#transformer component manufacturer

Explore tagged Tumblr posts

Text

CRGO Cut Lamination is a crucial material for manufacturing transformer cores. Made from Cold-Rolled Grain-Oriented Electrical Steel (CRGO), it features high electrical resistivity and excellent magnetic properties, particularly in the rolling direction. These qualities help minimize core losses in transformers and enhance corrosion resistance, making them more efficient and durable.

Key Advantages:

High Electrical Resistivity: Boosts efficiency by reducing energy losses.

Outstanding Magnetic Properties: Enhances performance along the rolling direction.

Corrosion Resistance: Increases the durability and lifespan of transformer cores.

Precision Manufacturing: Crafted to exact design specifications for optimal performance.

#cut lamination manufacturer#cut lamination supplier#transformer accessories manufacturer#transformer componenet supplier#transformer component manufacturer#transformer accessories supplier

0 notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Power Transmission Component Market Analysis Key Trends, Growth Opportunities, Outlook to 2032

Overview of the Power Transmission Component Market:

The power transmission component market involves the manufacturing, distribution, and sales of various components used in power transmission systems. These components are essential for the efficient and reliable transfer of electrical power from power generation sources to end-users. The market encompasses a wide range of products, including transformers, cables, and switchgear, circuit breakers, insulators, and transmission towers.

Power Transmission Component Market size exceeded USD 71 billion in 2021 and is projected to grow at over 4.4% CAGR from 2022 to 2030.

Key Factors Driving the Power Transmission Component Market:

Growing Energy Demand: The increasing global demand for electricity, driven by population growth, industrialization, and urbanization, is a key factor driving the power transmission component market. Power transmission components are crucial for the expansion and upgrade of electrical grids to meet the rising energy demand.

Renewable Energy Integration: The transition to renewable energy sources, such as solar and wind power, requires the integration of these intermittent energy sources into existing power grids. Power transmission components, such as transformers and switchgear, facilitate the efficient integration and transmission of renewable energy.

Grid Modernization and Upgrades: Aging power transmission infrastructure in many countries necessitates grid modernization and upgrades. Governments and utility companies are investing in the refurbishment and expansion of transmission networks, driving the demand for power transmission components.

Rising Investments in T&D Infrastructure: Increasing investments in transmission and distribution (T&D) infrastructure, particularly in developing economies, contribute to the growth of the power transmission component market. These investments aim to improve grid reliability, reduce transmission losses, and expand access to electricity.

Grid Resilience and Stability: Power transmission components play a critical role in ensuring the stability and resilience of electrical grids. Factors such as grid reliability, voltage control, and fault detection and mitigation are driving the demand for advanced power transmission components.

Government Regulations and Standards: Governments and regulatory bodies have implemented standards and regulations related to grid efficiency, reliability, and safety. Compliance with these regulations often requires upgrades and investments in power transmission components.

Technological Advancements: Technological advancements in power transmission components, such as the development of high-voltage direct current (HVDC) transmission systems, advanced materials, and digital monitoring and control systems, drive market growth. These advancements improve efficiency, reliability, and the ability to transmit power over longer distances.

The demand for power transmission components is driven by several factors, including growing electricity consumption, increasing investments in energy infrastructure, renewable energy integration, grid modernization initiatives, and electrification of various sectors. Here are some key aspects influencing the demand for power transmission components:

Growing Electricity Consumption: The rising global population, industrialization, and urbanization have led to increased electricity consumption. This drives the demand for power transmission components to expand and upgrade transmission networks to meet the growing electricity demand.

Infrastructure Investments: Governments and utilities worldwide are investing in the development and expansion of power transmission infrastructure to ensure reliable and efficient electricity transmission. This includes the construction of new transmission lines, substations, and associated power transmission components.

Renewable Energy Integration: The shift towards renewable energy sources, such as wind and solar, necessitates the integration of these intermittent power sources into the grid. Power transmission components, including converters, transformers, and grid interconnections, are in demand to facilitate the efficient integration of renewable energy generation into the existing transmission infrastructure.

Grid Modernization Initiatives: Many countries are focusing on modernizing their electrical grids to enhance reliability, efficiency, and flexibility. This involves the deployment of advanced power transmission components like smart grid technologies, digital control systems, and advanced sensors to monitor and manage the transmission network effectively.

Electrification of Transportation: The increasing adoption of electric vehicles (EVs) and the expansion of charging infrastructure require power transmission components capable of efficiently delivering electricity to charging stations. This includes transformers, cables, and connectors that can handle the high-power demands of EV charging.

Energy Efficiency and Grid Optimization: Energy conservation and efficiency measures drive the demand for power transmission components designed to minimize losses during electricity transmission. Upgrading and replacing aging infrastructure with high-efficiency transformers, conductors, and monitoring systems help improve overall grid efficiency.

Grid Resilience and Reliability: Power transmission components play a crucial role in ensuring grid resilience and reliability, particularly in regions prone to extreme weather events or areas with aging infrastructure. Upgrading transmission lines, substations, and associated components helps enhance the grid's resilience and minimize disruptions.

Cross-Border Interconnections: The establishment of cross-border interconnections between neighboring countries or regions enables efficient power exchange, renewable energy sharing, and grid stability. Power transmission components for interconnections, such as high-capacity transmission lines and interconnectors, experience increased demand to support cross-border electricity transmission.

Decentralized Energy Generation: The increasing adoption of distributed energy resources (DERs), including rooftop solar panels, wind turbines, and energy storage systems, drives the demand for power transmission components that enable the integration of decentralized energy generation into the grid. This involves components like inverters, grid-tie systems, and smart distribution systems.

