kids my age, whom I knew to work the front at trendy cafés or as busboys in the back, but who was I to turn up my nose at a job my own mother had worked? Especially when I was struggling to find a better one to occupy my time.

Thus, my coming of age was to be set against the backdrop of towering pallets and “unsafe conditions,” as the great US Department of Labor put it.

…

“Thud, thud, thud,” echoed the sound of my steel-toed boots, like ominous sonar pulses broadcasting my location for Big Brothers unseen, as I reported for my first day.

They were steel-toed, my ‘Learning Ambassador’ Tyderius (“But You Can Call Me Tee”) had explained that day, because we legally were not allowed on the 'Order Picking Floor' without them.

He said that as easily as he did the various other protocols he claimed ensured our safety, such as my colleagues and I being armored to the gills in protective goggles, hi-vis vests, and IDs. Most of them, including Tee, were years older than me—many of them with children my age, and, therefore, with nothing to say to me, the kid who hadn’t yet found his place in the grand scheme of things. Well, most of them excepting Tee.

He was both disarming/charming and stuck with the unenviable task of training 30 newcomers on the usage of Order Pickers (OPs), which were the Amazon equivalents of warehouse forklifts in all ways except for how you strapped onto the ‘fork’ as you drove.

“Well, young man,” Tee had said, with a reassuring smile, when I’d questioned him on the speed limit of these OPs, “You mustn’t take too much stock in what people around here say. They’ll tell you that speed is all that matters, but we’ll go easy on your first month. Your safety, of course, is our biggest priority.”

That first week it was a chaos of hours-long shifts in the bowels of the warehouse pallet-matrix, never sure of where you were except in relation to the other boots, sonar pulses giving each other away, with only our mandated three 20-minute respites in between. On my second, I didn’t need to be a poet to describe how I had hesitated at the sight from my Order Picker at its zenith, placing inventory on the highest of pallets.

From above, it was like looking down the maw of a great beast – shelves and shelves of sky-high pallet racks like teeth in a cavernous gullet, with only your harness to cling to keep from falling in.

Thenceforth, it was like frenzy had been unleashed upon our 30-man herd.

It was quickly becoming apparent that the reason T was training 30 people at once was because the pressure for high Pick Rates, our inventory rate per shift, had eaten through those who had come before us and were now eating at us. We were no longer in the bowels but the intestines—the claustrophobic linings of the matrix digesting us faster and faster in its Kafkaesque acid nightmare of Pick Rates and accuracy measures, especially as our weakest links began thinning the safety of the herd.

Surprisingly, though, despite my general youth and aimlessness, I was not one of the culled.

It was during that zenith of my second week that I had the epiphany that saved me:

The matrix was not chaos, but—in fact!—order and organization at a magnitude far beyond what a single human could ever conceive.

It was self-evident by its very structure, which I saw as I looked across the tops of hundreds of rows of shelves containing hundreds of pallets packed with thousands of boxes of inventory. The only thing keeping me from getting swallowed was the harness I was clinging to. The machine at my back: my Order Picker.

The screen between me and my machine told me everything—from where I needed to go to how fast I needed to do it—and saved me from trying to conceive of the scale of the impossible.

Thus, the only way to survive was to plug in, physically strapping yourself into your Order Picker and mentally strapping yourself to its screen, becoming one with your personal shuttle of order and efficiency as a cog in the greater machine.

...

In the end, the Fulfillment Center, for me, was only for the summer. Just as it was for my mother’s own Amazon freezer stint. Even then, I didn’t stay beyond Tee’s one month of leeway. My eyes had been opened.

My future would be as one with the machines in Data Engineering.

By enabling the data gathering that scientists need to speak with machines, you become the interface between man-made horrors and man himself, the way I had been and will continue to be at the matrix.

Long after leaving Amazon and my Order Picker behind.

4 notes

·

View notes

Text

Sooooooooooooo~

Not only have I been doing overtime this week, but we got a new hire....

For reference, I'm a woman under 30 (at least until next year 😅) working not just in a warehouse, but the maintenance department. And on the produce side, so most of the area is cold, especially down by the freezer section.

Now, the maintenance shop isn't 'cold', but there is a garage type door at the back for big deliveries from outside, and my section (I work on the huge batteries that power the jacks/forklifts) has TWO doors that exit out to the refrigerated warehouse part for people to drive in for battery switches. So my section can get cold. Jacket/hoodie recommended.

Now, with working with batteries, in a warehouse, not only do you have to worry about acid (and it eating holes in your clothes), but the batteries are also dirty. Like, black dust dirty.

AND we have a 'uniform'. Basically, thick work jeans that are provided ASAP, a black shirt that says maintenance, and slip and oil resistant, steel toe boots, which you are required to buy before you start and are compensated for with a receipt shown with a dollar limit that is very fair.

So why is it that this new hire, who is also a woman (and in her early twenties), thought it'd be ok to show up in leggings, what I can only call glorified slippers, and like 3-4 inch long acrylic nails?

So of course I told her she couldn't work in what she was wearing. For one, it's cold. Two it's dangerous to have soft shoes like that. If a battery falls on your foot in something like that, your ENTIRE foot is going to be broken. And three...leggings aren't going to hold up if you get acid splashed on them...

So I had to take her to my boss to see if there was ANYTHING that could be done, like spare clothes or boots or something. And she was simply told to go home and change. She was hired like a week ago, so she had time to go out and buy boots. And simple jeans would suffice until her work jeans came in, I could handle anything even remotely involving acid until then.

