#vertical gearbox

Explore tagged Tumblr posts

Text

Alienskart is the e-marketplace for B2B, B2C, commercial equipments and hardware store. Alienskart is your one step destination for all your industrial needs. We specialize in providing high quality motors, gearboxes, wires, switch gears, drives and hardware to businesses of all sizes, consisting of trustful brands as Havells, ABB, polycabs, castrol, SnPc power solutions, Siemens, bonfiglioli etc. Gearboxes are one of our main products. You will get different types of gearboxes like worm gearboxes, vertical gearboxes, bevel helical gearbox, aluminum gearboxes, bonfiglioli gearboxes etc. For more queries: 8818081001

#Alienskart#bevel helical gearbox#gearbox#vertical gearbox#bonfiglioli gearbox#online electronics store

0 notes

Text

Shop Worm gearbox online at Alienskart Web now

Alienskart is the e-marketplace for B2B & B2C commercial equipments & Hardware stores. Alienskart is your one-step destination for all your industrial needs. We specialize in providing high quality industrial motors, gearboxes, switchgear, drives & hardware to all businesses of all sizes, consisting of trustful brands as Havells, ABB, polycabs, castrol, bonfigioli, snpc power solutions, crompton greaves, legrand etc.

#Alienskart web#Gearbox#Worm gearbox#bonfiglioli gearbox#branded gearbox#vertical gearbox#E-commerce shopping stie

0 notes

Text

Why Some Gearboxes Last for Years While Others Fail in Just a Few Months

Have you ever asked yourself why some industrial gearboxes fail within a few months while others run perfectly for years? It’s science, strategy, and smart choice, not luck or chance. The life of your gearbox directly affects operating efficiency, unplanned downtime, and even employee safety, no matter what your industry—manufacturing, mining, or automation.

Gearboxes, the heart of most mechanical systems, are responsible for speed control and torque transmission. Catastrophic effects might be the outcome of a single failure, such as halted production lines, damaged equipment, and costly repairs. In reality, many failures can be prevented. You can extend lifespan and performance by applying judicious decisions based on your awareness of the engineering principles that govern reliable gearbox design and the root causes of gearbox failure. Let’s look at the factors that make gearboxes that survive a few production cycles endure while their counterparts fail to do so.

Material Quality

Construction quality comes first and foremost. Expensive gearboxes feature precision bearings, alloyed materials, and hardened steel materials designed to withstand high RPMs and extreme pressure and temperature changes. Inexpensive gearboxes, however, tend to take shortcuts, increasing the rate of wear and tear.

Expectancy Failure or Poor Dimension

Inadequate gear sizes amount to work failure. Calculate the parameters of the torque, speed, and load when selecting a gearbox. Undersized gearboxes become overloaded. Then, they break down, start wearing out, and eventually overheat.

Expert Advice: Always cross-check your load condition with a gearbox manufacturer or engineer before selecting.

Ineffective Lubrication Methods

Your gearbox’s lifeblood is lubrication. Gear damage, heat buildup, and friction can be caused by using the wrong lubricant or by not taking care of it. Choosing the right viscosity and performing regular oil analysis can make a big difference.

Environment of Operation

Temperature, humidity, dust, and chemical exposure extremes can accelerate the degradation of gearboxes. Special gears manufactured to withstand some environmental conditions last longer. Repeat failures are unavoidable if your gearbox is not sealed or coated for your environment.

Maintenance and Observation

Thermographic imaging, vibration tests, and regular inspections can catch issues before they become costly failures. Well-maintained gearboxes can readily outlast others by several years.

Customisation Options and Manufacturer Support

Customisation and maker support are integral to gearbox life. A professional supplier ensures your gearboxes cater to your special needs through the provision of tailor-made configurations, technical assistance, and post-sales service. Factory-made gearboxes are designed with optimal performance and longevity, from housing materials and gear ratios to custom specifications. The best business partner prolongs the equipment lifespan and enhances performance.

Conclusion:

The parameters for assessing the longevity of gearboxes include the effort expended under load, environmental influences, and engineering calculations. The efforts made in the selection suitable for your requirements, in maintenance, and in careful consideration of potential troubles can all greatly enhance the lifespan of a gearbox.

For solutions that are customised for your operational necessities, go for a specially manufactured gearbox from a trusted supplier. Do not just buy gearboxes; build reliability along the way.

#reduction gearbox manufacturers#gear box manufacturing ahmedabad#gearbox repair ahmedabad#gearbox manufacturer#gearbox repair services ahmedabad#buy worm reduction gearbox#gearbox vertical ahmedabad#gearbox repair cost ahmedabad#double reduction gearbox ahmedabad#reduction gear manufacturers#industrial sector gearboxes#industrial worm drive reduction gearbox#industrial gearbox manufacturers in india#industrial gearbox manufacturers#industrial gearbox repair near me

0 notes

Text

MTR Repair’s

(800)987-2724

mtrservice.com

I am writing to introduce you to our repair service, MTR Repair, which specializes in repairing a variety of equipment and machinery for the food and beverage industry. Our team of certified technicians has extensive training and experience in repairing slurry pumps, Aodd pumps, positive displacement pumps, gearboxes, blowers, and other equipment.

At MTR Repair, we understand the importance of minimizing downtime and maximizing productivity. That's why we focus on reducing the Mean Time to Repair (MTR) of your equipment. MTR is the average time it takes for equipment to be diagnosed, repaired, and recovered after experiencing a failure

. By proactively improving the MTR, we can reduce availability losses due to repairs and speed up the equipment's rate of recovery from failures and breakdowns

Our comprehensive repair services ensure that your equipment is repaired efficiently and reliably. We use original spare parts and closely monitor operational data to detect possible causes of failure before they occur

. Our local service technicians conveniently bring the repair solution to your facility, providing fast response time and factory training

#CentrifugalPumps

#ScrewPumps

#DiaphragmPumps

#GearPumps

#HydraulicGearPumps

#VacuumPumps

#LobePumps

#VanePumps

#ProgressingCavityPumps

#SplitCasePumps

#HydraulicPumps

#EndSuctionPumps

#SelfPrimingPumps

#JetPumps

#PlungerPumps

#MultistagePumps

#pumprepair#mining gearbox plasticmolding sandgravel#mtrrepair#aoddpump#positivedisplacementpump#alfalaval#cherrybernell#slurrypump#vertical pump