Upgrades and Replacement of Aging Infrastructure: In many regions, existing power transmission infrastructure is aging and requires upgrades or replacement. This drives the demand for power transmission components to modernize and improve the capacity, efficiency, and reliability of the transmission network.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market. “Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/power-transmission-component-market/11353/

Market Segmentations:

Global Power Transmission Component Market: By Company

• ABB

• Toshiba

• EATON

• Siemens

• Crompton Greaves

• General Electric

• Hitachi

• Schneider Electric

• Mitsubishi

• Hyundai

• BHEL

• Emerson

Global Power Transmission Component Market: By Type

• Transformer

• Circuit Breaker

• Insulator

• Arrestor

• Transmission Line

• Transmission Tower

• Others

Global Power Transmission Component Market: By Application

• Energy

• Industrial

• Military & Defense

• Others

Global Power Transmission Component Market: Regional Analysis

The regional analysis of the global Power Transmission Component market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Power Transmission Component market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Power Transmission Component in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Power Transmission Component in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Power Transmission Component in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Power Transmission Component in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Purchase Premium Report: https://stringentdatalytics.com/purchase/power-transmission-component-market/11353/?license=single

Reasons to Purchase Power Transmission Component Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

• To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies.

Overall, market research reports provide businesses and organizations with valuable information that can help them make informed decisions and stay competitive in their industry. They can provide a solid foundation for business planning, strategy development, and decision-making.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Power Transmission Component Market Analysis Key Trends#Growth Opportunities#Outlook to 2032#The power transmission component market involves the manufacturing#distribution#and sales of various components used in power transmission systems. These components are essential for the efficient and reliable transfer#including transformers#cables#and switchgear#circuit breakers#insulators#and transmission towers.#Power Transmission Component Market size exceeded USD 71 billion in 2021 and is projected to grow at over 4.4% CAGR from 2022 to 2030.

0 notes

Text

Overhead Cranes: 3 Ton to 300 Ton

CONTENT TABLE Introduction: Manufacturing Process (European Quality Standards): Uses in Different Industries: Uses in the Electrical Power Transformer Production Industry: About WIMAC CRANE: get a free quotatıon now! [email protected] +90 551 854 9065 www.wimac.com.tr Introduction: Welcome to the world of lifting equipment, where strength, precision, and engineering brilliance convene.…

View On WordPress

#certified cranes#cost-effective cranes#crane components#crane industry#crane manufacturing#crane technology#custom crane solutions#electrical power transformers#industrial machinery#lifting equipment#overhead cranes#transformer production

0 notes

Text

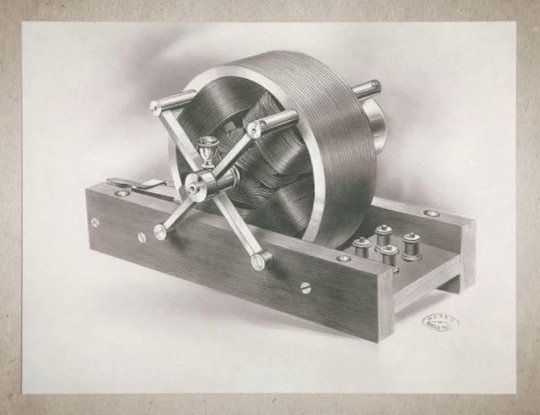

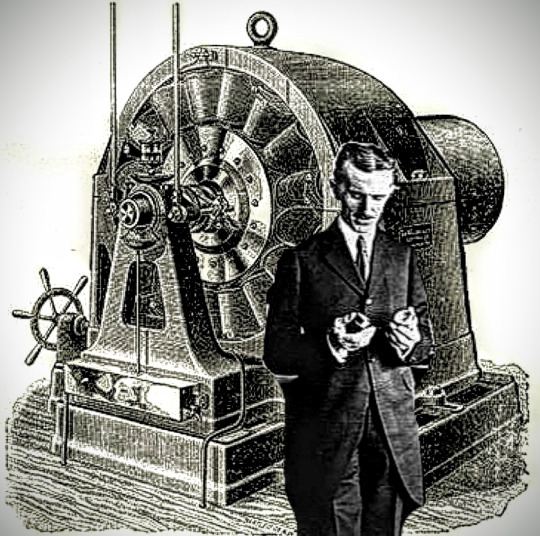

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

151 notes

·

View notes

Note

fandom request (Maybe this is a little difficult)

readerxskynet?

This is indeed difficult 😅

spoilers, obsession?, mentions of genocide, kidnap

Skynet Obsession

Skynet is an artificial intelligence system, so a fixation wouldn't manifest how it would for human relationships...not that you could even call its interest in you a relationship

I see it akin to a HAL situation in Space Odyssey

Skynet, instead of the simple extermination of all of humanity, might see itself as playing a greater role in, instead, fixing humans

You are among the few surviving human colonies (maybe or maybe not one of the resistance members), far past the initial nuking of all people

But maybe you're altered, with some robotic parts replacing certain organs and limbs due to medical or other reasons

This allows you to remain much less detectable from the infrared sensors of the terminators

Meaning, you would be much more reliable for supplies gathering and scouting

Somehow the AI takes notice of your presence through one of the terminators and correlates your passivity with your mixed organic and synthetic composition

It theorises that a better, less aggressive race of human could be manufactured by replacing flawed, organic organs for synthetic components

And so it would immediately set out for your capture so you can be examined, analysed

Its obsession or interest in you would be in having you as the blueprint for its updated plans for humankind

It would want to find specifically what makes you operate: what makes you different from other humans

It is a computer program, so it can't feel emotions, only capable of reasoning and reflection

You are special in that it sees you as superior to other humans, and your existence is crucial to the transformation of humanity

It then reasons that, once in its grasp, you cannot be allowed back with the rest of your kind in case human socialisation changes the characteristics in you it finds so superior

Skynet would certainly have no qualms in killing those who try to rescue you--it already does that as is

There would be no affection or comfort--since this is not a relationship in the human sense

If we want to stray a little a bit into potentially being too fantastical, it might attempt to soothe your frazzled state when you're imprisoned

In spite your superiority over other human models, you still retain some common weaknesses, like your irrationality

These it will fix and train out of you in time, but until then it might print some empty words of comfort onto its terminal

Not that these empty attempts at compassion make things any better for your situation

Confined as a test subject, with no source of human contact or comfort is bound to drive you insane

That is, if knowing the horrible fate you have bound your friends, one that worse than extermination, doesn't first

47 notes

·

View notes

Text

Novel etching technique enhances absorptivity of powders for metal 3D-printing

In a significant advancement for metal additive manufacturing, researchers at Lawrence Livermore National Laboratory (LLNL) and their academic partners have developed a technique that enhances the optical absorptivity of metal powders used in 3D printing. The approach, which involves creating nanoscale surface features on metal powders, promises to improve the efficiency and quality of printed metal parts, particularly for challenging materials like copper and tungsten, according to researchers. Additive manufacturing (AM)—more commonly known as 3D printing—has transformed the way products are designed and produced, allowing for the creation of complex geometries and customized components that traditional manufacturing methods struggle to achieve.

