#vacuum form plastic sheets

Explore tagged Tumblr posts

Text

Vacuum Form Plastic Sheets for Molding

Vacuum forming is a widely used plastic molding process in which a sheet of plastic is heated to a pliable temperature and then formed over a mold using vacuum pressure. This technique is commonly employed in industries such as automotive, packaging, and consumer goods for producing items with complex shapes. Vacuum Forming Sheet Manufacturers In Ahmedabad play a crucial role in this process as they provide the necessary material that can be shaped and molded to various specifications. The demand for these sheets has been steadily increasing due to the versatility and efficiency of vacuum forming, making it a popular choice for manufacturers.

What Are Vacuum Form Plastic Sheets?

Vacuum form plastic sheets are specially designed plastic materials that are heated to a soft and flexible state, allowing them to conform to the shape of molds under vacuum pressure. These sheets are typically made from thermoplastic materials like ABS, PETG, polystyrene, and polycarbonate, each chosen for their unique properties such as durability, flexibility, and ease of processing. Once the plastic sheet is heated and placed over the mold, a vacuum system pulls the air out from underneath the sheet, forcing it to take the shape of the mold. The molded plastic is then cooled and hardened, ready for use in a variety of applications.

Materials Used in Vacuum Forming Sheets

The choice of material used in vacuum forming plastic sheets is critical to the final product’s quality, strength, and appearance. Some of the most common materials used in vacuum forming include ABS (Acrylonitrile Butadiene Styrene), which is known for its impact resistance and toughness, and PETG (Polyethylene Terephthalate Glycol), which is highly transparent and offers good chemical resistance. Polystyrene is also a popular option due to its cost-effectiveness and ease of processing. Polycarbonate sheets are favored for applications requiring high-impact strength and optical clarity. Manufacturers select materials based on the intended application, the required physical properties, and the desired aesthetic finish.

Applications of Vacuum Formed Plastic Sheets

Vacuum formed plastic sheets are used in a wide range of industries, from automotive and packaging to medical and consumer products. In the automotive industry, vacuum forming is used to create interior panels, dashboards, and trim pieces. Packaging manufacturers use vacuum-formed plastic sheets to produce custom packaging for products like electronics, food items, and cosmetics. In the medical field, vacuum-formed plastic sheets are used for protective covers, trays, and even medical device components. The versatility of vacuum forming makes it suitable for both small and large-scale production, providing manufacturers with an efficient way to produce complex parts at a relatively low cost.

Advantages of Using Vacuum Forming in Plastic Molding

One of the primary advantages of vacuum forming is its cost-effectiveness, especially for short to medium production runs. The process requires minimal tooling compared to other plastic molding techniques, such as injection molding, which significantly reduces upfront costs. Additionally, vacuum forming can be used to create intricate shapes and textures, providing designers with greater flexibility. The process is also relatively fast, making it ideal for industries that require rapid prototyping and quick turnaround times. Vacuum forming also offers the ability to use a wide range of plastic materials, each suited to different end-use requirements, enhancing the flexibility of the manufacturing process.

Selecting the Right Vacuum Forming Sheet Manufacturer

When it comes to sourcing vacuum forming plastic sheets, it’s crucial to choose a manufacturer that offers high-quality materials and a reliable production process. In India, there are many reputable vacuum forming plastic sheet manufacturers who cater to both domestic and international markets. Vacuum Forming Sheets Manufacturers In India, for example, are known for their expertise in producing high-grade plastic sheets that meet the specific needs of various industries. These manufacturers ensure that their plastic sheets are produced using the latest technologies, offering superior durability, flexibility, and ease of molding. It is essential to select a manufacturer that can provide the right material specifications and production capabilities to meet the requirements of your project.

Understanding the Role of Vacuum Forming in Product Development

The vacuum forming process is particularly valuable during the product development phase because it allows for the rapid prototyping of parts. With vacuum-formed plastic sheets, manufacturers can quickly produce functional prototypes that accurately represent the final product design. This is especially beneficial for industries such as consumer electronics, automotive, and packaging, where design iterations are common and speed to market is critical. Vacuum forming helps manufacturers refine their designs before moving to full-scale production, reducing the risk of costly mistakes and improving the overall efficiency of the development process.

Quality Control and Precision in Vacuum Forming

Quality control is a crucial aspect of vacuum forming plastic sheets. The process must be closely monitored to ensure that the material is properly heated and molded to the correct specifications. Any inconsistencies in the temperature, pressure, or material quality can lead to defects in the final product, affecting its strength, appearance, and functionality. Leading vacuum forming sheet manufacturers in India implement strict quality control measures to ensure that their products meet industry standards and customer expectations. These measures include regular testing of the raw materials, as well as continuous monitoring during the forming process to detect and correct any issues promptly.

Conclusion

In conclusion, vacuum form plastic sheets are a vital component in the vacuum forming process, offering manufacturers the flexibility to produce a wide range of products with intricate shapes and designs. The use of vacuum forming has grown in popularity due to its cost-effectiveness, versatility, and ability to produce high-quality products with relatively low tooling costs. When selecting a vacuum forming sheet manufacturer, it is essential to consider factors such as material quality, production capabilities, and the manufacturer’s experience in meeting industry-specific requirements. By partnering with reputable Vacuum Forming Plastic Sheets Manufacturers In India, businesses can ensure the success of their molding projects and achieve high-quality results.

Frequently Asked Questions (FAQs)

What is the difference between vacuum forming and other plastic molding processes? Vacuum forming is a relatively simple process that uses heat and vacuum pressure to mold plastic sheets into specific shapes. Unlike injection molding, which injects molten plastic into molds under high pressure, vacuum forming relies on a heated plastic sheet and vacuum pressure. This makes it more cost-effective for low to medium production runs and simpler in terms of tooling requirements.

What materials are commonly used in vacuum forming? Common materials used in vacuum forming include ABS, PETG, polystyrene, and polycarbonate. Each material offers different properties such as impact resistance, transparency, and flexibility, allowing manufacturers to choose the most suitable option for their specific applications.

How do I choose the right vacuum forming sheet manufacturer? When selecting a vacuum forming sheet manufacturer, consider factors such as the quality of materials, production capabilities, lead times, and the manufacturer’s experience with your industry. It's important to choose a supplier who can meet your specific material requirements and provide consistent quality across production runs.

What are the advantages of vacuum forming for product development? Vacuum forming is ideal for product development as it allows for rapid prototyping and quick iterations. Manufacturers can quickly create functional prototypes that mimic the final product, enabling design adjustments before moving to full-scale production. This can significantly reduce development time and costs.

0 notes

Text

Latex (Fox/MC)

i wish i had an evil sugar daddy to buy me expensive sex toys. siiiighs and kicks a rock. anyway, yayyyyy latex i luv u so much

day 16: latex second person. somewhat softer fox but. coerced happy ending, he keeps you forever type of way.

"Well, well, well. Isn’t that a beautiful sight?"

The room almost seemed to shudder, walls contracting and the floor caving in, as the black latex, pulled to a shimmering tightness in the study, metal frame, like a sheet of pure liquid void, constricted around your naked body almost instantly, every inch of breathable space removed by the suction of the vacuum.

You’d had the good sense to fill your lungs with air before it was switched on. Fox has been kind enough to let you know about that, at the very least, so once it was turned off, you did your best to keep your chest still and steady, and your belly was slightly distended from the amount of air you managed to pull into your burning lungs before it was gone completely..

The latex clung to every inch of your body like a second skin, suctioned tight to every curve and crevice of bone structure, rendering your form slick and smooth and utterly featureless.

It was an appealing concept.

One that Fox was good enough to indulge, every now and then.

He was sitting across from you (even if you couldn't see him), smiling placidly and silently watching as the latex continued to suck and squeeze around your curves, only growing tighter as each second ticked by.

Once it was finished, the vacuum clicked off automatically.

