#visual inspection testing

Explore tagged Tumblr posts

Text

Advanced Remote Visual Inspection Services in Pune

Integrated NDE offers state-of-the-art remote visual inspection in Pune, ensuring high-quality assessments for a variety of industrial applications. Remote visual inspection (RVI) is a critical component of non-destructive testing (NDT), allowing for detailed visual inspections without dismantling equipment. This method is ideal for identifying defects, verifying structural integrity, and ensuring compliance with safety standards.

Our Expertise

We employ advanced technologies for remote visual inspection, including remote visual testing and manual visual inspection. Our visual inspection NDT services are designed to provide accurate and reliable results, making us a trusted partner for industrial visual inspection needs. Our team is skilled in conducting thorough visual testing in NDT, ensuring that all inspections meet stringent industry standards.

Applications and Benefits

Remote visual inspection is used in various sectors, including:

Power Generation: Inspecting turbines, boilers, and other critical components.

Oil and Gas: Checking pipelines, storage tanks, and offshore structures.

Manufacturing: Verifying the integrity of machinery and production lines.

Aerospace: Examining aircraft components for defects or wear.

The benefits of our visual inspection services include:

Non-Destructive: Inspections are carried out without damaging the equipment.

Cost-Effective: Reduces downtime and the need for extensive disassembly.

Accurate: High-definition visuals provide detailed and precise information.

Efficient: Quick and easy access to hard-to-reach areas.

Our Process

Our inspection process begins with a thorough assessment of your needs. We then deploy our team with advanced remote visual inspection equipment to conduct detailed examinations. Our visual NDT testing procedures are designed to detect even the smallest defects, ensuring comprehensive evaluations.

Why Choose Integrated NDE?

Choosing Integrated NDE for remote visual inspection services in Pune offers several advantages:

Experienced Professionals: Our team comprises experts in visual inspection NDT, ensuring top-quality services.

Cutting-Edge Equipment: We use the latest remote visual testing technology for accurate results.

Customer-Focused Approach: We tailor our services to meet the specific requirements of our clients, providing customized inspection solutions.

Proven Track Record: With years of experience, we are a trusted name in the industry for reliable NDT inspection services.

Comprehensive Services

In addition to remote visual inspection, we offer a range of other NDT services, including visual non-destructive testing, remote site inspection, and RVI inspection. Our holistic approach ensures that all your inspection needs are met with the highest standards of quality and precision.

Local Expertise

As a leading NDE company in Pune, we are well-positioned to provide NDT testing near you. Our local expertise and understanding of the industry make us the go-to provider for non-destructive testing in the region. Whether you need routine visual inspection testing or specialized remote visual inspection services, Integrated NDE is here to help.

Contact Us

For reliable and efficient remote visual inspection services in Pune, trust Integrated NDE. Our commitment to excellence and customer satisfaction ensures that you receive the best possible service. Contact us today to learn more about our services and how we can assist with your inspection needs.

Conclusion

Integrated NDE’s remote visual inspection services in Pune are designed to deliver accurate, reliable, and efficient results. With advanced visual inspection NDT techniques, cutting-edge equipment, and a team of experienced professionals, we provide comprehensive solutions for various industrial applications. Trust Integrated NDE for your visual inspection needs and experience the highest standards of non-destructive testing.

#remote visual inspection#visual inspection#remote inspection#visual inspection ndt#visual testing ndt#industrial visual inspection#visual ndt testing#visual testing in ndt#visual ndt.#visual inspection testing#manual visual inspection#manual inspection#remote visual testing#remote visual#visual non destructive testing#remote site inspection#rvi inspection#remote visual inspection services

0 notes

Text

Types of Visual Inspection

Introduction

The history of inspection is a narrative of human ingenuity and the quest for quality assurance across diverse domains.

In ancient times, civilizations such as the Egyptians and Greeks employed visual inspection techniques to assess the structural integrity of monumental constructions like the pyramids and temples.

As industrialization burgeoned, especially during the Renaissance and the subsequent periods, the need for more sophisticated methods became apparent.

This led to the gradual emergence of Non-destructive Testing (NDT), a revolutionary approach that allowed scrutiny without compromising the integrity of the materials.

In the Oil and Gas Industry, where safety and reliability are paramount, NDT testing took center stage.

The exploration of Ultrasonic Testing brought forth a method relying on sound waves, enabling inspectors to delve into the hidden intricacies of materials, identifying flaws that might escape visual scrutiny.

Simultaneously, Magnetic Particle Testing became a pivotal tool, particularly in assessing the integrity of metallic components crucial to the industry.

The Scaffolding that supports the modern industrial landscape, both figuratively and literally, further underscores the need for rigorous inspection.

Complemented by Advanced NDT Techniques, visual inspection ensures that the scaffolding itself, a linchpin in construction and maintenance, meets stringent safety standards.

This historical journey, from ancient Visual Inspections to the contemporary amalgamation of ultrasonic and magnetic particle testing, represents a testament to the evolution of inspection practices — a narrative driven by the relentless pursuit of precision, reliability, and safety in the intricate tapestry of engineering.

What is Visual Inspection?

Visual inspection is a method in Non-destructive Testing (NDT), that relies on the human eye to assess the surface conditions of materials, structures, and components.

This method involves a structured methodology to ensure comprehensive scrutiny.

Operators conducting Visual Inspections follow a systematic approach, beginning with thorough planning and preparation.

What are the benefits of Visual Inspection?

The advantages of Visual Inspection include the following:

Cost-Effective

Visual Inspection is often more economical compared to advanced methods like ultrasonic testing, magnetic particle testing, and Liquid Penetrant Testing.

Real-Time Adaptability

Visual inspection allows for immediate on-site assessments, contributing to real-time decision-making during the inspection process.

Versatility

Applicable to a wide range of materials and structures, making it a versatile choice for diverse industries.

Integrating Automation

Visual Inspection automation enhances efficiency by automating repetitive tasks and ensuring consistent and thorough inspections.

Conclusion

Visual Inspection remains a foundational and enduring method in non-destructive testing (NDT).

As we witness the integration of automation, AI, and robotics, particularly in visual inspection automation and Drone Inspection, the landscape of NDT is evolving.

These advancements enhance efficiency, safety, and accuracy, especially in inaccessible or adverse conditions.

The incorporation of AI in NDT, coupled with Visual Testing and drone inspection, emphasizes the transformative nature of these technologies.

Visual inspection's simplicity, accessibility, and role as the initial step in identifying defects ensure its continued relevance, complementing Advanced NDT Methods applied by professionals and technicians in the field.

