#swift technoplast

Explore tagged Tumblr posts

Text

The Role of Plastic Pallets in Reducing Product Damage During Transport

The key in today’s fast-moving supply chain and logistics ecosystem is to ensure products aren’t damaged in transit. Damages can lead to financial losses, customer dissatisfaction, and supply chain inefficiencies. One effective approach is using plastic pallets, which offer clear advantages over other pallet types.

1. Consistent and Durable Structure

Plastic pallets have a uniform or smooth manufacture with a regular structure without naked lumber as compared to other pallets which may have irregularities or tendency to warp. Having consistent shapes helps to equalize the load in a product, improving the stability of the load during transport and reducing the odds of shuffling and tumbling.

2. Better Resistance to Impact and Environmental Factors

Transportation can be exposed to diverse environmental conditions such as humidity, rain, and temperature. These pallets are also moisture and damp-resistant, suitable for shipments that may be exposed to humid environments. They also do not soak up water, which can cause swelling and weakness that could threaten stability.

3. Design Options to Fit Specific Product Needs

There are different designs of plastic pallets depending on the use or the industry. Some pallets can be reinforced to support heavier loads and others are designed to stack, allowing for better organization of shipments preventing tipping or falling over during transit.

4. Smooth Surface for Gentle Product Support

The polished and splinter-free finish of plastic pallets makes them perfect, for transporting goods such as electronics and pharmaceutical or food items, without the risk of scratches or damages commonly seen with types of pallet materials. They effectively protect goods during transport.

5. Hygienic and Easy to Clean

Product damage can occur due, to contamination in industries such as food production and healthcare settings where maintaining cleanliness is crucial for product safety and quality assurance purposes Plastics pallets offer a nonporous surface that can be easily sanitized making them a preferred choice for handling sensitive products.

A clean plastic pallet plays a significant role, in reducing the likelihood of contamination impacting the integrity and safety of products during transportation.

6. Lightweight for Easier Handling and Reduced Strain

7. Long-Lasting Durability Means Fewer Replacements and Fewer Risks

Plastic pallets are known for their longevity. They don’t wear down easily, even with frequent use and movement. A pallet that can withstand repeated transit without degrading helps ensure consistent product protection. With fewer replacements needed, the likelihood of using old, damaged, or weakened pallets is reduced, further safeguarding the goods being transported.

Conclusion

These pallets reduce product damage in transit thanks to their robust design, durability, and versatile construction. Even in adverse logistics conditions, they protect goods effectively. For companies aiming to cut costs and enhance customer satisfaction, plastic pallets are a cost-effective, eco-friendly supply chain solution.

By ensuring product safety, minimizing losses, and streamlining logistics, plastic pallets from Swift Technoplast make a smart investment for businesses focused on safe, damage-free transport.

#swift technoplast#Plastic pallets#Export Pallets#shipping pallet#cargo pallet#plastic pallets suppliers#plastic pallet manufacturer

0 notes

Text

Export Pallets Manufacturers in India: Catering Global Logistics Needs

Export pallets are crucial for efficiently transporting goods across international borders, ensuring reliability and durability throughout the supply chain. In India, manufacturers have risen to the challenge of producing high-quality export pallets that meet international standards, contributing significantly to global trade facilitation and logistics management.

Importance of Export Pallets

Export pallets serve as essential tools in international logistics for several reasons:

Compatibility: Designed to meet international shipping standards, export pallets ensure compatibility with various transportation modes, including sea freight, air cargo, and land transportation.

Durability: Built to withstand the rigors of long-distance transportation, export pallets offer robustness and reliability to protect goods during transit.

Compliance: Manufacturers ensure export pallets comply with international regulations and standards for packaging and transportation, facilitating smooth customs clearance and compliance procedures.

Manufacturing Processes in India

Indian manufacturers employ advanced manufacturing processes to produce export-quality pallets:

Heat Treatment: Export pallets often undergo heat treatment to meet ISPM 15 standards, which regulate wood packaging materials to prevent the spread of pests and diseases across borders.

Injection Molding: Utilizing plastic materials, injection molding allows for precise customization and production of durable plastic export pallets that meet international hygiene and durability standards.

Leading Manufacturers in India

India hosts several leading manufacturers specializing in export pallets:

Balaji Industries: Known for their expertise in wooden pallets, Balaji Industries offers heat-treated export pallets that comply with ISPM 15 regulations, ensuring global acceptance.

Swift Technoplast: Specializing in plastic packaging solutions, Swift Technoplast manufactures lightweight and durable plastic export pallets suitable for international shipping.

Nilkamal Limited: A pioneer in the plastics industry, Nilkamal produces export pallets made from high-quality materials that meet stringent international standards for durability and reliability.

Sustainability and Environmental Considerations

Export pallet manufacturers in India prioritize sustainability by using eco-friendly materials and adhering to international guidelines for responsible packaging. Plastic export pallets, for example, can be recycled and reused, contributing to environmental conservation efforts.

Applications Across Industries

Export pallets find widespread applications across various industries in India:

Agribusiness: Used for exporting agricultural produce, ensuring freshness and minimizing damage during transit.

Manufacturing: Essential for shipping finished goods and components to global markets, maintaining product integrity and reliability.

Pharmaceuticals: Critical for transporting pharmaceutical products under controlled conditions, complying with international hygiene and safety standards.

Innovations and Future Outlook

The future outlook for export pallets in India is promising, driven by innovations in material science and manufacturing technology. Manufacturers are exploring lightweight yet robust materials and integrating smart technologies to enhance pallet performance and efficiency in global supply chains.

Conclusion

Export pallets manufacturers in India play a pivotal role in facilitating global trade and logistics by offering durable, compliant, and sustainable solutions. With a commitment to quality and innovation, Indian manufacturers are well-positioned to meet the evolving demands of international markets for reliable export pallets. As global supply chains continue to expand, the role of export pallets in ensuring efficient and secure transportation of goods remains indispensable, reinforcing India's significance in the global logistics landscape.