It almost felt too good (good enough for you to ignore the breathlessness anyway) to be suspended and kept so still, wrapped up tight like a fragile, and cared for package. The constant thrumming pressure in your body, that made your ear ring and your heart pound, made it feel that much tighter, too.

"Absolutely perfect." Fox purred, sultry and sumptuous, his tail wagging idly behind him, his voice giving away every ounce of his pleasure. “You’ve always looked perfect in bondage, though. Hardly a surprise.”

“Hmmph..." You whined at his praise, almost surprised that you still had the voice to (when your featured were so compressed and smushed down), blinded and helpless as you were as you tried to move, your shoulders flexing and your tight body tensing and relaxing in short succession.

It wasn't bondage in the traditional sense, because you could...sort of move.

But, in the frame and packed between the two sheets of plastic, like a caught animal or insect, each movement was languid and slow, like moving through water, so...you stopped trying to move all together.

He stood, finally, the metal heels of his shoes (putting him at an equal height to you) making you shiver with each step, and moved closer to you, before slowly running his finger tips over the smooth surface of the latex, like he was caressing a rare and beautiful sculpture, his expression caught in a mixture of awe and appreciation, and primal hunger.

You didn’t even need to see it to know that much was true, and just that was enough to make you shiver again.

His fingers were warm and comforting too, without even a hint of claws, a far cry from his usual treatment of you, making the gradual asphyxiation that much more worth it.

"Just look at you." He murmured, his voice a low and hungry, and deeply worshipping whisper, tracing the smooth black like a blind man reading braille. "So beautiful, so lovely, my pet. You're everything I could have possibly wanted.”

He continued to caress you, both hands now slowly moving over and across your body, making every inch of your covered flesh that much more sensitive and needy for him.

"Like a piece of art. Hmph,” He barely suppressed a chuckle. “I ought to hang you on the wall, and charge my best clients to come gawk at you. Wouldn't that be a fine thought?"

You whimpered at the idea (knowing he may very well do it), your thighs tensing slightly under his touch, the most you would allow yourself to move in this state.

He chuckled again, clearly enjoying the sight of you squirming and wriggling in the inky black.

"Even better,” He stared with a little click of his tongue (condescension was his natural inclination, after all). “How about I display all my offerings like this, hm, like my own personal gallery? Let everyone see the masterpieces I get to enjoy whenever I please." He leaned in closer."And you, my darling, you would be my masterpiece. My Mona Lisa."

You couldn't see him through the sheet of latex, couldn’t see his handsome features smirking and goading you, so well suited to his position of dominance over you (over others) but you could feel him, feel his burning warmth, his intimidating presence.

And that too was an appealing concept, certainly...

"Yes, I think I quite like that idea.” He breathed out, his other hand pressed to the empty space beside you as he leaned in, somehow feeling even closer than before. “A little collection of living statues, on display for my own personal viewing and entertainment. And you…”

His slim hips pressed against your thigh, and you could feel the beginnings of an erection stirring in his well-tailored pants, even through the layer of latex and fabric.

“You'd be the perfect centrepiece, wouldn't you, my darling? Trapped and bound, forever on display, like the work of art you are."

Your thighs tensed up again as he rubbed himself against you, another helpless whimper lurching from your throat as breathlessness rapidly approached, as he grew more and more excited and aroused next to you.

"Mmm, such a gorgeous sound," He purred, his hand moving down to the firm, compressed flesh of your chest, feeling for the slightly swelled edge of your nipple, pressed right up against the plastic, and teasing it, continuing to grind his hips against your thigh and indulge himself all the while. "You'd enjoy that, wouldn't you? Spending…nhh,” His body stilled for a moment, overwhelmed by his own pleasure. “T-The rest of your days trapped like this, helpless and trapped on display for my own amusement?"

"Hfff..."

You breathed out your final lungful of air, finding your throat hitching and contracting on nothing suddenly.

“But you should know by now that I’m not asking for your permission, darling. I mean, you can't even talk in this state, can you?" Fox tittered (the authentic, honest cackle of a fox, a predator, instead of the practised chuckle of a showman), watching indulgently as your breath caught in your empty throat, again and again.

He leaned in a little closer, his breath warm and his body hot.

"I bet you wouldn't want to, even if you could. I bet,” He gave your nipple a mean flick, making you whine again. “You'd just want to be a good little sculpture for me, hmm? Hah,” He breathed out another laugh. “I knew someone just like that, before. So resistant to being a person…but the perfect object, when I wanted him to be~”

You tried to swallow another breath as he was reminiscing, but the plastic was too tight, too encasing, too much, fuck, too much-!

"Hmm, getting a little breathless, are we?" He asked with another murmur of pleasure, dark amusement in his tone as he watched you struggle with your breath, your attempts to swallow met with the unyielding rubber caressing and constricting around your throat. “What a shame. I do hate blemishes in my art pieces, though, and well…” He dragged a single finger up and down your trembling stomach. “Air holes are so unsightly, aren't they, darling?"

You whimpered, trying to give your head a little shake, pleading for his understanding and mercy, pleading for breath.

"Ah ah," He chastised you, his fingers stopping at the slope of your mons, giving it an indulgent rub, tittering again when your body stilled and you moaned, without the air to do it. "Can't have you shaking your head at me, now, can we? After all, you're supposed to be a good little statue. Just a piece of art for me to look at and admire, and take down as I please."

You whimpered again, keeping still as best you could (despite how much you wanted to keen your hips forward in the tight space) but pleading, with noises alone, for something, a break, mercy, anything when your head was spinning so much.

He drew it out as long as he possibly could, relishing in your trembling and rubbing his erection against your thigh, jerking erratically as a result of your breathlessness

Eventually, though, he took pity on you. He grabbed the organic seal in the latex, which was slit down the middle of the sheet, in his thumb and forefinger and pulled it apart, providing you with just enough space for your lips to escape the suction of the vac bed and take in a desperate lungful of air.

You coughed as soon as it hit you, taking in gasping gulps, your bound body still shivering as you readjusted, like breaching the surface of an ocean.

"There we go, that's much better, isn't it?" He said with good humour, rubbing his thumb over your trembling lips, letting the seal slide up higher and revealing more of your face to the open air. "Take your time, take everything you need.”

"T-Thank you...hahh..." You breathed out, your head sagging forward slightly (your face slick with sweat) as your spotty vision gradually subsided and you acclimated back to having a body.

"A little gift of mercy," He said with a shrug and another practised chuckle. "I can't have my prized pet passing out on me, after all...mm,” He hummed thoughtfully, tipping his head to the side, his eyes creasing handsomely with thought. “We do need to improve your lung capacity though, don't we? That was barely two minutes..."

"Mm...mmhmm," You nodded as best you could, taking in another few deep breaths and giving him an appreciative (if trembling) smile as you raised your head again to look at him. “Yes, sir.”

"And perhaps if you behave nicely, I'll give you a little extra time to catch your breath," He mused, stepping forward again, his fingers tracing down your neck and over your shoulders. "But I won't give you too much, will I? I do want to admire my pieces as they should be, after all."

"No sir," You replied quickly, giving your head another little shake as you felt a rush of heat run down your body and to your groin.

You knew how to play his game. You played it well.

Exceptionally well, if you did so say yourself.

It certainly also helped that you enjoyed playing the game, too.

"Good girl," He praised, his tone dipping down to something almost soft and light, as he continued to indulgently stroke and caress every inch of your encased body, gently tipping your chin up to look you in the eye. "Are you enjoying yourself, my darling? I certainly hope so, this was an awfully expensive luxury for you, if not..."

"Yes, I’m enjoying it. I just…mm…” You explained quietly, letting your hand shift downwards, with what little breathing room you were allowed, feeling the growing slick between your legs. “I just wanted to feel it. See if it’s as good as it always looked.” You took in a little sigh as your fingers grazed your swollen clit, still looking him in the eyes. “It’s even better.”

