#roto molded pallets

Explore tagged Tumblr posts

Text

Why Plastic Pallets Are in High Demand Across Industries in India

In today’s fast-paced and competitive industry environment, efficient logistics and safe product handling are critical to success. One such invention that has made a significant difference is Plastic pallets.

For businesses across India, where diverse industries operate in varying climates and conditions, plastic pallets are proving to be the ultimate choice. Here’s why:

1. Durability That Outlasts Traditional Options

Plastic pallets are designed to withstand significant weight and rigidity. Though classic pallets are susceptible to splitting, decaying or breaking completely, plastic pallets keep their basic shape and changes storage structure for years at a time.

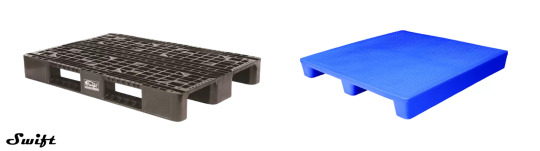

For instance, Swift’s Roto Molded Plastic Pallets, made from 100% virgin material, provide superior strength and longevity, making them an ideal solution for heavy-duty applications.

2. Hygiene and Cleanliness: Perfect for Food and Pharma

High hygiene selectivity is imperative for the Food, Pharmaceutical and Chemical industries. Being non-porous, moisture resistant and easy to clean plastic pallets are an ideal choice where hygiene is the utmost concern. Swift’s Food-Grade Pallets, specifically designed for these industries, not only guarantee that hygiene requirements are fulfilled but also provide durability.

3. Weather-Resistant for India’s Diverse Climates

From the humid shores of Kerala to arid Rajasthan, India’s varied climates can be punishing on traditional pallets. On the other hand, plastic pallets are significantly impervious to climatic conditions ensuring reliability while sending products through ruthless summers or monsoon showers.

4. Lightweight Yet Strong

Plastic pallets are much lighter than traditional pallets, even though they are quite popular. Plastic pallets offer the best strength against breakage. Not only does this reduce shipping costs, but it’s also easier and safer for workers to handle. For Industries managing high volumes of logistics across India, Swift’s Rackable Pallets offer a perfect combination of lightweight design and heavy load-bearing capacity.

5. Eco-Friendly and Sustainable

As sustainability becomes more significant, plastic pallets are also a responsible choice. Most are created with recyclable materials to limit the environmental footprint. Plus their longevity also means fewer replacements, leading to less landfill waste. Swift’s Recyclable Pallets help Industries align with their green goals without compromising on quality.

6. Safety First

Plastic pallets do not have nails protruding at any point, making them safe to use; there are no sharp edges or splinters. This becomes particularly important in high handling applications like warehousing and distribution centers. Swift’s Safety Pallets, for instance, are designed with smooth edges and robust construction to prevent workplace injuries.

7. Customization for Specific Needs

Indian industries are as diverse, and their logistics requirements vary correspondingly. Plastic pallets can be customized for specific requirements whether it is for printed materials, electronic products or agricultural produce. For instance, Swift’s Printing and Packaging Pallets are designed specifically to meet the specialized needs of the printing industry.

8. Compliance with Global Standards

You have to fall in line with international shipping laws if your industry deals with export. Plastic pallets also comply with these standards, for example ISPM-15 legislation prohibits untreated conventional pallets in international trade. Swift’s Export Pallets are developed as per these regulations hence are a no-hassles choice for industries that seek to go global.

Case Study: A Leading Indian FMCG Company

A renowned FMCG company in India recently switched to Swift’s Food-Grade Plastic Pallets for transporting its packaged food products. The result? A significant reduction in product damage during transit and improved warehouse efficiency. The lightweight yet sturdy design of the pallets also led to a 15% decrease in shipping costs.