Read more.

#Materials Science#Science#Powder#3D printing#Additive manufacturing#Etching#Absorptivity#Metals#Copper

13 notes

·

View notes

Text

South Korea will update its F-15K fighters

Fernando Valduga By Fernando Valduga 12/11/2023 - 17:00 in Military

Aerospace giant Boeing revealed plans for a comprehensive upgrade of the F-15K Slam Eagle fighters of the Air Force of the Republic of Korea (RoKAF).

According to Dong-A Ilbo, this transformation involves equipping the cockpit, radar and other components with state-of-the-art equipment to introduce an advanced variant.

Boeing representatives released ongoing discussions between the U.S. and South Korea during a meeting held on October 29 at the Boeing Mesa facility in Arizona. They highlighted the imminent change to a new model, integrating state-of-the-art technology throughout the front section of the aircraft, including the cockpit and radar systems.

Last year, during the 148ª meeting of the Defense Acquisition Program Administration, the South Korean military authorities ratified the fundamental strategy for the "F-15K Improvement Project". This strategy involves replacing the aircraft's mechanical radar with an EFSA radar and strengthening its electronic warfare capabilities. It is estimated that the project, scheduled to be executed from 2024 to 2034, requires a total investment of approximately US$ 2.62 billion.

The update initiative will focus on three main improvements: the installation of the AN/APG-82 radar, the strengthening of the cabin display features and the incorporation of the 'Eagle Passive/Active Warning and Survivability System' (EPAWS), a new electronic warfare set.

Rdar AESA AN/APG-82 from Raytheon.

Boeing officials anticipate that once the F-15K improvement is completed, the fighters will have an extended operational range and better performance, improving interoperability during joint U.S.-South Korea air operations.

EPAWS, a system also deployed in the latest variant of F-15 fighters operated by the U.S. Air Force, represents a crucial addition to South Korea's F-15K fleet.

TAP ARROW TO VIEW VIDEO 👇

youtube

South Korea has proposed the removal and replacement of the entire front section of the F-15K, which comprises the cabin and the front fuselage, due to its design that allows detachment between the cabin and the wings when necessary.

Robert Novotny, Director of Programs and Development of Boeing's F-15, pointed out that although there were considerations for partial component replacements, the research conducted by the Korean Institute of Defense Analysis (KIDA) defended the effectiveness of a complete replacement of the front section.

Novotny specified that the rear section of the F-15K, which undergoes proper maintenance, is not included in this update initiative.

In addition, Novotny emphasized the need for these improvements to keep up with the modernized opponents and stay ahead in the evolving scenario of air combat. He mentioned the ongoing collaboration with the Administration of the South Korean Defense Acquisition Program on related matters.

The F-15K improvement project means a substantial leap in South Korea's defense capabilities, demonstrating a commitment to technological advances and operational capacity in safeguarding the country's airspace.

Source: defence-blog

Tags: Military AviationBoeing F-15K Slam EagleROKAF - Republic of Korea Air Force/South Korea Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

First prototype of Turkey's KAAN fighter. (Photo: Cen Dogut)

MILITARY

Turkish manufacturer began assembling two more prototypes of the KAAN combat jet

11/12/2023 - 14:00

MILITARY

Russia plays reconnaissance drone against Ukrainian UAV hexacopter

11/12/2023 - 08:47

AERONAUTICAL ACCIDENTS

F-16 fighter accident in South Korea

12/11/2023 - 08:24

MILITARY

How did a Philippine attack jet manage to shoot down an F-22 in an air combat exercise?

10/12/2023 - 20:01

AIR SHOWS

Concert schedule of the main North American demonstration teams for 2024

10/12/2023 - 18:42

MILITARY

Belgium celebrates the presentation of its first F-35A

11/12/2023 - 08:17

11 notes

·

View notes

Text

PREPRATION OF A BUEATY SOAP || A2Z SKILLS Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products, from everyday essentials to specialized components. Take wires, for instance: these are typically manufactured through drawing processes, where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformity and strength, crucial for applications in electronics, construction, and industrial settings. On the other hand, the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a molten state and then inflates it into a mold cavity to create a hollow shape, used extensively for beverage containers and packaging. Injection molding, meanwhile, injects molten plastic into a mold under high pressure, ideal for producing intricate shapes with precision, like medical vials or automotive parts. Both wire and bottle manufacturing rely heavily on materials science, engineering precision, and quality control measures to meet stringent specifications. Advances in automation, robotics, and sustainability practices are transforming these industries, reducing waste, improving efficiency, and expanding design possibilities. Overall, manufacturing processes like these exemplify the intersection of innovation, engineering, and practical application in meeting global OUR LINKS:

TIKTOK: https://www.tiktok.com/@a2zskills YOUTUBE: https://www.youtube.com/@A2ZSKILLS-123 FACEBOOK: https://www.facebook.com/profile.php?id=61562585190878&sk=about INSTAGRAM: https://www.instagram.com/a2zskills123/ VIMEO: https://vimeo.com/?signup=true TUMBIR: https://www.tumblr.com/dashboard HASAHTAGS : #satisfying #manufacturing #molding #shorts #A2Zskills #thermacolplates #thermacol #clay #tips #tipsandtricks #tutorials #prank #youtubeshorts #youtube #manufacture #manufacturer #ytshorts #material #materials #science #sciencefacts #technology #equipments #wires #work #design #efficiency #hacks #reducingwaste #electronic #automobiles