0 notes

Text

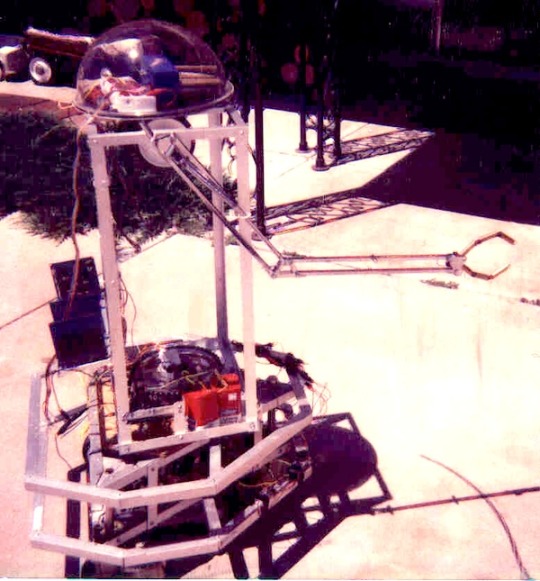

S.A.M by "Bill" (1978). "S.A.M (Short for "Sentient, Autonomous Mechanism" or "Smart Ass Machine", depending on his (and my) mood on a given day, was one of my first real robot projects, started in 1978 when I was around 15. His "brain" was a single-board Z-80 computer (the big square object in the middle of his "back" in this picture), with many bits of TTL I/O, a couple of serial ports, a bunch of counter-timers, and several D/A & A/D channels. The base was taken from the book "How to Build a Computer Controlled Robot" by Todd Loofbourrow - I had built the robot in the book, and had used my KIM-1 to control it. Later, I decided that just a little platform was kind of boring, so I added the upper torso shown here. The torso (mounted on a "lazy-susan" turntable bearing) is rotated by a heavy-duty gear motor driving a chain and sprocket assembly from a bicycle. The base is powered by two of the (apparently no longer available, which is sad) all-metal rubber-tired "motorized wheel" assemblies that Herbach & Rademan used to sell, with a large rubber-tired caster in front. The head platform (mounted on a small "lazy-susan" bearing) was originally rotated by a surplus gearbox from a Mattel "Big Trak" with some rubber-tired wheels mounted on the output shafts. This arrangement was later replaced by a small gear-head motor driving a large gear mounted to the center of the turntable. The device in the head with the tubes sticking out the front is a directional light tracking device. Each tube has a CDS photocell at the bottom, and is painted flat black inside. A comparator circuit tells the computer which direction the brightest light is coming from. This device could also tilt up and down with a small gear-head motor, to track light sources vertically. Most of the circuitry was installed on small plug-boards from Radio Shack, mounted in a card rack below the CPU card. This rack could be tipped back 90 degrees to facilitate easier access for testing. In addition to motor driver circuits, there was a "Sweet Talker" speech synthesizer board so he could talk. Power came from a large "gel-cell" marine battery (for powering trolling motors on boats), which was slung near the ground in the center of the base. Two 6V lantern batteries (later replaced by a 12V motorcycle battery) provided separate power for the electronics. All motors were isolated from the electronics via relays and/or opto-isolators. After these pictures were taken, a set of metal panels was installed on the "facets" of the base, with lever switches behind them for collision sensing. A Polaroid sonar range-finder was also added later. If you check out the other photos of S.A.M., you will notice an "arm" sticking out the front. This was a prototype made from an old swing-arm desk lamp and some "fingers" from a robot hand design using brass tubing, bicycle chain, and 1/16" steel cable to allow natural bending of each finger. It was later replaced with a much heavier duty aluminum framework arm operated by two 12VDC linear actuators." – My Home Robot Projects, by Bill.

25 notes

·

View notes

Note

when people talk about the new rules for 2026 i hear them say it’s gonna be an “engine formula” a lot. what does this mean?

FORMULA EXPLAINED - Part One Engine Formula

When referencing the FIA's new set of rules & regulations for the 2026 season, you may hear people talking about something called "engine formula".

Engine Formula is all the parts that are put together to make the engine work like components and batteries.

The 2026 engine is to be a 50/50 split between internal combustion engine and electrical power, dropping the MGU-H (which i'll cover soon) and massively upping the MGU-K (which will also be covered soon) to a power output of 350kW or around 469bnp.

The current hybrid (engine) set-up includes the energy store, the V6 engine, the turbocharger, and two other components.

Said components are the MGU-H and the MGU-K. Let's start by focusing on:

What they are

What their purpose is

MGU-H Motor Generation Unit - Heat The MGU-H is a compound of the hybrid-electric internal combustion engine. (this is literally just the name of the engine) Its job is to convert heat energy from exhaust gas into electrical energy. - Acts as an anti-lag system for the turbocharger.

MGU-K Motor Generation Unit - Kinetic The MGU-K is a kinetic energy recovery system connected to the crankshaft with the main task of converting kinetic energy into electrical energy. Much like the MGU-H but different. - Kinetic energy is the energy an object has because of its motion. - The crankshaft is another engine component. It is a piston that converts the linear motion generated by the engine into rotational motion. (in simpler words, it converts the vertical movement of the pistons into horizontal rotational movement which drives the wheels via the gearbox.)

For 2026 they plan on completely dropping the MGU-H system and upping the MGU-K system to have a significantly larger power output (as stated above). Removing the MGU-H is the most significant change being made to the engine as they are literally removing a whole component.

They are making this drastic change as they deemed it "too complex, with too little road relevance for manufacturers." - essentially, a bit too difficult for manufacturers (the people that make it) to understand completely how to make it, as they are more used to working on engines build for the roads. Hence "road relevance".

------------------------------------------------------------------------------

That's a wrap for part one of "FORMULA EXPLAINED" by copythat!

Thanks for your read! If you're new here, have a quick read at my intro post for this series.

*all feedback and constructive criticism is welcome!*

also, if you'd like to - follow my Instagram! @/copythatblogs

#f1#motorsports#driving#formula racing#sports#formula 1#journalism#sports journalism#engineering#electric#vehicle#circuit#electric vehicles#cars#fast cars#research#engine formula#2026#fia#rules#regulations#formula one#f1 2024#f1blr#FORMULA EXPLAINED#copythatblogs#copythat FORMULA EXPLAINED

16 notes

·

View notes

Photo

SSC Tuatara (1 of 100).

