#vial filling and capping machines

Explore tagged Tumblr posts

Text

Vial Filling, Stoppering & Cap Sealing Machine

Vial Filling, Stoppering & Cap Sealing Machine is preferred choice for filling and capping small vials containing injectables such as antibiotics. These devices are renowned for their extraordinary features, which allow them to do necessary tasks like filling, capping, and sealing operations on one single platform similar to a cake walk. Due to such nature of equipment it is called Monoblock vial filling, stoppering and capping machine.

A leading manufacturer of vial filling and capping machines in India, Adinath International offers vial filling capping combi machines with unique mechanical configurations for accurate, dependable, and stable plugging and capping arrangements. These devices, which can handle several vials per minute, are extensively used in the pharmaceutical sector. Both sterile and non-sterile applications can make use of them. There are option of two different types of filling mechanism in the machine in which one is piston pump type filling and another is peristaltic pump type filling. We can offer any of filling option as per user requirements.

Adinath International, a top provider of vial filling and sealing machine, provides a range of vial filling machines with various capacities so you can select the one that best suits your needs.

Automatic two head vial filling machine

Automatic four head vial filling machine

Automatic six head vial filling machine

Automatic eight head vial filling machine

Small vial filling machine

#vial filling and capping machines#vial filling capping combi machines#vial filling and sealing machine

0 notes

Text

Filling and Capping Machines: Revolutionizing Packaging Efficiency

In today's fast-paced manufacturing industry, efficiency and precision are paramount. One crucial aspect of production lines is the packaging process, which involves filling containers with products and securely sealing them. To streamline this process and enhance productivity, filling and capping machine has emerged as indispensable tools.

What are Filling and Capping Machines?

Filling and capping machines are automated systems designed to accurately fill containers with various products, ranging from liquids and powders to pastes and creams. These machines then apply caps or closures to the filled containers, ensuring airtight seals and product integrity.

Key Components of Filling and Capping Machines

Filling System:

Piston Fillers: Ideal for viscous products like creams and ointments.

Time-Fillers: Suitable for liquids with consistent flow rates.

Net Weight Fillers: Ensure precise filling by weight, commonly used for powders and granules.

Volume Fillers: Fill containers to a specific volume, often used for liquids.

Capping System:

Press-On Cappers: Apply caps with a simple pressing motion.

Screw Cappers: Tighten caps with a rotary motion, ensuring a secure seal.

Plug Cappers: Insert plugs into containers, commonly used for bottles and vials.

Benefits of Using Filling and Capping Machines

Increased Efficiency: Automation significantly reduces labor costs and speeds up the packaging process.

Improved Accuracy: Precise filling and capping mechanisms minimize product waste and ensure consistent quality.

Enhanced Productivity: High-speed machines can handle large volumes of products, boosting overall output.

Consistent Quality: Automated systems maintain consistent quality standards, reducing the risk of defects.

Reduced Labor Costs: Fewer manual operators are required, leading to lower labor expenses.

Improved Safety: Automated machines reduce the risk of workplace injuries and accidents.

Factors to Consider When Choosing a Filling and Capping Machine

Product Type: The type of product being packaged will determine the appropriate filling and capping system.

Container Size and Shape: The size and shape of the containers will influence the machine's design and capacity.

Production Volume: The desired production rate will dictate the machine's speed and throughput.

Level of Automation: The level of automation required will depend on specific needs and budget constraints.

Maintenance Requirements: Consider the machine's ease of maintenance and the availability of spare parts.

By investing in reliable and efficient high speed liquid filling machines, manufacturers can optimize their packaging processes, reduce costs, and enhance overall productivity.

