#vibration control and seismic design

Explore tagged Tumblr posts

Text

The experts in Tecoustics noise and vibration control take pride in offering specialized seismic solutions and product designs that are guaranteed to deliver the best performance and durability.

0 notes

Text

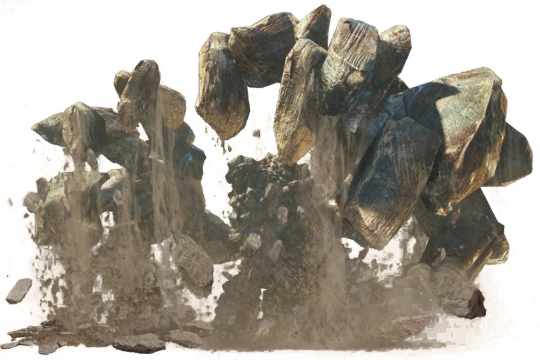

Autumn screams about how good monster hunter designs are 1: Shara Ishvalda

this guy isnt really my favorite monster or anything but its one of the monsters i feel the most strongly about if that makes any sense to you. i dont know who needs to be told this but rock monsters are fucking cool. dude looks like a fucking primordial god of the very ground we stand on.

i think its safe to say its sick as FUCK that they actually like. didnt just use the same type of rock for this dude. like theres actual variation in this guy's armor which you dont really see much of in media containing big rock dudes. including monster hunter itself

basarios for example is just like. a rock wyvern. with one kind of rock. but i really think it goes to show how much the design team for monster hunter has improved given that basarios is from the first game and shara ishvalda is relatively new. i just think thats pretty damn neat.

there are no good pictures of this so you gotta trust me when i talk about how cool it looks when you weaken its parts. most monsters just like put a texture over its leg or its head and call it a day but with shara its much more unique. like it actually changes the color of the rocks.

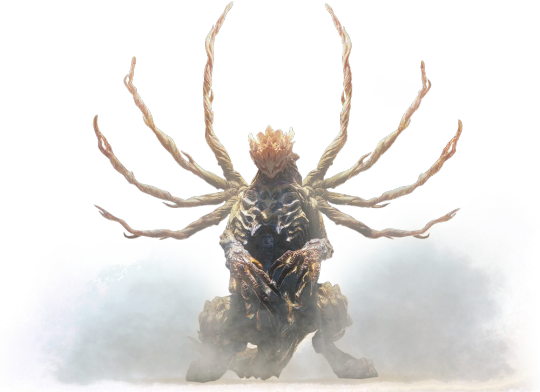

anyway once you crack this cold boy open youre greeted with the most terrifying eldritch nightmare youve seen in your entire goddamned life

im not sure how to describe this thing other than it being cool as hell. its wings are like. fucking veiny. and look like roots. they look like exposed nerves. and this fuckin guy causes seismic activity by CONTROLLING VIBRATIONS. this guys fuckin clothes were kept on with vibrations. and i just. fucking need to talk about how goddamn cool that concept is and how they utilize it.

THIS BITCH FUCKING MAKES DRAGON BALL LAZERS BY VIBRATING THE GODDAMNED AIR. ITS JUST STRAIGHT UP DOING SOME GOKU SHIT. IT ALSO JUST DOES A SPIRIT BOMB?? FROM DRAGON BALL?? MADE OUT OF VIBRATIONS??? AS ITS ULTIMATE ATTACK??? ITS FUCKING AWESOME.

AND IT GETS FUCKING SCIENTIFICAL IN THIS BITCH. IT VIBRATES THE SAND TO MAKE IT ACT LIKE A LIQUID. THATS A REAL THING. THATS JUST ACTUAL SCIENCE.

and dont worry it gets scarier when you hit it more

it opens its fucking eyes. i dont like that. it gives me the heeby jeebies. its great though. its modeled in a specific way to always be looking at the camera no matter what angle youre at. so its just fucking staring at *you*. not the hunter. but like actual you in real life.

quite beautiful and also fucking terrifying if i say so myself.

the lotus flower motif on its design is really cool. i didnt know you could make a design basedon a flower that goddamned terrifying but i like it.

unfortunately there arent many good pictures of it but when you break its parts off with your big cool weapon its like. a fucking amethyst geode. this fucking thing is just rocks all the way down.

in conclusion i think its really neat how capcom managed to make a creature seem so fucking terrifying and incomprehensible in a game where the creature still fucking make sense as part of an ecosystem no matter how wild they get. i dont know what monster i'll be screaming about next but i probably will. probably astalos or something

119 notes

·

View notes

Text

A massive device has landed not too far from an underground facility, and has been sending large rumbles deep into the ground for weeks now. The earthquakes have been constant since.

DATA LOG FOR STRUCTURE BELOW.

The Seismic Ear is an 850 meter tall, imposing stationary automation built by the irradiated. Designed to be dropped onto a planets surface from orbit, the Seismic Ear sends destructive "Taps" into the ground using six enormous slamming weights flanking the structure. the automation then listens to the ground using the tips of these taps, to determine the distance, shape, and potentially composition of any underground structure within an average range of 1,400 km.

DEPLOYMENT:

Seismic Ears are usually stored on cargo vessels, and then dropped onto a chosen site from orbit. The shape of the six flanking pistons, plus the device atop the structure (usually airbrakes or thrusters) allows it to control its descent into the atmosphere partially, insuring it impacts face first into the ground. Usually at supersonic speeds. Once landed, the automation will begin probing the soil using instruments in the front of the central chassis. Once the local composition is determined, it will begin the "Tapping".

TAPPING:

Once a Seismic Ear is ready, they begin extending their six hammers high into the air, and then letting gravity do the rest of the work. Depending on the soil composition: The automations can deploy a tiny atomic bomb within the sensing fingers of the hammers to ensure a good Tap. They repeat this for several years to build up an accurate history of Taps.

HEARING:

After a single Tap, the structure will listen to the vibrations sent throughout the depths, and using the information provided, construct a detailed map of the underground networks. The Irradiated commonly use this to spy on underground facilities.

REPURPOSE

After the local area is mapped completely, the Seismic Ears then go into a dormant state, to act as either a Communications tower, or a landing pad for future Irradiated activities.

REMOVAL

The Seismic ear may be large and imposing from the ground, and deeply rooted within the impacted area, but for automation sizes, it's still fairly small. Some strong firepower from another similarly sized automation can easily topple such a structure, if one managed to get a hit on it, without the irradiated constantly protecting the device. usually from orbit with another long-range G-class automation.

ASSESSMENT:

Can be destroyed with persistent attacks. Damages environment around it. High value for dense materials, strong heat shielding, and advanced electronics hidden deep within.

