#two-color injection molding machine

Explore tagged Tumblr posts

Text

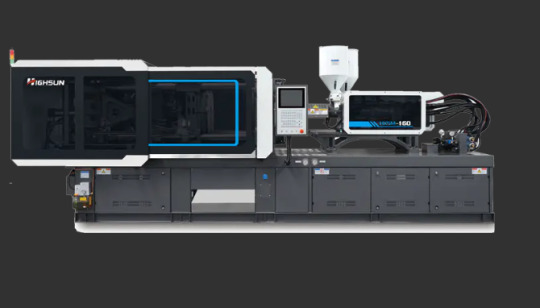

HXS160: HXS two-color injection molding machine

The “new breakthrough” of the hydraulic injection molding machine has realized “pressure valve ring control” and “energy supply and demand matching”,professional shape future !

Pressure valve ring control: The actual pressure is compared with the set pressure in real time and corrected until the actual pressure is equal to the set pressure.

Matching energy supply and demand: How much energy does the injection molding machine do, how much energy the power system provides, and very little energy loss.

0 notes

Text

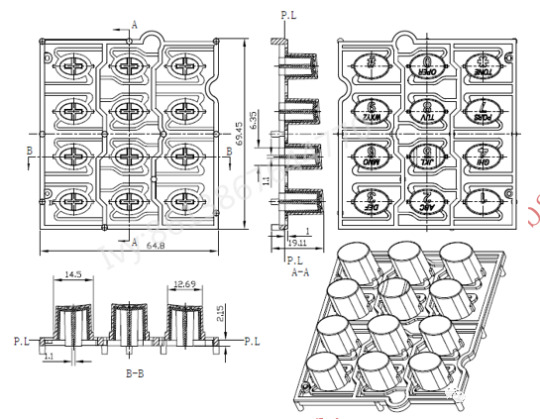

Double-Color Injection Molds for Household Products 🧴🧼🍱

Aero Mould Co., Ltd. — Professional Plastic Mold Manufacturer with 10+ Years of Experience

We provide precision double-color molds for various household applications:

✅ Double-Color Bottle Cap Molds – Enhanced sealing, eye-catching design ✅ Double-Color Silicone Wash Basin Molds – Flexible & durable, ideal for daily use ✅ Double-Color Lunch Box Molds – Stylish and leak-proof, perfect for food storage ✅ Optimized for Two-Shot Injection Machines ✅ Multi-cavity mold design for high-efficiency production

🛠 All molds are made with high-precision CNC machining, hardened steel, and optimized cooling for faster cycle times.

📩 Contact us for your custom double-color molding solutions!

📧 Email: [email protected] 📞 WhatsApp/WeChat: +86 13989656287

#DoubleColorMold#2KMold#TwoShotMold#HouseholdMold#BottleCapMold#LunchBoxMold#SiliconeMold#PlasticInjectionMold#AeroMould#MoldManufacturer#Overmolding

0 notes

Text

Innovative Molding Solutions: PEEK Mold, 2K Mold, and Machined Insert by Yakon

In the rapidly evolving world of precision molding, manufacturers seek cutting-edge solutions to enhance product performance and durability. Yakon Mold, a leading mold-making specialist, offers state-of-the-art molding solutions, including PEEK Mold, 2K Mold, and Machined Inserts. These advanced techniques cater to diverse industries, ensuring high precision, strength, and longevity in molded components.

PEEK Mold: High-Performance Polymer Molding

Polyether ether ketone (PEEK) is a high-performance thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability. PEEK molding is widely used in aerospace, medical, automotive, and industrial applications where high-temperature resistance and durability are critical.

Advantages of PEEK Molding:

High-Temperature Resistance: Withstands temperatures up to 260°C, making it ideal for extreme environments.

Excellent Chemical Resistance: Resistant to aggressive chemicals, acids, and solvents.

Superior Mechanical Strength: Offers excellent wear resistance and durability.

Biocompatibility: Perfect for medical applications, including surgical instruments and implants.

Yakon Mold specializes in precision PEEK molding, ensuring tight tolerances and flawless surface finishes to meet industry standards.

2K Mold: Advanced Two-Shot Molding Technology

2K molding (Two-Shot Injection Molding) is an innovative technique that enables the production of complex, multi-material, and multi-color components in a single process. This method is widely used in automotive, medical, and consumer electronics industries.

Key Benefits of 2K Molding:

Enhanced Product Functionality: Combines hard and soft materials for superior performance.

Improved Aesthetic Appeal: Allows seamless integration of colors and textures.

Reduced Assembly Costs: Eliminates the need for secondary assembly, reducing manufacturing time and costs.

Stronger Bonding: Ensures high adhesion between different materials, enhancing durability.

At Yakon Mold, we employ advanced machinery and expert engineering to deliver high-precision 2K molds, ensuring superior quality and efficiency.

Machined Insert: Reinforced Molding for Durability

Machined Inserts play a crucial role in strengthening molded components, providing structural integrity and enhanced performance. These inserts are commonly used in industries requiring high-strength parts, such as automotive, electronics, and aerospace.

Advantages of Machined Inserts:

Increased Strength and Longevity: Improves component durability and load-bearing capacity.

Enhanced Threading Capabilities: Ideal for applications requiring secure fasteners and screws.

Precision Engineering: Ensures accurate fit and superior performance.

Versatile Material Options: Available in brass, stainless steel, aluminum, and other metals.

Yakon Mold offers high-precision machined inserts tailored to specific application needs, guaranteeing optimal performance and reliability.

Why Choose Yakon Mold?

With years of expertise in mold manufacturing, Yakon Mold stands out as a trusted partner for industries requiring high-precision molding solutions. Our commitment to innovation, quality, and customer satisfaction ensures that clients receive the best-in-class molds tailored to their specific needs.

For more information on PEEK Mold, 2K Mold, and Machined Insert solutions, visit www.yakon-mold.com and explore our cutting-edge molding technologies today.

0 notes

Text

Advantages of Two-Component Injection Molding

Two-component injection molding, also known as 2K molding or multi-shot molding, is a process that makes parts using two different materials or colors. It's widely used in industries like automotive, medical, electronics, and consumer goods because it’s efficient and creates high-quality, complex products.

In this blog, we will break down the key advantages of two-component injection molding in simple terms.

What is the Two-Component Injection Molding?

Before diving into the benefits, let’s understand what two-component injection molding is.

In this process, two different materials are injected into a mold in one machine cycle. These materials could have different properties, colors, or textures. For instance, one material might be rigid plastic, and the other could be soft rubber. Together, they create a single finished part with combined properties.

This process is different from traditional molding because it eliminates the need for assembling multiple parts later.

Advantages of Two-Component Injection Molding

1.Combining Materials in One Step

One of the biggest advantages of this process is the ability to combine two materials in a single production step.

For example, imagine a toothbrush. The handle is made of hard plastic for durability, while the grip is made of soft rubber for comfort. In traditional manufacturing, these two parts would be made separately and then joined together. With two-component injection molding, both materials are molded together at the same time.

This saves time, reduces labor costs, and ensures a strong bond between the materials.

2.Cost Efficiency

By combining multiple processes into one, two-component injection molding can significantly lower production costs.

Fewer assembly steps: Since the parts are molded together, there’s no need for manual assembly, reducing labor costs.

Lower material waste: The process is highly precise, meaning less material is wasted compared to traditional methods.

Faster production cycles: Producing parts in a single step speeds up the entire process.

In the long run, these savings add up, especially for large production volumes.

3.Improved Product Design

Two-component injection molding allows manufacturers to create more innovative and functional designs.

Complex shapes: The process can create products with intricate designs that would be difficult or impossible to achieve with traditional methods.