0 notes

Text

Walk-in Interview: Injectable Manufacturing – QA, Production, QC & Engineering | Vadodara & Ahmedabad Join at Zydus Lifesciences Greenfield Injectable Manufacturing Plant! Are you a talented professional looking to advance your career in the pharmaceutical industry? Here's an exciting opportunity to be part of our state-of-the-art injectable manufacturing plant in Ahmedabad (Changodar). We are seeking experienced professionals for various positions in Production, Engineering, Quality Control, Packing, and Quality Assurance. Job Details: Injectable Manufacturing Positions – Vadodara Walk-in Interview Location: Ahmedabad, Gujarat, India Division: Fill and Finish (Injectable Manufacturing Plant) Job Posted On: October 09, 2024 Walk-in Interview Date: Sunday, October 20, 2024 Timings: 9:30 AM to 5:00 PM Venue: Four Points by Sheraton Vadodara, 1275, Ward No 7, Fatehgunj, Vadodara 390002, India Available Roles and Requirements 1. Production Operator (Autoclave, Filling, Compounding, Washing/Tunnel/Capping & Lyophilizer) Qualifications: D.Pharm / DME / ITI Experience: 1 to 7 years Responsibilities: Operate production machines such as Autoclave, Filling, Compounding, Washing, Capping, and Lyophilizer in the manufacturing unit. Shift In Charge Qualifications: B.Pharm / M.Pharm / B.E / B.Tech Experience: 6 to 10 years Responsibilities: Supervise and control production areas, including aseptic filling, vial washing, autoclaving, and lyophilization. Experience with machine qualification activities is a plus. 2. Engineering Process Maintenance – Operator Qualifications: Diploma / ITI Experience: 1 to 6 years Responsibilities: Maintain and operate HVAC systems, AHUs, water systems, and process equipment. Handle breakdowns, instrumentation, and process equipment calibration. 3. Quality Control (QC) QC Microbiology Officer/Executive Qualifications: M.Sc. (Microbiology) Experience: 1 to 6 years Responsibilities: Conduct media and culture management, MLT, bio-burden tests, water sampling and testing, environmental monitoring, and qualification of instruments for injectable dosage forms. QC Biotech (Analyst) Qualifications: M.Sc. / M.Tech Experience: 2 to 4 years Responsibilities: Perform analysis of biotechnological products (recombinant proteins, monoclonal antibodies) using HPLC, Electrophoresis, etc. QC Chemical (Analyst) Qualifications: B.Pharm / M.Sc. Experience: 2 to 4 years Responsibilities: Conduct chemical analysis using HPLC, GC, and other analytical instruments. Experience in stability studies and bioassay is required. 4. Packing Packing Operator Qualifications: D.Pharm / DME / ITI Experience: 1 to 7 years Responsibilities: Operate and troubleshoot packing line machines like vial labeling, blister, cartonator, and track and trace systems. Packing Shift In Charge Qualifications: B.E / B.Tech / B.Pharm Experience: 2 to 7 years Responsibilities: Supervise packing operations, including handling automatic packing lines for PFS, vial, and cartridge. 5. Quality Assurance (QA) Executive/Senior Executive (IPQA/Validation/Analytical QA) Qualifications: B.Pharm / M.Pharm / M.Sc. Experience: 2 to 8 years Responsibilities: Handle IPQA, validation, qualification, and analytical QA activities for the injectable manufacturing plant. [caption id="attachment_58045" align="aligncenter" width="930"] Zydus Biologics Job Openings for Production Department[/caption] Candidate Requirements Strong understanding of cGMP documentation and guidelines. Familiarity with cGMP requirements for injectable manufacturing. Excellent attention to detail and ability to work in a team-oriented environment. Walk-in Interview Details Date: Sunday, October 20, 2024 Time: 9:30 AM to 5:00 PM Venue: Four Points by Sheraton Vadodara, 1275, Ward No 7, Fatehgunj, Vadodara 390002, India What to Bring: Updated CV Latest passport-sized photo Salary slip Relevant documents

0 notes

Text

Pharmaceutical Filling Machines and their Applications

The pharmaceutical industry relies on accurate and efficient technology to deliver life-saving treatments. One crucial component in this process is the pharmaceutical filling machine. These machines play a vital role in ensuring accurate and consistent dosing of medications into various containers, from tablets and capsules to vials and syringes.

Pharmaceutical Filling Machines

From Powders to Liquids, Filling Every Need

Pharmaceutical filling machines are the workhorses of pharmaceutical production. They automate the process of filling pre-determined quantities of medication into specific containers. This not only ensures accuracy and consistency but also significantly increases production speed compared to manual filling. These machines are designed to handle a wide range of products, from delicate powders and tablets to viscous liquids and creams.

The Uses of Pharmaceutical Filling Machines

Ensuring Sterility and Streamlining Production

The applications of pharmaceutical filling machines extend far beyond simply filling containers. Many machines are equipped with features that ensure the sterility of the filling process, a critical factor in maintaining the safety and efficacy of medications. Additionally, some filling machines can be integrated with other equipment such as capping and labeling machines, creating a streamlined production line for maximum efficiency.

Types of Pharmaceutical Filling Machines: A Machine for Every Need

Pharmaceutical Filling Machines Manufacturer in India

At Lodha Machines, we understand the diverse needs of the pharmaceutical industry. That's why we offer a wide range of pharmaceutical filling machines. We manufacture Pharmaceutical Filling Machines in India and offer a variety of pharma machines, including:

Liquid Filling Machines: Liquid Filling Machines ensure accurate and efficient filling for medications with various viscosities, from thin liquids like mouthwashes to thicker syrups and suspensions. These machines utilize different filling methods depending on the product's properties, ensuring consistent dosing for every container.

