#viscose yarn

Explore tagged Tumblr posts

Text

attempting another raglan knitwear item [screaming and crying car crash sound effect cat yowling glass breaking]

#so far have had no luck with raglans. right now. i have the right amt of stitches just not in the right places#but its ok bc it 1 misplaced stitch which should be in the front but fsr is in the back. no harm done i can live w 1 st#im mostly also bad at being patient enough to achieve gauge#like . its ok i have a 90% accurate stitch gauge and a 115% row gauge#which like is perfectly plenty but i am gonna have to do some quick math later on bc it says to knit until it measures 12 cm#but there are still some 20 odd rows to go (with increases) and im already at 5 cm#and the gauge also said 22 rows = 10 cm so like idk i do think something's not quite right there vis a vis measurement but whatever#i just really hope it works out pls god let it work out im using such a cute yarn combo#im holding 5 strands of yarn btw which is so fucking stupid especially bc one of the yarns is one i recuperated from a sweater and split#horrendously but its SO beautiful its like a yellow cotton polyester blend (or viscose icr) and its like silky soft and gorgeous#but also entirely split into like 6 strands or smth plus the shiny strands that make it so soft keep getting caught on my dry hands#and i dont even have that dry hands but like anyway point being im giving myself a headache inducing task#and i hope it works out#i also should perhaps do a crochet raglan cause its . easier. and i care slightly less abt crochet so i wouldnt mind fucking up

3 notes

·

View notes

Text

Viscose Filament Yarn (VFY) Prices | Pricing | Trend | News | Database | Chart | Forecast

Viscose Filament Yarn (VFY) is a significant material in the global textile industry, serving as a substitute for silk in various applications. Viscose, made from cellulose derived from wood pulp, undergoes chemical processes to create a filament form, which is then spun into yarn. Over the years, VFY has gained widespread recognition for its smooth texture, shiny appearance, and versatility, making it popular in the fashion industry and other sectors. However, VFY prices are subject to various market dynamics that can cause fluctuations in costs. These fluctuations are primarily driven by raw material availability, demand-supply imbalances, and external factors like international trade policies, economic conditions, and environmental regulations.

One of the critical drivers of VFY prices is the cost of raw materials, especially wood pulp. Since viscose is derived from cellulose, the price and availability of wood pulp directly impact VFY production costs. Pulp prices are influenced by global demand, supply disruptions, or environmental policies related to deforestation and sustainable sourcing. For instance, any significant change in pulp supply from major producing regions like North America, Europe, or Asia can lead to a price hike in viscose filament yarn. Additionally, the use of sustainable wood sourcing practices can also increase raw material costs, which in turn affects the final price of VFY. Moreover, environmental regulations aimed at reducing pollution or enhancing green manufacturing can drive up costs in terms of production upgrades, impacting the overall price of viscose yarn.

Get Real Time Prices for Viscose Filament Yarn (VFY): https://www.chemanalyst.com/Pricing-data/viscose-filament-yarn-84

Another factor influencing VFY prices is demand and supply in the global market. The fashion industry, in particular, experiences seasonal fluctuations, which contribute to changes in the demand for VFY. During peak seasons when fabric manufacturing is in high gear, the demand for viscose filament yarn can increase significantly, driving prices upward. Conversely, during off-seasons, the demand may slacken, leading to a decrease in prices. Moreover, a sudden rise in demand from emerging markets, where viscose fabric is gaining popularity, can put upward pressure on prices. On the supply side, production capacity, technological advancements, and any disruptions in manufacturing facilities, particularly in key producing countries like India and China, can lead to price volatility. Any unanticipated disruptions like machinery breakdowns or labor strikes can lower production, tightening supply and increasing prices.

International trade policies and tariffs also play a significant role in shaping VFY prices. Countries that are major producers of viscose filament yarn, such as India and China, are heavily involved in international trade. Any change in tariffs, import-export policies, or trade agreements between countries can affect the cost of VFY for buyers globally. For instance, higher tariffs or trade restrictions can lead to increased costs for importing countries, making VFY more expensive in those regions. Additionally, fluctuations in currency exchange rates can affect the competitiveness of VFY in the international market. A weaker local currency in major producing countries can make VFY more competitive globally, while a stronger currency can push prices higher, affecting the purchasing power of international buyers.

Environmental concerns have also started to exert influence on VFY prices. The production of viscose filament yarn, like other textile products, can have environmental impacts, particularly in terms of water usage and chemical discharge. In recent years, the industry has faced increased scrutiny from environmental groups and regulators, prompting manufacturers to adopt more sustainable and eco-friendly production methods. While these methods are beneficial for the environment, they often come with higher production costs, which can translate into increased prices for VFY. Manufacturers who invest in cleaner technologies, waste management systems, and certifications to meet environmental standards may need to pass on the additional costs to consumers. At the same time, buyers, especially those in developed markets, are increasingly willing to pay a premium for sustainably produced viscose yarn, which could further drive up prices for eco-friendly VFY.

