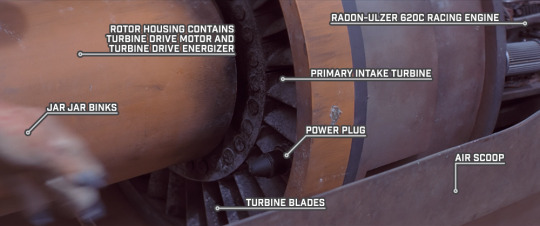

#turbine drive motor

Text

Oh, Dare It Is

STAR WARS EPISODE I: The Phantom Menace 00:48:47

#Star Wars#Episode I#The Phantom Menace#Tatooine#Xelric Draw#Mos Espa#Slave Quarters Row#rotor housing#turbine drive motor#turbine drive energizer#Radon-Ulzer#620C racing engine#primary intake turbine#power plug#air scoop#turbine blade#Jar Jar Binks

0 notes

Text

Mercedes-AMG ONE „F1 Technology for the Road“.

Affalterbach. Mercedes-AMG ONE (combined weighted fuel consumption: 8.7 l/100 km; combined weighted CO2 emissions: 198 g/km; combined weighted electrical consumption: 32 kWh/100 km)[1].

Exceptional E PERFORMANCE hybrid drive with 1.6-litre V6 engine and four electric motors.

The E PERFORMANCE hybrid drive of the Mercedes-AMG ONE comes directly from Formula 1 and has been realised in close cooperation with the experts at Mercedes-AMG High Performance Powertrains in Brixworth.

It consists of a highly integrated and intelligently networked unit comprising one hybrid, turbocharged combustion engine with a total of four electric motors. One has been integrated into the turbocharger, another has been installed directly on the combustion engine with a link to the crankcase and the two remaining motors drive the front wheels.

The high-revving power unit is boosted by a high-tech turbocharger. The exhaust gas turbine and compressor turbine are positioned at a distance from each other and connected by a shaft. This allows a lower installation position for the turbocharger.

On the shaft is an approx. 90 kW electric motor. Electronically controlled, this drives the turbocharger shaft directly, accelerating the compressor wheel up to 100,000 rpm before the exhaust gas flow takes over. The Formula 1 designation for this unit is MGU-H (Motor Generator Unit Heat).

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach.

Driving Performance is our Passion! Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz and Exclusive Partner for Pagani Automobili. Mercedes-AMG Handcrafted by Racers.

#amg#amgone#amgprojectone#one#projectone#mercedesamg#mercedes#mercedesbenz#mercedesamgf1#affalterbach#onemanoneengine#f1technology#f1engine#f1#techology#pagani

16 notes

·

View notes

Text

When Kelly Johnson was designing the A-12/YF-12 /MD-12 SR-71 he didn’t want the weight to be added for a starter on the airplane. He said the more it weighs the more fuel it will need. It was decided that two V-8 engines would be able to do the job. To start the Blackbird the fastest airplane in the world wasn’t exciting enough on top of that it sounded like the Indianapolis 500 getting the SR-71 ready to fly!

For this purpose alone, two of either above-mentioned Nailhead V8s were fused via a common transmission and drive shaft to work in tandem, then placed inside a metal housing mounted on four wheels with a trailer hitch and dubbed the AG330 "start cart." The resulting Chimera was attached directly to the Blackbird's two engines. Using the combined drive shaft, the two V8s spun the turbines to the point they could sustain compression by themselves. Nailhead V8s served as impromptu starter motors for the SR-71 and its cousins, the A-12 Archangel and the YF-12 fighter, until at least 1970, when the bulk of them were replaced with Chevy 454 V8s.

These were also phased out when a new, quieter pneumatic system was implemented to do the same job as the start cart at most airbases on U.S. soil the Blackbird and company operated from. Some remained for longer at auxiliary bases abroad, including a handful with the original Buick Nailheads, until the Blackbird and all its variants were retired in 1998. autoevolution.com/news/buick-wil…

Click here to listen to more information m.youtube.com/watch?embeds_r…

@Habubrats71 via X

22 notes

·

View notes

Text

The Jaguar C-X75 concept car. This never actually went to production but at least 3 of the *actual* hybrid supercar concepts were put together. These used a small diesel engine to drive two turbines, which in turn powered the electric motors. Any actual figures are mostly speculation.

Another 6 or 7 were made as bare-bones models with V8 engines for production of the James Bond 007 movie "Spectre" of which at least a couple remain in museums.

13 notes

·

View notes

Text

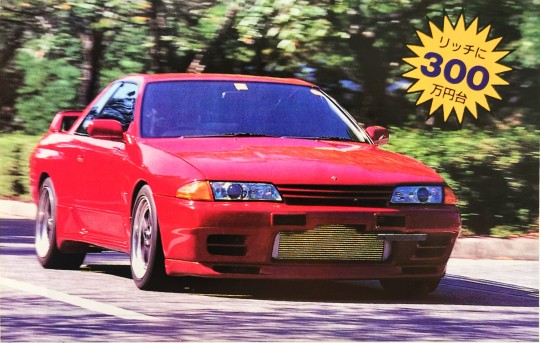

BNR32

The 550 horsepower specification emphasizes durability and is ideal for fully tuned basses!

Blast Tuning continues to build fast cars in the Tokai region, a fiercely competitive area. The tuned car that our sister shop, Used Car Blast, recommends is this 1993 GT-R.

