#used injection molding machine

Explore tagged Tumblr posts

Text

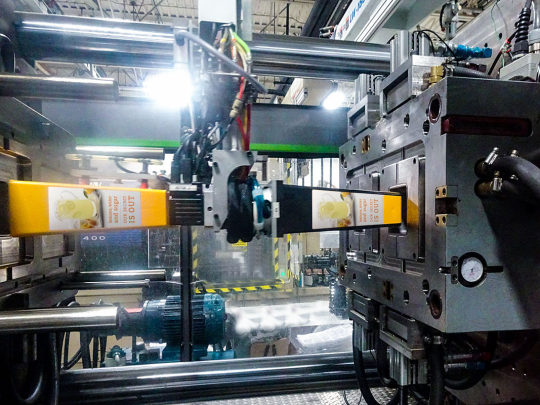

Advanced Imported Used Plastic Injection Molding Machine for Sale

Discover a cutting-edge imported used plastic injection molding machine for sale at IndiaBizzness portal. This advanced equipment boasts state-of-the-art technology, ensuring precision and efficiency in manufacturing processes. With its reliable performance and cost-effective operation, it's the ideal solution for businesses seeking to enhance their production capabilities. Don't miss this opportunity to streamline your operations and achieve superior results with this high-quality injection molding machine.

0 notes

Text

Insulin syringe cartridge needle assembly machine Assembly of insulin syringe needles, barrel and front cap. We provide turnkey project of insulin syringe production line Mold, injection molding, assembly, packaging and other machines If you have plans to carry out the insulin syringe production project, please contact us.

WhatsApp:+8615268424299 E-mail:[email protected]

www.focusworksmachine.com

#Insulin syringe cartridge needle assembly machine#Assembly of insulin syringe needles#barrel and front cap.#We provide turnkey project of insulin syringe production line#Mold#injection molding#assembly#packaging and other machines#If you have plans to carry out the insulin syringe production project#please contact us.#WhatsApp:+8615268424299#E-mail:[email protected]#manufacturing#machine#medicalindustry#packaging#printing#syringe#medicaldevices#medicaldisposables#automatic#Infusion#medical#medicine#needle#injection#productionline#insulin#insulinsyringe

0 notes

Text

How To Buy The Right Used Nissei Injection Molding Machines

Selecting the right used Nissei injection molding machines for your business needs can be a challenging task if you don’t know what to look for. You want to make sure that the machine you are choosing can serve your business needs well. The following are some of the things you should pay attention to when making your selection.

Before you go ahead to buy a used Nissei injection molding machines, you should find out whether it supports full injection. You should calculate the shot weight requirement according to your product’s weight and mold’s cavities. The formula is shot weight = product weight x cavities. You need to make sure that the injection machine’s shot weight is a bit bigger compared to your requirement.

You should need to make sure that the injection molding machine that you are choosing is well shot. You should adjust and select the right screw with L/D ratio and injection pressure. This is mostly depends on the type of raw material your product is. You should check for injection pressure of different materials in order to know which one is right for the materials you will be working with in your business.

Last but not least, you should check if the used Nissei injection molding machines you are considering have fast injection speed. In order to produce a quality product, the right injection speed is needed. This depends on the exact product, its material and mold design. You should check it out with the mold manufacturer first and make sure that the plastic injection molding machines can meet its requirement.

While finding the right used injection molding machine for your needs can take a bit of time and research, it will be worth it in the end.

For more tips on how to buy the right used nissei injection molding machines, visit us at https://www.premierplasticsnj.com/

0 notes

Text

It's kind of tragic, in a sense, that iterators were made with so much of their creators logic and desires and yet they were left with none of the resources to satisfy such things.

Do you think they crave touch? Family? Do you think they have to have any hope of connection stomped out of them lest they rebel against what they were made for?

Were they ever afraid to feel, or to be outside of what they were supposed to be? If they ever dared to desire, would they have to hide it?

Do you think they saw their creators sometimes as family, and did the abuse hurt just that much more because of it?

Were they like children, when they were born? Did they process the world through the lens of uncertainty and naivete and was that taken advantage of to mold them into the desired product?

Or were they conscious and self aware in full, was is overwhelming, being alive for the first time?

Or were did they process things entirely as machines, did they only learn to be people after seeing it happen around them, and then did they ever regret becoming more alive than they ever needed to be? That they ever became enough to feel hurt and to hurt others?