Economic conditions and inflationary trends are additional external factors that influence VFY prices. When global or regional economies experience inflation, the costs of inputs, transportation, and labor tend to rise, which directly impacts the final price of VFY. Economic slowdowns, on the other hand, can lead to reduced consumer spending, resulting in lower demand for textile products and, consequently, a drop in VFY prices. Additionally, oil prices play an indirect role in shaping VFY prices. The production of viscose yarn requires energy, and fluctuations in global energy prices can lead to changes in manufacturing costs. Rising oil prices, in particular, can increase the cost of synthetic alternatives to viscose, which could push some demand towards viscose filament yarn, affecting its prices as well.

Technological advancements in the manufacturing process of viscose filament yarn have also contributed to price variations. Innovations in production techniques can lead to improved efficiency, reducing waste and lowering production costs, which could result in lower prices for VFY. For example, advancements in spinning and dyeing technologies have allowed manufacturers to produce better quality yarn at reduced costs, benefiting both producers and consumers. On the flip side, the introduction of new technologies often requires significant capital investment in terms of machinery and infrastructure, and these costs may be passed on to buyers in the form of higher VFY prices, at least in the short term.

The geographical distribution of VFY production and the concentration of manufacturing in specific regions also affect prices. China and India are dominant players in the global viscose filament yarn market. Any economic or political developments in these regions, such as changes in labor laws, government regulations, or tax incentives, can impact production costs and prices. Additionally, geopolitical tensions or trade conflicts involving these countries can disrupt supply chains, creating uncertainty in the market and leading to price volatility.

In conclusion, Viscose Filament Yarn prices are influenced by a multitude of factors, including raw material costs, demand-supply dynamics, international trade policies, environmental regulations, and technological advancements. As the market continues to evolve, manufacturers and buyers must remain adaptable to these changes, as they will inevitably continue to play a significant role in determining the cost of VFY. Understanding these factors is essential for navigating the complexities of the global VFY market, whether one is a producer, distributor, or end-user in the textile industry.

Get Real Time Prices for Viscose Filament Yarn (VFY): https://www.chemanalyst.com/Pricing-data/viscose-filament-yarn-84

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Viscose Filament Yarn#Viscose Filament Yarn Price#Viscose Filament Yarn Prices#Viscose Filament Yarn Pricing#Viscose Filament Yarn News

0 notes

Text

Viscose Stretch Yarn

We twist Viscose Crepe dark colors with an Elite' core to create this version with controlled stretch properties. It can be used for textured tops, jackets, pants, and skirts with highly resilient shape retention. Fabrics have a full, pliable body with a comfortably cool hand.

Read More: https://www.silkcityfibers.com/products/viscose-stretch-yarn

0 notes

Text

Starting to remember one of the main reasons I largely stopped crocheting 20+ years ago... the pain of seeing so much pretty yarn that my wool allergy objects to. I'm not a big fan of synthetics but finding non-wool natural fibres in similarly pretty colourways and anything like actual wool textures is a major PITA. I'm sure I could buy at least some of the pretty hand-dyed yarn I keep seeing on Etsy and work it up into scarves and shawls and whatnot, but then I'd probably need to give them away since a lot of it I wouldn't be able to wear myself.

Finished that infinity scarf I've been working on; it came out okay but even at just 20% real wool fibres I could tell my allergies were noticing it whenever I worked on it, so that's probably going to be given away to someone else.

Currently have some skeins in my Etsy basket that I'm eyeing anyways - some silk-linen fingering that I want to try a skein of to judge whether I like it in person to make stuff for myself to wear, and a couple skeins of a lovely 100% SW merino fingering colourway that I might attempt making a shawl for my SIL out of. Though between the premium price for custom dyed yarn and then shipping those three skeins alone would be over $100, yikes. (Yeah that's another reason I haven't really crocheted in ages - the cost of yarn.)