#worldbuilding#screi#gamedev#music#artists on tumblr#scifi#3d artwork#blender3d#blender#new music#scifiart#space weapon#weapon concept

3 notes

·

View notes

Text

Partnering with Mason Industries, Tecoustics offers a wide array of products designed to meet the specific needs of various projects, from residential to industrial.

#Tecoustics

#MasonIndustries

#NoiseControl

#VibrationControl

0 notes

Text

Industrial Structural/Ducting/Insulation Works

1. Industrial Structural Works

Scope: Structural works encompass the design, fabrication, and installation of steel and metal frameworks essential for supporting industrial facilities. This includes load-bearing structures, platforms, towers, and custom-designed frames for specific equipment. These structures form the backbone of manufacturing plants, warehouses, energy facilities, and other heavy-duty industrial settings.

Materials and Techniques: Often, structural steel and alloys are selected for their strength, flexibility, and durability. Advanced welding, cutting, and bolting techniques are applied for robust assemblies, ensuring the structure can withstand operational loads, weather conditions, and seismic activity. Structural coatings, like galvanization or anti-corrosion treatments, are frequently applied to extend the lifespan of the steel.

Applications: Structural frameworks support piping systems, industrial equipment, conveyors, and platforms. They’re vital for maintaining safety and operational efficiency in sectors such as oil and gas, power generation, chemical processing, and mining.

2. Industrial Ducting Works

Purpose: Ducting systems are crucial for the controlled movement of air, gases, fumes, and particulates within industrial facilities. Proper ducting ensures efficient ventilation, dust extraction, and temperature regulation across processing areas. Ductwork is critical in industries like pharmaceuticals, food processing, power plants, and metalworking.

Materials and Durability: Ducting is typically constructed from galvanized steel, stainless steel, or specialized composites, selected based on factors like temperature resistance, pressure tolerance, and chemical exposure. Insulated ducting is used in high-temperature applications, while corrosion-resistant materials are essential for handling caustic or corrosive substances.

Installation and Design Considerations: Precision in duct design minimizes air leakage, reducing energy costs and improving system efficiency. In addition to standard round or rectangular ducts, custom shapes and sizes can be fabricated to fit specific layouts, ensuring optimal airflow and minimal resistance. Strategic placement of dampers, filters, and access points allows easy maintenance and system control.

3. Industrial Insulation Works

Purpose: Insulation is applied to pipes, ducts, tanks, and equipment to control temperature loss, conserve energy, and ensure operational safety. Industrial insulation is particularly important in facilities handling extreme temperatures, from steam plants to refrigerated warehouses, where thermal efficiency and personnel safety are priorities.

Types of Insulation Materials:

Fiberglass: Commonly used for its versatility and effective thermal control, fiberglass is applied in lower to moderate temperature systems.

Mineral Wool: With high-temperature resistance, mineral wool is often used around hot piping and equipment.

Ceramic Fiber: Suited for ultra-high-temperature applications, ceramic fiber insulation is lightweight and extremely heat-resistant.

Foam Insulation: Used in low-temperature applications, especially in refrigerated or cold storage settings.

Additional Benefits: Besides thermal control, insulation can offer soundproofing, vibration dampening, and even protection from fire hazards in sensitive areas. Quality insulation reduces condensation on cold surfaces, helping prevent moisture-related corrosion and mold growth, which are essential for maintaining hygiene in food and pharmaceutical industries.

Maintenance and Inspection: Insulated systems need periodic inspection and maintenance to ensure the integrity of the materials, especially in harsh or variable environmental conditions. Aging or damaged insulation must be replaced promptly to prevent energy loss and maintain system efficiency.

Key Benefits of Industrial Structural, Ducting, and Insulation Works

Enhanced Operational Efficiency: Proper structural support, air management, and thermal insulation reduce energy consumption, improve equipment performance, and create safer environments for employees.

Safety Compliance: Meeting industrial standards and regulations, especially regarding load-bearing structures, air quality, and temperature control, ensures a safer workspace and reduces liability risks.

Cost Savings: Efficiently designed and installed structural, ducting, and insulation systems significantly lower energy costs and minimize equipment maintenance, ultimately leading to long-term cost savings.

Conclusion

Engaging experienced contractors for industrial structural, ducting, and insulation works ensures each component meets industry standards and is customized to meet the demands of the facility. By investing in high-quality design, materials, and installation, industries can boost productivity, maintain safety, and prolong the life of their infrastructure.

#Industrial Structural/Ducting/Insulation Works#Best Industrial Boiler Supplier#Thermic Fluid Heater Provider#Complete Heating and Cooling Solutions

0 notes

Text

The importance of bearing pads and UHMW plastic in construction and engineering

In the world of construction and engineering, choosing the right materials is crucial for ensuring durability, performance, and safety. Two essential components that often come into play in various structural and mechanical applications are Bearing Pad and UHMW Plastic. GRM Custom Products specializes in offering these high-quality materials, designed to meet the demands of various industries.

What is a Bearing Pad?

A bearing pad is a key element used in structural applications to provide support and distribute loads across a wide area. They act as buffers between two structural components, such as beams and girders, allowing for controlled movement and reducing stress at load points. Bearing pads are commonly used in bridge construction, building foundations, and other heavy-duty structures where load distribution is essential to prevent structural damage over time.

Key Benefits of Bearing Pads:

Load Distribution: Bearing pads help evenly distribute weight across a larger surface, preventing localized stress and potential structural failure.

Vibration Absorption: They absorb vibrations and shock, increasing the longevity of structures and reducing wear on components.

Flexibility: Bearing pads accommodate small movements and expansions, crucial for bridges and other structures that undergo temperature fluctuations or seismic activity.

GRM Custom Products provides bearing pads made from high-quality materials that ensure long-lasting durability and reliable performance in demanding environments.

UHMW Plastic: The Ultimate Material for Tough Conditions

UHMW plastic (Ultra-High Molecular Weight Polyethylene) is another critical material widely used in various engineering applications. It is known for its excellent properties, such as high wear resistance, low friction, and incredible durability.

Why Choose UHMW Plastic?

Low Friction: UHMW plastic has a very low coefficient of friction, making it ideal for applications that require sliding or movement, such as bearings, rollers, and wear plates.

High Impact Resistance: It can withstand high impact forces without cracking or breaking, making it perfect for use in heavy-duty environments.

Corrosion and Chemical Resistance: UHMW plastic is resistant to chemicals, moisture, and corrosion, which makes it ideal for use in harsh industrial settings.

Longevity: With its high wear resistance, UHMW plastic lasts longer in applications where regular wear and tear would typically degrade other materials.