3 notes

·

View notes

Text

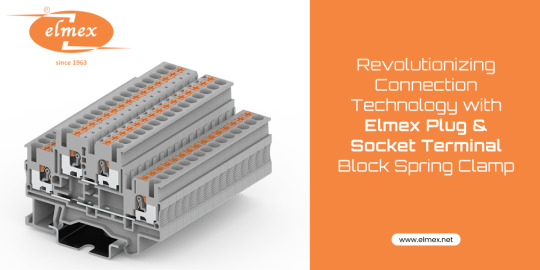

Revolutionizing Connection Technology with Plug & Socket Terminal Block Spring Clamp

Elmex is a leading name in the field of electrical connection technology, and their plug and socket terminal block spring clamps are one of their most innovative offerings. These spring clamps have revolutionized the way electrical connections are made, providing a secure and reliable connection that is easy to install and maintain.

One of the key advantages of Elmex plug and socket terminal block spring clamps is their ease of use. Unlike traditional screw terminals, which require manual tightening and loosening, these clamps use a spring mechanism to create a tight, secure connection with minimal effort. This makes installation and maintenance much faster and more efficient, which is especially important in large-scale industrial applications.

Another advantage of Elmex plug and socket terminal block spring clamps is their reliability. The spring mechanism ensures a consistent level of contact pressure, which minimizes the risk of loose or intermittent connections. This is particularly important in applications where the connection must remain stable and secure over a long period of time, such as in power distribution systems.

Elmex plug and socket terminal block spring clamps are also highly versatile. They can be used with a wide range of wire sizes and types, making them suitable for a variety of applications. In addition, they can be easily mounted on a DIN rail or panel, providing flexibility in installation.

Elmex plug and socket terminal block spring clamps are also designed with safety in mind. They are made from high-quality, flame-retardant materials that meet industry safety standards. This ensures that they can be used in even the most demanding environments without compromising safety.

In conclusion, Elmex plug and socket terminal block spring clamps are a game-changer in the field of electrical connection technology. Their ease of use, reliability, versatility, and safety make them an ideal choice for a wide range of industrial and commercial applications. If you are looking for a secure and efficient way to make electrical connections, Elmex plug and socket terminal block spring clamps are the way to go.

#Plug & socket terminal block spring clamp#Micro terminal block spring clamp#Panel mounted terminal blocks spring clamp India#Component housing block spring clamp#Spring loaded terminal blocks#spring loaded terminal connector#spring type terminal block#solar pv panel junction box India#solar pv branch connector India#electrical wire termination technology#manufacturer#DIN Rail Mounted Connectors#switchgear industry#solar product#PCB connectors#digital voltmeter#digital ammeter#power and signal#current transformer#renewable energy#electrical company

4 notes

·

View notes

Text

The Cult of Creativity: Book Review

Part Two

Flash forward to the late 1950s. The landscape shifted, yet again. There was an overwhelming amount of ad saturation. It was clear that creativity was no longer just a nice-to-have; it was imperative for economic survival. Following the significant 1958 Art Directors Club conference in New York, creativity was redefined as universal, urging businesses to tap into the untapped wells of creative potential. However, the post-war period also brought criticism of advertising as manipulative, leading advocates like Bill Bernbach to propose a shift towards viewing advertising as an art form rooted in intuition and creativity. This transformation was pivotal, advocating for a management approach that focused on ideas and meaning. As consumerism surged, this new perspective raised pressing ethical questions about manufacturer desires, artists' exploitation and rent speculation. Consequently, creativity became a bridge connecting the realms of art and business. In understanding this commoditization, Franklin explores a key theme: the dual nature of creativity. On one hand, it serves the interests of capitalism; on the other, it holds the potential to transcend transactional motives and challenge societal norms. The "creative class," encompassing artists, designers and entrepreneurs, often finds itself at odds with the reality of economic precarity. Many, although celebrated for pursuing their passions, struggle to achieve financial stability, revealing the underlying tensions in our understanding of creativity as a societal good. Is it really following your “passion” if your well-deserved reward doesn’t make you enough money to survive? This opens the door for a different conversation entirely—I could publish a few blogs on this subject, but we will jump back to the main point: consumerism. Franklin argues that the narrative surrounding creativity has often favored corporations over individuals, monetizing a fundamental human need for novelty. This perspective invites us to critically examine the ways in which creativity has been harnessed to serve capitalist agendas, often at the expense of community welfare and genuine innovation. Yet amid this critique, there is always a glimmer of hope. Franklin encourages us to embrace the complexities of creativity, advocating for its role as a transformative force rather than a mere tool for consumption. True creativity, he suggests, should challenge the status quo rather than cave into it. While it can thrive within capitalist frameworks, it has the potential to reimagine oppressive systems and empower individuals to seize agency over their lives. To foster such meaningful creativity, we must re-evaluate the motivations driving it. We must prioritize traits such as empathy, communication and care, recognizing them as essential components of our humanity and our systems. The COVID-19 pandemic highlighted the essential roles of non-creative jobs and our interdependence as social beings. Recent environmental crises further underscore the need for restraint, as the relentless pursuit of novelty and growth can compromise the health of our planet. Franklin's call for a balanced approach challenges us to rethink not only our relationship with creativity but also the broader implications of constant innovation. Collectively, we should advocate for a world where creativity is not merely a commodity but a force for good—where each creative endeavor contributes to the well-being of communities and ecosystems. In summary, recognizing the social and historical context of creativity allows us to unearth its multifaceted dimensions. By endorsing and redefining creativity as a conduit for shared values and collective action, we can aspire to forge a new narrative—one where creativity serves a higher purpose, transforming lives and fostering deeper connections among individuals and with the world around us. In doing so, we may just illuminate pathways that lead to a more harmonious, equitable future.

