#turbine engines for sale

Explore tagged Tumblr posts

Text

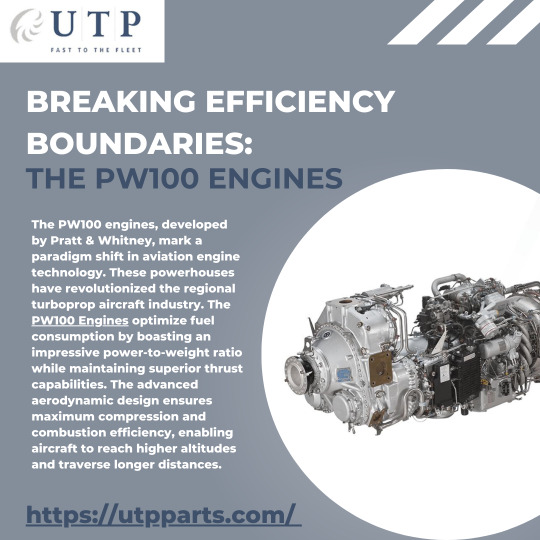

Breaking Efficiency Boundaries: The PW100 Engines

The PW100 engines, developed by Pratt & Whitney, mark a paradigm shift in aviation engine technology. These powerhouses have revolutionized the regional turboprop aircraft industry. The PW100 Engines optimize fuel consumption by boasting an impressive power-to-weight ratio while maintaining superior thrust capabilities. The advanced aerodynamic design ensures maximum compression and combustion efficiency, enabling aircraft to reach higher altitudes and traverse longer distances. Additionally, their low-emission features and reduced noise levels align with environmentally sustainable goals, making the PW100 engines an ecologically conscious choice. The PW100 engines have redefined what it means to be efficient in aviation. With their exceptional performance, reliability, and environmental consciousness, these engines continue to set new standards in the regional turboprop aircraft industry. For more information, visit our website.

0 notes

Text

8/29/2024 - 9/6/2024

If I had a nickel for every time I took a vacation in a small European naval power that historically punched above its weight in global affairs I'd have two nickels, which... ah, you know the rest.

Just got back from a trip to the Netherlands and Belgium that was basically: Amsterdam -> Apeldoorn -> Utrecht -> Den Haag -> Brussels -> Ghent -> Amsterdam. I will now proceed to talk to myself about the highlights below the cut.

Still can't sleep on planes. I even took a sleeping pill and bought a fancy new neck pillow thing to help, but instead I was just exhausted and strangling myself. My dinner also didn't sit well with me, so every time I was about to fall asleep, my gag reflex would trigger and I felt like I was gonna throw up. Seven hours of this was not very relaxing.

Landed at ass o'clock in the morning local time and had 6 hours to kill before hotel check in. I've always read that spending time outdoors in natural sunlight helps regulate your circadian rhythm and can fight jet lag, so I took us to look at some windmills. This was kind of a blur and I'm not certain it made much of a difference because I did end up crashing and taking a nap in the afternoon anyway.

Acknowledging that I am biased about this because I am 1) American and 2) literally a traffic engineer by trade, I simply cannot describe the Netherlands as anything other than "car-hostile". I felt actively unsafe driving around each city we visited because there are so many people on bicycles everywhere, who have right of way. Hell, even as a pedestrian I didn't feel safe because they come at you from every direction and you gotta keep your head on a swivel at all times. In The Hague I watched a woman get knocked into by a cyclist who just shouted over her shoulder "Let op voor fietsen!" ("Watch out for bikes!") and carried on.

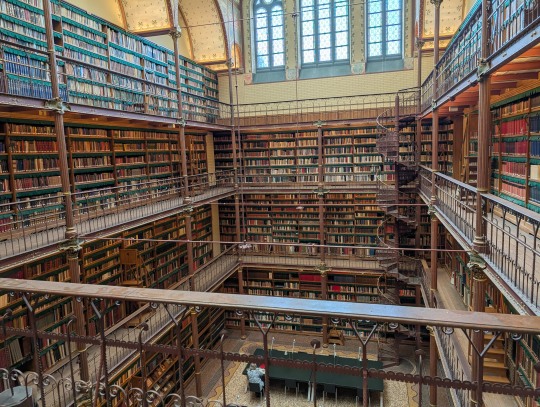

Amsterdam ended up being more interesting than I was expecting and now I kinda wish I had dedicated one more day for it in the itinerary. Convenient and easy mass-transit system, some of the best bookstores I've ever been in, and beautiful canals everywhere you look.

Were I forced to describe the geography of the Netherlands, I would have to call it "suspiciously flat." I also got to continue my tradition of traveling to foreign countries, seeing literal hundreds of spinning wind turbines all over the place, and seething with jealousy.

Utrecht was a neat, smaller city with a central canal that I wish I had set aside more time for. Felt like a place where you'd actually want to live more than a touristy city.

The Mauritshuis in The Hague is where Vermeer's Girl with a Pearl Earring is located, and you know that before you even get to that room because she's plastered on 99% of everything for sale in the gift shop right at the entrance.

When we drove over the Netherlands-Belgium border, it started getting overcast. These gray skies hung around for four days, and dissipated as soon as we traveled back north on the final day. All of my memories of this country will now have a gray/de-saturated filter on them.

I know Brussels has a reputation of being a run-down or dangerous city among Europeans, but it just felt like a regular American city to me (specifically like the architecture/street layout of Boston with the political importance of Washington DC). Like, I don't know what to tell you, sometimes cities have visible homeless people, unsightly graffiti, and ethnic minority neighborhoods? It's gonna be okay, I promise. Amsterdam felt like Weenie Hut Jr. by comparison.

Going through the European Parliament building was very cool and very well laid-out and informative. Definitely a personal highlight of the trip for me.

The Belgian War Museum kinda just felt like some rich guy's personal collection of artifacts the public shouldn't have had access to? Not a lot of labels explaining what you're looking at in any language.

Belgian chocolate is fine. Not bad, but I mean it's chocolate, that's hard to screw up, you know?