Powder Filling Machines: Designed for precise dosing of powdered medications, Powder Filling Machines can handle a wide range of powder flow characteristics. They often employ auger filling systems or volumetric dosing techniques to accurately measure and fill powders into capsules, tablets, and other dry dosage forms.

Injectable Liquid Filling Machines: Injectable Liquid Filling Machines are crucial for maintaining the sterility and safety of injectable medications. They incorporate features like laminar airflow systems and sterilized filling nozzles to ensure aseptic filling of syringes and vials with liquid pharmaceuticals.

Dry Syrup Filling Machines: Efficiently handle the unique flow properties of dry syrups, which can be both light and fluffy yet prone to clumping. Dry Syrup Filling Machines utilize specialized filling techniques to ensure accurate and consistent dosing, preventing issues like underfilling or product bridging within the container.

Syrup Filling Machines: Ideal for filling various types of syrups and suspensions, Syrup Filling Machines offer versatility for handling liquids with a range of viscosities. They often utilize volumetric filling principles or pump systems to ensure consistent and accurate dosing for each container, maintaining the intended concentration of the medication.

Ointment Filling Machines: Precisely dispense ointments, creams, and gels, ensuring consistent product delivery for topical medications. Ointment Filling Machines handle viscous materials with ease, employing filling techniques like piston pumps or volumetric dosing systems to accurately fill tubes, jars, or other containers.

Tablet and Capsule Filling Machines: High-speed machines for accurate counting and filling of tablets and capsules. Lodha Machines, a leading capsule filling machine manufacturer, offers a variety of options to suit your needs, from basic capsule fillers to high-capacity machines with automated counting and sorting systems (capsule filling machine price may vary depending on features).

Capping and Sealing Machines: Securely seal containers after filling, ensuring product integrity and preventing contamination. Capping and Sealing Machines are comes in various configurations, from simple capping machines for applying lids to more complex sealing systems that utilize heat, pressure, or a combination of both to create a tamper-evident seal.

Sticker Labeling Machines: Apply labels for product identification and information. Sticker Labeling Machines integrate seamlessly with filling lines, automatically placing labels on containers with precise positioning and ensuring consistent application. They can handle various label types and sizes, providing essential product information for patients and healthcare professionals.

Ampoule Filling Machines: Designed for the specific requirements of filling ampoules, which are fragile glass vials used for sterile injectable medications. Ampoule Filling Machines handle ampoules with care, employing gentle filling processes and sterilized environments to maintain product sterility and prevent breakage.

Vial Filling Machines: Efficiently fill vials of various sizes, used for a wide range of liquid and powdered medications. Vial Filling Machines offer versatility, accommodating different vial sizes and ensuring consistent filling levels. They may utilize volumetric filling methods or pump systems depending on the product's characteristics.

Sterile Filling Machines: Maintain a sterile environment throughout the filling process, critical for injectable medications and other pharmaceuticals requiring aseptic conditions. Sterile Filling Machines incorporate advanced features like laminar airflow systems, HEPA filters, and sterilized filling components to prevent contamination throughout the filling process.

Conclusion

One stop solution for Pharmaceutical Machinery

Pharmaceutical filling machines are a critical investment for any pharmaceutical company. They ensure the accuracy, efficiency, and sterility of medication production. Lodha Machines, a trusted pharmaceutical machinery manufacturer company that are offering variety of pharma machine in india, including tablet making machine manufacturers and Powder Filling Machine, offers a comprehensive range of filling machines to meet your specific needs. Contact Lodha Machine today to discuss how our machines can help you streamline your production process and deliver life-saving medications with confidence.

If you have any questions regarding the filling machines for pharmaceutical industry, please visit our site or contact our team at Lodha Machine at [email protected] or +91-9687731331, +91-9687631331.

#Pharmaceutical Filling Machines#Top Pharmaceutical Filling Machines#Pharmaceutical Filling Machines Manufacturer#Pharmaceutical Filling Machines in India

0 notes

Text

Comprehensive Guide to Modern Packaging Machinery

Injectable Vial Filling Machine Line The Injectable Vial Filling Machine Line is designed to efficiently handle the process of filling liquid drugs into vials with precision and sterility. injection vial filling machine are critical in pharmaceutical production environments where maintaining product integrity and adhering to strict regulatory standards are paramount. They often feature advanced technologies such as robotic systems, integrated vision inspection, and high-speed filling capabilities. The versatility and customization options allow for handling various vial sizes and product viscosities, making them ideal for a range of pharmaceutical applications, from small-volume drugs to large-scale vaccine production.