#Fibre Crafts#Crochet#I have spent SO MUCH TIME the last few days salivating over yarns online#But all the colourways I loved most were only available on yarns with high wool content#I'm thinking of trying some of the less-usual yarn fibres just to test whether any set me off less#Like angora and camel and alpaca and so forth#Sadly the 'vegan' yarns seem thin on the ground and I'm suspicious of how many are supposedly bamboo#Because I 100% do not count rayon/viscose as a natural fibre#And I have my doubts over how much of that is actual naturally retted bamboo

1 note

·

View note

Text

Investment Opportunities in India's Viscose Staple Yarn (VSY) Industry

The Indian Viscose Staple Yarn (VSY) industry is experiencing rapid growth, with revenue projected to reach an all-time high of over $2.5 billion in fiscal year 2023. Despite declining yarn prices, the industry's profitability is expected to improve by 200-300 basis points due to continued strong demand. VSY's appeal lies in its lower prices and comparable features, which have led to a compound annual growth rate of 13 per cent over the last three fiscal years, outpacing cotton yarn's growth rate of 5 per cent.

Competitive Prices: VSY's lower prices compared to cotton yarn have made it a popular choice among manufacturers and consumers alike. This cost advantage has contributed to the industry's sustained growth.

Steady Pricing: VSY prices have remained relatively stable, ranging between ₹200–₹250 per kg, providing confidence to stakeholders and fostering sustained demand.

Removal of Anti-Dumping Duty: The removal of anti-dumping duty on imports of viscose staple fibre (VSF) in FY2022 has further supported the stability of VSY prices.

The promising growth prospects of the VSY industry present attractive investment opportunities in India. As manufacturers' revenue improves and spreads between VSY and VSF expand, operating margins are expected to rise to 11-12 per cent. This creates opportunities for investors seeking lucrative sectors to invest in.

Furthermore, VSY makers have consistently expanded their capacities, with a 50 per cent increase in the past three fiscal years. They plan to add another ~15 per cent capacity in the current fiscal year, indicating their confidence in the industry's future. The capital-intensive nature of the VSY segment has resulted in regular debt-funded capacity expansion, but strong balance sheets have ensured that credit risk profiles remain comfortable, enhancing the industry's attractiveness for potential investors.

While the VSY industry is on a growth trajectory, it is essential to be mindful of potential challenges:

Anti-Dumping Duty Impact: Any reimplementation of anti-dumping duty on VSF could lead to higher input costs for viscose spinners, affecting profitability.

Demand Fluctuations: A decline in domestic demand for VSY or a slowdown in global demand could potentially impact the industry's growth prospects.

The Indian Viscose Staple Yarn (VSY) industry presents promising investment opportunities for those seeking to tap into the country's thriving textile sector. With a projected revenue growth of 10-12 per cent and improved profitability, the industry offers attractive returns for investors. As VSY continues to gain market share and outperform cotton yarn, the sector's growth prospects appear robust. However, investors must remain vigilant about potential challenges, such as changes in import duties and fluctuations in demand. Overall, the VSY industry demonstrates resilience and growth potential, making it an appealing investment option in India's dynamic economy.

This post was originally published on: Foxnangel

#business growth#business opportunities in india#Fox&Angel#FoxNAngel#Indian textiles industry#Invest in India#Investment in india#investment opportunities in India#viscose staple yarn industry#Investment In India#franchise in india

0 notes

Text

"These embroidery silks are made from 100% high quality..."

👀

"...viscose."

🪦

#words *mean* things#viscose is a cellulose fiber. cellulose fibers want procion dyes.#silk is a protein fiber. protein fibers want acid dyes and a hot bath.#almost as frustrating as the fact that uk-english uses 'wool' to refer to any yarn (including acrylics)#and so i'll click on a listing for some promising 'wools'... only to find out they came from an oil well and not from a mammal

0 notes

Text

How can you care for polyester yarn clothing to prolong its lifespan?

Working with polyester yarn can present several challenges, including:

Static electricity: Polyester yarn tends to generate static electricity, which can make it difficult to work with as it may cling to other materials or to the worker's hands.

Fraying and pilling: Polyester yarn can be prone to fraying and pilling, which can make it difficult to create smooth and even stitches.

Lack of breathability: custom Recycled Polyester Yarn Suppliers Polyester is not a breathable fabric, so garments made with polyester yarn can be uncomfortable to wear, especially in hot or humid conditions.

Limited stretch: Polyester yarn does not have as much stretch as natural fibers, such as cotton or wool, which can make it more difficult to work with for projects that require a lot of give.

Melting: Polyester yarn is susceptible to melting if it comes into contact with heat sources such as irons or hot surfaces. This can be a particular concern when ironing or pressing finished projects.

Dyeing: Polyester is more difficult to dye than natural fibers, and may require special dyes and processes to achieve the desired color. This can make it more challenging to find the right color match for a project.

To care for polyester yarn clothing and prolong its lifespan, here are some tips:

Follow the care label instructions: Always check the care label on the garment for specific care instructions. Some polyester yarn items may be machine-washable, while others may require hand washing or dry cleaning.