During my research before this trip I kept seeing a general consensus that Bruges is super touristy and sanitized and feels fake and that Ghent was better for a more "authentically" preserved medieval center. I'm glad I opted to go there instead because it exceeded my expectations. Awesome architecture everywhere you turn, way fewer crowds than I expected, and it still felt lived in by modern people rather than a giant open-air museum.

Literally did not see a single physical Euro at all on this trip. Both of these countries are entirely cashless societies, and everyone (both tourists and locals) used chip readers and contactless payment for damn near every interaction. If anything, I saw tons of "Card Only/No Cash" signs and none of the opposite.

99 notes

·

View notes

Text

There's a whole lot of towns out there that you'll never visit. Most of them are chock full of people you'll never meet. Tulsa, for example. Never been there, might never go there. And that makes me a little sad.

Sure, I only have enough time on this earth to visit so many towns. And when I'm there, I don't have enough time to interrogate every single one of the locals to see if, say, any of them have a set of Mopar F-body windshield wiper linkages sitting in the back of their garage. They'll just go to waste, damned to irrelevance by my lack of time. That's what the MBAs call a "market inefficiency."

The internet has helped, sure, but you can only demand what other people have supplied. Any quick browse on a model-specific forum is full of lonely folks crying out to the heavens for a specific piece of trim, or an entire automatic transmission, that they will never receive. And it's a lot of work to put that stuff up for sale. Who knows what's actually inside that weird pile of oil-stained gewgaws that Pawpaw left behind before he joined that alien cult and drank all that Flavor-Aid? His surviving next-of-kin sure don't know the difference between a 4.11 and a 3.90 rear end, nor are they willing to teach themselves that information in order to list it on eBay for twenty bucks.

Don't worry, though, I have a solution. That solution is that the Boston Dynamics warehouse is not secured very well. Their robots are powered by a two-stroke lawnmower engine: it's like they wanted me to show up with a turbine-generator-powered plasma cutter and chop right through the rebar holding the walls of their robot storage lockup together. After that, it was a quick couple of dozen trips to the local electronics store to get the right USB-to-serial cable, and I soon had my harem of semi-autonomous Parts-Seeking Drones® roving the backwoods of America.

So, if you see a lanky, creaking doglike shape lurking outside your yard tonight, smelling oddly of pre-mix and human arterial blood, let it in your garage. All it wants to do is scan your spare parts so I can find that goddamn last piece of dash trim for the cruise control lever on my Volare. Don't worry: I won't have the robots kill you if you decide not to sell it to me after all. It would be hypocritical of me to judge another hoarder. We'll have coffee when I come see your town for the first time! We can trade junk and be best friends and call each other on the phone afterward and talk about nitrous oxide. No promises on what the robots will do if they search your entire property and don't find any Plymouth Volare stuff, though. I forgot to program that part before I let them out of radio range.

247 notes

·

View notes

Text

Blackbird pilot tells why the SR-71 could fly at Mach 3.55 so long as 427C weren’t exceeded

The Blackbird

The SR-71, unofficially known as the “Blackbird,” was a long-range, Mach 3+, strategic reconnaissance aircraft developed from the Lockheed A-12 and YF-12A aircraft.

T-shirts Habubrats 2

CLICK HERE to see The Aviation Geek Club contributor Linda Sheffield’s T-shirt designs! Linda has a personal relationship with the SR-71 because her father Butch Sheffield flew the Blackbird from test flight in 1965 until 1973. Butch’s Granddaughter’s Lisa Burroughs and Susan Miller are graphic designers. They designed most of the merchandise that is for sale on Threadless. A percentage of the profits go to Flight Test Museum at Edwards Air Force Base. This nonprofit charity is personal to the Sheffield family because they are raising money to house SR-71, #955. This was the first Blackbird that Butch Sheffield flew on Oct. 4, 1965.

The first flight of an SR-71 took place on Dec. 22, 1964, and the first SR-71 to enter service was delivered to the 4200th (later 9th) Strategic Reconnaissance Wing at Beale Air Force Base, Calif., in January 1966.

The Blackbird was in a different category from anything that had come before. “Everything had to be invented. Everything,” Skunk Works legendary aircraft designer Kelly Johnson recalled in an interesting article appeared on Lockheed Martin website.

The SR-71 could fly at Mach 3.55

Today there are many rumors about just how fast the SR-71 could go. The J58 engine temperature limited the top speed. The speed limit for the airplane ironically had nothing to do with the airframe; it had to do with the engines. Right in front of the engine compressor was a temperature probe that reported the temperature to the pilot; when the temperature was around 427C, 800 degrees Fahrenheit, that’s as fast as they were allowed to go.

However, a cold blast from frigid weather could make a difference in reducing the temperature. This would enable the airframe to go faster without harming the engines.

David Peters, former SR-71 Blackbird pilot, explained to me;

Blackbird pilot tells why the SR-71 could fly at Mach 3.55 so long as 427C weren’t exceeded

This print is available in multiple sizes from AircraftProfilePrints.com – CLICK HERE TO GET YOURS. Dawn at 80.000ft – SR-71 Blackbird

‘A little clarification on the speed thing. You are absolutely correct on the 427C. The issue is that I have been limited to less than Mach 3 on a few occasions because the outside air temperature was quite above standard and 427C came up at about 2.95. On other occasions like the Murmansk deal I got above 3.4 (3.49 on the one occasion) and wasn’t close to 427C. The actual limiting airspeed is around 3.55 that is where the spike being at full retraction loses the intercept on the shock wave and can no longer position it correctly in the inlet. ‘Also the overflow of the shock starts to go over the wing and interfere with the flight controls. So the limiting speed as configured would be about 3.55 so long as you don’t exceed 427C.’

Mike Relja, who worked on in with the SR-71‘s for over 30 years, added;

‘I don’t know of any warranty that P&W had or any other parts manufacturer for that matter.

Don’t exceed 427C

‘On the March 6th [Mar. 6, 1990] speed run Ed Yeilding stated that Don Emmons gave them permission to fly the max limit of 3.3 M, they asked Lockheed if they could exceed that number and Lockheed said no if the aircraft had an unstart above 3.3 it may go out of control and come apart hard to keep the pointy end forward. Also, no fuel flow limits established above 3.3 M were ever tested.