Injectable Powder Filling Machine The Injectable Powder Filling Machine stands out for its ability to accurately dispense powdered pharmaceuticals into containers. This machine is essential for products that require high levels of precision and contamination-free environments, such as antibiotics and hormone treatments. It typically incorporates advanced dosing technologies and can be adapted to various powder properties, ensuring consistent fill weights. Additionally, these machines are designed to integrate seamlessly with other line components, providing a streamlined and efficient production flow.

Ampoule Filling & Sealing Machine Line Ampoule Filling & Sealing Machine Lines are specialized in handling the delicate process of filling and sealing ampoules. These machines are crucial for ensuring the sterility and integrity of high-potent solutions, often used in hospital and emergency settings. They are equipped with mechanisms to precisely fill liquid at high speeds and seal the ampoules hermetically, often under inert gas atmospheres to protect sensitive solutions from oxidation and degradation. Their robust design and precise control systems ensure high throughput and minimal product waste.

Dry Syrup Powder Filling Machine Line The Dry Syrup Powder Filling Machine Line is specifically engineered to fill dry syrup powder into bottles efficiently and with minimal exposure to contaminants. This line is particularly important for pediatric medications and dietary supplements, where dosage accuracy is crucial. The machines typically feature auger or vacuum-based filling systems to handle various powder granularities and flow characteristics. Integration with capping and labeling solutions makes the dry syrup powder filling machine line a complete solution for dry powder packaging needs.

Liquid Filling Machine Line The Liquid Filling Machine Line is versatile and can be used across various industries, including pharmaceuticals, cosmetics, and food and beverages. Injectable liquid filling machine are designed to fill liquids with different viscosities into containers of assorted shapes and sizes. With options for volumetric or gravimetric filling, injectable liquid filling line ensure high precision and minimal product waste. The incorporation of cleaning-in-place (CIP) systems and compatibility with sterile filling processes makes them ideal for sensitive and high-purity liquid products.

Tube Filling Machine Tube Filling Machines are essential for packaging semi-solid products, such as creams, ointments, and gels, in soft collapsible tubes. They ensure accurate dosing and sealing under hygienic conditions, crucial for pharmaceutical and cosmetic products. Tube filling Machine can accommodate a wide range of tube materials and sizes, and they often include features such as hot-air sealing systems and high-speed filling capabilities. The ability to provide tamper-evident seals and aesthetic finishing options like embossing makes these machines highly valuable in their respective markets.

Tablet Counting Machine Labeling Machines play a pivotal role in the packaging lines of various industries by applying labels precisely and efficiently to a wide range of products and packaging types. These machines are designed to handle different label materials and adhesives, providing high-quality labeling solutions that comply with branding and regulatory information requirements. Advanced features like real-time barcode verification and integration with digital printing technologies allow for high customization and flexibility in label design and application.

Cartoning Machine Cartoning Machines are designed to automatically erect, fill, and close cartons with high efficiency and accuracy. These machines are vital in industries ranging from pharmaceuticals to consumer goods, where they enhance packaging integrity and production line speed. Capable of handling a variety of carton designs and sizes, these machines often integrate with other line equipment to provide a seamless packaging process. They may also include features such as leaflet insertion and batch code printing, adding to their functionality and value in comprehensive packaging solutions.

0 notes

Text

Zonesun is a manufacturer of cap sealing machinery, with a variety of cap sealing machines, including manual, semi-automatic, and fully automatic. There are linear and rotary capping machines. The application fields are also very wide, including beer, red wine, perfume, vials, and other capping machines. Moreover, ZONESUN can connect the capping machine, filling machine, labeling machine, and boxing machine together to form a complete set of packaging equipment, making your production easier.

0 notes

Text

Automatic Rotary Vial filling and capping machine

Automatic Rotary oil Vial filling and capping machines:The equipment is automatic filling and capping machine, which makes the high-viscosity filling and ordinary pressure filling into one.

