#the Future of Aerospace in India

Explore tagged Tumblr posts

Link

1 note

·

View note

Text

Green and Eco-Friendly Blasting Media: Current Development, Trends, and Future Challenges

——An In-Depth Industry Analysis for Manufacturing Managers and Environmental Engineers

Introduction: The Revolution of Blasting Technology in the Era of Environmental Transformation

As global environmental regulations tighten (e.g., EU REACH, U.S. EPA standards) and the ESG (Environmental, Social, Governance) concept gains traction, the manufacturing industry is increasingly demanding sustainable surface treatment technologies. Traditional blasting media, such as silica sand and steel grit, are under scrutiny due to dust pollution, high energy consumption, and health risks. In contrast, green and eco-friendly blasting media are emerging as a core breakthrough for industry transformation. This article combines the latest market data and technological trends to analyze the current development and future challenges in this field, providing strategic insights for decision-makers.

I. Market Status: Policy-Driven Growth and Technological Advancements

1. Market Size and Growth Potential

According to Grand View Research, the global blasting media market reached $5.2 billion in 2023, with the share of eco-friendly media rising from 12% in 2018 to 28% in 2023, achieving a compound annual growth rate (CAGR) of 9.7%. By 2030, the market share of green media is expected to exceed 45%, with the Asia-Pacific region (especially China and India) becoming a growth engine due to manufacturing upgrade demands.

2. Mainstream Eco-Friendly Media Types

Plant-Based Materials (walnut shells, corn cobs): Biodegradable, low dust emission (70% less than silica sand), suitable for precision parts.

Synthetic Ceramic Particles (alumina, silicon carbide): High hardness, reusable 5-8 times, reducing long-term costs.

Ice/Dry Ice: Zero-residue technology, with over 40% penetration in the aerospace sector.

Recycled Glass Beads: Made from waste glass, reducing carbon emissions by 65% compared to traditional processes.

3. Policy and Industry Standards Driving Adoption

The EU Circular Economy Action Plan aims to increase industrial waste recycling to 70% by 2030.

China’s 14th Five-Year Plan tightens blasting dust emission limits to 10mg/m³ (previously 20mg/m³).

Automotive giants (e.g., Toyota, Volkswagen) have incorporated "green blasting certification" into supply chain standards.

II. Technological Advantages and Business Value: Why Choose Green Media?

1. Environmental Benefits

Dust Control: Plant-based media reduce dust concentration to <2mg/m³ (compared to 15-20mg/m³ for silica sand), lowering the risk of silicosis.

Carbon Reduction: Each ton of recycled glass beads reduces CO₂ emissions by 1.2 tons compared to new steel grit.

Waste Management: 95% of synthetic ceramic media can be recycled, reducing landfill costs.

2. Economic Breakthroughs

Lower Lifecycle Costs: In the automotive industry, switching to ice media reduced annual maintenance costs by 18% per production line (source: Frost & Sullivan).

Improved Efficiency: High-precision ceramic particles increase blasting speed by 30% and reduce rework rates.

III. Future Challenges: Technological Bottlenecks and Industry Collaboration

1. Technical Pain Points

Material Limitations: Plant-based media have low hardness (Mohs 2-3), making them unsuitable for hard substrates like high-strength steel.

Cost Barriers: Green media prices remain 20-50% higher than traditional materials, hindering adoption by SMEs.

Lack of Recycling Systems: Only 35% of global companies have media recycling equipment, relying on third-party processing.

2. Industry Collaboration Challenges

Lack of Standardization: Differing definitions of "eco-friendly media" across countries create barriers to cross-border procurement.

Insufficient R&D Investment: SMEs lack funding for new material testing (single certification costs exceed $50,000).

IV. Solutions: Innovation and Ecosystem Building

1. Technological Breakthrough Paths

Composite Material Development: For example, "bio-resin + ceramic" hybrid media balancing hardness and biodegradability.

Smart Blasting Equipment: AI algorithms optimize media usage, reducing waste.

Cryogenic Plasma Technology: A zero-media alternative to physical blasting (currently in the lab stage).

2. Industry Ecosystem Recommendations

Policy Subsidies: Governments should offer tax credits for green media procurement (e.g., U.S. IRA Act).

Industry Alliances: Establish cross-company recycling networks to share regeneration facilities.

Customer Education: Use Life Cycle Assessment (LCA) reports to quantify long-term benefits and boost decision-maker confidence.

V. Conclusion: Green Blasting—A Must for Sustainable Manufacturing

Eco-friendly blasting media are not just a compliance requirement but a strategic choice for cost reduction, efficiency improvement, and brand value enhancement. To overcome the dual challenges of technological evolution and market education, innovation, policy coordination, and industry collaboration are essential to transition this field from an "optional solution" to an "industry standard."

Keywords: Green blasting media, eco-friendly surface treatment, sustainable manufacturing, blasting technology trends, industrial carbon neutrality, ESG compliance

Data Sources: Grand View Research, Frost & Sullivan, European Environment Agency, China Ministry of Ecology and Environment. Further Reading:

2024 Global Surface Treatment Technology White Paper

Pathways to Carbon Neutrality in Manufacturing: Starting with Blasting Processes

2 notes

·

View notes

Text

KODIAK, Alaska—At Coast Guard Air Station Kodiak, the USCGC Stratton, a 418-foot national security cutter, was hemmed into port by a thin layer of ice that had formed overnight in the January cold. Named for the U.S. Coast Guard’s first female officer, Dorothy Stratton, the ship was not designed for ice; its home port is in Alameda, California. After serving missions in the Indo-Pacific, it was brought to Alaska because it was available.

Soon the sun would rise, and the ice would surely melt, the junior officers surmised from the weather decks. The commanding officer nevertheless approved the use of a local tugboat to weave in front of the cutter, breaking up the wafer-like shards of ice as the Stratton steamed away from shore and embarked toward the Bering Sea.

In the last decade, as melting ice created opportunities for fishing and extraction, the Arctic has transformed from a zone of cooperation to one of geopolitical upheaval, where Russia, China, India, and Turkey, among others, are expanding their footprints to match their global ambitions. But the United States is now playing catch-up in a region where it once held significant sway.

One of the Coast Guard’s unofficial mottos is “We do more with less.” True to form, the United States faces a serious shortage of icebreaker ships, which are critical for performing polar missions, leaving national security cutters and other vessels like the Stratton that are not ice-capable with an outsized role in the country’s scramble to compete in the high north. For the 16 days I spent aboard the Stratton this year, it was the sole Coast Guard ship operating in the Bering Sea, conducting fishery inspections aboard trawlers, training with search and rescue helicopter crews, and monitoring the Russian maritime border.

Although the Stratton’s crew was up to this task, their equipment was not. A brief tour aboard the cutter shed light on the Coast Guard’s operational limitations and resource constraints. Unless Washington significantly shifts its approach, the Stratton will remain a microcosm of the United States’ journey in the Arctic: a once dominant force that can no longer effectively assert its interests in a region undergoing rapid transformation.

During the Cold War, the United States invested in Alaska as a crucial fixture of the country’s future. Of these investments, one of the most significant was the construction of the Dalton Highway in 1974, which paved the way for the controversial Trans-Alaska Pipeline and the U.S. entry as a major player in the global oil trade. Recognizing Alaska’s potential as a linchpin of national defense, leaders also invested heavily in the region’s security. In 1957, the United States began operating a northern network of early warning defense systems called the Distant Early Warning Line, and in 1958, it founded what became known as the North American Aerospace Defense Command.

