#Spherical Bearing

Explore tagged Tumblr posts

Text

What Are Pot PTFE Bearings and Why Are They Essential for Your Projects?

Pot PTFE bearings are specialized components designed for various engineering applications, particularly in construction and infrastructure projects. These bearings play a crucial role in ensuring the stability and longevity of structures by allowing for controlled movement and load distribution. In this blog post, we'll explore what Pot PTFE bearing are, their unique features, and their benefits in comparison to other bearing types, including spherical bearings and UHMWPE bearings.

What is a Pot PTFE Bearing?

Definition: A Pot PTFE bearing consists of a cylindrical pot filled with a polytetrafluoroethylene (PTFE) liner, which provides a low-friction surface for moving parts. It allows for angular movements and accommodates rotations while supporting vertical loads.

Design: The design typically includes a metal housing that contains a spherical PTFE disc. This spherical shape facilitates movement in multiple directions, providing flexibility in various applications.

Key Features of Pot PTFE Bearings

Low Friction: The PTFE liner significantly reduces friction between the bearing surfaces, resulting in smoother operation and reduced wear.

Corrosion Resistance: Pot PTFE bearings are resistant to chemicals and environmental factors, making them suitable for harsh conditions.

Durability: These bearings have a long service life due to their robust construction and material properties.

Versatility: Pot PTFE bearings can be used in a wide range of applications, from bridges to industrial machinery.

Benefits of Using Pot PTFE Bearings

Enhanced Performance: The low-friction properties of PTFE bearings lead to improved efficiency in moving parts, reducing energy consumption.

Maintenance-Free Operation: Unlike traditional bearings that require regular lubrication, Pot PTFE bearings often operate without maintenance, saving time and resources.

Adaptability: These bearings can accommodate various loads and movements, making them ideal for dynamic applications.

Pot PTFE Bearings vs. Other Bearings

When comparing Pot PTFE bearings to other bearing types such as spherical bearings and UHMWPE bearings, it's essential to consider their unique advantages.

Spherical Bearings:

These bearings provide high load-bearing capabilities and can accommodate angular misalignments. However, they may require more frequent maintenance due to increased friction.

Pot PTFE bearings offer a smoother operation and longer lifespan compared to spherical bearing, making them a preferable choice for long-term projects.

UHMWPE Bearings:

Ultra-high-molecular-weight polyethylene (UHMWPE) bearings are known for their impact resistance and low wear characteristics. However, they may not provide the same level of low friction as PTFE.

In applications where extreme temperature variations and chemical exposure are a concern, Pot PTFE bearings outperform UHMWPE bearings due to their superior chemical resistance and stability.

Applications of Pot PTFE Bearings

Pot PTFE bearings are utilized across various industries and applications, showcasing their versatility and effectiveness:

Bridges: Used to allow for controlled movement and load distribution, ensuring structural integrity.

Industrial Machinery: Helps in reducing friction and wear in moving parts, improving overall efficiency.

Marine Applications: Their corrosion resistance makes them ideal for use in environments exposed to water and harsh conditions.

Seismic Isolation: Pot PTFE bearings can accommodate movements caused by earthquakes, providing additional safety and stability.

Conclusion

In conclusion, Pot PTFE bearings are an essential component for ensuring the efficiency and durability of various engineering applications. Their unique properties, such as low friction, corrosion resistance, and adaptability, make them a superior choice compared to other bearing types like spherical bearings and UHMWPE bearings. By understanding the advantages and applications of Pot PTFE bearings, engineers and project managers can make informed decisions that lead to successful outcomes in their projects.

For more information on Pot PTFE bearings and other engineering solutions, visit Metal Engineering. Explore how our products can help you achieve optimal performance and reliability in your projects.

0 notes

Text

In the realm of industrial technology, Igus stand as a beacon of innovation and reliability. Igus is a manufacturer of high-performance polymers for movement based in Cologne, Germany. We have been developing and producing motion plastics – innovative products made of lubrication-free plastics – since 1964. They include energy chains, cables, plain bearings, lead screw technology, robots, and intelligent sensors that help our customers improve their technology and cut costs.

Visit us at: https://www.igus.in/ Call: +91-80-69116900 [email protected]

#Cable Carriers#Spherical Bearing#Bearing Technology#Motion Control#Robotics Innovation#Automation Solutions#Robotics Technology

0 notes

Text

Bearing & Tools Syndicate - Trusted Bearings Distributors in India. https://www.btsbearings.com/

1 note

·

View note

Note

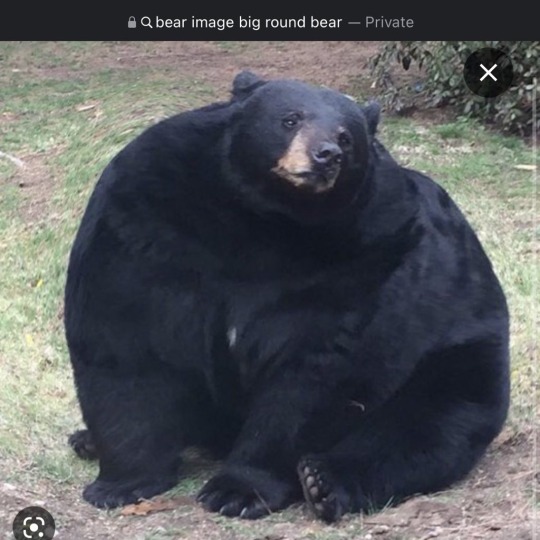

can i see your roundest bear?