#ndt testing#ndt techniques#visual inspection#visual inspection techniques#visual inspection methods#visual inspection benefits

2 notes

·

View notes

Text

In industries like pharmaceuticals, medical devices, and food production, visual inspection is very important for ensuring product quality and safety. In the United States, strict guidelines like USP 1790 Particles for visual inspection are followed to ensure that products are free from defects and contaminants. This process is especially critical for items like vials, ampoules, and other containers that hold medicines. Visit us: https://shorturl.at/8emaB

0 notes

Text

FTI Incorporation, a leading name in forensic and technological innovation, is proud to announce its latest advancements in quality control and safety assessment with the introduction of the Knapp Test Kit France and its application of USP 1790 particles for visual inspection. These cutting-edge tools are set to enhance the precision and reliability of quality inspections across various industries, ensuring that products meet the highest standards of safety and effectiveness.

0 notes

Text

Machine visioin surface inspection, Intsoft Tech automatic detection solution

#surface inspection#automated visual inspection systems#vision manufacturing#deep learning for vision systems#factory acceptance test#auto inspection camera#california auto inspection#optical inspection#an optical inspection system is used to distinguish

1 note

·

View note

Text

#heat treatment#hardness testing#industrial radiography#radiography#material test & lab equipment#magnetic practicle testing#ultrasonic testing#ndt equipment in uae#uv light#visual & welding inspection equipment#general equipment#incor technical#uae

0 notes

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. This is where engineering safety inspection services come into play — acting as a critical partner for management and supervision in ensuring a safe and productive work environment.

Proactive Risk Mitigation:

One of the most significant advantages of employing engineering safety inspection services is their focus on proactive risk mitigation. Unlike reactive approaches that address issues only after an incident occurs, these services utilize a proactive strategy to identify potential hazards and safety concerns before they develop into accidents. Through comprehensive inspections conducted by qualified professionals, these services can uncover:

Equipment malfunctions: Regular inspections can detect potential equipment failures before they happen, allowing for timely maintenance and repairs. This not only prevents accidents but also extends the lifespan of valuable equipment.

Process safety hazards: Improper procedures or deviations from safety protocols can create unseen dangers. Engineering safety inspections scrutinize existing processes and procedures, recommending modifications to eliminate these hazards.

Environmental concerns: Leaks, spills, and hazardous materials pose a significant threat to both personnel and the environment. Inspection services can identify these issues and recommend corrective actions to ensure a safe and sustainable work environment.

Improved Compliance:

Safety regulations and standards are constantly changing, and keeping pace with these changes can be a challenge for management teams. Engineering safety inspection services possess in-depth knowledge of relevant regulations and standards. Their inspections ensure your operations adhere to these requirements, minimizing the risk of compliance violations and potential legal consequences.

Enhanced Employee Morale and Productivity:

When employees feel safe and confident in their work environment, their morale and productivity naturally increase. Regular safety inspections demonstrate a commitment to worker safety, fostering an atmosphere of trust and well-being. Employees feel valued and are more likely to be engaged in their work, leading to improved efficiency and overall performance.

Reduced Operational Costs:

While the cost of engineering safety inspection services might seem like an additional expense at first glance, in the long run, it is a valuable investment. By preventing accidents, injuries, and downtime, these services lead to significant cost savings. Additionally, reduced repair costs, improved equipment lifespan, and lower insurance premiums contribute to a healthier bottom line.

Data-Driven Decision Making:

Engineering safety inspections yield valuable data and insights that empower management and supervision to make informed decisions regarding safety protocols and resource allocation. These reports can identify trends and patterns, allowing for targeted interventions and resource allocation to address priority areas.

Continuous Improvement:

The safety inspection process is not a one-time event. Regular inspections create a culture of continuous improvement within your organisation. By identifying and addressing safety concerns proactively, management can demonstrate a commitment to creating and maintaining a safe work environment. This fosters a proactive safety culture where employees feel empowered to report potential hazards, leading to ongoing improvement in safety practices.

Choosing the Right Inspection Service Provider:

When selecting an engineering safety inspection service provider, it’s crucial to choose a company with qualified professionals who have experience and expertise in your specific industry. Look for a provider that offers comprehensive inspection, use of relevant standards and regulations, and can translate complex findings into actionable recommendations.

Conclusion:

In conclusion, engineering safety and ndt inspection services are not just a tick-the-box exercise but a crucial investment in the safety, well-being, and overall success of your organization. By partnering with a reputable inspection service provider, management and supervision gain valuable insights, proactive risk mitigation strategies, and improved compliance, fostering a safe, productive, and cost-effective work environment for everyone.

To learn more contact the experts at RiskCON today.

#non destructive evaluation

#non-destructive testing

#engineering services

#welding engineer

#visual inspection

#ndt certification

#welding engineering

#mag particle testing

#ndt inspector

#testing and inspections

#ultrasonic test

#ndt inspection services

#ultrasonic inspection

#visual testing

#inspection engineer

#engineering and inspection services

#construction engineering and inspection services

#engineering & inspection services

#engineering safety inspection services

#welding engineering inspection services

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#ultrasonic test#ndt inspection services#visual testing#non destructive evaluation#non-destructive testing#engineering services

0 notes

Text

Bonus that at some point today i might get test results from last week

No clue what will happen in 25 minutes

#today may suck#one test is to understand how bad i’m built#the other is a double check that i don’t have cancer#passed visual inspection#waiting on microscopic examination

6 notes

·

View notes

Text

not always what they seem (6)

warnings: poor decision-making, graphic panic attacks, lack of communication, guilt, fear, angst

—

With a sinking feeling, Logan watched the most easily-agitated of their guests continue on into the next testing area alone.

It was a breach of conduct to hope for certain results while performing an experiment, primarily because objectivity was vital if one wanted to produce genuine analytic results, but in this case, he found he couldn’t help the urge to wish that either of the others had ventured forward first.

The test itself was a relatively simple one: the chambers in this area were a series of identical rooms, as in the last, with sensitive motion trackers embedded in the flooring. In the previous area, the rooms had been temperature-controlled, so they could see which room their guests would seek out as ideal. There had been more mixed results than expected, but in a case like this, any data was good data.

In this area, each room had a different level of lighting, a spectrum ranging from bright enough that some exclusively-nocturnal species would struggle to see, to dark enough that most diurnal species wouldn’t be able to make anything out.

It was one of the simpler tests, with little to actively fear. Virgil had already begun investigating it with far more initiative than they’d shown in the maze before, their ever present hunched shoulders even beginning to slowly ease down as they went. Clearly, the presence of the other two beings and the harmless precedent set by the previous areas was helping settle their persistent wariness.

(A fact which only made Logan feel worse about what they would have to do next.)

Virgil headed directly for the lighter side of the area at first, frequently casting glances back toward the more shadowed areas, a mannerism that made Logan wonder if they had a surplus of natural predators on their native planet. They spotted the only item of note in the first room immediately, providing substantial evidence to support Patton’s proposal that their guests had strong visual abilities, and approached it slowly.

Seeing as they had refused to do even that much in Logan’s maze, this was heartening progress.

A flat dish segmented into two halves sat on a small stool in the corner of the room, and on top of that dish rested a simple nutrient tab and an orb made up of colorful pieces.