This blast-tuned car is equipped with a Nismo turbine, strengthened actuator, high cam, and more, and its displacement has been increased to 2.7L. The power output is 550 horsepower with a boost of 12 kg/m2. Even now, it has been designed to be extremely fast. Moreover, the engine itself is packed with the know-how that Blast has cultivated over the years, so there is still plenty of room for durability.

Tuning with normal engine

When doing so, the bottleneck is always the lack of durability of the oil pump and valve guide. Trouble always occurs when the engine is rotated over 8,000 rpm and blows out, but this engine has been completely replaced with a stronger one. Big turbos such as T88 can handle over 600 horsepower.

It is perfect for hard tuned base cars.

When I actually test drove it, I felt that the displacement was increased.

It takes full advantage of the benefits of the motor, and rotates smoothly from low to high speeds. Although it is equipped with a high cam and large-capacity injector, the idling is stable, and with this good finish, you can even use it for commuting once you get used to the OS twin plate.

It's very natural.

The price is now 3.48 million yen. base car

There is nothing better for both.

PIC CAPTIONS

●The main injector has been replaced with a 720cc large-capacity type, and the ground level has been adjusted using a blast original computer. The engine room looks normal.

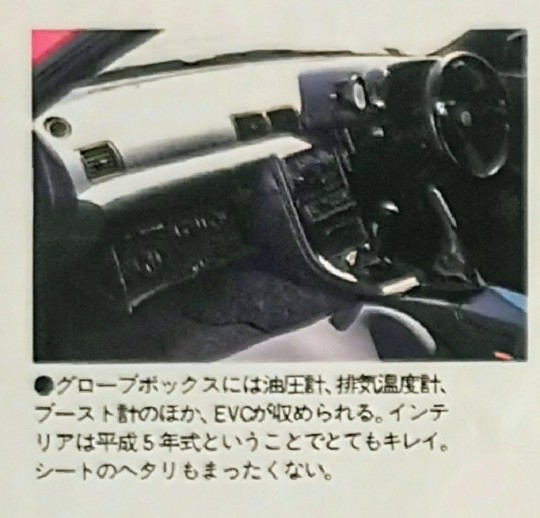

●The glove box houses the oil pressure gauge, exhaust temperature gauge, boost gauge, and EVC. The interior is very clean as it is a 1993 model. There is no sagging of the seat at all.

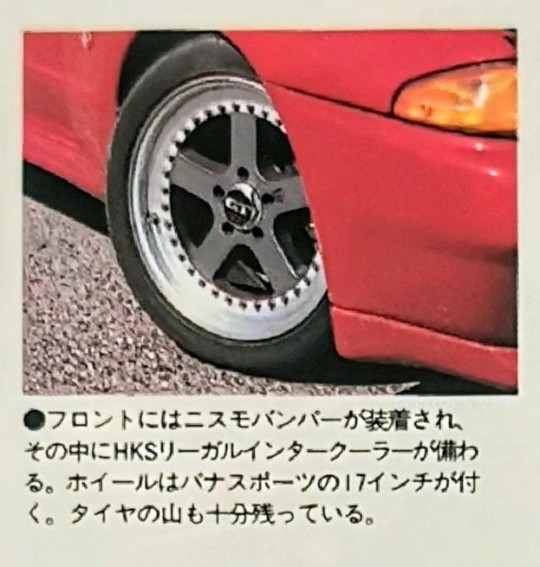

●A Nismo bumper is installed at the front, and an HKS legal intercooler is installed inside it. It comes with 17-inch PanaSports wheels. There's still plenty of tires left.

INFO BOX

Skyline GT-R

1993 model inspected March 2010

3.48 million yen

Tune data: Displacement 2.7ℓ

Reinforced connecting rod

Reinforced oil pump

Reinforced valve guide

Nismo turbine

Reinforced actuator

Blast computer

720cc injectors

68 degree/68 degree cam

HKS Legal I/C

EVC

OS Twin plate Clutch

Bilstein C ring coilover reinforced suspension

SHOP INFO

used car blast

380-1 Kawado, Matsukawado-cho, Kasugai-shi, Aichi 486

0568-84-7740

Test drive of tuned car is OK. Of course, we also purchase items, and we also offer loans at 5.9%, which is cheaper than other stores. Please come to our store once!

22 notes

·

View notes

Photo

(via XM1 Abrams Main Battle Tank by DarkWizard83 on DeviantArt)

The original prototype vehicle that led to one of - if not the - most powerful tank in the world, and current backbone of Us armored forces, the M1 Abrams MBT. Born out of the failed German-American MBT-70 project, the XM1 was developed by the Chrysler Motor Corporation, and in 1978 Chrysler delivered to the Army a sleek, low-silhouette heavy tank that incorporated every major technological feature of the day, including computerized controls and a laser rangefinder.

But the most significant design feature of the new tank was its use of Chobham composite armor on the hull and turret. While the exact nature and composition of Chobham armor remains a closely guarded secret, the evidence suggests that it utilizes a matrix of ceramic armor tiles, layered between the vehicle's internal steel and external armored plating. When a high-velocity projectile - such as a round fired from a tank or an anti-tank missile - hits the armor, the explosion produces a high-velocity jet of gas that shears through the armor plating. In normal armor, this jet of gas - once it had passed through the outer armor - would blast into the hull of the tank, causing irreprible damage and often killing the crewmen inside. However, with Chobham armor's interweaved layers of ceramic composite, the forces that would normally tear into a tank's hull are forced to spread out and dissipate over a much wider area, leaving the inner hull intact. This not to say that Chobham armor renders a tank invincible - any hit will still cause exterior damage, and a powerfiul direct hit could still damage or disable the tracks or sensitive electronic equipment. But it would keep the crew alive, and often protect the tank itself enough to keep fighting.