After the fall of the Soviet Union, such exigencies seemed excessive. The north once again became a domain for partnership among Arctic countries, a period that many call “Arctic exceptionalism”—or, as the Norwegians put it, “high north, low tension.”

But after the turn of the millennium, under President Vladimir Putin, Russia took a more assertive stance in the Arctic, modernizing Cold War-era military installations and increasing its testing of hypersonic munitions. In a telling display in 2007, Russian divers planted their national flag on the North Pole’s seabed. Russia wasn’t alone in its heightened interest, and soon even countries without Arctic territory wanted in on the action. China expanded its icebreaker fleet and sought to fund its Polar Silk Road infrastructure projects across Scandinavia and Greenland (though those efforts were blocked by Western intervention). Even India recently drafted its first Arctic strategy, while Turkey ratified a treaty giving its citizens commercial and recreational access to Svalbard, a Norwegian archipelago in the Arctic Ocean.

Over the past decade, the United States lagged behind, focusing instead on the challenges posed to its interests in the Middle East, the South China Sea, and Ukraine. Its Arctic early warning system became outdated. Infrastructure off the coast of Alaska that climatologists use to predict typhoons remained uninstalled, seen as a luxury that the state and federal governments could not afford. In 2020, an engine fire in the sole Coast Guard Arctic icebreaker nearly scuttled a plan to retrieve scientific instruments and data from vessels moored in the Arctic Ocean. Two years later, a Defense Department inspector general report revealed substantial issues with the structural integrity of runways and barracks of U.S. bases across the Arctic and sub-Arctic.

Until recently, U.S. policymakers had little interest in reinstating lost Arctic competence. Only in the last three years—once Washington noticed the advances being made by China and Russia—have lawmakers and military leaders begun to formulate a cohesive Arctic strategy, and it shows.

On patrol with the Stratton, the effects of this delay were apparent. The warm-weather crew struggled to adapt to the climate, having recently returned from warmer Indo-Pacific climates. The resilient group deiced its patrol boats and the helicopter pad tie-downs with a concoction conceived through trial and error. “Happy lights,” which are supposed to boost serotonin levels, were placed around the interior of the ship to help the crew overcome the shorter days. But the crew often turned the lights off; with only a few hours of natural daylight and few portholes on the ship through which to view it anyway, the lights did not do much.

The Coast Guard is the United States’ most neglected national defense asset. It is woefully under-resourced, especially in the Arctic and sub-Arctic, where systemic issues are hindering U.S. hopes of being a major power.

First and foremost is its limited icebreaker fleet. The United States has only two working icebreakers. Of these two, only one, the USCGC Healy, is primarily deployed to the Arctic; the other, the USCGC Polar Star, is deployed to Antarctica. By comparison, Russia, which has a significant Arctic Ocean shoreline, has more than 50 icebreakers, while China has two capable of Arctic missions and at least one more that will be completed by next year.

Coast Guard and defense officials have repeatedly testified before Congress that the service requires at least six polar icebreakers, three of which would be as ice-capable as the Healy, which has been in service for 27 years. The program has suffered nearly a decade of delays because of project mismanagement and a lack of funds. As one former diplomat told me, “A strategy without budget is hallucination.” The first boat under the Polar Security Cutter program was supposed to be delivered by this year. The new estimated arrival date, officials told me, will more likely be 2030.

“Once we have the detailed design, it will be several years—three plus—to begin, to get completion on that ship,” Adm. Linda Fagan, the commandant of the Coast Guard, told Congress last April. “I would give you a date if I had one.”

The Government Accountability Office (GAO) has long warned that the U.S. government and military, including the Coast Guard, have made serious miscalculations in their Arctic efforts. For one, the Coast Guard’s acquisition process for new boats is hampered by continual changes to design and a failure to contract competent shipbuilders. Moreover, the GAO found in a 2023 report that discontinuity among Arctic leadership in the State Department and a failure by the Coast Guard to improve its capability gaps “hinder implementation of U.S. Arctic priorities outlined in the 2022 strategy.”

Far more than national security is at stake. The Arctic is a zone of great economic importance for the United States. The Bering Sea alone provides the United States with 60 percent of its fisheries, not to mention substantial oil and natural gas revenue. An Arctic presence is also important for achieving U.S. climate goals. Helping to reduce or eliminate emissions of carbon dioxide, methane, and black carbon in the Arctic protects carbon-storing habitats such as the tundra, forests, and coastal marshes.

Capt. Brian Krautler, the Stratton’s commanding officer, knows these problems well. Having previously served on Arctic vessels, he was perhaps the ideal officer to lead the Stratton on this unfamiliar mission. After a boarding team was recalled due to heavy seas and an overiced vessel, Krautler lamented the constraints under which he was working. “We are an Arctic nation that doesn’t know how to be an Arctic nation,” he said.

The Stratton reached its first port call in Unalaska, a sleepy fishing town home to the port of Dutch Harbor. Signs around Unalaska declare, “Welcome to the #1 Commercial Fishing Port in the United States.” The port is largely forgotten by Washington and federal entities in the region, but there is evidence all around of its onetime importance to U.S. national security: Concrete pillboxes from World War II line the roads, and trenches mark the hillocks around the harbor.

As Washington pivoted away from the Arctic, Alaska and its Native communities have become more marginalized. Vincent Tutiakoff, the mayor of Unalaska, is particularly frustrated by the shift. Even though Washington made promises to grant greater access to federal resources to support Indigenous communities, it has evaded responsibility for environmental cleanup initiatives and failed to adequately address climate change.

Federal and state governments have virtually abandoned all development opportunities in Unalaska, and initiatives from fish processing plants to a geothermal energy project have been hindered by the U.S. Energy Department’s sluggish response to its Arctic Energy Office’s open call for funding opportunities. “I don’t know what they’re doing,” Tutiakoff said of state and federal agencies.

Making matters worse, the U.S. Army Corps of Engineers is moving ahead to make the northern Alaska city of Nome the site of the nation’s next deep-water port rather than build infrastructure near Unalaska, the gateway to the American Arctic and the port of call for the few patrol ships tasked with its security. It seems that the decision was based on the accessibility needs of cruise ships; Unalaska is not necessarily a vacation destination.

By failing to invest in places like Unalaska, the United States is hobbling its own chances for growth. The region could be home to major advances in the green energy transition or cloud computing storage, but without investment this potential will be lost.

In the last year, the United States has tried to claw back some of what it has lost to atrophy. It has inched closer to confirming the appointment of Mike Sfraga as the first U.S. ambassador-at-large to the Arctic. In March, the U.S. Marine Corps and Navy participated in NATO exercises in the Arctic region of Finland, Norway, and Sweden. The U.S. Defense Department hosted an Arctic dialogue in January ahead of the anticipated release of a revised Arctic strategy, and the State Department signed a flurry of defense cooperation agreements with Nordic allies late last year.

Nevertheless, it has a long way to go. Tethered to the docks at Dutch Harbor, the weather-worn Stratton reflected the gap between the United States’ Arctic capabilities and its ambitions. Its paint was chipped by wind and waves, and a generator needed a replacement part from California. Much of the crew had never been to Alaska before. On the day the ship pulled into port, the crew milled about, gawking at a bald eagle that alighted on the bow and taking advantage of their few days in port before setting out again into hazardous conditions.

“I know we’re supposed to do more with less,” a steward aboard the Stratton told me, “but it’s hard.”

7 notes

·

View notes

Text

@swradiogram not great reception tonite!

We tQi÷ sog ogram 383 of Shortwave Radiogram.