“Mm, naughty, naughty…” He smirked, watching as you eased your fingers deeper inside yourself, the latex doing nothing to hide it. “You’re getting excited, aren’t you?”

“Yes, sir.” You replied obediently, not finding any reason to hide it.

He chuckled again at your reply, his eyes intently watching you as you shifted your hand even lower, the latex still sucked tight around your fingers as they twitched and thrust inside of you. "Mm, and feel what exactly?” He continued to probe, moving his hand back to tease your nipple. “The restriction? The way you're completely helpless for me?” His smirk softened slightly. “Or just how completely beautiful and perfect you look right now?"

"Mm...all of the above?" You suggested with a dreamy smile, still a little out of it, as the wet slide of your fingers in your cunt made your breathing shake again.

He laughed his authentic laugh, barking and ripping with genuine delight, which sent a shiver down your spine.

"Of course, a little masochist like you would love this sort of thing. You're really far too much, darling. But I'll give you a reward for your honesty, how does that sound?"

“That sounds wonderful, sir.”

“Good girl. Now, take a deep breath-”

61 notes

·

View notes

Text

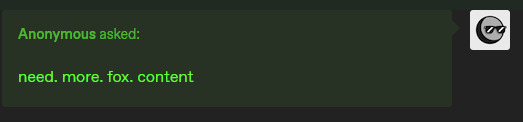

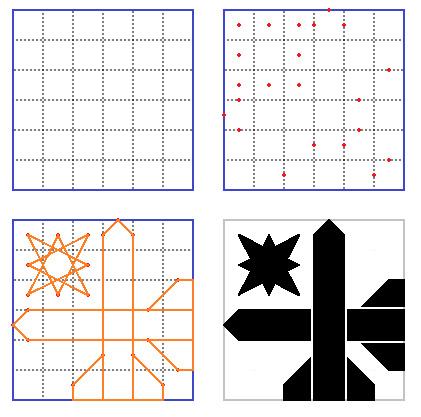

Obsessive Dr. Stone fans (such as yours truly) may find that a kingdom of science stencil is a very powerful thing to have, as I will demonstrate. Fortunately for all of you, I have come up with a reliable way to draw this emblem.

You can draw it on a sheet of math paper and cut it out, or trace it to a sheet of plastic and have it last a long time. You can stencil it on the copper sulfate! (or your preserve jars)

The simplest objects can take on a new meaning, such as a small cardboard box

How about a battery for your phone? (this one's great at running vacuum tube filaments)

It goes great on a rustic notebook or journal

Got any form of measuring or scientific instrument lacking a touch of pride? now they can belong to the kingdom of science, such as this old analog multimeter.

You can stencil it on the age meter !

Maybe you are an ethusiast who got a telescope to your name, even if it's made from stuff you found in the dump

I would love to know that somewhere out there, someone's made this. If you do, please let me know by any means, and I promise I will at least share it here in my blog.

As dumb as it may be (and I do feel kinda dumb feeling this way about horny science veggietales), deep down I want to believe that at least some of us are not just fans and we do share a vision, and despite the distance or perhaps not even knowing each other at all, we can still come together in unity under this symbol.

I'd like to believe that we can have that small connection, which feels so rare and so yearned for these days. The world is too chaotic and brutal to feel like you don't belong anywhere.

#dr. stone#dr stone#dcst#drstone#kingdom of science#art#suika#dr.stone#dr stone suika#suika dr stone#dcst suika

260 notes

·

View notes

Text

The latest render of my planned Eurorack case, the 9U×104HP design I've been planning. I tried making the pieces of the frame more clear by making the edges of each look more like plywood, added some cables — the one from the output module across to the mixer and the one providing power — and spent a really disproportionate amount of time changing the knob on the output module to be a pretty accurate facsimile of the Davies 1900H knobs I've taken to using. (I'll swap the other modules' knobs for the proper ones soon; having one good copy of the 1900H means I can reuse it in the appropriate colors all over the system.)

There's kind of a lot of apparently wasted space in there. I designed the thing around the idea that each row of modules was effectively its own volume, a cuboid of the 104HP by about six inches deep, and then making the case contain those. Now, it's hard to find a Eurorack module that's actually 6" deep — most commercial modules now seem targeted to super-shallow skiff cases — but I was concerned because I'm, you know, making most of these myself, and I think the idea was to accommodate a whole Eurocard prototyping board set in there on end. That said, the case as shown actually takes up less space than my existing 3U×84HP case when it's open, though with the angles involved that's got a lot of empty space too.

At any rate, I need to break the individual planks back out to a set of 2d CAD drawings that I can get cut at the makerspace; I believe the whole thing fits into a single half-sheet of three-quarter inch plywood, and once I confirm that I can start getting the wood and the rails. And of course I'm going back and forth on whether the case needs a lid for some degree of portability, and whether that would be just completing the implied oblong, or some shallower shape in wood or plastic. It might actually work better to have the cover be a vacuum-formed bubble of plexiglass — hmmm.

2 notes

·

View notes

Text

Made from robust plastic materials, our vacuum form plastic sheets are perfect for a wide range of applications. Whether you're producing packaging, signage, or protective components, these sheets offer excellent impact resistance and formability. Their versatility ensures they perform in industries like retail, automotive, and healthcare. Lightweight, durable, and easy to work with, these sheets provide reliable results for any project.

0 notes

Text

Essential Steps to Prevent Water Damage in Your Home After a Hurricane

When a hurricane strikes, the damage can be overwhelming, especially when it comes to water intrusion. Protecting your home from further water damage after a storm is crucial to minimizing repair costs and preventing health risks like mold growth. Here’s a guide to help you safeguard your home from water damage after a hurricane.

1. Take Immediate Action to Remove Standing Water

Why It’s Critical:Standing water can quickly deteriorate your floors, walls, and belongings. It can also lead to mold, which grows within 24-48 hours of water exposure. The sooner you remove the water, the better.

Steps to Follow:

Use a Wet/Dry Vacuum: If you have one, use it to suck up standing water from floors, carpets, and furniture. If there’s a lot of water, you may need to rent or hire a pump.

Sump Pumps for Basements: If your basement is flooded, make sure to use a sump pump to clear out the water quickly.

Move Items Out of Water’s Reach: Shift valuable or sensitive items like electronics, documents, and furniture to higher ground to prevent them from being damaged further.

2. Dry the Affected Areas to Prevent Mold Growth

Why It’s Critical:Mold grows fast in damp conditions, often starting within a day after water exposure. Mold can cause severe damage to your property and health issues such as respiratory problems and skin irritations.

Steps to Follow:

Use Dehumidifiers: Dehumidifiers help to reduce humidity and remove excess moisture from the air. This is especially important in rooms like basements or any area that’s been flooded.

Increase Airflow: Open windows, and use fans to circulate the air and help dry wet areas. If it’s safe to do so, run the HVAC system to help with drying.

Remove Wet Materials: Remove carpets, furniture, or drywall that has been soaked. If these materials are left behind, mold will form and spread, making the cleanup process much more difficult.

3. Inspect Your Roof for Damage

Why It’s Critical:Your roof bears the brunt of storm winds and rain. If it’s compromised, water can seep into your home, worsening the situation and leading to leaks, mold, and further structural damage.

Steps to Follow:

Look for Missing or Damaged Shingles: Check your roof for shingles that have been torn off or loosened by the storm. These gaps need to be sealed quickly to prevent rainwater from entering.

Cover Exposed Areas: If you find any open spots on your roof, use tarps or plastic sheeting to cover them temporarily until professional repairs can be done.

Clear Gutters and Downspouts: Ensure that gutters and downspouts are free of debris, as blocked gutters can overflow and cause water damage to your home’s foundation.

4. Seal Off Windows and Doors

Why It’s Critical:Broken or unsealed windows and doors can allow rain to flood into your home, worsening water damage and causing further issues like mold and mildew.