The jet fighter inspired teardrop canopy, which is suspended within the dynamic fuselage body, is complemented by vertical stabilizing fins at the rear, revealing the cars stunning speed capabilities. The streamlined design has been tuned to produce a near perfect front to rear aero balance, incredible thermal efficiency to ensure stability at all speeds up to its terminal ground velocity along with unrivaled high speed acceleration. The design of the Tuatara goes further than visual appearance. The intentional design of the body was meticulously crafted to carry the car through the air with unprecedented ease. Boasting an industry leading coefficient of drag of 0.279, the Tuatara is well balanced between unmatched aerodynamics and precision downforce at top speed.Rear static winglets, side mounted buttresses, forward static wing, and a rear active wing manipulate the smooth flowing air to distribute precision down force on the wheels. Air is also diverted to intakes that efficiently cool the powerful drive train, then expelled through perforations in the body to sustain the deliberate airflow. Downforce is systematically applied across the hypercar, providing perfect balance at all speeds.The heart of the Tuatara is an engineering masterpiece in and of itself. Years of meticulous design and engineering at SSC North America culminated into unadulterated power generated from an engine built from the ground up exclusively for the Tuatara. The smooth, balanced power produced offers both incredible performance and a unique hypercar experience. To ensure the engine met the standards of quality, performance, and durability that the hypercar market demands, SSC North America partnered with Nelson Racing Engines to fabricate and manufacture the V8 engine that powers this next generation hypercar.The Tuatara’s unprecedented power is transferred to a CIMA 7 speed transmission, integrated with a state-of-the-art Automac AMT system that operates the engagement and selection of movement in the gearbox. The system includes hydraulic driven components and sensors to produce high force engagement, position accuracy, and load control within milliseconds. The clutch and gear selection actuation are electrically operated, providing high precision and strategic operation. The core of the system is powered by a powerful automotive microprocessor, ensuring exceptional safety and performance.