Enhanced aesthetics: Two different colors or materials can be combined seamlessly, improving the appearance of the final product.

Multi-functionality: Different materials can add specific functions, such as a soft-touch grip or a watertight seal.

These design options open up endless possibilities for creating better products.

4.Stronger Bond Between Materials

When two materials are joined during the molding process, the bond between them is much stronger compared to glue or mechanical fasteners.

This makes the final product more durable and reliable. For example, in automotive parts, where durability is crucial, two-component molding ensures the parts can withstand stress, vibration, and temperature changes.

5.Enhanced Product Quality

Since the process is automated and precise, the quality of the final product is often superior to parts made using traditional methods.

Consistent results: The process ensures every part is made to the same high standard, reducing defects.

Reduced risk of errors: By eliminating manual assembly, there’s less chance of mistakes.

Better material properties: Combining materials can improve the overall strength, flexibility, or appearance of the product.

High-quality parts are essential in industries like healthcare, where even small defects can lead to big problems.

6.Eco-Friendly Manufacturing

Two-component injection molding is also an environmentally friendly option.

Less waste: The precise injection process minimizes material waste.

Reduced energy use: Producing parts in one step uses less energy than making and assembling multiple components.

Recyclable materials: Many of the materials used in this process can be recycled, further reducing environmental impact.

As more companies focus on sustainability, this is a significant advantage.

Applications for Two-Component Injection Molding

This technology is used in many industries, such as:

Automotive: Parts like dashboards, switches, and handles combine hard and soft materials for comfort and durability.

Medical devices: Items like syringes and grips benefit from precision and material combination.

Consumer goods: Products like power tools, toothbrushes, and razors often use this process for improved functionality and aesthetics.

Electronics: Cases for phones or remote controls are made with two-component molding for durability and style.

Challenges to Consider

Although two-component injection molding has many benefits, it also has some challenges:

Higher initial cost: The machines and molds used for this process can be more expensive than traditional ones. However, these costs are often offset by long-term savings.

Complex setup: Designing molds for two materials require expertise and careful planning.

Material compatibility: Not all materials bond well together, so careful selection is essential.

These challenges are manageable with the right expertise and planning, making two-component injections molding a worthwhile investment.

Conclusion

Two-component injection molding is changing the game in manufacturing. It combines materials in one step, saving time and money, improving quality, and unlocking new design options. While the setup might be more complicated at first, the long-term benefits are worth it.

As industries look for better, faster, and more eco-friendly solutions, two-component injection molding is set to play an important role in manufacturing. If you want to learn more about it and talk to an expert, visit our website.

0 notes

Text

(Inter)National Lego Day

Construct creative builds with this beloved, versatile toy, enjoy the hilarious LEGO Movie or visit a LEGOLAND theme park with your family.

Lego – have you played with it? These little plastic colored bricks have been sparking creativity and joy in both children and adults of all ages for almost 70 years! Small but mighty, Lego bricks inspire creativity, and thanks to their ingenious design, they can be used to make virtually anything you can imagine, from cars to dinosaurs, houses to aliens – if you can dream it, it can probably be built out of Lego.

As such a versatile toy that appeals to all ages of people, it’s not surprising that Lego is now recognized as the World’s Most Powerful Brand, towering over Google, Nike, and Ferrari to claim the top spot in 2017, but as with most gigantic companies, Lego started from humble origins and International Lego Day marks the very beginning.

History of Lego

International Lego Day is held on the very same day that Danish carpenter, Godtfred Kirk Christiansen, first submitted his patent for the original Lego brick in 1958. Like no other brick that had come before this toy brick would have a sophisticated interlocking brick system, making it strong, versatile, and less likely to fall apart when simply knocked over.

Not one to mess around, Godtfred made sure not only to patent the design for his single Lego brick, but also to patent the concept of multiple bricks being used together in a building system, and this protected his design from being ripped off by competitors. Although this day is often seen as the birthplace of Lego as we know it, the company itself was in fact founded by Godtfred in 1932, creating a variety of wooden toys, and taking the name Lego from the Danish words “LEg GOdt” which translate to “play well”.

Ahead of their time, Lego was one of the very first toy manufacturing companies to buy an injection mold machine with which to create plastic toys, a move which shortly led them to create the very first plastic Lego brick in 1949. In the 17 years from 1949 to 1966, Lego grew exponentially into a global company that was retailing in 42 countries. They now boasted a product range that now contained 57 Lego sets and 25 Lego vehicles and with factories that were producing more than 706 million Lego elements each year – but the company didn’t stop growing.

In 1967 the LEGOLAND Band was established and in 1968, the very first LEGOLAND opened its doors to the public, attracting more than 625,000 visitors in its first season. Today there are 9 LEGOLANDS across Europe, Asia and the US, with a further three due to open in the next few years.

Nowadays Lego is a truly global enterprise, its strong brand identity, and still unique simplistic design, keeps it a favorite amongst children, while its history and versatility make it even more collectible to adults.

International Lego Day Timeline

1932 LEGO founder starts a woodworking shop in Denmark

In a small woodworking shop in Billund, Ole Kirk Christiansen makes all types of furniture and household items. But his favorite creations are toys for his sons, so he eventually names his company LEGO–a combination of two Danish words meaning “play well”.

1946-1949 Plastic bricks are first sold by the LEGO company

A wood shortage following WWII makes manufacturers look for alternative ways to create products. Christiansen gets his hands on the first plastic-injection molding machine in Denmark and starts selling the Automatic Binding Brick, the predecessor to today’s stackable blocks.

January 28, 1958 LEGO patent application is submitted

With Christainsen’s son, Godtfred, at the helm, the company submits their patent application for the tubes and studs that would add stability and connectivity to the plastic blocks. This anniversary coincides with International LEGO Day each year.

1976 LEGO minifigures are introduced

Realizing that the sets might be more fun if a human dimension was added, the company releases the iconic yellow-faced humanoid bricks.

2014 LEGO feature film is released

When watching his son play with LEGOs, a Hollywood producer gets the idea to make an animated movie. It is a huge hit and grosses more than $450 million, with more films coming in the following years.

10 super-fun facts about Lego

In 2016 LandRover set the World Record for the largest piece of Lego construction with their huge 43-foot-high replica of Tower Bridge. This monumental structure used 5,805,846 individual pieces of Lego which would have stretched all the way to Paris in France if laid out end to end.

If Lego Minifigures were to be classed as a population, they’d be the largest population in the world! With more than 4 billion of them in total.

There are so many Lego bricks in the world, that it’s estimated that they outnumber people 80 to 1.

Despite the first Lego brick having been made in 1958, you could still interlock one with a Lego brick-built today – the design hasn’t changed a bit!

In 2009, James May created a house entirely out of Lego! The house took more than 3.3 million bricks to make and even had a working toilet, a bed, and a shower!

Lego is now so popular that 7 sets are sold every second.

Although Lego is played by both girls and boys, women and men, they still have a bit of a way to go before they reach gender equality with roughly 86% of their Lego Minifigures being male.

If you were to collect all the Lego bricks in the world and stack them together then they would be 2,386,065 miles tall!

Although Lego makes toys they are also classed as the world’s biggest tire manufacturer, making over 400 million tires each year to keep their fleet of various lego vehicles rolling.

Although Lego was the first to patent the Lego brick that we know today, they didn’t technically invent them. The story has it that the salesman who came to sell Godtfred his first plastic injection mold machine was carrying an example interlocking brick in his pocket which had been designed and patented by Hilary Fisher Page. Godtfred improved on the design by perforating the brick and adding tubes on the bottom to help tighten the connection.