‘P&W did give them clearance to exceed 427 CIT for 30 minutes to a limit of 450 CIT but that wasn’t needed they stayed at the book limit of 427 CIT.’*

The engines maker Pratt & Whitney would not warrant or guarantee anything beyond 427; after that, all bets are off the engine could come unglued or you could shed turbine blades. The SR-71 crewmembers were too responsible to risk and exceeded the temperature limit. They wanted to keep the warranty on the engines, the J58’s.

*SR-71 pilot Ed Yeilding (who along with JT Vida as RSO flew the Blackbird during the speed run of Mar. 6, 1990) told me that another reason they didn’t exceed 3.2 is that they were afraid they’d run out of gas before they got to Dullas airport.

Be sure to check out Linda Sheffield Miller (Col Richard (Butch) Sheffield’s daughter, Col. Sheffield was an SR-71 Reconnaissance Systems Officer) Twitter X Page Habubrats SR-71, Instagram Page SR71Habubrats and Facebook Page Born into the Wilde Blue Yonder Habubrats for awesome Blackbird’s photos and stories.

Blackbird pilot tells why the SR-71 could fly at Mach 3.55 so long as 427C weren’t exceeded

@Habubrats71 via X

#sr71#sr 71#sr 71 blackbird#aircraft#usaf#lockheed aviation#mach3+#habu#aviation#reconnaissance#cold war aircraft#aviation military#aviation military pics#military aircraft#military aviation

40 notes

·

View notes

Text

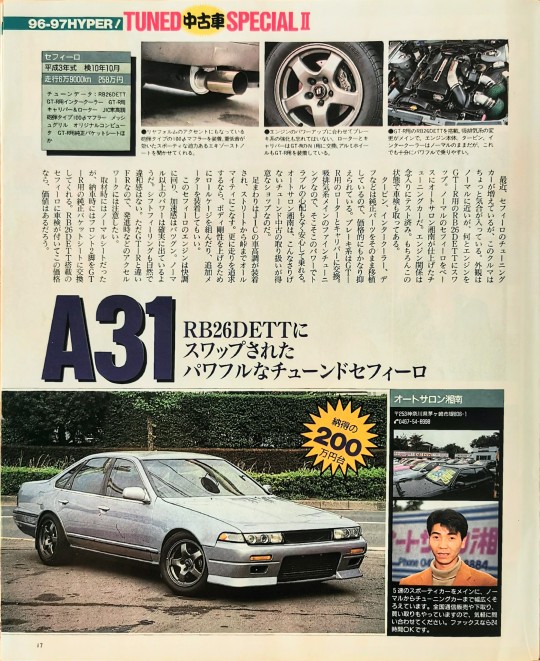

A31

Powerful tuned Cefiro swapped to RB26DETT

Recently, the number of Cefiro tuned cars has been increasing, but this car is a bit more spirited. Although the appearance is close to stock, the engine was swapped to the RB26DETT for GT-R. This is a tuned car finished by Auto Salon Shonan based on the normal Cefiro. The engine has been carefully tested. Of course, the vehicle was inspected in this condition.

Turbine, intercooler, DETT

Since the parts such as the front cover are transplanted directly from genuine parts, the price is also quite low. The brake system was replaced with GT-R rotors and calipers. The main focus is fine tuning on the intake and exhaust systems, so you can ride with peace of mind without worrying about any trouble with a decent amount of power. Auto Salon Shonan is a great place to handle such discreetly tuned used cars.

It's a special shop.

The suspension is equipped with JIC coilovers, making it versatile from streets to mountain passes. If you want to pursue even better performance, you can install a roll cage or an additional meter to increase body rigidity.

The engine of this Cefiro runs smoothly and the acceleration is outstanding. It definitely seems to be producing more power than normal. The shift feeling is natural and there is no discomfort. However, unlike the GT-R, it is an FR model, so be careful when using the accelerator when starting off.

At the time of interview, it was a normal seat.

However, when the car is delivered, the two front seats will be replaced with genuine GT/R bucket seats. Cefiro equipped with RB26DETT comes with vehicle inspection at this price

If so, it might be worth it.

PIC CAPTIONS

-Equipped with a bullet-type 100 muffler that also accents the rear form. It delivers a powerful, sporty exhaust note with deep bass.

●As we increase the power of the engine, we also do not forget to strengthen the brake system. The rotor and caliper were replaced with GT-R NI versions, and the GT-R aluminum wheels were also installed.

●Equipped with RB26DETT for GT-R. The main changes are to the intake and exhaust system, and the engine, turbine, and intercooler are still stock, but they are still powerful enough and easy to ride.

INFO BOX

Cefiro

1991 model inspection October 2010

Mileage 69,000km 2,580,000 yen

Tune data: RB26DETT

Intercooler for GT-R

GT-R Caliper & rotor

JIC vehicle height adjustment

Cannonball type 100 muffler

Original Computer

Genuine bucket seat for GT-R etc.

SHOP INFO

Auto Salon Shonan

836-1 Tsutsumi, Chigasaki City, Kanagawa Prefecture 253

0467-54-8998

We mainly have 5-speed sporty cars, but we have a wide range of cars from normal cars to tuned cars. We also do nationwide mail order sales, trade-ins, and purchases, so please feel free to contact us. Fax is available 24 hours a day.

50 notes

·

View notes

Text

Excerpt from this story from Inside Climate News:

In the early 2000s, a long-time Louisiana engineer and entrepreneur thought it would be natural for the oil and gas industry in the Gulf of Mexico to expand into offshore wind. The industry could use the same workforce, the same shipyards and possibly even the same platforms to generate renewable power.

With designs, data and offshore leases from Texas, Herman Schellstede and his team planned to build a 62-turbine wind farm off Galveston’s coast— one of the first such proposals in the United States and the first in the Gulf of Mexico.

The team approached banks and even Koch Industries seeking financing for the $300 million wind farm, he said. But financing nascent offshore wind was apparently too risky a proposition in the wake of the 2008 financial meltdown. The wind farm was eventually scuttled.