Steps to Follow:

Cover Broken Windows: If you have broken windows, cover them with heavy-duty plastic sheeting or plywood. This will prevent rainwater from entering and causing additional damage.

Seal Gaps Around Doors: Check the weather stripping around doors for gaps. Use caulk or sealant to block any leaks. If doors are severely damaged, temporary boards can be used to seal them until you can get proper repairs.

5. Check Your Plumbing for Leaks

Why It’s Critical: Flooding can damage your plumbing, causing leaks that can continue to cause water damage long after the hurricane. Pipes, fixtures, and appliances that were submerged are vulnerable to breaking or leaking.

Steps to Follow:

Inspect Visible Pipes: Check all exposed pipes in your home for cracks or leaks. If you notice any issues, it’s important to address them as soon as possible to prevent further water entry.

Clear Drains: Ensure that drains are not blocked by debris. You may need to clear the pipes to prevent backups.

Check Appliances: Inspect appliances such as washing machines and dishwashers for leaks, especially if they were affected by flooding.

6. Tackle Potential Electrical Hazards

Why It’s Critical:Water and electricity don’t mix, and flooding can create hazardous conditions, including electrical shocks or fires. Ensuring your electrical system is safe is critical to protecting your home.

Steps to Follow:

Turn Off the Power: If you haven’t already, turn off the power to your home at the circuit breaker to prevent electrical hazards.

Check Wiring: After the water has been removed, check wiring and electrical outlets for any damage. If there’s any sign of water damage, it’s best to contact an electrician for repairs.

Avoid Using Water-Damaged Appliances: Do not use appliances that were exposed to water until they have been inspected by a professional.

7. Document the Damage for Insurance Claims

Why It’s Critical:In order to receive compensation for storm damage repairs, you’ll need to document everything for your insurance claim. Accurate records can help speed up the process.

Steps to Follow:

Take Photos and Videos: Capture detailed photos and videos of all the damage, including the affected areas of your home, furniture, and personal belongings.

Create a Detailed Inventory: Write down the items that were damaged, including their make, model, and estimated value. This will help support your claim.

Contact Your Insurance Company: File your claim as soon as possible to begin the repair process. Provide your insurance company with all the documentation you’ve collected.

8. Consult Professionals for Major Repairs

Why It’s Critical:Certain repairs, especially those related to mold removal, structural damage, and roof repairs, should be handled by professionals. These issues require expertise and specialized equipment to resolve properly.

Steps to Follow:

Hire a Licensed Contractor: If your home has suffered significant damage, hiring a licensed contractor is essential. They’ll ensure that repairs are done correctly and up to code.

Consider Mold Remediation: For extensive mold growth, contact a certified mold remediation professional. They have the training to safely remove mold without further contaminating your home.

Conclusion

After a hurricane, your first priority should be to prevent further water damage by acting quickly and addressing any immediate issues. By removing standing water, drying out your home, inspecting for roof damage, and sealing gaps in windows and doors, you can minimize damage and protect your home. Document everything for insurance claims, and don’t hesitate to consult professionals for major repairs. Taking these proactive steps will help you get your home back to normal and prevent costly long-term damage.

#HurricaneDamage#WaterDamageRepair#FloodDamagePrevention#MoldPrevention#StormDamageCleanup#HomeRestoration#HurricanePreparation#WaterDamageTips#EmergencyRepairs#RoofDamageRepair#PlumbingAfterFlood#ElectricalSafetyAfterFlood#InsuranceClaimsTips#FloodCleanupGuide#PostHurricaneSafety

0 notes

Text

The Importance of Packaging Films: Enhancing Product Protection, Shelf Life, and Consumer Appeal

Packaging films are an essential component in modern packaging systems, providing numerous benefits for manufacturers, retailers, and consumers alike. These films are made from various materials, including plastics, paper, and laminates, designed to encase products and ensure their safety, stability, and appeal. From food and beverages to electronics and pharmaceuticals, packaging films have a significant role in extending the shelf life, preserving product quality, and enhancing brand presentation. In this article, we will explore the importance of packaging films and the key benefits they provide across different industries.

Key Features of Packaging Films

Product Protection: One of the primary functions of packaging films is to protect products from physical damage, contamination, and environmental factors such as moisture, air, light, and temperature fluctuations. By acting as a barrier, packaging films prevent spoilage, contamination, and damage during storage, handling, and transportation.

Enhanced Shelf Life: Packaging films, particularly those made from materials with excellent barrier properties like polyethylene, polypropylene, or PET, can effectively preserve the freshness of perishable products such as food, beverages, and pharmaceuticals. By creating airtight, moisture-resistant packaging, these films help maintain product quality for longer periods, reducing food waste and increasing consumer satisfaction.

Lightweight and Cost-Effective: Packaging films are lightweight compared to other types of packaging materials such as glass or metal, making them a cost-effective option for manufacturers and distributors. Their lightweight nature helps reduce transportation costs and energy consumption, contributing to a more sustainable supply chain.

Versatility in Design: Packaging films offer flexibility in design and functionality. They can be produced in various thicknesses, sizes, and forms, such as rolls, sheets, or pouches, to suit the specific needs of a wide range of products. Whether it's a flexible pouch, shrink wrap, or blister packaging, films can be tailored to meet the unique packaging requirements of different industries.

Customization and Branding: Packaging films provide an excellent opportunity for branding and marketing. Custom-printed films allow manufacturers to display their logos, product information, and promotional messages, helping create an appealing visual identity and differentiate their products from competitors on the shelves.

Benefits of Packaging Films

1. Food Industry

In the food industry, packaging films are crucial for maintaining the safety and quality of food products. The films used for food packaging are designed to protect against moisture, oxygen, and light, which are the primary factors that cause food spoilage. Types of packaging films commonly used in food packaging include flexible films, barrier films, and vacuum-sealed films. These materials help preserve taste, texture, and nutritional value while extending the shelf life of products.

For example, vacuum-sealed films are commonly used to pack meats, cheeses, and ready-to-eat meals. These films remove air from the packaging, which helps prevent oxidation, bacterial growth, and spoilage. Additionally, the films are often designed to be microwaveable or oven-safe, making them convenient for consumers.

2. Pharmaceutical and Healthcare Industry

Packaging films are also critical in the pharmaceutical and healthcare industries, where the protection of medicines, medical devices, and health products is paramount. Films used in pharmaceutical packaging need to meet stringent regulations and standards to ensure the integrity and safety of the product. These films are designed to prevent contamination, tampering, and degradation due to moisture, light, and air.

Blister packs, which are commonly used for pills and tablets, rely on packaging films to ensure the product remains sterile and protected until it is ready for consumption. Additionally, medical packaging films can help extend the shelf life of sensitive medical products, such as wound dressings and surgical instruments, by providing a sealed environment.

3. Consumer Goods and Electronics

Packaging films play a crucial role in protecting consumer goods and electronics during shipping and storage. For fragile items like electronics, packaging films provide an added layer of protection against scratches, moisture, and dust. Specialized films, such as anti-static packaging films, are often used to safeguard sensitive electronic components from static electricity, which can cause damage.

For other consumer goods, such as cosmetics, toiletries, and household items, packaging films help prevent contamination and maintain product integrity. The transparency of many packaging films allows consumers to view the product inside, providing an added appeal for retail presentation.

4. Sustainability and Environmental Benefits

While packaging films are primarily designed for protection and preservation, manufacturers are increasingly focusing on producing more sustainable and eco-friendly films. Many packaging films are now made from recyclable or biodegradable materials, which helps reduce waste and the environmental impact of packaging. Additionally, the lightweight nature of these films reduces the overall carbon footprint associated with transportation.

Some innovative films are also designed to be compostable, allowing consumers to dispose of them in an environmentally responsible way. As sustainability becomes a priority for both consumers and companies, the demand for eco-friendly packaging solutions, including biodegradable and recyclable films, is growing rapidly.