Locate Us

Sonipat, Haryana - 131301

+91-8700900663

1 note

·

View note

Text

Plastic Pallets Manufacturers in Delhi: Enhancing Logistics Efficiency and Sustainability

Plastic pallets have become integral components of modern logistics and supply chain management, offering enhanced durability, hygiene, and sustainability benefits over traditional wooden pallets. In Delhi, the capital city of India, the demand for plastic pallets is driven by the region's robust industrial sector, stringent hygiene standards, and the need for efficient material handling solutions. This article explores the landscape of plastic pallet manufacturing in Delhi, focusing on key manufacturers, their product offerings, market trends, and the advantages of plastic pallets in the local context.

Introduction to Plastic Pallets

Plastic pallets are designed to facilitate the transport, storage, and handling of goods in various industries, including pharmaceuticals, food and beverage, retail, and manufacturing. Unlike wooden pallets, which are prone to moisture absorption, splintering, and contamination, plastic pallets offer superior resistance to these factors, ensuring longer service life and enhanced product safety.

Growth of Plastic Pallets Manufacturers in Delhi

Delhi, as a major industrial and commercial hub in India, has witnessed a significant rise in the adoption of plastic pallets. The city's expanding manufacturing base, coupled with increasing exports and stringent regulatory requirements, has fueled the demand for reliable and hygienic pallet solutions. Manufacturers in Delhi cater not only to local industries but also to national and international markets, leveraging their strategic location and advanced manufacturing capabilities.

Key Manufacturers in Delhi

1. Swift Technoplast Pvt. Ltd.

Swift Technoplast Pvt. Ltd. is a leading manufacturer of plastic pallets in Delhi, known for its innovative product designs and high-quality standards. The company offers a diverse range of pallet solutions tailored to meet specific industry requirements, including heavy-duty pallets for automotive and industrial applications, and hygienic pallets for pharmaceutical and food sectors. Swift Technoplast emphasizes customization and sustainability in its manufacturing processes, contributing to efficient material handling practices in Delhi's industrial landscape.

2. Vishakha Industries

Vishakha Industries specializes in manufacturing durable and cost-effective Plastic Pallets Manufacturers in Delhi. The company's pallets are renowned for their robust construction, resistance to chemicals and impact, and compatibility with automated handling systems. Vishakha Industries caters to a wide range of industries, from electronics and textiles to logistics and distribution, providing tailored pallet solutions that optimize operational efficiency and product safety.

3. Modi Industries

Modi Industries is a prominent player in Delhi's plastic pallet manufacturing sector, offering a comprehensive portfolio of pallets designed for various industrial applications. The company's pallets are crafted from high-quality plastics, ensuring reliability in demanding environments such as warehouses, distribution centers, and manufacturing facilities. Modi Industries focuses on continuous product innovation and customer-centric solutions, supporting Delhi's evolving logistics needs with advanced material handling solutions.

Advantages of Plastic Pallets

Plastic pallets offer numerous advantages that make them preferable over traditional wooden pallets, especially in Delhi's industrial environment:

Durability: Plastic pallets are resistant to moisture, corrosion, and impact, maintaining their structural integrity over extended periods.

Hygiene: Unlike wooden pallets, plastic pallets do not absorb liquids or harbor bacteria and pests, ensuring compliance with strict hygiene standards in industries such as pharmaceuticals and food processing.

Safety: Plastic pallets are designed to be lightweight yet robust, reducing the risk of workplace injuries during handling and ensuring the safe transport of goods.

Environmental Sustainability: Many plastic pallets are recyclable and reusable, contributing to sustainable practices by minimizing waste generation and promoting resource efficiency.

Market Trends and Outlook

The market for Plastic Pallets Manufacturers in Delhi is poised for continued growth, driven by ongoing industrialization, infrastructure development, and advancements in logistics management. Manufacturers are focusing on enhancing product durability, customization capabilities, and sustainability to meet the diverse needs of local industries. The adoption of automated warehouses and smart logistics solutions further augments the demand for versatile and reliable plastic pallets that integrate seamlessly into modern supply chains.

Conclusion

Plastic pallets have become indispensable assets in Delhi's logistics and supply chain operations, offering superior durability, hygiene, and sustainability advantages over conventional alternatives. Leading manufacturers such as Swift Technoplast Pvt. Ltd., Vishakha Industries, and Modi Industries are at the forefront of this transformation, providing innovative and tailored pallet solutions that meet the evolving needs of Delhi's industrial landscape. As the demand for efficient material handling solutions continues to grow, plastic pallets will play a pivotal role in enhancing logistics efficiency and sustainability across diverse sectors in Delhi and beyond.

Locate Us

Sonipat, Haryana - 131301

+91-8700900663

1 note

·

View note

Text

India Pallets Market: Innovations Driving Efficiency in Supply Chain Management

Introduction to India Pallets Market: The pallets market in India plays a crucial role in the logistics and supply chain industry by providing an efficient and standardized means of handling, storing, and transporting goods. Pallets are flat platforms made from wood, plastic, metal, or composite materials, designed to support and protect goods during their movement within warehouses, distribution centers, and during transportation.

Types of Pallets:

Wooden Pallets: Traditional and widely used in India, wooden pallets are known for their affordability and recyclability. They are suitable for various industries, including agriculture, pharmaceuticals, FMCG (Fast Moving Consumer Goods), and more.

Plastic Pallets: Plastic pallets are gaining popularity due to their durability, resistance to moisture and chemicals, and longevity. They are often used in industries requiring strict hygiene standards, such as food and pharmaceuticals.

Metal Pallets: These are sturdy and durable, making them ideal for heavy-duty industries like automotive and manufacturing. They are known for their longevity and ability to withstand harsh conditions.

Composite Pallets: These are a combination of different materials, often blending the benefits of wood and plastic. They offer a balance between strength, durability, and environmental considerations.