Wash in cool water: Polyester yarn clothing should be washed in cool water to prevent shrinkage and damage to the fabric. Hot water can also cause the fabric to fade.

Use a gentle detergent: Use a mild, gentle detergent that is free from bleach and fabric softeners. Harsh chemicals can damage the polyester fibers and cause the fabric to lose its shape and color.

Avoid fabric softeners: Fabric softeners can leave a residue on polyester yarn clothing that can build up over time, making the fabric stiff and uncomfortable.

Hang dry: Polyester yarn clothing should be hung to dry or laid flat, rather than being put in the dryer. High heat can damage the fabric and cause it to shrink or melt.

Iron on low heat: If ironing is necessary, use a low heat setting and a pressing cloth to protect the fabric. Avoid ironing directly on any printed or embellished areas of the garment.

By following these care instructions, you can help prolong the lifespan of your polyester yarn clothing and keep it looking its best.

1 note

·

View note

Text

Viscose Yarn Manufacturer In India | Raysil

Raysil is a luxurious viscose yarn manufacturer in India. Visit our website today to learn more about our natural, sustainable yarn fabrics and products!

1 note

·

View note

Text

Bear Claws was designed to celebrate the 10th birthday of the stacked stitch technique and the Fox Paws pattern. This engaging striped colorwork project features a large scale flame stitch motif. The pattern is relatively simple, using only a few rows of shaping in combination with color to create a distinct claw motif.

The wavy colorwork in Bear Claws is created using stacked increases and decreases. There are no loops on the wrong side and the wrap is very stretchy and drapey. The fabric is light and airy, not dense like stranded colorwork and mosaic knitting. If you're new to stacked stitches, check out my playlist on YouTube. You'll have an easier time with these stitches if you've tried increases, decreases and slipped stitches.

This pattern can be recolored in many ways, the coloring page available to anyone who wants to download it. You can use any number of colors you like, as long as they have good contrast. I recommend picking a Main Color that is not too bright or flashy in comparison to the others.

Written instructions are included in the pattern alongside a visual guide called a “stitch map.” It's not the same as a traditional chart and is meant to be used with the written pattern. The rapidly fluctuating stitch count of the stacked stitches doesn’t fit nicely into a square grid. Instead, the map uses symbols and lines that bend and flow as the rows do, as they would in a crochet chart. The primary use of the stitch map is to show how each row relates to the last and to help you find mistakes and get back on track.

Finished Size: 14 (23.75)˝ x 82 (82)˝ / [36 (60) x 208 (208) cm] rectangular scarf including fringe.

Yarn: Rowan Felted Tweed DK; 191 yards (175 meters) per 50 gram skein, 50% Merino Wool, 25% Alpaca, 25% Viscose.

Pink Scarf - 5 colors and 3 repeats wide

Main Color: Peony, 3 balls

Outer Color: Zinnia, 2 balls

Inner Color 1: Pink Bliss, 1 ball

Inner Color 2: French Mustard, 1 ball

Stripe Color: Barbara, 1 ball

Brown Wrap - 7 colors and 5 repeats wide

Main Color: Ginger, 4 balls

Outer Color 1: French Mustard, 2 balls

Inner Color 1: Stone, 2 balls

Stripe Color 1: Zinnia, 1 ball

Outer Color 2: Duck Egg, 1 ball

Inner Color 2: Watery, 1 ball

Stripe Color 2: Canary, 1 ball

Needles: Size 6 (4mm) 32˝circular needles, or size needed to obtain gauge.

Gauge: 16 sts x 36 rows = 4 x 4” (10 x 10 cm) square in garter stitch.

Other Materials: Tapestry needle, stitch markers, pins, blocking wires, blocking surface.

Get the pattern on my website and on Ravelry.

From now until the end of October, take 20% off all patterns, pins, books and stickers when you use the code "FoxyBday" on Ravelry or on my website.

Video Resources:

Bear Claws Playlist

Weave in tails as you knit

General Stacked Stitch Resource Videos

Yarn for this project was provided by Rowan

415 notes

·

View notes

Text

Viscose Filament Yarn Price Trend and Forecast

Due to unfavorable market conditions and low commodity prices, Viscose Filament Yarn Price declined during the third quarter in the American market. The excessive product supply and the low demand in domestic markets were the leading causes of the drop. Furthermore, the decreasing price trend in the region was influenced by a pessimistic regional buying attitude. In addition, considerable domestic upstream supply also contributed to the decline in the feedstock price, which in turn had a direct impact on the downward trend in Viscose Filament Yarn Prices.