well it is Fat Bear Friday

576 notes

·

View notes

Text

now that i have a chance to post this LOOK WHAT I FOUND AT THE THRIFT STORE YESTERDAY

I found songbird in one of the stuffed animal bins and then my mom found rainbow dash hanging up on a rack. They’re both build a bears from the MLP movie, and had no stains or anything!! I only ended up getting rainbow dash cause I wanted to give her better fabric hair and even though songbird had cool wings, I didn’t actually know who she was when I first saw her… I kinda wanted to get her and make her into like, a custom apple bloom or something cause the coat color is similar, but i also have no clue how to remove the factory embroidery without damaging the fabric. and lets be real idk if I would ever actually get around to doing all that

Anyways I now have a fluttershy and rainbow dash build a bear from two separate thrift stores… my army grows… (that’s a joke i don’t plan on getting anymore)

#me rambling#i cannot help that my mlp fixation never truly left since 5th grade#i had gotten a ty rainbow dash plushie at a yard sale and told myself i wasn’t gonna redo her hair like im doing with flutteryshy#cause of all the minky i’ll need to order#but NOW i have the build a bear and her hair cannot be satiated with just a brush rubber bands and spite#however it’s also a lot less matted than fluttershys was so i’m not in a rush to start looking#i’ll probably post what fluttershy looks like when she’s done cause i’m realizing now i ever posted her here#she’s a little silly looking but i love her#i think she’ll look a lot better with the right mane style cause this one is not hiding how spherical her head is#i may be crazy but i am free

6 notes

·

View notes

Text

Just remembered im good at crochet

I need to make a beebo plushie

#i need to look up designs for little guys#then just wing it i guess#my crochet credentials: scarf. mittens. multiple granny squares. teddy bear. spherical little guy with feet#i dont have the colors but i have the power

10 notes

·

View notes

Text

mop

4 notes

·

View notes

Text

Well I sure have now

Have you seen him

5K notes

·

View notes

Text

Marc Bearings is the leading Manufacturer of Spherical and Tapered Roller Bearings. We at Marc Bearings Pvt. Ltd., Rajkot, Gujarat, India, manufacture, supply, and export extensive range of spherical, tapered, and cylindrical roller bearings along with the 1300+ types of bearings to both Indian as well as international customers, as we have our presence in more than 15 countries around the world. We are known for delivering these at nominal prices, with premier quality and exceptional durability. For more details: https://marcbearings.com/bearing/

0 notes

Text

KEC Bearings stands out as a premier manufacturer of plain spherical bearings. Renowned for their dedication to precision and quality, KEC Bearings delivers robust and dependable bearing solutions for a wide array of industrial uses. Their comprehensive selection of spherical plain bearings guarantees exceptional performance and durability, adhering to the highest industry standards.

#plain spherical bearings manufacturer#plain spherical bearing#plain spherical bearing supplier#plain spherical bearing exporter

0 notes

Text

Top Spherical Bearings Supplier in Delhi

Spherical bearings are a type of bearing that allow rotation around a central point in two directions that are perpendicular to each other. A spherical bearing is a bearing that permits rotation about a central point in two orthogonal directions (usually within a specified angular limit based on the bearing geometry).The Spherical Bearing is a structural bearing which consists of a set of concave & convex mating steel backing plate with a low friction sliding interface in between thereby permitting rotation by incurve sliding. As a leading Spherical Bearings Supplier, Shiv Sai Bearing is committed to delivering top-notch components that meet the highest industry standards. Our extensive range of spherical bearings, including the ITB-C1BE3DBC, is selected to provide optimal performance and reliability for your specific applications. Located in Delhi, Shiv Sai Bearing combines local expertise with a global perspective to offer premium spherical bearings and outstanding customer service.

For more details clicks here - https://www.shivsaibearing.in/delhi/spherical-bearings/ITB-C1BE3DBC

0 notes

Text

How Can Steel Mill Transfer Cars Improve Efficiency in Industrial Operations?

Steel mill transfer cars are vital components in the steel production process, playing a significant role in transporting heavy loads across the mill. These robust, durable machines are designed to move materials such as steel coils, slabs, billets, and more with ease and precision. In this blog, we will explore the importance of steel mill transfer cars, their benefits, and the role of advanced equipment like Shock Transmission Units (STUs) in enhancing their performance.

What Are Steel Mill Transfer Cars?

Steel mill transfer cars are specialized vehicles designed to transport heavy loads within a steel mill. They offer:

Enhanced safety for workers by reducing manual labor

Efficient transportation of materials over long distances

Customizable designs to meet the specific needs of each steel mill

Durability to withstand the harsh conditions of steel production environments

The primary goal of these transfer cars is to boost efficiency and safety in steel mills. These machines come in various types, including electric, battery-powered, and rail-mounted, depending on the specific requirements of the operation.