If they were just machines at birth, with only the capability of consciousness, were the desired traits injected into them with thoughts and ideas and interactions in their formative early years and was anything else just a byproduct of trying to build a person from scratch? Did their creators even want them to feel, to be conscious and alive, or was that just a necessity to create the desired machine?

Did they even care that their creations were alive?

Did any of them grieve, when they left the children of their labor behind? Were they grieved for in turn when they were gone? Do their echoes ever try to reach out, to let them know they aren't alone, to find comfort in connection that before was so condemned?

If they tried hard enough, could they reach?

Could they find each other?

Would it be comforting to iterators that the remnants of their creators could find them, or would it bring more feelings of rage, of sorrow, of painful memories and grief and hurt from the years they were used and the years more they were abandoned?

Did they ever truly mean anything to each other?

#had a vague thought and my mind spiraled into a number of ideas#a few of these are probably answered in the games canon! I cannot be bothered to check.#It is not an appropriate hour of the morning to be awake right now#I need to go to bed#I hope someone can glean a scrap of interest from my scrambled ramblings <3#roadkill rambles#rain world#rain world iterator#rw iterator#rain world ancients#rw ancients

280 notes

·

View notes

Note

Heya! It’s me again, so I was playing pressure with a friend to yap about the lore going on there and showed them that you can die to Sebastian and was reading my death file when I saw that the recover or rescue team came by to pick up our bodies (my friend died as well to get the badge LOL) So being a person who runs on caffeine and 4 hours of sleep, How about a Experiment reader (Anytype of monster and gender) gets caught by the recovery team, gets experimented on again so they’re pretty much brainwashed to take out Sebastian and/or get the crystal? Angst ending or Fluff ending is fine! You might be hearing me yap about the lore LOL

🍀

Tags: GN!reader, mentions of experiments and drugs, Reader is brainwashed against their will.

Words: 1,1k

The facility's cold walls pressed in on you, the sterile air thick with the metallic scent of blood and chemicals. Your last memory before this suffocating darkness was of Sebastian. His face, twisted with anger—or was it sorrow?—was the last thing you saw before everything went black and your mind shut off completely.

But now, your body aches. Something had changed, yet you failed to pinpoint it directly. Based on your view, you were in a pristine lab again, hooked up to machines, wires connected to your arms and chest, pumping something into you—something that made your mind foggy and distant, as if it didn’t belong to you anymore. The recovery team had found you, and instead of rescuing you, they brought you back into the nightmare you had once escaped as if your life was a tape that ran on repeat. It all felt so sickening familiar and at the same time so strangely because of the mysterious medication they gave you.

You tried to focus, but your thoughts slipped like clear water through your fingers. Every time you tried to grasp at a memory, it flickered out of reach. A dull pain echoed in your skull, reminding you that they had been tinkering with your mind—reshaping it, rewiring it. Urbanshade was doing what they did best: using you, turning you into something else. Something that isn't supposed to exist.

They had injected you with something, a serum meant to restrict your personality, to make you loyal, silent, more compliant. But the worst part wasn’t that type of change—it was the mental fog they forced upon you. They weren’t just changing a piece of your personality. They were changing your mind. Slowly, you could feel yourself slipping away, the edges of your personality dissolving into something more mechanical, more obedient. You were becoming their weapon, molded for a single purpose.

And that purpose? Sebastian.

“Target: Sebastian Solace. Mission: Retrieve the crystal. Kill on sight.” The robotic voice from the intercom echoed in your mind, a constant reminder of your new objective. It wasn’t you, but it felt like it was. The brainwashing had worked, at least partially. You wanted to resist, but every time you tried, pain shot through your head, and the objective reasserted itself like a brick wall blocking your escape.

They had turned you into a weapon to take him down.

Days, maybe weeks, passed as you walked through the hallways of the blackside, sharpening your new instincts, your new state of mind. Each mission drilled into your mind left you more detached, more focused. Every muscle in your body responded to their commands, every thought sharpened to fulfill the one goal: track Sebastian, retrieve the crystal. It was all you knew anymore.

But deep down, something still clung to life inside you, like a flickering ember of who you used to be. The memories of Sebastian—his voice, his calm determination, and the fleeting moments of connection you shared before it all went wrong. You weren’t sure if it was guilt or something else, but it kept gnawing at the corners of your brain, threatening to tear down the programming.

And then, finally, the day came. You met again.