Market Trends:

Rise of Plastic Pallets: The demand for plastic pallets is growing due to their superior attributes in terms of hygiene, durability, and reusability. Industries are gradually shifting towards plastic pallets to comply with international hygiene standards and to reduce the risk of contamination.

Automation Integration: With the increasing use of automation in warehouses and distribution centers, pallets are being designed to be compatible with automated systems, such as robotic forklifts, enhancing efficiency and reducing labor costs.

Eco-Friendly Focus: There is a growing awareness of environmental concerns, leading to a demand for eco-friendly pallet options. This has led to the development of pallets made from recycled materials and those designed for easy recycling after their lifecycle.

Pallet Rental and Sharing Models: As businesses look to optimize costs and reduce wastage, pallet rental and sharing models are gaining traction. This allows companies to access pallets as needed, reducing the need for long-term ownership and storage.

Key Players: The India pallets market is served by several manufacturers and suppliers, including:

Supreme Industries Ltd.

Balmer Lawrie & Co. Ltd.

Swift Technoplast Pvt. Ltd.

U.P. Twiga Fiberglass Ltd.

Spanco Enterprises

Schoeller Arca Time Materials Handling Solutions India Pvt. Ltd.

Challenges:

Lack of Standardization: The absence of a uniform standard for pallet sizes and designs can lead to inefficiencies in logistics operations.

Infrastructure Constraints: Inadequate transportation and storage facilities can impact the overall effectiveness of pallet usage.

Limited Awareness: Some businesses, particularly smaller ones, might not be aware of the benefits of using pallets in their operations.

Conclusion: The India pallets market is witnessing dynamic growth due to increasing industrialization, changing consumer preferences, and a drive towards efficiency and sustainability. As industries evolve, the choice of pallets will continue to be influenced by factors such as material characteristics, environmental concerns, and technological advancements.

0 notes

Text

INDIA PALLETS MARKET ANALYSIS (2020-2027)

Pallets are an important tool across the logistics industry. It is a flat platform that can carry the load in the warehouse. They are basically used to store, protect, store, and transport materials during material handling. It is a portable platform and improves the operational efficiency of the warehouses by enabling easy movement of stacked goods.

The India pallets market is projected to surpass INR 25000 Cr. by the end of 2027, in terms of revenue, growing at CAGR of 13.9% during the forecast period (2020 to 2027).

Drivers

Rapid growth in the manufacturing industries in India is predominantly propelling the market growth of the pallets. According to the India Brand Equity Foundation, manufacturing industry has emerged as one of the high growth sectors in India. India is expected to become the fifth largest manufacturing country in the world by the end of the year 2020. The government aims to achieve a 25% GDP share and 100 million new jobs in the sector by 2022.

Increasing development of the warehousing industry in India is expected to drive the market growth of the pallets. Increase in the overseas trade coupled with the expansion of the warehousing industry in India is another major factor expected to propel the market growth of the pallets. Moreover, improvement in the supply chain management is creating demand for warehouses which in turn augmenting the market growth of the pallets.

On basis of states, other states dominated the India pallets market in 2019, reporting 31% market share in terms of revenue, followed by Maharashtra and Tamil Nadu, respectively.

Figure 1. India Pallets Market, Revenue Share (%), By States, 2019

Market Restraints

The decline in international trade from India is projected to hamper the market growth of the pallets. For instance, in September 2019, India’s exports declined for the second time in three months in August as global trade tensions and sluggish demand brought down shipments by 6.1%.

An environmental concern associated with the plastic pallets and strict regulations regarding the production of plastic is projected to hamper the market growth of the pallets.

Market Opportunities

Increasing utilization of pallets in the pharmaceutical industry for storing and transportation of the pharmaceutical product is projected to offer new market opportunities. Growing geriatric population coupled with the increasing prevalence of the chronic disease is creating demand for healthcare products such as drugs and devices. The growth of the pallets market is also attributed to the expansion of the pharmaceutical industry.

The advent of disposable plastic pallets as it has a lower negative impact on the environment is projected to offer potential opportunities in the near future. Growing demand for lightweight plastic pallets as they increase the payload capacity and are also easy to clean is propelling the market growth. Also, the use of disposable plastic pallets reduces the cleaning and shipping cost time. Hence, the growing use of disposable plastic pallets is projected to bolster the market growth.

Figure 2. India Pallets Market – Opportunity Analysis

Market Trends

Expanding e-commerce industry due to growing trend of digitalization and online shopping is creating demand for logistics services is projected to foster the market growth pallet. Increasing spending by consumers on housing as well as other consumer goods due to increasing disposable income is further expected to foster the market growth of the pallets. Moreover, the expansion of chemical industries is also creating demand for the logistics of chemical products thereby fueling the market growth.

RFID chips embedded pallets are gaining popularity in the market and this is expected to spur the market growth of the pallets. RFID chips embedded pallets enable easy traceability and real-time information of the products during transportation. Moreover, it also measures the temperature, humidity, and impact during transportation. RFID chips embedded pallets are majorly used in the chemical, pharmaceutical, and food &beverage industry.

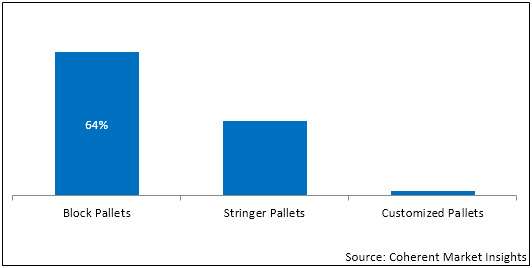

Figure 3. India Pallets Market, Revenue Share (%), By Structural Design, in 2019

On the basis of structural design, block pallets the India pallets market in 2019 with around 64% of market share in terms of revenue, followed by stringer pallets and customized pallets, respectively.

India pallets Market - Impact of Coronavirus (Covid-19) Pandemic

Rapid surge in demand for medical supplies, household essentials, and food products as compared to the pre-Covid-19 scenario has led to the changes in product category in this distribution channel. These changes has boosted the demand for corrugated boxes, cartons, pallets and other packaging products and is further expected to foster the growth of the India pallets Market till mid quarter of 2021.