Another key crew safety feature is the vault-like armored compartment that houses the Abrams' primary ammunition. One of the primary causes of a tank's destruction has not been the direct result of armor-pierecing hits, but the inderict results of those hits ignigting and detonating the tank's munitions. To protect this, a kevlar and steel armored plate seperates the crew from the ammunition store. Same with the tank's fuel supply. Even if the compartments were pierced, and the ammunition or fuel ignited, the protective plates would insulate the crew from explosion and fire.

In combat, the Abrams has proven to be second to none. During Operation Desert Storm in 1991, M1s were able to take out Iraqi tanks at distances as long as 4km. Of the nearly 2,000 Abrams to see combat in the conflict, only 18 were ever taken out of service due to combat damage, and none resulted in any crew casulties. In 2003 and onwards during Operation Iraqi Freedom, the Abrams again demonstrated a mastery of the battlefield, driving to Baghdad virtually unopposed. However, the Abrams clearly showed its vulnerability to ambush attacks, with a number of M1s severly damaged and disabled from RPGs, and far more frequently by roadside IED bomb traps. However, even when caught in some of the largest IED explosions, crew casualties have so far been astoundingly low, a testament to the M1s protection and survivability.

While no future M1's are planned for production, a number of older models are currently slated for upgrade to current standards over the next few years, and the Abrams will continue to serve with the Us Army and Marine Corps. for mcuh of the century to come.

M1 Abrams Vehicle Stats:

Type: Main battle tank

Manufacturer: General Dynamics Land Systems

First deployed: 1980

Crew: 4

Length: 9.76 m

Width: 3.65 m

Height: 2.88 m

Weight: 61.4 tons

Armor: Classified

Armament, primary: 1 x 105mm M68 rifled tank gun; later models equipped with 120mm M256 smoothbore tank gun

Armament, secondary: 2 x 7.62mm FN-Browning M240 machineguns, 1 x .50-cal Browning M2 BMG machinegun

Ammo stowage, primary: 55 rounds

Ammo stowage, secondary: 11,000 rounds 7.62mm, 1,000 rounds .50-cal

Powerplant: Textron Lycoming AGT1500 1,500hp gas-turbine engine

Max speed: 72 km/h

Max range: 498km

Operators: Australia, Egypt, Kuwait, Saudi Arabia, USA

14 notes

·

View notes

Photo

Hyundai N Vision 74 (prototype).

Hydrogen fuel cell EVs aren't particularly sexy, or at least, they weren't. Say hello to the Hyundai N Vision 74 concept, a high-performance hydrogen fuel cell-powered EV meant to bridge EV power and performance with liquid fuel range. Hyundai's N high-performance sub-brand has been working on battery and fuel cell-powered performance prototypes for seven years now, and the project is beginning to bear some exciting fruit. The N Vision 74 aims to solve the biggest issue with high-performance EVs: the lack of range. The N people call it a "hydrogen hybrid."

Running flat-out, batteries don't last long. A previous all-electric prototype, the RM20e, only had 25 miles of range when driven on a racetrack, and while making the battery bigger would give it more range, it would also significantly increase the weight and hurts performance. Hyundai's solution: add a hydrogen fuel cell instead which combines compressed hydrogen from onboard tanks with oxygen in the atmosphere to create electricity and water, then use that electricity to power the electric motors.

With just 4.2 kilograms of hydrogen onboard and a fully charged 62.4-kWh battery, Hyundai claims the N Vision 74 has a range of more than 373 miles when driven gently. It's bound to be much less when driven hard, as the dual rear electric motors suck down electrons to the tune of more than 580 hp and 664 lb-ft of torque. That's enough to give the sleek, angular coupe a top speed of over 155 mph and the ability to hit 60 mph in four seconds. The company is looking into adding a front motor in future prototypes which would reduce acceleration times even further.

In addition to adding range, the fuel cell also reduces refueling time to just five minutes. The battery, meanwhile, is capable of charging at 800 volts, which should drop its charging time from 10 percent to 80 percent to under 18 minutes, based on production Hyundai EVs with similar battery technology. The fuel cell can pump out a maximum of 95 kW to help power the motors or recharge the battery.

The fuel cell itself is located under the hood, while a pair of hydrogen storage tanks are fitted in the trunk. A T-shaped battery fits behind and between the two seats, keeping the heaviest component in the center of the car for better weight distribution.

Regardless of source, power is fed to a pair of motors on the rear axle, one driving each rear wheel. This allows the computer to perform torque vectoring in the same fashion as an electronically controlled limited slip differential, a trick the N engineers used to great success on the RM20e concept.

Keeping the fuel cell, battery, and motors cool presents an enormous challenge, so the N Vision 74 features three separate cooling circuits serving each system separately. The goal is to have the car run a flat-out lap of the challenging Nürburgring Nordschleife without overheating and reducing power.