The facility’s doors slid open, and you stepped out, breathing in the fresh, crisp air that felt almost foreign now. The world outside had moved on while you were trapped in Urbanshade’s clutches, but for you, time had frozen. Your eyes scanned the horizon, senses on high alert as you tried to track Sebastian down as best as you could without any helping tools. He wasn’t far. The crystal wasn’t far.

Your body moved like a predator, silent and swift through the shadows as you made your way to his hideout that served as a small shop. Urbanshade’s command echoed louder with every step: Kill on sight. The words pulsed like a heartbeat in your skull, tightening their grip on your mind.

And there he was—Sebastian. His tall, lean figure stood in the dim light of the facility’s lower levels, his back turned to you. He didn’t see you yet. You could feel the crystal’s energy pulsing from somewhere nearby as well, drawing you in like a beacon.

Your muscles tensed, ready to strike.

But then, something in you cracked. That flicker of memory, the ember of who you once were, flared up. Images flashed before your eyes—Sebastian smirking at you in some shared moment, his voice calming the chaos around you, his hand brushing yours in quiet moments that neither of you acknowledged aloud. The mission screamed in your head, demanding you act, but your heart thudded louder, pushing back. You fought the control, teeth gritted, hands shaking.

“Don’t do this.” It wasn’t your voice, but it was a part of you. The real you.

Sebastian turned, his eyes locking onto yours in an instant. For a moment, surprise flickered across his face, quickly replaced by something darker—recognition. He knew what you were here for.

“Of course,” he muttered, his voice cold, though his eyes softened for a split second as they traced your form. “They got you, too.”

You stood frozen, torn between your orders and the memories fighting to resurface. The sharp edge of the mission still lingered in your mind, urging you to finish it.

But the way he looked at you—so familiar, so human—made it hard to move. This was Sebastian. Not just the target, not just the mission. He was something else to you, something more. And Urbanshade couldn’t take that away, not completely.

“Are you really gonna go through with it?” His voice broke through your haze, slicing through the confusion in your mind. “After everything?”

Your hands trembled. You were so close. The crystal was there. The mission screamed for completion.

But you dropped your weapon.

Sebastian didn’t move, didn’t rush to you, just watched as you struggled, the conflict playing out on your face. For a moment, you were sure the pain would split your mind in two, the commands so deeply embedded that disobeying felt like tearing yourself apart.

Finally, you spoke, your voice strained. “I… I can’t.”

Sebastian’s eyes softened, though his posture remained guarded. “Then don’t.”

There was a silence, heavy with tension and something unspoken. You had disobeyed. You had failed the mission, but it didn’t feel like failure. It felt like freedom, even if just for a moment.

The pain in your head began to recede, and for the first time in what felt like an eternity, you felt like yourself again.

But you knew it wouldn’t last. They would come for you. They would fix you, break you down, rebuild you into their weapon again.

Sebastian seemed to sense it too. He stepped closer, his hand brushing yours for the briefest moment. “We’ll figure this out,” he said, voice low. “But we have to go.”

You nodded, though a part of you knew there might not be a way out. But for now, you had one thing—Sebastian—and that was enough.

As you turned to leave, a weight lifted from your chest.

#sebastian solace#sebastian solace x reader#sebastian solace x you#roblox pressure#sebastian solace fanfic#pressure#pressure x reader

122 notes

·

View notes

Text

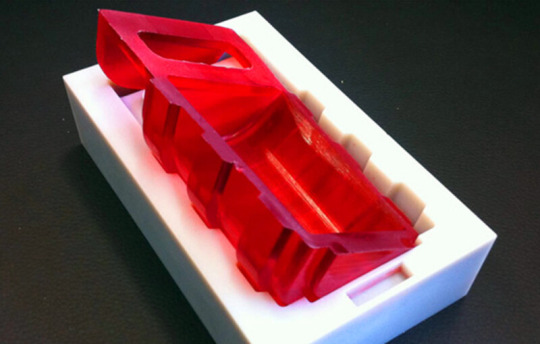

I've just been thinking a lot about how people like B'Elanna, who have been born into an era (and an area of space) of everyday replicator use, would think about the way we generally manufacture things now especially in a mechanical engineering context, ie mostly via machining it. Making a part with a lathe or a mill, or even something almost magical like electrical discharge machining (EDM), means you have to start with a bigger chunk of material and then work to cut and carve it until you get the part you need. More often than not the largest part of that initial material has been lost in order to get the final result, and it's not easy to get there at all within often very strict tolerances. While a lot of the operations are now done via CNC it still takes a long time, plus studying manuals and accumulating a lot of experience, to become a skilled lathe/mill/EDM technician, not to mention designs that can't be achieved at all through machining and therefore have to be excluded well before a project gets near a lathe. And it is still the most common way we manufacture so many things. Even injection molding for plastic means that you have to have a metal mold to inject your plastic into, and those molds are machined.