Applications of Packaging Films

Flexible Packaging: Flexible films, such as stand-up pouches, sachets, and wrappers, are commonly used for snacks, beverages, and food products. These films can be printed with attractive designs and are easy to handle, making them ideal for both manufacturers and consumers.

Shrink Films: Shrink films are widely used for bundling and packaging items such as bottled beverages, electronics, and food trays. The film shrinks tightly around the product when heated, providing a secure and tamper-evident seal.

Blister Packaging: Blister packs are made using a combination of a rigid plastic backing and a flexible film that forms the blister cavities. These are commonly used for tablets, capsules, and small consumer goods.

Barrier Films: Barrier films are designed to protect products from oxygen, moisture, and light, making them suitable for packaging high-value or perishable products such as coffee, cheese, and pharmaceuticals.

Conclusion

Packaging films are an essential part of modern packaging systems, offering numerous benefits including product protection, extended shelf life, and increased convenience for consumers. Their versatility, cost-effectiveness, and ability to enhance brand visibility make them an invaluable asset across industries such as food, pharmaceuticals, electronics, and consumer goods. As sustainability becomes more important, innovations in packaging films will continue to evolve, with a focus on eco-friendly materials and sustainable practices.

Ultimately, packaging films help ensure that products reach consumers in optimal condition, reduce waste, and provide manufacturers with an effective way to enhance their products’ shelf life and appeal. Whether for food preservation, product protection, or brand enhancement, packaging films remain an indispensable element in the packaging industry.

0 notes

Text

TS-1000 Thermoforming Machine: The Ultimate Solution for High-Precision Plastic Packaging

The TS-1000 Thermoforming Machine by INPAK is a cutting-edge innovation designed to meet the growing demands of the plastic packaging industry. As a leading thermoforming machine manufacturer, INPAK has combined advanced technology with efficiency to create a product that offers reliable, high-speed performance. This machine is the ideal choice for businesses looking to streamline their production lines with a high-quality plastic packaging machine that provides precision and flexibility.

INPAK, known for its expertise in the production of thermoforming machines, continues to lead the way in providing sustainable and innovative solutions. The TS-1000 Thermoforming Machine is engineered for use in various applications, including food packaging, industrial plastic components, and other high-demand production needs. With its exceptional capabilities and easy integration into existing production systems, the TS-1000 is a game-changer in thermoforming technology.

What is the TS-1000 Thermoforming Machine?

The TS-1000 Thermoforming Machine is a high-performance system designed for forming plastic materials into precise, durable shapes for packaging. It uses heat and pressure to shape thermoplastic sheets, turning them into various packaging products such as containers, trays, and lids. The machine is optimized for high-speed production while maintaining superior accuracy, making it a popular choice for businesses requiring consistent results.

As a thermoforming machine manufacturer, INPAK has developed the TS-1000 with advanced features that ensure high operational efficiency and flexibility. This machine's ability to handle a variety of materials such as PET, CPET, PP, PVC, PS, OPS, and PLA, makes it suitable for producing an array of plastic packaging products, ranging from food containers to industrial applications.

How Does the TS-1000 Thermoforming Machine Work?

The TS-1000 Thermoforming Machine operates by heating plastic sheets to a pliable state and then using vacuum or air pressure to form them into the desired shape. The machine utilizes advanced servo-driven systems for precise control over each step of the forming process. The upper and lower heaters are independently adjustable, allowing for optimal energy usage and consistent heat distribution, which ensures the best possible forming results.

Additionally, the TS-1000 incorporates a high-powered vacuum system and adjustable heating trays, enabling the machine to handle a wide range of materials. The system’s advanced sensors provide real-time monitoring and control, adjusting parameters to avoid sheet sagging and improve overall production quality. This makes the TS-1000 a reliable and efficient machine for businesses in need of high-precision plastic packaging machines.

Key Features and Specifications of the TS-1000

The TS-1000 Thermoforming Machine boasts a range of features designed to enhance production efficiency and product quality. With a maximum mold size of 1000 x 750 mm and a cycle speed of up to 70 cycles per minute, the TS-1000 is ideal for high-volume production needs. It can handle sheets up to 1040 mm wide and a maximum thickness of 1.5 mm, making it a versatile machine for various plastic packaging applications.

Other notable features of the TS-1000 include servo-driven transport chains, adjustable sheet edge heaters, and an energy-efficient system with a vacuum pump capacity of 200 m³/h. These advanced components contribute to faster, more accurate production while keeping operational costs low. The TS-1000 is also equipped with a user-friendly control system, making it easy to adjust settings and monitor performance in real time, ensuring consistent output and high-quality results.

Applications of the TS-1000 Thermoforming Machine

The TS-1000 Thermoforming Machine is widely used in a variety of industries, from food packaging to industrial-grade plastic components. Its versatility allows it to produce high-quality food packaging machines, including containers, trays, and lids. The machine’s ability to work with eco-friendly materials like PLA further enhances its appeal to businesses looking to adopt more sustainable packaging solutions.

This thermoforming machine is also suitable for producing packaging for medical products, electronics, and other industries that require custom plastic forms. With its advanced features, the TS-1000 is capable of forming complex shapes with precision, making it an ideal choice for manufacturers who require high-performance plastic packaging machines for both large and small runs.

Why Choose the TS-1000 for Your Business?

Choosing the TS-1000 Thermoforming Machine from INPAK offers businesses a wide range of benefits, including improved production efficiency, cost savings, and consistent product quality. The machine’s advanced technology, including servo-driven motors and automated controls, ensures precise forming and reduces the need for manual adjustments. This results in fewer errors and reduced waste, contributing to a more efficient production line.

As a trusted thermoforming machine manufacturer, INPAK has designed the TS-1000 with long-term reliability in mind. Whether you're producing food containers, medical packaging, or other plastic products, the TS-1000 provides an efficient and cost-effective solution for your production needs. The machine’s ability to handle a wide variety of materials, coupled with its energy-efficient design, makes it an ideal choice for businesses seeking a high-performance plastic packaging machine that can keep up with evolving industry demands.

youtube

0 notes

Text

What is Food-Grade rPET and Why Is It Important?

Definition and Uses

Food-grade rPET (recycled polyethylene terephthalate) refers to recycled PET that meets rigorous safety standards for contact with food products. It is produced from post-consumer plastic waste, recovering and repurposing bottles and containers, and offers a sustainable alternative for manufacturers and packaging companies. Typically, food-grade rPET is utilized in a wide range of applications including food and beverage packaging, containers, and various other forms of consumer products.

Importance in Reducing Environmental Impact

The use of food-grade rPET sheets significantly contributes to the reduction of environmental impact. By recycling PET, fewer raw materials, such as virgin plastic, are required, leading to decreased energy consumption and minimized waste. Furthermore, implementing rPET into the production cycle helps in reducing carbon footprints, fostering a circular economy that promotes sustainability. As companies shift toward eco-friendly packaging solutions, rPET serves as a pivotal aspect of their transition towards greener alternatives.

How Does Decontamination Work in the Production of rPET Sheets?

Vacuum Decontamination Methods

Decontamination is crucial in ensuring that food-grade rPET sheets are free from contaminants. One effective approach involves vacuum decontamination methods, which remove impurities through a series of temperature and pressure adjustments. By applying heat under vacuum conditions, volatile organic compounds and other contaminants are effectively vaporized, ensuring the integrity of the recycled material. This not only enhances the quality but also ensures compliance with food safety regulations.

Solid-State Polycondensation (SSP) Procedures

In addition to vacuum methods, solid-state polycondensation (SSP) is utilized to further purify rPET. This process involves heating the recycled flakes under specific conditions that promote the removal of remaining contaminants, ultimately increasing the intrinsic viscosity of the material. The result is a higher-quality food-grade rPET that meets or exceeds regulations set forth by food safety authorities. Incorporating both vacuum decontamination and SSP in the production process significantly enhances the purity of the final product.