As cool as the numbers are, they're nothing compared to the car itself. Inspired by the Giorgetto Giugiaro-designed 1974 Hyundai Pony Coupe concept, the N Vision 74 looks like a restomod '70s supercar. We see a lot of Lancia 037 and DeLorean DMC-12 in the look, enhanced with massive side air intakes and an enormous rear wing, neither of which would look out of place on a modern Lamborghini. We love the turbine-style 20-inch front and 21-inch rear wheels, which have been wrapped in what must be the widest tires ever on a Hyundai, 295 width up front and 325 in the rear. The pixelated headlights from the Hyundai Ioniq 5 give it a real retro-futuristic look we can't help but love.

The DeLorean bit is no accident. When Hyundai wasn't able to bring the Pony Coupe to market for a variety of reasons (lack of a proper engine, not to mention lacking general market awareness and acceptance), Giugiaro continued to refine the design and eventually sold the new version to DeLorean.

31 notes

·

View notes

Photo

The 1972 Cadillac-Jacuzzi Barcelona was a 6 wheel drive, amphibious limousine; developed for the Arabian market, as an appealing, top end of top ends model, powered by a proposed turbine engine (though it would've been much more likely to be powered by the 8.2 liter V8 at the top of the Cadillac range at the time), it's styling was quite unconventional, and it was actually powered by a Jacuzzi-jet (powered by the turbine) at the rear. It had room for 9, with the driver taking a central driving position. The prototype was shown at the Geneva International Motor Show to great fanfare, though was criticized for being "uneconomical", and it would be proven correct as in 1973, the Saudi Oil Crisis would prove that, despite 200 orders, mostly from the region, that such a lavish, expensive car, would not prove viable even in limited production. The sole prototype would be privately sold in 1980, and would wind up surviving the cutting torch by the skin of it's teeth, as right before it was set to be cut up for scrap, it was purchased by the Henry Ford Museum in Dearborn Michigan, and is proudly on display there, having been restored to full functioning order, though under the aforementioned 8.2L v8, rather than the original turbofans, that are on display next to it, in semi-restored, and cutaway conditions.

3 notes

·

View notes

Text

The Role of Variable Speed Drives in Modern Industrial Applications

Variable Speed Drives (VSDs), also known as Inverters or Frequency Converters, have become indispensable components in modern industrial applications. They offer numerous benefits, including energy efficiency, improved process control, and enhanced equipment reliability. In this blog post, we will explore the key roles of VSDs in various industrial sectors and discuss the factors to consider when selecting the right VSD for your specific application.

The Importance of Inverter Repair

VSDs are complex electronic devices that can experience malfunctions or failures over time. Therefore, it is crucial to have a reliable inverter repair service in place. When an inverter breaks down, it can disrupt production processes and lead to significant financial losses. Inverter repair professionals can diagnose and fix issues efficiently, ensuring minimal downtime and maintaining optimal system performance.

Industrial Applications of VSDs

VSDs are widely used across a variety of industrial sectors, including:

Manufacturing: VSDs are used to control the speed of motors driving production machinery, such as conveyors, pumps, fans, and compressors. This enables precise control over processes, reduces energy consumption, and improves product quality.

Building Automation: VSDs are employed in HVAC systems to regulate fan speeds and pump flows, optimizing energy efficiency and maintaining comfortable indoor environments.

Water and Wastewater Treatment: VSDs are used to control pumps and blowers in water and wastewater treatment plants, ensuring efficient operation and reducing energy costs.

Oil and Gas: VSDs are used in various applications, including controlling pumps, compressors, and fans in oil and gas production facilities.

Renewable Energy: VSDs are essential components in wind turbines, solar inverters, and other renewable energy systems, enabling efficient power generation and grid integration.

By understanding the key roles of VSDs in modern industrial applications and carefully selecting the right VSD for your needs, you can optimize your operations, improve energy efficiency, and enhance overall system performance.

Source

0 notes

Text

Lubricants Market Outlook: Demand Forecast and Competitive Landscape

The global lubricants market size is expected to reach USD 180.21 billion by 2030, registering a CAGR of 3.8% over the forecast period, according to a new report by Grand View Research, Inc. Growth in demand for biobased lubes owing to their eco-friendly characteristics is poised to pave way for higher demand over the coming years. Furthermore, the manufacturers are shifting and expanding their production units in developing nations owing to various factors, such as availability of raw materials and reduced infrastructure & labor costs. This, in turn, is anticipated to boost the market growth over the forecast period. Typical oil manufacturers use crude oil, CBM, tight oil, and other additives to formulate all types of lubricants.

Medical was the largest application for PEG, accounting for more than 40% of market share in 2022. Superior blending, hygroscopicity, and non-toxic properties of PEG have resulted in high demand for the chemical in numerous pharmaceutical products such as tablets and ointments. Increasing pharmaceutical expenditure, particularly in emerging economies of India, China, and Brazil, is expected to boost PEG market over the forecast period. Growing demand for paints & coatings coupled with the increasing use of PEG as a solvent due to its low VOC emissions is anticipated to fuel market growth over the next six years.

Economic growth in emerging markets, such as China, India, and Brazil, has led to the betterment of public transportation in these regions. This trend is expected to further strengthen commercial automotive lubricant demand. The Asia Pacific automotive industry is anticipated to witness a high growth rate over the forecast period owing to rapid economic development, mega construction projects, and the introduction of various favorable policies by the government, such as 100% FDI and “Smart Cities”. Rapid industrial development and growing demand for high-performance luxurious passenger cars have also attracted heavy investments from international automotive players.