Get free sample copy here: https://www.coherentmarketinsights.com/insight/request-sample/4036

Competitive Section

Key players are operating in the India pallets market are Saraswati Engineering Limited, Schoeller Arca TIME Material Handling Solution, Mekins Group, Swift Technoplast Private limited, Doll Plast Pallets, JIT Wood Packaging, LEAP India Pvt. Ltd., Spanco Enterprises, Bharadwaj Packaging Private Limited, Aristoplast Products Pvt. Ltd., B.D. Industries (India) Pvt. Ltd., Total Pack, and DNA Packaging Systems

Download PDF brochure: https://www.coherentmarketinsights.com/insight/request-pdf/4036

About Us:

Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions.

What we provide:

• Customized Market Research Services

• Industry Analysis Services

• Business Consulting Services

• Market Intelligence Services

• Long term Engagement Model

• Country Specific Analysis

Contact Us:

Mr. Shah

Coherent Market Insights Pvt. Ltd.

Address: 1001 4th ave, #3200 Seattle, WA 98154, U.S.

Phone: +1-206-701-6702

Email: [email protected]

Source: https://www.coherentmarketinsights.com/market-insight/india-pallets-market-4036

0 notes

Video

youtube

Advanced Design Hydraulic Hand Pallet Truck By Swift Technoplast Private Limited, Mumbai - https://youtu.be/mvCJmsN97Ms

0 notes

Text

Increasing Demand From Manufacturing Industries To Impel The Growth Of Pallet Market In Future

The global pallet market is segmented into product type such as plastic pallets, corrugated cardboard pallets, wood pallets, metal pallets, lightweight plywood pallets and press wood pallets. Among these segments, wood pallet segment is expected to occupy top position in overall pallet market during the forecast period. Further, benefits of wood pallets such as high strength, lightweight, recyclable and cost-effectiveness are believed to be major growth driver of the wood pallet market. Moreover, rising demand from end use industries is anticipated to drive the growth of the wood pallet market. However, plastic pallet segment is projected to showcase highest CAGR during the forecast period.

Global pallet market is expected to flourish at a significant CAGR of 4.8% during the forecast period. Moreover, the global pallet market is expected to garner significant revenue by the end of 2021. Increasing shipping activities in the world and positive growth of food & beverage & manufacturing industry is anticipated to fuel the demand for pallets in the next few years.

Request Free Sample Report @ https://www.researchnester.com/sample-request/2/rep-id-118

Asia Pacific captured the highest percentage of market share in overall pallet market in 2016. Further, Asia-Pacific is anticipated to witness highest CAGR during the forecast period. Factors such as increasing number of warehouses and storage facilities coupled with rising number of manufacturing plants in the region are believed to propel the growth of the Asia Pacific pallet market. Moreover, Middle East and Africa region is expected to showcase significant growth during the forecast period. Growing trade volume in the region is anticipated to accelerate the demand for pallet market.

Growth in Trade Activities across the Globe

Growth of manufacturing activities in emerging nations is anticipated to accelerate the demand for pallets in the upcoming years. Moreover, rise in the number of product shipping is also likely to fuel the growth of pallet market. Moreover, as per United Nations conference on trade and development, in 2015, global shipments expanded by 2.1. Moreover, world shipments are expected to expand in the upcoming years which further, are anticipated to escalate the demand for pallets.

Rapid Urbanization

Rapid urbanization in the world has positively impacted the growth of food & beverage, manufacturing and construction industries. Moreover, increasing installation of manufacturing units by these companies are expected to positively impact the demand for pallet during the forecast period.

Although, fluctuation in the raw material price and low availability of raw material suppliers are some of the key factor which is likely to dampen the growth of pallet market during the forecast period.

The report titled “Global Pallet Market Analysis & Opportunity Outlook 2021” delivers detailed overview of the global pallet market in terms of market segmentation by product, by application, by shape and size, by usage and by region.

Further, for the in-depth analysis, the report encompasses the industry growth drivers, restraints, supply and demand risk, market attractiveness, BPS analysis and Porter’s five force model.

To Know More Ask The Analyst @ https://www.researchnester.com/ask-the-analyst/rep-id-118

This report also provides the existing competitive scenario of some of the key players of the global pallet market which includes company profiling of Totre Packaging, Spruce Impex Pvt Ltd., Gee Enterprises, Spanco Enterprises, Pilco Storage Systems Private Limited, Swift Technoplast Private Limited, Brambles Limited, Loscam Australia Pty Ltd and ORBIS Corporation. The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the global pallet market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

Buy This Premium Report @ https://www.researchnester.com/payment/rep-id-118

About Us:-

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact for more Info:

Ajay Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Swift introduces its new 4 Drum Spill Containment Pallet for Maximum hazardous Spill Prevention! Engineered to protect your workspace and the environment. . Swift Technoplast Private Limited www.swiftind.co.in +91 88888 25423 [email protected]

#swift technoplast#spill containment#Spill Pallets#Workplace Safety#Sustainability#Eco friendly#Plastic pallet#plastic pallets#plastic industry#plastic manufacturer#Drum Spill Containment Pallets#Drum Spill Pallets

0 notes

Text

Meet Swift at MH15 SAMA Extravaganza 2024 Road Safety Event, Igatpuri

Navi Mumbai – Swift Technoplast, a global leader in road safety solutions, is proud to announce its participation in the upcoming MH15 SAMA Extravaganza 2024 event as a Platinum Sponsor on 31st Aug & 1st Sep at Jayshin lake, Vaitarana Resort, Igatpuri. With over 16 years of experience in the industry, our company has been at the forefront of innovative product design and development, providing premium quality road safety products to over 30 countries worldwide.

The SAMA event is one of the most significant gatherings for industry professionals, offering a platform to showcase the latest advancements and trends in road safety. As a Platinum Sponsor, Swift will be highlighting its commitment to enhancing road safety standards through cutting-edge technology, smooth processes, and a steadfast dedication to quality.