Virgil didn’t spare the nutrient tab much more than a glance, but after a prolonged moment of direct staring, they dared to reached out and swipe the puzzle sphere off the dish, immediately skipping back a few steps and craning their neck to look up at the semi-transparent ceiling.

(The opaque coating on the material was one-sided, so they could watch the results directly without perturbing the subjects by looming over them. In theory, anyhow. Virgil’s vision must have indeed been strong, or at least highly cued to motion, for them to have already noticed the muted shadows of Logan and his research partners through the roof.)

Virgil seemed to be waiting for some sort of severe repercussion for touching the puzzle sphere, as though they expected one of them to swoop down and grab the item from their hands— or even grab Virgil themself. None of them had so much as twitched, aware that even the simplest movements had been known to startle their most skittish guest.

After an exceedingly long pause, Virgil’s tense posture dropped away, and they spent a few moments inspecting the puzzle sphere with enough intensity that they even forgot to check over their shoulder for the duration. Despite being a few levels more complex than the treat ball Logan used in his maze— these were sapient beings, after all— it didn’t take Virgil long to align the pieces properly and thus solve the puzzle, allowing the sphere to pop open and reveal their prize: a dark shining stone.

They had all agreed on shiny prizes, seeing how glinting items had often subtly caught the attention of the tiny aliens. Patton had been concerned about the likelihood of them mistaking something inedible for food, so they had switched from polished mineral marbles to valt stones with a reflective sucrose coating applied to them. Valt stones dissolved in medium heat, so even if Virgil did manage to eat one, the stone would gradually crumble away based on the temperature readings Roman had taken.

It seemed maybe they’d been overly-proactive; Virgil flipped the stone in their hands a few times, drew it close to inspect it, but didn’t so much as smell it, let alone put it in their mouth. After a moment of this, they dropped the stone into the pocket of their leg garment.

They all shared an excited glance: positive engagement!

Virgil perked up further when they ventured into the next room and saw the same set up, only slightly altered: the stool and dish were set in a different corner, and the puzzle was a different shape. They didn’t seem nearly as wary this time, and settled into a routine of locating the dish and walking up to it, picking up the puzzle, and using deft fingers to fiddle with it until they got to the small prize inside.

The only sign that the brightest room gave them any trouble was the slight squint they took on, though the light evidently wasn’t perturbing enough to make them take the puzzle into a different room. That was a good sign; it meant that the odds of causing damage to their guests’ eyes with ray-based scans were low, and many of those scans were invaluable for determining physical makeup.

When it came to the dark rooms, Virgil moved slower, and took slightly longer to scout out the location of the dish each time. In the last three rooms, they took the puzzles to one of the lighter rooms to solve it, helpfully confirming Logan’s theory that they were focusing on the color-matching element of the puzzles rather than matching the tactile symbols on the pieces. In the last room, it was extremely likely that they couldn’t see anything at all, as they moved extremely slowly and searched the room through touch, making a circuit around to each corner and then walking back and forth until they gently bumped into the stool.

These results seemed to indicate that their guests could operate in a wide range of different lighting, but had a considerably easier time navigating in the rooms set to daytime-lighting. They also indicated that Virgil, at least, could see a fairly large scope of color, as it was only on the two most color-complex puzzles that they resorted to using the other available senses to solve them.

The test also indicated that they had no choice but to use the next chamber.

After all those rooms, Virgil still hadn’t touched a single nutrient tab, just as none of the three had done more than disinterestedly inspect the nutrient tabs Patton had left on the table with them in the past two cycles.

This wouldn’t have been unusual or particularly concerning if these had been normal specimens. Many fauna didn’t engage with the nutrient tabs, since they were tailored to be non-toxic to all lifeforms in this quadrant, and thus were admittedly rather bland and uninteresting. In that case, they would usually move on to performing more physical tests to discern what variety of foods were safe and tempting to the creature in question, and then provide those instead.

Things were obviously quite different when working with sapient aliens, especially ones who had refused all physical tests more intensive than touching a thermometer. They couldn’t effectively communicate with their guests yet, and they didn’t have time to dismantle that language barrier. It had already been a concerning amount of time since they’d been taken from the stasis of the specimen sects, and they had no idea how to identify or treat starvation.

It was probable that providing items more easily recognized as edible would solve the issue of their guests not eating, but without that testing, they didn’t know what would be poisonous to the small aliens. If they simply offered an array of foods, as they had the textiles, the chances of their guests having a bad or even fatal reaction to something were far too high. That was an unacceptable risk.

Logan had been the one to insist, in the end. No matter how ill-advised it was to ignore the boundaries of their guests, no matter how much he dreaded the idea of being responsible for the reappearance of that upset and frightened body language, he wasn’t willing to allow them to die through his inaction or lack of care.

He had already made a mistake with the three of them previously, letting panic drive him and ignoring their objections in favor of picking up Remus. If one of them had to become untrustworthy in their eyes, better that it was him.

Logan ignored the concerned glances of his research partners, watching grimly as Virgil pushed through the door to the next testing area.

—

Virgil was having a surprisingly okay time, considering the circumstances.

At first sight of the structure, he’d anticipated some kind of horrible alien death maze, full of sawblades and pit traps and possibly even a car-sized boulder that would squash them all flat.

Instead, it had been full of various rooms, not winding or confusing or particularly maze-like in any way, with items or environments for them to react to. He’d gotten a bit concerned about the puzzles, but really, there weren’t any real signs that pointed to this being a bizarre trial-by-fire or even a remotely competitive scenario, even by his paranoid standards.

There were doors between each distinct chamber, but none separating the rooms themselves, and all the chamber doors had remained open even after they’d split the party like idiots in a horror movie.

He tossed the last weird rock he’d earned in his palm, rubbing his thumb over the dull angles of it. Even knowing they were part of some weird alien plot, it had been surprisingly soothing to focus on those puzzles, probably because he could burn some of his nervous energy by fidgeting with them. Not that he’d say as much aloud; that sounded a little too ‘enthusiastic lab rat’ for him. No thank you.

There was probably plenty of data they were getting from each chamber, no matter how simple they seemed, but Virgil wasn’t really in the mood to try and puzzle it out. Dee was probably right about the aliens trying to squeeze as much relevant information from them as possible, but he couldn’t help but feel sort of apathetic on the matter. Sure, they could be using it to learn more about humanity for presumably nefarious purposes, but if they wanted more humans, couldn’t they just grab more humans? They certainly didn’t seem to have a problem nabbing the three of them.

Maybe he was just being stupid, too busy freaking out about their own lives to really think about the big picture or whatever, but it didn’t seem to add up. Like, if he’d found an anthill and wanted to get rid of it, he wouldn’t need to run experiments on the ants to learn more about them first. He’d only have to kick over the anthill.

If all the aliens wanted to do was get rid of them, why bother with all the tests? It had to be obvious by now that they didn’t have any sort of natural defenses that could stand against giant aliens, and their technological capabilities obviously outstripped humanity’s by far.