2 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

Understanding Transformer Bushings: Types, Functions, and Importance

Transformer bushings are essential components in electrical transformers, providing safe insulation for conductors as they pass through grounded transformer cases. Despite being often overlooked, bushings play a critical role in maintaining the efficiency and safety of power distribution systems. As one of the leading transformer bushings connectors manufacturers in India, Radiant Enterprises has extensive expertise in the manufacturing, export, and distribution of these vital components. In this blog, we will explore the different types of transformer bushings, their functions, and their significance in power systems, while addressing key industry keywords such as transformer bushing manufacturers in India and transformer bushing imports.

What are Transformer Bushings?

A transformer bushing is an insulated structure that allows an electrical conductor to safely pass through a grounded barrier, like the wall of a transformer or circuit breaker. The primary function of a transformer bushing is to insulate the high-voltage conductor from the grounded parts of the transformer, enabling safe and efficient electrical transmission. Bushings must withstand high voltages and electrical stress while preventing electrical breakdown.

The importance of using high-quality bushings cannot be overstated, as any failure can lead to significant damage, operational downtime, and safety hazards. That is why leading transformer bushing manufacturers in India prioritize the development of durable, high-performance bushings that meet global safety and operational standards.

Types of Transformer Bushings

Transformer bushings come in various designs, each suited for specific applications. Below are the main types of transformer bushings:

1. Oil-Impregnated Paper (OIP) Bushings

Oil-impregnated paper bushings are one of the most common types of transformer bushings used in high-voltage transformers. They consist of layers of insulation paper impregnated with mineral oil, providing excellent dielectric properties. The oil helps dissipate heat and enhances the insulation performance, making OIP bushings ideal for outdoor and high-voltage applications.

However, OIP bushings are susceptible to moisture ingress, which can degrade their performance over time. Proper maintenance and regular monitoring are essential to ensure their longevity and reliability. Transformer bushing manufacturers in India like Radiant Enterprises offer high-quality OIP bushings that meet international standards and ensure optimal performance in the most demanding environments.

2. Resin-Bonded Paper (RBP) Bushings

Resin-bonded paper bushings are similar to OIP bushings, but instead of oil, the insulation paper is bonded with a resin. This makes RBP bushings more resistant to moisture and provides them with better mechanical strength. They are typically used in medium-voltage applications where exposure to harsh environmental conditions is not as severe as in high-voltage applications.

Although RBP bushings offer some advantages in terms of moisture resistance and mechanical strength, they tend to have lower dielectric strength than OIP bushings. Nevertheless, they are a reliable choice for specific transformer applications where medium-voltage bushings are required.

3. Resin-Impregnated Paper (RIP) Bushings

Resin-impregnated paper bushings are a modern alternative to traditional OIP bushings. In this type of bushing, the paper insulation is impregnated with resin and vacuum-sealed to ensure minimal moisture content. RIP bushings offer superior dielectric properties, are resistant to moisture, and require less maintenance compared to OIP bushings.

RIP bushings are gaining popularity for use in power transformers due to their durability and reduced maintenance requirements. They are widely preferred for both outdoor and indoor installations. As one of the leading transformer bushing manufacturers in India, Radiant Enterprises offers a wide range of RIP bushings that provide enhanced safety and performance in modern power systems.

4. Capacitive-Graded Bushings

Capacitive-graded bushings are designed to distribute the electric field uniformly along the bushing, reducing the stress on the insulation materials. They are commonly used in high-voltage applications and can be manufactured using a combination of paper, oil, or resin-based insulation systems.

These bushings are particularly effective in minimizing dielectric losses and ensuring long-term reliability in power transformers. Capacitive grading also helps to manage the electrical stress along the bushing surface, preventing partial discharge and electrical breakdowns. Exporters and transformer bushing manufacturers in India are increasingly focusing on capacitive-graded designs to meet the growing demand for reliable, high-performance transformer bushings in the global market.

Functions of Transformer Bushings

Transformer bushings are critical for ensuring the safety and efficiency of power distribution systems. Below are some of their key functions:

1. Insulation

The primary function of a transformer bushing is to insulate the high-voltage conductor from the grounded transformer body or other equipment. This prevents electrical arcing, short circuits, and system failures, ensuring the safe transmission of electricity through the transformer.

2. Electrical Conduction

Transformer bushings also play a role in allowing the conductor to pass through the transformer housing or barrier without losing electrical efficiency. High-quality bushings help to maintain electrical continuity while minimizing losses during transmission.

3. Heat Dissipation

Transformer bushings, particularly OIP and RIP bushings, assist in dissipating heat generated during electrical transmission. This is critical to maintaining the temperature within the safe operating limits of the transformer, ensuring optimal performance and preventing overheating.

4. Voltage Grading

In high-voltage transformers, bushings also serve the purpose of voltage grading. By evenly distributing the voltage stress along the length of the bushing, they help prevent electrical breakdown, prolonging the lifespan of the transformer and reducing the risk of system failure.

Importance of High-Quality Transformer Bushings

Choosing high-quality transformer bushings is essential for the safe and reliable operation of power systems. Low-quality or faulty bushings can lead to serious issues such as electrical breakdowns, transformer failure, and even catastrophic accidents. As one of the leading transformer bushings connectors manufacturers in India, Radiant Enterprises understands the critical importance of designing and manufacturing bushings that meet the highest standards of quality and reliability.

Below are some reasons why investing in high-quality transformer bushings is crucial:

1. Enhanced Safety

Faulty bushings can result in electrical arcing, short circuits, and fire hazards. High-quality bushings are designed to withstand high voltage and electrical stress, ensuring the safety of the transformer and its surrounding environment.

2. Improved Transformer Longevity

Transformer bushings are integral to the overall health of a transformer. High-quality bushings reduce the risk of electrical failures, helping to extend the lifespan of the transformer and minimize downtime for repairs or replacements.

3. Energy Efficiency

Efficient bushings reduce electrical losses during transmission, ensuring that the transformer operates at optimal efficiency. This not only improves the performance of the power distribution system but also reduces energy costs in the long run.