0 notes

Text

Automatic Screw Capping Machine in Sharjah

Automatic Screw Capping Machine in Sharjah: Shiv Shakti Machtech: Shiv Shakti Machtech is a renowned creator and producer of turnkey packaging systems. Through constant client collaboration, Shiv Shakti Machtech has amassed a substantial understanding of liquid filling procedures. What is an Automatic Screw Capping Machine? They design an Automatic Screw Capping Machine as a mechanical device to apply screw caps onto containers, such as bottles, jars, and vials, automatically. It utilizes a conveyor system to transport containers through the capping process, where it securely tightens caps onto the containers using precise torque control. Key Features of the Automatic Screw Capping Machine High Precision These machines are equipped with torque control mechanisms to ensure consistent and precise capping, preventing over-tightening or under-tightening of caps. Versatility Automatic Screw Capping Machines can handle a variety of container shapes and sizes, making them adaptable to different packaging requirements. Speed and Efficiency They offer rapid capping capabilities, significantly increasing production efficiency and throughput. Customizable Many models are customizable to accommodate specific cap types, container materials, and production line configurations. User-Friendly Interface Modern machines often feature user-friendly touchscreens for easy setup, monitoring, and adjustments. We Provide Automatic Screw Capping Machine in Sharjah Including Dibba Al-Hisn, Abu Musa, Khor Fakkan, Sir Abu Nu'ayr, Nahwa, Al Khan, Kalba, Ar Rufaysah, Hasat Al Bidiyah, Hizayib Az Zanah, Ghayl, Sharjah, Tarif Kalba, Al Jazirah, Sharjah, Wadi Shi, Lulayyah, Sahanah, Minazif, Hiyawah, Ghunah, Shis, Rafa', Hayat, Sharjah, Al Hamriya Etc. Read the full article

1 note

·

View note

Text

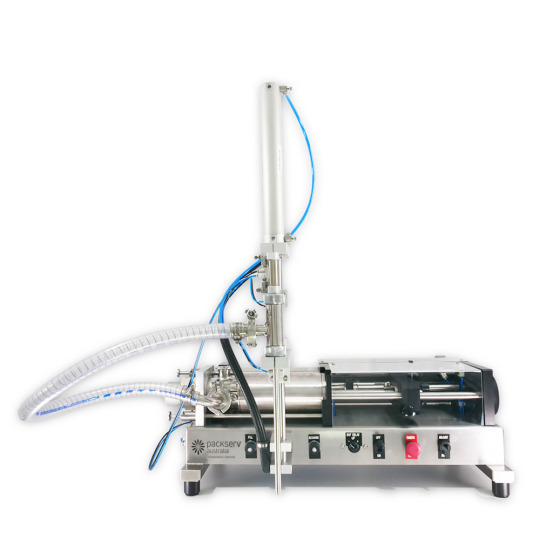

Small Vial Filling Machine

Small Vial Filling Machine uses to fill vials for pilot batch production requirements in injectable pharmaceuticals. This small monoblock machine is having 3 operations on single platform. Due to 3 operations filling, rubber stoppering and cap sealing on single platform it is also called as 3 in 1 vial filling machine. Machine is suitable for wide range of vials from 2ml to 100ml vial sizes and provide production output up to 20 vials per minute.

In contrast to traditional piston pump type filling, peristaltic pump type filling is more recent to be adopted in the pharmaceutical business. The benefit of filling with a peristaltic pump is that there is very little possibility of contamination because the liquid only comes into contact with silicon tubing, which can be changed after each batch. Also, compared to other types of fillings, the number of pieces needed for autoclaving is extremely low.

As a producer of vial filling machines using Peristaltic pumps, we offer a variety of machine models with filling speeds ranging from 10 vials to 300 vials per minute. The peristaltic pump needs to be calibrated once for each type of liquid before the fill volume can be changed via the machine’s HMI panel. Depending on the needs of the client, this servo-driven vial filling machine is available with or without a stoppering unit. Peristaltic pumps with one or more channels can be installed based on the desired output and speed.

#vial filling machine#servo-driven vial filling machine#peristaltic pump type filling#vial filling and capping machines

0 notes

Video

tumblr

Automatic Vial Liquid Bottle Filling Stoppering Capping Machine Manufacturer | Sinoped

0 notes

Text

How does a liquid filling and capping machine work?

Liquid Filling and Capping Machine Demystified

Ever wondered how those neatly filled and sealed bottles of your favorite beverages or cosmetics come to be? The answer lies in the marvel of technology known as the liquid filling and capping machine. Let's take a closer look at how these machines work their magic:

Liquid Filling:

The process begins with the liquid filling part. The machine typically has a tank or reservoir where the liquid product is stored. A pump system or a gravity-based mechanism is used to transport the liquid from the tank into the bottles or containers.

Precision Measurement:

The liquid filling and capping machine ensures precise measurement of the liquid being dispensed into each bottle. This accuracy is essential to maintain consistency in product volume.

No Mess, No Waste:

These machines are designed to minimize spills and waste. They are equipped with nozzles or spouts that dispense the liquid smoothly into the containers, leaving little room for mess.

Container Transport:

Once the liquid is filled, the containers move along a conveyor belt or another transport system to the capping station. This movement is typically synchronized with the filling process for efficiency.

Capping Mechanism:

At the capping station, different capping mechanisms come into play. For screw caps, there are rotating wheels or chucks that tighten the caps onto the containers. Other capping methods, like snap caps or press-on caps, have their specialized mechanisms.