47 notes

·

View notes

Text

Yamaha Celebrates 25th Anniversary of the Revolutionary R1

Yamaha Motor Europe is proud to celebrate the 25th anniversary of the ground-breaking R1 with dedicated activities planned at the Yamaha Racing Experience (YRE). This year the YRE will be held at the legendary Mugello Circuit in Italy on the 21st and 22nd of July and will bring together some of Yamaha's biggest stars and enthusiasts to honour the remarkable legacy of the iconic machine. Since its launch, the Yamaha R1 has redefined standards of performance and innovation in the industry. Its 25-year journey of evolution is a testament to Yamaha's dedication to engineering excellence, which cemented the R1 as an icon of speed, power, and cutting-edge technology that revolutionised the sports bike market. Making its grand entrance in 1998, at the core of the R1 was an innovative, compact, and lightweight 998cc, liquid-cooled, 20-valve, double overhead camshaft, four-cylinder engine which featured a five-valve-per-cylinder head with redesigned valve sizes to boost torque and improved porting. However, the real game-changer came from Project Leader Kunihiko Miwa's ingenious decision to create the world's first vertically stacked gearbox in a production motorcycle, which resulted in a lighter, shorter engine that allowed for a longer swing arm, enhancing traction while maintaining a conventional sports bike wheelbase. In addition to its innovative powertrain, the 1998 R1 introduced an all-new aluminium Deltabox II chassis, a heavily braced alloy swingarm, a Yamaha Monoshock shock absorber, and upside-down 41mm fully adjustable front forks developed in collaboration with Öhlins. This Grand Prix-inspired compact chassis and suspension setup offered unrivalled handling and manoeuvrability, setting a new benchmark for modern sports bikes, with the R1 producing an astonishing 150PS while weighing only 177 kg. The R1's racing success was equally remarkable. At the prestigious Isle of Man TT, the bike made history in 1999 when David Jefferies stormed to the TT Formula One victory, in the process setting a record 121,235 mph lap, before going on to win the Senior race and the Production TT, confirming the R1’s racing pedigree to the world. As Yamaha continued to refine and improve the R1, the 2000 model was launched with revisions to over 250 parts, including engine and chassis enhancements, more aerodynamic bodywork, and a new titanium muffler. Two years later, in 2002, Yamaha introduced the next generation of R1, led by Project Leader Yoshikazu Koike, which showcased a groundbreaking vacuum-controlled fuel injection system that provided refined power output and a new Deltabox III frame which was lighter and yet 30% stronger in torsional rigidity. The year 2004 marked the arrival of the fourth generation R1 featuring new engine with larger bore and shorter stroke and closed-deck cylinder design, as well as fracture-split (FS) connecting rods, RAM-air intake, new under-seat exhausts, revised chassis geometry and a sharpened body design. For the first time a production motorcycle was achieving the 1:1 power to weight ratio, thanks to the 180PS delivered by the completely new power train. The R1 that was unveiled in 2007 boasted Yamaha's innovative YCC-T ride-by-wire throttle system and electronically controlled variable air intake funnels (YCC-I). Project Leader Makato Shimamoto also introduced a new four-valve design motor, slipper clutch, an improved Deltabox frame as well as improved brakes and suspension. Building on its legacy, Yamaha launched the next generation R1 in 2009, featuring a ground-breaking crossplane crankshaft engine, directly derived from Yamaha’s MotoGP M1. This unique design reduced inertia forces and delivered a more linear throttle connection. Next to that, Development Leader Toyoshi Nishida introduced twin fuel injectors, a new lightweight aluminium Deltabox frame, cast magnesium subframe and cutting-edge electronics. This model set the standard for handling and performance in the world of racing in 2009, highlighted by the incredible performance of American Ben Spies in WorldSBK, with the rookie recording 14 wins in 28 races to claim the 2009 title. Reinforcing the competitiveness of the R1 that year, the YART Yamaha EWC team was crowned Endurance World Champions, while Leon Camier won 19 out of 26 races on his way to lifting the British Superbike Championship, and Katsuyuki Nakasuga clinched his first Japanese Superbike Championship title. Constantly looking to innovate, the 2012 R1 incorporated a traction control system that adjusted ignition timing, fuel delivery, and throttle opening to maintain optimal traction, enhancing drivability and fuel consumption. To mark another ground-breaking step, the 2015 R1 was launched with a powerful 200PS engine and was the first production motorcycle equipped with a six-axis Inertial Measurement Unit (IMU) and electronic support systems – developed and proven in MotoGP. With a dry weight of 179 kg and a host of racing features the 2015 R1 has been a sensation. Project Chief Hideki Fujiwara also introduced the top-of-the-line, limited edition R1M which featured electronically controlled suspension, a lightweight carbon-fibre cowl, and an onboard data logger to cater to the needs of serious racing and track day devotees. The 2018 R1 model offered riders an even more extensive array of sophisticated electronics, and the addition of a Quick Shift System (QSS) with a blipper function for clutchless up and downshifting took the R1 and R1M’s performance on the street and track to the next level. The R1’s handling performance was refined with more progressive mapping on the Lift Control System as well as revised suspension settings – and the Öhlins Electronic Racing Suspension on the R1M featured a revised interface for a more intuitive set-up. For 2020, the R1 featured a CP4 engine with new cylinder head, camshafts and injection system – while the extensive electronic rider aids were refined to ensure even higher levels of controllability. A new EBM (Engine Brake Management) enabled the rider to select one of three different engine braking forces to match riding conditions – and the new Brake Control (BC) system gave added confidence and control when cornering. With revised damping valves and a reduced spring rate, the R1’s 43mm KYB forks provided increased feedback for a more natural handling feeling. And for improved chassis performance and reduced lap times the R1M was equipped with a new rear shock and uprated Öhlins ERS NPX gas pressurised forks. Over recent years, the R1 and R1M have continued to evolve and remain a dominant force on the racing scene, with Pata Yamaha Prometeon Official WorldSBK Team’s Toprak Razgatlıoğlu and Andrea Locatelli leading the charge in the FIM Superbike World Championship. The highlight of which was Razgatlıoğlu’s 2021 WorldSBK Championship winning season that saw the Turkish rider rack up 13 race wins and 16 further podiums on his way to the title, while Italian Locatelli has grown from strength-to-strength on the R1 and has 11 podiums to his name so far. On top of this, the R1 has demonstrated its prowess all over the world, with the Yamaha Factory Racing Team winning the historic Suzuka 8 Hours endurance race four times in a row between 2015-2018, plus Cameron Beaubier (2015, 2016, 2018, 2019, 2020) and Jake Gagne (2021, 2022) securing seven of the last eight AMA Superbike titles. In 2021, Nakasuga would lift an incredible tenth Japanese Superbike Championship, with Tommy Hill (2011), Josh Brookes (2015), Tarran Mackenzie (2021), and Bradley Ray (2022) all being crowned British Superbike Champions on the R1. As the legacy of the R1 continues to grow, Yamaha remains committed to pushing the boundaries of innovation with the introduction of the R1 GYTR. GYTR (Genuine Yamaha Technology Racing) is Yamaha’s in-house specialist racing component division that has been developing performance enhancing technology for over 40 years. Designed specifically for track-day riders and racers who recognise Yamaha’s winning performance and premium quality, the 2023 R1 GYTR is faster and more precise than ever. Manufactured to comply with FIM Stock 1000 regulations, this high-specification machine provides individuals and teams with the ultimate canvas to create their own unique superbike. The R1 GYTR is equipped with over 25 GYTR race specification components including an Akrapovic race exhaust system, racing ECU, wiring harness, GYTR chassis parts, drive system and complete race cowling in primer white – plus much more. The R1 GYTR is available exclusively from GYTR PRO SHOPS. To mark such a momentous anniversary, the Yamaha Racing Experience at Mugello will host the celebration activities for the R1, with the Tuscany circuit, renowned for its fast and challenging track layout that makes it a favourite among riders and fans alike, providing the perfect setting to honour such an incredible machine. Usually the event is exclusive to R1M customers, however the 2023 YRE will be open for the first time to R1 owners to mark this momentous occasion, with two different options available to them to attend. There are 25 spots available to R1 owners for the whole two days program, where they can enjoy the full Yamaha Racing Experience along with the R1M customers – which includes track sessions on both days, the ability to get advises from Yamaha racing technicians to give their bikes the optimum setup, exclusive tours of the Pata Yamaha Prometeon WorldSBK pit box, and much more. Click here to learn more and register for the two-day whole YRE experience. There is also an option for R1 owners to attend just on Saturday, where they can register for up to two track sessions for free and still enjoy the event atmosphere, and go behind the scenes in the Pata Yamaha Prometeon garage. For more information on this option and to register to attend just on Saturday, click here. The track sessions at the YRE will see owners get the chance to meet and ride alongside some of Yamaha’s biggest stars from WorldSBK, including Pata Yamaha Prometon WorldSBK riders Toprak Razgatlıoğlu and Andrea Locatelli, the GYTR GRT Yamaha WorldSBK Team duo of Remy Gardner and Dominique Aegerter, GMT94 Yamaha WorldSBK Team’s Lorenzo Baldassari, Yamaha Motoxracing WorldSBK Team’s Bradley Ray, plus YART Yamaha Official EWC Team’s Niccolò Canepa. The 25th-anniversary celebration at the YRE promises to be an exclusive experience for all R1 and R1M owners to come together and celebrate these iconic machines, with a special exhibition of R1s from across the years and including a collection of some of the most memorable race bikes, with the event showcasing the R1’s enduring legacy in the world of motorcycling. Paolo Pavesio Marketing and Motorsport Director, Yamaha Motor Europe “We are proud to honour the 25th anniversary of the Yamaha R1 in 2023. The R1 has been a game-changer in the world of motorcycles, pushing the boundaries of performance and innovation and constantly evolving to be at the pinnacle of the racing world. It is a bike that has redefined what is possible during the last 25 years with technology and innovations derived directly from MotoGP and WSBK. The Yamaha Racing Experience at Mugello will be something special this year, the perfect opportunity to salute such an iconic machine together with our customers and some of Yamaha's biggest stars.” For more Yamaha Motorcycles UK news check out our dedicated page Yamaha Motorcycles UK or head to the official Yamaha Motorcycles UK website yamaha-motor.eu/gb/en/ Read the full article

2 notes

·

View notes

Text

Types of Plummer Block and Their Applications

Introduction

In any industrial setup where rotating shafts are involved, proper support and stability are crucial. One of the most important components used for this purpose is the Plummer block. A Plummer block houses and protects bearings while supporting shafts that are subjected to heavy loads and tough working conditions. At Nisuka Industries, a leading conveyor gearbox manufacturer in India, we recognize the critical role that Plummer blocks play in ensuring machinery efficiency, longevity, and safety.