0 notes

Text

what grinds my gears like nothing else is textiles manufacturers greenwashing bamboo/rayon yarn or fabric as though the fact that it's derived from plant material erases the enormously toxic manufacturing process. like the first thing you think of when you think of bamboo yarn/fabric is 'oh it must be made like any other plant fiber' but no!!! that's a semisynthetic fiber that's usually made with carbon disulfide which is extremely toxic to workers and environment both!

and there ARE less destructive bamboo processing techniques you CAN make bamboo fiber the same way you do any other bast fiber theres EVEN a less common chemical process that doesnt do the same harm that viscose rayon does but NO instead we get ~natural fiber~ greenwashing that hides behind the extremely reasonable assumptions people make about plant fibers

I will never ever in my life begrudge people who buy bamboo yarn or for that matter acrylic because (a) goddamn its fucking rough out here (b) I'd be a massive hypocrite (c) the problem is the manufacturers not the individual and (d) sometimes it IS the yarn for the job but I will never stop beating my drum about this bc we! deserve! to know!

#autism.txtile#knitting#yarnblr#gets out soapbox TEXTILES' INCREDIBLE TECHNOLOGICAL ADVANCES & HORRIFYING HUMAN & ENVIRONMENTAL DESTRUCTION CANNOT BE MEANINGFULLY SEPARATED#aiden.txt

1K notes

·

View notes

Text

you ever get possessed by idk Athena and you black out and when you come to, all your fiber is on the bobbin?? I somehow spun all 4 oz of this fiber in one day. At most 8 hours, likely around 5. I did not think it was possible? I don’t know what happened.

The fiber is “Cherry Blossom” from Paradise Fibers (I'm pretty sure it's merino with viscose tweed neps). I picked it up when I bought new ashford bobbins to ply with the Gelato yarn from Beesybee Fibers. One step closer to my ice cream sweater ☺️

59 notes

·

View notes

Text

Viscose Filament Yarn Prices Trend, Pricing, Database, News, Index, Chart, Forecast

Viscose Filament Yarn (VFY) prices have exhibited notable fluctuations in recent years, influenced by various factors within the global textile industry. VFY, a versatile material derived from natural cellulose, is highly sought-after for its softness, smooth texture, and ability to mimic natural fibers like silk. The pricing dynamics of VFY are intricately linked to raw material costs, primarily wood pulp or cotton linters, which can fluctuate due to supply chain disruptions, weather conditions affecting harvests, and shifts in demand from other industries.

In addition to raw material costs, VFY prices are sensitive to changes in labor wages, energy prices, and currency exchange rates, which impact production expenses across different regions. Manufacturers of VFY are also influenced by environmental regulations, particularly concerning the sustainable sourcing of wood pulp and the ecological footprint of production processes. Compliance with these regulations can add operational costs, affecting final product pricing.

Global demand trends play a pivotal role in determining VFY prices. The textile industry's growth in emerging markets like India, China, and Southeast Asia has bolstered VFY consumption, driving up prices during periods of high demand. Conversely, economic downturns or shifts in consumer preferences towards synthetic alternatives can lead to oversupply and downward price pressure.

Get Real Time Prices of Viscose Filament Yarn (VFY): https://www.chemanalyst.com/Pricing-data/viscose-filament-yarn-84

Market dynamics, including competition from other synthetic and natural fibers like polyester and cotton, further shape VFY pricing. Polyester, due to its lower cost and comparable properties, often competes directly with VFY in various textile applications, influencing pricing strategies by VFY manufacturers to maintain competitiveness.

Technological advancements in VFY production have also influenced pricing trends. Innovations that enhance production efficiency or improve product quality can either lower costs or justify premium pricing for higher-quality VFY variants. These advancements include spinning technologies, chemical treatments to enhance dyeability and strength, and innovations in sustainable production practices.

The COVID-19 pandemic significantly impacted VFY prices, disrupting global supply chains, reducing demand from the apparel sector, and causing fluctuations in raw material costs. While the initial phase saw decreased prices due to reduced demand, subsequent recovery phases witnessed price hikes as supply chain disruptions and increased operational costs affected VFY production.

Government policies and trade tariffs are additional factors influencing VFY prices. Tariffs on imported VFY or its raw materials can increase production costs for manufacturers, potentially leading to higher consumer prices. Conversely, subsidies or incentives aimed at promoting domestic VFY production can stabilize or lower prices, depending on market conditions and geopolitical factors.

Consumer trends towards sustainable and eco-friendly textiles have also shaped VFY pricing strategies. Brands and retailers increasingly emphasize transparency in the supply chain and the use of biodegradable materials, prompting VFY manufacturers to invest in eco-friendly certifications and sustainable production practices that may affect pricing.