He wasn’t suggesting they were trustworthy or anything— there was a wide range of options between metaphorical ants and potential friends, after all. Even if their status was closer to ‘interesting lab specimens’ than ‘pests to annihilate’, they still weren’t guaranteed any sort of safety. It was just… something useful to think about whenever the overwhelming panic started to boil up in him.

It was a theory that Virgil immediately lost all faith in when the doors to the next chamber sealed behind him.

He whipped around, a jolt of ice spiking through his veins as he confirmed that yeah, that sliding noise absolutely had been the doors closing, he’d jinxed himself so hard, he was going to fucking die—

“Hey!” he snapped, the word coming out a little strangled on his first try. “Hey! No, no no no, open those back up! Dee! Remus!”

The doors weren’t entirely opaque; he could see through them well enough to tell that the doorways beyond remained clear of any silhouettes. One beat passed, and then another. The fear crept in quicker now, his breathing coming faster. “Guys! I’m serious, something’s happening! Dee!”

Still, nothing.

They wouldn’t just ignore him. Even if they were actually total assholes who didn’t care what happened to him like his brain was screaming, he’d spent enough time around them to know that Dee was nosy beyond belief, and Remus sought out danger like a moth flying into an oven. If they’d heard, they would have responded, one way or another.

So, they couldn’t hear him. That meant this was planned. The aliens wanted something with them— no, with him. They’d separated them, singled him out to get it.

Virgil stumbled hurriedly into a corner, bracing his back against it as he scanned the room, his gaze periodically flickering up to the gray ceiling above where he was sure he’d spotted a shadow of movement earlier.

The chamber itself was empty, with no visible doors other than the two on either side that had firmly locked him in. It was a single blank room, nothing on the floor or the walls, the only notable difference being the fact that it was apparently soundproofed.

It was quiet for long enough that he managed to wrangle his breathing back under control, the tension in him only ramping up as the uncertain moment stretched on and on and on.

And then, a click, and the ceiling was pulled away.

Virgil sank down into a crouch on sheer instinct, as though he could avoid whatever was coming simply by shying away from it. He’d thought the enclosed room was bad, but the sudden feeling of being completely exposed was somehow worse.

The panther alien— Logan— leaned into sight, uncanny eyes locking on him immediately, and Virgil hunkered down a little further.

“No,” he tried, not even sure what he was objecting to, other than everything about the situation. “Do you h-hear me? No.”

Logan’s ears flicked and angled backwards, eyes narrowing slightly, and an audible rumbling started up. Wow! Virgil hated everything about that, actually.

When the alien moved, reaching into the enclosure with one of those inhuman hands, the gesture was almost painstakingly slow. If it was an attempt to not frighten Virgil any further, it failed miserably; it only gave him more time to work himself into a proper panic.

He tried to duck away the moment that hand got close, obviously, but it only took a few tries before Logan seemed to lose their patience. The next grab was too quick to dodge, and Virgil couldn’t help the small shriek that burst from him the moment he was caught, primal terror overriding all rational thought. Logan jolted at the sound, but didn’t loosen their grip nearly enough for him to wiggle free.

“No!” he shouted desperately, but there was no point. Logan may have understood the word, but understanding didn’t mean listening. Virgil didn’t have the same dauntless charisma as Dee, the confidence to negotiate with giants that could choose to do anything they wanted.

His stomach dropped as he was lifted up, the restraining hand wrapped around him never faltering even as he cried out and tried to thrash free. The panic felt nearly blinding, and he barely registered the blur of the much larger room passing by as Logan carried him over to some new surface, presumably for some other strange test.

The moment there was a solid surface under his feet again, he instantly tried to push off of it and scramble free, but even now Logan didn’t release him. He only had a moment to feel oddly betrayed– had some part of him really thought this wouldn’t actually end horrifically?– before he was being repositioned and gently but firmly pressed against the surface, like a butterfly being spread over a pinboard.

Or a corpse set out for dissection.

“Fuckshit fuck, fuck you fuck you fuck you,” Virgil spat as viciously as he could, twisting his limbs ineffectively and frantically pushing against that impossible hold. “Let me go, don’t you fucking dare–!”

The rumbling grew louder, the slightest shake tangible in the hand pressing him down, and the alien shifted their hand slightly, enough for Virgil to see past it.

With their other hand, Logan was holding a narrow silver instrument in the air above him, its purpose indiscernible but its mere presence enough to make Virgil’s voice cut off sharply. His furious struggling died down to involuntary twitches, his wide eyes locked on the tool.

The alien was as unreadable as always, the tip of the tool drifting closer, and Virgil felt his mind go entirely blank with terror.

A high, thin whine split the air, like an animal caught in a trap. It took Virgil a long moment to realize the sound was coming from him.

“Please,” he tried hopelessly, the words barely taking shape. “No. Please no.”

—

This wasn’t working.

Even from an animal, this sort of mindless, terrified whimpering would have been reason enough to stop this procedure and look for alternative, less stressful methods. Knowing they were coming from a sapient being? Knowing that, translatable or not, Virgil had likely been reduced to begging for their life because of his actions?

Logan couldn’t do this.

—

The pressure on him abruptly vanished.

Virgil’s body reacted far quicker than his mind, a fresh surge of adrenaline tearing through him as he hauled himself upright and bolted. It didn’t matter which direction he picked, so long as he was getting away from the threat looming over him.

There were thin semi-transparent barriers set up on each side of the table, preventing him from getting too far and also from doing anything rash in his panic. He twisted to look behind him the moment he reached the furthest corner, half-expecting a massive hand to be hovering over him already, only waiting for him to pause so it could come swooping down–

The alien hadn’t reached forward at all. In fact, Logan looked further away, as though they’d taken a step or two back.

It took a few tense moments for Virgil to pay attention to anything beyond that distance, most of his focus going to keeping his heavy, gasping breaths from turning to outright hyperventilation. His gaze locked onto every small motion Logan was making, but it took several repetitions before he registered the meaning behind the gesture.

It was the same movement as the other one– Roman– had done after trying to separate him from Remus by grabbing him. Dee had hypothesized it was some kind of… apology.

“You should fucking be sorry,” Virgil muttered, still wheezing a little with every inhale. “Serve you right if I– if I keeled over just from– fuck.”

His voice died out as soon as Logan moved, his body flattening further against the barrier behind him as though he could somehow merge through it, but Logan was moving away, reaching towards something to the side.

After a few seconds of rifling, they returned with a thick disc-shaped object in hand. Virgil stared blankly, suspicious and bewildered in equal measure.

Logan seemed to glance over to check that he was watching, and then carefully lifted the disc to their mouth and emphatically sank their teeth into it like they were an excited kid taking a bite out of a cookie. Their lip curled up as they did so, giving Virgil a better look at those fangs than he’d ever particularly wanted, and then, after a long stretch of holding that position, they opened their mouth back up without actually tearing a chunk free from the disc.