At GRM Custom Products, we offer UHMW plastic solutions tailored to meet the specific needs of your project, whether it involves high-impact or low-friction applications.

Applications of Bearing Pads and UHMW Plastic

Both bearing pads and UHMW plastic are incredibly versatile and find their uses in various industries, including:

Construction: Bearing pads are used in bridges, buildings, and other infrastructure to manage load distribution and provide flexibility in movement. UHMW plastic is often utilized for construction machinery parts that require durability and smooth movement.

Manufacturing: UHMW plastic is ideal for conveyor systems, gears, and bearings in manufacturing plants, while bearing pads are used to reduce wear and tear on structural components.

Marine and Offshore: Both materials are commonly used in harsh marine environments due to their resistance to corrosion, water, and extreme weather conditions.

Why Choose GRM Custom Products?

At GRM Custom Products, we take pride in delivering top-quality bearing pads and UHMW plastic products to meet the rigorous demands of the construction, manufacturing, and engineering industries. Our materials are designed to offer superior performance, ensuring that your projects stand the test of time. We understand that every project is unique, and that’s why we offer custom solutions to meet your specific needs. Whether you’re looking for standard products or custom-engineered components, GRM Custom Products is here to provide you with the best solutions in the market.

Conclusion

When it comes to structural integrity and material performance, the right components make all the difference. Bearing pads and UHMW plastic from GRM Custom Products are essential in ensuring the longevity and safety of your projects. With years of experience and a commitment to quality, we provide reliable solutions that you can trust. For more information or to discuss your specific project needs, contact GRM Custom Products today!

#conroe#construction#grmcp#industrial#uhmw plastic#Texas#united states#USA#bearing pads#GRM Custom Products

1 note

·

View note

Text

Dynemech Anti Vibration Solutions: - Dynemech Anti Vibration Wedge Mount with an edge bending machine attached

Wedge Mounts: For accurate vibration damping and levelling. The broad contact surface of the three-piece levelling wedge enables optimal vibration control and offers excellent levelling adjustability. These heavy-duty anti vibration pads provide superior vibration isolation and shock absorption.

FAQs:

1. What are the main causes of vibrations in machinery used in industry?

Numerous causes, including uneven loads, misalignment, resonance, and external disturbances like nearby buildings or seismic activity, can create vibrations in industrial machinery. Proper use of Anti Vibration mounts for machines and vibration dampening techniques are critical for industrial vibration control.

2. How might vibrations affect the way that industries operate?

Industrial activities may be significantly impacted by vibrations. They may result in structural damage to machinery and equipment, raising maintenance expenses and causing downtime. Additionally, vibrations have the potential to impair measurement precision and accuracy as well as interfere with the operation of delicate equipment like electrical panels. Furthermore, high vibration levels can put employees' health and comfort at risk, which can lower output and increase the risk of accidents. Effective machinery vibration control using anti-vibration mounts and vibration damping pads is essential.

3. Which sectors can profit from the anti-vibration products offered by Dynemech?

Across a variety of industries, including manufacturing, automotive, aerospace, pharmaceuticals, research labs, and others, Dynemech provides flexible solutions. Our anti vibration mount and vibration mounting products, made from materials like stainless steel, galvanized steel, and powder coated finishes, are suitable for applications ranging from CNC machine tools and presses to generators and motors.

4. Can Dynemech's products be tailored to meet certain needs?

Yes, Dynemech's solutions, including our anti vibration pad, anti-vibration bush, and antivibration mount offerings, can be tailored to fit specific needs of the manufacturing process as well as the requirements of the equipment used. From custom spring mounts and wire rope isolators to specialized flange mounts and metal cushions, we have the expertise to provide vibration-damping elements designed for your unique application.

The goal of Dynemech Anti Vibration Technology is to offer creative, useful solutions that effectively isolate vibrations. With our help, the overall quality of interior environments is improved as machinery can function with lower vibration levels and vital, sensitive equipment is shielded from all disruptive vibrations. Furthermore, our technique improves the longevity and efficiency of both structures and machinery.

Principal Advantages: 1. Dynemech's anti-vibration pads, including options like anti vibration pad for generator and anti vibration pad for motor, may be easily and affordably fitted, minimizing downtime and associated expenses.

2. Dynemech AVMs ensure optimal performance and efficiency by offering highly accurate machine alignment and leveling. Our anti vibration mounting pad and machine mounting pads provide a sturdy construction.

3. Dynemech's solutions, from vibration damping pads to noise reduction mounts, effectively lessen vibrations, reducing wear and tear and extending the life of machinery and equipment.

4. Improved Structural Safety: Industrial environments are made more structurally sound and safer by using high-strength materials like AISI 304 stainless steel and employing high-quality production techniques.

5. Dynemech's solutions like leveling feet and rubber buffers eliminate the need for grouting, which expedites the installation process and lowers associated costs. Our products feature easy installation and low maintenance.

6. By reducing undesired vibrations and noise, our solutions like double acting mounts and NBR rubber components create a more comfortable working environment. From support pipes to threaded bushing, we cover a wide range of industrial applications.

#IndustrialApplications, #MachinerySafety, #AntiVibration, #VibrationReduction, #PrecisionLeveling, #Safety in Structure, machinery installation, vibration control, and equipment stability#Vibrationmounts, #Antivibrationmounts#Machinerymounts

To know more- https://www.vibrationmountsindia.com/products/

Dynemech Systems Pvt Ltd. Mob: +91-9810760131 ; +91-9911145131 Email: [email protected] www.vibrationmountsindia.com | www.vibrationdampingpads.com

1 note

·

View note

Text

Innovations in Ready-Mix Concrete Technology in Pakistan

The construction industry in Pakistan is evolving rapidly, with increased urbanization and demand for modern infrastructure. One critical material driving this transformation is ready-mix concrete. Offering precision, quality, and efficiency, ready mix concrete in Pakistan has become a cornerstone for builders aiming to meet tight deadlines while ensuring durability and structural integrity. As construction demands surge in both urban and rural areas, the technology surrounding ready-mix concrete has seen significant innovation. These advances have optimized construction processes, reduced costs, and enhanced the quality of structures across the country.

The Growth of Ready-Mix Concrete in Pakistan

Ready-mix concrete (RMC) is a specialized form of concrete that is manufactured in a plant and delivered to construction sites in a ready-to-use form. It offers various advantages over traditional concrete mixing methods, which are often done on-site and are susceptible to errors in measurement, quality control, and consistency.