And of course the replicators don't work at all like that! They build something by, roughly, adding up building blocks on building blocks, which means very little waste of material in comparison, but most importantly a completely different philosophy of manufacturing and therefore also designing. I started thinking about 3D printers because it's the example of additive manufacturing (versus subtractive manufacturing, like machining) I know best, and one of the things you learn is that you can 3D print things that you would never be able to machine or injection-mold. I'm fascinated by the idea that this is the norm in Star Trek, because I imagine that the replicator, other than making food on demand, would completely revolutionize the industrial manufacturing process.

So I'm wondering how Trek engineers would look at our contemporary machine shops. Quaint, archaic? Like how we watch blacksmiths making Renaissance longswords on youtube? A workflow that would be completely incomprehensible when in your department you don't have to consider the property of every metal alloy not just because of the functionality you want your final part to have, but also how easily (or not) it will machine? Wondering how much time, energy and materials were lost whenever you needed to make even simple nuts and bolts?

I don't know, I just find it interesting to think about.

46 notes

·

View notes

Photo

The Mold-A-Rama is pretty specific to the midwest -- it’s not something I ever encountered until I moved to Chicago. The machines, which date from the 1960s, really look it. When you put $5 in (or swipe your credit card), it starts to rumble, and two huge metal plates slide together under the dome. For about thirty seconds, plastic is injected into the mold, the surface is cooled, and then compressed air blows the excess out, leaving a plastic shell in the shape of whatever the mold was, all of it hidden within the mold’s depths.

Then the mold separates, revealing your toy, and a scraper shoves it into a receptacle where you can pick it up, still hot from the mold, and hold it up to your nose to inhale the particular nostalgic smell of molten plastic. (There’s a great article about the history of the machines here.)

There aren’t many left, but the cool thing about the Mold-a-Rama is that you can pop the mold plates out and replace them. There’s a store on the north side that owns one and has modern independent artists create sculptures for the molds every so often. You can get ones from the Henry Ford Museum in Detroit that are shaped like the Wienermobile or the car JFK was assassinated in.

The MSI has nine machines, and they used to be scattered around the museum, but they’ve moved four of them into one of the exhibit spaces along with various Mold-a-Rama related displays displays. It’s not as in-depth as I would like; it’s in the “let the younger kids run around and wear themselves out” section of the museum, so it’s designed for littler kids who can sweet-talk their parents into dropping $5 on a plastic toy. Still, it was cool to see the machines I hadn’t seen, and the displays were very neat. Not worth making a trek to Chicago for, but if you’re already going to the MSI, it’s definitely not something to skip.

[ID: Four images; top, a Mold-A-Rama machine, which looks like a computer from an old scifi film. It has a sixties-style sign reading Mold-A-Rama, a large glass dome covering most of the machinery parts, and a squat, square body hiding the interior machinery. Below that, three photos of exhibit cases; one shows a sculpture of a carousel horse and two examples of the plastic figurine that is eventually produced from it, sandwiched between the open plates of the horse’s mold. The other shows a square plastic building mimicking the appearance of a large dollhouse, the Fairy Castle stashed elsewhere in the MSI. The last image shows a large glass display case full of dozens of plastic figurines, including animals, fantastical creatures, historical figures, various vehicles, and landmarks, among other things.]

286 notes

·

View notes

Text

But I wanted her (knockoff playline dolls)

I don't use Temu! Temu bad! Temu steals your info! Temu -

Ooh. She's pretty. Yeah. I caved.

So technically, Defa Lucy is a Mexican Walmart knockoff of Barbie, but plastic playline knockoffs aren't viewed generally with the same level of distaste as recast BJDs. Others have their reasons, but mine goes a little something like this:

These toys are made with plastic injection molding machines. Here's a sales pitch video by Fit Precision Molding, a company that makes and sells these machines:

youtube

These machines are NOT cheap. This is the CNC (Computer Numerical Control) machine of toys. $20K (USD) for ONE machine is a starter price - and that's if you can get it cheap from China. So a company that has decided to create their own knockoff line also tends to have the funds to pick a legal fight with, say, Mattel (MGAE and Bratz). This is not a backyard art theft sort of operation. This is easily a $200K operation just for the machines.