Companies, such as ExxonMobil and Chevron, are directly involved in the production of lubricants for specific applications, these companies are further involved in supply agreements with major end-users to ensure steady sales of lubricants. Companies, such as Total, Shell, Amsoil, and Castrol, have entered into exclusive supply agreements with Tata Motors & Vestas Wind Systems to supply their lubricant brands. Global as well as regional industry players are developing direct sales channels, especially for automotive lubricant users, at their local service centers. Some companies also participate in annual events of their end-users and showcase their products at offer prices.

For More Details or Sample Copy please visit link @: Lubricants Market Report

Lubricants Market Report Highlights

The market is estimated significantly due to the increasing demand for automotive oils and greases on account of the growing trade of vehicles and their spare parts

Lubricants are majorly used as diesel engine oils, gearbox lubricants, and transmission oils in passenger cars, commercial vehicles, and motorcycle segments of the automotive sector. As per OICA, global motor vehicle production reached 85, 016,728 in 2022, which is anticipated to drive the product demand

Gas turbine oil is a high-performance oil created to help gas turbines run more efficiently and reliably while also enhancing the safety and productivity of power plant operations

Asia Pacific dominated the market with a revenue share of 44.6% in 2023. A rising number of consumers is demanding advanced technological products with superior performance characteristics. This factor is conducive to market growth.

Gain deeper insights on the market and receive your free copy with TOC now @: Lubricants Market Report

We have segmented the global lubricants market on the basis of application, base oil, and region.

#Lubricants#LubricantsMarket#MarketAnalysis#SyntheticLubricants#BioBasedLubricants#IndustrialLubricants#AutomotiveLubricants#SustainabilityInLubricants#MarketTrends#LubricationTechnology#GlobalMarketInsights#PerformanceLubricants#OilAndGas#IndustrialApplications#LubricantsIndustry

0 notes

Text

How Embedded Software Design Improves Efficiency in Industrial Controls

In the fast-paced world of industrial controls, efficiency isn’t just a goal—it’s a necessity. As industries strive to streamline operations and enhance productivity, embedded software design emerges as a pivotal element driving these improvements. But what exactly makes embedded software so crucial for industrial controls, and how can it reshape operational efficiency? Let's delve into how this technology is revolutionizing the sector.

The Backbone of Industrial Controls: Embedded Software

Embedded software forms the core of many modern industrial control systems. Unlike general-purpose software, embedded software is tailored for specific functions within dedicated hardware systems. This specialization allows it to manage and control hardware more efficiently than traditional software applications.

For instance, in an automated manufacturing plant, embedded software controls everything from conveyor belts to robotic arms. Its primary role is to ensure that these components work seamlessly together, performing tasks with precision and reliability. The result? Reduced downtime, fewer errors, and enhanced productivity.

Real-Time Performance: A Game Changer

One of the most significant advantages of embedded software in industrial controls is its real-time performance. Industrial systems often require immediate responses to changing conditions—whether it's adjusting the speed of a motor or recalibrating sensors. Embedded software, designed for real-time operation, can make these adjustments instantly, ensuring that processes remain smooth and efficient.

Consider a power plant where embedded software manages the operation of turbines and generators. The software continuously monitors performance metrics and makes rapid adjustments to maintain optimal efficiency. This real-time capability not only prevents potential issues but also maximizes the plant's output and reduces energy consumption.

Enhancing Reliability and Safety

Reliability and safety are paramount in industrial environments. Embedded software contributes significantly to both by offering robust and fail-safe solutions. Unlike general software that may be prone to crashes or slowdowns, embedded systems are optimized to perform specific tasks with high reliability. They are less likely to experience software conflicts or performance degradation.

Additionally, embedded software often includes built-in safety features that help prevent accidents and equipment failures. For example, it can monitor critical parameters and trigger alarms or shut down equipment if it detects unsafe conditions. This proactive approach minimizes risks and ensures a safer working environment.

Streamlining Maintenance and Upgrades

Maintenance and upgrades are essential for keeping industrial systems running efficiently. Embedded software simplifies these processes through its modular design. Instead of overhauling entire systems, operators can update or replace specific components without disrupting the entire operation.

Modern embedded systems also support remote diagnostics and troubleshooting. This means that technicians can identify and resolve issues from a distance, reducing the need for on-site visits and accelerating the resolution of problems. By streamlining maintenance and upgrades, embedded software helps maintain high levels of operational efficiency and reduces costs.

Optimizing Resource Management

Efficient resource management is critical for industrial success. Embedded software excels in this area by providing precise control over various processes. It helps manage resources such as energy, raw materials, and labor more effectively.

For instance, in a factory setting, embedded software can analyze data from production lines to optimize material usage and reduce waste. By fine-tuning processes based on real-time data, it ensures that resources are used efficiently, which leads to cost savings and reduced environmental impact.

Supporting Advanced Features and Integration

As industrial controls become more sophisticated, embedded software supports advanced features and seamless integration with other systems. For example, it can enable the integration of IoT devices, allowing for advanced data analytics and predictive maintenance.

Embedded software also supports automation and advanced control strategies that enhance overall system performance. This capability is essential for industries looking to adopt cutting-edge technologies and maintain a competitive edge in a rapidly evolving market.