In Pakistan, ready-mix concrete has gained immense popularity due to its convenience and time-saving benefits. With growing urban centers like Karachi, Lahore, and Islamabad, the demand for high-quality, consistent concrete solutions has spurred the growth of the ready-mix concrete sector. Leading companies such as Allied Materials have played a key role in providing state-of-the-art ready-mix concrete solutions for residential, commercial, and infrastructural projects across the country.

Advancements in Ready-Mix Concrete Technology

High-Performance Concrete (HPC)

One of the significant innovations in ready-mix concrete in Pakistan is the development of High-Performance Concrete (HPC). HPC is designed to withstand higher stress levels, making it ideal for high-rise buildings, bridges, and other structures that need additional strength and durability. This type of concrete offers superior mechanical properties, increased resistance to environmental degradation, and enhanced workability.

In Pakistan, HPC is being used in large-scale infrastructure projects, where it ensures durability and long-term stability, reducing the need for frequent maintenance and repairs.

Self-Compacting Concrete (SCC)

Another cutting-edge innovation in ready-mix concrete technology is Self-Compacting Concrete (SCC). SCC is designed to flow and settle into every corner of a mold or formwork without the need for mechanical compaction. This concrete is highly fluid, ensuring that it fills even the most intricate forms without segregation of materials or air bubbles.

In Pakistan, the use of SCC has grown due to its ability to reduce labor costs and improve the quality of finished structures. By minimizing the need for vibration and manual compaction, SCC ensures a smoother surface finish, reduces construction time, and enhances overall structural performance.

Green Concrete

Sustainability is an increasing priority in Pakistan’s construction industry, and this has led to the development of green concrete technologies. Green concrete is designed to have a lower environmental impact by incorporating waste materials like fly ash, slag, or silica fume, which replace some of the traditional cement content.

Green concrete is not only more environmentally friendly but also offers superior durability and resistance to chemicals and extreme weather conditions. As the demand for sustainable construction grows in Pakistan, green concrete is expected to become more prevalent in both public and private sector projects.

Fiber-Reinforced Concrete (FRC)

Fiber-Reinforced Concrete (FRC) incorporates various fibers—such as steel, glass, or synthetic fibers—into the concrete mix to enhance its tensile strength and durability. FRC is particularly beneficial in Pakistan’s seismic zones, where structures need additional reinforcement to withstand earthquakes.

The use of FRC in ready-mix concrete improves the performance of buildings, roads, and bridges by preventing cracking, improving load-bearing capacity, and extending the lifespan of structures. As seismic activity continues to pose a risk in regions like Baluchistan and Khyber Pakhtunkhwa, fiber-reinforced ready-mix concrete is becoming an essential material for enhancing structural resilience.

Ultra-High-Performance Concrete (UHPC)

Ultra-High-Performance Concrete (UHPC) is an advanced form of concrete that offers exceptional strength, durability, and versatility. It is capable of withstanding compressive strengths of over 150 MPa, making it ideal for demanding construction projects that require enhanced durability, such as bridges, tunnels, and high-rise buildings.

UHPC is also highly resistant to environmental factors like chloride penetration, freeze-thaw cycles, and abrasion, making it ideal for Pakistan’s coastal regions and areas with extreme weather conditions. The use of UHPC in ready-mix concrete plants in Pakistan is transforming the way complex infrastructure projects are executed, providing long-lasting solutions that minimize maintenance and repair costs.

Pervious Concrete

Pervious concrete is another innovation that has made its way into the Pakistani construction sector. It is a type of concrete that allows water to pass through, making it an ideal solution for areas prone to flooding or where stormwater management is a concern. By allowing water to percolate into the ground, pervious concrete helps reduce surface runoff and replenishes groundwater levels.

In cities like Karachi, where urban flooding is a recurring issue, the adoption of pervious concrete in infrastructure projects is a forward-thinking solution to managing excess rainwater and preventing drainage problems. As climate change leads to more unpredictable weather patterns, innovations like pervious concrete will become increasingly important for urban development in Pakistan.

3D Printed Concrete

One of the most futuristic innovations in the global construction industry, including Pakistan, is the use of 3D printing technology with ready-mix concrete. 3D printed concrete allows for the creation of complex architectural shapes and designs with high precision and minimal waste. This technology is still in its nascent stages in Pakistan but holds immense potential for revolutionizing how buildings and structures are constructed.

3D printed concrete can significantly reduce construction time, labor costs, and material waste, making it an attractive option for sustainable and cost-effective building solutions. As technology advances, we may see 3D printing become a more common construction technique in Pakistan’s future development projects.

The Impact of Innovations on Pakistan’s Construction Industry

The innovative technologies in ready-mix concrete have significantly impacted the construction industry in Pakistan, offering solutions that meet the increasing demands for faster, more efficient, and more sustainable building methods.

Enhanced Durability and Structural Integrity

The development of HPC, SCC, and FRC has improved the durability and structural integrity of buildings and infrastructure projects in Pakistan. These advanced forms of concrete offer enhanced resistance to environmental factors, such as humidity, extreme temperatures, and seismic activity, ensuring that structures stand the test of time.

Faster Construction Times

With innovations like SCC, fiber-reinforced concrete, and 3D printed concrete, construction times have been reduced significantly. Builders and contractors can now complete projects faster, improving overall project efficiency and reducing labor costs. This is particularly beneficial for large-scale projects in cities like Lahore, Karachi, and Islamabad, where urban development is accelerating rapidly.

Sustainable Construction Practices

The introduction of green concrete and pervious concrete has paved the way for more environmentally conscious construction practices in Pakistan. These innovations help reduce carbon emissions, minimize waste, and promote sustainable development by incorporating recycled materials and improving water management systems in urban areas.

Cost-Effective Building Solutions

Ready-mix concrete technology has made construction more cost-effective by reducing the need for on-site mixing, minimizing errors, and enhancing material efficiency. In addition, advanced concrete types such as FRC and HPC require less maintenance and offer longer lifespans, providing builders and developers with significant cost savings over time.

Choosing the Right Ready-Mix Concrete Supplier in Pakistan

As the demand for ready-mix concrete continues to grow, choosing a reliable supplier becomes crucial for the success of any construction project. Companies like Allied Materials are at the forefront of providing innovative, high-quality ready-mix concrete solutions tailored to the unique needs of Pakistan’s construction industry.

When selecting a ready-mix concrete supplier, it’s important to consider factors such as the quality of materials, adherence to safety and environmental standards, and the ability to deliver consistent, reliable products on time.

Conclusion

Ready mix concrete in Pakistan is evolving at a rapid pace, with innovations such as High-Performance Concrete, Self-Compacting Concrete, and Fiber-Reinforced Concrete leading the charge. These advancements are transforming how buildings and infrastructure projects are constructed, offering improved durability, efficiency, and sustainability.