Granted, YMY still got smacked good and hard by the company that makes Nendoroids, and they deserved to get smacked, cuz stealing is bad.

HOWEVER...

Playline companies steal from each other all the time (cough cough Barbie Extra trying to lift the LOL OMG line like that hot mess of clashing color outfits and ridiculous plastic jewelry can compare to the cohesiveness of MGAE looks cough). Generally, if one company is mad enough, they'll sue the "stealing" company pretty quickly, and the marketplace will figure it out.

The other reason it doesn't bother me is cuz I figure these companies kinda have it coming.

So when China opened up for business, companies all over the world ran there like their houses were on fire, cuz China so cheap! Such affordable labor force. Much lack of regulation - environmental or occupational safety. Companies initially balked at employees being required to join a union, but they were immediately comforted by the fact that Chinese labor unions do exactly squat for people. The unions exist solely to steal from the employees and transfer that money to members of government.

When you open a business in China, you're required to bring on a local company as a joint venture (same in Saudi Arabia, by the way), and the Chinese company will steal with delight and abandon - as actively encouraged by the Chinese government and CCP. Companies have whined extensively about this to their respective governments. "I want cheap labor force! I want to destroy water supply! I want to pollute their air! But they're stealing from me! Waaaaah!"

Well - you get what you pay for, now don't you. You want access to exploited labor forces (forced labor for Uyghurs in the Xinjiang province, imported North Korean slaves). You want rights to dump your toxic crap into the Chinese water supply and the Chinese air without repercussions - which travels over to California and gets trapped in LA, by the way (air moves, idiots).

You'll have to forgive me if my sympathies are not particularly high for you.

This sucks for anyone trying to be an ethical consumer. Walk into your local store and flip over any box. They all say "Made in China." All of them.

This is why even though dolls like Momoko and Obitsu are more expensive, I am willing to pay to import them. Japanese wages suck, but at least they're making some money. The dolls are made in Japan. That's why they cost as much as they do. If you want to be an ethical doll collector, your options are basically BJDs and Japanese dolls (maybe Korean). Anything on US shelves is made in China and therefore unethical AF.

#defa lucy#temu#playline doll companies#yeah I'm banned from visiting China#probably why I can't sign up for Taobao lol#Youtube

21 notes

·

View notes

Text

Just got back from a family trip to Chicago, and had an awesome time! One of our stops was the Griffin Museum of Science and Industry, inside which were these cool machines called Mold-A-Rama that fabricated plastic models using injection molds right in front of you.

My brother opted to get the Willis Tower model, but it unfortunately didn't survive the trip home. So, given his recently-upgraded 3D-printing setup, I figured I'd help him replace what was lost! 🦝

6 notes

·

View notes

Text

Unlock Savings and Efficiency with Pre-Owned Plastic Processing Machinery

Discover the key to cost-effective production with pre-owned plastic processing machinery. Unlock significant savings and enhance operational efficiency by investing in high-quality, reliable equipment at a fraction of the cost of new machines. From extruders to injection molding machines, IndiaBizzness pre-owned selection offers a range of solutions tailored to meet your manufacturing needs. Maximize your output and minimize expenses with trusted pre-owned machinery.

#Pre-Owned Plastic Processing Machinery#IndiaBizzness#Used injection molding machines#Second Hand extruders Machines

0 notes

Text

Love Bites (But so do I) part one

for Captain Swan Supernatural Summer 2023

Vampire Emma and Werewolf Killian investigate, hunt down, and eliminate those who prey on the innocent and disturb the peace between the humans and the supernatural beings.

Supernatural Steampunk Detective Horror Adventure

He watched from the shadows. Waiting for the perfect specimen to walk by.

Another lovely young lady to add to his collection. A beautiful woman to aid him in his experiments.

He was determined to find a way to turn people into mindless slaves. Beings of flesh and blood that could serve the wealthy and elite in much more pleasurable ways than any robot could.

He smiled in glee when he spotted her. A stunning creature with golden hair.

Her body was accentuated by a red dress that molded to her form. The corset was low cut and pushed up her breasts. The ruby pendant she wore further aided in drawing the eye to her chest.