How to celebrate International Lego Day

Whether you’re five or sixty-five, you’re never too old to celebrate International Lego Day. Here are a few things that you could do to celebrate the day:

Play with Lego! Perhaps the most obvious thing to do on International Lego Day is to play with Lego of course! Grab your old lego set, or buy one especially for the day and sit down for a few hours of relaxing and creative fun. If you now have children yourself then make a sculpture together and take a moment to remember how many generations have grown up with Lego by their side.

Watch the Lego Movie! Lego has become so iconic that it even has its own movie dedicated to it. In fact, there are now two! Fun for all the family, cozy up on the sofa with some popcorn and watch as Lego figures come to life in stunning animation.

Visit LEGOLAND. And finally, for perhaps the most immersive Lego experience, pack your bags and take a trip to one of the many LEGOLAND theme parks. Be wowed by the impressive Lego structures and ride the exhilarating roller coasters for a day you’ll never forget.

Source

#Lego company#patented#Lego brick#28 January 1958#anniversary#USA#history#International LEGO Day .#InternationalLegoDay#Toys `R` Us#travel#I still miss it#original photography#Manhattan#New York City#summer 2013#Chicago#Illinois#2016#evening light#CTA#vacation#indoors#outdoors#tourist attraction#landmark#Michigan Avenue#cityscape#architecture#Toys 'R' Us

0 notes

Text

Design Essentials of Two-color Injection Mold

1. Classification Structure of two-color mold is closely related to two-color injection molding machine. There are seven categories of two-color machines, but two categories are commonly used. Correspondingly, there are two types of two-color injection molds, namely Asian two-color molds and European two-color molds. Two-color injection molding machines in Taiwan and Japan have two parallel…

View On WordPress

0 notes

Text

Understanding PVC Compound and Resin: Key Differences, Processing, and Applications

What is PVC Compound and Resin?

Polyvinyl Chloride (PVC) is a highly versatile thermoplastic polymer, widely recognized for its durability, flexibility, and cost-effectiveness. It plays a pivotal role in numerous industries, including construction, automotive, footwear, electrical, and healthcare. PVC materials generally come in two primary forms: PVC Resin and PVC Compound.

PVC Resin: PVC resin is the fundamental raw material produced through the polymerization of vinyl chloride monomer (VCM). In its basic form, it is a white powder, and although it forms the backbone of PVC products, it must undergo further processing before it becomes usable in most applications.

PVC Compound: PVC compound is a more advanced, processed version of PVC resin. It is created by blending the resin with various additives such as stabilizers, plasticizers, fillers, pigments, and other modifiers. These additives enhance and customize the properties of the resin, resulting in a compound with tailored characteristics such as improved flexibility, strength, color, or weather resistance. The exact composition depends on the intended application, whether for manufacturing pipes, footwear soles, Kids chuchu shoes PVC compound, or insulation materials.

Difference Between PVC Resin and PVC Compound

1. Raw Material vs. Processed Product: PVC Resin is the raw, unaltered polymer produced from vinyl chloride monomer. It serves as the base material for PVC products but cannot be used directly in manufacturing without further processing. PVC Compound is the processed, application-ready version of PVC resin. Through the addition of additives, the compound acquires specific properties tailored for particular industrial uses.

2. Processing and Usability: PVC Resin is not ready for direct use and must undergo compounding before being transformed into end products. PVC Compound is ready for industrial processes like extrusion, injection molding, or blow molding, enabling manufacturers to produce items such as pipes, cables, or footwear immediately.

3. Customization: PVC Resin in its raw form has limited application due to its basic properties. PVC compounds can be fully customized through additives to meet various performance requirements, such as flexibility, rigidity, UV resistance, or flame retardancy, depending on the industry’s needs.

4. Applications: PVC Resin is primarily used as a base material in the production of PVC compounds. — PVC Compound finds wide-ranging applications across industries, such as the production of pipes, profiles, wires, footwear, and medical devices.

How PVC Resin is Transformed into Vinyl Compound

The transformation of PVC resin into a vinyl compound involves a series of carefully controlled processes, typically performed in specialized facilities.

1. Blending and Mixing: The process begins by thoroughly mixing PVC resin with the required additives like plasticizers (to increase flexibility), stabilizers (for durability), fillers, and pigments. These additives are chosen based on the intended properties of the final product, ensuring the compound meets specific performance criteria for its end-use.

2. Fusion Process: Once the ingredients are mixed, the compound is heated to a specific temperature to initiate fusion, allowing the resin particles to combine with the additives. This is carried out in machines such as high-speed mixers or extruders to ensure consistent distribution of the additives throughout the material.

3. Cooling: After the fusion process, the compound is rapidly cooled to stabilize it for further processing. Once cooled, the compound can either be pelletized for use in extrusion and molding, or left in powder form for certain applications.

4. Extrusion or Molding: The PVC compound, now stabilized and uniform, is ready for manufacturing. Various techniques can be used to form the compound into finished products, such as: Extrusion: To produce items like pipes, profiles, and cables. Injection Molding: To create footwear soles, automotive parts, or electrical components. Blow Molding: Ideal for manufacturing containers, bottles, and other hollow items.

Conclusion

In summary, PVC Resin is the fundamental raw material that forms the basis of all PVC products. However, to meet the unique demands of various industries, it must be transformed into PVC Compound through the addition of customized additives. This transformation process ensures the material is ready for industrial applications, ranging from flexible footwear to rigid piping systems. The ability to tailor PVC compound’s properties makes it indispensable in modern manufacturing.

#PVCCompound

#PVCResin

#PlasticIndustry

#PolyvinylChloride

#MaterialScience

#Manufacturing

#IndustrialMaterials

#PlasticSolutions

#VinylCompound

#SustainablePlastics

#PVCProcessing

#CustomPVCCompound

#Thermoplastics

#PlasticAdditives

#EcoFriendlyMaterials

#polymers#pvc resin#supplier#plastic#pvc dana#trade#manufacturer#pvc strap compound#ladies belly pvc compound#pvc sole compound

0 notes

Text

Ultra Purge C1420: Concentrated Purging Compound for Efficient Cleaning Across Multiple Applications

Ultra Purge C1420 is a high-efficiency, concentrated purging compound designed for diverse thermoplastic applications. This advanced formula is ideal for cleaning injection molding, extrusion, blow molding (with or without an accumulator), and sheet extrusion machinery. The compound is formulated with powerful cleaning additives, ensuring thorough cleansing without any abrasive effects, thus protecting both the machinery and the operator.

Before use, Ultra Purge C1420 needs to be mixed with unfilled virgin resin in a 1:2 ratio (one part Ultra Purge to two parts virgin resin). This mixture makes it perfect for removing color and material residues, as well as black specks and carbon deposits. The compound is effective at processing temperatures ranging from 160°C (320°F) to 350°C (662°F), making it versatile for various thermoplastic processes.

Ultra Purge C1420 is particularly recommended for polymers such as HDPE, LDPE, PP, POM, PVC, TPU, TPE, ABS, and Nylon. For injection molding applications, use one full barrel for color changes and black specks removal, and ½ barrel for machine shutdowns. Similarly, for extrusion, apply 1 to 1½ full barrels for color changes and black specks removal, and one full barrel for shutdowns. In blow molding, use one full barrel for color changes and black specks removal, and ½ barrel for shutdowns.

Safety is a priority with Ultra Purge C1420. It complies with FDA regulations (21 CFR), meaning all components are either GRAS (Generally Recognized As Safe) or permitted for direct or indirect food contact. This ensures the compound is safe for use in food-related applications.

In conclusion, Ultra Purge C1420 offers a powerful, efficient, and safe solution for maintaining the cleanliness and efficiency of various thermoplastic processing machines. Its easy-to-use formula and broad application range make it an essential tool for manufacturers looking to enhance productivity and equipment longevity.