Future Trends in Embedded Software for Industrial Controls

Looking ahead, embedded software will continue to play a crucial role in the evolution of industrial controls. Emerging technologies such as AI and machine learning are expected to be integrated into embedded systems, further enhancing their capabilities. These advancements will bring about even greater efficiencies, enabling industries to operate at unprecedented levels of productivity and innovation.

Conclusion

Embedded software design is a cornerstone of modern industrial control systems, driving significant improvements in efficiency, reliability, and resource management. By offering real-time performance, enhancing safety, streamlining maintenance, and supporting advanced features, embedded software transforms how industries operate. As technology continues to advance, the role of embedded software will only become more integral, leading to even greater advancements in industrial control systems.

Embracing embedded software is not just about keeping up with technological trends; it’s about harnessing its full potential to drive efficiency and achieve operational excellence. As industries look towards the future, embedded software will undoubtedly be at the forefront of this transformative journey.

To Know More About ,

0 notes

Text

Mercedes-AMG ONE „F1 Technology for the Road“.

Affalterbach. Mercedes-AMG ONE (combined weighted fuel consumption: 8.7 l/100 km; combined weighted CO2 emissions: 198 g/km; combined weighted electrical consumption: 32 kWh/100 km)[1].

Exceptional E PERFORMANCE hybrid drive with 1.6-litre V6 engine and four electric motors.

The E PERFORMANCE hybrid drive of the Mercedes-AMG ONE comes directly from Formula 1 and has been realised in close cooperation with the experts at Mercedes-AMG High Performance Powertrains in Brixworth.

It consists of a highly integrated and intelligently networked unit comprising one hybrid, turbocharged combustion engine with a total of four electric motors. One has been integrated into the turbocharger, another has been installed directly on the combustion engine with a link to the crankcase and the two remaining motors drive the front wheels.

The high-revving power unit is boosted by a high-tech turbocharger. The exhaust gas turbine and compressor turbine are positioned at a distance from each other and connected by a shaft. This allows a lower installation position for the turbocharger.

On the shaft is an approx. 90 kW electric motor. Electronically controlled, this drives the turbocharger shaft directly, accelerating the compressor wheel up to 100,000 rpm before the exhaust gas flow takes over. The Formula 1 designation for this unit is MGU-H (Motor Generator Unit Heat).

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion! Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz and Exclusive Partner for Pagani Automobili. Mercedes-AMG Handcrafted by Racers.

#amgone#amgprojectone#f1technology#f1#amg#mercedesamg#mercedes#mercedesbenz#mercedesamgpetronas#mercedesamgf1#affalterbach#onemanoneengine

9 notes

·

View notes

Text

Did you know two Buick Nailhead V8 engines were used to start the SR-71 Mach 3+ plane because the Blackbird didn’t have a starter?

The Blackbird

The SR-71, unofficially known as the “Blackbird,” was a long-range, Mach 3+, strategic reconnaissance aircraft developed from the Lockheed A-12 and YF-12A aircraft.

The first flight of an SR-71 took place on Dec. 22, 1964, and the first SR-71 to enter service was delivered to the 4200th (later 9th) Strategic Reconnaissance Wing at Beale Air Force Base, Calif., in January 1966.

The Blackbird was in a different category from anything that had come before. “Everything had to be invented. Everything,” Skunk Works legendary aircraft designer Kelly Johnson recalled in an interesting article appeared on Lockheed Martin website.

Cool Video Explains how SR-71 Blackbird’s J58 Turbo-Ramjet Engine Works

The speed of the SR-71 exceeded 2,000 mph. Other planes of the era could, in theory, approximate that speed but only in short, after-burner-driven bursts. The Blackbird maintained a record-setting speed for hours at a time. At such velocity, friction with the atmosphere generates temperatures that would melt the conventional airframe.

Two Buick Nailhead V8 engines to start the SR-71 Mach 3+ plane

When Kelly Johnson was designing the A-12/YF-12 /M-21 and SR-71 he didn’t want the weight to be added for a starter on the airplane. He said the more it weights the more fuel it will need. It was decided that two Buick Nailhead V8 engines would be able to do the job.

Did you know two Buick Nailhead V8 engines were used to start the SR-71 Mach 3+ plane because the Blackbird didn’t have a starter?

SR-71 Blackbird AG330 start cart

Not only starting the Blackbird, the fastest airplane in the world, was exciting, but also sounded like the Indianapolis 500 was getting the SR-71 ready to fly thanks to the two V8 engines as you can hear in the following video.

youtube

According to Autoevolution, for this purpose alone, two of either above-mentioned Nailhead V8s were fused together via a common transmission and drive shaft to work in tandem, then placed inside a metal housing mounted on four wheels with a trailer hitch and dubbed the AG330 “start cart.” The resulting Chimera was attached directly to the Blackbird’s two engines. Using the combined drive shaft, the two V8s spun the turbines to the point they could sustain compression by themselves. Nailhead V8s served as impromptu starter motors for the SR-71 and its cousins, the A-12 Archangel and the YF-12 fighter, until at least 1970, when the bulk of them were replaced with Chevy 454 V8s.

Did you know two Buick Nailhead V8 engines were used to start the SR-71 Mach 3+ plane because the Blackbird didn’t have a starter?

Phased out

These were also phased out when a new, quieter pneumatic system was implemented to do the same job as the start cart at most airbases on US soil the Blackbird and company operated from. Some remained for longer at auxiliary bases abroad, including a handful with the original Buick Nailheads, until the Blackbird and all its variants was retired in 1999.