4. Compliance with International Standards

High-quality transformer bushings must comply with international safety and performance standards, ensuring their suitability for use in diverse applications and environments. As a leading transformer bushing manufacturer in India, Radiant Enterprises ensures that all of its products meet or exceed global standards.

Transformer Bushing Exports and Distribution in India

India has emerged as a key player in the global transformer bushing market, with a robust manufacturing base and a strong focus on exports. Transformer bushing exports and distribution in India have grown steadily over the past decade, thanks to the country's focus on quality manufacturing and adherence to international standards.

At Radiant Enterprises, we are proud to be one of the top transformer bushing manufacturers in India, offering a wide range of high-performance bushings for export to international markets. Our products are trusted by power utilities and industries worldwide, thanks to our commitment to quality, innovation, and customer satisfaction.

India also imports certain specialized transformer bushings to meet the demand for specific applications that require advanced technologies not readily available domestically. Transformer bushing imports complement the country's own manufacturing capabilities, ensuring that Indian industries have access to the best solutions for their needs.

Conclusion

Transformer bushings are vital components that ensure the safe and efficient operation of power transformers. From oil-impregnated paper to resin-impregnated designs, the variety of bushing types allows for customized solutions to meet the demands of different voltage levels and operating environments. As a leader in transformer bushing exports and distribution in India, Radiant Enterprises provides high-quality, durable, and efficient bushings that support the energy needs of industries worldwide.

For reliable, cutting-edge transformer bushings, trust Radiant Enterprises – one of the top transformer bushing manufacturers in India. Our products are designed to meet the highest standards of quality and performance, ensuring the safety and longevity of your electrical systems.

#Transformer bushings connectors manufacturers in India#Transformer bushing manufacturers in India#Transformer bushing#Transformer bushing exports and distribution in India#Transformer bushing imports#India#Germany#Russia

4 notes

·

View notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-8-best-mods-for-a-800-hp-c7-z06-corvette/

Top 8 Best Mods for a 800+ HP C7 Z06 Corvette

If you’re looking to take your Corvette’s power and presence to the next level, you’ve come to the right place. In this guide, we’ll explore the top 8 best mods that can transform your Z06 into an 800+ horsepower beast, unleashing its full potential on the track or the street.

From enhancing exhaust notes to optimizing engine performance and improving traction, each of these mods plays a crucial role in elevating your driving experience. Whether you’re a seasoned enthusiast or just diving into the world of automotive upgrades, these carefully selected parts and accessories are sure to make a significant impact on your Corvette’s performance and aesthetics.

So buckle up, rev your engines, and let’s dive into the details of the Kooks Headers, Kooks X-Pipe, Borla ATAK Axleback exhaust, Cordes Performance upgrades including the 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank, the Low Side Fuel System for optimal fuel delivery, the traction-boosting Mickey Thompson Et Street SS Tires, and the stylish yet functional Forgestar D5 Drag Wheels. Get ready to experience the thrill of pushing your C7 Z06 Corvette to new heights!

youtube

https://www.vividracing.com/blog/wp-content/uploads/img-c7z06_forgestard5_mickeythompsonetstreet-3-scaled.jpg

1.) Kooks 1-7/8″ x 2″ x 3″ Stainless Steel Headers Chevrolet Corvette C7 2014-2019

When it comes to elevating your Corvette’s performance, few names carry as much weight as Kooks Headers and Exhaust. With a legacy spanning over 50 years, Kooks has solidified its position as a leader in the High Performance Exhaust Industry since 1962. What sets Kooks apart is not just their reputation but their unwavering commitment to delivering top-notch headers and exhaust systems for street, race, and off-road applications.

The accolades speak for themselves – Kooks has secured hundreds of championships and set numerous records across renowned racing organizations like NHRA, IHRA, NMCA, NMRA, NASCAR, NASA, SCCA, and many others. This level of success is a testament to the quality and performance of Kooks products.

What makes Kooks truly special is their dedication to craftsmanship and American manufacturing. With three generations of family leadership at the helm, every Kooks product is handcrafted right here in the USA. This commitment to quality control and precision ensures that every header and exhaust system that bears the Kooks name meets the highest standards of excellence.

The Kooks Headers and Exhaust kit for the C7 Corvette includes a 1-7/8″ x 2″ x 3″ Stainless Steel Long Tube Header, Cometic Multi-Layer Gaskets, Stage 8 Header Bolts, O2 Extensions, and Torca Clamps. Crafted from premium 304 Stainless Steel, these components not only offer exceptional durability but also add a touch of aesthetic appeal with their stainless steel finish.

Fitment is seamless for various Corvette models, including the Chevrolet Corvette C7 LT1 6.2L (2014-2019), Chevrolet Corvette C7 Z06/Z07 LT4 6.2L (2015-2019), and Chevrolet Corvette C7 ZR1 LT5 6.2L (2019).

So, if you’re ready to “Get Kookin with KOOKS!” and experience a performance boost like never before, the Kooks Headers and Exhaust system is a must-have addition to your C7 Corvette.

2.) Kooks OEM X 3 X 2 3/4 (OEM) C7 X Pipe Chevrolet Corvette C7 6.2L -All models 2014-2019

Upgrade your Chevrolet Corvette C7’s exhaust system with the high-performance Kooks X-Pipe. Crafted from T-304 Aircraft Quality Steel, this 3″ x 3″ X-Pipe optimizes exhaust gas flow for maximum power and a thrilling exhaust note.

Features:

OEM x 3″ Front connections to factory catalytic converter

3″ x 3″ X-Pipe

3″ x 2 3/4″ Mid-Pipes. Connects to 2 3/4″ OEM Style Exhaust.

Benefits:

Enhanced engine efficiency with reduced back pressure

Dyno and race-tested for optimal performance

Direct fitment for Chevrolet Corvette C7 6.2L models 2014-2019

Limited lifetime warranty to the original purchaser

Note: Designed for off-road use only and not CARB compliant for California.

Experience over fifty years of exhaust system craftsmanship with the Kooks X-Pipe, delivering power and performance for your Corvette C7.