Now, 33 years after the first offshore wind farm was built in waters off Denmark, it’s still unclear if the time is right — or will ever be right — for the United States. In those years, only four wind farms generating 242 megawatts of power have been built off the U.S. coast; the largest just went into service in 2024.

Last year, inflation, supply chain problems and other macroeconomic issues led to the cancellation or renegotiation of about half of all proposed offshore wind projects. And while the Biden Administration is moving as quickly as possible to approve new lease sales and projects — expanding the amount of power generated by 10-fold — former President Donald Trump has promised to end offshore wind if elected.

The industry and advocates, however, do not seem daunted. Studies show offshore wind could meet 5% of the nation’s energy needs by 2035, and up to 25% by 2050.

“We’re all in this room today, not because we just see offshore wind as a massive opportunity — which it is to build you clean energy — but also we see the necessity of offshore wind,” said Amanda Lefton, vice president of offshore development for the renewable energy company RWE.

Lefton, speaking at an April conference of the offshore wind industry in New Orleans, said the technology is needed to meet national and state decarbonization goals. RWE is developing projects off the East Coast and California and working to create a supply chain for offshore wind in the Gulf of Mexico with a large Louisiana-based coalition.

“We know the fundamentals exist in these markets,” said Lefton, the former head of the U.S. Bureau of Ocean Energy Management who leads RWE’s East Coast operations. “We know that it’s not an if, it’s a when.”

2 notes

·

View notes

Text

Best CNC Gear Hobbing Machine Distributor in Coimbatore – Gear Hobbing Solutions

When it comes to high-quality gear manufacturing, precision and efficiency are key. That’s why companies across industries trust CNC gear hobbing machines for their gear cutting needs. If you are looking for the most reliable CNC gear hobbing machine distributor in Coimbatore, look no further than Gear Hobbing Solutions. We offer cutting-edge technology, world-class machines, and excellent service to help your business grow.

In this article, we will explain why Gear Hobbing Solutions is the best choice and how CNC gear hobbing machines can boost your production quality.

What is CNC Gear Hobbing?

CNC gear hobbing is a process used to cut gears with precision using a specialized tool called a hob. Controlled by advanced computer systems (CNC – Computer Numerical Control), the machine ensures that every gear tooth is manufactured to exact specifications. It’s faster, more accurate, and more reliable than manual gear cutting methods.

As a leading CNC gear hobbing machine distributor in Coimbatore, we ensure you get machines that offer the highest levels of precision, efficiency, and reliability.

Importance of CNC Gear Hobbing Machines in Modern Industries

Today, industries like automotive, aerospace, industrial equipment, agriculture, and renewable energy heavily depend on gears. Poor-quality gears can result in machinery breakdowns, low productivity, and high maintenance costs. That’s why having a high-performance CNC gear hobbing machine is critical.

At Gear Hobbing Solutions, we offer machines that deliver:

Precision cutting for perfect gear shapes

High-speed operation for faster production

Repeatability for consistent quality

Ease of use for reduced labor costs

By choosing the right CNC gear hobbing machine distributor in Coimbatore, you invest in your company's future.

Why Gear Hobbing Solutions is the Best CNC Gear Hobbing Machine Distributor in Coimbatore

Choosing the right distributor is just as important as choosing the right machine. Here’s why Gear Hobbing Solutions stands out:

1. Top-Quality Machines

We supply only the best CNC gear hobbing machines, built with modern technology and superior materials. Our machines offer multi-axis movement, high spindle speeds, and excellent surface finish quality.

2. Wide Range of Models

Whether you need machines for small gears or large industrial gears, we have the perfect solution for you. We provide machines suited for different production scales and gear types.

3. Competitive Pricing

At Gear Hobbing Solutions, we believe in offering value. Our machines are priced competitively, ensuring you get the best technology without stretching your budget.

4. Expert Support

We don't just sell machines; we provide complete technical support, installation assistance, training, and after-sales service. Your success is our priority.

5. Fast Delivery

Being the leading CNC gear hobbing machine distributor in Coimbatore, we ensure prompt deliveries so your production doesn't face delays.

Applications of CNC Gear Hobbing Machines

Our machines are used across a wide range of industries, including:

Automotive Industry: Cutting gears for transmissions and engines

Aerospace Sector: Manufacturing precision gears for aviation applications

Industrial Machinery: Producing gears for heavy machinery and automation systems

Renewable Energy: Gears for wind turbines and solar equipment

Agricultural Equipment: Gears for tractors, harvesters, and other farm machinery

No matter your industry, we have the right CNC gear hobbing solution for you.

Key Features of Our CNC Gear Hobbing Machines

At Gear Hobbing Solutions, our machines are packed with advanced features:

Multi-axis Control: For making complex gear designs

Automatic Lubrication Systems: Reduces machine wear and extends tool life

High-Speed Spindles: Increases production efficiency

User-Friendly CNC Interface: Easy for operators to learn and program

Durable Construction: Machines designed to last for years with minimal maintenance

When you choose us as your CNC gear hobbing machine distributor in Coimbatore, you are guaranteed machines with outstanding features.

How CNC Gear Hobbing Machines Boost Your Business

Here’s how investing in a quality CNC gear hobbing machine can transform your operations:

Higher Productivity: Machines run faster and produce more gears per shift

Better Quality: Precision cutting ensures fewer defects and reworks

Lower Costs: Automated operations reduce labor and material waste

Customer Satisfaction: Delivering top-quality gears will enhance your reputation

Competitive Advantage: Advanced machines allow you to meet tight deadlines and large orders

Tips for Choosing the Right CNC Gear Hobbing Machine

Selecting the right machine is crucial. Here are some tips:

Know Your Requirements: Understand the size, type, and volume of gears you plan to produce.

Check Machine Specifications: Look for spindle speed, workpiece size, and automation levels.

Evaluate Brand Reputation: Partner with trusted brands through authorized distributors like Gear Hobbing Solutions.

Plan Your Budget: Invest wisely by considering not just the initial cost but also long-term operational benefits.

After-Sales Service: Ensure you get reliable support for installation, maintenance, and troubleshooting.