Tightness Control:

Liquid filling and capping machines often include sensors to monitor the tightness of the caps. This ensures that each container is securely sealed to prevent leakage or contamination.

Labeling and Inspection:

In some setups, labeling and inspection stations follow the filling and capping process. Labels are applied, and the containers are inspected for any defects or discrepancies.

Batch and Data Control:

Modern machines are often equipped with software that allows for precise control over batch sizes, filling levels, and data recording. This data helps manufacturers maintain quality control.

Variety of Containers:

These machines can handle a wide variety of containers, from bottles and jars to vials and tubes. They are adaptable to different shapes and sizes.

Speed and Efficiency:

Liquid filling and capping machines are known for their speed and efficiency. They can fill and cap hundreds of containers per minute, making them invaluable in high-production industries.

In conclusion, a liquid filling and capping machine is a complex piece of machinery that streamlines the packaging process, ensuring accuracy, efficiency, and product integrity. So, the next time you open a perfectly filled and sealed bottle, you'll know it's the result of the precision and technology of a liquid filling and capping machine at work.

Follow us for updates and engaging content on Facebook, Twitter, LinkedIn, Instagram, and YouTube.

#liquid filling and capping machine#liquid filling capping machine#capping machine#liquid filling machine#liquid fillers#cappers

0 notes

Text

Hester Biosciences, a leader in animal healthcare and vaccines, is currently hiring talented professionals for production and engineering roles at their facility in Gujarat. If you have relevant qualifications in Microbiology, Biotechnology, Pharmacy, or Mechanical Engineering Job Overview Company: Hester Biosciences Position: Production – Officer to Senior Executive Engineering – Assistant Manager/Senior Executive Qualification: For Production: MSc in Microbiology/Biotechnology or B Pharmacy For Engineering: B.E. Mechanical Experience: Production: 1 to 7 years Engineering: 6 to 10 years Location: Gujarat Number of Vacancies: Multiple Hester is a leading biosciences company known for its high-quality vaccine production and innovative healthcare solutions. They are looking for individuals who can contribute to their dynamic teams in both production and engineering departments, ensuring the company's continued growth and success. Key Responsibilities 1. Production Roles (Officer to Senior Executive) As part of the production team, you will be working on various processes within Hester’s vaccine manufacturing unit. Depending on your specific role, your key responsibilities will include: Egg Section: Handling eggs for pre-incubation, candling, and harvesting. Performing aseptic handling in accordance with cGMP practices (current Good Manufacturing Practices). Fill Finish: Working on the manufacturing of lyophilized drug products. Managing aseptic filling, lyophilization, and packaging. Machine Operator: Operating and maintaining vial washing, filling, and capping machines to ensure efficient production. Candidates applying for these positions should have hands-on experience in pharmaceutical or biotech manufacturing environments and familiarity with Good Manufacturing Practices (GMP). Strong attention to detail and knowledge of aseptic procedures are essential. 2. Engineering Roles (Assistant Manager/Senior Executive) In the engineering department, you will take charge of critical operations to maintain and optimize production processes. Key responsibilities for engineering roles include: Utility Engineer: Overseeing the operation and maintenance of utilities such as HVAC systems, boilers, and compressors. Proficiency in AutoCAD, ERP systems, and MS Office tools is a must to manage projects and processes. Equipment Maintenance: Responsible for the mechanical maintenance of production equipment and machinery. Ensuring smooth operation and quick resolution of any technical issues through preventive maintenance and troubleshooting. Ideal candidates for these roles will have a strong foundation in mechanical engineering with experience in utility management, equipment maintenance, and process optimization. [caption id="attachment_105907" align="aligncenter" width="930"] Hester Hiring for Production and Engineering Roles[/caption] How to Apply send your resume to the HR team at [email protected]

0 notes

Video

youtube

Monoblock Feeding Filling Stoppering and Capping Machine for Vial Bottles

0 notes

Text

How Packaging Machinery Can Save Your Business Time and Money

When packaging machinery breaks down it interrupts production – this costs companies time, money and customer satisfaction. This is the main reason it is essential to invest in regular maintenance. Relying on best quality packaging machinery is inevitable.

Human error – overfilling containers, damaging packaging and applying incorrect labels or tightening caps – wastes products and leads to unhappy customers. Automation enables greater consistency in output.

Flow Fillers for Portion-Counted Product Packaging

Using packaging machinery can increase productivity and reduce production costs, while improving hygiene standards. It can also eliminate hand contact with food and medicine to ensure high product quality and safety standards. However, the cost of purchasing and operating this equipment is a significant dynamic that needs to be considered carefully.