There are several types of Plummer blocks, each designed to handle specific applications and environments. In this blog, we will explore the major types of Plummer blocks and their typical industrial uses.

Types of Plummer Block

1. Standard Plummer Blocks (SN Series)

The most common type of Plummer block is the Standard Series (SN Series). These blocks are designed for general-purpose applications. They are robust and can accommodate both spherical roller bearings and ball bearings, providing excellent load-handling capacity.

Applications:

Conveyor systems

Agricultural machinery

Fans and blowers

Light mining equipment

At Nisuka Industries, we often pair SN Series Plummer blocks with our products like conveyor belt tensioner manufacturer in India solutions to enhance performance and reduce maintenance needs.

2. Heavy-Duty Plummer Blocks (SD Series)

Heavy-duty Plummer blocks, also known as SD Series, are used in very demanding environments where extremely high loads and harsh conditions are present. These blocks are larger, made with stronger materials, and can handle both radial and axial loads efficiently.

Applications:

Mining operations

Cement plants

Crushers

Heavy conveyor systems

For industries that require strength and reliability, heavy-duty Plummer blocks are a perfect match, especially when installed alongside robust conveyor systems driven by solutions from a trusted SMSR gearbox manufacturer in India like Nisuka Industries.

3. Split Plummer Blocks

Split Plummer blocks are designed with a housing that can be separated into two parts, making installation and maintenance very convenient. This design allows easy replacement of bearings without removing the shaft, saving downtime and labor costs.

Applications:

Conveyor belts

Material handling systems

Marine industries

Paper and pulp industries

Split Plummer blocks are an ideal choice where frequent maintenance or bearing replacement is needed, helping industries maintain consistent productivity.

4. Flanged Plummer Blocks

Flanged Plummer blocks differ from the standard design by having a mounting flange. These blocks are used when the shaft must be supported perpendicular to the mounting surface.

Applications:

Vertical conveyors

Pump shafts

Vertical drive shafts

Gear drives

With products like conveyor belt tensioner in India and specialized gearboxes, Nisuka Industries ensures that flanged Plummer blocks are integrated into systems where space and alignment are critical factors.

5. Take-Up Plummer Blocks

Take-up Plummer blocks are specially designed to allow adjustment of the shaft position. They are used where the system needs to accommodate shaft expansion, tensioning, or contraction due to operational demands.

Applications:

Conveyor belt tensioning systems

Crushers and screening machines

Vibratory screens

Bucket elevators

As a recognized conveyor gearbox manufacturer in India, Nisuka Industries often supplies take-up Plummer blocks with adjustable systems that ensure smooth conveyor operations, minimizing wear and tear.

Importance of Choosing the Right Type of Plummer Block

Choosing the correct Plummer block is essential to maximize the performance of the entire system. Selecting the wrong type can lead to bearing failures, misalignment, increased downtime, and costly repairs.

Key factors to consider include:

Load capacity (both radial and axial)

Shaft size

Operating environment (dusty, wet, clean, etc.)

Installation space and accessibility

Maintenance requirements

Working with an expert like Nisuka Industries ensures you get the right advice, high-quality products, and excellent after-sales support to make the best choice.

Why Trust Nisuka Industries?

At Nisuka Industries, we pride ourselves on being more than just a Shaft mounted gearbox manufacturer in India. We offer complete solutions that enhance industrial efficiency and reliability. Whether you are looking for high-quality gearboxes, Plummer blocks, or conveyor belt tensioner in India, we provide end-to-end support — from consultation to installation and beyond.

Our strengths include:

Top-quality manufacturing with precision engineering

Expertise in handling heavy-duty industrial requirements

Custom solutions based on client needs

Prompt delivery and strong after-sales support

With decades of experience in the industry, Nisuka Industries has become a preferred partner for industries across India and internationally.

Conclusion

Plummer blocks play a vital role in supporting rotating shafts in various industries. From standard types for everyday applications to heavy-duty and flanged designs for specialized systems, the right Plummer block can drastically improve system efficiency and lifespan.

Understanding the different types of Plummer blocks and their applications is essential for maintaining machinery health and productivity. Whether you operate in mining, cement production, agriculture, or conveyor systems, choosing the right Plummer block is crucial.

Trust Nisuka Industries, the leading conveyor gearbox manufacturer in India, Plummer block manufacturer in India, and supplier of conveyor belt tensioner in India, to provide reliable, durable, and efficient solutions for all your industrial needs.

0 notes

Text

The Tiny Guardians of Rotating Machinery: Why Bearing Protection Is Everyone’s Business

Bearings Fail for Surprising Reasons—But “Surprise” Is Preventable

Whether you run paper mills in Pune or food‑grade mixers in Chicago, most bearing catastrophes trace back to one root cause: foreign material (water, dirt, vapors) infiltrates the housing and degrades the lubricant film. Once that microfilm breaks down, metal meets metal; heat skyrockets; spalling starts; and—boom—there goes your production schedule.

Enter the Bearing Protector. Think of it as the first bouncer at the club door, a mechanical face seal or lip seal that physically blocks fluid ingress while keeping grease or oil inside. Simple? Yes. But simplicity is power: no friction‑induced wear surfaces, no electronics to fail, just a rugged barrier that extends mean time between failures.

2. From Protector to Isolator: Same Goal, Higher IQ

If bearing protectors are the bouncers, the Bearing Isolator is the concierge—sophisticated, non‑contact, and designed to manage pressure changes as well as contamination. Typically built from bronze, PTFE, or stainless composites, an isolator uses a labyrinth path and centrifugal pumping action. Airborne dust or water can enter, but the tortuous channel and internal “flinger” force push it back out before it ever kisses the lubricant.

Why does that matter? Because non‑contact means no wear. Plants using isolators report seal life approaching the life of the rotating equipment itself—sometimes 15 years or more. They also slash energy losses: no drag, no heat, no torque penalty.

For high‑speed compressors, vertical pumps, or gearboxes that see frequent shaft vibration, the Bearing Isolator isn’t optional; it’s mission‑critical.