Why Coimbatore Prefers Gear Hobbing Solutions

Coimbatore, known as the "Manchester of South India," is a hub for manufacturing industries. We are proud to be the preferred CNC gear hobbing machine distributor in Coimbatore, thanks to our local presence, quick service response, and deep understanding of the market.

Companies across Coimbatore trust us because:

We understand their business needs.

We provide tailor-made solutions.

We support their growth journey with advanced technology.

Our Commitment to Excellence

At Gear Hobbing Solutions, we don’t just sell machines – we build partnerships. We are committed to offering the best CNC gear hobbing machines that help your business achieve new heights of success.

We believe in continuous improvement, customer-first approach, and delivering value through every product and service we offer. Our team is always ready to assist you with the best advice, training, and technical support.

Conclusion

If you are looking for a reliable, experienced, and trusted CNC gear hobbing machine distributor in Coimbatore, Gear Hobbing Solutions is your best choice. With our world-class machines, expert team, and customer-centric approach, we help you take your gear manufacturing to the next level.

Contact us today to learn more about our CNC gear hobbing machines and how we can support your production needs!

0 notes

Text

In India, Flowmore is the firm with the most end suction pump sales. End-suction pumps are used in a huge range of applications since they are a cost-effective and actual pump technology. Furthermore, Flowmore offers personalized solutions. It is crafted to your exact specifications. It comes in addition to manufactured pumps. Everything you need to know about Flowmore best-selling end suction pump is covered in this tutorial.

Do you know what an “end suction pump” is?

End suction pumps, a subset of centrifugal pumps, have a single impeller instead of two and are one-stage designs. The suction pipe and casing are next to each other at one end. There is a discharge exit on the other side. Comparing end suction pumps to other types of centrifugal pumps, they are relatively cheap. Flowmore end-suction pumps can handle any type of liquid that your company handles. Flowmore also offers a wide range of sizes, materials, and styles to satisfy all of your needs. End-suction pumps happen to pump a wide variation of fluids. These entail harsh chemicals and greasy material. It also includes abrasive slurries and hot and cold water.

How do end suction pumps operate?

There is one impeller in the massive majority of end-suction pumps only. Because they are moving on the impeller vanes, pumped liquids move faster. After going through the impeller, the liquid enters the casing, where its high velocities cause diffusion to change the pressure. The mainstream of end-suction pumps happen to be driven by an alternating current (AC) motor. They can, however, also be propelled by air motors, hydraulic motors, direct current electric motors, diesel and petrol engines and steam turbines.

Different kinds of end suction pumps

Two principal types of end suction pumps are there:

A closed-coupled end suction pump design

This type of pump does not need a separate connection. It is because the impeller is related to the motor shaft openly. Most of the End-suction Pumps India are used to pump water in houses and commercial edifices. These are close-coupled. They are reasonably priced and constructed from both iron and plastic.

Suction pump installation on the frame

This kind of pump uses a system of bearings and connections to physically separate the motor from the pump. The end suction pump mounting surface is used in harsh industrial settings. They are usually a bedplate. You can unplug the pump from the motor using the included connector.

0 notes

Text

Enhance Equipment Lifespan with Advanced Industrial Oil Purification Systems from A R Engineering

In today’s industrial environment, maintaining the purity and quality of lubricants and transformer oils is vital to ensure smooth machinery operations and avoid costly breakdowns. At A R Engineering, we specialize in high-performance Industrial Oil Purification Systems that restore oil properties and eliminate impurities to extend machinery life and reduce maintenance costs.

As reputed Industrial Oil Purification System Manufacturers, we design systems that deliver efficient, eco-friendly oil filtration and purification for various industrial applications.

Why Oil Purification is Crucial for Industries

Impurities such as water, dust, sludge, and oxidation by-products can drastically reduce the performance of industrial oils. Without proper filtration, this contamination leads to:

Increased wear and tear

Reduced equipment efficiency

Unscheduled downtime

Higher operational costs

Our advanced Industrial Oil Purification Systems tackle these issues head-on using proven filtration and dehydration techniques.

A R Engineering – Leading the Way in Oil Purification

We are trusted Industrial Oil Purification System manufacturers in Pune, known for robust designs, high efficiency, and user-friendly controls. Whether you operate in the power sector, manufacturing, or heavy machinery, our systems are tailored to your specific oil maintenance needs.

Our Comprehensive Offerings Include:

✅ Industrial Oil Filtration Machines Perfect for filtering turbine oils, hydraulic oils, and transformer oils to remove contaminants and restore functionality.

✅ Industrial Oil Filtration Plants Fully automated units capable of continuous oil purification, ideal for large-scale operations and critical industries.

✅ Oil Filter Machines & Oil Filtration Machines Reliable and easy-to-operate machines to handle various oil types and contamination levels.

✅ Oil Filteration Plants (Yes, we handle every spelling!) Designed with multi-stage filtration systems for maximum purification effectiveness.

Trusted Globally – Export-Ready Solutions

As established Industrial Oil Purification Systems exporters in Pune and India, we deliver quality systems that meet global standards. Our systems are widely used by clients across the Middle East, Southeast Asia, and Africa.

We are also among the most reliable Industrial Oil Purification System Suppliers in India, offering local service, fast installation, and dedicated after-sales support.

Why Partner with A R Engineering?

Made in Pune, Trusted Globally We are renowned Industrial Oil Purification Systems manufacturers in Pune with cutting-edge production capabilities.

Exporters with a Strong Global Network As Industrial Oil Purification Systems exporters in India, our footprint extends across international markets with satisfied customers in various industries.

Custom Engineered Solutions Whether you need a standalone oil purifier or a complete industrial oil filtration plant, we provide tailored systems to suit your capacity and contamination level.

Get Clean Oil. Get Maximum Uptime. Choose A R Engineering.

For efficient and reliable Industrial Oil Purification Systems, partner with one of the most trusted names in the industry. We combine technology, experience, and service to help you get the most out of your oils—and your equipment.

Visit: https://conserveyouroil.com/industrial-oil-purification-systems.html Contact us now to request a quote or a customized oil purification solution.