The Role of Extrusion in Ensuring Purity

Single-Screw Extruder Functions

Extrusion plays an essential role in transforming decontaminated rPET flakes into usable sheets. Single-screw extruders effectively mix and melt the material, allowing for a thorough integration of additives that further enhance the performance of food-grade rPET sheets. This process ensures a homogenous product devoid of any impurities, achieving the necessary specs for food-contact applications.

Melting and Conveying Process at High Temperatures

During the melting and conveying stages, temperatures must be optimized to facilitate the removal of any residual contaminants. This high-temperature processing not only ensures that any remaining impurities are eradicated but also assists in achieving the desired viscosity and flow characteristics for the food-grade rPET sheets. The high temperatures combined with efficient conveying infrastructure lead to the production of a clean and reliable end product.

Advanced Filtration Techniques for Food-Grade rPET

Types of Filtration Used

To achieve the desired purity of food-grade rPET sheets, advanced filtration techniques are employed throughout the production process. Various filtration technologies such as melt filters, screen changers, and fine filtration systems are utilized. These systems are critical in removing micro-contaminants, additives, and other particulate matter from the rPET melt.

Effectiveness in Removing Micro-Contaminants and Additives

The effectiveness of these filtration techniques ensures that the final food-grade rPET sheets maintain high standards of cleanliness. As contaminants are removed at multiple stages in the production cycle, the material's quality is significantly improved. This rigorous approach to filtration supports compliance with health and safety standards necessary for food contact materials, reinforcing the overall value of using food-grade rPET sheets in packaging applications.

For those seeking a reliable partner in food-grade packaging solutions, Intco Plastic offers exceptional products, including their Food-grade R-PET Sheet, which has been certified by the appropriate food safety authorities.

As the market moves towards sustainability and environmental awareness, utilizing food-grade rPET not only serves a functional purpose but also aligns with your commitment to reducing plastic waste. The solution offered by Intco Plastic may streamline your packaging operations while ensuring adherence to all safety regulations.

Washing and Pre-Treatment Processes: Ensuring a Clean Start

Initial Washing Steps

The initial washing steps are pivotal in removing significant surface contaminants from post-consumer PET materials. This phase typically involves several mechanical processes such as rinsing, soaking, and agitating the shredded PET flakes in water to dislodge foreign materials. Labels, lids, and rings can often cling to the surface and must be removed thoroughly to ensure high-quality end products. By executing these washing procedures effectively, the foundation for producing clean food-grade rPET sheets is established, thus paving the way for subsequent treatments.

Removing Labels, Lids, and Rings

Label and lid removal occurs during the washing step and is critical for quality. The adhesives used in labels can pose a risk of contamination, while lids and rings can impede the recycling process. Therefore, specialized equipment such as label removers and centrifugal washing systems are utilized. These machines employ mechanical agitation to ensure that all recyclable components are stripped away, leaving a clean substrate suitable for further processing.

Chemical Treatments for Additional Safety

Once the physical contaminants have been eliminated, chemical treatments are employed to enhance the safety and reliability of the recycled material. Various detergents and cleaning agents are applied to dissolve any remaining contaminants that mechanical washing may not have addressed. This chemical washing process is crucial in ensuring that any residues, odors, or chemical traces are removed. Such treatments are especially important for food-grade applications, as even minute contaminants could compromise product safety and quality.

Addressing Challenges in Producing High-Quality Food-Grade rPET

Quality of Postconsumer Scrap Materials

The quality of postconsumer scrap materials significantly impacts the production of high-quality food-grade rPET sheets. Variability in the source of recycled materials can introduce impurities that affect the final product's properties. By carefully sorting and categorizing the incoming materials, manufacturers can minimize risks associated with inferior-quality inputs. It’s essential to implement a stringent quality control process during the collection and segregation phases to ensure that only suitable materials proceed through the production pipeline.

Steps to Improve Material Performance and Consistency

To enhance the performance and consistency of food-grade rPET sheets, manufacturers often go through various upgrading procedures. Integrating advanced sorting technologies and purification methods can lead to uniform quality in the raw materials. Additionally, investing in training and operational best practices can help staff effectively manage the sorting and cleaning processes. Recognizing the importance of these steps will not only elevate the end user's experience but also foster trust in the sustainability claims associated with these products.

Integrated Solution for High-Quality Food-Grade Recycled PET Sheets

For manufacturers aiming to achieve a quality guarantee in their food-grade rPET efforts, integrating advanced processing technologies can provide a powerful advantage. Adopting a comprehensive approach that includes not only washing and chemical treatments but also state-of-the-art filtration techniques ensures all contaminants are addressed thoroughly. This solution can drive efficiency and reduce variability in the end product. As outlined by Intco Plastic, their integrated solutions are designed specifically to meet the rigorous standards required for food-grade applications.

Choosing the Right Manufacturer for Your rPET Needs

Selecting a reliable manufacturer for food-grade rPET sheets is essential to ensuring your products meet high safety and quality standards. Engaging with companies that prioritize compliance with FDA and EFSA regulations will provide you peace of mind. It's advisable to assess manufacturers' certifications and their commitment to sustainable practices. Companies like Intco Plastic not only deliver high-quality Food Grade Recycled PET Sheet solutions but also emphasize on sustainable materials made from recycled inputs. This commitment reflects their understanding of both environmental responsibility and the priorities of today’s packaging landscape.

Conclusion

When it comes to the production process of food-grade rPET sheets, eliminating all contaminants is crucial. From the initial washing and chemical treatments to addressing challenges with postconsumer scrap material quality, the steps taken will ultimately influence the integrity of the final product. By partnering with manufacturers that provide integrated solutions and uphold stringent compliance standards, you can achieve a high-quality, sustainable product fit for food contact applications. Embracing these methods not only enhances your operational efficiency but also solidifies your dedication to environmental sustainability.

0 notes

Text

0 notes

Text

Creating Interactive Displays with Vacuum Form Plastic Sheets

In today’s fast-paced retail environment, interactive displays have become essential for capturing consumer attention and enhancing the shopping experience. A key material that plays a significant role in the creation of these displays is the vacuum form plastic sheet. Utilizing vacuum forming techniques not only streamlines the manufacturing process but also allows for the production of visually appealing and functional designs. This article will explore how to create interactive displays using vacuum form plastic sheets, focusing on the benefits, techniques, and practical applications.

Understanding Vacuum Forming Sheet

Vacuum forming is a manufacturing process that involves heating a plastic sheet until it becomes pliable and then using a vacuum to shape it over a mold. The resulting product is a lightweight, durable, and highly customizable form. A Vacuum forming sheet is often made from thermoplastics such as polystyrene, polycarbonate, or acrylic, which can easily be shaped and molded. These materials are ideal for creating interactive displays due to their versatility and ability to be manufactured in various colors and finishes.

The Advantages of Vacuum Sheet for Packing

One of the most significant benefits of using a Vacuum sheet for packing is its ability to protect products during transit and display. The vacuum-formed sheets create a snug fit around items, reducing movement and the risk of damage. This is especially important for fragile products or those with intricate designs. Additionally, the lightweight nature of vacuum-formed packaging reduces shipping costs and environmental impact.

Moreover, vacuum sheets are easy to produce in bulk, making them an efficient option for manufacturers looking to create interactive displays on a large scale. The quick turnaround time associated with vacuum forming allows for rapid prototyping and production, enabling businesses to adapt quickly to market trends or consumer demands.

Designing Interactive Displays

Creating an interactive display starts with a well-thought-out design. When using a plastic sheet for vacuum forming, it is essential to consider the display’s purpose, target audience, and the type of interaction desired. Whether the goal is to inform, entertain, or promote products, the design should facilitate user engagement.