Flow fillers are designed for products that are counted by portions, instead of weight. These machines use a hopper that’s set up to scan count candy pieces or tablets and can fill small bottles. They’re best suited for liquids, oils, and thin edible products.

Blister Packing Machines: These machines form a platform in a plastic shell, then add blister board backers that are adhered with glue or by hand to the back of the plastic. Then, the products are placed on the platform and a heated soft plastic layer shapes itself around them to create a sealed blister pack. They’re commonly used for food and pharmaceutical products.

Tablet Fillers for Portion-Counted Product Packaging

Packaging machinery can be utilized to fill a pouch or bottle with products that are counted by portions. These machines include a hopper that scan counts product pieces or tablets before placing them in the bottle, and a filler head that pushes the correct number of items into the bottles accurately. Some examples of such products are heavy sauces, cosmetic creams and thick shampoos.

Another form of packaging equipment is the vertical form fill seal machine, which makes stand-up pouches and plastic bags from a continuous flat film roll and fills them simultaneously with products and seals the filled bags. This type of packaging is capable of handling liquids and solids.

Having representatives from several packaging machinery manufacturers examine existing packaging procedures can help find ways to improve production efficiency and lower costs prior to progression to new equipment. Understanding math included in cost per film utilization will also aid the business to budget properly and exploit packaging materials with efficiency.

Vertical Form Fill Sealing Machine

VFFS machines (also known as vertical baggers) are an effective packaging solution for powdered products. Typically, these machines start with a roll of film that’s pulled by belts to a forming tube that shapes it into the desired pouch size.

Once the bag is formed, a dosing system positioned around the forming tube can fill it with your product. Then, the same sealing jaws that formed the bag form a seal on its top edge, creating a finished and ready-to-ship package.

If you have a need for additional printing, the machine can add date/batch codes and graphics to each completed package. It’s also possible to add a tear notch or euro punch so that the bag can hang on a display for easy retail sales. Depending on how your bags will be used, you can even choose to have the machine add a zipper for added convenience and security. You can find a number of trustworthy packaging machinery companies offering a range of vertical form fill seal machines to fit any type of product and bag.

Liquid Filling Machine

A liquid filling machine pours a fluid into containers that may be bottles, vials, cans, or pouches. Liquid packaging machines may also wash and sterilize containers to remove dust, contaminants, or microbial growth. Some machines have multiple fill heads that increase a machine’s top speed and capacity.

While the exact specifications of liquid filling machinery vary, most systems follow the same general principle. Bottles or jars pass along a conveyor in the machine and are filled before continuing on to the next step of production. The precise technology varies by product and container type, but inline liquid packaging systems are less expensive and more easily upgraded than rotary systems.

Overflow filling machines are especially useful for clear containers because they can produce consistent levels of liquid in each bottle even if the contents of each bottle differ slightly. You must also consider your desired automation level and production capacity when selecting liquid filling machines. Buying from the best supplier will help you get quality and advanced machinery in customized specifications at lucrative costs.

Conclusion

Business means investment. Packaging machines are a major investment to run any business. First choose the right packaging machines for your needs considering the health and well-being of your production line and ensuring that you get the most value out of your investment.

0 notes

Text

Packaging Machines - The Various Types Used in Popular Industries

Defining packaging machines is made easier by knowing the different parts of the manufacturing process. Simply put, it may be a type of machinery that is purposely used for sealing, wrapping, filling, cleaning, packaging and forming goods at varied automation levels. In some industries, the list may include those used while sorting, accumulating and counting items. automatic tin seaming machine

Before proceeding to the basic types of machines, it is also best to have a view of the different package types where packaging machinery is often used. Examples range from aerosol containers, blister packs, bags and pouches, pallets and intermediate bulk containers and cartridges to cans, cases, cups and trays, drums, tubes, vials and capsules. As for its applications, there are a number of industries making use of these industrial products. Popular ones are automotive, cosmetic and perfumery, electronics, chemical and petrochemical and food industries. They also cater to military, music, video, software, household products, garment, stationary, tobacco and pharmaceutical industries.

Types of packaging machines

There are a number of classifications when it comes to packaging machines. The list includes accumulators, bagging, batching and bundling machinery as well as box making, capping, closing and cartooning machinery. Below are explanations for all these types of packing machines. automatic can seamer

As the name implies, an accumulator or accumulating machinery is used in order to make gathering of goods easier during the manufacturing process. As for bagging machines, expect that products are placed easily in their respective pouches, sacks or bags. Batching machinery on the other hand allows preparation of the goods before they are packaged or processed. Banding machines help secure the items with the aid of bands. At times, this is also called as sleeving machines.