#Industrial Oil Purification System Manufacturers#Industrial Oil Purification System Suppliers in India#industrial oil filtration plant#Industrial Oil Purification Systems manufacturer in pune#Industrial Oil Purification Systems suppliers in pune#Industrial Oil Purification Systems exporter in pune#Industrial Oil Purification Systems manufacturer in india#Industrial Oil Purification Systems exporter in india#Industrial oil filtration machines#Industrial oil filtration plant#Oil filter machines#Oil filteration plants#Oil filtration machines

0 notes

Text

PW100 engines are famous for various aircraft, from regional airliners to business jets. These engines are known for their reliability, efficiency, and low maintenance requirements, making them a cost-effective option for operators of all sizes. With a wide range of PW100 Engines For Sale, buyers can choose various models and configurations to suit their needs. Whether you're looking for a new or used engine, plenty of options are available. In addition to their performance and reliability, PW100 engines are known for their low noise and emissions levels, making them an environmentally friendly choice for operators who prioritize sustainability. So if you're in the market for a high-quality aircraft engine, consider PW100 engines for sale. Their proven track record and wide range of applications make them an excellent choice for operators looking to maximize efficiency and minimize costs.

0 notes

Text

Gear Oil Pump Manufacturer In Ahmedabad, India

In the rapidly evolving industrial sector, dependable and efficient machinery is crucial to maintaining uninterrupted operations. One of the most essential components in any lubrication or fluid handling system is the gear oil pump. It ensures the smooth transfer of lubricants and viscous fluids under high pressure and temperature. At the forefront of this domain is Nisuka Industries, a trusted Gear Oil Pump Manufacturer in Ahmedabad, India, known for delivering exceptional products and industry-grade reliability since 1994.

Ahmedabad – The Industrial Backbone of Gujarat

Ahmedabad has emerged as a key hub for engineering and industrial manufacturing in India. With its established ecosystem of skilled labor, infrastructure, and transport connectivity, the city provides an ideal foundation for companies like Nisuka Industries to thrive. The location advantage also ensures timely delivery and access to top-tier raw materials, helping maintain both quality and competitive pricing.

Nisuka Industries – Your Trusted Partner for Gear Oil Pumps

Nisuka Industries stands tall as one of the most reliable gear oil pump manufacturers in Ahmedabad, India, with decades of experience, advanced production facilities, and ISO-compliant processes. Every pump produced is the result of careful engineering, material selection, and rigorous quality checks.

The company uses premium-grade materials such as cast iron, SS-304, SS-316, and bronze, chosen specifically for their durability, corrosion resistance, and thermal tolerance. This ensures long operational life, minimal maintenance, and consistently smooth performance—qualities that industrial clients demand.

Features that Set Nisuka Gear Oil Pumps Apart

High-Efficiency Design: Optimized to deliver continuous fluid flow under varying operational conditions with minimal energy usage.

Thermal Compatibility: Designed to perform efficiently in high-temperature applications, especially in industries like plastics, chemicals, and food processing.

Sturdy Construction: Built with robust materials to resist wear, corrosion, and mechanical stress.

Custom-Built Options: Available in multiple configurations to suit various pressure, flow rate, and installation requirements.

Easy Maintenance: Designed for quick installation, simple servicing, and low downtime.

Applications of Gear Oil Pumps

Nisuka gear oil pumps are trusted across multiple industrial sectors for a variety of applications:

Thermal Oil Circulation: Ideal for heat-intensive systems like thermal fluid heaters and processing lines.

Industrial Lubrication: Powers lubrication systems in gearboxes, compressors, and heavy-duty machines.

Hydraulic Power Systems: Facilitates fluid transfer in hydraulic presses and control systems.

Energy & Utility Plants: Used in generators, turbines, and industrial power units.

Manufacturing Plants: Plays a vital role in conveyor belts, packaging machines, and other factory machinery.

Focused on Quality and Support

What makes Nisuka Industries stand out among other manufacturers is not just its superior product range, but its unwavering focus on after-sales support and customer satisfaction. Clients receive expert technical assistance, ready availability of spares, and long-term maintenance guidance. The company has earned trust by maintaining quality standards through a well-structured QC process, from procurement to dispatch.

More Than Just Gear Oil Pumps

In addition to gear oil pumps, Nisuka Industries is a well-established name in related industrial machinery components. The company is also a trusted:

Shaft Mounted Gearbox Manufacturer in India

Conveyor Gearbox Manufacturer in India

These gearboxes are widely used in material handling systems, conveyor belts, crushers, and industrial drives. Nisuka's SMSR gearboxes are known for their rugged construction, compact design, and ease of maintenance—making them ideal for heavy-duty operations.

By combining gear oil pumps with high-quality conveyor and shaft-mounted gearboxes, Nisuka provides an integrated solution to industries looking to streamline their operations with reliable power transmission and lubrication systems.

Why Choose Nisuka Industries?

Established Since 1994: Over 30 years of experience in pump and gearbox manufacturing.

Quality You Can Trust: ISO-compliant manufacturing and strict quality control at every stage.

Customization Expertise: Tailored solutions to meet specific industrial needs.

Strong Local Network: Serving major industries across Gujarat and other Indian states.

Affordable & Reliable: Competitive pricing without compromising on durability or performance.

Looking Ahead

As industrial processes become more automated and energy efficiency gains importance, the demand for high-performance gear oil pumps and gearboxes will continue to grow. Companies need reliable partners who can deliver consistent quality, timely service, and technical support. Nisuka Industries is well-positioned to lead the way as a preferred gear oil pump manufacturer in Ahmedabad, India, while also supporting clients with dependable gearbox solutions.

Conclusion

When it comes to finding a reliable and experienced Gear Oil Pump Manufacturer in Ahmedabad, India, Nisuka Industries is the name industries trust. With an unmatched blend of quality craftsmanship, engineering expertise, and a strong track record in gearbox manufacturing, Nisuka delivers complete mechanical solutions for various industrial applications. Whether you're in need of a durable gear oil pump, a rugged conveyor gearbox, or a precision-built shaft-mounted unit, Nisuka has you covered.