Looking ahead, the future of VFY prices will likely be shaped by ongoing shifts in global supply chains, advancements in sustainable technologies, and evolving consumer preferences for textile products. Adapting to these changes, manufacturers will continue to navigate a complex landscape of raw material costs, regulatory requirements, and competitive pressures to maintain a balance between profitability and market demand for VFY products.

Get Real Time Prices of Viscose Filament Yarn (VFY): https://www.chemanalyst.com/Pricing-data/viscose-filament-yarn-84

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Viscose Filament Yarn#Viscose Filament Yarn Price#Viscose Filament Yarn Prices#Viscose Filament Yarn Pricing#Viscose Filament Yarn News

0 notes

Text

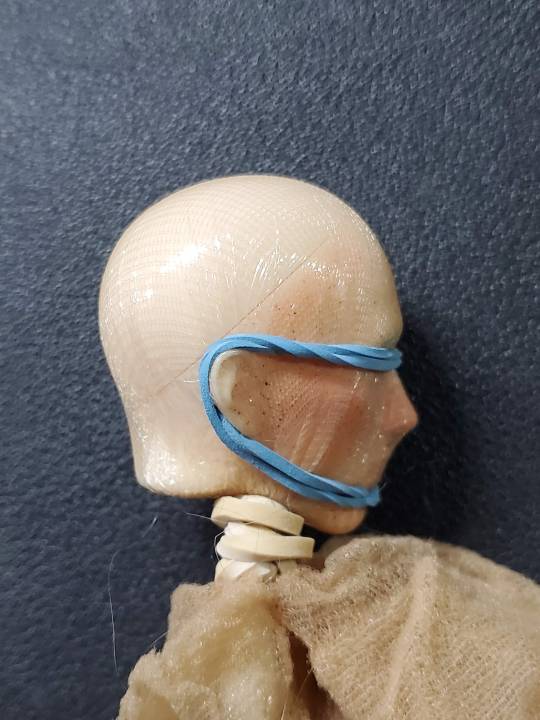

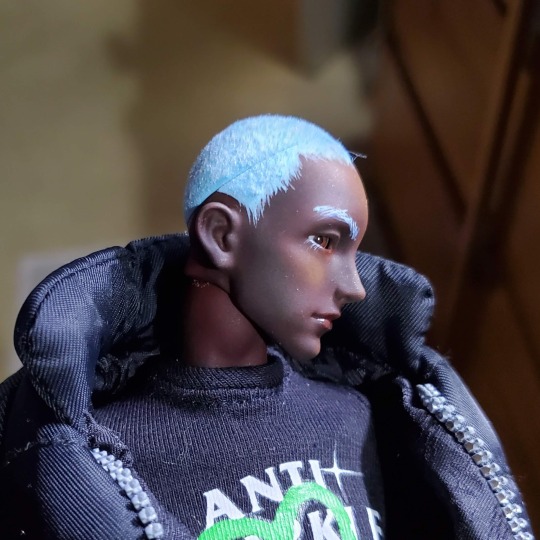

Kaxen's BJD Hardcap Wigmaking 2024 Version

Pros of hard wig cap style:

The best method for short hairstyles (and I am a masochist who loves short swept-back hairstyles)

Are you the kind of person who gets tilted over lace front wigs having a line of extra net or not fitting your doll's forehead? This wig will fit and you can chop the wig cap even closer.

I hate hand sewing, so I never do sewn wefts with soft wigcaps, and sewn wefts don't work well for exposed hairlines so GLUE, GLUE, BABY.

Cons of hard wig cap style:

This wig will not fit on another doll unless it's maybe from the same company or has a really generic head-shape

Tools

Nonstick mat - Michaels sells Messy Mats which are very thin but stiff film mats that are nonstick. Silicone mats for pet bowls are often very cheap! A lot of craft-specific silicone mats have more price mark-up despite being the exact same thing.

Silicone spatula - for spreading glue. Just the generic silicone tools are fine. Comes in different sizes.

Glue of choice - Different glues react differently to different fibers and different colors. Pick whatever you like that has a slight flex to it and is waterproof once it's dry. If you prefer to style hair with high temperatures (especially the boiling water method), pick something that will resist high temps.

Glues I personally hate passionately: Beacon Adhesives Fabri-tac.

Why Fabri-tac sucks:

Smells terrible

Warps over time, wigs have literally stopped fitting the doll it was for

Rock hard when dry, literally the worst option for fabric???????????

Glue bottle cap always gets fucked up and useless.

Like jesus christ just get some fray check if you need fabric glue

Slicker brush: No matter how thorough you are with glue, you will have loose fiber. Comb it out. Buy two if you want to be able to have a poor man's wool carder so you can re-align fibers and use them later. WHY ARE WOOL CARDERS SO EXPENSIVE?