Bundling machines are those that have the capability to pile goods before they are wrapped or banded. Box making machines make it easy for cardboard to be transformed into boxes. The so-called capping machines are responsible for placing or snapping caps into the containers where they are needed. Closing machines are basically made in order to make tying wires or metal straps easier around the neck of pouches or bags. With all these descriptions on each type of packaging machinery, one may conclude that the function of the machine is related to the name given to the equipment type.

View More: automatic can seaming machine

0 notes

Text

Semi-automatic Volumetric Cup Filling Machine Producers In India

The high-speed STB-10C tea packing machine is made to do a 10cm3 dosing filter sachet with a high velocity of 110 bags/min. It’s a dip tea bag-making machine that automatically varieties double chamber tea bags with rolled teabag paper. Meanwhile, it makes a tough tag out of rolled tags stapled with staples and cotton threads. As a leading tea packing equipment supplier, Synda STB-10A is an integral teabag packaging machine with the functions of the filter paper packing machine, tag and threads attach, as properly as envelope packing machine. In order to satisfy heavy tea bag manufacturing, we've a kind of super high-speed STB-15 Filter Tea Bag Packing Machine.

The STB-50G is a robust pyramid teabag and premade envelope packing machine that provides a super good envelope compared to other rolled film-made envelopes. It can also be compacted and systemized for filter teabag and outer sachet. The tea filling machine is specifically designed for black tea, green tea, white tea, free leaf tea, and flower tea.

The machine frames and management cabinets are created from chrome steel and the mechanics inside the machine are servo driven for top precision purposes. Volm offers three main traces of vertical packaging machines equipment tailored to go nicely with the application of the customers’ needs. From special dosing techniques to distinctive package deal sorts and granular to liquid products, these machines may be constructed upon to create a one-of-a-kind custom packaging resolution. Performance-proven construction ensures NBE liquid filling methods are built to handle extended obligation cycles and endure harsh course of environments. NBE engineered-to-application liquid filling methods provide total process advantages by outputting precisely crammed containers, whereas reducing product loss, and enhancing labor safety and efficiency.

Empty containers are positioned inside a vibrating system the place they are distributed and ... Monobloc of filling and capping in a single machine, low spaceoccupied. Rotary working system for each filling and capping, working stably and excessive efficient. We can deliver absolutely built-in options for sorting, filling and packaging of fluid merchandise.

The machine was crated properly and survived transport from New York To Los Angeles with no issues at all. We have 5 containers four Oz to 1 Gallon and they volumetric filler machine all work great within the machine. We even have two jars that with some retooling additionally run on the machine without a hiccup.

Accommodating a broad range of container shapes in volumes from 15mL to five gallons the Pro/Fill® 3000 runs at speeds to 250 containers/min., with accuracies to ± 0.10% dependent upon dose dimension and product. Ideal-Pak Pase Massman LLC Ideal-Pak® liquid filling machines are designed to deliver the best levels of precision, productivity, ease of use, and reliability in computerized, semi-automatic or handbook configurations. Individually designed to go well with the wants and budgets of their clients, Ideal-Pak® automatic liquid fillers include automatic PLC-controlled conveyor techniques volumetric filler machine, lid placers and closers for hands-free operation. Contact us right now to find out more about our line of automated liquid filling machines. Ideal-Pak®’s semi-automatic liquid filling machines ship the flexibility to course of smaller batches of product efficiently while sustaining high accuracy. Capmatic Capmatic supplies an in depth range of liquid filling machines for a broad variety of applications from pharmaceutical to food and beverage functions and beyond.

BellatRx presents a full range of totally automated and semi-automatic packaging methods to fill non-viscous and viscous liquids accurately. Liquid fillers embody monoblocs, inline fillers, piston and tube fillers, that deal with microtubes, vials and cartridges in pharmaceutical, cosmetic, biotech, food, e-liquid and other industries. Aesus Packaging Systems manufactures liquid fillers that may handle a variety of viscosities, from water and water-like liquids to oils and lotions. Filling machines function easy dial-in fill volume changes to change over from functions requiring milliliters from ones requiring gallons, all on the same machine.

This control is functional through the operation of the filler. Our machines are built with a view to zero maintenance via robust design and using... Automatic adjustment of the product volume to be filled in accordance with its temperature. Powerblock is one machine placed on one monoblock base, with the ability volumetric filler machine to fill several merchandise. Full computerized peak adjustment of the quantity ring and product bowl. The compact VF-1 can fill about 250 bottles per hour, whereas the bigger version, the VF-4 can fill about 500 bottles per hour, in good hygienic circumstances and with no product spillage.

1 note

·

View note