3. Where Each Solution Excels (And Where It Doesn’t)

Criterion

Bold Protector Strengths

Bold Isolator Strengths

Cost

Low upfront cost, easy retrofit

Higher cost, but lifecycle ROI

Shaft Speed

Moderate (≤ 1,800 rpm typical)

Excellent for high rpm

Contact

Light or partial contact

Zero contact, zero wear

Media Resistance

Good versus splash, moderate chemicals

Excellent versus vapors, fine dust, wash‑down

Maintenance Need

Periodic inspection for lip/seal wear

Virtually maintenance‑free

The key takeaway: equipment class and risk tolerance should drive the decision. A small agitator in a benign environment? A Bearing Protector may be just right. A multi‑million‑dollar turbine in a refinery? You’ll sleep better with a Bearing Isolator.

4. Humanizing Reliability: Stories From the Shop Floor

Sanjay, a maintenance lead at a paper plant in Maharashtra, recalls replacing the same pump bearings every four months. “We blamed the vendor, the operators—anyone but ourselves,” he laughs now. The root cause? Warm, fiber‑laden wash water sneaking past a tired rubber lip seal. Switching to a split‑fit Bearing Isolator added less than ₹15 k per shaft but extended bearing life to 18 months and cut overtime call‑outs to near zero.

On the other side of the globe, Laura, a craft‑brewery engineer in Oregon, wanted FDA‑compliant sealing on her can‑line conveyors. She opted for food‑grade stainless Bearing Protector assemblies. “It’s not glamorous,” she says, “but it keeps caustic CIP solution out of our bearings and off my Friday night worry list.”

Those stories reveal a deeper truth: bearings don’t fail in isolation—they fail in context. The right seal choice is often the cheapest form of stress reduction an engineer can buy.

5. Installation Nuances That Make or Break Your ROI

Even the finest Bearing Isolator can’t save a shaft if it’s mis‑aligned or installed backward (yes, that happens). Keys to success include:

Surface Prep – A nicked or corroded housing bore destroys concentricity.

Alignment & End‑Play – Check coupling, correct soft‑foot, set axial float.

Vent Path – Isolators need a weep or vent to function; block it and you’ve created a pressure cooker.

Training – Teach techs the “why,” not just the torque spec.

Do these basics, and you’ll harvest the full life‑cycle savings the manufacturer promises.

6. Future Trends: Smart Seals & Industry 4.0

Imagine a Bearing Protector embedded with a micro‑sensor that measures moisture ingress in real time, sending alerts before contamination can bloom. Or an Bearing Isolator that uses additive‑manufactured channels to fine‑tune labyrinth geometry for specific shaft speeds. Those concepts are no longer sci‑fi. OEMs are prototyping seals that integrate vibration and temperature MEMS chips, feeding data into cloud dashboards.

For startups building next‑gen rotating equipment, partnering early with seal innovators can differentiate your product long before the first customer demo.

Final Word: Small Components, Massive Consequences

If you stand on a refinery catwalk or a pulp mill mezzanine and listen, you’ll hear a symphony of rotating machinery—the metallic heartbeat of industry. The health of that heartbeat often hinges on a tiny circle of metal or elastomer. Overlook it, and you invite downtime; respect it, and you unlock years of reliable service.

So, next time budgeting season rolls around and someone suggests trimming maintenance costs by using generic seals, share the stories of Sanjay and Laura. Remind them how a Bearing Protector or Bearing Isolator isn’t an expense—it’s an investment in calm nights, full production quotas, and equipment that outlives its depreciation schedule.

Because in the end, the best‑run plants aren’t defined by their biggest assets, but by how well they protect the smallest.

0 notes

Text

Vertical turbine pump happens to be a kind of centrifugal pump. It can be used to transport liquids. These are like clean water and rainwater. It also includes corrosive industrial wastewater and seawater. These are widely used in water companies and sewage treatment plants. There are also power plants and steel plants and mines with other industrial and mining enterprises included. Some also come along like municipal water supply and drainage and flood control and drainage and fire fighting projects.

The Vertical turbine Pump can be driven by a solid shaft motor, a hollow shaft motor or a diesel engine.

Driven by a solid shaft motor, the pump and motor are connected through the coupling, the pump structure includes a motor base with an anti-reverse device.

Driven by a hollow shaft motor, the pump and motor are connected through the motor shaft, and do not need the motor base and coupling.

Driven by a diesel engine, the pump and diesel engine are connected via a right-angle gearbox and a universal coupling for transmission.

Function of a Vertical Turbine Pump work

Flowmore Vertical turbine pumps operate on the centrifugal principle. It generates speed by using an impeller. It is used to apply centrifugal force to the moving liquid. The main difference between a turbine pump and a centrifugal pump is the impeller design.

Flowmore Turbine pumps have smaller diameter impellers Compared to most centrifugal pumps. It comes with rows of numerous small vanes. These vanes happen to recirculate the fluid as it goes from the suction end to the outlet. The fluid enters the edge of an impeller vane, not through the eye, and is accelerated not only tangentially in the direction of rotation, but also radially outward in the casing channel by centrifugal force.

0 notes

Text

Alienskart is the e-marketplace for B2B, B2C, commercial equipments and hardware store. Alienskart is your one step destination for all your industrial needs. We specialize in providing high quality motors, gearboxes, wires, switch gears, drives and hardware to businesses of all sizes, consisting of trustful brands as Havells, ABB, polycabs, castrol, SnPc power solutions, Siemens, bonfiglioli etc. For more queries: 8818081001 https://alienskart.com/motors

#Alienskart#online shopping site#aluminium gearbox#bonfiglioli gearbox#vertical gearbox#worm gearbox#bevel helical gearbox

0 notes

Text

High-Quality VMC Job Work Services in Ahmedabad

In today’s fast-paced manufacturing industry, precision and efficiency are crucial for maintaining high-quality production standards. VMC (Vertical Machining Center) job work plays an essential role in achieving these standards by offering precision machining for various industrial components. If you’re looking for reliable and efficient VMC job work services in Ahmedabad, you’ve come to the right place.

VMC job work involves the use of advanced vertical machining centers to perform a wide range of operations such as milling, drilling, and boring on various materials, including metals, plastics, and composites. With a focus on quality, speed, and accuracy, VMC job work has become an integral part of industries such as automotive, aerospace, engineering, and electronics.