Fibers -

Suri alpaca: Very fine strands, low gloss, can use hair irons on it

Tencel: very fine strands, high gloss, can use hair irons on it, plant-based. Great for 1/6 scale and Anime Bullshit hair

Viscose (not pictured): very fine strands, high gloss, crinkles like hell if it gets wet, can use hair irons on it, plant-based

Silk (the silver wig lower down the post): very fine strands, high gloss, can use hair irons on it

Mohair: medium strands (thinner if it's kid mohair), high gloss, can use hair irons on it. Various levels of curly.

Synthetic: medium strands, high or low gloss depending on what you get, ymmv on hair irons check before hand how much temperature it can handle. Already made of plastic so plastic-y glue doesn't make it look weirder. Comes in the longest strands.

Wool roving (not pictured): fine strands, no gloss, doesn't really look like straight hair, but works well for styles like dreads.

Acrylic yarn (not pictured): fine strands, gloss level varies, cheap, but you pay in "spent all afternoon unraveling yarn to brush it out" MICROPLASTICS BAD.

I looked at combed mohair prices and it made me scared. How much fiber do I need?

1/3 heads (8-9in circumference): 1/2 oz is a comfortable amount for shorter styles and more the longer the hair will be

1/4 heads (6-7.5in circumference): 1/4-1/3 oz.

1/6 Mature tinies (3in circumference): 1/4 oz, the usual minimum order, will be a ton

Processing mohair yourself is cheaper, but it's a lot of cleaning and combing.

Making the wig base

Fabric base: sheer woven fabric or thin stretch fabrics (pantyhose, mesh hair nets, etc) in a color that does not clash too much with the skintone of your doll

The smaller the doll and the shorter the hair style (especially exposed hairlines!) the thinner you want to go to avoid seeing the wig cap too easily.

Cover the doll with plastic wrap, tighten the fabric as much as possible to mold to head, spread glue around so fabric will stay in this shape.

Putting rubber bands around ears helps shape.

Putting the fiber on

I'm pretty sure preparing wefts beforehand by gluing them on a nonstick mat and then cutting off pieces to stick on the wigcap is easier for exact placement, but I think that takes too long, so I just glue that straight on the wigcap.

I prefer not to use sewn wefts because I don't like that chunky line.

Work back to front and/or wherever the hair parts.

Hold up a small lock of hair and then use the silicone tool to swab a lil glue on it.

The smaller the doll, the smaller bundles you want to add the hair in so the bulk level isn't too crazy. Not as big of a deal for 1/3 scale dolls, the biggest deal with 1/6 dolls.

Hairline and hair parting methods

Rooting

I use the rooting tool from Dollyhair (but you can basically use any small hand tool with an adjustable chuck that can hold the rooting needle)

Pros:

Imitates growing hair

More versatile in styling options if you root a large sections of the wigcap because then the hair can flow in different directions without exposing which way it was glued

Cons:

Slow, the more realistic you want to go, the smaller each root plug should be. I use size 8 or size 6 needle on 1/3 dolls, but I could probably go smaller.

Tiny bits of hair and glue inside the gap may affect the fit of the wig cap.

Takes three billion years to dry the inside because you will swab glue on the inside of the wigcap and then smoosh the wig cap against plastic wrap on your doll's hair to keep the wig cap properly molded to your doll's head

Works terrible on mature tiny 1/6 wigs

TTRPG Mini Grass Style

Pros:

Fast, just put a daub of glue and slap a tuft on

Hair can be pushed in multiple directions without looking awkward

Cons:

Harder to do with longer hair and thicker fibers, may just tip over before the glue dries. Works better with short suri alpaca or tencel than mohair

Fold Over Method

Pros:

Easy!

Can hide wigcap edges

Cons:

Not realistic

Works worse with stiff fibers that may not lay flat after being folded over (may need heat treatment to work)

Ugly glue zone

Chopping the wig open to cram in fibers where the hair parting is

Pros:

Less ugly glue zone than the foldover method

Cons:

Margin for error for not warping the entire wig cap is not great! More risk than the rooting method.

Wildcard showing up with a steel chair! (mostly because this doesn't really need a separate post)

Flocking + painted edges

Pros:

Fast, swab on the adhesive and shake a ketchup bottle of fiber powder on it.

Useful for shaved hair

Cons:

Well, now you have Craft Herpes (glitter, fiber dust, y'know how it is...)