I'm Kim Andrew Elliott in Arlington, Virginia USA.

Here is the lineup for today's program, in MFSK modes as noted:

1:40 MFSK32: Program preview (now) 2:48 MFSK32: India launches space docking mission 6:41 MFSK64: Microwaving to recycle insulated wire* 11:25 MFSK64: Images of the week* 27:12 MFSK32: Closing announcements

Please send reception reports to [email protected]

And visit http://swradiogram.net

We're on swradiogram.bsky.social now

And X/Twitter: @SWRadiogram

tdwDCwu

From AFP via Phys.org:

India rocket launches space docking mission

December 30, 2024

India launched a rocket December 30 carrying two small spacecraft to test docking in space, a critical step for the country's dreams of a space station and a manned Moon mission.

The mission is "vital for India's future space ambitions", Jitendra Singh, the country's science and technology minister, said in a statement ahead of the launch, which was broadcast live by the Indian Space Research Organisation (ISRO).

Prime Minister Narendra Modi announced plans last year to send a man to the Moon by 2040.

The PSLV-C60 rocket, which blasted off Monday evening at the Sriharikota launch site with shooting flames as it soared into the night sky, included two 220-kilogramme (485-pound) satellites.

ISRO has dubbed the mission SpaDeX, or Space Docking Experiment.

"PSLV-C60 successfully launches SpaDeX and 24 payloads," it said in a statement.

The mission is intended to "develop and demonstrate the technology needed for rendezvous, docking, and undocking of two small spacecraft", it added.

The technology is "essential" for India's Moon plans, it added, calling it a "key technology for future human spaceflight and satellite servicing missions".

It will involve a "precision rendezvous", manoeuvering satellites orbiting Earth at speeds of 28,800 kilometres per hour (17,895 miles per hour).

Their relative velocities will be reduced to 0.036 kph to "merge to form a single unit in Space", ISRO said.

The world's most populous nation has a comparatively low-budget aerospace programme that is rapidly closing in on the milestones set by global space powers.

"Through this mission, India is marching towards becoming the fourth country in the world to have space docking technology," ISRO added, after Russia, the United States and China.

The world's most populous country has flexed its spacefaring ambitions in the last decade with its space programme growing considerably in size and momentum, matching the achievements of established powers at a much cheaper price tag.

In August 2023, it became just the fourth nation to land an unmanned craft on the Moon after Russia, the United States and China.

See also: https://www.dw.com/en/india-successfully-launches-its-first-space-docking-mission/a-7118792 8

Shortwave Radiogram now changes to MFSK64 …

tRhuP * o,:tv ic¥i ie eaeo Ìi

eoM x euteuù øute¼ I,z t oteeception report to radiogram@veri zon.net

From New Atlas:

MicrowaeRord ;qet tŒ×e9gtfor copper and carbon black

By Michael Franco OueembeoI !ttiroyQew technique quickly and cheaply carbonizes the PVC insulation on wires like these, leaving behind undamaged copper

The new technique quickly and cheaply carbonizes the PVC insulation on wires like these, leaving behind undamaged copper

Italian and Japanese researchers have developed a novel method to free copper wire from its PVC coating, by treating electric cables with microwaves. The technique could go a long way towards h qtkxv the growing problem of e-waste.

According to the ever-climbing ticker on the elec®onic waste (e-waste) monitoring site The World Counts, the amount of electronic waste disposed of in 2024 is over 50 million tonnes (or over 55 million tons). Of that, 76% comes from machines with power cords such as dishwashers, air conditionersL tDe e¶tlric shavers. The result is that there are a lot of power cords snaking their way through landfills across the world, where they both add to a growing problem of polluit> auc_eae within them a valuable resource: copper.

Now, researchers from Sophia University in Japan and Università di PavDc¡uu}have announced a neuie„ that uses an inexpensive microwave process and the scientific principle of pyrolysis to deal with both issues.

Pyrolysis refers to using high temperatures to turn solids into a gas and a solid residue. This process typically takes place in an inert, or oxygen-free environment.

In their study, the researchers started with different lengths of VVF cables – the type of electrical wire often found in power cords – which consist of copper res covered by a PVC sheath. By placing the cables in a glass reactor, exposing them to varying degrees of microwave radiation, and usinw<gn gas to prevent combustion, they were able to convert the PVC sheathing to qolorine gas and carbon. The copper was left behind to be harvested and reused.

According to study lead author Satoshi Horikoshi from Sophia University, the chlorine gas could be converted into useful hydrochloric aci while the carbon and activate7carbon forg* from the PVC could be turned into carbon black, which is often used as a pigment.

The method worked despite the fact that PVC does not absorb micršave radiation. Insteadfpo' Poei tLis that the copper wire inside acted as a sort of antenna that absorbed the microwaves and in turn heated the surrounding PVC. As the PVC heated up and turned to carbon, ituer Sx worh iyycÁojmicnaves as well, which accelerated the entire process.

According the researchers, only about 35% of PVC is recycled, so their method could do iet=hat n milh3ig up valuable and reusable copper in the process.

"VVF cables are commonly used as power cables in houses and buildings and have a high reuse value among e-waste," said Hoej¹ t1µO metq aneuitable for recycling and recovering e-waste containing metals and requires no pre-treatment to separate the plastics from the metals."

Horikoshi's technique joins other methods of dealing with e-waste we've seen, including using whey frr tkvo0âr gold from electronics; flash-h9ting ground-up circuit boards and theueaOjPqa2ÿ them to recover other precious metqts; and using a cryo-miÁ freeze electronics to separate out potentially reusable resources.

The new study has been published in the journal, RSC Advances.

4 notes

·

View notes

Text

Global Aluminum Knob Market Trends and Future Growth Analysis 2024 - 2031

The global aluminum knob market is experiencing substantial growth, driven by the increasing demand for lightweight and durable components across various industries. Aluminum knobs are widely used in consumer goods, electronics, automotive, and furniture, making them essential in contemporary manufacturing and design.

Overview of Aluminum Knobs

The global aluminum knob market is poised for continued growth, fueled by the increasing demand for lightweight, durable, and aesthetically pleasing components across various industries.

Aluminum knobs are small, typically cylindrical or rounded fixtures made from aluminum, designed to facilitate user interaction with devices or furniture. Their lightweight nature, resistance to corrosion, and aesthetic appeal make them a popular choice in many applications.

Types of Aluminum Knobs

Industrial Aluminum Knobs

Designed for machinery and equipment, these knobs are engineered for durability and functionality.

Often feature textured surfaces for better grip.

Furniture Aluminum Knobs

Commonly used in cabinets, drawers, and doors, these knobs come in various designs and finishes to enhance aesthetics.

Available in decorative styles for modern and traditional furniture.

Electronic Aluminum Knobs

Used in various electronic devices such as audio equipment and appliances.

Often designed with precision for smooth operation and tactile feedback.

Market Drivers

Growing Demand for Lightweight Materials

The increasing emphasis on reducing weight in various applications, especially in automotive and aerospace industries, is driving the demand for aluminum knobs. Their lightweight properties contribute to overall efficiency and performance.

Aesthetic Appeal

The aesthetic versatility of aluminum knobs is propelling their use in furniture and consumer goods. Manufacturers are increasingly incorporating stylish and customizable designs, making aluminum knobs an attractive option for end-users.

Environmental Considerations

Aluminum is a recyclable material, which aligns with the growing trend towards sustainability. The ability to recycle aluminum without degradation in quality is encouraging manufacturers to choose aluminum knobs over other materials.

Regional Analysis

North America

North America is a significant market for aluminum knobs, driven by a robust manufacturing base and high demand from the automotive and furniture sectors. The region's focus on innovation and quality further supports market growth.

Europe

Europe also plays a critical role in the aluminum knob market, with many prominent manufacturers and designers located in the region. The demand for aesthetically pleasing and functional designs is high, particularly in the furniture and home appliance industries.

Asia-Pacific

The Asia-Pacific region is expected to witness rapid growth in the aluminum knob market. Countries like China and India are experiencing a surge in manufacturing activities, particularly in electronics and automotive sectors, driving the demand for aluminum knobs.

Key Players in the Market

AluFlex

A leading manufacturer specializing in high-quality aluminum knobs for various applications, known for its innovative designs.

Hafele

Offers a wide range of aluminum knobs for furniture and hardware solutions, focusing on aesthetics and functionality.

Dura Knobs

Known for its industrial-grade aluminum knobs, Dura Knobs provides durable solutions for machinery and equipment.

Future Trends

Customization and Personalization

As consumer preferences shift towards personalized products, manufacturers are increasingly offering customizable aluminum knobs. This trend is expected to enhance customer engagement and satisfaction.

Smart Technology Integration

The integration of smart technology in various applications is likely to influence the design of aluminum knobs. Future knobs may incorporate features such as touch sensitivity and integrated controls for electronic devices.

Sustainable Manufacturing Practices

With the growing emphasis on sustainability, manufacturers are likely to adopt eco-friendly practices in the production of aluminum knobs. This may include using recycled materials and implementing energy-efficient manufacturing processes.

Conclusion

The global aluminum knob market is poised for continued growth, fueled by the increasing demand for lightweight, durable, and aesthetically pleasing components across various industries. As technological advancements and sustainability trends shape the market landscape, stakeholders must innovate to meet the evolving needs of consumers. With a focus on customization and smart integration, the future of aluminum knobs looks promising, ensuring their relevance in the manufacturing and design sectors for years to come.

#Global Aluminum Knob Market Size#Global Aluminum Knob Market Trend#Global Aluminum Knob Market Growth

3 notes

·

View notes

Text

Top investors in space in India

Why Venture Capitalists Are Betting Big on India’s Space Sector

A Thriving Ecosystem of Space Startups: India’s space ecosystem is no longer limited to government-run entities like the Indian Space Research Organisation (ISRO). Today, a surge of innovative space startups are taking the stage, offering cutting-edge solutions in satellite technology, launch services, space data analytics, and more. Companies like Skyroot Aerospace, Agnikul Cosmos, and Pixxel lead the charge, each carving out a unique niche. These startups are pushing the boundaries of what’s possible, driving investor interest with the potential for high returns in a relatively untapped market.

Strong Government Support and Policy Reforms: One of the key reasons behind the surge in space venture capital in India is the proactive stance taken by the Indian government. Recent policy reforms have opened the doors for private players to participate in space activities, previously dominated by ISRO. Establishing IN-SPACe (Indian National Space Promotion and Authorization Center) is a significant step, providing a regulatory framework that encourages private sector involvement. Such government support has given investors in space in India the confidence to back ambitious projects, knowing there’s a clear path for private ventures.

Cost-Effective Innovation as a Competitive Edge: India’s reputation for cost-effective innovation is another major attraction for investors. Launching satellites at a fraction of the cost compared to global competitors has positioned India as a hub for affordable space technology. This competitive edge not only allows Indian space startups to thrive domestically but also makes them attractive on the international stage. Investors are keen to support companies that can deliver world-class technology with lower capital outlays, reducing investment risks while promising impressive returns.

Global Interest in Indian Talent and Expertise: India’s space sector is not just about affordability; it’s about world-class talent. The country boasts a deep pool of highly skilled engineers, scientists, and entrepreneurs with expertise in aerospace and technology. This talent pool has been instrumental in driving innovation and attracting global attention. International investors are increasingly looking to partner with Indian space startups, recognizing the country’s unique blend of technical prowess and entrepreneurial spirit.

A Growing Market for Space-Based Services: The market for space-based services, including satellite communications, Earth observation, and data analytics, is expanding rapidly. In India, this growth is driven by rising demand from industries such as agriculture, telecommunications, logistics, and defense. With space technology playing a crucial role in optimizing these sectors, investors see an opportunity to capitalize on the potential for domestic and international applications. Space-based services represent a lucrative market, attracting space venture capital in India to back startups that can cater to these needs.

Strategic Partnerships and Collaborations: Indian space startups are not working in isolation; they are forming strategic partnerships with global companies and space agencies. Collaborations with NASA, ESA (European Space Agency), and private companies have opened up new opportunities for technology sharing, funding, and market access. These partnerships have also strengthened investor confidence, as they reduce risks and validate the technology being developed by Indian companies. For investors in space in India, such collaborations signal a promising future, driving more venture capital into the sector.

A New Era of Commercial Space Exploration: The idea of commercial space exploration, once confined to science fiction, is now becoming a reality. From reusable rockets to satellite constellations, Indian space startups are exploring new frontiers that were once considered out of reach. This new era of commercial space exploration has piqued the interest of venture capitalists who see the potential for profitable exits through IPOs, acquisitions, and global partnerships. With private space missions no longer just a dream, space venture capital in India is ready to fuel the next big leap.

Encouraging Signs from Successful Fundraising Rounds: The confidence in India’s space sector is evident from the successful fundraising rounds by leading space startups. Companies like Skyroot Aerospace and Agnikul Cosmos have secured millions in funding from top-tier venture capital firms. These funding rounds not only provide the necessary resources for scaling but also act as a signal to other investors that the Indian space market is mature and ready for high-stakes investment. The momentum created by these early successes is a clear indicator of why investors in space in India are increasingly willing to place their bets.

Conclusion: A Promising Orbit for Investment India’s space sector is on an exciting trajectory. With a favorable policy environment, a surge of innovative startups, and a proven track record of cost-effective solutions, it’s no wonder that space venture capital in India is booming. As the country continues to explore new frontiers and expand its role in global space exploration, venture capitalists are set to play a pivotal role in shaping the future. For those looking to invest in the final frontier, India’s space industry presents a unique opportunity to be part of a revolution that’s only just beginning.

#305, 3rd Floor, 5 Vittal Mallya Road, Bengaluru, Karnataka, 560001, India

5 Ring Road, Lajpat Nagar 4, 3rd Floor, New Delhi-110024

#Keywords#best venture capital firm in india#venture capital firms in india#popular venture capital firms#venture capital firm#seed investors in bangalore#deep tech investors india#startup seed funding india#funding for startups in india#early stage venture capital firms#invest in startups bangalore#funders in bangalore#startup investment fund#fintech funding#india alternatives investment advisors#best venture capital firms in india#business investors in kerala#venture capital company#semiconductor startups#semiconductor venture capital#investors in semiconductors#startup seed funding in India#deep tech venture capital#deeptech startups in india#semiconductor companies in india#saas angel investors#saas venture capital firms#saas venture capital#b2b venture capital#space venture capital in india

2 notes

·

View notes

Text

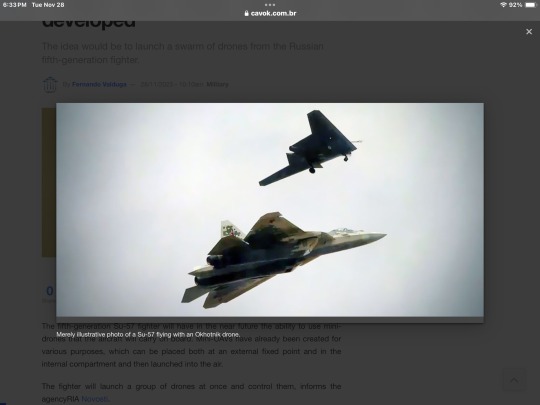

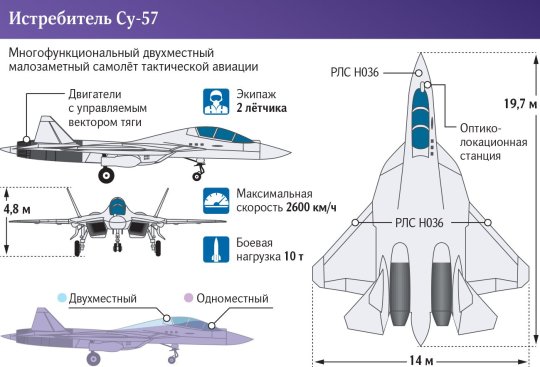

Drone to be launched from Su-57 would have already been developed

The idea would be to launch a swarm of drones from the Russian fifth-generation fighter.

Fernando Valduga By Fernando Valduga 28/11/2023 - 10:10am Military

Merely illustrative photo of a Su-57 flying with an Okhotnik drone.

The fifth-generation Su-57 fighter will have in the near future the ability to use mini-drones that the aircraft will carry on board. Mini-UAVs have already been created for various purposes, which can be placed both at an external fixed point and in the internal compartment and then launched into the air.

The fighter will launch a group of drones at once and control them, informs the agencyRIA Novosti.

The mini-UAV has the direct task of carrying out attack operations, performing reconnaissance and electronic suppression of enemy attack weapons. The launch of dozens of drones by a group of Su-57 will provide a breakthrough in air defense, overloading their information channels and reaching air defense systems both with the help of drones and with their own means of destruction.

In recent years, the development of unmanned technology, both in the civil and military fields, has grown at a rapid pace. In November 2021, Viktor Kladov, Director of International Cooperation and Regional Policy at Rostec State Corporation, said that as early as the next decade, manned combat aircraft will be gradually replaced by unmanned drones. This is due not only to the technological advantages of drones, but also to their ability to work in collaboration with other drones and manned aircraft.

The state-owned company is actively developing unmanned aerial vehicles (UAVs) capable of exchanging information and collaborating with Checkmate and Su-57. This opens up new perspectives for the creation of the so-called "drone swarm" - a concept in which several drones work together to perform different tasks in combat conditions.

A Su-57 fighter will be able to carry more than a dozen reconnaissance and attack drones and unmanned electronic warfare systems in the internal compartment of the fuselage. The UAVs will interact through secure communication channels both with the on-board complex of the carrier aircraft and with each other. One of the main advantages of this approach is the ability to effectively carry out complex missions that were previously inaccessible to combat aircraft. A swarm of drones can perform reconnaissance, attack targets, maintain air superiority and perform other tactical missions.

Previously, the Federal Intellectual Property Service issued the RU2807624 patent to the United Aircraft Corporation for a two-seat multifunctional aircraft for use as an air control center and ensuring interaction between aviation and military formations with network-centric methods to control weapons objects on the battlefield. It is assumed that due to a wide range of communication media, including satellite, high-speed communication channel and installation of equipment for group information transmission over long distances, the aircraft will also be used as a control point for unmanned aerial vehicles.

Tags: Military AviationDronesRFSAF - Russian Federation Aerospace Force/Russian Aerospace ForceSukhoi Su-57 Felon

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

HELICOPTERS

Bell is selected for the X-Plane conceptual phase of DARPA's SPRINT program

27/11/2023 - 22:52

MILITARY

IMAGES: Philippine and U.S. Air Forces successfully conduct joint maritime patrol

27/11/2023 - 22:02

Prime Minister Modi's outcast in a Tejas LCA took place in Bengaluru, where Hindustan Aeronautics Limited (HAL) is headquartered (Photo: Ministry of Defense of India)

MILITARY

Indian Prime Minister flies, and the Indian Air Force will acquire 97 more LCA Tejas

27/11/2023 - 17:00

MILITARY

Elbit Systems will provide self-protection suites for A330 MRTT aircraft

27/11/2023 - 15:05

Among the newly acquired military equipment are included 11 Mil Mi-24P Hind attack helicopters that will be updated in two batches. (Photo: Ministry of Defense of Serbia)

HELICOPTERS

Serbian Armed Forces receive 11 Mi-24P attack helicopters purchased from Cyprus

27/11/2023 - 14:37

AERONAUTICAL ACCIDENTS

U.S. Navy starts investigation and releases images of the P-8 that sweeped the runway and stopped inside the sea in Hawaii

27/11/2023 - 10:16

7 notes

·

View notes

Text

CADOpt Technologies: Premium PTC Partner & Top Value-Added Reseller In India

In the fast-evolving landscape of digital design and engineering, having a reliable partner for computer-aided design (CAD) solutions is crucial. CADOpt Technologies has emerged as a beacon of excellence in this domain, establishing itself as a premium PTC partner and one of the top value-added resellers in India. This article delves into the myriad ways CADOpt Technologies stands out, offering insights into their services, solutions, and customer-centric approach.

Comprehensive Solutions Offered by CADOpt Technologies

CAD Software Solutions

One of the core offerings of CADOpt Technologies is their suite of CAD software solutions. These tools are designed to enhance productivity, improve design accuracy, and streamline the engineering process. Some of the key software solutions provided include:

Creo: A robust 3D CAD software that supports product design and development from concept to manufacturing.

Windchill: A product lifecycle management (PLM) solution that facilitates collaboration and data management across the product development lifecycle.

ThingWorx: An industrial Internet of Things (IoT) platform that enables smart, connected operations and products.

Training and Support Services

Understanding that software is only as good as the people using it, CADOpt Technologies places a strong emphasis on training and support. They offer comprehensive training programs tailored to different user levels, ensuring that clients can fully harness the power of their CAD tools. Additionally, their dedicated support team is always on hand to assist with any technical issues, providing timely and effective solutions.

Customization and Integration

Every business has unique needs, and CADOpt Technologies excels in offering customized solutions. They work closely with clients to understand their specific requirements and tailor their CAD tools accordingly. Moreover, their expertise in software integration ensures seamless incorporation of CAD solutions into existing workflows, enhancing overall efficiency.

Why CADOpt Technologies is a Top Value-Added Reseller

Industry Expertise

One of the key factors that set CADOpt Technologies apart is their deep industry expertise. They have a team of seasoned professionals with extensive experience in various sectors, including automotive, aerospace, consumer goods, and industrial equipment. This diverse expertise enables them to provide insights and solutions that are precisely aligned with industry-specific challenges and opportunities.

Customer-Centric Approach

At the heart of CADOpt Technologies' success is their unwavering commitment to customer satisfaction. They adopt a consultative approach, working closely with clients to understand their goals and challenges. This collaborative mindset ensures that the solutions provided are not only effective but also add significant value to the client's business.

Strong After-Sales Support

After-sales support is a critical aspect of any technology partnership, and CADOpt Technologies excels in this regard. Their dedicated support team provides ongoing assistance, ensuring that clients can maximize the benefits of their CAD solutions. From troubleshooting technical issues to providing regular updates and maintenance, CADOpt Technologies is committed to long-term client success.

The Future of CADOpt Technologies

Innovation and Growth

Looking ahead, CADOpt Technologies is poised for continued growth and innovation. They are constantly exploring new technologies and trends to stay ahead of the curve. Their ongoing investment in research and development ensures that they can offer cutting-edge solutions that meet the evolving needs of their clients.