#PurgingCompound#IndustrialCleaning#InjectionMolding#Extrusion#BlowMolding#PlasticProcessing#ManufacturingSolutions#EfficiencyInManufacturing#CleanProduction#IndustrialProducts

0 notes

Note

I'm cutting in here to say three things--

1. Please, please everyone do yourself a favor and read Mikey's artist Steve headcanon that mentions heavy metal music. As a metal head, it's burned into my fucking brain forever in the best way

2. IS THIS ANON IN MY HEAD? I FUCKING LOVE FRANCIS BACON!

Literally, actually, I can't make this shit up. The first time I encountered his works in an art history textbook and then a subsequent lecture, I literally pestered my professor for 20 minutes after class and then scoped out said professor's office hours to glean even more information about Bacon.

Plus, like a fucking dork, the background of my phone is currently "Painting 1964"

Which I love because, exactly, it's so fucked up and so beautiful yet also if you look into it, it's considered to be a heavily political, anti-fascist painting, even if some parts of that meaning Bacon himself denied while critics conspired previous to as well as after his death.

3. I have no restraint and wish to give examples now that this anon and Mikey have brought to my attention the parallels present. I can not be stopped, lmao.

"Two Figures on a Couch" from 1967

So, first, just. gay. that's what I have to say about this work. It's so gay and incredible. The way the figures blur together? The way they're part of the same being but separate? The way the public would've seen this as so violent and wrong and yet they can't look away because of the sheer quality of the brush strokes and heavy distortion, just trying to piece together what's happening, what does it mean? This 👏🏻 piece 👏🏻 fucks 👏🏻

"Three Studies for George Dyer" 1964

Also very gay and incredible, Bacon created many, many, many studies dedicated to his lover George Dyer before his death, as you can see illustrated by the paintings above.

But, also, after Dyer's suicide in their shared hotel room just days before Fracis Bacon's retrospect (super rare, by the way, that living artists receive lifetime retrospect, much less retrospecs in such an iconic place as) in Paris, France. Works of Dryer after his death including a series with triptych peices (relevant because triptychs, if you don't know, traditionally are saved for religion context, and the fact that they were being used to represent love for another man, by a man? Unheard of!! (at that time, of course)). These are grouped together as 'the black triptychs':

"Triptych, August 1972"

"Triptych, May-June 1973"

"In Memory of George Dyer, 1971"

Not a part of the triptychs but a clear experience of grief is, "Self Portrait" from 1971 after his lover's death

The colors in this always strike me alongside the smeared, distorted style, of course, this is a man who doesn't know who he is, where he is, what he's supposed to do without his lover by his side. God, I just love it.

And, begrudgingly, if we have to move on beyond the black triptychs...

"Study after Velázquez's Portrait of Pope Innocent X" 1953

Bacon did lots of works of varying popes, including works that seem to be the pope confronting Dyer, but the above is likely his best known. I don't know about you, but I certainly feel the spiritual unrest and the transcendence of time here.

Plus, I absolutely could read all of those action lines as representing the hot searing pain of being transformed by vita-rays accompaning the serum injected into his body all at once? Okay, even the faint bars around the figure in the painting as perhaps an enclosure, maybe an electric chair, or... Howard Stark's machine? Is that too much of a stretch?

Further, those golden lines of paint that make it seem like the pope is enclosed here? Almost like a cage? Those show up throughout Francis Bacon's work. It's been read into beyond stylistic as part of a subconscious experience of Francis Bacon being trapped in a society that did not accept his sexuality and left him feeling isolated and imprisoned by the inescapable expectations, confined and contained, never to escape beyond the mold he was crammed into

...does that sound familiar to anyone?

Also, with all this catholicism-adjacent discussion, is now a good time to mention Francis Bacon was, on top of all the other parallels, born in Ireland, (although he moved to England as a teenager)? 'Cause he was.

"Man in a Cap" 1945

I don't know about you, but this, all I see is a man in a military style cap screaming. But... is he screaming in pain, being obliterated in active warfare, or is he screaming chaotic orders in a flurry of movement for his troops to follow, causing the destruction and agony of others? Is it something else? There's so much to see in all of Bacon's work.

Bacon witnessed the trauma of WWII like others alive at that time, but he didn't serve because he had too severe of asthma--like Steve pre-serum. Although he did volunteer in Civil Defense and worked in Air Raid Precautions. Essentially, he helped fight fires and do search and rescue around London until there was too much dust and rubble from the destruction, and he had to step away.

Another point I feel the need to make is that Francis Bacon destroyed a lot of his own works by setting them on fire. He was a raging perfectionist. He wanted everything to have meaning, and if he couldn't get it right, it wasn't right and he just couldn't have that. Again, does that sound like anyone you might be familiar with?

So, thank you for coming to my TedTalk. Take away: I love Francis Bacon, I love Steve Rogers, and Mikey's anon has made me love them both that much more now.

OK! OK! OKAAAY! I ONLY JUST LEARNED ABOUT THE ARTIST FRANCIS BACON, BUT HIS WORK IS EXACTLY WHAT I PICTURE WHEN I THINK ABOUT STEVE'S ARTWORK 🤯🤯 ESPECIALLY HOW YOU HEADCANON HIM WORKING TO HEAVY METAL MUSIC SOMETIMES!!

NOT TO MENTION FRANCIS WAS GAY!!

AND THERE IS SOMETHING SO VIOLENT AND YET SMOOTH AND SEDUCTIVE ABOUT HIS WORK. THE DISTORTED SMEARING GIVES STEVES TRANSCENDANCE BETWEEN TIMES! THE VIOLENCE THE WAR HE'S SEEN! THE RELIGIOUS SUBJECTS HIS CATHOLIC UPBRINGING! THE SEDUCTION IN HIS STRUGGLE WITH BEING QUEER WHEN IT WASN'T ACCEPTED! THE REPEATED IMAGES OF HIS LOVER COULD BE BUCKY!! OH MY GODDD

I'm sorry for yelling but I'm EXCITED asdfghjkl

OH MY GOD OKAY THANK YOU FOR SHARING THIS ABSOLUTE WEALTH!!! I AM SCREAMING BECAUSE YOU'RE SO FUCKING RIGHT YOU'RE SOOOO FUCKING RIGHT AND IM YELLING TOO!!!!

cuz ok ok ok ok ok i also see steve's work as like,,,, abstract emotion that's also.... definable. not abstract in the sense of colors and shapes, etc, but shadows. sharp, shadowed emotions. blocks of color shrouded by a dark centerpiece. raw emotion etched into fading expressions exacerbated by smudges of flesh and lines of pain. and that seems to be exactly how francis bacon paints his artwork. PLUS hiding his lover in plain sight (something jc leyendecker also did, which is also how i picture steve's artwork when he's doing more commercial projects-- the sharp edges, the attention to detail, the way the men were painted with care that screamed queerness if you read between the lines). but god, the raw pain in bacon's work absolutely echoes the way i imagine steve holing up in his studio. letting the paintbrush etch his heart onto the canvas-- all raw flesh and blood and emotion screaming to get out. shrouded identity in faces that smear into something only half-recognizable as man. it's him, but who is he? who has he always been? a strong sense of justice doesn't necessarily equate to a strong sense of self, and Steve lives that notion plainly through a world who never wanted him to love who he was, just as he was.

#steve rogers#artist steve rogers#artist steve#stucky#please mind I'm not an actual art critic or historian I'm just a big nerd

50 notes

·

View notes

Text

How to deal with the surface of plastic injection molding mold appears gloss defect?

Plastic injection molding mold will appear a lot of difficulties, injection molding mold is composed of two parts of the moving mold and the fixed mold, the production of plastic products need to use the mold injection molding, is through the injection molding machine will plastic raw materials into the injection mold cavity, after cooling and curing to form the injection molding parts. In the mold manufacturing process, how to deal with the surface of plastic injection molding mold appears gloss defect?