Conclusion

Plastic pallets have started revolutionizing the manner in which Indian industries operate their logistics and warehousing. They offer several benefits, including resistivity, cleanliness and sustainability as well as cost efficiency; things that are needed in varying degrees by various sectors of the Indian industry. Ultimately, transitioning to plastic pallets is investing in durability and future strength no matter your industry, whether manufacturing, warehousing or retail.

Upgrade your operations today with Swift’s Plastic Pallets—India’s choice for smarter, safer, and more sustainable industry solutions!

#plastic pallets manufacturers in india#plastic pallets#plastic pallets supplier#roto molded pallets#plastic pallet near me#cost of plastic pallets#blue plastic pallets#swifttechnoplast

0 notes

Text

Best Roto molded Pallets in tamilnadu | Roto Molded pallets

Roto-molded pallets offer several advantages over traditional pallets. They are known for their exceptional durability, capable of withstanding rough handling and harsh environments. Additionally, roto-molded pallets are often lighter in weight, resistant to corrosion, and can be easily customized to suit specific load-bearing requirements, making them a preferred choice for various industries.

0 notes

Text

plastic pallet manufacturers

Allwin’s plastic pallets are designed to tackle the toughest material handling and storage challenges. Built with precision and advanced technology, our pallets offer durability, cost-effectiveness, and eco-friendly benefits. Resistant to chemicals, solvents, and cleaning agents, they ensure hygiene and long-term performance. Whether you need Injection Molded or Roto-Molded Pallets, Allwin provides a wide range of reliable solutions to streamline operations and improve efficiency. Easy to clean and built for heavy loads, our pallets help businesses enhance logistics while maintaining superior quality and sustainability. Choose Allwin for smarter, stronger, and safer storage solutions!

0 notes

Text

Polycon Gulf: Leading Water Tank Manufacturers and Suppliers in UAE

Polycon Gulf stands out as a premier name in the realm of water tank manufacturing and supply in the UAE. With a commitment to quality, innovation, and customer satisfaction, Polycon Gulf has become synonymous with reliability and excellence. Specializing in a diverse range of products, Polycon Gulf caters to various needs, from water storage solutions to spill containment pallets and custom rotomolded products.

Water Tank Manufacturing Excellence

Polycon Gulf is renowned for its cutting-edge Roto-Molding technology, setting the benchmark for water tank manufacturing in the UAE. The company's extensive product line includes easily washable tank sheds at attractive prices. These sheds, crafted with precision, ensure not only durability but also ease of maintenance, making them an ideal choice for both residential and commercial applications.

Polycon Dual Face Pallets: Safety and Sterility Combined

Polycon Gulf takes pride in its innovative Polycon Dual Face Pallets, designed with a focus on safety and sterilization. These pallets boast easy cleaning features, making them a preferred choice for industries requiring a sterile environment. The use of advanced materials ensures that these pallets maintain their integrity even under challenging conditions, providing a reliable solution for various industries.

Versatile Product Range: Road Barriers to Illuminated Planters

Beyond water tanks, Polycon Gulf excels in producing a diverse range of products. From road barriers and spill containment pallets for road safety to underground storage tanks and illuminated planters for decorative purposes, Polycon Gulf's product portfolio caters to an array of needs. The company also offers customized wastebins and trolleys at attractive prices, addressing the unique requirements of different industries.

Advanced Coating Technologies: Rotolining and Internal Polymer Coating

Polycon Gulf prioritizes the longevity and durability of its products. The utilization of advanced coating technologies such as Rotolining and Internal Polymer Coating ensures an anticorrosive lining, making the products suitable for a wide range of environments. Whether it's plastic tanks or GRP tanks, Polycon Gulf guarantees the highest standards in manufacturing.

Pontoon Floats for Marine Applications

Polycon Gulf's commitment to innovation extends to marine solutions. The company manufactures pontoon floats, pontoon bridges, marine floats, and buoys that meet stringent quality standards. These products provide reliable and durable solutions for various marine applications, reflecting Polycon Gulf's dedication to delivering excellence across industries.