Expansion Plans

CADOpt Technologies has ambitious plans for expansion, both geographically and in terms of service offerings. They aim to extend their footprint across India and beyond, bringing their world-class CAD solutions to a broader audience. Additionally, they are exploring new verticals and industries, leveraging their expertise to drive digital transformation in various sectors.

Conclusion

CADOpt Technologies stands out as a premium PTC partner and top value-added reseller in India, thanks to their innovative solutions, exceptional customer service, and deep industry expertise. Their comprehensive suite of CAD software, coupled with their commitment to customization, training, and support, makes them a trusted partner for businesses seeking to enhance their design and engineering capabilities. As they continue to grow and innovate, CADOpt Technologies is set to play a pivotal role in shaping the future of the CAD industry in India and beyond. For more information on CADOpt Technologies and their offerings, visit their official website or contact their support team for personalized assistance.

#CADOptTechnologies#PTCPartner#CADSolutions#ValueAddedReseller#IndiaTech#CreoSoftware#WindchillPLM#ThingWorxIoT#EngineeringExcellence#DigitalTransformation#TechInnovation#CustomerSupport#CADTraining#IndustryExpertise#ProductDesign#EngineeringSoftware#CADIntegration#TechGrowth#InnovationInCAD#FutureOfDesign#TechResellerIndia

2 notes

·

View notes

Text

From Campus to Career : MITCORER creates exciting opportunities in Corporates and Railway Engineering fields

Embarking on the journey from campus to career is a pivotal moment for engineering graduates, filled with anticipation and excitement. At MITCORER (MIT College of Railway Engineering and Research), this transition is not just a step, but a leap towards a future filled with opportunities and achievements. Renowned for its excellence in both corporate and railway engineering fields, MITCORER goes above and beyond to prepare its students for success in their professional endeavors.

MITCORER's commitment to academic excellence forms the cornerstone of its approach to placement preparation. The institution leaves no stone unturned in ensuring that students receive a robust education that not only equips them with technical knowledge but also hones their critical thinking and problem-solving skills. With a curriculum designed to meet industry standards and evolving trends, students graduate from MITCORER well-prepared to tackle the challenges of the real world.

However, MITCORER's efforts do not end with academics. Recognizing the importance of industry exposure and practical experience, the institution goes the extra mile to facilitate internships, projects, and industry interactions for its students. From corporate giants to niche railway engineering firms, MITCORER invites a diverse array of companies to its campus, providing students with firsthand exposure to the workings of the industry.

In the mechanical engineering field, for instance, MITCORER ensures that its students have access to opportunities in leading companies such as Tata Motors, Mahindra & Mahindra, Larsen & Toubro, Bosch, and Siemens. These companies offer internships and job placements across various domains, including manufacturing, automotive, and aerospace, allowing students to explore their interests and gain valuable experience.

Similarly, in civil engineering, students have the chance to intern or work with reputed companies like Larsen & Toubro, Shapoorji Pallonji, Hindustan Construction Company (HCC), Tata Projects, and Gammon India. These companies are involved in a wide range of projects, from infrastructure development to real estate, providing students with exposure to diverse aspects of civil engineering.

In the E&TC (Electronics and Telecommunication) and CSE (Computer Science and Engineering) fields, MITCORER ensures that students have access to opportunities in both IT giants and startups. Companies like Infosys, TCS, Wipro, IBM, and Google actively recruit MITCORER graduates, offering them roles in software development, data analytics, cybersecurity, and more.

Moreover, MITCORER takes pride in its global reach, with alumni spread across more than 10 plus countries, making significant contributions to society through their engineering expertise. Whether it's designing sustainable infrastructure, revolutionizing transportation systems, or developing cutting-edge technologies, MITCORER alumni are at the forefront of driving positive change in society.

In conclusion,

By providing a strong academic foundation, ample industry exposure, and a global perspective, MITCORER ensures that its students are well-equipped to excel in both corporate and railway engineering fields. As graduates embark on their professional journeys, they carry with them the values instilled by MITCORER – excellence, innovation, and a dedication to serving society through engineering.

#MITCORERSuccess#EngineeringJourney#CareerLeap#IndustryPreparation#GlobalOpportunities#EngineeringExcellence#RealWorldReady#IndustryInsights#FutureEngineers#SocietyServingEngineers

3 notes

·

View notes

Text

Unleashing Power and Precision: A Comprehensive Guide to Indian Air Force Fighter Planes

Introduction

The Indian Air Force (IAF) stands as a symbol of strength and prowess in the vast skies above the subcontinent. Over the years, it has acquired a formidable fleet of fighter planes, each a marvel of engineering and a testament to the nation's commitment to aerial defense. In this blog post, we will delve into the Indian Air Force Fighter Planes list, exploring the capabilities and features that make them the guardians of the Indian airspace.

Evolution of the Indian Air Force

The IAF has come a long way since its inception in 1932. From its humble beginnings with obsolete biplanes, the force has evolved into a modern and technologically advanced air arm. The backbone of the IAF's aerial might lies in its fleet of fighter planes, which have played a crucial role in safeguarding the nation's sovereignty.

Key Considerations in Fighter Plane Selection

Before diving into the list of Indian Air Force fighter planes, it's essential to understand the criteria that govern the selection of these aerial assets. The IAF considers factors such as range, speed, agility, firepower, and electronic warfare capabilities when choosing its fighter planes. These aircraft are designed to operate in diverse environments, from the scorching deserts of Rajasthan to the high-altitude regions of the Himalayas.

Indian Air Force Fighter Planes List

Sukhoi Su-30MKIThe Su-30MKI, a Russian-origin aircraft, has become the backbone of the IAF's fighter fleet. With its twin-engine design, long-range capabilities, and advanced avionics, the Su-30MKI is a versatile and lethal platform. It can carry a variety of air-to-air and air-to-ground missiles, making it a potent force in both aerial combat and ground attacks.

Dassault RafaleThe Dassault Rafale, a French-made multirole fighter, represents the cutting edge of modern military aviation. Its advanced radar systems, electronic warfare capabilities, and precision-guided munitions make it a force to be reckoned with. The Rafale has significantly bolstered the IAF's strategic capabilities, providing an edge in both air superiority and ground attacks.

MiG-29The MiG-29, a stalwart in the IAF's fleet, has undergone various upgrades to enhance its performance. Known for its agility and speed, the MiG-29 is a fourth-generation fighter that can hold its own in air-to-air combat. Its role in providing air defense and escorting other aircraft adds a layer of versatility to the IAF's operations.

TejasDesigned and manufactured indigenously, the Light Combat Aircraft (LCA) Tejas is a point of pride for India's aerospace industry. With its lightweight design and advanced avionics, the Tejas is tailored for maneuverability. As the IAF continues to induct Tejas variants, it marks a significant stride toward self-reliance in defense production.

JaguarWhile originally designed for ground attack missions, the Anglo-French SEPECAT Jaguar has been adapted for various roles within the IAF. Equipped with a combination of precision-guided munitions and a formidable gun, the Jaguar serves as a potent asset in both air-to-ground and anti-ship operations.

Strategic Importance of Fighter Planes

The role of fighter planes extends beyond just engaging in dogfights. They serve as a critical component of national defense, acting as a deterrent and providing a strategic advantage. The IAF's fighter planes play a pivotal role in ensuring air superiority, conducting reconnaissance, and delivering precision strikes when needed.