The following is the causes and solutions of the surface gloss defect of plastic injection molding mold and. Hope to help you.

1. The mold finish is poor, the cavity surface has rust, etc., the mold exhaust is poor.

2. The mold gating system has defects, should increase the cold well, increase the flow channel, polishing main channel, diverter and gate.

3. The material temperature and mold temperature are low, if necessary, the local heating method can be used at the gate.

4. The processing pressure is too low, the speed is too slow, the injection time is insufficient, the back pressure is insufficient, resulting in poor compactness and the surface is dark.

5. The plastic should be fully plasticized, but to prevent the degradation of the material, the heat should be stable, the cooling should be sufficient, especially the thick wall.

6. Prevent cold material into the parts, if necessary, use self-locking spring or reduce the nozzle temperature.

7. The use of recycled material is too much, the quality of plastic or coloring agent is poor, mixed with water vapor or other impurities, the quality of the lubricant used is poor.

8. Clamping force to be enough.

0 notes

Text

Everything You Need to Know about Thermoforming

Thermoforming technology is one of the most commonly used molding methods in molded plastic material packaging, it is a thermoplastic sheet (PP/PET/PS/ABS/PVC/PE) as the molding object of the molding technology.

Although the thermoforming process has been developed in the early 20th century, it was not until the 1960s that it began to be vigorously applied to industrial production.

After continuous development and changes, the vacuum forming process has now achieved a high degree of automation and mechanization, through the continuous improvement of the thermoforming equipment, improve the temperature control of the thermoforming machine and the transmission method of the technical difficulties, to solve the high tensile and high-precision pressure forming products process technology, including solving the processing of different plastic materials as well as the thick sheet material processing technology problems.

With the development of the plastic thermoforming industry, thermoforming application areas are becoming more and more extensive, from the beginning of the thin sheet of thermoforming to the present can replace the injection molding machine products of thick plate thermoforming, from the simple thermoforming food trays, electronic trays to the present logistics thermoforming turnover trays, hardware tool carts, cooling water towers, bathtubs, and inwardly ride the car's thermoforming parts and so on, from the original thermoforming packaging products to become a part of the thermoforming product, can say that now plastic thermoforming products are everywhere in our lives. It can be said that now plastic thermoforming products are everywhere in our lives.

Principles of Thermoforming Process

Thermoforming process is a common plastic processing process, which is a process of heating and softening plastic sheet or plastic film, then adsorbing it on the surface of the mold by suction or pressure, and then cooling and molding it. vacuum forming process is widely used in the manufacture of various plastic products, such as plastic pallets, plastic boxes, plastic tableware, plastic toys and so on.

The principle of thermoforming process is to heat the plastic sheet or plastic film to a certain temperature to make it soften, and then adsorb it on the surface of the mold by suction or pressure to form the desired shape. The mold for the suction molding process usually consists of two parts, the upper mold and the lower mold. The space between the upper and lower molds is the molding space. In the pressure forming process, the space between the upper and lower molds is usually an air-tight space where plastic sheets or plastic films are adsorbed onto the surface of the mold by suction or air pressure to form the desired final shape or plastic components.

Commonly Used Materials for Thermoforming

Commonly used materials for thermoforming: PVC, PS, PET, PP.

PVC

PVC sheet is a widely used and popular materials, PVC film can be divided into food grade and industrial grade two kinds, and can be made into transparent, color, anti-static, gold-plated, flocking and other kinds of sheet with the sub vacuum forming, which is mainly characterized by high transparency, good surface luster, less crystalline and easy to sub molding, made of products with a small water line, the use of plant impact resistance, the Taiwan U.S. FDA, Japan's PL Food hygiene standards, made of products widely used in toys, food, electronic products, medicine, electrical appliances, gifts, cosmetics, stationery and other products packaging.

PS

PS hard sheet low density, poor toughness, easy to burn, combustion will produce styrene gas (a harmful gas), so generally used in the production of a variety of industrial trays.

Applications:

PS sheet is a new type of environmentally friendly packaging material developed in recent years. With its excellent vacuum molding performance, good impact resistance, environmental performance and hygiene performance, it is widely used in the fields of medicine, food, toys, electronics and clothing.

PET

Good toughness, high transparency, easy to burn, burning will not produce harmful gases, is an environmentally friendly material. But the price is high, suitable for high-grade products, Europe and the United States, the bubble shell is generally required to use PET hard sheet. But it is not easy to heat sealing, encapsulation is more difficult, in order to solve this problem, people in the PET surface composite on a layer of PVC film, named PETG hard sheet, but the price is higher.

PET important features:

1. Excellent transparency and finish, good display effect.

2. Excellent surface decorative properties, can be printed without surface treatment, easy to press patterns, easy metal processing (vacuum plating metal layer).

3. Good mechanical strength.

4. Good barrier performance to oxygen and water vapor.

5. Good chemical resistance, can withstand the erosion of a variety of chemical substances.

6. Non-toxic, reliable hygiene performance, can be used for food, drugs and medical equipment packaging, and can be Y-ray sterilization of its packaging items.

7. Good adaptability to environmental protection, can be economically and conveniently recycled; its waste incineration treatment, does not produce environmentally harmful substances. Good thermoforming performance, comparable to ordinary PVC sheet, can be vacuum-formed to produce PET thermoforming products with excellent performance; PET sheet is considered to be the ideal packaging material in line with environmental requirements.

PP

PP sheet is made of PP resin through the process of beer, calendaring, cutting edge, etc. It has the characteristics of light weight, bright and calm surface, good heat resistance, high mechanical strength, excellent chemical stability and electrical adiabaticity, and non-toxicity, etc. It can be made into beverage cups, food containers, and other daily necessities after thermoforming.

PP main features:

Can be used for a long time at 100 ℃ and can withstand 121 ℃ high temperature sterilization treatment, moisture-proof performance is outstanding, reliable health performance, widely used in food packaging. It has excellent folding performance.

What are the Steps of Thermoforming Process

Mold Design and Production

Molds are key to the manufacturing process of thermoformed products. It needs to be made by hand or CNC machining, etc., taking into account the size and shape requirements of the product as well as the process flow.

According to user requirements or sample specifications, the first production of good plastic molds, general conditions, are the use of gypsum production of plastic molds, but there are also wood and metal carving products for the mold, plastic production molds with the lowest cost of gypsum molds, followed by plating of copper molds, the most expensive is the aluminum mold.

Gypsum molds made after the first to let it dry naturally or dry completely, and then according to the product surface convex and concave specifics, with 1-2 mm drilling flower does not affect the product packaging model of the low-concave drilling of many small holes, if it is a product such as boxes, but also have to be drilled around the edges of a number of small holes, so that the production of thermoforming, can be pumped out of the air, the mold drilled holes, but also have to be gypsum molds hardening, hardening treatment! The method is to soak the molds in a thick liquid solution of isotopes and then dry them.

Material Selection

According to the material requirements of the product, choose the appropriate plastic sheet material common plastic sheet material are PVC, PE, PET and so on. Before molding thermoforming, the plastic sheet needs to be cut and trimmed to match the mold.

Heating Plastic Sheets

Add the raw material into the thermoforming machine equipment for heating. Melting temperature and time according to different raw materials and product requirements, generally between 150 ° C and 200 ° C. When heated, the raw material gradually soften, transformed into a better plasticity condition.

Forming

The softened plastic is placed over the top of the mold and an air compressor is started to suck out the gas from the mold to rapidly forming plastic sheets. This step keeps the plastic tight against the mold surface for better molding.