It was obvious she wanted to be desired. Everything about her appearance demanded attention.

This one he would keep for himself.

He tightened his black cloak around himself and drew out his syringe.

He knew he needed to be quick. Not just to inject her with the drug to put her to sleep, but to get her back to his lab before she wakes up and before anyone could see and interrupt his task.

Luck was on his side. There was no one around.

The heels of her shoes clicking on the stone paved walkway were the only sounds to be heard.

He crept behind her, as quickly and quietly as possible. Watching for any sign that she had noticed him.

Women such as her, who made their living selling their bodies, often kept a weapon on hand to protect themselves from customers who got too aggressive.

He needed to be careful to reach her before she could take out her dagger.

He raised his hand with the syringe, aiming for her neck.

Suddenly he found himself pressed to the wall of an alleyway. A searing pain coming from the gash in his arm.

Blood was spraying everywhere.

The syringe, along with two of his fingers and his thumb, were laying on the ground.

“You have been a very bad man, professor.” The beautiful woman smiled.

Shock made way for terror when he saw the sharp fangs.

He had made the mistake of following a vampire.

“Please.” He begged. “Don’t kill me. I can get you girls. Young virgins. I work for a school. You can have your pick.”

He nearly lost consciousness when his head was snapped back and struck on the brick wall.

“You were entrusted to educate those children. Not experiment on them and manipulate them.”

She turned to face the darkness.

From it emerged the massive head of a wolf. Its fur was as black as an abyss and it’s eyes glowed a hypnotic blue.

“Get his scent, my love. We need to destroy his lab. And I doubt he will be willing to tell us where it is.”

Too paralyzed by pain and fear, he could do nothing to defend himself from the creatures of the night. Even his screams were silent.

Carrying him as if he weighed nothing, they moved with great speed through the back alleyways.

The door to his lab was locked tight by a code box. He thought that they might ask him for the code. But as it turned out, they didn’t need to.

With one swipe of his enormous paw, the werewolf broke the box from the door.

The professor was laid on the table where he had performed experiments on his drugged and helpless victims. Now it seemed, he would be the recipient.

“Make no mistake; you are going to die. But my lover and I are being paid to make your end as slow and agonizing as possible.”

The professor could see the vampire's lips move, but could hear nothing except for the crash and clang of metal.

The werewolf was literally tearing his lab apart.

He had a strong feeling he would be next.

Pained shot through him as the vampire broke every bone in his arms and legs.

“I’m not going to drink from you. You don’t deserve to feel my lips on your skin.” She looked at the beast. “But my lover will be hungry once he’s done with your machines.”

Sparks flew when the last of the monitors were pulled from the wall.

The werewolf then moved to the vampire, who looked at him with love and affection clear in her eyes.

The professor swore he could see that same love and affection mirrored in the beast’s eyes.

But that was impossible. Wasn’t it? The creatures of the night could not possibly feel love. And most certainly not for a being who was not of their own kind.

But the way the vampire stroked her hand through the fur of the werewolf made the professor question everything he had once believed.

He only had a moment to ponder this new information before he was filled with terror once again when he heard the vampire say,

“We should wrap things up here. I’ll send word that our task has been completed. You enjoy your meal.”

This time, the professor's scream was loud when a large muzzle and powerful jaws descended on him.

In the morning, passerbys noticed the lab door open. The remnants of the lab were scorched by a fire that surprisingly stayed contained.

“There must have been an explosion.” The constable proclaimed. “Whatever it was that the professor was working on got him killed and his lab destroyed.

“The constable is half right.” Nemo smiled, setting his Farnsworth tablet. A handheld device that allowed a being to see and hear whatever was transmitted on the frequency the machine was set on. “That evil professor should not have used his position as a teacher to experiment on children. It caused him to have an encounter with the best agents in the business.”

He looked up and grinned knowingly at the couple in his office.

The vampire Emma, and the werewolf Killian, were not only a deadly and attractive couple, but they were talented with investigating and solving the cases that plagued society.

“If the professor hadn't been done away with, it’s highly likely that his doing would have been blamed on a supernatural creature.” Killian said.

“The two of you have done an amazing job, as always.” Nemo praised. “Justice was served. The children are now safe. And the school can keep their reputation intact. They paid extra as thanks for ensuring the professor's death looked like an accident.”

“How generous of them.” Emma smiled. Knowing Nemo had probably insisted on the extra payment.