@Habubrats71 via X

19 notes

·

View notes

Text

Epoxy Resin Market Dynamics, Top Manufacturers Analysis, Trend And Demand, Forecast To 2030

Epoxy Resin Industry Overview

The global epoxy resin market size was estimated at USD 11.25 billion in 2023 and is expected to grow at a CAGR of 6.3% from 2024 to 2030.

Increasing demand for paints and coatings is anticipated to drive market growth significantly during the forecast period. Increasing demand for epoxy resins is attributed to growing spending on construction, particularly residential construction, especially in North America and Western Europe. The rapid growth in global manufacturing activities is expected to fuel the demand for paints & coatings used in the production of motor vehicles and other durable goods, as well as industrial maintenance applications. This is expected to boost the demand for epoxy resins globally.

Gather more insights about the market drivers, restrains and growth of the Epoxy Resin Market

Asia Pacific has been the leading consumer of epoxy resins, fueled by increasing demand from China and India. Infrastructure development, along with increasing automotive production, has fueled paints & coatings demand in the region. Increasing disposable income and willingness to spend are expected to drive the market over the coming years.

In the recent past, global automotive production increased rapidly due to growing demand from middle-class families and rising disposable income across emerging nations such as China, India, Brazil, Vietnam, and others. The rise in automotive demand propelled the consumption of paints & coatings across the automotive industry, thereby fueling the demand for epoxy resins. However, volatile raw material price of epoxy resin is expected to restrain the market growth during the forecast period.

In addition, the outbreak of COVID-19 negatively impacted the demand for epoxy resin in various applications, including paints & coatings, adhesives, wind turbines, and others, owing to the stalled manufacturing activities, restrictions in supply and transportation, and economic slowdown across the globe in 2020. Moreover, the recommencing industrial operation is projected to positively influence the market demand in the coming years.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global medical polyoxymethylene market size was estimated at USD 117.69 million in 2023 and is projected to grow at a CAGR of 6.4% from 2024 to 2030.

• The global multi-med adherence packaging market size was valued at USD 327.73 million in 2023 and is expected to expand at a CAGR of 6.0% from 2024 to 2030.

Market Concentration & Characteristics

The market space is moderately consolidated with the presence of key companies, such as 3M, Aditya Birla Management Corp. Pvt. Ltd, BASF SE, and Sika AG. These companies adopt various strategic initiatives, such as new product launches, partnerships, capacity expansions, and collaborations, to expand their presence in the market. For instance, in March 2024, Safic-Alcan announced its expansion by collaborating with BB Resins Srl. BB Resins Srl is a manufacturer of epoxy resin hardeners, which boasts an extensive range of products specifically designed for the coatings, construction, and adhesives sectors. With this collaboration, Safic-Alcan aims to expand its business across Poland.

The industry is characterized by a high degree of innovation. Technological advancement, upgradation of electronic products, and circuit assembly have propelled PCB fabrication technology toward micro via, fine-trace, high-density tracing, and multi-layers. The usage of epoxy resins enhances thermal dissipation, dimensional stability, and dielectric loss, therefore, propelling the demand for epoxy resins in the manufacture of CCL. In recent years, the electronic industry has grown rapidly, thereby increasing the demand for PCBs across the globe.

In addition, stringent regulations shape the market’s demand and supply dynamics. Stricter regulations on volatile organic compounds (VOCs) and hazardous substances can limit the use of certain raw materials and formulations. This can lead to a shift in market preferences towards eco-friendly and compliant products. For instance, the European Union’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires comprehensive data on the safety of chemical substances, pushing manufacturers to innovate and produce safer epoxy resin formulations

Key Companies & Market Share Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

The following are the leading companies in the epoxy resin market. These companies collectively hold the largest market share and dictate industry trends:

3M

Aditya Birla Management Corporation Pvt. Ltd.

Atul Ltd

BASF SE

Solvay

Huntsman International LLC

KUKDO CHEMICAL CO., LTD.

Olin Corporation

Sika AG

NAN YA PLASTICS CORPORATION

Jiangsu Sanmu Group Co., Ltd.

Jubail Chemical Industries LLC

China Petrochemical & Chemical Corporation (SINOPEC)

Hexion

Kolon Industries, Inc.

Techstorm

NAGASE & CO., LTD

Order a free sample PDF of the Epoxy Resin Market Intelligence Study, published by Grand View Research.

0 notes

Text

Aimant de samarium fer-nitrogène, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 3 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Aimant de samarium fer-nitrogène 2024-2030”, publié par QYResearch, la taille du marché mondial de Aimant de samarium fer-nitrogène devrait atteindre 56 millions de dollars d'ici 2030, à un TCAC de 3.6% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Aimant de samarium fer-nitrogène (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Aimant de samarium fer-nitrogène comprennent Sumitomo Metal Mining, Daido Electronics, etc.

Figure 2. Classement et part de marché des 3 premiers acteurs mondiaux de Aimant de samarium fer-nitrogène (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The key market drivers for the Samarium Iron Nitrogen Magnet (SmFeN) market:

1. Growth of the Automotive Industry: The increasing demand for high-performance motors and actuators in the automotive industry, such as those used in electric vehicles, has been a major driver for the SmFeN magnet market.

2. Expansion of the Electronics and Consumer Devices Sector: The growing use of SmFeN magnets in various electronic devices and consumer products, including speakers, headphones, and hard disk drives, has contributed to the market's expansion.