#Gear Oil Pump Manufacturer In Ahmedabad#Gear Oil Pump supplier In Ahmedabad#Gear Oil Pump exporter In Ahmedabad

0 notes

Text

Maximize Equipment Efficiency with Karroter’s Centrifugal Oil Cleaning Machine

In the demanding landscape of industrial operations, machine reliability and fluid cleanliness play a critical role in maintaining peak performance. Among the top solutions available today, Karroter’s centrifugal oil cleaning machine stands out for its innovative design, exceptional performance, and cost-effectiveness. Designed to meet the rigorous demands of modern industries, this advanced centrifugal oil filtration skid is reshaping the way companies handle oil purification and system maintenance.

Why Centrifugal Oil Cleaning Machines Are Crucial for Industry

Centrifugal oil cleaning machines are an essential component in many industries including manufacturing, power generation, marine, and heavy machinery sectors. These machines offer a non-consumable method to remove fine particles, sludge, and moisture from engine and hydraulic oils.

Traditional filtration methods rely on disposable filters that require regular replacement and maintenance. In contrast, a centrifugal oil filtration system leverages centrifugal force to separate contaminants from oil, resulting in:

Reduced operating costs

Improved equipment lifespan

Minimal machine downtime

Enhanced energy efficiency

Karroter’s Centrifugal Oil Filtration Skids: A Trusted Industry Solution

Karroter has built a strong reputation in the industry for delivering robust, reliable, and scalable centrifugal oil cleaning machines. Their systems are engineered with precision to deliver consistent performance in the harshest industrial environments.

Key Features of Karroter’s Centrifugal Oil Filtration Skids:

No filter element: Zero recurring cost on consumables

High separation efficiency: Removes sub-micron particles, water, and sludge

Compact and modular design: Easy to install and maintain

Versatile application: Suitable for diesel engines, compressors, gearboxes, and more

Environmentally friendly: Supports sustainable operations by minimizing waste

These features make Karroter’s centrifugal oil filtration system ideal for businesses aiming to reduce operational overheads while maximizing efficiency and reliability.

Industries Benefiting from Centrifugal Oil Filtration Systems

Industries across sectors are increasingly adopting centrifugal oil filtration solutions to maintain the integrity of their lubricants and hydraulic fluids. Applications include:

Power plants (turbine oil cleaning)

Marine and shipping (engine oil maintenance)

Manufacturing (hydraulic and gear oil filtration)

Construction and mining (heavy equipment oil cleaning)

Railways and transportation (diesel engine oil maintenance)

By integrating Karroter’s centrifugal oil cleaning skids into their maintenance routines, businesses can enjoy a noticeable improvement in productivity and a significant reduction in unexpected machine failures.

How Centrifugal Oil Cleaning Works

Karroter’s machines operate on the principle of centrifugal force. When contaminated oil enters the machine, it spins at high speed, forcing heavier contaminants to the periphery while clean oil remains at the center and is redirected back into the system. This physical separation method ensures high-efficiency filtration without degrading oil properties, making it a preferred solution for sensitive and high-load applications.

Customer-Centric Innovation by Karroter

Karroter continues to innovate in the centrifugal oil filtration space with an unwavering focus on user-friendly design, reliability, and tailored solutions. Their R&D team consistently works with industry experts and clients to refine and evolve their offerings, ensuring optimal alignment with market needs.

Why Choose Karroter’s Centrifugal Oil Cleaning Machines?

Proven track record in industrial oil purification

Customizable solutions for various equipment types

Excellent customer support and after-sales service

Competitive pricing without compromising quality

Karroter is committed to delivering excellence in centrifugal oil cleaning solutions, helping industries maintain uptime, reduce oil disposal costs, and contribute to sustainable operations.

Conclusion: A Smart Investment for Every Industry

For businesses looking to streamline operations and ensure uninterrupted performance, Karroter’s centrifugal oil filtration skids offer a powerful and efficient solution. With decades of industry experience, proven technology, and a customer-focused approach, Karroter is a name industries can rely on for top-tier centrifugal oil cleaning machines.

0 notes

Text

Here’s why SR-71 crews used the most dangerous material (except fissionable nuclear material) to start the Blackbird engines

Mach 3+ strategic reconnaissance aircraft

The SR-71, unofficially known as the “Blackbird,” was a long-range, Mach 3+, strategic reconnaissance aircraft developed from the Lockheed A-12 and YF-12A aircraft.

CLICK HERE to see The Aviation Geek Club contributor Linda Sheffield’s T-shirt designs! Linda has a personal relationship with the SR-71 because her father Butch Sheffield flew the Blackbird from test flight in 1965 until 1973. Butch’s Granddaughter’s Lisa Burroughs and Susan Miller are graphic designers. They designed most of the merchandise that is for sale on Threadless. A percentage of the profits go to Flight Test Museum at Edwards Air Force Base. This nonprofit charity is personal to the Sheffield family because they are raising money to house SR-71, #955. This was the first Blackbird that Butch Sheffield flew on Oct. 4, 1965.

The first flight of an SR-71 took place on Dec. 22, 1964, and the first SR-71 to enter service was delivered to the 4200th (later 9th) Strategic Reconnaissance Wing at Beale Air Force Base, Calif., in January 1966.

The Blackbird was in a different category from anything that had come before. “Everything had to be invented. Everything,” Skunk Works legendary aircraft designer Kelly Johnson recalled in an interesting article appeared on Lockheed Martin website.

No need for a traditional starter

To save on weight, the Skunk Works eliminated a traditional starter for the Blackbird. So, they figured out another way to start the SR-71.

Here’s why SR-71 crews used the most dangerous material (except fissionable nuclear material) to start the Blackbird engines

This print is available in multiple sizes from AircraftProfilePrints.com – CLICK HERE TO GET YOURS. SR-71A Blackbird 61-7972 “Skunkworks”

Former Blackbird pilot Richard H. Graham explains in his book SR-71 Revealed The Inside Story;

‘The high flashpoint brings up another problem. Most jet engines use igniter plugs, nothing more than a very hot spark plug, if you will. Using these igniter plugs they used with the JP-7 and just drowns it out, it won’t ignite. Kelly [Johnson] put his engineers to work, and he said, ‘OK, gentlemen, how are we going to start this?’ They came up with a very unique way. Triethylborane – TEB for short. Each engine has a one-and-a-quarter pint. If I had it in a squirt gun and I squirted it into the atmosphere, it would go Kaboom! – it explodes with contact with the atmosphere. And that’s how we started the engines. As the engines rotate, at the right time, it sprays this amount of TEB into the turbine section, which goes kaboom, which in turn lights the engine. When you take the throttles up into the afterburner, it puts this metered amount of TEB in that lights up the JP-7. You get 16 shots for each engine.’