As urbanization continues to rise and construction demands grow, ready-mix concrete will remain an essential component of Pakistan’s future development. By adopting the latest technologies and innovations, Pakistan’s construction industry can achieve new heights in quality and performance.

0 notes

Text

What is Structural Bearing and Why is it Essential for Bridge Construction?

When it comes to large-scale infrastructure like bridges, the role of structural bearing becomes crucial. These bearings not only support the weight of the bridge but also accommodate movements and loads caused by environmental factors, ensuring the safety and longevity of the structure. In this blog, we will explore what a structural bearing is, how it works, and why it is critical in bridge construction.

What is a Structural Bearing?

A structural bearing is a component placed between two structural elements, such as the deck and piers of a bridge, to facilitate controlled movement and distribute loads. It supports the superstructure and allows for necessary flexibility, preventing damage from forces like expansion, contraction, and seismic activities.

Key Functions of Structural Bearings in Bridge Construction

• Load Transfer: One of the primary purposes of a structural bearing is to transfer the weight of the bridge superstructure to the substructure (piers or abutments) efficiently. The bearing helps in distributing this load evenly to avoid stress concentration.

• Movement Accommodation: Bridges are subject to various forces, including traffic loads, thermal expansion, and wind. A structural bearing allows controlled movement in response to these forces, ensuring the bridge remains functional and intact.

• Vibration Damping: Structural bearings can absorb vibrations caused by traffic or external factors like earthquakes, ensuring the stability of the structure and enhancing safety.

• Durability and Protection: By reducing wear and tear on bridge joints and structures, structural bearings increase the longevity of the bridge, making them a vital part of sustainable infrastructure design.

Types of Structural Bearings

Various types of structural bearings are used depending on the specific needs of the bridge. Each type is designed to accommodate different forms of movement and load capacities:

• Elastomeric Bearings: These bearings are made from layers of rubber and steel. They are highly flexible and can accommodate both vertical loads and horizontal movements. Elastomeric bearings are common in short-span bridges.

• Pot Bearings: Pot bearings consist of a metal pot containing an elastomeric disc. They allow rotation and slight translation and are used in bridges that experience significant loads and movements.

• Sliding Bearings: Sliding bearings are designed to permit movement in a specific direction. They use a sliding surface, usually Teflon or stainless steel, to enable longitudinal motion while restricting vertical movement.

• Spherical Bearings: Spherical bearings allow movement in any direction and are used in complex bridge designs that experience multiple types of stresses.

Why Structural Bearings Are Essential for Bridges

• Bridge Bearing: Bridges are dynamic structures that require flexibility to accommodate shifts in load, temperature, and environmental factors. A bridge bearing plays an essential role in achieving this flexibility. It ensures that the weight of the bridge is appropriately transferred to the piers while allowing for movement without causing damage.

• Safety Assurance: Without a functional structural bearing, a bridge is at risk of failure due to excessive stress or movement. Bearings help control the expansion and contraction caused by temperature variations, preventing structural cracks and breakdowns.

• Cost Efficiency: Properly installed and maintained structural bearings reduce wear and tear on other bridge components, leading to lower maintenance costs over time. By extending the life of the bridge, they offer significant savings on repairs and replacements.

Choosing the Right Structural Bearings

Selecting the appropriate structural bearing for a bridge depends on several factors, including the type of bridge, the load it will carry, and the environmental conditions it will face. Engineers need to evaluate these factors carefully to ensure that the bearing will perform its role effectively.

• Load Capacity: The bearing must be capable of withstanding the maximum expected load. This includes both the dead load (the weight of the bridge itself) and the live load (traffic and other dynamic forces).

• Movement Requirements: The bearing should allow for the necessary amount of movement, whether it's vertical displacement, horizontal movement, or rotation. Choosing a bearing that restricts necessary movement could lead to damage over time.

• Environmental Conditions: Bearings used in harsh environments (extreme temperatures, high humidity, or areas prone to seismic activity) must be made of materials that can withstand these conditions. Elastomeric and pot bearings are popular choices for these types of settings.

• Maintenance Needs: Some types of bearings require regular maintenance to function correctly, while others, like elastomeric bearings, are relatively low maintenance. It's important to consider the long-term care needed for the chosen bearing type.

Bridge Bearing Maintenance

Proper maintenance of bridge bearings is essential for the longevity and safety of the structure. Over time, bearings may degrade due to exposure to environmental factors like moisture and temperature changes. Regular inspections and maintenance can prevent major issues and extend the life of both the bearing and the bridge.

• Inspection: Regular visual inspections are necessary to check for signs of wear, corrosion, or movement restriction. Engineers should also check the alignment and performance of the bearings during these inspections.

• Lubrication: Bearings with sliding surfaces or moving parts may require lubrication to ensure smooth operation. This is especially important for metal components that are prone to corrosion or wear.

• Replacement: Bearings that show significant wear or damage must be replaced promptly to avoid structural issues. Engineers should keep track of the lifespan of each bearing and plan for timely replacements to prevent failures.

Conclusion

In bridge construction, structural bearings are a critical component for ensuring flexibility, durability, and safety. Whether you're working with elastomeric bearings for a short-span bridge or pot bearings for larger, more complex structures, the right bearing selection can make all the difference in the performance and longevity of the bridge. Proper maintenance and regular inspections will also ensure that the bridge bearings continue to function efficiently, safeguarding the structure for years to come. Visit Our Website Metal Engineering

0 notes

Text

Bearing Pads and Neoprene Bearings: Key Parts in Today's Construction

In the world of construction and engineering, the importance of materials that ensure durability, safety, and longevity cannot be overstated. Among these vital materials, Bearing Pad and Neoprene bearing stand out as essential components that play a critical role in various structural applications. At GRM Custom Products, we specialize in providing high-quality bearing pads and neoprene bearings designed to meet the rigorous demands of modern construction projects.

What Are Bearing Pads?

Bearing pads are critical elements in construction that serve as a cushion between two surfaces, typically between a concrete structure and a steel or concrete beam. They are designed to distribute loads evenly, reduce vibrations, and accommodate slight movements caused by temperature changes, seismic activities, or other environmental factors. Bearing pads help in minimizing the stress on the structure, thereby enhancing its lifespan and ensuring safety.