Step 1: Conceptualization and Sketching The first step in designing an interactive display is to brainstorm ideas and sketch potential layouts. Think about the key features that will attract customers, such as touchscreens, rotating displays, or integrated lighting. Consider how the vacuum forming process can enhance these features by creating a cohesive look that seamlessly integrates different elements.

Step 2: Creating a 3D Model Once the sketches are finalized, creating a 3D model of the display can help visualize the final product. Various software options are available for this purpose, allowing designers to simulate how the display will look and function. This stage is crucial for identifying any potential design flaws or adjustments that may be needed before proceeding with the mold creation.

Step 3: Fabricating the Mold The next step is fabricating the mold for the vacuum forming process. The mold can be made from various materials, including wood, metal, or plastic, depending on the complexity of the design and the intended production volume. A well-crafted mold ensures that the final product will match the design specifications and allows for precise detailing in the vacuum-formed plastic sheet.

Step 4: Vacuum Forming the Plastic Sheets Once the mold is ready, it’s time to begin the vacuum forming process. First, the chosen Vacuum forming sheet is heated until it becomes malleable. It is then placed over the mold, and a vacuum is applied to draw the plastic tightly against the mold's contours. This process creates an exact replica of the mold in the plastic sheet, resulting in a highly detailed and durable display.

Enhancing Interactivity with Technology

To create truly engaging interactive displays, integrating technology into the design is essential. Various components can be incorporated into vacuum-formed plastic displays to enhance user interaction.

Touchscreens and Sensors Integrating touchscreens into vacuum-formed displays allows customers to interact with the product or service. These touchscreens can display product information, videos, or promotional materials, creating an engaging experience for the consumer. Additionally, sensors can be incorporated to detect movement, triggering specific actions such as lighting up or playing sound effects when customers approach.

Lighting Effects Lighting plays a crucial role in attracting attention to interactive displays. LED strips or backlighting can be embedded within the vacuum-formed plastic sheets to create visually appealing effects. These lights can highlight key features, provide information, or simply create an inviting atmosphere that draws customers in.

Augmented Reality (AR) Incorporating augmented reality into interactive displays can elevate the customer experience to new heights. By using a smartphone or tablet, customers can scan QR codes or images on the display to access additional content, such as virtual tours, product demonstrations, or special offers. This integration not only enhances interactivity but also encourages customers to engage with the brand on a deeper level.

Practical Applications of Vacuum Form Plastic Displays

The versatility of vacuum-formed plastic displays allows for their use across various industries, from retail to exhibitions. Here are some practical applications of interactive displays created with vacuum forming sheets:

Retail Environments In retail spaces, vacuum-formed displays can be used to showcase products in an eye-catching manner. Interactive displays can provide customers with information about new products, promotions, or even product comparisons. Brands can also use these displays to tell their story, enhancing brand recognition and loyalty.

Trade Shows and Exhibitions Trade shows are an excellent opportunity for businesses to showcase their products and services. Vacuum-formed displays can create unique booth designs that attract visitors. By incorporating interactive elements, such as touchscreens or AR experiences, companies can leave a lasting impression and generate leads.

Museums and Educational Institutions In museums and educational settings, interactive displays created from vacuum forming sheets can enhance learning experiences. Touchscreens can provide visitors with additional information about exhibits, while interactive models can engage audiences in a hands-on manner, making learning fun and memorable.

Conclusion

Creating interactive displays with vacuum form plastic sheets offers a myriad of possibilities for engaging consumers and enhancing their experience. The process of Plastic sheet for vacuum forming not only allows for the production of detailed and durable designs but also provides opportunities for incorporating technology to create truly interactive displays. By understanding the benefits and practical applications of vacuum sheets, businesses can effectively capture consumer attention and drive engagement in various environments. As technology continues to evolve, the potential for innovative displays will only grow, making vacuum forming an essential tool in the world of interactive design.

Frequently Asked Questions (FAQs)

How can I incorporate graphics into my vacuum-formed display? Graphics can be applied to vacuum form plastic sheets using various methods, such as screen printing, digital printing, or vinyl decals. Integrating graphics directly during the forming process can also create a seamless look.

What industries can benefit from using vacuum form plastic sheets? Many industries can benefit from using vacuum form plastic sheets, including retail, education, healthcare, and exhibitions. Any industry that requires interactive displays can utilize this technology to enhance customer engagement and communication.

Is vacuum forming environmentally friendly? While traditional vacuum forming may involve plastics that are not biodegradable, many manufacturers now offer eco-friendly options, including recyclable materials and biodegradable plastics. It’s essential to research and choose suppliers committed to sustainable practices.

0 notes

Text

Plastic Thermoforming: An Essential Guide to the Process and Applications

Plastic thermoforming is a versatile manufacturing process that has become a cornerstone in industries ranging from packaging to automotive. It involves heating a plastic sheet to a pliable forming temperature, shaping it into a specific mold, and then trimming it to create a finished product. This method is favored for its efficiency, cost-effectiveness, and adaptability to a wide variety of applications.

The Thermoforming Process

Thermoforming involves several key steps:

Heating: A plastic sheet is heated to a specific temperature, making it soft and moldable. Common materials include ABS, PETG, PVC, and polycarbonate.

Shaping: The heated plastic is stretched over or into a mold using vacuum, pressure, or mechanical force. This step determines the shape and features of the final product.

Cooling: The formed plastic is cooled to retain its shape.

Trimming: Excess material is removed, and additional features like holes or cuts are added for functionality.

Types of Thermoforming

Thermoforming can be divided into two main types:

Vacuum Forming: In this process, a vacuum is used to pull the plastic sheet tightly against the mold. It is ideal for creating detailed designs and is commonly used in packaging and signage.

Pressure Forming: Here, compressed air is used to force the plastic into the mold. Pressure forming allows for more intricate detailing and is often used for high-end products like medical devices and automotive parts.

Advantages of Plastic Thermoforming

Cost-Effectiveness: Compared to injection molding, thermoforming has lower tooling costs, making it suitable for small to medium production runs.

Design Flexibility: Thermoforming supports complex geometries and can accommodate a wide range of sizes, from small containers to large vehicle panels.

Quick Turnaround: The simplicity of the process enables faster production cycles.

Material Variety: A broad spectrum of plastics can be used, offering options for durability, transparency, and recyclability.

Applications of Plastic Thermoforming

Plastic thermoforming finds applications across diverse industries:

Packaging: Used for blister packs, clamshells, and food containers.

Automotive: Dashboards, door panels, and protective covers.

Medical: Trays, enclosures, and protective casings.

Consumer Products: Toys, appliance components, and storage solutions.

Signage and Displays: Custom shapes for advertising and branding.

Challenges and Innovations

Despite its advantages, thermoforming has some challenges, such as material waste and limitations in wall thickness uniformity. However, ongoing innovations are addressing these issues. Advances in biodegradable plastics and more efficient trimming techniques are making thermoforming more sustainable and precise.

For more info:-

Thermoformed Products

Mold Design

0 notes

Text

Understanding Toys Packaging Trays | Uno Plast

Toys packaging trays are specially designed containers that hold and display toys securely. They are often made from materials like PVC, HIPS, or PET and are formed through processes such as vacuum forming or pressure forming. These trays not only protect toys from damage but also enhance their visual appeal on retail shelves.

Benefits of Using Toys Packaging Trays

Product Protection: Packaging trays shield toys from physical damage during transportation and handling, ensuring they reach consumers in perfect condition.

Enhanced Presentation: Clear trays allow consumers to view the product without opening the package, increasing the likelihood of purchase.

Brand Visibility: Customizable trays can feature brand logos and colors, reinforcing brand identity and recognition.

Tamper Evidence: Secure packaging trays provide evidence of tampering, ensuring product integrity and consumer trust.

Environmental Considerations: Many packaging trays are recyclable, aligning with sustainable practices and consumer preferences.

Materials Used in Toys Packaging Trays

The choice of material impacts the durability, clarity, and environmental footprint of the packaging tray. Common materials include:

PVC (Polyvinyl Chloride): Known for its clarity and durability, PVC is widely used in packaging trays.