Challenges and Future Developments

While the IAF's fleet of fighter planes is formidable, it is not without challenges. The need for continuous upgrades, technological advancements, and the emergence of new threats require constant vigilance and adaptation. The IAF is actively pursuing modernization initiatives, including the development of next-generation fighter aircraft, to maintain its edge in an ever-evolving geopolitical landscape.

Conclusion

In conclusion, the Indian Air Force's fighter planes stand as a testament to the nation's commitment to aerial defense. From the iconic MiG-21s of yesteryears to the state-of-the-art Rafales and Tejas of today, each aircraft in the IAF's inventory plays a crucial role in securing the skies above India. As the nation continues to invest in indigenous defense production and embraces cutting-edge technology, the future of the IAF's fighter fleet looks promising, ensuring that the Indian skies remain safeguarded for generations to come.

3 notes

·

View notes

Text

Excellence in Non-Ferrous Forging & Casting in India

Non-ferrous forging and casting have emerged as critical processes in the manufacturing landscape, contributing significantly to India's industrial prowess. With a focus on metals like aluminum, copper, brass, and bronze, the country's expertise in non-ferrous forging and casting has reached new heights. Let's explore the excellence that India brings to these essential metallurgical processes.

Non-ferrous forging in India is marked by precision and skill, as manufacturers leverage advanced techniques to shape metals into components with superior mechanical properties. The forging process involves applying heat and pressure to mold metals into desired forms, enhancing their strength and durability. Indian forging facilities are equipped with state-of-the-art technology, ensuring the production of high-quality components that meet international standards.

Casting, another integral part of non-ferrous metal processing, is equally impressive in India. Foundries across the country use advanced casting methods to create intricate and complex shapes from molten non-ferrous metals. The attention to detail in the casting process is evident in the precision components that are vital to various industries.

Industries such as automotive, aerospace, and electronics in India benefit significantly from the excellence in non-ferrous forging and casting. The automotive sector, for instance, relies on these processes for manufacturing engine components, transmission parts, and lightweight structural elements. The use of non-ferrous metals contributes to fuel efficiency and sustainability, aligning with global trends.

In the aerospace industry, where precision and reliability are paramount, non-ferrous forging and casting play a crucial role. Components like aircraft engine parts and structural elements are crafted with meticulous attention to detail, ensuring the highest standards of performance and safety.

The electronics industry in India also reaps the rewards of non-ferrous forging and casting. The superior thermal conductivity of non-ferrous metals makes them ideal for applications such as heat sinks and connectors. The corrosion resistance of these metals ensures the longevity of electronic components in various environments.

As India continues to position itself as a global manufacturing hub, the excellence in non-ferrous forging and casting becomes a cornerstone of its industrial success. The commitment to quality, technological advancement, and sustainability places India at the forefront of non-ferrous metallurgy, contributing to the growth and competitiveness of its industries on the world stage. The journey of excellence in non-ferrous forging and casting in India is undoubtedly a testament to the nation's capabilities in shaping the future of manufacturing.

3 notes

·

View notes

Text

Unlocking the Power of Silicon Manganese: Sarda Metals

Silicon manganese is a critical alloy used in various industries, each benefiting from its unique properties and versatility. Sarda Metals, a renowned producer and leading metals manufacturer in India, has been at the forefront of supplying high-quality silicon manganese for countless applications. In this article, we explore the diverse areas where silicon manganese makes a significant impact.

Electronics: Powering the Digital World

Silicon manganese is a key ingredient in the world of electronics. Its exceptional conductivity and durability make it an ideal component for semiconductors, transistors, and integrated circuits. These tiny yet powerful devices are the backbone of our digital world, driving everything from smartphones to computers.

Solar Panels: Harnessing Clean Energy

The renewable energy sector relies on silicon manganese for the production of solar panels. These panels use silicon as a semiconductor to convert sunlight into electricity efficiently. As the world shifts toward sustainable energy sources, silicon manganese plays a pivotal role in supporting this transition.

Construction: Building for the Future

In the construction industry, silicon manganese is used in high-strength materials such as silicones and sealants. These materials provide durability and weather resistance, making them invaluable for sealing structures against the elements.

Medical Devices: Precision and Biocompatibility

Silicon manganese-derived silicones find applications in the medical field. They are used in the production of biocompatible medical implants, such as breast implants and catheters, due to their non-reactive nature and flexibility.

Automotive Industry: Driving Innovation

The automotive sector benefits from silicon manganese in various components, including sensors, engine control units (ECUs), and tire pressure monitoring systems (TPMS). These components enhance vehicle performance, safety, and efficiency.

Aerospace: Soaring to New Heights

Silicon manganese-based materials are essential in aerospace applications, thanks to their lightweight and high-temperature resistance. They contribute to the construction of aircraft components and spacecraft, ensuring safe and efficient travel beyond our atmosphere.

Kitchenware: Enhancing Culinary Experiences

In the kitchen, silicon manganese-derived silicones are used to create non-stick cookware, baking molds, and kitchen utensils. Their heat resistance and non-reactive properties make cooking a breeze.

Glass Industry: A Clear Choice

Silicon dioxide (silica), derived from silicon, is a fundamental component in the glass manufacturing process. It enhances the transparency, strength, and heat resistance of glass products.

Chemical Industry: Catalyzing Innovation

Silicon compounds play a pivotal role in various chemical processes, acting as catalysts that drive the production of a wide array of products, ranging from plastics to pharmaceuticals.

But let's delve deeper into the world of silicon manganese, expertly manufactured by the industry leader, Sarda Metals, a renowned metals manufacturer in India. It's more than just an alloy; it stands as a catalyst for progress and innovation across a multitude of sectors. As we forge ahead in the realms of technology and environmental sustainability, silicon manganese emerges as a critical player in shaping our future.

Silicon manganese isn't merely an alloy—it's the very foundation upon which countless innovations are built. Join us in recognizing its profound significance as we strive to construct a brighter and more sustainable future together.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#SiliconManganese#SardaMetals#Metallurgy#Alloys#SteelProduction#IndustrialMaterials#Mining#MetalIndustry#RawMaterials#Manufacturing#Steel#Metals#Production#ManganeseAlloy#QualityMaterials#SustainableIndustry

3 notes

·

View notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

Remembering Dr. APJ Abdul Kalam on His Birth Anniversary 🎂🚀

On the occasion of Dr. APJ Abdul Kalam Jayanti, Mewar University pays tribute to the Missile Man of India whose vision and dedication continue to inspire us all.✨

Let us honor his memory by striving for excellence and working towards a brighter future. 🚀📚

#APJAbdulKalam #KalamJayanti #Inspiration #MissileMan #PeoplePresident #Scientist #EducationForAll #Innovation #DreamsComeTrue #AbdulKalam #SpaceScientist #RoleModel #YouthInspiration #EducationMatters #Motivation #Aerospace #Determination #TopUniversityInRajasthan #MewarUniversity #BestUniversityInRajasthan #Cuet #KnowledgeToWisdom #ApplyNow

2 notes

·

View notes

Text

Why B.Tech Is More Than Just a Degree: Building Future Innovators.

Arya College of Engineering & I.T. has many courses but A Bachelor of Technology (B.Tech) degree represents far more than just an academic qualification; it is a comprehensive platform for building future innovators, leaders, and entrepreneurs who can drive technological progress and societal development.

More Than Just a Degree: The Multifaceted Value of B.Tech

1. Gateway to Diverse and High-Demand Career Opportunities

B.Tech graduates possess specialized technical skills in fields such as computer science, electrical, mechanical, and information technology engineering, making them highly sought after across industries globally. The demand for these professionals spans startups to established corporations, offering roles in software development, AI, cybersecurity, data science, aerospace, healthcare, and more. This versatility ensures graduates can find rewarding and lucrative careers in multiple sectors.

2. Financial Stability and Career Growth

Graduates with a B.Tech degree typically enjoy better starting salaries-averaging Rs 8-10 lakh per year in India, which is significantly higher than other disciplines have greater earning potential over time. Engineering degrees also correlate with more frequent wage increases and easier job placements, providing a financially stable future.

3. Development of Leadership and Entrepreneurial Skills

Beyond technical expertise, a B.Tech education cultivates critical thinking, complex problem-solving, and collaborative skills essential for leadership and entrepreneurship. Graduates are equipped to innovate, manage teams, and launch startups that can disrupt industries with new products and services. This opens doors to leadership roles and entrepreneurial ventures, empowering graduates to shape the future of technology and business.

4. Innovation and Creativity at the Core

B.Tech programs emphasize innovation, encouraging students to apply scientific and engineering principles to solve real-world problems creatively. Graduates contribute to developing breakthrough technologies, from AI algorithms to cybersecurity solutions, driving continuous technological advancement and societal improvement.

5. Continuous Learning and Adaptability

The rapidly evolving technology landscape demands lifelong learning. B.Tech curricula instill a strong foundation in core principles while fostering adaptability to emerging technologies. Graduates are prepared to stay current through certifications, advanced courses, and professional development, ensuring sustained relevance and career advancement.

6. Holistic Personal and Professional Development

Pursuing a B.Tech degree enhances personal growth by developing problem-solving abilities, critical thinking, and teamwork. It also offers networking opportunities with peers, faculty, and industry professionals, broadening horizons and opening pathways for mentorship and collaboration 67.

7. Accessibility and Flexibility for Various Learners

B.Tech programs are accessible not only to fresh high school graduates but also to diploma holders and working professionals seeking to upgrade their skills and qualifications. This flexibility allows a wide range of learners to benefit from advanced technical education and expand their career prospects.

In summary, a B.Tech degree is a transformative journey that equips students with technical expertise, fosters innovation and creativity, and prepares them for leadership and entrepreneurial roles. It offers financial stability, diverse career opportunities, and continuous professional growth, making it a powerful foundation for building future innovators who can navigate and shape the technological world of tomorrow.

Source: Click Here

#best btech college in jaipur#best engineering college in jaipur#best engineering college in rajasthan#top engineering college in jaipur#best private engineering college in jaipur#best btech college in rajasthan

0 notes

Text

India’s Best Source for Inconel 625 ASTM B446 Round Bars – Applications & Availability

Neptune Alloys is a well-established name in the metal market in India that deals in top-grade alloy solutions for a range of industrial applications. With a reputation as a top Inconel 625 ASTM B446 Round Bar Suppliers in India, the organization has always provided products that are known for their performance and quality. With the increasing need across industries for aerospace, marine engineering, and chemical processing, the need for Inconel 625 ASTM B446 Round Bar Manufacturers in India has also taken on a vital role. These round bars have earned a name for themselves as having exceptional strength, resistance to corrosion, and durability in harsh conditions. The strategic availability of Inconel 625 ASTM B446 Round Bar reflects a move towards high-performing materials for engineering and manufacturing. With a focus on precision and quality checks, suppliers such as Neptune Alloys are changing the standards across the market.

Future Outlook for Inconel 625 Manufacturing in India: Projections and Growth Potential

India has emerged as a prominent hub for high-performance metal alloys, especially in the production of Inconel 625 ASTM B446 Round Bar. With a rise in industrialization and global demand for corrosion-resistant and high-strength materials, the future of Inconel 625 manufacturing in India appears highly promising. Indian manufacturers are not only meeting domestic needs but are also expanding their global footprint through innovation, technological advancement, and competitive pricing.

The Inconel 625 ASTM B446 Round Bar in Mumbai market has gained notable traction due to its strategic location for exports and access to skilled labor and advanced manufacturing facilities. The city serves as a major center for alloy production and distribution, supporting the supply chain for both Indian and international clients. Leading Inconel 625 ASTM B446 Round Bar Manufacturers are integrating automation, quality management systems, and sustainable practices to meet evolving global standards, making them key players in the international market.

India is also home to some of the top Inconel 625 ASTM B446 Round Bar Suppliers in India, offering products that adhere to ASTM, DIN, ANSI, and API standards. These suppliers ensure precision engineering and deliver bars with superior mechanical strength, corrosion resistance, and durability, making them ideal for use in aerospace, marine, chemical, and oil & gas industries. Furthermore, the presence of experienced Inconel 625 ASTM B446 Round Bar Supplier networks across India has enabled streamlined distribution, reduced lead times, and consistent product availability across markets.

While Inconel 625 remains the flagship product, India’s alloy manufacturing strength extends to other key materials as well. The country is recognized as a top-rated Monel 400 Round Bar Supplier, delivering nickel-copper alloy bars known for their resistance to seawater and acidic environments. These are extensively used in marine engineering and heat exchangers. Likewise, the demand for X750 Spring Wire Supplier in India is growing due to the wire’s use in high-temperature environments like gas turbines and nuclear reactors. Indian suppliers are now catering to these requirements by offering precision-drawn spring wires that meet international tolerance levels.

Another alloy gaining popularity is Nitronic 60, a material known for excellent wear and galling resistance. As a leading Nitronic 60 Round Bar Supplier in India, manufacturers are offering bars suited for valve stems, pump shafts, and fasteners, making them critical in petrochemical and food processing applications. At the same time, the country has made strides as a prominent Inconel 825 Round Bar Supplier, with this alloy being widely used for its resistance to sulfuric acid and phosphoric acid environments, particularly in chemical and pollution control equipment.

The rise of Inconel 625 round bar production in India is also supported by government initiatives promoting Make in India and increased investment in advanced metallurgy and engineering sectors. Export trends indicate a significant uptick in international demand, particularly from Europe, the Middle East, and Southeast Asia. Indian companies are responding by scaling up production, improving packaging standards, and expanding warehousing facilities near ports to meet export volumes efficiently.

In addition to technological growth, the sector also benefits from a highly skilled workforce. Metallurgists, engineers, and production experts play a crucial role in maintaining quality, innovating new alloy grades, and optimizing processes. This has helped Inconel 625 ASTM B446 Round Bar Manufacturers in India maintain a competitive edge while adhering to environmental and safety regulations. Manufacturers are also implementing eco-friendly methods such as energy-efficient furnaces, recycling systems, and emission control protocols, aligning with global sustainability goals.

In conclusion, India’s metal industry, especially in the high-performance alloy segment, is poised for sustained growth. The expanding production and export of Inconel 625 ASTM B446 Round Bar, combined with the country’s rising role as a Monel 400 Round Bar Supplier, X750 Spring Wire Supplier in India, Nitronic 60 Round Bar Supplier in India, and Inconel 825 Round Bar Supplier, indicate a bright future. Indian manufacturers are no longer just competing; they are setting new benchmarks in quality, affordability, and innovation—cementing India’s position on the global metallurgical map.

For more details:

Product: Inconel 625 ASTM B446 Round Bar Supplier

Also visit: Round Bar Weight Chart in mm kg Ft

#Inconel 625 ASTM B446 Round Bar#Inconel 625 ASTM B446 Round Bar manufacturers in india#Inconel 625 ASTM B446 Round Bar suppliers#Inconel 625 ASTM B446 Round Bar suppliers in india

0 notes