Quality Assurance and Customization

Polycon Gulf prioritizes quality, ensuring that each product, including polyethylene water tanks in the UAE, meets stringent standards. The company also offers customization options for its products, allowing clients to tailor solutions to their specific needs.

In conclusion, Polycon Gulf stands as a beacon of excellence in the water tank manufacturing industry. With a commitment to quality, innovation, and customer satisfaction, Polycon Gulf continues to shape the landscape of water storage solutions and beyond in the UAE.

Polycon products

car/tank shed

Track barrier

#water tank suppliers near me#Porta Cabin Manufacturer in UAE#Best Porta Cabin Manufacturer in Uae#Spill Containment Pallets in UAE

1 note

·

View note

Text

Different Types of Plastic in Packaging

Did you know that about 2 million plastic bags are used every minute worldwide? There are many different types of plastics used in the packaging industry. Most plastic contains a small number or logo to help identify the plastic used, so you can familiarise yourself on the type and whether you can recycle this. The symbol is mostly located at the base of the product or on the back of the item directly on the plastic. Read More..

1 note

·

View note

Link

Plastic pallets are made from heavy-duty materials that are durable, recyclable and hygienic. Buy plastic pallets online in India from Gujarat Shopee that are considered best for shipping a variety of goods ensuring a greener supply chain.

#buy plastic pallets online India#plastic pallets manufacturers in india#plastic pallets#plastic pallet suppliers#roto molded plastic pallets#4 way entry pallets#2 way entry pallets

0 notes

Text

Plastic-Pallets - Nilkamal Material Handling

Nilkamal pallets are developed in close association with the user industry and technological advances in material handling and storage systems.

They meet environmental considerations are proven more economical in the long run, also improving storage and handling systems in the process.

Nilkamal plastic pallets are easy to clean and handle and withstand commonly used chemicals, solvents, and cleaning agents. This section gives detailed information about our range of Injection Molded and Roto-Molded Pallets.

0 notes

Text

Roto-Molded Pallets: A Modern Solution for Stronger, Safer, and Ease of Material Handling

The Modern Roto Molded Plastic Pallets are efficient and reliable for material handling solutions and more crucial than ever in the new industrial scenario. At all times, warehouses, factories and distribution centers are in need of the finest and quality pallets in place to help streamline their operations.

For those, roto-molded pallets are possibly the strongest answer as they can provide both the durability and safety that one wants and stay active for a long time compared to regular traditional pallet options.

1. Strength and Durability for Heavy-Duty Applications One of the best characteristics about roto-molded pallets is that they are excellent in dealing with heavy-duty loads. Even assembled pallets can be prone to weak points—between many points of attachment—however due to rotational molding the pallets are being created in one piece structure, and these pallets avoid those problems. This makes them ideal for purpose applications such as holding heavy weights in storage or to be transported.

2. Custom Design for Load-Bearing Efficiency Roto-molded pallets offer the flexibility of custom design to meet specific load-bearing capacities. This customization ensures that businesses can choose the perfect pallet size and strength for their unique operations, maximizing efficiency while maintaining safety. Whether you have to handle lower loads or severe weights, roto-molded pallets can be designed to accommodate your exact requirements, making them a truly modern solution for varying industrial needs.

3. Sturdy, One-Piece Construction for Longevity The one-piece construction of roto-molded pallets significantly contributes to their long-lasting nature. Since they are molded as a single unit, there are no joints or seams that could weaken over time or under stress. It leads in an extremely durable product that needs minimum maintenance, providing long-term cost savings. For companies seeking a solution that reduces replacement frequency and improves overall efficiency, roto-molded pallets are the ideal choice.

4. Enhanced Safety with Anti-Skid Design Safety is always a concern in material handling, and roto-molded pallets are designed with this in mind. They often come with specially designed anti-skid tops, reducing the risk of goods slipping during transport or storage. This feature not only enhances the safety of workers but also protects valuable cargo from damage, Ensuring seamless and secure operations.

5. Compatibility with Modern Material Handling Equipment In today’s highly mechanized environments, seamless integration with material handling equipment is crucial. Roto-molded pallets are suitable for most standard equipment, like forklifts, pallet jacks, and automated conveyor systems. This compatibility means that businesses can upgrade their material handling without having to question if their pallets will fit into their current infrastructure or not.

Conclusion

As industries continue to evolve, finding reliable and innovative material-handling solutions is essential for maintaining operational efficiency. Roto-molded pallets are an obvious choice for a modern solution to meet the demanding industrial setting under one roof. Their superior strength, customizability, and safety features make them a valuable asset for any business seeking to improve its material handling processes.

For reliable, durable pallet solutions, Swift Technoplast offers quality and customization tailored to your material handling needs.

#Plastic pallet price#heavy duty plastic pallets#plastic pallets near me#plastic pallets manufacturers in india#plastic pallets for sale near me#plastic pallets#cost of plastic pallets#pallet plastic#plastic pallets manufacturer#RotomoldedPallets#Roto molded pallet#roto pallet#roto molded#roto molded pallets

0 notes

Text

Industrial Plastic Pallet Manufacturer

Plastic pallets are now revolutionizing the logistics and manufacturing sectors with their unmatched reliability and innovation. Durable, long-lasting solutions designed to handle industrial loads save businesses a bundle in efforts to optimize operations. Made using state-of-the-art methods such as rotational moulding, plastic pallets are flexible, weather-resistant, and chemical-proof—making them a must in many industries.

Allwin is the leading manufacturer of roto-molded plastic pallets, committed to quality and conformance to industrial standards. Its durability and hygiene have enabled Allwin to become a name businesses trust in helping them improve their supply chain processes. This guide will go in-depth into the materials, benefits, and applications of plastic pallets so that you can make an informed decision for your operational needs.

Understand about the Plastic Pallets and it’s Materials

Plastic pallets are made from a variety of materials, each designed to satisfy certain industrial needs. Some of the most common materials used include:

High-Density Polyethylene (HDPE):

HDPE is renowned for being strong and durable, an ideal choice for heavy-duty applications. It can also withstand extreme temperatures and not easily degenerate from chemicals, which secures its performance in the long term.

Polypropylene (PP):

Known for its rigidity and lightweight properties, PP is a great material for industries that focus on efficiency. Its moisture resistance and impact resistance make it ideal for export purposes.

Recycled Plastics:

For environmentally conscious businesses, recycled plastic pallets offer an eco-friendly solution. Slightly less strong than virgin materials, they are cost-effective and help reduce environmental footprint.

See Also: Spill Pallets for Every Industry

Benefits of Using Plastic Pallets

Plastic pallets are the preferred choice in industries due to their numerous benefits. Here are some key benefits:

Durability:

Plastic pallets and pallet containers are designed to withstand heavy loads, impacts, and extreme weather conditions. Roto-moulded pallets, in particular, are designed to handle the rigors of industrial applications.

Hygiene and Cleanliness:

Unlike wooden pallets, plastic pallets do not absorb moisture or provide a habitat for bacteria. This makes them very easy to clean and sanitize, hence suitable for food, pharmaceutical, and healthcare industries.

Lightweight:

Plastic pallets are much lighter compared to wooden pallets. This significantly brings down the costs related to shipping and manual handling. Their light weight also reduces workplace injuries.

Manufactured using precise molding techniques, plastic pallets provide uniformity in size and weight. This consistency enhances compatibility with automated systems, improving operational efficiency.

Weather and Chemical Resistance:

These pallets are resistant to extreme weather conditions and chemical exposure, ensuring they last long and are reliable even in tough environments.

Recyclability:

These pallets are resistant to extreme weather conditions and chemical exposure, ensuring they last long and are reliable even in tough environments.

Read more: Industrial Plastic Pallet Manufacturer

More information read our blog :- Industrial Plastic Pallet Manufacturer

0 notes

Text

A Guide to Know About Plastic Pallets

Plastic pallets are revolutionizing logistics with their durability, hygiene, and adaptability. Designed to withstand heavy loads and harsh environments, they are lightweight, weather-resistant, and easy to clean, making them ideal for industries like food, pharma, and retail. Made from materials like HDPE, PP, or recycled plastics, they offer sustainability and long-lasting performance. Types include stackable, four-way, and export pallets, catering to diverse needs. Allwin, a trusted leader in roto-molded plastic pallets, provides high-quality solutions tailored for every industry, ensuring cost-efficiency and operational excellence for businesses.

0 notes

Text

Exploring the Functions and Designs of Plastic Pallets

Plastic Pallets are an important equipment for the smooth movement and storage of goods in the fields of transportation and material handling. There are some other options of pallets but plastic pallets are becoming popular due to its robust design and versatility. In this blog post, we will explore the functions of plastic pallets, as well as their applications across a range of industries.

Functions of Plastic Pallets:

1. Material Handling Efficiency: Plastic pallets are designed to improve the efficiency of material handling tasks in warehouse operations, manufacturing industries.Their robust designe allow them to move goods with speed and ease, making them compatible with all kind of material handling equipment, including hydraulic stackers, Hydraulic pallet trucks, and forklifts.

2. Compliance with Industry Standards: Plastic pallets are available in multiple sizes and designs to comply with industry standards and regulations. Whether it's (GMA) the Grocery Manufacturers Association Standard pallet size or custom dimensions tailored to specific applications, plastic pallets offer strength to meet diverse requirements.

3. Weight Capacity: Plastic pallets are surprisingly robust and they can easily carry heavy loads while being lightweight. They can store and move a variety of goods, from little packages to large machines, because they are designed to endure high static and dynamic loads.

Designs of Plastic Pallets:

1. Export Pallets: Export One Way plastic pallets are made specially for international transportation. Export pallets also called as Shipping Pallets of One Way cargo Export pallets. These robust and lightweight designs of plastic pallets are made from recycled plastic or HDPE material. They provide environmentally friendly and cost-effective solutions for exporting goods globally.

2. Rackable Pallets: Rackable plastic pallets are made to withstand the demands of storage in pallet racking systems. These Pallets are specifically designed for pallet racking systems. Their strength and robust bottoms allow them to carry huge weights without buckling or breaking down. These pallets increase vertical storage capacity by ensuring secure and stable storage in warehouse racks.

3. Nestable Pallets: Due to their special construction, nestable plastic pallets can save up important storage space by nesting inside one another while not in use. They are perfect for companies with limited warehouse space or those trying to maximize storage efficiency because of this space-saving feature.

4. Hygienic Pallets: Hygienic Plastic pallets also called as roto molded plastic pallets are made for sectors like the pharmaceutical and food processing industries, where hygienic conditions are required.. These pallets feature anti-skied, smooth surfaces, rounded corners, and robust construction to prevent the accumulation of dirt. They are easy to sanitize and clean ensuring compliance with strict hygiene standards.

Conclusion: Plastic Pallets play a vital role in enhancing material handling efficiency and ensuring compliance with industry standards across various sectors. At Swift, We provide Plastic pallets with a countless number of designs and functions tailored to meet the various needs of Recent businesses. Plastic pallets have proven important in many sectors globally, from ensuring hygienic storage and compliance with industry requirements to improving material handling efficiency. With their robust design and versatility, Plastic Pallets Play a important role in transportation sectors.

#plasticpallets#plasticmanufacturer#plasticproducts#plastic industry#plastic pallets supplier#plastic pallet near me#cost of plastic pallets#hdpe pallet#pvc pallets

0 notes

Text

Exporting Excellence: SWIFT Exporting Finest Plastic Pallets Worldwide

With over 20 years of experience, Swift Technoplast has become a familiar face in Indian industrial packaging. We’re renowned for their top-notch plastic pallets, designed to meet the unique needs of various industries. Whether you need secure chemical storage or efficient shipping solutions, Swift Technoplast has a plastic pallet for the job.