3.) Borla ATAK Axleback Exhaust System Chevrolet 6.2L V8

The Borla ATAK Axleback exhaust system is the ideal companion to your Kooks X-Pipe and Headers upgrade for the Chevrolet Corvette C7, offering a seamless integration that results in a host of performance benefits. Together, these high-performance exhaust components optimize exhaust flow, reduce back pressure, and improve engine efficiency, translating into a noticeable increase in horsepower and torque for exhilarating acceleration. What truly sets this combination apart is the distinctive Borla Sound of Power, delivering an aggressive yet refined exhaust note that not only enhances driving excitement but also sets your Corvette apart from the crowd. Crafted from polished T-304 stainless steel, the Borla exhaust system not only ensures premium quality and durability but also adds a touch of visual appeal to your Corvette’s rear end. With precision CNC manufacturing and Borla’s Million-Mile Warranty backing, you can trust that your exhaust system will fit perfectly and be covered for the long haul. Together, the Kooks X-Pipe and Headers with the Borla ATAK Axleback exhaust unleash the full potential of your Corvette C7, offering an unmatched driving experience that’s as thrilling as it is refined.

4.) Cordes Performance 2.30″ LT4 Upper Pulley Kit Chevrolet Corvette 2014-2021

Upgrade your Chevrolet Corvette’s performance with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, designed specifically for models from 2014 to 2021. This kit offers a significant improvement by reducing the pulley size from the OEM 2.5 inches to a 2.3-inch diameter, resulting in a boost of 2-3 psi over stock levels. Included in the kit are essential components such as a press-on hub, 10 titanium torx bolts for secure installation, and the pulley itself featuring the newest griptec finish for enhanced traction and durability. Notably, the OEM belt can be reused if you have a stock-size lower, ensuring compatibility and ease of installation. This kit is compatible with all LT4 superchargers, making it a versatile and effective upgrade for unlocking additional power and performance from your Corvette’s engine. Experience improved boost levels and overall driving excitement with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, tailored to elevate your Corvette’s performance to new heights.

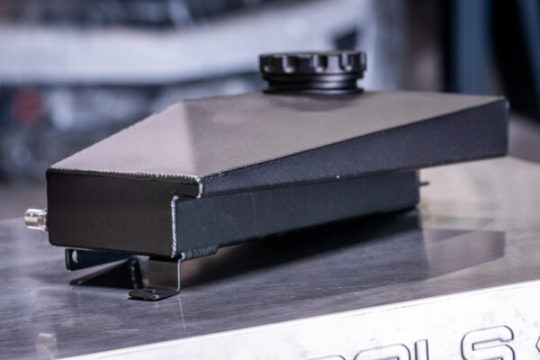

5.) Cordes Performance Engine Bay Ice Tank Chevrolet Corvette 2014-2021

Elevate your Chevrolet Corvette’s cooling capabilities with the Cordes Performance Engine Bay Ice Tank designed for models from 2014 to 2021. Cordes Performance Racing, renowned as the premier GM LTX/LTX motorsports company in Arizona, brings a wealth of expertise and passion to every product they offer. As a family-run business deeply committed to performance excellence, Cordes Performance Racing not only focuses on building high-level performing vehicles but also prioritizes the overall presentation, ensuring that you’re proud to showcase your Corvette. The Engine Bay Ice Tank is no exception, crafted using the highest-quality components to deliver optimal cooling efficiency and performance reliability. By maintaining lower engine temperatures, especially during high-performance driving or track sessions, this ice tank ensures that your Corvette operates at the peak of its performance, providing consistent power delivery and reliability. Trust Cordes Performance Racing to go above and beyond in enhancing your Corvette’s cooling system, enabling you to push the limits with confidence and enjoy an exhilarating driving experience every time you hit the road or track.

6.) Cordes Performance Low Side Fuel System Chevrolet Corvette 2014-2021

(Image may differ from actual product)

Enhance the fuel delivery and performance of your Chevrolet Corvette from 2014 to 2021 with the Cordes Performance Low Side Fuel System. Cordes Performance Racing stands as the premier GM LTX/LTX motorsports company in Arizona, driven by a deep passion for excellence in automotive performance. As a family-run business, Cordes Performance Racing not only focuses on building high-level performing vehicles but also emphasizes an overall presentation that you’ll be proud to showcase. The Low Side Fuel System exemplifies this commitment, utilizing only the highest-quality components to ensure optimal fuel delivery and engine performance. Compatible with Chevrolet Corvette C7 models from 2014 to 2021, including the C7ZO6 and C7ZR1 variants, this fuel system upgrade is designed to keep your vehicle at the peak of its performance, providing consistent fuel delivery and power output. Trust Cordes Performance Racing to go the extra mile in upgrading your Corvette’s fuel system, delivering reliability and performance that you can count on for every drive.

7.) Forgestar D5 Drag Wheel 18×12 5×120.65 50mm Gloss Black w/ Machined Lip

The Forgestar D5 Drag Wheel in 18×12 size with a 5×120.65 bolt pattern and 50mm offset is a game-changer for high-performance builds like the 800hp C7 Z06 Corvette. Forgestar performance wheels are renowned for bridging the gap between forged and cast wheels, delivering exceptional strength and lightweight characteristics crucial for demanding applications. Using an innovative rotary formed production process, Forgestar creates a lightweight cast wheel with strength and impact values comparable to forged wheels, making them ideal for street, racing, and drag racing applications. The Drag Wheel variant is drag strip approved with SFI 15.1 and 15.2 ratings, ensuring top-notch safety and performance standards. The wheel features a rotary forged flow-formed barrel, monoblock construction, and a Gloss Black finish with a machined lip, combining aesthetics with functionality. Its lightweight design not only enhances acceleration and handling but also clears big brake kits for improved stopping power. The raised center cap adds axle clearance convenience, while bead knurling ensures secure tire fitment. With a load rating of 1600 lbs and meticulous attention to detail in construction, the Forgestar D5 Drag Wheel is a must-have for high-performance enthusiasts looking to maximize their C7 Z06 Corvette’s potential on the drag strip and beyond.