The Importance of Steel Mill Transfer Cars in Operations

Steel mill transfer cars play a critical role in the efficiency of production. Without these cars, steel mills would rely on manual labor or less efficient methods of material transportation, leading to:

Increased risk of injury for workers

Lower production rates

Higher operational costs due to time-consuming manual transport

Increased wear and tear on equipment from frequent use

By using steel mill transfer cars, steel production becomes smoother, faster, and more reliable. These cars can handle extreme weights and transport materials safely, reducing the need for excessive manpower.

Benefits of Using Steel Mill Transfer Cars

Steel mills benefit in numerous ways from incorporating transfer cars into their production process, including:

Increased Safety: Steel mill transfer cars minimize the risk of accidents and injuries by automating the transport of heavy materials.

Cost Efficiency: These machines reduce the need for manual labor, which cuts down on operational costs.

Improved Productivity: Transfer cars can quickly and efficiently move materials across the mill, boosting overall production speed.

Durability: Built to withstand harsh environments, transfer cars offer long-lasting performance.

By enhancing the transportation of steel products, transfer cars contribute significantly to the overall productivity and profitability of the mill.

The Role of Shock Transmission Units (STUs) in Steel Mill Transfer Cars

One of the most critical innovations in improving the performance of steel mill transfer cars is the integration of Shock Transmission Unit (Stu). These units are designed to absorb and control the forces generated during the transportation of heavy loads, ensuring smoother and safer operations. STUs are especially valuable in high-impact scenarios where the shock and vibrations can damage both the materials being transported and the equipment itself.

Shock Absorption: STUs help in minimizing the impact on the car when transporting heavy steel loads.

Extended Equipment Life: By reducing vibrations and shocks, STUs can extend the lifespan of steel mill transfer cars and other machinery.

Improved Safety: The integration of STUs enhances the safety of operations by minimizing sudden jolts or shocks that could lead to accidents.

Incorporating Shock Transmission Units (STUs) into transfer cars ensures that they operate more smoothly and with less wear and tear, ultimately improving the efficiency of the entire steel production process.

Customization and Advanced Features in Steel Mill Transfer Cars

Steel mill transfer cars are highly customizable to meet the unique needs of each production facility. Depending on the specific requirements, transfer cars can be outfitted with:

Automated Controls: For improved precision and efficiency

Load-Sensing Technology: To monitor and adjust for different load weights

High-Capacity Batteries: For longer operational periods in battery-powered models

Robust Shock Transmission Units (STUs): To protect the car and its cargo from damage during transportation

These features, combined with the integration of modern technology, make steel mill transfer cars an indispensable tool in steel production facilities.

Why Invest in Steel Mill Transfer Cars?

For any steel mill looking to improve its efficiency, investing in steel mill transfer cars is a must. The benefits extend far beyond simple material transportation. They lead to:

Increased Operational Efficiency: By automating and streamlining material transport, production rates can be significantly improved.

Enhanced Worker Safety: Transfer cars reduce the physical strain on workers and minimize the risks associated with manual material handling.

Long-Term Savings: With reduced labor costs and improved equipment longevity, transfer cars offer long-term financial benefits.

In addition, the use of advanced components like Shock Transmission Units (STUs) further enhances the value of these cars, ensuring smoother operations and less downtime due to equipment failure.

Conclusion

Steel mill transfer cars are essential for modern steel production, offering numerous benefits in terms of efficiency, safety, and cost-effectiveness. With the addition of Shock Transmission Units (STUs), these cars become even more effective at transporting heavy loads with minimal impact on the equipment and materials. If your steel mill is looking to improve its productivity and operational safety, investing in steel mill transfer cars with advanced features like STUs is a wise choice.

For more information on steel mill transfer cars and their customization options, visit Metal Engineering.

#Steel Mill Transfer Car#Shock Transmission Unit (Stu)#Pot Bearing#Pot Ptfe Bearing#Spherical Bearing

0 notes

Text

Igus is a manufacturer of high-performance polymers for movement based in Cologne, Germany. We have been developing and producing motion plastics – innovative products made of lubrication-free plastics – since 1964. They include energy chains, cables, plain bearings, lead screw technology, robots, and intelligent sensors that help our customers improve their technology and cut costs.

Visit us at: https://www.igus.in/ Call: +91-80-69116900 [email protected]

#Cable Carriers#Spherical Bearing#Bearing Technology#Motion Control#Robotics Innovation#Automation Solutions#Robotics Technology

0 notes

Text

0 notes

Text

Decent Machinery: Your Reliable Partner for High-Quality Bearings

Decent Machinery introduces premium spherical roller bearings, engineered to elevate your machinery's performance. Our bearings are designed to withstand heavy loads and operate in harsh conditions, ensuring reliability and durability. Experience smooth rotation and reduced friction, enhancing the efficiency of your machinery. Trust Decent Machinery for superior quality and precision in every spherical roller bearing.

0 notes

Text

Get an in-depth look at the different parts that comprise a spherical roller bearing and their respective roles in ensuring reliable, high-load performance.

0 notes