HIPS (High Impact Polystyrene): HIPS offers good impact resistance and is cost-effective, making it suitable for various toy packaging applications.

PET (Polyethylene Terephthalate): PET is valued for its strength and recyclability, appealing to environmentally conscious brands and consumers.

Manufacturing Processes

The manufacturing process determines the quality and functionality of the packaging tray. Common methods include:

Vacuum Forming: This process involves heating a plastic sheet and forming it over a mold using vacuum pressure, creating a precise and durable tray.

Pressure Forming: Similar to vacuum forming but with additional pressure applied, resulting in higher detail and better surface finish.

Uno Plast: Leading the Way in Toys Packaging Trays

Uno Plast stands out as a premier manufacturer and supplier of toys packaging trays. Their commitment to quality, customization, and customer satisfaction makes them a preferred choice in the industry.

Customization and Design

Understanding that each toy has unique packaging needs, Uno Plast offers customized solutions tailored to specific product dimensions and branding requirements. Their design team collaborates closely with clients to create packaging that not only protects the toy but also enhances its market appeal.

Quality Materials

Uno Plast utilizes high-quality materials such as PVC, HIPS, and PET, ensuring that their packaging trays are durable, clear, and environmentally friendly. Their selection of materials aligns with industry standards and caters to diverse client preferences.

Advanced Manufacturing

Employing advanced manufacturing techniques like vacuum forming and pressure forming, Uno Plast produces packaging trays with precision and consistency. Their state-of-the-art facilities enable them to handle large-scale production while maintaining high-quality standards.

Commitment to Sustainability

Recognizing the importance of environmental responsibility, Uno Plast focuses on using recyclable materials and sustainable manufacturing practices. Their eco-friendly approach appeals to brands and consumers committed to reducing environmental impact.

Client-Centric Approach

Uno Plast places a strong emphasis on customer satisfaction. They offer timely delivery, competitive pricing, and responsive customer service, building long-term relationships with clients across various industries.

Applications of Toys Packaging Trays

Toys packaging trays are versatile and can be used for a wide range of products, including:

Action Figures: Securely holding figures in place, preventing damage and showcasing the product effectively.

Educational Toys: Organizing components neatly, making it easy for consumers to see all parts included.

Electronic Toys: Providing protection against static and physical damage, ensuring the toy functions properly upon purchase.

Collectibles: Offering a clear view of the item while keeping it protected, appealing to collectors who value both display and preservation.

0 notes

Text

Let’s face it, there are very few instances where humidity is not your friend. Proper storage of your personal properties and treasures is a key example of when you should not overlook this environmental factor. In short, there are certain budget-friendly options when it comes to storage units that do not account for humidity control, and much of the responsibility falls on you with knowing what’s inside your container and how susceptible it is to humidity. No matter your storage needs, humidity needs to be factored in. Here at SAM, we work hard to make sure that your property is protected from environmental elements such as heat, humidity and moisture. However, it’s important to understand how to protect your belongings in a storage unit from humidity. Don’t Let Storage Unit Humidity Sneak Up on You Don't underestimate the damaging effects of humidity on your belongings. It’s important to be mindful of this invisible threat when it comes to choosing your storage unit and how those units are packed. We want to help you understand and address the issue of environmental factors when it comes to your storage needs. Part of our storage container experience comes with a number of assurances. That’s why we offer materials that help mitigate humidity. We’re also happy to demonstrate techniques you can use when it comes to packing a storage unit that will protect your belongings from these environmental harms. One such technique is to be sure and store items in sealed containers. This can and often includes airtight plastic bins with secure lids. Small or medium-sized containers like this will help to keep out the humidity as well as dust and potential pests depending, of course, on how long your personal items are stored. When it comes to fabrics such as clothing, bedding or linens, another option is to consider vacuum-sealed bags. These have been popular for a while as they effectively protect against moisture, mildew and odors. Here at SAM, we can also assist with other ideas such as how to apply protective coatings to sensitive items such as metal, tools or any small or medium-sized machinery. With humidity comes moisture and, of course, moisture is no friend to metals and tools. Do you need to create a moisture barrier for your storage unit? That’s not a problem. Our team can show you how to use heavy-duty plastic sheeting or tarps to keep moisture away. Pallets are also a good idea as they elevate your boxes or stored items off the ground. This allows air to breathe beneath your boxes and bins. Circulating air is crucial when it comes to preventing moisture buildup. Let SAM Show You How to Protect Your Belongings from Storage Humidity These are just a few quick examples of how one can shield storage units and stored property from the silent evil that is humidity and its close cousin moisture. If you’re looking to store your belongings, we can show you how to do it safely and with peace of mind. At SAM Store and Move we offer smart and affordable solutions for all of your storage needs, both short and long term. Contact us today or fill out the free quote form. Read the full article

0 notes

Text

Rotomolding vs. Other Plastic Manufacturing Processes: A Comparative Analysis

Plastic manufacturing encompasses a diverse array of techniques, each with its unique strengths and limitations. Rotomolding, also known as rotational molding, stands as a prominent player in this field, offering distinct advantages and disadvantages compared to other popular methods.

In this blog, we will explore the key characteristics of rotomolding and contrast them with those of injection molding, blow molding, and thermoforming, empowering you to make informed decisions for your manufacturing needs.

Rotomolding:

Rotomolding Process: Involves heating plastic resin within a rotating mold, allowing it to melt and coat the mold’s inner surface, creating hollow, seamless parts.

Advantages:

Design Flexibility: Exceptional freedom to create complex shapes, undercuts, and varying wall thicknesses.

Cost-Effectiveness: Low tooling costs make it suitable for small to medium production runs.

Large Part Production: Ideal for manufacturing large, hollow parts.

Uniform Wall Thickness: Ensures consistent wall thickness and structural integrity.

Stress-Free Parts: Produces durable and impact-resistant parts.

Disadvantages:

Cycle Time: Longer cycle times compared to some other methods, potentially impacting production speed.

Material Limitations: Works best with certain types of thermoplastics.

Surface Finish: May require secondary operations to achieve smooth finishes.

Injection Molding:

Process: Involves injecting molten plastic into a closed mold under high pressure

Advantages:

High Production Rates: Ideal for mass production with fast cycle times.

High Precision: Produces parts with excellent dimensional accuracy and intricate details.

Wide Material Selection: Compatible with a vast range of thermoplastic and thermoset materials.

Disadvantages:

High Tooling Costs: Initial investment in molds can be substantial.

Design Limitations: Complex geometries and undercuts can be challenging or costly to achieve.

Wall Thickness Limitations: Limited ability to create parts with varying wall thicknesses.

Blow Molding:

Process: Involves inflating a heated plastic tube (parison) within a mold to create hollow parts.

Advantages:

Cost-Effective for Hollow Parts: Suitable for producing bottles, containers, and other hollow shapes with relatively low tooling costs.

High Production Rates: Offers fast cycle times for mass production.

Good Surface Finish: Generally produces parts with smooth surfaces.

Disadvantages

Limited Design Flexibility: Less suitable for complex shapes or parts with intricate details.

Wall Thickness Control: Can be challenging to achieve precise wall thickness control.

Material Limitations: Primarily used with thermoplastics with good melt strength.

Thermoforming:

Process: Involves heating a plastic sheet and forming it over a mold using vacuum or pressure.

Advantages:

Low Tooling Costs: Molds are relatively inexpensive compared to injection molding.

Quick Turnaround: Suitable for prototyping and small production runs.

Large Part Production: Can produce large, thin-walled parts

Disadvantages:

Limited Design Complexity: Less suitable for parts with deep undercuts or intricate details.

Material Limitations: Primarily used with thermoplastic sheets.

Wall Thickness Variations: Can be challenging to maintain consistent wall thickness throughout the part.

Choosing the Right Process