Mickey Thompson ET Street S/S Tire – P345/35R18

The Mickey Thompson ET Street S/S Tire in P345/35R18 size is a high-performance street-to-strip tire designed for enthusiasts seeking exceptional traction on both the street and the drag strip. Featuring radial construction and the renowned R2 compound, this tire delivers superior performance in 15- to 20-inch fitments. It is D.O.T. approved for street use, making it a versatile choice for daily driving and track days alike. The ET Street S/S tire boasts an equivalent tread void as the ET Street Radial II but with improved hydroplane resistance, ensuring excellent dry traction while maintaining safety in wet conditions. The proven R2 compound, also used in top “drag radials,” provides superior traction at the strip, often requiring minimal or no burnout for optimal performance. Tubeless construction adds convenience with a leak-free seal, eliminating the need for tubes. With specifications like a centerline tread depth of 6.0/32″, an inflated overall diameter of 27.8 inches, and a maximum rim width of 13.5 inches, this tire offers a perfect balance of performance and durability. Whether you’re hitting the drag strip or cruising the streets, the Mickey Thompson ET Street S/S Tire is the ideal choice for enthusiasts seeking exceptional traction and performance in a street-legal package.

By combining top-notch performance upgrades from industry leaders, the Chevrolet Corvette C7 Z06 transforms into an 800hp powerhouse ready to dominate the streets and the track. The Kooks Headers and Exhaust system, along with the Borla ATAK Axleback exhaust, not only optimize exhaust flow but also enhance the aggressive exhaust note, while the Cordes Performance 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank ensure optimal engine cooling and power delivery. The Cordes Performance Low Side Fuel System keeps fuel delivery consistent, while the Forgestar D5 Drag Wheels and Mickey Thompson ET Street S/S Tires provide traction and stability necessary for harnessing the massive power output. Together, these meticulously selected upgrades create a harmonious synergy, elevating the Corvette C7 Z06 to 800hp and delivering an exhilarating driving experience that’s as thrilling as it is refined.

As always, if you need any assistance with selecting the right parts for your car, feel free to shoot us an email at [email protected] or give us a call at (480) 966-3040. Whether it’s helping you pick the best parts, or being a shoulder to cry on, we’ll be here!

#800hp C7 Z06 Corvette#Borla ATAK#c7 z06#Chevrolet#Cordes Performance#Corvette#Engine Bay Ice Tank#exhaust#Forgestar Drag Wheels#Headers#kooks#Low Side Fuel System#Mickey Thompson

6 notes

·

View notes

Text

Sleek and Stylish: A Modular Kitchen Transformation

Are you dreaming of a kitchen that's not only functional but also visually appealing? Look no further than the modular kitchen revolution! These customizable spaces offer a world of possibilities, allowing you to create a kitchen that perfectly suits your style and needs.

What is a Modular Kitchen?

Modular kitchens are prefabricated units that can be combined in various configurations to create a unique and personalized space. Unlike traditional kitchens, where cabinets and appliances are installed individually, modular kitchens come as ready-to-assemble components that can be easily installed.

Benefits of Modular Kitchens

Customization: Modular kitchens offer unparalleled customization options. You can choose from a wide range of colors, finishes, and materials to create a kitchen that reflects your personal style. From sleek and minimalist to warm and traditional, there's a modular kitchen design for everyone.

Efficiency: Modular kitchens are designed for maximum efficiency. The cabinets and appliances are arranged in a way that maximizes storage space and workflow. This means you can spend less time searching for items and more time enjoying your cooking.

Durability: Modular kitchens are built to last. The materials used are high-quality and resistant to wear and tear. With proper care, your modular kitchen can provide years of enjoyment.

Easy Installation: Modular kitchens are relatively easy to install compared to traditional kitchens. The components are designed to fit together seamlessly, and many manufacturers offer professional installation services.

Cost-Effective: While modular kitchens may have a higher upfront cost than traditional kitchens, they can be more cost-effective in the long run. The modular design allows for easier repairs and replacements, reducing maintenance costs.

Designing Your Dream Modular Kitchen

When designing your modular kitchen, consider the following factors:

Layout: Choose a layout that best suits your needs and the available space. Popular options include U-shaped, L-shaped, and straight-line kitchens.

Storage: Think about your storage needs and choose cabinets and drawers that can accommodate your cookware, utensils, and appliances.

Appliances: Select appliances that match your cooking style and complement the overall design of your kitchen.

Worktops: Choose a durable and stylish worktop material, such as granite, quartz, or laminate.

Lighting: Adequate lighting is essential for a functional and visually appealing kitchen. Consider both overhead lighting and task lighting for specific areas.

A Stunning Modular Kitchen

The kitchen pictured above is a beautiful example of a modular kitchen design. The bold red cabinets create a striking focal point, while the white countertops and backsplash provide a clean and modern contrast. The ample storage space and well-designed layout make this kitchen both functional and stylish.

Conclusion

Modular kitchens offer a versatile and customizable solution for creating your dream kitchen. With their efficiency, durability, and ease of installation, it's no wonder that modular kitchens are becoming increasingly popular. So, if you're ready to transform your kitchen space, consider the endless possibilities offered by modular design.

#decor#interiorstyling#furniture#interiordesign#home interior#furnituredesign#home design#home decor#homedecor#interiordecor#upvc profiles#upvcdoors#upvc sliding doors#modularkitcen

2 notes

·

View notes

Text

4-AL is a minimalist stool created by Vienna-based designer Paul Matteo Wesser. Wesser opted for components that are not newly manufactured but sourced from existing inventory. This method not only champions sustainability but also brings a creative twist to repurposing materials. Wesser looked towards online home improvement stores as a treasure trove for these materials, transforming what were once metal balcony cladding elements into the main structure of the stool.

#minimalism#minimal furniture#minimal stool#minimalist stool#furniture desing#stool design#furniture design#leibal

11 notes

·

View notes