Cooling

After the plastic softens and forms, the cooling and solidification process begins. This process requires uniform temperature and pressure on the plastic sheets surface and interior of the plastic to achieve the final effect.

Removing the Product

After the plastic has completely cooled, open the mold and remove the molded components.

Trimming and Polishing

Trim and shape the removed molded components, removing excess plastic and trimming the edges.

Quality Control

Check the appearance quality and size accuracy of the molded products to ensure they meet customer's requirements.

Thermoforming Machine Operation

The thermoforming machine is the core equipment for thermoforming production. During operation, the corresponding workpiece needs to be made according to the size and shape of the product, the material is placed into the upper mold of the thermoforming machine, and the lower mold is placed on the material. Then turn on the heating plate for heating, which is usually completed within 2-5 minutes. Pay attention to the temperature and time during the heating process to avoid overheating or overcooling. After the heating time is over, turn off the heating plate and suck into the lower mold to form the material.

Thermoforming vs. Injection Molding

Injection Molding

1. Advantages: Stable product quality: The injection molding machine automatically controls the temperature, pressure, time and other factors to produce stable product quality and meet the requirements. Injection molding processing with higher pressure can produce precise products with good surface quality and high precision.

At the same time, injection molding is highly variable and applicable to a wide range of materials, including thermoplastics, thermosets and rubber, etc., and automated production can be realized. The injection molding process adopts plastic granules as raw materials, avoiding environmental problems such as dust, waste water and exhaust gas produced by traditional processing methods, and meeting the requirements of environmental protection.

2. Disadvantages: High investment is needed to purchase injection molding machines and molds, and the production process of products requires high technical level and production experience. In addition, the service life of injection molding machine is relatively short and the maintenance cost is high.

Thermoforming

1. Advantages: The advantages of thermoforming process are low cost, high production efficiency, short manufacturing cycle, simple production process, high manufacturing precision, stable product quality and so on. Thermoforming process can produce a variety of shapes of plastic products, such as flat, three-dimensional, curved surface, etc., can meet the needs of different customers. Thermoforming process of plastic products have good wear resistance, corrosion resistance, high temperature resistance, low temperature resistance, pressure resistance and other characteristics, widely used in various fields.

Thermoforming process method is simple, the equipment needed is simpler than injection molding, the cost is also lower, the process requirements are lower, the fault tolerance rate is high, and the processing process can be quickly adjusted. Moreover, thermoforming can produce larger size products, which is applicable to a wide range of products.

2. Disadvantages: Thermoforming processing pressure is low, precision and surface quality is relatively poor compared to injection molding. At the same time, can only process thermoplastic plastics, and thermosetting plastics and other materials are not applicable.

Comparison of Injection Molding and Thermoforming

Injection molding requires high investment, but the surface quality of the product is good and the precision is high, while the cost of thermoforming is relatively low, but the surface quality and precision are worse.

The material variability of injection molding can be strong, while automated production can be realized, while the thermoforming process can only process thermoplastic materials.

Injection molding processing requires a higher level of craftsmanship than thermoforming processing.

Application of Thermoforming

Thermoforming products have a wide range of applications. Thermoforming products can be made into different shapes and sizes according to the needs of the products, which are suitable for different fields.

For example, it can be used to make furniture and daily necessities in the household field, electronic shells and panels in the electronic field, medical devices and packaging in the medical field, and automobile parts and interior decoration in the automobile field. With the continuous development of various fields, the demand for vacuum forming products will be more and more, which provides a broad market space for the development of the thermoforming industry.

Thermoforming process has a wide range of applications, mainly used in the following areas

1. Packaging industry: Thermoforming can produce a variety of shapes of plastic food packaging boxes, plastic trays, plastic bags, etc., widely used in food, medicine, cosmetics, electronic products and other industries.

2. Household industry: Thermoforming can produce a variety of shapes of plastic household goods, such as plastic chairs, plastic tables, plastic storage boxes, etc.

3. Toy industry: Pressure forming can produce a variety of shapes of plastic toys, such as plastic blocks, plastic puzzles, plastic models, etc.

4. Automotive industry: Thermoforming can produce various shapes of automotive interior parts, automotive exterior parts, automotive parts and so on with vacuuming forming, pressure forming or twin sheet forming.

Conclusion

The continuous innovation and development of thermoforming technology provides new opportunities for the thermoforming industry With the progress of science and technology and the change of product demand, thermoforming technology is also constantly innovating and improving.

At present, with the enhancement of environmental protection consciousness, green and environmentally friendly thermoforming materials and manufacturing processes have become the hotspot of the industry. Based on this, the thermoforming molding industry can develop environmentally friendly thermoforming molding products by introducing new materials and processes to meet the market demand and gain a competitive advantage.

The specialization level of the thermoforming industry in terms of process and equipment is also improving With the continuous development of the thermoforming process, the performance of the thermoforming machinery and equipment is also improving the degree of automation, the production efficiency and product quality have also been significantly improved At the same time, the specialization of the thermoforming technology is also becoming more and more demanding, requiring practitioners to have the relevant professional knowledge and skills. These positive factors will further promote the development of the thermoforming industry.

As an important method of manufacturing plastic products, thermoforming has a wide range of applications, good performance and quality as well as opportunities for continuous innovation and development. With the development of various industries and growing consumer demand, the thermoforming industry is expected to achieve greater development in the future.

However, it should be noted that the thermoforming industry is also facing challenges such as intensified market competition and technological upgrading, and it needs to continuously improve its competitiveness and innovation ability in order to achieve an advantageous position in the fierce market competition.

0 notes

Text

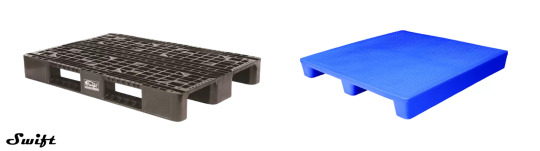

Exporting Excellence: SWIFT Exporting Finest Plastic Pallets Worldwide

With over 20 years of experience, Swift Technoplast has become a familiar face in Indian industrial packaging. We’re renowned for their top-notch plastic pallets, designed to meet the unique needs of various industries. Whether you need secure chemical storage or efficient shipping solutions, Swift Technoplast has a plastic pallet for the job.

Swift Technoplast doesn’t just churn out generic plastic pallets. We understand that every industry has its own needs. That’s why usage of materials like ultra-durable HDPE and flexible LLDPE to craft custom pallets. Need a specific size to fit your warehouse layout? No problem. Want a bright color for easy identification? We can do that too. Swift tailors each pallet to seamlessly integrate with your unique operation.

Swift is committed to provide its customers with the highest quality plastic pallets to streamline their supply chains.

Being a leading plastic pallets manufacturer in India SWIFT has gained recognition for its exceptional product quality and its dedication to export the top quality of products worldwide, offering variety of plastic pallet like Roto Molded Plastic Pallets, Heavy Duty Injection Molded Plastic Pallets, Rackable Pallets, Storage Pallets, One way cargo Pallets, Printing & Packaging Plastic Pallets for various industries.

Here are some of the benefits of using SWIFT Plastic Pallets:

1. High-quality Plastic Pallets

Swift Technoplast takes immense pride in the quality they deliver. Our engineers design each and every plastic pallet with precision, adhering to the strictest international standards. Each pallet goes through a series of harsh tests to guarantee its dependability. This dedication translates to peace of mind for their customers, knowing their products can travel the world safely and securely.

2. Customization options in Plastic Pallets

Swift understands that one-size-fits-all doesn’t apply to pallets! We offer a range of customization options available to ensure the perfect fit for your industrial needs. Whether you have a bulky heavy machine that needs a specific platform or want your pallets to match your company’s vibrant colors, Swift can create custom sizes and colors to match your vision.