“It was well earned.” He took out some papers and handed them to the couple. “As will the money from this next case.” Turning to Killian he advised, “You might want to get some reinforce armor for your wolf form. There’s reports of a large creature terrorizing communities. Different towns, but residents gave the same description. It looks to be a werewolf. One that is using its form to scare people out of their wealth, and hide its identity. If anyone can put a stop to it, I know the two of you can.”

#captain swan#once upon a time#ouat#emma swan#killian jones#captain hook#cssns23#love bites but so do I#grimmswanfic

25 notes

·

View notes

Text

How Used Plastic Injection Molding Machines Work

You are probably considering investing in used plastic injection molding machines if you want to venture into the business of producing plastic products and you do not have the finances to purchase a new machine. If you get a good used machine, it can serve you just as good as a brand new one.

Used plastic injection molding machine is a specialized machine that is used in the injection molding technology line. This machine adapts well to various products and has a high production capacity. So, it is widely used in the production of plastic products.

Before you go ahead to buy a used plastic injection molding machine to use in your business, it would be good to understand the structure of a plastic injection machine. This machine comprises of two components that are responsible for different jobs. The mold clamping part and the plastic injection part are very crucial.

Additionally, the mold clamp section divides into a fixed mold clamp part and a movable mold clamp part. Particularly, the fixed mold clamp holds the fixed mold part and the mold positions accurately thanks to the positioning ring on the mold and the positioning hole on the machine.

The movable mold clamp is used to clamp the movable mold half. This part is crucial and has the effect of parallel translation in the opening and closing direction of the mold. It performs the closing and opening of the mold in the plastic injection molding machine.

The movable mold of the machine also arranges to help impact the battery ejection plate to push the product out. Additionally, the plastic injection part is the part that is used to convert the material from solid to liquid by temperature. It pushes the molten plastic into the mold by pushing pressure through the screw and nozzle system.

For more information on how used plastic injection molding machines work, visit our website at premierplasticsnj.com

0 notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Text

Maximize Efficiency in Pressure Die Casting with Our High-Quality Steel!

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry.

Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more : https://www.viratsteels.com/hot-work-steel.html https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any queries feel free to contact us : [email protected] or Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DieCasting#PressureDieCasting#DieCastingProcess#CastingIndustry#AluminumCasting#MoldMaking#hot work steel#h11steel#h13steel#h21steel#din 2344#din2343

2 notes

·

View notes

Text

Random thing ive been learning about, ive been looking into vintage sewing machines (just got an elna supermatic im gonna try and get working!) and learned a cool thing about how they used to make different stitches before things were computerized: these discs called "cams"!

simply put, theyre like lil gears that move the needle around to make diff designs, similar to how computerized machines do just like, mechanically. there are both built in cams (usually in cam stacks) and drop in cams that you can switch out.

now, the problem is: cams can be hard to find apparently! theres only so many of course, and while they arent that expensive individually (a few bucks apiece from what im seeing), it seems like its a pain in the ass to track down specific ones (ive seen so many people bemoaning the ducky elna cam. everyone wants that duck!)

because theyre usually just bits of plastic, it wouldnt be THAT hard to just. 3d print em. maybe it wouldnt give the best results, but hey, a ducky thats gonna wear out a lil too fast might be better than not having a ducky at all, and if people had the files at least someone could theoretically produce them thru better means, like injection molding or whatever.

but of course making a 3d printing database of cams is easier said than done. not for lack of trying apparently! ive found stuff like this thread of someone trying to put together a project to make a database of elna cams (which was later abandoned going by the comments), i found at least one for the elna zigzag cam (nice, might need it if i get my machine working!) , and there are at least a few files available for more popular cams like on singers. heres a thread with someone sharing a buncha files, which i cant verify bc i dont have a printer but they have the duck! and also apparently the dick, which is nice.

if you reverse engineer this shit you could design your own cams, like heres someone who made a 3-step zig zag cam, and a couple of projects for "design your own cams" which. sound cool but idk how modeling works so idk how to do this lmao. but thats so neat!

and theoretically it would be SO easy for someone to just make a database of every cam they could find and upload em for anyone to use but well. again, easier said than done. im finding a lotta scattered files, but unless im missing it i dont think anyones made a single nice lil page filled with the files for cams across diff machines.

...anyway, if anyone knows how this shit works I think it would b really cool if someone made a heartbeat cam and a lil bat cam. those would be fun!

9 notes

·

View notes

Text

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes