#traceable supply chain

Explore tagged Tumblr posts

Text

Illustration photo: Maize kernels being processed for food manufacturing (public domain)

Unveiling the Treasure of West Africa: Maize Grains from Sahel Agri-Sol

July 5, 2024

In the heart of West Africa, where the fertile lands of Mali stretch under the warm African sun, Sahel Agri-Sol cultivates nature's bounty - maize grains that stand unrivaled in quality, flavor, and versatility. As a leading producer and exporter of agricultural commodities, we invite food and cosmetics manufacturers worldwide to discover the transformative power of our exceptional corn.

A Legacy of Excellence

Sahel Agri-Sol's story is deeply rooted in the rich agricultural tradition of Mali. For generations, our farmers have nurtured the land, combining time-honored techniques with modern sustainable practices. This unique approach results in maize grains that not only meet but exceed global standards, offering a product that's truly special in today's market.

For Food Manufacturers: Elevate Your Culinary Creations

Flavor Profile

Our maize grains boast a robust, slightly sweet flavor with nutty undertones - a testament to the unique terroir of West Africa. This distinctive taste can add depth and character to a wide range of food products, setting your offerings apart in a competitive market.

Versatility

From traditional cornmeal and polenta to innovative snack foods and gourmet popcorn, our maize adapts beautifully to diverse applications. Its superior texture and consistent quality make it ideal for:

Nutritional Excellence

Packed with essential nutrients, our maize is a powerhouse of:

For Cosmetics Manufacturers: Nature's Beauty Secret Unveiled

Innovative Ingredients

Unlock the potential of maize in your cosmetic formulations:

1. Corn Silk Extract: Rich in antioxidants, it offers anti-aging and skin-soothing properties.

2. Corn Oil: A lightweight, non-comedogenic oil perfect for moisturizers and hair care products.

3. Corn Starch: An excellent natural absorbent for powders and dry shampoos.

4. Microfine Cornmeal: Gentle exfoliant for body scrubs and facial cleansers.

Eco-Friendly Appeal

In an era where consumers demand natural, sustainable beauty solutions, our maize-derived ingredients offer a compelling narrative. Highlight the purity and origin of your ingredients, connecting your brand to the vibrant agricultural heritage of West Africa.

The Sahel Agri-Sol Advantage

1. Sustainable Cultivation

Our farms employ a blend of traditional wisdom and modern eco-friendly practices, ensuring minimal environmental impact while maximizing yield and quality.

2. Rigorous Quality Control

From seed selection to harvest and processing, every step is meticulously monitored. Our state-of-the-art facilities and stringent testing protocols guarantee purity, consistency, and safety.

3. Flexible Solutions

Whether you need bulk shipments or smaller quantities, we offer customizable packaging options to suit your specific requirements.

4. Year-Round Availability

Our strategic planning and extensive storage facilities ensure a stable supply throughout the year, protecting your production schedules from seasonal fluctuations.

5. Competitive Edge

By choosing Sahel Agri-Sol, you're not just buying superior maize - you're investing in a story of sustainability, tradition, and quality that resonates with today's conscious consumers.

6. Support and Expertise

Our team of agricultural experts and customer service professionals is always ready to assist you, from product selection to logistics support.

Global Reach, Local Impact

By partnering with Sahel Agri-Sol, you're not only elevating your products but also supporting sustainable agricultural practices and contributing to the economic development of West African communities.

Experience the Sahel Agri-Sol Difference

We invite you to discover the unparalleled quality of our West African maize. Contact us today to request samples, discuss your specific needs, or arrange a visit to our facilities in Mali. Let's explore how Sahel Agri-Sol's premium maize grains can revolutionize your product line and captivate your customers.

Bring the golden essence of West Africa to your global products. Choose Sahel Agri-Sol - where quality meets tradition, and innovation embraces nature.

Sahel Agri-Sol

Hamdallaye ACI 2 000,

« BAMA » building 5th floor APT 7

Bamako

Mali

Phone: +223 20 22 75 77

Mobile: +223 70 63 63 23, +223 65 45 38 38

WhatsApp/Telegram global marketing and sales: +223 90 99 1099

Email: [email protected]

Web sites

English https://sahelagrisol.com/en

Français https://sahelagrisol.com/fr

Español https://sahelagrisol.com/es

简体中文 https://sahelagrisol.com/zh

عربي https://sahelagrisol.com/ar

More

#West African maize#premium corn#Mali agriculture#food manufacturing ingredients#cosmetics natural ingredients#sustainable farming#global export#premium grains#traceable supply chain#nutritional corn#corn-based cosmetics#eco-friendly ingredients#innovative food products#African agricultural heritage#customizable solutions#year-round availability#quality control#traditional farming techniques#modern agricultural practices#economic development#conscious consumerism#versatile corn applications#gourmet corn products#maize-derived beauty ingredients#global food industry#international cosmetics market#agricultural commodities#exotic ingredients#culinary innovation

1 note

·

View note

Text

Ensuring Traceability in the Food Supply Chain

Traceability in the food supply chain refers to the ability to track and trace the journey of food products from their origin to the end consumer. This process involves monitoring each stage, including production, processing, distribution, and retail. It enhances food safety, quality, and transparency by providing a clear record of how products are handled and transported. In the event of contamination or recalls, traceability allows for swift identification and removal of affected products, thereby protecting consumer health and fostering trust in food systems. Effective traceability is key to managing risks and improving overall supply chain efficiency.

#Food Safety And Traceability#Food Safety Traceability Software#Traceability In Food Supply Chain#Traceability Of Food Supply Chain

0 notes

Text

#Blockchain in Supply Chain Traceability Solutions Market#Blockchain in Supply Chain Traceability Solutions Market Size#Blockchain in Supply Chain Traceability Solutions Market Share#Blockchain in Supply Chain Traceability Solutions Market Trends

0 notes

Text

How to Use Blockchain for Sustainable Supply Chain Management

#Sustainable supply chains#Blockchain transparency in supply chains#Blockchain for sustainability#Supply chain traceability#blockchain

1 note

·

View note

Text

Pharmaceutical Traceability Market is in Trends by Digitalization of Supply Chains

The pharmaceutical traceability market deals in tracking and tracing products in the pharmaceutical supply chain. Traceability solutions involve serialization, aggregation, and scanning of packaged pharmaceutical products to uniquely identify and track individual items or collections through facilities and different stakeholders. This helps meet regulations, prevent counterfeiting, automate recalls, optimize inventory, and enable digital supply chain visibility. The Global Pharmaceutical Traceability Market is estimated to be valued at US$ 4.96 Bn in 2024 and is expected to exhibit a CAGR of 9.5% over the forecast period 2024 To 2031. Key players operating in the Pharmaceutical Traceability are M&R Printing Equipment, MHM Siebdruckmaschinen GmbH, Lawson Screen & Digital Products, Sakurai USA, SPS TechnoScreen GmbH, ATMA Champ Ent. Corp., Systematic Automation, DECO TECHnology Group, TOSH (Italy), Thieme GmbH & Co. KG. Due to strict regulations imposed by governments and regional authorities, the demand for track and trace solutions is growing. Serialization requirements will drive significant investments in pharmaceutical traceability systems to ensure product authenticity and safety. With increasing online pharmacies and cold chain requirements, real-time traceability across the distribution network is gaining importance. Pharmaceutical companies are expanding globally to cater to foreign markets. Pharmaceutical Traceability Market Growth increases complexity and risk of supply chain disruptions. Traceability systems allow end-to-end visibility and monitoring of product movement across geographies. Data-driven recalls and exception management further optimize costs. The Global Pharmaceutical Traceability Market is estimated to be valued at US$ 4.96 Bn in 2024 and is expected to exhibit a CAGR of 9.5% over the forecast period 2024 To 2031. Key Trends: One of the key trends in the pharmaceutical traceability market is the digitalization of supply chain processes. Traditional paper-based systems are moving to connected digital platforms for traceability. Real-time product status and location updates are enabling data-driven decision making. Blockchain, IoT, and AI are introducing new opportunities to securely share supply chain data, flag risks proactively, and automate operations. This brings higher transparency while supporting compliance.

Porter's Analysis Threat of new entrants: The pharmaceutical traceability market has moderate barriers to entry due to high capital requirements for setting up manufacturing units and need for regulatory compliances. Bargaining power of buyers: Buyers have moderate bargaining power due to presence of many established players offering traceability solutions at competitive prices. Bargaining power of suppliers: Suppliers have low to moderate bargaining power as there are numerous component providers and raw material suppliers in the market. Threat of new substitutes: Threat of new substitutes is low as traceability solutions integrated with blockchain and IoT offer unique value proposition compared to traditional product tracking methods. Competitive rivalry: The market is highly competitive due to presence of numerous global and regional players offering a wide range of traceability solutions. Geographical Regions North America region dominated the pharmaceutical traceability market in 2024 and accounted for over 30% of the global market share. Major factors contributing to North America's large share include technological advancements, stricter regulations around product traceability and presence of key players and early adopters. The Asia Pacific region is projected to witness the fastest growth during the forecast period from 2024 to 2031. Increasing domestic manufacturing in countries like China and India coupled with growing awareness about supply chain integrity is expected to drive high demand for traceability solutions in Asia Pacific. Penetration of technologies like blockchain and IoT would further aid growth.

Get more insights on Pharmaceutical Traceability Market

For Enhanced Understanding, Dive into the Report in the Language that Connects with You.

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Pharmaceutical Traceability Market#Drug Traceability#Supply Chain Traceability#Pharma Supply Chain#Traceability Systems#Track And Trace#Pharmaceutical Compliance#Serialization#Anti-Counterfeiting#Drug Safety#Pharmaceutical Packaging

0 notes

Text

The Importance of Product Traceability in Modern Supply Chains

Introduction

In today's fast-paced and globalized supply chain environment, product traceability is no longer just a competitive advantage; it is an absolute necessity. Businesses across various industries are turning to product traceability to ensure operational transparency, compliance with regulations, and enhanced customer trust. From tracking the origins of raw materials to monitoring the entire production process and ensuring efficient delivery, product traceability is transforming how manufacturers manage and optimize their supply chains.

What Is Product Traceability?

Product traceability refers to the ability to track the journey of a product through its entire lifecycle, from raw materials to the final delivery. This includes tracking the product during manufacturing, distribution, and transportation. Traceability systems capture and record detailed information at every stage, allowing businesses to track the product’s movement downstream (from production to customer) and trace its origins upstream (raw materials and components).

The value of product traceability lies in its ability to provide transparency and insight into every step of the production and supply chain process. As supply chains become more complex, the importance of product traceability continues to grow.

The Role of Digitalization in Product Traceability

The digital transformation of industries, also known as Industry 4.0, has made product traceability much more efficient and powerful. The rise of technologies such as the Internet of Things (IoT), cloud computing, and artificial intelligence has significantly enhanced the ability to monitor products in real time. Through the integration of these technologies, manufacturers can now track production data at every step and address potential problems before they escalate.

Benefits of Product Traceability for Manufacturers

Product traceability offers a multitude of benefits for manufacturers, particularly in industries like automotive, pharmaceuticals, and food production, where safety, quality, and regulatory compliance are critical. Below are the key advantages:

Enhanced Quality Control: With product traceability, manufacturers can pinpoint the source of any defects or inconsistencies in production. This allows them to quickly isolate the issue, prevent further defects, and improve overall product quality.

Efficient Recalls: If a product issue arises, product traceability enables manufacturers to trace the defective batch back to its source and quickly remove it from circulation. This is especially critical in industries such as food and pharmaceuticals, where faulty products can have serious public health consequences.

Compliance with Regulations: Many industries require manufacturers to maintain detailed records of a product’s history. For instance, the automotive industry demands strict adherence to traceability to ensure the safety of vehicles. A robust traceability system helps businesses meet regulatory requirements and avoid penalties.

Overcoming Challenges in Implementing Product Traceability

While the benefits of product traceability are clear, implementing an effective traceability system comes with its own set of challenges. Some of the common challenges businesses face include:

High Initial Costs: Implementing traceability systems can require significant investments in hardware such as IoT sensors, RFID tags, and software platforms. However, the long-term gains in efficiency and compliance often outweigh these initial costs.

Integration with Legacy Systems: Older manufacturing facilities often rely on legacy systems that are not compatible with modern traceability solutions. This creates technological barriers that require upgrades, which can be costly and disruptive.

Managing Complex Data: Product traceability generates vast amounts of data. Effectively processing and analyzing this data can be overwhelming for businesses. Cloud computing and AI-driven analytics can help manufacturers make sense of this data and identify inefficiencies in their operations.

The Future of Product Traceability

Looking to the future, product traceability will continue to evolve alongside technological advancements. One of the most promising technologies for enhancing traceability is blockchain. Blockchain offers a decentralized, tamper-proof ledger that records every transaction and movement of a product through the supply chain. This would provide even greater transparency and security for businesses, enabling them to offer consumers detailed information about the journey of their products.

As consumer demands for safety, sustainability, and transparency grow, businesses that embrace traceability will be better positioned to differentiate themselves in the market. With blockchain and other digital technologies, product traceability will become more streamlined, secure, and efficient.

FAQs

What is product traceability?

Product traceability is the process of tracking a product’s journey through every stage of the supply chain, from raw materials to the final delivery to the customer.

Why is product traceability important for manufacturers?

Product traceability is vital for quality control, efficient recalls, regulatory compliance, and ensuring transparency in the production process.

What role does digitalization play in product traceability?

Digital technologies like IoT, cloud computing, and artificial intelligence enhance traceability by providing real-time data, improving efficiency, and automating many tracking processes.

How does product traceability support sustainability?

Product traceability allows companies to verify that their raw materials are sourced ethically and sustainably, helping reduce the environmental impact of their supply chain.

What are some challenges of implementing product traceability?

Challenges include high initial costs, technological barriers when integrating with legacy systems, and managing the vast amounts of data generated by traceability systems.

What is the future of product traceability?

The future of product traceability includes the adoption of blockchain technology, which provides a secure, decentralized ledger for tracking products and offers greater transparency and accountability.

Conclusion

In conclusion, product traceability is a critical component of modern supply chain management. It not only ensures compliance and quality but also builds consumer trust by providing transparency into the product’s journey. With advancements in technology, businesses have the tools to make their supply chains more efficient and sustainable through robust traceability systems. By embracing these technologies, manufacturers can gain a competitive edge and ensure long-term success in an increasingly complex and demanding marketplace.

0 notes

Text

The Human Cost of Avocado Theft in Kenya: Stories from Farmers Battling Crime and Corruption

Kenya’s avocado industry has emerged as a critical sector, driving economic growth and offering small-scale farmers a pathway out of poverty. With the global demand for avocados surging, particularly in Europe and Asia, Kenyan farmers have increasingly turned to avocado cultivation. However, this promising venture has become marred by a growing epidemic of avocado theft, leading to severe…

#avocado blockchain traceability#avocado cooperative Kenya#avocado export challenges#avocado export security#avocado farm protection#avocado farm security#avocado farmer stories#avocado farming challenges#avocado farming losses#avocado farming solutions.#avocado farming vulnerabilities#avocado industry corruption#avocado industry Kenya#avocado market regulation#avocado market transparency#avocado middlemen corruption#avocado supply chain Kenya#avocado theft#avocado theft epidemic#avocado theft in Kenya#avocado theft law enforcement#avocado theft prevention#economic impact of avocado theft#Embu avocado theft#Kenyan avocado economy#Kenyan avocado market#Kirinyaga avocado crime#Machakos avocado farming#Murang’a avocado farmers#organized crime in avocado trade

0 notes

Text

Unlock transparency and efficiency in supply chains with Blockchain and AI for traceability. Discover how Blockchain ensures immutable records of every transaction, while AI analyzes data for real-time insights. From tracking products to verifying authenticity, this powerful duo enhances accountability and trust across the supply chain. Stay ahead of the curve with Softlabs Group for innovative solutions reshaping supply chain traceability.

0 notes

Text

Strict Safety Regulations are Trending in the Anti-Counterfeit Packaging Market

The anti-counterfeit packaging market is observing a considerable growth at present, and this trend will continue in the years to come as well, because of the growth of the counterfeit industry all over the world.

The surge in strict product safety regulations with regards to counterfeiting is the newest trend in the industry. Subsequently, concentration of fake products is unceasingly increasing, government of numerous countries are employing strict regulations for controlling counterfeiting activities. These guidelines impact the industry positively and target to wipe out fake products.

The track and trace category, with regards to technology had the largest share in the industry. It is because of the high-volume acceptance of packaging techs, allowing manufacturers to track and trace their shipments and evade any technological impairments.

Pharma and healthcare will grow the fastest in the years to come. This has a lot to do with the fast acceptance of this kind of packaging in medical industry, due to the snowballing concerns regarding health and also an increase in the production of pharmaceuticals.

North American anti-counterfeit packaging market was the largest in the past, and it will continue to be like this in the years to come as well. This has a lot to do with the strong base of pharma, food and beverage, and consumer good companies, adopting anticounterfeit packaging. Seeing the future scenario, the U.S. will lead the regional market.

In the years to come, the industry will grow the fastest in the APAC, mainly because of the growing consciousness pertaining to the unscrupulous counterfeit activities among manufacturers. The growth can also be attributed to the increasing population along with the increasing disposable income, which is leading to the increasing demand for packaged food in the region, eventually boosting the market.

#Anti-Counterfeit Packaging#Brand Protection#Market Trends#Security Innovations#Authentication Solutions#Market Players#Product Traceability#Tamper-Evident Packaging#Supply Chain Security#Pharmaceutical Authentication#Food and Beverage Security#Market Insights#Packaging Technology

0 notes

Text

0 notes

Link

Download the thought paper to learn how enterprises can achieve a successful traceability transformation program.

0 notes

Text

ProfilePrint inks commercial contracts with three of Brazil’s top food companies

ProfilePrint, a Singapore-based company that provides A.I. driven solutions to ascertain and predict the quality and profile of food ingredients, officially announced the signing of commercial contracts to deploy the ProfilePrint technology with three of Brazil’s largest food companies – Louis Dreyfus Company Brasil, Olam Agrícola Ltda (Brazil) and Sucafina Brasil. Latin America is responsible…

View On WordPress

#AgTech#Artificial Intelligence in Agriculture#Business Partnerships in Food and Farming#Coffee#Food and Agribusiness#Food Processing#Food Quality#FoodTech#Ingredients#Supply Chain#Traceability

0 notes

Text

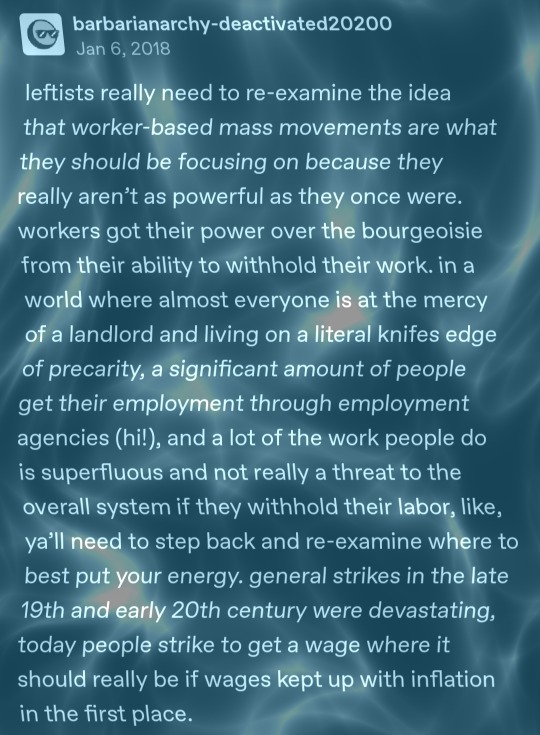

anticiv take of the day: workers have less power in 2024 than they did in the 1800s so you should stop trying to organize them. I make fun of anarchists for refusing to read Marx and Engels but you don't even need to know them. A Dickens novel or a high school history class should be enough to make this post look comically stupid. Never mind that the most successful revolutions did not involve wage laborers withholding their labor but literal feudal peasants.

the post goes on to instead advise disrupting supply chains with direct action. Disrupting supply chains with who? The only kind of adventurist sabotage you could do by yourself to actually make an impact on supply chains (and the post gestures at it, bringing up blackouts) - is shooting at power stations. This is almost the single easy way to get arrested by the FBI or equivalent as a leftist. They wouldn't need to manufacture bullshit RICO charges like they are currently already getting away with doing to the Stop Cop City folks, they can just use the actual terrorism charges they conspicuously avoid every time a Boogaloo shithead shoots at power stations. I'm not saying the deactivated OP or the person who put this post on my dash are feds - but recognize that this is the exact same kind of thing a fed would post. "Don't organize at work, it's too hopeless, commit traceable crimes with as few people as possible."

(I guess OP could also mean arson or bombings? The Weather Underground tried that, look up how it went for them - including the part where they all gave up on radical politics and became beltway Democrats, like every anticiv would do if they were offered the chance to.)

507 notes

·

View notes

Text

"Clothing tags, travel cards, hotel room key cards, parcel labels … a whole host of components in supply chains of everything from cars to clothes. What do they have in common? RFID tags.

Every RFID (Radio Frequency Identification) tag contains a microchip and a tiny metal strip of an antenna. A cool 18bn of these are made – and disposed of – each year. And with demands for product traceability increasing, ironically in part because of concerns for the social and environmental health of the supply chain, that’s set to soar.

And guess where most of these tags end up? Yup, landfill – adding to the burgeoning volumes of e-waste polluting our soils, rivers and skies. It’s a sorry tale, but it’s one in which two young graduates of Imperial College London and Royal College of Art are putting a great big green twist. Under the name of PulpaTronics, Chloe So and Barna Soma Biro reckon they’ve hit on a beguilingly simple sounding solution: make the tags out of paper. No plastic, no chips, no metal strips. Just paper, pure and … simple … ? Well, not quite, as we shall see.

The apparent simplicity is achieved by some pretty cutting-edge technical innovation, aimed at stripping away both the metal antennae and the chips. If you can get rid of those, as Biro explains, you solve the e-waste problem at a stroke. But getting rid of things isn’t the typical approach to technical solutions, he adds. “I read a paper in Nature that set out how humans have a bias for solving problems through addition – by adding something new, rather than removing complexity, even if that’s the best approach.”

And adding stuff to a world already stuffed, as it were, can create more problems than it solves. “So that became one of the guiding principles of PulpaTronics”, he says: stripping things down “to the bare minimum, where they are still functional, but have as low an environmental impact as possible”.

...how did they achieve this magical simplification? The answer lies in lasers: these turn the paper into a conductive material, Biro explains, printing a pattern on the surface that can be ‘read’ by a scanner, rather like a QR code. It sounds like frontier technology, but it works, and PulpaTronics have patents pending to protect it.

The resulting tag comes in two forms: in one, there is still a microchip, so that it can be read by existing scanners of the sort common within retailers, for example. The more advanced version does away with the chip altogether. This will need a different kind of scanner, currently in development, which PulpaTronics envisages issuing licences for others to manufacture.

Crucially, the cost of both versions is significantly cheaper than existing RFID kit – making this a highly viable proposition. Then there are the carbon savings: up to 70% for the chipless version – so a no-brainer from a sustainability viewpoint too. All the same, industry interest was slow to start with but when PulpaTronics won a coveted Dezeen magazine award in late 2023, it snowballed, says So. Big brands such as UPS, DHL, Marks & Spencer and Decathlon came calling. “We were just bombarded.” Brands were fascinated by the innovation, she says, but even more by the price point, “because, like any business, they knew that green products can’t come with a premium”."

-via Positive.News, April 29, 2024

--

Note: I know it's still in the very early stages, but this is such a relief to see in the context of the environmental and human rights catastrophes associated with lithium mining and mining for rare earth metals, and the way that EVs and other green infrastructure are massively increasing the demand for those materials.

I'll take a future with paper-based, more humane alternatives for sure! Fingers crossed this keeps developing and develops well (and quickly).

#I do really wish it could be read by regular scanners already though#that's what I thought at first#and that would've been fucking amazing#but this is still pretty cool#electronics#science and technology#green technology#ewaste#landfill#lithium#lithium mining#human rights#environment#climate action#climate hope#rfid#rfid technology#rfid tags#good news#hope

450 notes

·

View notes

Text

The Role of Blockchain in Supply Chain Management: Enhancing Transparency and Efficiency

Blockchain technology, best known for powering cryptocurrencies like Bitcoin and Ethereum, is revolutionizing various industries with its ability to provide transparency, security, and efficiency. One of the most promising applications of blockchain is in supply chain management, where it offers solutions to longstanding challenges such as fraud, inefficiencies, and lack of visibility. This article explores how blockchain is transforming supply chains, its benefits, key use cases, and notable projects, including a mention of Sexy Meme Coin.

Understanding Blockchain Technology

Blockchain is a decentralized ledger technology that records transactions across a network of computers. Each transaction is added to a block, which is then linked to the previous block, forming a chain. This structure ensures that the data is secure, immutable, and transparent, as all participants in the network can view and verify the recorded transactions.

Key Benefits of Blockchain in Supply Chain Management

Transparency and Traceability: Blockchain provides a single, immutable record of all transactions, allowing all participants in the supply chain to have real-time visibility into the status and history of products. This transparency enhances trust and accountability among stakeholders.

Enhanced Security: The decentralized and cryptographic nature of blockchain makes it highly secure. Each transaction is encrypted and linked to the previous one, making it nearly impossible to alter or tamper with the data. This reduces the risk of fraud and counterfeiting in the supply chain.

Efficiency and Cost Savings: Blockchain can automate and streamline various supply chain processes through smart contracts, which are self-executing contracts with the terms of the agreement directly written into code. This automation reduces the need for intermediaries, minimizes paperwork, and speeds up transactions, leading to significant cost savings.

Improved Compliance: Blockchain's transparency and traceability make it easier to ensure compliance with regulatory requirements. Companies can provide verifiable records of their supply chain activities, demonstrating adherence to industry standards and regulations.

Key Use Cases of Blockchain in Supply Chain Management

Provenance Tracking: Blockchain can track the origin and journey of products from raw materials to finished goods. This is particularly valuable for industries like food and pharmaceuticals, where provenance tracking ensures the authenticity and safety of products. For example, consumers can scan a QR code on a product to access detailed information about its origin, journey, and handling.

Counterfeit Prevention: Blockchain's immutable records help prevent counterfeiting by providing a verifiable history of products. Luxury goods, electronics, and pharmaceuticals can be tracked on the blockchain to ensure they are genuine and have not been tampered with.

Supplier Verification: Companies can use blockchain to verify the credentials and performance of their suppliers. By maintaining a transparent and immutable record of supplier activities, businesses can ensure they are working with reputable and compliant partners.

Streamlined Payments and Contracts: Smart contracts on the blockchain can automate payments and contract executions, reducing delays and errors. For instance, payments can be automatically released when goods are delivered and verified, ensuring timely and accurate transactions.

Sustainability and Ethical Sourcing: Blockchain can help companies ensure their supply chains are sustainable and ethically sourced. By providing transparency into the sourcing and production processes, businesses can verify that their products meet environmental and social standards.

Notable Blockchain Supply Chain Projects

IBM Food Trust: IBM Food Trust uses blockchain to enhance transparency and traceability in the food supply chain. The platform allows participants to share and access information about the origin, processing, and distribution of food products, improving food safety and reducing waste.

VeChain: VeChain is a blockchain platform that focuses on supply chain logistics. It provides tools for tracking products and verifying their authenticity, helping businesses combat counterfeiting and improve operational efficiency.

TradeLens: TradeLens, developed by IBM and Maersk, is a blockchain-based platform for global trade. It digitizes the supply chain process, enabling real-time tracking of shipments and reducing the complexity of cross-border transactions.

Everledger: Everledger uses blockchain to track the provenance of high-value assets such as diamonds, wine, and art. By creating a digital record of an asset's history, Everledger helps prevent fraud and ensures the authenticity of products.

Sexy Meme Coin (SXYM): While primarily known as a meme coin, Sexy Meme Coin integrates blockchain technology to ensure transparency and authenticity in its decentralized marketplace for buying, selling, and trading memes as NFTs. Learn more about Sexy Meme Coin at Sexy Meme Coin.

Challenges of Implementing Blockchain in Supply Chains

Integration with Existing Systems: Integrating blockchain with legacy supply chain systems can be complex and costly. Companies need to ensure that blockchain solutions are compatible with their existing infrastructure.

Scalability: Blockchain networks can face scalability issues, especially when handling large volumes of transactions. Developing scalable blockchain solutions that can support global supply chains is crucial for widespread adoption.