Why Choose VMC Job Work in Ahmedabad?

1. High Precision and Accuracy: VMC job work services ensure superior precision and quality in machining. The advanced CNC technology used in VMC machines allows for intricate designs and complex geometries to be produced with exacting accuracy. This is critical for industries that require high-quality, tight tolerance parts and components.

2. Versatility of Applications: VMC machines are versatile and can perform a wide range of operations, making them ideal for various industries, including:

Automotive: For machining parts like engine blocks, gearbox components, and chassis parts.

Aerospace: For manufacturing critical parts like turbine blades, engine components, and brackets.

Engineering & Manufacturing: For producing precision parts used in heavy machinery and equipment.

Electronics: For making intricate, small-scale components such as connectors and enclosures.

3. Skilled Workforce: In Ahmedabad, leading VMC job work providers employ highly skilled engineers and technicians with expertise in operating CNC VMC machines. These professionals ensure that your components are manufactured to the highest standards, with the perfect balance of speed and precision.

4. Timely and Cost-Effective Solutions: VMC job work in Ahmedabad is not only about precision but also about efficiency. These services are designed to optimize production timelines, ensuring that your components are delivered on time. Additionally, the cost-effectiveness of VMC machining makes it a preferred choice for businesses looking to produce high-quality components without compromising their budget.

5. Customization of Components: VMC job work offers flexibility in terms of customizing components based on your specific needs. Whether you need small, intricate parts or large, complex components, VMC job work providers in Ahmedabad can cater to your exact specifications, ensuring that the final product meets your requirements.

Benefits of VMC Job Work:

Precision: CNC-controlled machines ensure high levels of precision, minimizing errors and rework.

Speed: VMC machines can operate at high speeds, reducing production time significantly.

Reduced Costs: Automated processes reduce labor costs and material waste, making it a cost-effective solution for manufacturing.

Quality Control: Advanced features like tool changers and automated setups ensure uniform quality across all parts.

Flexibility: VMC machines can work with a variety of materials, including metals, plastics, and composites, making them suitable for a broad range of applications.

VMC Job Work in Ahmedabad – Why It’s the Best Choice

Ahmedabad is known for its thriving manufacturing sector, and VMC job work services in the city have gained a reputation for being top-notch. With a combination of advanced technology, skilled manpower, and a focus on customer satisfaction, VMC job work providers in Ahmedabad are equipped to meet the diverse needs of industries.

Whether you are looking for a one-off project or regular contract work, Ahmedabad-based VMC job work services can help you achieve the desired outcome with high efficiency and minimal turnaround time. From small-batch runs to large-scale production, these services can provide solutions tailored to meet your specific business needs.

Get in Touch with VMC Job Work Providers in Ahmedabad

If you are looking for reliable and high-quality VMC job work in Ahmedabad, reach out to one of the trusted providers in the city. Their expert team will ensure that your components are manufactured to the highest quality standards and delivered on time.

For more information or to get started with your VMC job work project, contact us today and experience the difference that precision and efficiency can make for your business.

0 notes

Text

Roles of Worm Reduction Gearbox in Conveyor Systems

Manufacturing operations together with mining activities and logistics services, depend on conveyor systems that efficiently transport materials throughout their operations. Worm reduction gearboxes serve as essential components to boost the operational levels of these systems. Users seek this gearbox type because it offers strong torque capacity within small dimensions. Worm reduction gearboxes enhance efficiency control speed and provide durable operations during conveyor use. This article investigates the essential functions of worm reduction gearboxes within conveyor systems, along with their necessity in industrial operations.

Torque multiplication and speed control

Worm reduction gearboxes increase torque by transforming high-speed motor input into low-speed, regulated output. This reduces wear and slippage by keeping optimum belt tension, avoiding overloading, and ensuring consistent material conveyance.

Higher Gear Reduction Ratios for Precision Control

Worm gearboxes, which offer up to 100:1 single-stage reduction, allow for precise speed control in conveyor applications, important for processes such as sorting, indexing, and metered material flow that require synchronized motion.

Self-Locking Load-Holding Mechanism

The inherent friction in worm gear systems enables mechanical braking to occur automatically, making external braking systems unnecessary and preventing conveyor back-driving or free-wheeling in gravity-fed situations.

Management of Axial and Radial Loads

Worm gearboxes efficiently handle axial and radial stresses due to their robust bearings and well-engineered gear meshing, ensuring smooth belt operation under heavy material loads without misalignment or excessive wear.

Heat Dissipation and Thermal Efficiency

Worm gears enhance longevity in high-duty cycle applications by minimizing losses due to friction and avoiding overheating in continuous operation when supplemented with heat-dissipating casings and high-performance lubrication.

Portable Design for Right-Angle and Inline Configurations

Space-saving conveyor systems can be combined due to the space-saving design, which accommodates both inline and right-angle power transmissions without requiring additional mounting space.

Noise reduction and vibration damping

Worm gears’ sliding contact mechanism dramatically lowers noise and vibration levels, which makes them perfect for conveyor applications in noisy settings like precision manufacturing, food processing, and pharmaceuticals.

Variable Frequency Drive (VFD) compatibility

Worm gearboxes and VFD-controlled motors work together smoothly to optimize conveyor performance depending on changing load needs by enabling real-time speed and torque adjustments.

Design that is Low Maintenance and Wear-Resistant

Worm gearboxes, made from self-lubricating components and high-strength alloy alloys, give long life with minimum maintenance, reducing operating expenses and downtime in conveyor systems.

Overload Protection and Absorption of Shock Load

The meshing action of worm gears inherently absorbs transient overloads and sudden shock loads, prolonging the lifespan of the conveyor system and the gearbox and preventing mechanical failures.

Conclusion

Worm reduction gearboxes serve essential functions in improving conveyor system operational performance. Such gearboxes play an essential role in industrial automation since they deliver both efficient torque control and energy conservation along with secure operation. Companies that need to enhance conveyor efficiency recognize worm-reduction gearboxes as an excellent investment because they process heavy loads while offering noise reduction and tight design compatibility.

Call to Action

High-quality worm reduction gearboxes provide the solution for conveyor system optimization. Our team is ready to help you obtain superior gearbox solutions designed exactly for your industrial operations. Contact us now.