“We are honored to be part of the “MH15 SAMA Extravaganza 2024” event as a Platinum Sponsor,” said Mr. Krishna Marathe, Managing Director of Swift Technoplast. “This opportunity allows us to connect with industry leaders, share our insights, and demonstrate our ongoing commitment to improving road safety across the globe.

Visitors to our booth at SAMA will have the opportunity to explore our premium products and learn more about our excellent solutions designed to meet the evolving needs of the road safety sector. Our team of experts will be on hand to discuss how our innovations can help enhance safety standards and address the unique challenges faced by the industry today.

0 notes

Text

Maximize storage efficiency with Swift's Drive-in rackable Plastic Pallets. It is designed with extended side edges for secure racking.

.

🏨 Swift Technoplast Private Limited 🌐 www.swiftind.co.in ☎ +91 9930 000 730 📨 [email protected]

#SwiftTechnoplast#RackablePallets#DriveInRacking#StorageSolutions#WarehouseEfficiency#PlasticPallets

0 notes

Text

Rebar Safety Caps: A Small Investment for Big Safety Benefits

In the construction industry, safety is paramount. One of the simplest yet most effective safety measures on a worksite is the use of rebar safety caps. Though they may seem like a small and negligible component,

the benefits of rebar safety caps are critical in preventing severe injuries and protecting workers from potentially fatal accidents.

The Hidden Dangers of Exposed Rebar

Reinforcing bars or rebars are important as they add strength to the concrete structures. But expose during construction and they prove dangerous. Exposed rebar have sharp ends on them which can become dangerous if, for instance, a worker trips/falls onto one. Exposed rebar can be very dangerous causing deep puncture wounds or impalements that can kill.

How Rebar Safety Caps Work

Safety caps, for rebar are created to shield the exposed tips of rebar and offer a barrier to reduce the risk of injuries. The most common types are:

Mushroom Caps: These are basic plastic caps that fit over the rebar ends. They are ideal for preventing minor scrapes and scratches.

Square Rebar Safety Caps: These are all metal caps built into a plastic outer shell These offer more protection by transferring the impact force across a larger area.

Safety Caps with Steel Inserts: For high-risk sites, these caps are supplemented by steel in order to reduce the risk of impalement even more.

Key Benefits of Using Rebar Safety Caps

Injury Prevention: Rebar safety caps are basically used to avoid injuries. They serve as an intercusion and have a protective function by limiting the risk of puncture and cut due to covering sharp, exposed ends.

Compliance with Safety Regulations: Most construction sites must adhere to strict safety regulations set by organizations such as OSHA (Occupational Safety and Health Administration). Using rebar safety caps helps companies meet these safety standards, reducing the risk of legal issues and fines.

Cost-Effective Safety Solution: Invest in safety caps for rebar as it is an investment that can lead to long term savings on costs. The costs associated with workplace injuries — medical bills, legal fees, lost productivity, and increased insurance premiums — far outweigh the minor expense of these caps.

Increased Worker Confidence: Visible safety measure helps workers feel secure and confident. In this way, productivity and less risk can improve the environment in general.

Choosing the Right Rebar Safety Caps for Your Project

Then again, not all rebar safety caps are the same and picking from a particular kind depends on what your construction site specifics. Consider the following factors:

Rebar Size and Diameter: Ensure the cap fits securely over the rebar to provide adequate protection.

Site Conditions: For sites with heavy machinery or high foot traffic, opt for heavy-duty caps with steel inserts.

Compliance Requirements: Check local safety regulations to ensure the chosen rebar safety caps meet the necessary standards.

Best Practices for Using Rebar Safety Caps

Inspect Regularly: Rebar safety caps should be inspected frequently for damage or wear and tear. Replace any that are cracked or deformed to maintain their protective function.

Train Workers: Educate your team on the importance of using rebar safety caps and the risks of exposed rebar. This helps foster a culture of safety on the site.

Standardize Usage: Make rebar safety caps a standard safety requirement on your construction sites. Consistent use reduces the chances of accidental injuries.

Conclusion

Rebar safety caps are a small but crucial investment that can significantly enhance the safety of your construction site. They save a lot of money as it keeps serious injuries away and comply with the safety laws for a low investment. Prioritizing such safety measures not only protects your workers but also helps build a reputation for safety and reliability in the industry. At Swift Technoplast, with 16+ years of expertise, we offer durable and eco-friendly rebar safety caps that meet industry safety standards. Choose Swift Technoplast for reliable solutions that keep your job site and team protected.

0 notes

Text

Eco-Friendly and Efficient: The Future of Plastic Pallets in Industry

In today’s evolving world, which prioritizes sustainability and environmental awareness, companies are increasingly seeking eco-friendly options that not only enhance efficiency but also positively impact the environment. An example of such a solution that is gaining popularity is the adoption of plastic pallets.

These versatile instruments signify a move, towards embracing eco methods, in the logistics and supply chain sectors.

The Benefits of Plastic Pallets

Sustainability: Plastic pallets are designed to be used and reused throughout their lifetime and are made of recyclable materials. They provide a more sustainable choice compared to other materials, aligning with eco-friendly business practices.

Durability and Longevity: Plastic pallets endure harsh conditions and heavy loads without splintering or warping over time, unlike traditional pallets. They are a choice as they last longer and reduce the amount of waste going to landfills.

Hygiene and Safety: In sectors, like the food and pharmaceutical industries cleanliness is crucial Plastic pallets boast porous surfaces that are simple to sanitize preventing contamination and meeting safety standards The absence of edges or splinters adds a layer of safety, for employees when handling and moving them

Cost-Effectiveness: Although plastic pallets may require an investment compared to alternative choices initially; their durability and minimal maintenance requirements can ultimately lead to cost savings in the long run. Moreover plastic pallets lighter weight can contribute to reduced transportation expenses and better fuel efficiency.