The Role of Neoprene Bearings in Construction

Neoprene bearings, a type of elastomeric bearing pad, are widely used in bridges, buildings, and other large structures. Neoprene is a synthetic rubber that offers excellent flexibility, resilience, and resistance to a wide range of environmental conditions, including temperature extremes, ozone, and chemicals. These bearings are particularly valuable in construction due to their ability to absorb and distribute loads while allowing for controlled movement within the structure. This movement might include expansion, contraction, or rotational shifts due to factors such as temperature variations or seismic forces. Neoprene bearings also help in reducing noise and vibrations, which is essential in structures like bridges that experience heavy traffic.

Applications of Bearing Pads and Neoprene Bearings

Bridges: Bearing pads and neoprene bearings are commonly used in bridge construction to support the load of the bridge deck while accommodating movement due to thermal expansion and contraction, traffic load, and seismic activity.

Buildings: In high-rise buildings, neoprene bearings are used to absorb vibrations and reduce noise, especially in areas with heavy machinery or where structural movements are anticipated.

Industrial Applications: Bearing pads are also utilized in various industrial applications where heavy machinery is involved. They help in isolating vibrations and protecting the structural integrity of the machinery and the building.

Why Choose GRM Custom Products?

At GRM Custom Products, we understand the critical role that bearing pads and neoprene bearings play in construction and industrial applications. Our products are manufactured to the highest standards, ensuring durability, reliability, and performance in even the most demanding environments.

Quality Assurance: Our bearing pads and neoprene bearings undergo rigorous testing to ensure they meet or exceed industry standards.

Customization: We offer customized solutions tailored to meet the specific requirements of your project. Whether you need a specific size, shape, or material, we can provide the perfect solution.

Expertise: With years of experience in the industry, our team of experts is always ready to assist you in selecting the right products for your project.

Competitive Pricing: We offer high-quality products at competitive prices, ensuring that you get the best value for your investment.

Conclusion

Bearing pads and neoprene bearings are indispensable in modern construction, providing the necessary support and flexibility that structures require to withstand various forces and conditions. At GRM Custom Products, we are committed to delivering top-quality products that ensure the safety and longevity of your construction projects. Whether you are building a bridge, a high-rise, or an industrial facility, our bearing pads and neoprene bearings are designed to meet your needs with precision and reliability. Choose GRM Custom Products for your next project, and experience the difference that quality and expertise can make. Contact us today to learn more about our products and services.

1 note

·

View note

Text

What You Need to Know About the Importance of Structural Engineering for Safe and Reliable Factory Buildings

In this article, we'll explore the role of structural engineering in ensuring safe and reliable factory buildings. From safeguarding assets to protecting lives, structural engineering is crucial for the integrity and longevity of industrial structures.

The integrity of factory buildings is critical to the success of industrial operations. Almost every production line and bustling warehouse is supported by a robust structure designed to withstand the rigors of day-to-day operations.

Top industrial Architect in India

.

Structural engineering, often overshadowed by its more visible counterparts, plays a pivotal role in ensuring the safety, reliability, and longevity of factory buildings.

For the best structural solutions in Ahmedabad, trust VMS Consultants. As the top structural consultant in Ahmedabad, we have a proven track record of designing safe and reliable factory buildings that meet the highest standards of structural integrity.

Structural Consultant in India

.

Here, we will discuss the significance of structural engineering in factory construction and maintenance, and why it plays a key role in ensuring lives and assets are safeguarded.

Understanding Structural Engineering in the Context of Factory Buildings

Structural engineering is a discipline that deals with the design, analysis, and construction of load-bearing structures, including buildings, bridges, and industrial facilities.

When it comes to factory buildings, the principles of structural engineering are crucial in ensuring structural stability, load-bearing capacity, and resistance to external forces such as wind, seismic activity, and heavy machinery vibrations.

Top industrial Project Management Consultant in India

.

Protecting Lives and Assets

The foremost concern in any industrial setting is safety. Factory buildings, often housing valuable equipment, raw materials, and personnel, must be engineered to withstand a myriad of potential hazards.

Structural engineers work tirelessly to design buildings that meet stringent safety standards and codes, minimizing the risk of structural failure, collapse, or damage during extreme events.

From seismic retrofitting to blast-resistant design, structural engineering strategies are employed to enhance the resilience of factory buildings against unforeseen calamities.

By conducting thorough structural analyses and employing advanced modeling techniques, engineers ensure that factory structures can withstand the forces exerted upon them, safeguarding both lives and assets in the process.

Manufacturing projects in Gujarat

.

Building for the Long Term

Beyond safety, structural engineering plays a crucial role in ensuring the reliability and longevity of factory buildings. Industrial operations demand structures that can withstand constant use, heavy loads, and harsh environmental conditions without compromising their integrity.

Through careful material selection, meticulous design, and rigorous quality control measures, structural engineers create buildings that stand the test of time.

By accounting for factors such as material strength, fatigue resistance, and environmental exposure, engineers ensure that factory buildings remain operational and structurally sound for years to come.

Whether it's a manufacturing plant, a distribution center, or a storage facility, the reliability of the structure is essential for maintaining uninterrupted operations and minimizing downtime.

Top factory Architect in India

.

Optimizing Space and Functionality

In addition to safety and reliability, structural engineering also plays a vital role in optimizing space utilization and functionality within factory buildings. Efficient layout design, strategic column placement, and innovative structural systems enable manufacturers to maximize floor space, streamline workflow, and accommodate evolving production needs.

Through intelligent design solutions such as mezzanine floors, clear-span structures, and high-ceiling designs, structural engineers help factories overcome spatial constraints and enhance operational efficiency.

By optimizing the structural framework to support various equipment configurations and workflow patterns, engineers empower manufacturers to adapt to changing market demands and scale their operations with ease.

Best industrial Architects in India

.

Safeguard Your Success with Structural Engineering

In conclusion, the importance of structural engineering in ensuring the safety and reliability of factory buildings cannot be overstated. From safeguarding lives and assets to optimizing space and functionality, structural engineers play a crucial role in shaping the built environment of industrial facilities.

As factories continue to evolve and expand in response to technological advancements and market dynamics, the need for robust, resilient structures will only grow.

By partnering with experienced Best Structural Consultant in Ahmedabad & Vadodara, VMS Consultants, manufacturers can ensure that their facilities are engineered to withstand the challenges of today and tomorrow, laying the foundation for continued success and prosperity.

Ready to build safer, more reliable factory buildings? Partner with VMS Consultants, your trusted experts in Engineering Architecture & Project Management Services.

Best factory Architect in India

.