#gearbox repair ahmedabad#gearbox repair cost ahmedabad#gear box manufacturing ahmedabad#double reduction gearbox ahmedabad#reduction gear manufacturers#gearbox repair services ahmedabad#reduction gearbox manufacturers#gearbox manufacturer#gearbox vertical ahmedabad#buy worm reduction gearbox

0 notes

Text

Top Industries Benefiting from Gearless Motor Technology

Gearless motor technology has become a game-changer in multiple industries due to its efficiency, durability, and low maintenance requirements. Unlike traditional motors with gears, gearless motors eliminate mechanical friction and energy loss, resulting in higher efficiency, smoother performance, and longer lifespan.

With advancements in direct-drive technology and permanent magnet motors, gearless motors are now widely used in electric vehicles, elevators, wind energy, robotics, and aerospace. This article explores the top industries benefiting from gearless motor technology and how they are transforming operations.

1. Electric Vehicles (EVs) and E-Bikes

The automotive industry is one of the biggest beneficiaries of gearless motor technology, particularly in the electric vehicle (EV) and e-bike markets. Gearless hub motors and direct-drive motors are commonly used in electric cars, scooters, bicycles, and e-rickshaws.

Benefits in EVs and E-Bikes:

Higher efficiency due to the absence of gear friction.

Quieter operation, making EVs more comfortable for urban commuting.

Less maintenance since there are fewer moving parts compared to traditional geared motors.

Regenerative braking capability, improving energy efficiency and battery life.

With the rise of sustainable transportation, gearless motors are playing a key role in reducing carbon emissions and enhancing the performance of electric mobility solutions.

2. Elevators and Lifts

Gearless traction motors have revolutionized the elevator industry, offering smooth, silent, and energy-efficient vertical transportation. Unlike conventional geared elevator systems, gearless motors provide direct drive to the hoisting mechanism, eliminating the need for oil lubrication and frequent repairs.

Advantages in Elevators:

Greater energy savings, reducing electricity costs in high-rise buildings.

Compact design, allowing architects to create more space-efficient buildings.

Higher load capacity, enabling smoother operation in commercial and residential buildings.

Minimal maintenance, making them ideal for high-traffic locations like malls, hotels, and offices.

With urbanization and high-rise infrastructure growth, gearless motors are becoming the preferred choice for modern elevator systems worldwide.

3. Wind Energy and Renewable Power Generation

Wind turbines have traditionally relied on geared generators, but direct-drive gearless generators are now being widely adopted in the renewable energy sector. These gearless wind turbines improve energy conversion efficiency and reduce mechanical failures caused by gearbox wear and tear.

Why Gearless Motors Are Ideal for Wind Turbines:

Higher efficiency in converting wind energy into electrical power.

Lower maintenance requirements, reducing operational costs in remote locations.

Longer lifespan, ensuring sustainable energy production over decades.

Quieter operation, minimizing noise pollution in wind farms.

With global efforts to expand renewable energy sources, gearless motors are helping increase wind energy adoption while reducing reliance on fossil fuels.

4. Robotics and Industrial Automation

The robotics industry requires precise, high-torque, and compact motor solutions, making gearless motors a preferred choice. Direct-drive motors in industrial robots improve accuracy, efficiency, and reliability, essential for industries such as manufacturing, logistics, and healthcare.

Benefits in Robotics and Automation:

Improved motion control, enabling precise robotic movements.

Compact size and lightweight design, making robots more agile.

Lower energy consumption, reducing operational costs in automated factories.

Reduced downtime, leading to higher productivity in industries like automotive and electronics.

As industries shift towards Industry 4.0 and smart manufacturing, gearless motors will continue to play a crucial role in robotic automation and AI-driven production.

5. Aerospace and Aviation

The aerospace industry requires high-performance, lightweight, and energy-efficient motor solutions, making gearless motors essential for aircraft systems, drones, and satellite applications.

How Gearless Motors Benefit Aerospace Applications:

Lighter weight, reducing fuel consumption in aircraft.

Higher reliability, essential for critical flight control systems.

Silent operation, minimizing noise in drone and satellite technology.

Minimal vibration, ensuring precision in aerospace navigation systems.

With the growth of electric aircraft, UAVs (Unmanned Aerial Vehicles), and space exploration, gearless motor technology is playing a significant role in enhancing propulsion efficiency and sustainability in aerospace engineering.

The Future of Gearless Motor Technology

With ongoing advancements in materials, electronics, and AI-powered control systems, gearless motors are set to expand into more industries. Some emerging trends include:

High-performance gearless motors in medical devices, such as MRI machines and robotic surgical equipment.

Magnetic levitation (maglev) transport systems, using gearless motors for ultra-fast trains.

Smart home appliances, integrating gearless motors for silent and energy-efficient operation.

As industries prioritize energy efficiency, sustainability, and automation, the demand for gearless motor technology will continue to grow across multiple sectors.

Conclusion

Gearless motor technology is transforming industries by offering higher efficiency, lower maintenance, and longer operational lifespan. From electric vehicles and elevators to wind energy and robotics, gearless motors are improving performance, reducing costs, and promoting sustainability.

With continued advancements in direct-drive motor systems, industries will further benefit from quieter, more reliable, and highly efficient motor solutions in the years to come. Businesses adopting gearless motor technology will gain a competitive edge while contributing to a more energy-efficient and sustainable future.

0 notes

Text

T3 AKA "Yetanotherthezeus" (1982) by Alan Dibley, Cheddar, UK. The Micromouse competition has come of age, and now the problem facing most competitors is not how to reach the target, but how to get there faster. The pre-match favourite at the 1982 British finals of Euromouse, Thumper, was beaten into fifth place by Alan Dibley's T3 which came first with a winning time of 1 min 13 secs. "T3 was my first second-generation mouse, and works quite differently. The single front wheel is driven by a motor and gearbox mounted on a vertical pivot. It is steered by a radio-control servo working through a pair of connecting links similar to steam-locomotive con-rods — but a bit smaller. The mouse has two rear wheels which are free running. The tricycle arrangement allows the mouse to turn about his own centre at corners and dead ends. … To turn, the mouse stops at the centre of the square. Then the software takes control of the servo, turns the front wheel 90° left or right, turns the motor on for the correct count of wheel pulses, straightens the steering, switches back to hardware steering control, and restarts the motor." – DIY about the mouse, by Alan Dibley, Practical Computing July 1984.

6 notes

·

View notes