Here is the list of customised sizes:

Product Code:Pallet Size

SIP-R24-6687GS : L660 X W870 X H165

SIP-R24-6810GS : L680 X W1080 X H165

SIP-R2-1212GS-SO : L1200 X W1200 X H170

SIP-R24-1207RP : L1200 X W700 X H260

SIP-H4-1675GS : L1060 X W750 X H180

3. Optimizing Supply Chains

Swift Technoplast gets it: in today’s fast paced business world, an efficient supply chain is the difference between winning and losing. We’ve channeled their years of experience into designing plastic pallets that prioritize efficiency. Each pallet is meticulously crafted with features like consistent size, easy stacking, and seamless compatibility with all kinds of material handling equipment. Finally it results in a smooth-running supply chain that translates to real benefits for your business.

4. Excellent customer service

At Swift Technoplast, passionate plastic pallet experts are on hand to answer your questions and navigate you through the ordering process. Their dedication goes way beyond the product. With a growing international presence, Swift has earned a global reputation for exceptional customer service. This combination of top-notch and friendly expertise makes them the clear choice for businesses seeking a reliable plastic pallet partner.

Conclusion

For over two decades, Swift Technoplast has been a household name in Indian manufacturing. We’re more than just a plastic pallet producer – we’re a team dedicated to building a greener future. Our comprehensive range of eco-friendly, high-quality pallets isn’t just good for the environment, it optimizes your supply chain too. Swift’s commitment to excellence goes global. We’re passionate about exporting the finest quality work worldwide, ensuring your goods travel safely and efficiently across continents.

If you are looking for a reliable and experienced Plastic Pallets manufacturer from India, then SWIFT is the perfect choice for you. Contact Us today to learn more about our products.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic

0 notes

Text

two color abdominal wheel mold

China bi injection mold maker, offer bi material exercise wheels mold, two color abdominal wheel mold, multi shot ab roller mold, pp tpr ab machine 2k mold

#China mold#2 component mold#bi material mold#multi shot mold#two color exercise wheels mold#2k ab dominal wheel mold#rotary mold ab roller#double ab machine mold

0 notes

Text

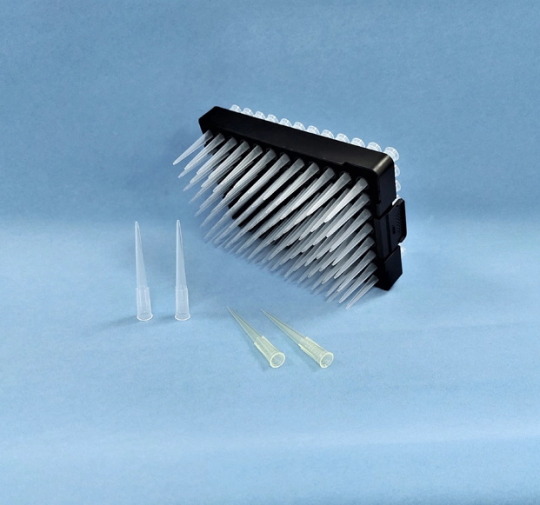

200ul Pipette Tips

200ul pipette tips are essential tools for precise liquid transfer in a laboratory setting. These tips are designed to fit onto pipettes and suction up a fixed volume of liquid, making it easy to measure and dispense accurately. 200ul pipette tips come in various size such as standard length and extra long tips, which are resistant to most chemicals and have low retention properties. The tips are also available in sterile options, making them suitable for use in microbiological applications. With their ease of use, accuracy, and versatility, 200ul pipette tips are an indispensable tool in any laboratory, facilitating scientific research and improving scientific outcomes.

200ul Pipette Tips Information

Product Description

200ul pipette tips are essential tools for efficient and accurate liquid handling in research and clinical laboratories. These tips come in high-quality materials which ensuring optimal sample uptake and minimal contamination risk. They are also compatible with a wide range of pipettes, making them versatile and convenient to use. Overall, 200ul pipette tips are indispensable for achieving reliable and reproducible results.

Features & Benefits

● Made of medical grade polypropylene from globally well-known manufacturer.

● Manufactured by Suitomo/DEMAG high-speed electric injection mold machine with highly precise mold in class 100000 clean workshop using automated processes.

● Unique polishing technology ensures smooth inner surface of the tip for precise pipetting with low residual.

● Stringent in-process QA and OQC to ensure the high quality of all tips.

● Compatible with main stream pipettors, such as Eppendorf/Gilson/Thermo single and 8 channel pipettors.

● Certified DNase-, RNase-, ATP-, and pyrogen-free.

● Excellent transparency for good visualization during pipetting.

● Precise graduation mark for easy pipetting.

● Availability of sterile/non-sterile, filter/no filter, regular/low-retention form.

● Two different lengths to select to meet versatile experimental requirements in the lab.

● The extra long tips are good for handling liquid from extra-long tube or very deep container.

Specifications of 200ul Pipette Tips

Cat.No.

Name

Color

Volume

Length

Filter

Sterile

Packaging

CS

Compatible

CT200A-0-T CT200A-1-T CT200A-3-T

200ul Standard Tips

Natural Color

200uL

50.55mm

N

Optional

Bulk: 1000 Tips/Bag Racked: 96 Tips/Rack Stacked box: 96x10/Box

20000/CS 4800/CS 9600/CS

Eppendorf®/ Thermo®/ Gilson®/Nichiryo®/ Oxford®/ Socorex® etc.

CT200A-0-Y CT200A-1-Y CT200A-3-Y

200ul Standard Tips

Yellow

Yellow

200uL

50.55mm

N

Optional

Bulk: 1000 Tips/Bag Racked: 96 Tips/Rack Stacked box: 96x10/Box

20000/CS 4800/CS 9600/CS

Eppendorf®/ Thermo®/ Gilson®/Nichiryo®/ Oxford®/ Socorex® etc.

CT200AL-0-T CT200AL-1-T

200ul Extra Long Tips

Natural Color

200uL

89.00mm

N

Optional

Bulk: 1000 Tips/Bag Racked: 96 Tips/Rack

5000/CS 4800/CS

Eppendorf®/ Thermo®/ Gilson®/Nichiryo®/ Oxford®/ Socorex® etc.

0 notes

Text

(Inter)National Lego Day

Construct creative builds with this beloved, versatile toy, enjoy the hilarious LEGO Movie or visit a LEGOLAND theme park with your family.

Lego – have you played with it? These little plastic colored bricks have been sparking creativity and joy in both children and adults of all ages for almost 70 years! Small but mighty, Lego bricks inspire creativity, and thanks to their ingenious design, they can be used to make virtually anything you can imagine, from cars to dinosaurs, houses to aliens – if you can dream it, it can probably be built out of Lego.

As such a versatile toy that appeals to all ages of people, it’s not surprising that Lego is now recognized as the World’s Most Powerful Brand, towering over Google, Nike, and Ferrari to claim the top spot in 2017, but as with most gigantic companies, Lego started from humble origins and International Lego Day marks the very beginning.

History of Lego

International Lego Day is held on the very same day that Danish carpenter, Godtfred Kirk Christiansen, first submitted his patent for the original Lego brick in 1958. Like no other brick that had come before this toy brick would have a sophisticated interlocking brick system, making it strong, versatile, and less likely to fall apart when simply knocked over.

Not one to mess around, Godtfred made sure not only to patent the design for his single Lego brick, but also to patent the concept of multiple bricks being used together in a building system, and this protected his design from being ripped off by competitors. Although this day is often seen as the birthplace of Lego as we know it, the company itself was in fact founded by Godtfred in 1932, creating a variety of wooden toys, and taking the name Lego from the Danish words “LEg GOdt” which translate to “play well”.