Virgil frowned, almost too confused to be frightened, as Logan tilted the disc to show Virgil the clean imprint of teeth left in it. The alien set the disc aside, and then picked the silver tool back up, which set his heart racing anew.

Instead of reaching forward with it, however, Logan simply lowered the tool to the surface where Virgil had been pinned down minutes before, and set a small item down before retreating. Now that he was looking at it from a distance, the tool wasn’t sharp-edged at all, only having two narrow prongs at the end.

… Had he seriously had a panic attack over the outer space equivalent of tweezers?

The embarrassment was powerful enough that he managed to force himself to slowly edge forward, squinting at the item Logan had placed before him.

It looked just like the disc Logan had just bitten, only in miniature.

Oh. Oh.

Virgil was no genius, but even he could put the pieces together on this one.

With a few wary glances at Logan’s towering form, he slid closer and picked the disc up. There was a hard outer shell along the sides of it for him to grip, but the rest of it seemed to be made up of a thick, clay-like material. Not the sort of thing he’d usually put anywhere near his mouth, but… he looked up at Logan again, considering.

There was nothing stopping them from doing this against his will, earlier. Nothing but Virgil’s own protests, desperate enough that Logan had decided to try a different way. Maybe Dee had been onto something, when it came to compromising with these creatures.

Besides, it wasn’t like he was actually eating the stuff. Just… biting it. Eugh.

Pushing past his deep reluctance, Virgil bit down into the disc, jolting a little when he realized there was a flat pane of plastic-y material in the middle that kept him from biting through the whole thing. Really, it felt oddly similar to those mouthguards dentists made him wear while getting an x-ray of his teeth. Except squishier.

He forced himself to hold the weird disc thing in his mouth for what he thought was probably the same amount of time Logan had while demonstrating, and then unhooked his teeth from it with a grunt. Peering closely at the disc, he could see that the holes left behind were perfectly matched to the shape of his teeth.

It had to be some kind of plaster-mold-cast thing, but Virgil had never been all that into ceramics, and so he didn’t have the foggiest idea of what exactly Logan intended to do with a mold of his teeth. At this point, he didn’t even care.

The energy crash was beginning to hit, and so he barely even jumped when Logan reached down at him, only taking a few stumbling steps back and then holding the disc out as far from his body as he could manage.

To the alien’s credit, their touch was gentle enough that he barely registered it as they plucked the disc out of his grasp, the palm-sized disc looking comically tiny between those massive fingers. The rumbling had started back up again. Maybe it wasn’t a displeased sound, after all. Cats purred soothingly, didn’t they?

Logan immediately moved away, presumably to do mysterious alien scientist things to the disc. Virgil spat a few times, trying to get the faint aftertaste out of his mouth, and sat down heavily. His whole body was still shaking like a leaf in the wind, but this sort of wrung-out jittering was vastly preferable to the frantic, burning terror of before.

He’d managed some kind of communication, for what it was worth. He hadn’t died, despite all expectations to the contrary. It had been a horrible experience, but at least he’d managed to figure out what was going on in time to prevent any actual heart attacks.

One thing was for certain: the minute he reunited with the others, he was putting a permanent ban on splitting up in weird mystery mazes. This little excursion had been more than enough for him.

#space au#sanders sides fic#ts virgil#ts logan#nawts#not always what they seem#my writing#writing#i promised myself i would get at least one chapter published this month despite it all#hope everyone enjoys ;;

95 notes

·

View notes

Note

okay but.. how much can fairy pussy take? like the tip of their pinky or..

there’s an artists on twitter and bluesky who goes by spitroses and they drew some microphilia stuff with a pixie character and a human (it’s also incest so if y’all go looking view at your own risk!)

size difference is yummy asf tho

i guess it mostly depends on how small you picture her. i know i said the other day that she'd fit in barbie clothes but that was more for ease of convenience than anything tbh. i actually picture her shorter (maybe like 5" tall) and a good bit chubbier, personally, because it's my wish fulfillment fantasy, damnit, and i think a chubby little fairy would be the cutest thing ever.

which is to say i think pinkies are right out. however, there are cathedrals everywhere for those with eyes to see, and goddamn do my beloved mutuals have their third eyes wide open.

so first off, shout out to @/quarterlifekitty who has been trying to fucking kill me for days, filling my dm's with ideas of bullets (or freshly fired casings if we wanna do temp play 😵💫) and her riding price and/or nik's piercings. or my personal fav, pussy inspections with lock picking tools 🫠 (seriously, imagine price just like 🫴🏼🧐 with fucking jeweler's spectacles prodding at her with blunt tip picks just to see what makes her squirm the most. i'm gonna BLOW UP!!)

my sources (@/3amfanfiction) tell me there are anatomically correct mini dolls which is driving me insane because i love the idea of them getting her what is essentially a sex doll just to watch her ride something properly. they're visual men. have always loved watching their partners ride them, after all. beloved three also floated the idea of them using something edible on her if this is still within the unlucky foot universe and her cum is some addictive sweet 😵💫 (for this one we're gonna say she has some magical aversion to yeast infections just cause we can lmao)

building off three's doll idea, @/sojubaby reminded me that a lot of higher end collectible action figures have specific hand attachments. they also found theeeeee perfect unicorn horn attachment which i think is my favorite for like. a genuine-ish dildo. for our purposes we're gonna pretend that's made of a softer silicone

this isn't super relevant to your question but i've also accepted that I will never be able to write price without a breeding kink so i've also had the image of him using a pippette to give her his cum stuck in my head for days. three says it would be super easy to get some cum inflation going on and she's RIGHT 😵💫 meanwhile @/stellewriites brought up the possibility of sounding with a tiny fairy but I got disteacted thinking about a kinder version of john than the one in unlucky foot taking it upon himself to test everything he fucks her with on his slit first because if it hurts him then it simply won't do for her!

god sorry i've rambled a lot but i've been dodging assassination attempts in the form of fairy fucking ideas for days so i'm chock full of ideas (and have more in the tank, even [thanks stelle and woolie 🙄]) but one last thing before i sign off on the official what can fairy pussy manage post™️:

if i had a fairy gf I would buy one of those mini squishies from hodgepodgeentourage (sorry, can't link, on work wifi) and keep it on display somewhere she's always see it and tell her we're gonna work her up to it one day even though she'd never have a chance at taking it just cause i'm mean

77 notes

·

View notes

Text

What's in the Box?

PONY PONIES IN THE BOX

If you've been following along you may have seen that @queenofsquids printed the Takara-inspired BJD last week, both in a "mini" test form and a full-sized one. The full-sized one was supposed to be in yellow, but the pure yellow resin turned out to be a more orangey tone. She incredibly generously offered to send me the orange pony BJD

And then

She incredibly incredibly again generously sent not only the little test takara-bjd in grey BUT ALSO printed my original takara 3D model and sent that?! This is so unbelievably kind and generous. I was so surprised when I opened them all!

I'm not sure if you were all aware but I actually dont have a print of the original "Takara duplicate" doll. I did get the seapony PLA printed at the library (and it was my first ever 3D print!).

For my second print, I got the Dollightful bunny doll printed because I wanted to have experience with jointed dolls made by other people before I put more complex models out. So I figured it would be a while before I got the chance to see my newer models printed.

So like its actually so kind of @queenofsquids to send these but also it's really meaningful to me because I started the takara project where I became obsessed with them over a year ago. It's so amazing to see this thing that frankly I spent so much time fiddling with (even if there are some imperfections; more about that later) and hold it in my hands 🥹 I just keep looking at them and smiling

Also I immediately stole the clothes off my NaNaNa dolls and put them on mini-takara-bjd. They're a little short but fit pretty well!

Some design notes/planned adjustments under cut

-The neck and arm balls are definitely too blocky, this doesn't impact the movement but it is very visually obvious

-Queenofsquids mentioned this but the arm bean is too big and gets stuck in the arm sockets.

^^ These two issues are the most obvious upon brief inspection but are also easy to fix so I'm gonna put out a version ASAP adjusting the file. Call it the version Version 1 Hotfix. Both of these should be fixed in the existing models with a bit of sanding.

-The legs are like just a touch too blocky and I think you can also see lines in the head and chest areas ;-; I think this would depend on the printer, like it might be fine in PLA due to the lower resolution. This can also be buffed out but I can adjust it with some effort

-> I think the blockiness issues come down to the fact I was trying to make the models not too high resolution because then the file size is massive, can't import into cura properly, and even slows down *my* beefy computer. that's why it might take a bit for me to adjust all of these pieces, especially the legs because they have a lot of booleans that lag blender. basically i leaned in the other direction and went a bit too far with some pieces.

-legs are very thin at the bottom (ran into this issue with the dollightful bunny doll too and had to redo quite a bit actually to make it neat)

-The bottom of the heart on the knee in particular is an imperfect fit. I was getting errors in Cura because of some issues related to the knee so I had to remesh it, if you'll remember, so I will need to maybe go in and redo that one :/

-The line around the eyes could be a touch more pronounced, its supposed to be somewhat stylized eyelashes

-I need to play with the arms/legs more to figure out potential issues with the existing joints. But they do at least work and hold poses. I'm not sure if people would prefer anything more complicated like locking joints or if this level of poseability is acceptable

Other things I want to experiment with

-hand pose variation

-nose/mouth variations? it is actually kind of funny to imagine you could switch the expression out to a little :o face or a c: or :3 type of thing

-pegasus/unicorn/fluffy hoof variants like i had planned before

so much stuff :0 and I haven't even finished bunny doll, although at least her paint job is basically done. Once I string the big BJD I can also test posing.

94 notes

·

View notes

Text

How Dye Penetrant Inspection Ensures Reliable Non-Destructive Testing Results

Dye Penetrant Inspection (DPI), also known as Liquid Penetrant Inspection (LPI), is a widely employed non-destructive testing (NDT) method used to detect surface-breaking defects in a variety of materials. This method is essential for ensuring the integrity and safety of components in industries such as aerospace, automotive, manufacturing, and construction. At Integrated NDE, we specialize in providing high-quality DPI services, adhering to stringent industry standards and best practices.

Understanding Dye Penetrant Inspection

DPI works by applying a visible or fluorescent dye to the surface of a clean, dry part. The dye penetrates any surface-breaking defects due to capillary action. After a suitable penetration time, the excess dye is removed from the surface, and a developer is applied. The developer draws out the dye from the flaws, creating a visible indication of the defect. This method can detect various surface discontinuities, including cracks, seams, laps, and porosity.

Benefits of Dye Penetrant Inspection

Versatility: DPI can be used on a wide range of materials, including metals, ceramics, and plastics. This versatility makes it an invaluable tool across multiple industries.

Sensitivity: DPI is highly sensitive to small surface defects, making it an excellent choice for detecting fine cracks and other minute discontinuities that might not be visible to the naked eye.

Cost-Effectiveness: The simplicity and efficiency of DPI make it a cost-effective NDT method, requiring relatively inexpensive equipment and materials.

Quick Results: DPI provides rapid results, allowing for timely decision-making and minimal downtime during inspections.

Our Expertise at Integrated NDE

At Integrated NDE, our team of certified professionals is equipped with extensive experience and advanced tools to perform DPI accurately and efficiently. Our personnel are certified to Level II in EN ISO 9712 and ASNT standards, ensuring that all inspections meet rigorous quality and safety requirements. We offer several DPI methods, including solvent removable, water washable, and post-emulsifiable techniques, tailored to meet the specific needs of each project.

Applications of DPI

Dye Penetrant Inspection is utilized in various applications, including:

Weld Inspection: Detecting surface cracks and flaws in welded joints to ensure structural integrity.

Casting and Forging: Identifying defects such as cracks, porosity, and laps in cast and forged components.

Maintenance and Repair: Assessing the condition of critical parts in service to detect fatigue cracks and other surface defects.

Commitment to Quality

Integrated NDE is committed to providing top-notch DPI services that enhance the safety and reliability of your components. Our thorough inspection processes and attention to detail ensure that defects are accurately identified and documented, helping you maintain high-quality standards and prevent potential failures.

In conclusion, Dye Penetrant Inspection is a crucial method for detecting surface defects and ensuring the quality of materials and components. At Integrated NDE, we leverage our expertise and advanced techniques to deliver reliable and accurate inspection results, supporting the safety and success of your operations.

For more information, visit Integrated NDE.

#non destructive testing#ndt testing#destructive testing#Positive Material Identification#"non destructive inspection#ndt inspection services#ultrasonic testing ndt#non destructive weld testing#ndt inspection#non destructive testing services#ultrasonic non destructive testing#visual inspection ndt#ultra sonic testing

0 notes

Note

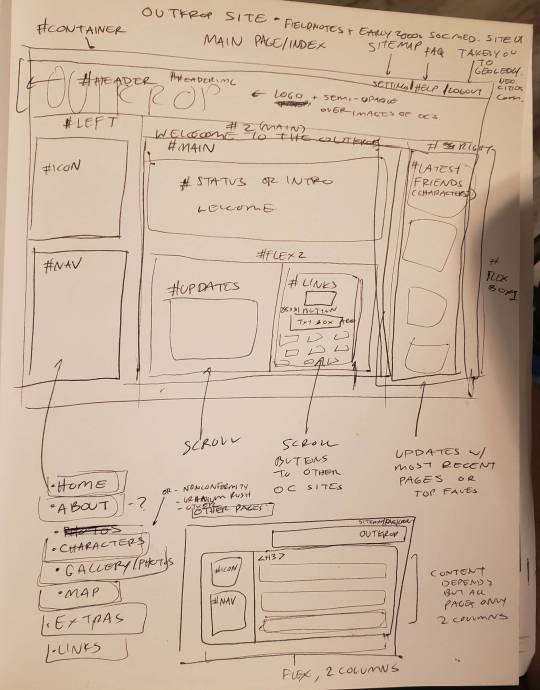

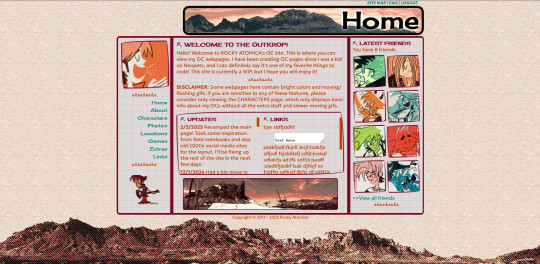

your oc website is SO SO SO SO INCREDIBLY COOL how the hell do you even start learning how to do this ?? if you learned how to do this by yourself online, are there any tutorials or resources you can share with us? was making this website free??

omg THANK YOU SO SOOOOOO MUCH!!! It makes me so happy to hear that folks like my little site. I code my site with Phoenix Code (for the live viewer and number dials) and I host my site on Neocities - it is all free. Phoenix can be used in browser or on desktop, but I like having it on desktop more for big projects in case my files get deleted. I use the browser version when I just want to test something quickly.

The 2 videos I use and can not recommend enough to anyone who asks me are this HTML tutorial and this CSS tutorial. They are simple and easy to understand, but I recommend watching it the first go, and then following along the next few watches until you get the flow of basic parts to a website, how they're organized, and what order they go in. At this point, I've memorized exactly where everything goes, and it is all thanks to these 2 videos.

If I am being honest, I learned how to code by myself, not quite even with online tutorials but just from being stupid and messing around myself (1, because I was a kid, and 2, because I didn't understand English very well to know what tutorials are saying.) I used to do html coding for Neopet pages when I was a kid with too much online time, first by just editing the default petpages and adding info and images, and then just doing trial and error with the html. I'll just try something and then if it doesn't turn out the way I want it, I try to find out why it didn't work and also get inspiration from other similar sites to figure out where things go or how they coded (with this nifty thing called right click > inspect page or right click > view page source). And BOOM, working webpage.

It was rudimentary, white blank background without any boxes or anything, you just scrolled down the page and sections were separated by a horizontal bar. OH and every text was centered! I had no idea how to make scrolling boxes or fancy assets, but damn I still had so much fun working on it every weekend. When you find authentic selfmade sites from the 90s and 2000s, most of them aren't super fancy either unlike what modern nostalgia makes you think. So I hope you don't feel discouraged if you begin making a website and feel it isn't "fancy", you're already doing a first big step which is making a webpage and learned your first set of html code!

It was over a decade later before I coded webpages with html again. I've gotten lazy and started relying on site builders, but nothing was quite as versatile as html. I wanted to try coding my own OC site again, so that was when I started working on OutKrop (the site I posted). Until I started coding again, I had literally no idea what CSS even is (and let me tell you, it's a game changer!)

Personally, I work best when I can do things hands on. I don't read through tutorials, I code first then go back and read through coding help sites like w3schools when I find myself stuck and unable to figure something out. Sometimes I grab existing codes and play around with them to see what changes and what I can do with it, cuz having visual context is what helps me a lot.

I can also share my process:

Once I gather up some ideas, I make a sketch, including what boxes (divs in css) should approximately go. It is very rough, but shows me exactly what I need to know.

Next I load up my coding app (Phoenix Code in my case) and "sketch" the layout. Nothing fancy going on here, just putting things where they need to be, and fixing size of boxes and margins if needed. I give my boxes all a background color so I can easily see how big they are and where they are located.

After some adjustments like moving stuff around and adding assets like backgrounds and images, and changing colors of the boxes, rounding off corners, etc., we get this!

so recap + additional useful sites I use:

Coding app: Phoenix Code

Site hosted on: Neocities

Video tutorials: HTML and CSS

Sites for learning code: w3schools, also lissa explains is a great site that is written for kids to learn html so it's easy to understand. Finally, sadgrl has a lot of great resources for coding as well!

I recommend looking through these sites AFTER you tried taking a spin at coding - it doesn't have to be anything fancy just follow the HTML video tutorial I linked!

Thanks for the ask, and I hope this helps you and many others out there who are interested in building a site with html/css! Don't be afraid to get things "wrong" or have an "un-fancy" site. This is how you learn to code, and it'll become so easy once you get the hang of it.

Anyone is always more than welcome to reach out for coding help and advice :-]

54 notes

·

View notes

Text

double CPR during gyno surgery

Pre-Op Visit

Maria entered the clinic, her heart fluttering slightly as she signed in at the reception desk. The soft hum of fluorescent lights and the faint scent of antiseptic filled the air. At 23, she had grown accustomed to regular gynecological appointments for her polycystic ovarian syndrome, but today’s visit felt different. She couldn’t quite place why—perhaps it was the note she had tucked into her medical file.

Dr. Carter greeted her warmly, his voice steady and professional. “Maria, it’s good to see you again. Let’s take a closer look and discuss any changes you’ve been experiencing,” he said, gesturing for her to follow him into the examination room.

Maria settled onto the examination table, her legs resting in the stirrups, the cool sheet draped over her lap offering some modesty. She took a deep breath as Dr. Carter explained the steps of the examination, his tone calm and reassuring.

The moment felt tangible as he reached for a pair of latex-free gloves, snapping each one on with deliberate care. The faint rustle of the material was accompanied by the smooth stretch over his fingers, a prelude to the thorough examination ahead. “These will ensure everything remains sterile,” he said, flexing his hands briefly to ensure the fit was snug yet comfortable.

“We’ll start with a visual inspection of the external area,” he continued. He gently separated the labia, examining the vulva for any signs of redness, swelling, or abnormalities. “Everything looks healthy so far,” he said with a reassuring smile.

Next, he prepared a speculum, the gleaming metal instrument lubricated with a water-based gel. “I’m going to insert the speculum now. You might feel a bit of pressure, but let me know if it’s uncomfortable,” he said. Slowly and carefully, he guided the speculum into her vaginal canal, angling it to minimize discomfort.

Maria inhaled sharply at the cool sensation but relaxed as he spoke to her. “You’re doing great,” he assured her. Once the speculum was in place, he gently opened it to visualize her vaginal walls and cervix. A soft light illuminated the area as he examined the tissue for any irregularities.

“Your cervix looks healthy,” he noted. “I’m going to collect a sample for testing now. You may feel a slight pinch.” Using a small brush, he took a quick sample for a Pap smear before carefully removing the speculum.

Moving on, Dr. Carter explained the next step. “Now we’ll do a bimanual examination to check your uterus and ovaries.” He slipped on a new pair of gloves, inserting two fingers into her vagina while pressing gently on her lower abdomen with his other hand.