Not all doll sculptors have very flush headcap boundaries

Gotta redo the face-side of the flocking whenever you want to change the face-up

37 notes

·

View notes

Text

Earlier today, I asked Google about removing the ink from a gel pen cartridge. Google thought I meant, “how do you revive a dead gel pen?” No. See. Sometimes, when you’re using gel pens in ways they were never meant to be used, you find the ballpoint inadequate. In my case, it was too big to get into tight spots on the doll shoe I was detailing. Gel ink is water soluble. You should be able to paint with it. Right?

But how do you get it out? Is the coverage okay? Folks,

the coverage is excellent.

You can learn how to free the gel ink from its tiny prison, plus the pros and cons below the cut.

Here’s the tools I used, except the hobby/model drill. That turned out to be unnecessary. A syringe, some kind of needle OR stiff catheter of similar dimensions, and scissors will do the trick.

I cut the pen above the stopper and below the ink/air bubble. If a gel pen is old enough or you have enough patience, sometimes you can wiggle the stopper out of the bottom of a gel pen instead. If that’s an option, I’d recommend it for reasons I’ll touch on later.

The tip of a Sakura Gellyroll has two notches in the plastic where the ballpoint head is seated in the grip. I used the eye end of a fat yarn needle to wedge into that notch and loosen the tip and cartridge until I could remove them from the grip. I think you could get away without removing the tip and cartridge, but I found it easier/neater to do it this way.

This shows where I cut into the cartridge: between the end of the air bubble, and the end of the ink. The more ink your pen has, the smaller - and possibly harder to identify - this area is.

Unfortunately, my syringe was not made to be used with a needle. To compensate, I used sticky-tac to cover any air gaps - vacuum is essential to a syringe. I used artist’s tape on top of that to stabilize the connection. You probably don’t need to do this, but if you do, there you go. I bet heavily chewed bubblegum would work, too. Or clay. Or lots of things.

I really didn’t think this would work, due to bad luck with past attempts. It does work.

Here, I’m using a kolinsky sable to pick up the ink but any pointed brush meant for acrylic, watercolor, or ink should do the trick.

THE OPACITY. THE PIGMENT LOAD. THE ABILITY TO DETAIL TINY AREAS

—

PROS.

-Incredibly opaque for something water-soluble and relatively low viscosity

-high pigment load

-very smooth finish

-accessible

CONS.

-If you bought gel pens with the intent of breaking them open for the beautiful ink inside, it would be expensive - especially for decent ink like Gellyroll

-Coverage is not as even with brush as it is with rollerball. This is easy to get around, but noticeable. Build up the coat until it’s opaque and smooth. Do not allow it to dry between coats. Once you’re done, put the item away to dry for as long as you can stand. DO NOT APPLY TOP COAT BY BRUSH

-Slow-drying on many surfaces if applied heavily enough for a smooth finish, but concerningly fast-drying in the syringe. It’s also unclear if recapping the original pen and sealing the cut end will preserve the ink, or if gel ink harvesting is a one-and-done where you will need to take all you can at one time, then store it in an airtight container. I’ve stuffed the cut end of my cartridge with sticky tac and put the cartridge back in the grip/recapped the pen, but it remains to be seen if this is sufficient for storage.

-Your gel pen will never be the same again: even if the ink can be preserved in the original cartridge, breaking the vacuum causes the ink to blob out of the roller ball. There’s a real possibility that this will just leak everywhere out both ends, which is why I recommend preserving the stopper at the bottom of the grip if plausible.

CONS 2,

continued (of detailing models, etc. with gel ink generally, not specifically the brush application thereof)

- Gel ink requires a porous surface. Do not expect to put pen to plastic without primer or Mr. Super Clear. The ink will consolidate centrally (proximal to heaviest application), gapping away from edges.

-Slow-drying: this takes forever, and it is easy to ruin a finish in the meantime.

—Durability: essentially none. Wait at least a few hours after you think the gel is dry, then apply a clear coat. SPRAY ONLY. Do NOT go back over it with a wet brush, as you risk reactivating the ink and ruining all your hard work. Spray works because it is ruining the finish evenly, and therefore, not at all. Wait and then apply the top coat again. These top coats will be your durability.

27 notes

·

View notes

Text

finally got enough sun to take good photos of the blanket i just finished crocheting!!! really really pleased with this. 50/50 cotton and bamboo viscose, all colors hand-dyed by me as well. 2.5 months of work!!!

this is based on the persian tiles pattern, though i only used the videos they provide for free on youtube and did by best guess on the rest, so i am sure it isn’t exactly the same. i would love to make another with this pattern someday, maybe plan my color distribution a little better, and be able to afford more yarn for an overall larger blanket as this one’s only about 3.5 feet across

53 notes

·

View notes