Ahead of their time, Lego was one of the very first toy manufacturing companies to buy an injection mold machine with which to create plastic toys, a move which shortly led them to create the very first plastic Lego brick in 1949. In the 17 years from 1949 to 1966, Lego grew exponentially into a global company that was retailing in 42 countries. They now boasted a product range that now contained 57 Lego sets and 25 Lego vehicles and with factories that were producing more than 706 million Lego elements each year – but the company didn’t stop growing.

In 1967 the LEGOLAND Band was established and in 1968, the very first LEGOLAND opened its doors to the public, attracting more than 625,000 visitors in its first season. Today there are 9 LEGOLANDS across Europe, Asia and the US, with a further three due to open in the next few years.

Nowadays Lego is a truly global enterprise, its strong brand identity, and still unique simplistic design, keeps it a favorite amongst children, while its history and versatility make it even more collectible to adults.

International Lego Day Timeline

1932 LEGO founder starts a woodworking shop in Denmark

In a small woodworking shop in Billund, Ole Kirk Christiansen makes all types of furniture and household items. But his favorite creations are toys for his sons, so he eventually names his company LEGO–a combination of two Danish words meaning “play well”.

1946-1949 Plastic bricks are first sold by the LEGO company

A wood shortage following WWII makes manufacturers look for alternative ways to create products. Christiansen gets his hands on the first plastic-injection molding machine in Denmark and starts selling the Automatic Binding Brick, the predecessor to today’s stackable blocks.

January 28, 1958 LEGO patent application is submitted

With Christainsen’s son, Godtfred, at the helm, the company submits their patent application for the tubes and studs that would add stability and connectivity to the plastic blocks. This anniversary coincides with International LEGO Day each year.

1976 LEGO minifigures are introduced

Realizing that the sets might be more fun if a human dimension was added, the company releases the iconic yellow-faced humanoid bricks.

2014 LEGO feature film is released

When watching his son play with LEGOs, a Hollywood producer gets the idea to make an animated movie. It is a huge hit and grosses more than $450 million, with more films coming in the following years.

10 super-fun facts about Lego

In 2016 LandRover set the World Record for the largest piece of Lego construction with their huge 43-foot-high replica of Tower Bridge. This monumental structure used 5,805,846 individual pieces of Lego which would have stretched all the way to Paris in France if laid out end to end.

If Lego Minifigures were to be classed as a population, they’d be the largest population in the world! With more than 4 billion of them in total.

There are so many Lego bricks in the world, that it’s estimated that they outnumber people 80 to 1.

Despite the first Lego brick having been made in 1958, you could still interlock one with a Lego brick-built today – the design hasn’t changed a bit!

In 2009, James May created a house entirely out of Lego! The house took more than 3.3 million bricks to make and even had a working toilet, a bed, and a shower!

Lego is now so popular that 7 sets are sold every second.

Although Lego is played by both girls and boys, women and men, they still have a bit of a way to go before they reach gender equality with roughly 86% of their Lego Minifigures being male.

If you were to collect all the Lego bricks in the world and stack them together then they would be 2,386,065 miles tall!

Although Lego makes toys they are also classed as the world’s biggest tire manufacturer, making over 400 million tires each year to keep their fleet of various lego vehicles rolling.

Although Lego was the first to patent the Lego brick that we know today, they didn’t technically invent them. The story has it that the salesman who came to sell Godtfred his first plastic injection mold machine was carrying an example interlocking brick in his pocket which had been designed and patented by Hilary Fisher Page. Godtfred improved on the design by perforating the brick and adding tubes on the bottom to help tighten the connection.

How to celebrate International Lego Day

Whether you’re five or sixty-five, you’re never too old to celebrate International Lego Day. Here are a few things that you could do to celebrate the day:

Play with Lego! Perhaps the most obvious thing to do on International Lego Day is to play with Lego of course! Grab your old lego set, or buy one especially for the day and sit down for a few hours of relaxing and creative fun. If you now have children yourself then make a sculpture together and take a moment to remember how many generations have grown up with Lego by their side.

Watch the Lego Movie! Lego has become so iconic that it even has its own movie dedicated to it. In fact, there are now two! Fun for all the family, cozy up on the sofa with some popcorn and watch as Lego figures come to life in stunning animation.

Visit LEGOLAND. And finally, for perhaps the most immersive Lego experience, pack your bags and take a trip to one of the many LEGOLAND theme parks. Be wowed by the impressive Lego structures and ride the exhilarating roller coasters for a day you’ll never forget.

Source

#Lego company#patented#Lego brick#28 January 1958#anniversary#USA#history#International LEGO Day .#InternationalLegoDay#Toys `R` Us#travel#I still miss it#original photography#Manhattan#New York City#summer 2013#Chicago#Illinois#2016#evening light#CTA#vacation#indoors#outdoors#tourist attraction#landmark#Michigan Avenue#cityscape#architecture#Toys 'R' Us

0 notes

Text

Precision in Plastics: Unveiling the Expertise of FDX Molding

In the dynamic world of manufacturing, the demand for high-quality plastic parts is ever-growing. As industries evolve, the need for a reliable and proficient injection molding manufacturer becomes paramount. Enter FDX Molding, a leading player in the field, equipped with state-of-the-art facilities and a skilled team to meet the burgeoning demands of clients.

At the heart of FDX Molding’s operations lies a cutting-edge factory, strategically equipped to handle large-scale production without compromising on precision. Boasting 11 CNC machines, 9 EDM machines, and 14 injection molding machines, the facility is a testament to FDX Molding’s commitment to excellence. The injection molding machines, with capacities ranging from 86 to 1600 tons, ensure versatility in molding various plastic parts with precision and efficiency.

One of the key strengths of FDX Molding is its team of highly skilled professionals. Well-versed in a myriad of injection molding techniques, including two-shot molding, large molding, and insert molding, the team brings a wealth of expertise to the table. This diverse skill set empowers FDX Molding to cater to a wide range of client needs and specifications.

Two-shot molding, a specialized technique mastered by FDX Molding, involves the creation of complex parts with two different materials or colors. This advanced capability opens up new possibilities for clients seeking innovative and intricate designs in their plastic parts. The meticulous execution of two-shot molding sets FDX Molding apart as a manufacturer capable of turning conceptual designs into tangible, high-quality products.

Large molding is another area where FDX Molding excels. With the ability to handle substantial volumes of plastic material, the company ensures that clients with extensive production requirements can rely on them for seamless and efficient manufacturing. The large molding expertise extends to diverse industries, including automotive, electronics, and consumer goods.

Insert molding is yet another dimension of FDX Molding’s proficiency. This technique involves inserting metal or other components into the mold before the plastic is injected, creating a secure and integrated final product. Whether it’s enhancing strength, adding functionality, or streamlining assembly processes, insert molding is a valuable technique that FDX Molding employs with precision.

Beyond the technical prowess, FDX Molding prioritizes the quality of the molded parts. Each product that leaves the facility is a testament to the dedication to excellence. The combination of cutting-edge machinery, skilled professionals, and stringent quality control measures ensures that clients receive plastic parts that meet or exceed industry standards.

The versatility of FDX Molding extends to its ability to cater to various industries, from automotive to electronics and beyond. The adaptability to different molding techniques and the capacity to handle diverse materials make FDX Molding a preferred choice for businesses seeking a reliable partner in injection molding.

In conclusion, FDX Molding stands as a beacon of precision and reliability in the injection molding landscape. With a well-equipped facility and a team of experts proficient in diverse molding techniques, the company ensures that clients receive plastic parts that not only meet their specifications but also surpass their expectations. As industries continue to evolve, FDX Molding remains at the forefront, ready to shape the future of injection molding with innovation, expertise, and a commitment to excellence.

0 notes