The Future of Plastic Pallets in Industry

The rising emphasis, on sustainability in industries is driving a growing need for friendly items such, as plastic pallets. Several trends indicate that plastic pallets will play a crucial role in the future of logistics and supply chain management:

Increased Recycling Initiatives: Many businesses are adopting closed loop systems to recycle plastic pallets once they have served their purpose aiming to minimize impact and promote an economy.

Technological Advancements: Advancements in manufacturing have led to the development of more effective plastic pallets with upgraded designs and materials, enhancing their capabilities across various uses.

Global Standards and Certifications: As companies prioritize sustainability as a measure of success, in the business landscape they will increasingly pursue certifications for their packaging and materials. In this context, plastic pallets that adhere to eco criteria are poised to emerge as the top choice, for businesses aiming to demonstrate their dedication to environmental responsibility.

E-commerce Growth: The rise of online shopping has led to an increased demand, for logistics services like never before Plastic pallets offer an lightweight solution that can improve effectiveness and reduce shipping costs making them an ideal option, for the e commerce sector.

Conclusion

It’s clear that there is a shift, towards logistics solutions lately. Plastic pallets are leading the way by providing eco friendly options that enable businesses to boost efficiency and lessen their environmental impact.

At Swift Technoplast, we provide innovative plastic pallet solutions that meet the demands of modern industries, helping you optimize your supply chain and promote sustainability.

#heavy duty plastic pallets#plastic pallets near me#pallet plastic#plastic pallets manufacturer#plastic pallets supplier#hdpe pallet#pvc pallets#shipping pallet

0 notes

Text

Introducing All New Drum Spill Pallets for Maximum Containment

Improve Your Spill Management! Managing hazardous liquids and chemicals requires top-notch spill containment solutions to protect your employees and the environment.

The all new drum spill containment pallets models, are designed to provide superior protection and efficiency in your workplace.

Here are the top reasons why these new pallets are the ideal choice for your spill containment needs:

1. High Sump Capacity for Maximum Protection

Swift’s Four Drum Spill Pallet features upto 525-liter sump capacity, making it the perfect solution for managing larger spills. The large sump ensures even in the event of heavy leaks; spills are contained and do not reach the floor, reducing slip hazards. On the other hand, the Two Drum Spill Pallet offers a reliable 200-liter sump capacity, providing effective containment for smaller spill management needs.

2. Built for Durability and Strength

Both the Drum Spill Containment Pallets are built from heavy-duty, long-lasting materials. These pallets are strong enough to carry dozens of drums at the same time without buckling or breaking under any conditions. If you have to keep chemicals, oils, and other hazardous liquids or even acid containers on these pallets, then there is certainly a peace of mind with their solid construction.

3. Compliance with Safety Standards

Our pallets ensure full compliance with EPA 40 CFR 264.175, SPCC, and NPDES regulations, making it easier for your business to meet all necessary safety standards. By choosing the Drum Containment Pallets, we can remain in compliance and prevent costly fines and dangerous spills that could harm nature.

4. User-Friendly Design for Easy Handling

With features like removable grates and a low-profile design, these pallets are not only easy to use but also easy to maintain. You can quickly load and unload drums using forklifts or manual lifting, while the grates simplify cleanup. Plus, the lightweight construction allows for seamless mobility and positioning within your workspace.

5. Versatile Solutions for Various Applications

These new drum spill containment pallets are ideal for many different industries. No matter if you would be using it in manufacturing, chemical handling these pallet specialization meets your spill containment needs. They are versatile drums, used in numerous different work environments due to their ability to accommodate a few drum sizes and configurations.

6. Cost-Effective Long-Term Investment

By choosing High quality Drum Spill Containment Pallets, you’re investing in a solution that saves money in the long run. These pallets help prevent spills that could lead to costly cleanups and equipment damage. This way, you reduce the probability of fines or legal problems.

In conclusion, All in all, Swift Technoplast introduces its new drum spill containment pallets the DSCP-SL2 for 200-liter capacities and the DSCP-SL4, which comes with a sump capacity of up to 525 liters, ensure complete protection while ensuring compliance throughout your business premises. Whether you need a compact solution or a high-capacity option, these pallets improve workplace safety and efficiency.

Don’t leave spill management to chance—upgrade to our all-new drum spill containment pallets today and safeguard your workspace, employees, and the environment.

#Spill Containment Pallet#Spill Pallets#Spillage Pallet#Drum pallet#Pallet Drum#pallet spill containment#Drum Spill Containment Pallets#Drum Spill Pallets

0 notes

Text

The Advantages of Injection Molded Pallets: Durability, Efficiency, and Sustainability in Logistics

Pallets play a crucial role in the logistics world and, as such, picking out the right ones can be hard when you want to strike that perfect balance between efficiency and sustainability.

Injection molded pallets provide durability, light weight and are environmentally friendly which has made them the optimal choice for most businesses seeking ways to make their operations run smoothly.

1. Durability You Can Rely On Injection molded pallets are made from HDPE, which resists moisture, chemicals, and UV rays. It is especially heavy-duty for maximum load capacity. Unlike traditional pallets, they won’t splinter or rot, ensuring safe transportation and reducing replacement frequency. Additionally, this durability means less downtimes and supply chain interruptions.

2. Lightweight for Enhanced Efficiency Pallets are lighter than metal options, which makes them easier to handle and stack. This lightweight design may maximize storage efficiency and reduce shipping rates that helps overall operations in terms of performance. It is also easy to maneuver that can result in quick load and unload times, promoting faster productivity as well.

3. Environmentally Friendly Solution Injection molded pallets are often made from recycled HDPE and are fully recyclable themselves. An environmentally conscious method by its nature reduces waste and resource utilization with time, this fits right into the sustainability objectives. By choosing these pallets, businesses can also demonstrate their commitment to environmentally responsible practices to their customers.

4. Versatile Applications

These pallets are most commonly used in the pharmaceutical and food industry as they ensure cleanliness, hygiene, and can be manufactured with a material that suits customers’ requirements. This makes them more versatile and useful for a range of products across various packaging dimensions.