And as is typical of this younger generation, instead of considering that all this was for her safety (and she was told all this when she was hired and given a list of requirements and recommendations for her boots and where she could get them), we were saying this to get her fired, or we were in some way trying to 'control' her and just a bunch of BS.

Um....I don't think she still has a job but....if she does come back? I'm not looking forward to working with her. She's going to be nothing but problematic, I think.

4 notes

·

View notes

Text

The Common Reasons For Warehouse Accidents

The warehouse has become a dangerous place for you. The effectiveness of warehouse accidents will have a direct impact on the effectiveness of the business. It has become critical to adopt warehouse safety protocols in order to avoid these types of hazards. The following are some of the most prevalent causes of warehouse accidents, as well as some solutions to prevent them.

Accidental fall: Vertical tubes are commonly used in warehouses to store items. These storage units are frequently tall, which may be the cause of a fall. Almost half of all workplace injuries occur at a height of 15 feet or less. It is critical to prevent these types of mishaps by restricting workers from mounting ladders to collect things and other associated mechanisms utilised in the warehouse, such as an automated system or a forklift.

Slips And Trips: A simple slip on the warehouse's moist flooring can cause significant damage. That is why a slip is one of the most common injuries in the warehouse management process. There are several methods for avoiding these types of accidents. Such as making sure your warehouse is well-organized, filling gaps in the flooring, and so on.

Motion: Every year, the most injuries in the warehouse are caused by motion. This involves repeated action and improper lifting of goods. There are several ergonomic methods for preventing this that benefit the workforce and are worth considering. Start with the fundamental warehouse automation procedure.

Poisonous And Hazardous Substances: The poisonous and hazardous commodities, such as corrosive acid, are the second most dangerous items in the warehouse. You must guarantee that your employees are properly equipped for handling these types of items. Gloves, ventilation, a face mask, and other such items are examples. Make sure your warehouse has a designated area for handling anything poisonous or possibly harmful. Train your employees in various tactics so that they can respond fast and avert major harm.

Anyspaze, one of the best warehouse management companies in India, has professionals on board who are well-known for doing a thorough analysis of the business requirements of any sector while keeping all safety protocols in mind. The company handles all of your logistical activities, including transportation, quality control, storage, and reporting, while ensuring the employee's complete safety. Tracking the whereabouts of items in the warehouse becomes much easier with tech-based inventory management systems. So, with Anyspaze, you can get the greatest logistics and warehousing services at the most inexpensive pricing.

Forklifts, for example, have a high potential for mishaps and are the cause of many injuries in the warehouse every year. Employee training has become increasingly crucial in preventing this. Also, ensure that any heavy machinery in your warehouse is in good working order and is regularly maintained.

Anyspaze, market leading warehouse storage provider, the greatest commercial storage solutions for all of your business's storage issues. The company provides flexible warehouse storage space for rent to keep your items safe at extremely inexpensive costs. Anyspaze is a countrywide network of retailers that may greatly assist your business in ensuring on-time last-mile delivery. Businesses may rent customised and smart warehouses with centralised networks and tech-based logistics services from the company. Anyspaze is a well-known company in the storage and logistics market, specialising in FMCG, Oil & Gas, Lubricants, and other industries. With Anyspaze smart warehouse solutions, you can enjoy reduced inventory management expenses, better delivery speed, comprehensive fulfilment solutions, and 0% weight discrepancy.

Source: https://anyspaze.livejournal.com/7723.html

3 notes

·

View notes

Note

Okay so, I work in a warehouse for a big bad company that we all know and hate (they just have scheduling options so I can go to college and work pretty much whatever hours i want so…😒🖐🏻 gotta stay for now; we’re also gonna pretend we don’t know the company I’m talking abt for the sake of online safety purposes) but we got this new manager in our maze of leadership and he’s one of those ones you’d catch trynna go between the gate bars on the pasture and not over istfg like… we have speed bumps galore in our parking and he’ll fly through going like 20 ignoring the 🛑 signs and cross walks yeah?? So I’m doing my job on a pit (heavy drive equipment like forklifts, pallet riders, cage puller, etc) and I’m mentioning a really big safety issue and he brushes it off like I didn’t almost get the stupid knocked out’o me by an even bigger pit cause they didn’t stop at a 🛑 sign. He pulls this binder out and goes “well the standard for driving pit is..” like… 😒 I slapped that binder out of his hand so fast and he stared at me like a fckin white woman staring at her ill behaved kid in Walmart like 👁👁 w the pursed lips and all right?? I told this man that not only does he not drive pit himself but he shouldn’t be textbook handling a safety concern when “safety is our #1 priority!” And he tells me I need to watch my attitude so I told him to watch how much shine he puts on the top of his head cause maybe there were so many pit accidents that that night because the 💡 were reflecting like high vis. Asked if he used shine or if he spit shines, he left me alone for awhile and then came and said he took care of the safety concern by holding a meeting with our safety crew about the failure of pit stops. Well HE GOT ON A PIT AND I WAS BEHIND HIM 🫣 this man drove straight into a barrier and then looked at me like 😳 I reported his accident so fckin fast like 😈🤠 (cause we have to, but also bc he was abt to just drive off like it didn’t happen and like??) the safety man was so fckin happy abt it, cause so far everyone’s had little scuffs with this guy apparently and I was one of the last people hed done it to ig since I don’t interact with many people at work; just there to pay bills tbf 🐻 (sorry for this being so long 😭🖐🏻)

istg managers are the most annoying ppl in the world 😭😭 so glad he got his karma 🙏

4 notes

·

View notes