Address: Chitrakoot Flats, Ground floor, Behind Time of India, Off Ashram Road, Ahmedabad, Gujarat, India,380009

Call: 79 40236236

Email: [email protected]

Website: https://www.vmsconsultants.com/

0 notes

Text

Global Seismic Brackets Market Size,Growth Rate,Industry Opportunities 2024-2030

Global Info Research announces the release of the report “Global Seismic Brackets Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030” . This report provides a detailed overview of the market scenario, including a thorough analysis of the market size, sales quantity, average price, revenue, gross margin and market share.The report provides an in-depth analysis of the competitive landscape, manufacturer’s profiles,regional and national market dynamics, and the opportunities and challenge that the market may be exposed to in the near future. Global Seismic Brackets market research report is a comprehensive analysis of the current market trends, future prospects, and other pivotal factors that drive the market.

According to our (Global Info Research) latest study, the global Seismic Brackets market size was valued at USD million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of % during review period.

Seismic Brackets are designed and constructed to resist virtually all code specified seismic forces in the event of an earthquake and it limit the displacement of the auxiliary mechanical and electrical engineering facilities, control the vibration of the facilities, and transmit the load to the bearing structure. therefore, keeping non-building structural components of essential facilities operational and intact.

Global top 4 key companies of global Seismic Brackets are Atkore, Eaton, nVent, and Meide Group, which together account for about 30% of the market share. The main production regions are located in North America, Europe, China, Australia, New Zealand and other regions. In terms of their product types. Wall brackets and roof brackets both hold about 30% market share, and equipment support brackets hold about 25% market share. In terms of applications, industrial facilities hold about 45% of the market share, and commercial premises hold about 30% of the market share.

The Global Info Research report includes an overview of the development of the Seismic Brackets industry chain, the market status of Industrial Facilities (Wall Brackets, Roof Brackets), Commercial Venues (Wall Brackets, Roof Brackets), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Seismic Brackets.

Regionally, the report analyzes the Seismic Brackets markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Seismic Brackets market, with robust domestic demand, supportive policies, and a strong manufacturing base.

Market Segmentation Seismic Brackets market is split by Type and by Application. For the period 2019-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. Market segment by Type: Wall Brackets、Roof Brackets、Equipment Support Brackets、Other Market segment by Application:Industrial Facilities、Commercial Venues、Residential、Other Major players covered: Atkore、Eaton、nVent、Meide Group、Justrite、Legrand、ASC Engineered Solutions、fischer、ISAT、Mason Industries、PHD Manufacturing、Gripple、RIKTA、Tracklok、Vibro-Acoustics、Chatsworth Products、Kinetics Noise Control、Labconco、AtlasIED The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Seismic Brackets product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Seismic Brackets, with price, sales, revenue and global market share of Seismic Brackets from 2019 to 2024. Chapter 3, the Seismic Brackets competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Seismic Brackets breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Seismic Brackets market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Seismic Brackets. Chapter 14 and 15, to describe Seismic Brackets sales channel, distributors, customers, research findings and conclusion. Our Market Research Advantages: Global Perspective: Our research team has a strong understanding of the company in the global Seismic Brackets market.Which offers pragmatic data to the company. Aim And Strategy: Accelerate your business integration, provide professional market strategic plans, and promote the rapid development of enterprises. Innovative Analytics: We have the most comprehensive database of resources , provide the largest market segments and business information.

0 notes

Text

LED auto lights refer to the use of LED technology for both internal and external lighting. External lighting equipment involves thermal limits and EMC issues, as well as many complex standards for unloading load tests. LED auto lights can be widely used to create an in-car environment with a service life of 50,000 hours. The structure of LED is sturdy and not easily affected by vibration, and the light output brightness will not drop significantly during use. LED car lights are suitable for various lighting applications in automotive electronics, including headlights (high beam and low beam), fog lights, taillights, brake lights, turn signals, daytime running lights, pedal lights, instrument lights, license plate lights, door lights, interior lights, width lights, navigation, entertainment systems, backlights and indicator lights.

Advantages:

1. Energy saving: The light-emitting diode directly converts electrical energy into light energy, and the power consumption is only 1/10 of that of ordinary car bulbs, which can better save fuel consumption and protect the car circuit from being burned out by excessive load current.

2. Environmental protection: There is no ultraviolet and infrared in the spectrum, low heat, no radiation, low glare, and the waste can be recycled, no pollution, no mercury, safe to touch, and it is a typical green lighting LED source.

3. Long life: There is no loose part in the lamp body, and there are no shortcomings such as easy burning of filament light, heat deposition, and light decay. Under the appropriate current and voltage, the service life can reach 80,000-100,000 hours, which is more than 10 times longer than the life of traditional light sources. (It has the characteristics of one-time replacement and lifelong use)

4. High brightness and high temperature resistance. (Electric energy is directly converted into light energy, low heat, and can be touched by hand, safe and secure)

5. Small size. The designer can change the lamp mode at will to diversify the car shape. The reason why automobile manufacturers favor LED is entirely determined by the advantages of LED itself.

6. Good stability and strong anti-seismic performance of LED: resin encapsulation, not easy to break, easy to store and transport.

7. High luminous purity, clear and bright colors, no need for lampshade filtering, and light wave error within 10 nanometers.

8. Fast response speed, no hot start time required, can emit light within microseconds, while traditional glass bulbs have a 0.3 second delay, which can prevent rear-end collisions and ensure driving safety.

Disadvantages:

1: LED headlights are more expensive than ordinary headlights. (With the continuous popularization of LED applications, prices will be further reduced)

2: It is difficult to popularize car headlights, and the heat dissipation is not good. If the heat dissipation is not properly handled, it is easy to light decay, which affects the service life of the headlights.

3: There are no industry standards issued, and the product quality is uneven. The price of the same product produced with different LEDs varies by 1-2 times. Fortunately, a small number of companies implement standards higher than the general industry standards, so product quality control is better than most companies, such as SNGL brand companies, etc.

1 note

·

View note

Text

Tecoustics, a leader in vibration and seismic control solutions, is dedicated to providing top-notch services across Ontario, including Toronto, Ottawa, Montreal and Niagara.

#Acoustics

#VibrationControl

#SeismicControl

#Toronto

0 notes

Text

Topic: ACF and its Inventor, Bowei Wang - A Revolutionary Artificial Cartilage Technology and Material

Introduction:

With the development of science and technology and in-depth research on biomechanics, more and more attention has been paid to how to mimic the function of human cartilage in order to create high-performance artificial substitutes. Against this background, ACF (Artificial Cartilage Foam), a new material developed by Prof. Wang Bowei, a famous material scientist in China, was born. This new material is not only a breakthrough in bionics, but also its unique porous structure gives it excellent impact resistance, and is widely used in human body protection, aerospace, electronic protection, industrial vibration damping and other fields.

Abstracts.