Swift Technoplast doesn’t just churn out generic plastic pallets. We understand that every industry has its own needs. That’s why usage of materials like ultra-durable HDPE and flexible LLDPE to craft custom pallets. Need a specific size to fit your warehouse layout? No problem. Want a bright color for easy identification? We can do that too. Swift tailors each pallet to seamlessly integrate with your unique operation.

Swift is committed to provide its customers with the highest quality plastic pallets to streamline their supply chains.

Being a leading plastic pallets manufacturer in India SWIFT has gained recognition for its exceptional product quality and its dedication to export the top quality of products worldwide, offering variety of plastic pallet like Roto Molded Plastic Pallets, Heavy Duty Injection Molded Plastic Pallets, Rackable Pallets, Storage Pallets, One way cargo Pallets, Printing & Packaging Plastic Pallets for various industries.

Here are some of the benefits of using SWIFT Plastic Pallets:

1. High-quality Plastic Pallets

Swift Technoplast takes immense pride in the quality they deliver. Our engineers design each and every plastic pallet with precision, adhering to the strictest international standards. Each pallet goes through a series of harsh tests to guarantee its dependability. This dedication translates to peace of mind for their customers, knowing their products can travel the world safely and securely.

2. Customization options in Plastic Pallets

Swift understands that one-size-fits-all doesn’t apply to pallets! We offer a range of customization options available to ensure the perfect fit for your industrial needs. Whether you have a bulky heavy machine that needs a specific platform or want your pallets to match your company’s vibrant colors, Swift can create custom sizes and colors to match your vision.

Here is the list of customised sizes:

Product Code:Pallet Size

SIP-R24-6687GS : L660 X W870 X H165

SIP-R24-6810GS : L680 X W1080 X H165

SIP-R2-1212GS-SO : L1200 X W1200 X H170

SIP-R24-1207RP : L1200 X W700 X H260

SIP-H4-1675GS : L1060 X W750 X H180

3. Optimizing Supply Chains

Swift Technoplast gets it: in today’s fast paced business world, an efficient supply chain is the difference between winning and losing. We’ve channeled their years of experience into designing plastic pallets that prioritize efficiency. Each pallet is meticulously crafted with features like consistent size, easy stacking, and seamless compatibility with all kinds of material handling equipment. Finally it results in a smooth-running supply chain that translates to real benefits for your business.

4. Excellent customer service

At Swift Technoplast, passionate plastic pallet experts are on hand to answer your questions and navigate you through the ordering process. Their dedication goes way beyond the product. With a growing international presence, Swift has earned a global reputation for exceptional customer service. This combination of top-notch and friendly expertise makes them the clear choice for businesses seeking a reliable plastic pallet partner.

Conclusion

For over two decades, Swift Technoplast has been a household name in Indian manufacturing. We’re more than just a plastic pallet producer – we’re a team dedicated to building a greener future. Our comprehensive range of eco-friendly, high-quality pallets isn’t just good for the environment, it optimizes your supply chain too. Swift’s commitment to excellence goes global. We’re passionate about exporting the finest quality work worldwide, ensuring your goods travel safely and efficiently across continents.

If you are looking for a reliable and experienced Plastic Pallets manufacturer from India, then SWIFT is the perfect choice for you. Contact Us today to learn more about our products.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic

0 notes

Text

Essential Facts About Injection Moulded Pallets

Injection Moulded Plastic Pallet manufacturing has advanced throughout time, with businesses working hard to utilize the latest technologies. The technique aims to optimize the parts, enhancing their thickness and structure, lowering their weight, boosting their longevity, and creating ever-more intricate patterns. Today, there are several methods for producing plastic pallets, making it often challenging to decide which way would improve our company’s supply chain’s efficiency the most. Injection, thermoforming, blowing, compression, and roto-molding are some of the most popular manufacturing methods we can find today.