5. Cost-Effectiveness Over Time Although initial cost is relatively higher, the longevity and low weight of this material can result in significant savings due to high-resistance pallets allowing lower replacement rates and reduced shipping expenses. This means saving over the long haul. In the end, these pallets can even help to boost your business’s bottom line.

6. Our versatile HDPE Pallets Offering: Our HDPE injection-molded pallets include the SIP-M24–1212DH, SIP-M24–1210DM, and SIP-M24–1212NH models. Each is durable and versatile, with the SIP-M24–1212DH featuring a double-sided design, the SIP-M24–1210DM being lightweight and robust, and the rackable SIP-M24–1212NH suitable for heavy racking and lightweight cargo packaging. All are made from high-density polyethylene for maximum resistance.

Conclusion

Businesses looking for a blend of sustainability and economy will make the perfect investment with Swift Technoplasts’s injection molded pallets. They can raise the bar with durability and sustainability to any operations in logistics, thus being a practical solution for long-term saving.

#Injection Molded Pallets#Durable Plastic Pallets#Sustainable Pallets for Logistics#Lightweight HDPE Pallets#Recyclable Pallets for Supply Chain#Cost-Effective Pallets#Pallets for Warehouse Efficiency#Plastic Pallets for Shipping#HDPE Pallets Manufacturer#Pallets for Material Handling#Heavy-Duty Rackable Pallets#HDPE injection molded#plastic pallets

0 notes

Text

Roto-Molded Pallets: A Modern Solution for Stronger, Safer, and Ease of Material Handling

The Modern Roto Molded Plastic Pallets are efficient and reliable for material handling solutions and more crucial than ever in the new industrial scenario. At all times, warehouses, factories and distribution centers are in need of the finest and quality pallets in place to help streamline their operations.

For those, roto-molded pallets are possibly the strongest answer as they can provide both the durability and safety that one wants and stay active for a long time compared to regular traditional pallet options.

1. Strength and Durability for Heavy-Duty Applications One of the best characteristics about roto-molded pallets is that they are excellent in dealing with heavy-duty loads. Even assembled pallets can be prone to weak points—between many points of attachment—however due to rotational molding the pallets are being created in one piece structure, and these pallets avoid those problems. This makes them ideal for purpose applications such as holding heavy weights in storage or to be transported.

2. Custom Design for Load-Bearing Efficiency Roto-molded pallets offer the flexibility of custom design to meet specific load-bearing capacities. This customization ensures that businesses can choose the perfect pallet size and strength for their unique operations, maximizing efficiency while maintaining safety. Whether you have to handle lower loads or severe weights, roto-molded pallets can be designed to accommodate your exact requirements, making them a truly modern solution for varying industrial needs.

3. Sturdy, One-Piece Construction for Longevity The one-piece construction of roto-molded pallets significantly contributes to their long-lasting nature. Since they are molded as a single unit, there are no joints or seams that could weaken over time or under stress. It leads in an extremely durable product that needs minimum maintenance, providing long-term cost savings. For companies seeking a solution that reduces replacement frequency and improves overall efficiency, roto-molded pallets are the ideal choice.

4. Enhanced Safety with Anti-Skid Design Safety is always a concern in material handling, and roto-molded pallets are designed with this in mind. They often come with specially designed anti-skid tops, reducing the risk of goods slipping during transport or storage. This feature not only enhances the safety of workers but also protects valuable cargo from damage, Ensuring seamless and secure operations.

5. Compatibility with Modern Material Handling Equipment In today’s highly mechanized environments, seamless integration with material handling equipment is crucial. Roto-molded pallets are suitable for most standard equipment, like forklifts, pallet jacks, and automated conveyor systems. This compatibility means that businesses can upgrade their material handling without having to question if their pallets will fit into their current infrastructure or not.

Conclusion

As industries continue to evolve, finding reliable and innovative material-handling solutions is essential for maintaining operational efficiency. Roto-molded pallets are an obvious choice for a modern solution to meet the demanding industrial setting under one roof. Their superior strength, customizability, and safety features make them a valuable asset for any business seeking to improve its material handling processes.

For reliable, durable pallet solutions, Swift Technoplast offers quality and customization tailored to your material handling needs.

#Plastic pallet price#heavy duty plastic pallets#plastic pallets near me#plastic pallets manufacturers in india#plastic pallets for sale near me#plastic pallets#cost of plastic pallets#pallet plastic#plastic pallets manufacturer#RotomoldedPallets#Roto molded pallet#roto pallet#roto molded#roto molded pallets

0 notes

Text

निर्माल्य कलश: परंपरा व पर्यावरणाचा समतोल

धार्म��क विधी, पूजा, आणि साधनांमध्ये निर्माल्य म्हणजेच पूजा सामग्रीचे महत्व अतिशय महत्वाचे असते. निर्माल्य म्हणजे पूजा आणि धार्मिक क्रियाकलापांमध्ये वापरलेले फुलं, पानं आणि इतर नैसर्गिक पदार्थ. त्यामुळे, हे पदार्थ पर्यावरणाला हानी न पोहोचवता सुरक्षितपणे व्यवस्थापित करण्यासाठी निर्माल्य कलशाची निर्मिती करण्यात आली आहे. प्रत्येक धार्मिक कार्यक्रमाच्या शेवटी उरलेले निर्माल्य योग्य प्रकारे विसर्जित करणे आपली सामाजिक जबाबदारी आहे.

आधुनिक काळात सण उत्सवांत प्लास्टिकचा हि मोठ्या प्रमाणात वापर होताना आढळून येते. आणि ते प्लास्टिक निर्माल्य च्या माध्यमातून नदी तलाव व इतर जलाशयांत विसर्जित करण्यात येते त्यामुळे पर्यावरणाला मोठा धोका निर्माण होताना आपल्यास दिसून येते. पाण्याची नैसर्गिक शुद्धतेची पातळी खालावताना जाणवत आहे.