3. Advancements in Wind Energy Technology: The incorporation of SmFeN magnets in the generators and motors of wind turbines has driven the demand for these magnets in the renewable energy industry.

4. Increasing Adoption in Medical and Healthcare Applications: The use of SmFeN magnets in medical devices, such as magnetic resonance imaging (MRI) systems and surgical tools, has been a significant market driver.

5. Rising Demand for Energy-Efficient and High-Performance Motors: The need for energy-efficient and high-performance motors, which often utilize SmFeN magnets, has been a key factor driving the market growth.

6. Technological Advancements and Improved Manufacturing Processes: Advancements in SmFeN magnet production techniques, such as improved material composition and processing methods, have made these magnets more cost-effective and accessible.

7. Increasing Adoption in Industrial Automation and Robotics: The growing use of SmFeN magnets in industrial automation and robotics applications, including in actuators and positioning systems, has been a market driver.

8. Expansion of the Aerospace and Defense Industries: The use of SmFeN magnets in various aerospace and defense applications, such as guidance systems and sensors, has contributed to the market's growth.

9. Stringent Environmental Regulations and Sustainability Concerns: The shift towards more environmentally-friendly and energy-efficient technologies has driven the demand for SmFeN magnets, which offer improved performance and reduced environmental impact compared to traditional magnets.

10. Increasing Research and Development Activities: Ongoing research and development efforts to further improve the properties and performance of SmFeN magnets have led to the introduction of new and innovative products, thereby driving market growth.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

In the ever-evolving world of industrial automation, efficient motor control and energy management are crucial for enhancing productivity and reducing operational costs. This is where Danfoss Drives come into play, providing state-of-the-art solutions for a variety of applications. At Adhunik Automation India, we recognize the importance of integrating cutting-edge technology to optimize industrial processes, and Danfoss Drives are a testament to our commitment to excellence.

What are Danfoss Drives?

Danfoss Drives are advanced electronic devices used to control the speed, torque, and direction of electric motors. They are part of the broader category known as Variable Frequency Drives (VFDs), which regulate the power supplied to motors, allowing them to operate at optimal efficiency. By adjusting the motor speed to match the requirements of the application, Danfoss Drives help in reducing energy consumption, minimizing wear and tear, and extending the lifespan of the equipment.

Why Choose Danfoss Drives?

At Adhunik Automation India, we understand the diverse needs of our clients across various industries. Danfoss Drives stand out due to their reliability, efficiency, and versatility. Here are some reasons why Danfoss Drives are the preferred choice for many industries:

Energy Efficiency: Danfoss Drives are designed to optimize energy usage, leading to significant cost savings. By adjusting the motor speed based on demand, these drives can reduce energy consumption by up to 50%, making them an eco-friendly and cost-effective solution.

Enhanced Performance: With precise motor control, Danfoss Drives ensure that machines operate smoothly, reducing the risk of mechanical stress and extending the lifespan of equipment. This leads to less downtime and higher productivity, which are critical for industrial operations.

Scalability and Flexibility: Danfoss Drives are suitable for a wide range of applications, from small pumps and fans to large compressors and conveyors. Their modular design allows for easy scalability, enabling businesses to adapt to changing demands without extensive reconfiguration.

User-Friendly Interface: The intuitive interface of Danfoss Drives makes them easy to set up and operate. With advanced diagnostic tools and easy-to-read displays, operators can monitor performance and troubleshoot issues quickly, reducing maintenance time and costs.

Robust Design: Built to withstand harsh industrial environments, Danfoss Drives are known for their durability and reliability. They are equipped with protective features such as over-voltage, over-current, and short-circuit protection, ensuring safe and uninterrupted operation.

Applications of Danfoss Drives

Danfoss Drives are versatile and find applications in a wide range of industries. At Adhunik Automation India, we cater to various sectors, including:

Manufacturing: In manufacturing, Danfoss Drives are used to control conveyor belts, pumps, and fans, optimizing production lines for efficiency and precision.

HVAC Systems: Heating, Ventilation, and Air Conditioning systems benefit from Danfoss Drives by maintaining optimal air flow and temperature control, leading to energy savings and enhanced comfort.

Water and Wastewater Treatment: Danfoss Drives ensure efficient operation of pumps and blowers in water treatment facilities, contributing to water conservation and reducing energy costs.

Food and Beverage: In the food and beverage industry, Danfoss Drives help maintain consistent product quality by precisely controlling mixing, cooling, and packaging processes.

Renewable Energy: Danfoss Drives play a crucial role in wind and solar power generation, optimizing the performance of turbines and inverters for maximum energy output.

Partnering with Adhunik Automation India

As a trusted partner, Adhunik Automation India is committed to providing innovative solutions that meet the unique needs of our clients. By integrating Danfoss Drives into your operations, we can help you achieve greater efficiency, reduce energy consumption, and enhance overall productivity. Our team of experts is dedicated to providing comprehensive support, from installation and configuration to maintenance and troubleshooting.

Conclusion

Danfoss Drives represent a significant advancement in motor control technology, offering a range of benefits that contribute to the efficiency and sustainability of industrial processes. At Adhunik Automation India, we are proud to offer these state-of-the-art solutions to our clients, helping them stay competitive in an ever-changing market. If you are looking to optimize your operations and reduce energy costs, consider the reliability and performance of Danfoss Drives. Partner with us and take the first step towards a more efficient and sustainable future.

0 notes