The most dangerous material to start the SR-71 Blackbird engines

Mounted on each engine was a sealed tank, inerted with nitrogen gas and filled by maintenance with 600cc of TEB prior to each flight.

Former SR-71 Blackbird pilot David Peters explains: ‘An interesting note to this is the transport of it. If we landed away, servicing had to be hauled to our location. The NTSB lists TEB as the following most dangerous material, one step below fissionable nuclear material. The folks that handled this stuff were highly trained and good.’

Be sure to check out Linda Sheffield Miller (Col Richard (Butch) Sheffield’s daughter, Col. Sheffield was an SR-71 Reconnaissance Systems Officer) Twitter X Page Habubrats SR-71, Instagram Page SR71Habubrats and Facebook Page Born into the Wilde Blue Yonder Habubrats for awesome Blackbird’s photos and stories.

Photo credit: John Freedman and User:Jaydec via Wikipedia

Linda Sheffield Miller

Grew up at Beale Air Force Base, California. I am a Habubrat. Graduated from North Dakota State University. Former Public School Substitute Teacher, (all subjects all grades). Member of the DAR (Daughters of the Revolutionary War). I am interested in History, especially the history of SR-71. Married, Mother of three wonderful daughters and four extremely handsome grandsons. I live near Washington, DC.

@Habubrats71 via X

#sr 71 blackbird#aircraft#usaf#lockheed aviation#skunkworks#mach3+#habu#reconnaissance#cold war aircraft

15 notes

·

View notes

Text

Tommykaira M18Si version of the CA18DET S13 Nissan Silvia K's

SR20-equipped models coming soon

100% of the appeal of FR/mid-size sports cars

M18Si is based on the old Silvia with 175 horsepower and CA18DET. The engine has an original high cam, CP tuning, and a Garrett T25 modified turbine.

The conversion has squeezed out 205 horsepower. Of course, to accommodate the increased power, the suspension has been strengthened with reinforced springs and stabilizers, and the suspension is secured with large-capacity ventilated discs. An optional aero parts kit is also available for the exterior, enhancing the appeal of the car's running.

It was given a minor facelift in January this year, with the exterior modified and an SR20-series engine installed, so it is not currently on sale, but a new model based on the current Silvia is scheduled to be announced soon. We have high hopes for this machine that is an even more powerful version of the new Silvia!

For inquiries, please contact Tomita Auto at 075(461)6290

5 notes

·

View notes

Text

Comprehensive Biogas Treatment Solutions for Clean and Efficient Energy

Discover advanced biogas treatment solutions that enhance energy efficiency, reduce emissions, and ensure compliance with environmental regulations. Learn how your facility can benefit from clean energy innovation.

Introduction: What is Biogas and Why Treat It?

Biogas is a renewable energy source produced through the anaerobic digestion of organic matter such as agricultural waste, food scraps, and sewage. It primarily consists of methane (CH₄) and carbon dioxide (CO₂), along with trace amounts of hydrogen sulfide (H₂S), moisture, siloxanes, and other contaminants.

Untreated biogas can corrode equipment, emit harmful gases, and lower combustion efficiency. That's why biogas treatment solutions are essential—to purify the gas for energy generation, pipeline injection, or vehicle fuel.

Key Benefits of Biogas Treatment

✅ Improved Energy Efficiency: Cleaned biogas burns more efficiently in CHP units and boilers.

✅ Extended Equipment Lifespan: Removing corrosive compounds protects engines and turbines.

✅ Regulatory Compliance: Meet environmental and safety standards for emissions.

✅ Enhanced Revenue Streams: Treated biogas can be upgraded to biomethane for sale or grid injection.

✅ Odor Reduction: Eliminates foul-smelling compounds, improving air quality around plants.

Core Biogas Treatment Solutions

1. Desulfurization (H₂S Removal)

Hydrogen sulfide is highly corrosive and toxic. Treatment methods include:

Biological Scrubbers

Iron Sponge Filters

Activated Carbon Adsorption

Chemical Scrubbing (NaOH)

2. Moisture Removal (Dehumidification)

Moisture in biogas can condense and cause damage.

Cooling and Condensation

Chillers

Adsorption Dryers (Silica Gel, Molecular Sieves)

3. Siloxane Removal

Siloxanes form abrasive silica deposits during combustion.

Activated Carbon Filters

Refrigeration and Condensation

4. CO₂ Separation and Biogas Upgrading

To convert biogas into biomethane, CO₂ must be removed:

Pressure Swing Adsorption (PSA)

Water or Chemical Scrubbing

Membrane Separation

Cryogenic Separation

Tailored Solutions for Every Sector

Biogas treatment needs vary across industries:

🏭 Industrial Wastewater Plants

🌾 Agricultural Digesters

🏢 Municipal Waste Facilities

🛢 Landfills

🏘️ Community Bioenergy Projects

Customized systems can integrate modular designs, real-time monitoring, and automated control for optimal performance.

Choosing the Right Technology Partner

Look for providers with:

Proven installations in your industry

Scalable and modular systems

Ongoing technical support and maintenance

Integration with energy recovery systems (e.g., CHP)

Conclusion: Invest in Sustainable Energy Today

With growing demand for clean energy and stricter emission regulations, investing in advanced biogas treatment solutions is more than an environmental decision—it’s a smart business move. From protecting your equipment to unlocking new revenue streams, biogas purification is the key to a greener, more profitable future.

Call to Action: Looking to upgrade your biogas system or explore custom treatment solutions? [Contact Us] today to speak with an expert and get a free consultation.

0 notes