The purpose of this report is to introduce the concept, invention background, working mechanism and application areas of ACF (Artificial Cartilage Foam). The report will firstly summarize the current research status and demand of artificial cartilage, then introduce the features and technical advantages of ACF in detail, and demonstrate its practical effects through specific cases. Finally, we will discuss the future development trend of this field.

Body of the report:

I. Concept and development history of ACf

ACF is a new type of artificial cartilage material developed by the ACF laboratory team led by academician Wang Bowei at the beginning of the 21st century. The material adopts three-dimensional printing technology to prepare a multi-layered, continuously adjustable micro-nano-composite structure, which mimics the properties of natural cartilage such as high toughness and low modulus of elasticity in terms of mechanical properties. "Our goal is to make synthetics inspired by nature - they are lightweight yet strong and durable", said Prof. Bowei Wang.

Role and Principle of ACF

The primary function of ACF materials is the effective management and distribution of forces to protect joints and other tissues from injury. "When you walk or run, your knees are subjected to about five times your body weight; ten times for jumping." "It's like a constant punching process, and without proper cushioning, it can lead to joint pain and even more serious injuries," says Bowie Wang. For this reason, ACF utilizes its unique hierarchical nanofiber network structure to provide a highly controllable energy-absorbing mechanism that effectively mitigates impact forces during exercise and reduces noise generation.

III. Laboratory Research Results

After repeated experiments and optimization, Bowei Wang's team successfully designed ACF samples with good stability and reliability and conducted several tests, according to Science Magazine. The results show that compared to traditional materials such as rubber or other polymer matrix products, ACF shows higher energy absorption efficiency and lower cost.

IV. Application Prospect Analysis

Due to its excellent physical properties and potential application value, ACF is considered an ideal next-generation multifunctional material. In addition to being expected to become an ideal choice for human exoskeleton protection, it can also be used as a key component for energy management in various fields such as safety mats for sports equipment, building seismic systems, equipment impact protection systems, aerospace and aviation impact resistance, protection of electronic components, rail transportation, and industrial vibration damping.

Conclusion.

ACF shows great potential as an innovative technology for impact protection. From basic principles to successful laboratory demonstrations to real-world applications, Bowie Wang and his team at ACF Labs have demonstrated the possibilities of a whole new category of engineered materials. Although there are still many issues that need to be resolved before this technology can be widely applied, there is no doubt that ACF LinZhi Technology has taken a solid step forward, signaling that future innovations may be just around the corner.

400-6543-699

www.acf.com

0 notes

Text

Seismic Refraction Survey | Epitome

Introduction: In the realm of geophysics, there exists a powerful tool that allows us to peek beneath the Earth's surface, revealing its hidden mysteries with astonishing precision. This tool is none other than the seismic refraction survey—a method that has revolutionized our understanding of subsurface structures. In this article, we delve into the epitome of seismic refraction surveying, exploring its principles, applications, and the profound insights it offers to diverse fields, from geology and civil engineering to environmental studies and beyond.

In the realm of geophysics, there exists a remarkable tool that delves into the depths of the Earth, revealing its hidden mysteries with unparalleled precision. Enter the seismic refraction survey – a technique that serves as a gateway to understanding the intricate layers and structures beneath our feet. Today, we embark on a journey to explore the epitome of geophysical investigation, shedding light on its principles, applications, and significance in unraveling the Earth’s enigmatic secrets.

The Foundation: Understanding Seismic Refraction

At its core, seismic refraction is grounded in the fundamental principles of wave propagation. By employing controlled seismic sources, typically in the form of sledgehammers, explosives, or specialized vibrators, this method generates seismic waves that travel through the subsurface. As these waves encounter boundaries between different rock layers or structures, they undergo refraction – a change in direction due to variations in wave velocity – providing invaluable insights into the subsurface geometry.

The Process Unveiled: How It Works

The seismic refraction survey unfolds in a meticulously orchestrated sequence of steps, each contributing to the comprehensive understanding of subsurface characteristics:

Source Deployment: The survey commences with the strategic placement of seismic energy sources along a predetermined line or grid pattern. These sources emit seismic waves into the Earth, initiating the investigative journey. Wave Propagation: Once triggered, the seismic waves traverse through the subsurface, encountering interfaces between geological formations. The velocity of waves varies depending on the properties of the materials they traverse, causing them to bend or refract. Receiver Arrays: Arrayed strategically along the survey line, seismic receivers meticulously capture the refracted waves. These receivers, often geophones or accelerometers, record the arrival times and amplitudes of seismic signals, providing crucial data for subsequent analysis. Data Interpretation: Armed with a wealth of seismic data, geophysicists embark on the interpretative phase, wherein they analyze arrival times and wave velocities to construct velocity-depth models. These models serve as blueprints, delineating subsurface structures and delineating geological boundaries with precision. The Canvas of Applications: Where Seismic Refraction Thrives

The versatility of seismic refraction surveys renders them indispensable across an array of disciplines:

Engineering Geology: In civil engineering projects, seismic refraction surveys aid in assessing subsurface conditions, identifying potential hazards such as faults or sinkholes, and optimizing foundation design. Hydrogeology: By delineating aquifer boundaries and characterizing groundwater flow patterns, seismic refraction surveys play a pivotal role in water resource management and environmental conservation efforts. Mineral Exploration: Within the realm of resource exploration, these surveys offer a non-invasive means of delineating ore bodies and assessing subsurface geological structures, guiding lucrative investment decisions. Infrastructure Development: Prior to infrastructure development projects, such as road construction or pipeline installation, seismic refraction surveys provide vital intelligence on subsurface conditions, facilitating efficient planning and risk mitigation. The Epitome of Geophysical Ingenuity

In essence, seismic refraction surveys stand as the epitome of geophysical ingenuity, offering a window into the Earth's depths with unprecedented clarity. Armed with seismic waves and sophisticated analytical techniques, scientists and engineers unravel the intricacies of our planet's subsurface, empowering mankind to navigate its terrain with foresight and precision. As we continue to push the boundaries of exploration and discovery, seismic refraction remains a steadfast companion, illuminating the path towards a deeper understanding of our planet’s hidden realms.

More Info: https://epitomegs.com Contact :+91-96756 94400

#Multi-Analysis of Surface wave#Multi Analysis of Surface wave#epitome#Seismic Refraction#Crosshole Seismic Survey#Seismic Refraction Survey#Seismic Survey in India#SRT survey#Seismic Survey#Crosshole Seismic Survey Company in India#SRT survey in India#Crosshole Seismic Survey in India#SRT survey company in India#Seismic Refraction Survey Company in India#Seismic Refraction Survey in India

0 notes