Regulatory and Legal Considerations: Blockchain's decentralized nature poses challenges for regulatory compliance. Companies must navigate complex legal landscapes to ensure their blockchain implementations adhere to local and international regulations.

Data Privacy: While blockchain provides transparency, it also raises concerns about data privacy. Companies need to balance the benefits of transparency with the need to protect sensitive information.

The Future of Blockchain in Supply Chain Management

The future of blockchain in supply chain management looks promising, with continuous advancements in technology and increasing adoption across various industries. As blockchain solutions become more scalable and interoperable, their impact on supply chains will grow, enhancing transparency, efficiency, and security.

Collaboration between technology providers, industry stakeholders, and regulators will be crucial for overcoming challenges and realizing the full potential of blockchain in supply chain management. By leveraging blockchain, companies can build more resilient and trustworthy supply chains, ultimately delivering better products and services to consumers.

Conclusion

Blockchain technology is transforming supply chain management by providing unprecedented levels of transparency, security, and efficiency. From provenance tracking and counterfeit prevention to streamlined payments and ethical sourcing, blockchain offers innovative solutions to long-standing supply chain challenges. Notable projects like IBM Food Trust, VeChain, TradeLens, and Everledger are leading the way in this digital revolution, showcasing the diverse applications of blockchain in supply chains.

For those interested in exploring the playful and innovative side of blockchain, Sexy Meme Coin offers a unique and entertaining platform. Visit Sexy Meme Coin to learn more and join the community.

#crypto#blockchain#defi#digitalcurrency#ethereum#digitalassets#sexy meme coin#binance#cryptocurrencies#blockchaintechnology#bitcoin#etf

274 notes

·

View notes

Text

WHAT RULES ARE THESE THEN?

In the EU, they are known as Rules and Guidance for Pharmaceutical Manufacturers and Distributors 2017 (The Orange Guide). The equivalent in the US is the Code of Federal Regulations, Title 21, otherwise referred to as 21 CFR.

They have been in place for decades, and have become increasingly stringent as incidents have occurred in the supply chain to threaten the safety of patients. In 2007, one such incident occurred, resulting in death and serious adverse events, see below:

Inside Pharma

PHARMACEUTICAL SUPPLY CHAINS IN THE NEWS, FOR THE WRONG REASONS

THE HEPARIN TRAGEDY In 2007/8, pharmaceutical supply chains became the subject of global debate among key stakeholders, but for the wrong reasons. A tragic event occurred that shocked the world into realizing that pharmaceutical supply chains had the potential to kill and maim unsuspecting patients…

Read more

3 years ago · 2 likes · Hedley Rees

This tragic incident lead to legislation being passed on either side of the pond. In the EU, it was the Falsified Medicines Directive, 2011. In the US it was the Drug Supply Chain Security Act (DSCSA), 2013.

The aim of the legislation was to prevent such an incident ever happening again.

RULES IN THE ORANGE GUIDE WERE TIGHTENED TOO

In the EU, major changes were also made to the Orange Guide, Chapter 5: PRODUCTION.

This was to protect patients further, by placing obligations on companies manufacturing medicines to trace right back to the upstream sources of all materials used, to ensure they were genuine. The obligations also required traceability records to be kept, and audits carried out to ensure those companies were working to the regulations.

LEGISLATION DID NOT GO FAR ENOUGH

Unfortunately, as the legislation passed (for a number of reasons we can’t go into here) it only applied, and still does, to finished products as they travel from the finished product manufacturer to wholesalers and pharmacies.

Prevention of upstream adulteration, as per heparin, is dependent on manufacturers complying with the Orange Guide, Chapter 5 provisions.

TRUST ME, THEY COULD NEVER HAVE DONE THAT!

The thing to remember is that Good Manufacturing Practice (cGMP) applies to clinical trials, as well as commercial supply. It would have to, wouldn’t it, as the drugs are being tested on humans.

I would have more chance of climbing Everest naked (not a pretty sight!) than the manufacturers would have had in securing full traceability AND applying the cGMP rules for clinical trial supplies.

Something for medical freedom fighters to ponder, questions welcome :)

Hedley

16 notes

·

View notes