पर्यावरणावर होणारे दुष्परिणाम लक्षात घेता, म्हणूनच निर्माल्य कलश एक उत्कृष्ट पर्याय ठरत आहे. पूजेचे निर्माल्य आपण निर्माल्य कलशात दान करून आपण धार्मिक कर्तव्यांचं पालन करतानाच पर्यावरणाचे संरक्षण देखील करतो.

निर्माल्य म्हणजे काय? Nirmalya हा शब्द संस्कृत भाषेतील ‘निर्मल’ या शब्दापासून आलेला आहे, ज्याचा अर्थ शुद्ध किंव्हा पवित्र असा होतो. पूजा किंवा धार्मिक कार्यक्रमानंतर उरलेले फुलं, अक्षता, हळद-कुंकू, अगरबत्ती इत्यादींना निर्माल्य असे म्हणतात. याप्रकारे, हे सर्व पदार्थ निसर्गात विसर्जित करणं ही एक पारंपरिक प्रथा आहे, पण अनियंत्रित पद्धतीने विसर्जन केल्याने पर्यावरणाची हानी होऊ शकते.

निर्माल्य कलशाची गरज! धार्मिक उत्सव आणि पूजांच्या वेळी मोठ्या प्रमाणात निर्माल्य निर्माण होते. हे निर्माल्य नैसर्गिक असले तरी, त्याचे व्यवस्थापन योग्य पद्धतीने न केल्यास ते पर्यावरणास हानी पोहोचवू शकते. पर्यावरणाच्या संरक्षणासाठी निर्माल्याचे योग्य व्यवस्थापन करणे खूप महत्त्वाचं आहे.

निर्माल्य कलश ही एक सोपी, परंतु प्रभावी उपाययोजना आहे. या कलशांमध्ये निर्माल्य गोळा करून त्याचं विसर्जन योग्य ठिकाणी करता येते . यामुळे नद्या, तलाव आणि इतर जलस्रोतांच्या प्रदूषणाचं प्रमाण कमी होऊन पिण्यायोग्य पाण्याचे आपण संवर्धन करू शकतो.

निर्माल्य कलशाचे प्रकार “स्विफ्ट टेक्नोप्लास्ट“ सारख्या आधुनिक कंपन्या निर्माल्य कलशाच्या उत्पादन��त आघाडीवर आहेत. स्विफ्ट टेक्नोप्लास्ट च्या माध्यमातून हे कलश दोन प्रकारात उपलब्ध आहेत:

Nirmalya Kalash with Plastic Stand: हा प्रकार हलका आणि टिकाऊ आहे. प्लास्टिकचा वापर करून बनवलेला हा कलश स्टँड उपयोगात सोपा आणि दीर्घकालीन टिकाऊपणाचा आहे.याचा पर्यावरणास कोणताही अपाय नाही कारण यात वापरले जाणारे प्लास्टिक हे १०० टक्के पुनर्वापर करण्यायोग्य आहे.

Nirmalya Klash with MS Stand: हा प्रकार अधिक मजबूत आणि दीर्घकालीन टिकाऊपणाचा आहे. माइल्ड स्टीलचा वापर करून बनवलेला हा कलशस्टँड वजनाने जड असला तरी, त्याची टिकाऊपणा आणि स्थिरता उत्तम आहे.

निर्माल्य कलशाचे फायदे

पर्यावरण पूरक: निर्माल्य कलश वापरल्यामुळे निर्माल्याचे योग्य व्यवस्थापन होऊन पर्यावरणाचे संरक्षण होते.

सौंदर्यदृष्ट्या आकर्षक: हे कलश विविध आकार आणि रंगांमध्ये उपलब्ध असल्यामुळे धार्मिक स्थळांच्या सौंदर्यात भर घालतात.

दीर्घायुषी: निर्माल्य कलश उच्च दर्जाच्या प्लास्टिकपासून बनवलेले असल्यामुळे ते दीर्घकाळ टिकतात.

सुरक्षित: प्लास्टिकने बनवलेल्या या कलशांमुळे निर्माल्याचं संकलन सुरक्षित आणि स्वच्छ पद्धतीने करता येते.

निर्माल्य कलशाचा वापर कसा करावा?

पूजेच्या शेवटी निर्माल्य संकलित करा: प्रत्येक धार्मिक कार्यक्रमाच्या शेवटी उरलेले निर्माल्य हे निर्माल्य कलशमध्ये ठेवा आणि त्यात निर्माल्य जमा करा.

योग्य विसर्जन: एकदा कलश भरल्यावर, ते योग्य ठिकाणी जसं की, कंपोस्ट पिट, बागेतील खतं, किंवा महापालिकेच्या ठरवलेल्या ठिकाणी विसर्जित करा.

पुनर्वापर: निर्माल्य कलश स्वच्छ करून पुन्हा वापरता येतात, त्यामुळे एकदा घेतलेला कलश दीर्घकाळ चालतो.

कलश हा पर्यावरण पूरक, सुरक्षित आणि सोपा उपाय आहे. धार्मिक पूजेसाठी निर्माण होणाऱ्या निर्माल्याचे व्यवस्थापन करण्यासाठी हा एक उत्तम पर्याय आहे. निर्माल्य कलशाच्या वापरामुळे आपल्याला आपल्या धार्मिक कर्तव्यात कुठलाही अडथळा येत नाही आणि त्याचबरोबर पर्यावरणाचं संरक्षण देखील होते. त्यामुळे, Swift Technoplast सारख्या कंपन्या या अभिनव कल्पनांना प्रत्यक्षात आणून आपल्याला एक उत्कृष्ट पर्याय पुरवत आहेत. त्यामुळे आपल्या धार्मिक विधींमध्ये निर्माल्य कलशाचा वापर करून आपण पर्यावरण पूरक जीवनशैली अंगिकारू शकतो.

#Nirmalya kalash#Nirmalya kumbh kalash#Nirmalya dan Kalash#plastic products#plastic product manufacturer#plastic product supplier#kalash#nirmalya kalash near me

0 notes