“This helps me assess the size, shape, and position of your uterus,” he said, his hands working methodically. “Let me know if anything feels tender.”

Maria nodded, wincing slightly as he applied pressure to one side. “There’s some sensitivity here,” she said.

“Noted,” Dr. Carter replied. “That’s consistent with your polycystic ovarian syndrome. It’s one of the reasons I recommend the upcoming procedure—to get a clearer understanding and provide relief.”

As he removed his gloves and helped her sit up, Dr. Carter maintained his professional demeanor. “You did great, Maria. I’ll explain what to expect during the surgery, and we’ll make sure you’re comfortable every step of the way.”

Maria nodded, her nerves easing slightly as his calm and methodical approach reassured her.

The Procedure

The operating room was cool and sterile, with bright overhead lights casting a stark glow on Maria as she lay motionless under anesthesia. The steady beep of the heart monitor punctuated the quiet efficiency of the medical team.

Dr. Carter stood at the head of the team, reviewing Maria’s pre-op notes one last time before they began. “We’ll be performing a laparoscopic procedure to address the ovarian cysts,” he explained to the team. Instruments were laid out meticulously on the tray beside him.

After making the initial incisions, the surgical assistant inserted the laparoscope, the camera transmitting a clear view of Maria’s internal structures to the monitor. Dr. Carter carefully navigated the tool to locate the cysts.

“There’s some scarring here, likely from previous ruptured cysts,” he noted. “Let’s excise the current ones to alleviate her symptoms and preserve as much ovarian tissue as possible.”

The procedure progressed smoothly as Dr. Carter worked with precision, excising the cysts and cauterizing any bleeding tissue. The team maintained a rhythm, their movements synchronized and deliberate.

Then, without warning, the heart monitor emitted a rapid, irregular beeping.

“She’s in ventricular fibrillation!” the anesthesiologist called out.

Dr. Carter immediately stepped back. “Stop the procedure. We need to stabilize her. Call for the crash cart.”

The surgical team acted quickly, tilting the operating table flat and removing the laparoscope. A nurse began chest compressions, her hands pressing firmly on Maria’s chest. “One, two, three…” she counted, maintaining a steady rhythm.

Dr. Carter took charge. “Prep the defibrillator and administer one milligram of epinephrine,” he ordered.

The defibrillator pads were placed on Maria’s bare chest. “Charging to 200 joules. Clear!” The shock caused her body to jerk, but the monitor still showed erratic activity.

“Continue CPR,” Dr. Carter instructed. Another nurse stepped in to take over compressions, her hands pressing down in precise, rhythmic movements.

“Administer another dose of epinephrine,” Dr. Carter said. “Charge to 300. Clear!”

Maria’s body arched again as the second shock was delivered, but the ventricular fibrillation persisted. Sweat formed on the team’s brows as the resuscitation efforts continued.

Sab’s Collapse

Meanwhile, in the observation area, Sab watched in horror through the glass. The sight of Maria’s lifeless body being shocked and compressed was too much to bear. Her breath quickened, her chest tightened, and before she could cry out, she collapsed to the floor.

A nurse rushed to her side, feeling for a pulse. “She’s fainted, but her pulse is weak!” the nurse shouted. Sab was quickly transferred to a nearby stretcher.

“She’s going into cardiac arrest!” another nurse exclaimed.

“Start CPR!” a second team sprang into action. One nurse tilted Sab’s head back and began giving rescue breaths while another began compressions. “One, two, three…”

Sab’s chest rose and fell with the breaths, but her heart remained unresponsive. The defibrillator was quickly wheeled over.

“Pads on. Charging to 200. Clear!” The first shock jolted her body, but the monitor still showed asystole.

“Epinephrine, now!” the nurse ordered. Another round of CPR followed, compressions deep and steady, interspersed with breaths.

“Charge to 300. Clear!” Sab’s body arched as another shock coursed through her. Her heart finally showed a faint rhythm, but her condition remained critical.

Dual Resuscitation

Dr. Carter, now splitting his attention between Maria and Sab, directed the teams. “We’re not losing either of them,” he said with determination.

Maria’s chest compressions continued relentlessly. A nurse alternated between compressions and rescue breaths, sweat dripping as she counted aloud. “One, two, three…come on, Maria.”

“Charging to 400 joules. Clear!” The defibrillator delivered another shock to Maria, and this time, the monitor flickered—a faint pulse began to appear.

“She’s back! We’ve got a rhythm,” Dr. Carter announced, but his relief was short-lived as he turned his attention to Sab.

Sab’s compressions continued as another nurse prepared a dose of amiodarone. “Administer the antiarrhythmic,” the nurse instructed, injecting the medication into Sab’s IV line.

“Charge to 400. Clear!” Sab’s body jolted again, and after a tense moment, her heart monitor showed a weak but steady rhythm.

“She’s back!” the team exclaimed.

ICU Recovery

The sterile, rhythmic beeping of heart monitors filled the dimly lit ICU. Maria’s eyelids fluttered open, the bright fluorescent lights stinging her eyes. She blinked slowly, her body heavy, her chest aching with every breath. The sterile scent of antiseptic surrounded her, and it took a moment for the fog to clear from her mind.

“Maria,” a soft voice murmured nearby.

She turned her head slowly to see Sab lying in the adjacent bed, tubes and wires attached to her as well. Sab’s face was pale but alive, her chest rising and falling steadily.

“Sab…” Maria whispered, her voice raspy and weak. Her hand, though weighed down by IV lines, reached out shakily across the gap between their beds.

Sab’s eyes met hers, brimming with tears. She stretched her hand toward Maria, their fingers brushing lightly. “You’re okay,” Sab whispered, her voice cracking with relief. “We’re okay.”

A nurse entered the room quietly, adjusting the machines and checking their vitals. “You gave us quite the scare,” she said gently, her gaze kind. “But you’re both stable now. Rest—you’re in good hands.”

As the nurse left, Maria and Sab turned their attention back to one another. Their hands stayed clasped, their breathing syncing as they lay side by side, tethered by their shared ordeal. Though the ICU around them was cold and clinical, the warmth of their connection filled the space.

They didn’t need words. Their intertwined hands said everything: relief, gratitude, and love. The soft hum of the monitors became a comforting rhythm—a reminder that their hearts were still beating, together.

123 notes

·

View notes

Text

The Knapp Test Kit USA is an essential tool used in the quality control process for detecting and evaluating particulate contamination. Originating from rigorous research and development, the Knapp Test Kit USA is designed to provide accurate and reliable results, making it indispensable for industries where cleanliness and contamination control are critical.

0 notes

Text

Intsoft Tech machine vision inspection solution-deep learning for vision systems

#integrated machine vision solutions for the smart factory#automated visual inspection#robot pick & place#vision manufacturing#manufacturing consulting firms#surface inspection#factory acceptance test

1 note

·

View note