The packaging company of pallets firmly believes that plastic pallet injection manufacturing ensures the quality of every one of our goods. Moreover, it adheres to our corporate core principles of sustainability and environmental care.

What are the main benefits of each available injection molding form?

One of the most common procedures for giving this material the desired form and size is the manufacture of plastic pallets using injection. For large-scale production, especially when maintaining stability and uniformity over time is necessary for the same pallet design, this method proves ideal.

Through a hopper, the plastic is fed into the machinery. The frictional force and heating bands melt the plastic. The heating chamber discharges the hot plastic through a nozzle into a cavity or mold, where a refrigeration system cools and solidifies it. The pallet will then assume the shape of the attached mold.

Various injection system types

Injection moulding plastic pallets use two different production procedures: low-pressure and high-pressure systems. Each of them has unique qualities and benefits.

1. Low-pressure apparatus

In this instance, the mold cavity receives the introduction of the plastic substance and inert gas. That is to say, a gas that doesn’t cause the importance to be introduced to react chemically. In this process, typically, carbon dioxide or nitrogen activates the blowing agents in the polypropylene/polyethylene combination through heating, creating a stiff plastic material enclosing a cellular core.

2. High-pressure injection molding

High-density polyethylene (HDPE) or polypropylene (PP) plastic pallets are frequently made using high-pressure injection technology. It is a very accurate method that leaves a high gloss surface and doesn’t need any additional treatment.

In this production process, the raw material is heated to 250 degrees Celsius within a barrel with a spinning screw. Once it reaches the desired temperature, the machine injects the plastic into a mold. Here, it holds it under pressure, cools it, and then expels it at the other end. Therefore, the high-pressure injection molding method is the best choice when you require a plastic pallet with outstanding features.

Tailored Plastic Pallet Production: Professional Guidance for Every Business Need

1. Raw Materials Preparation.

Start with the stock’s raw elements. The following often accept five hundred kilos or one tonne. The following is a combination known as a formula. Permit mixing of the same hue. Inject the plastic pellets into the mixture and incorporate the color from the formula bundle. Heat the mixture to prevent warping of the plastic pallets in each injection lot. Part 2 then appeared.

2. Mold Alteration

Once the mold has been made, the mold department must be contacted, or the mold must be changed. Turn on the injection molding device for plastic. CANE must be utilized to transfer the mold from the lifting or moving mold to the injection molding machine. The injection department’s role is to perform this. Mounting the mold to the injection machine for plastic pallets involves coupling the mold to the coolant pipe.Cold molded plastic creates an injection moulded plastic pallet.

3. Adjustment in Injection Moulded Plastic Pallet

The majority of them are chiefs in the injection department. This will change around the time of the injection. A robot will be adjusted to handle and remove plastic pallets from the mold, and the quantity of plastic pallets required to create a full plastic pallet will be modified to align with the injection cycle.

4. Plastic Injection for Pallets.

The injection process initially injects a substantial amount of plastic pallets. Because plastic is still in its early stages, plastic pallets are not ideal. Plastic injection molding is insufficient. Furthermore, the machinery employed in plastic injection molding must undergo tuning. Such as changing the injection time and heating the syringe. Slower to provide more time for the polymers to flow into the mold. Additionally, they will begin to minimize the injection time each time they inject 1–10 plastic pallets into a whole exercise, making the process quicker. To be able to provide additional injections each hour.

5. Pallet Cuts made of Plastic.

The quality control division determines which injection moulded plastic pallet require customization. This includes tasks such as removing any protruding fins and runners cleanly. Plastic pallets may also incorporate rubber and plastic sealing. Quality control checks are conducted on plastic pallets before they are delivered to the warehouse.

6. Quality Check of Plastic Pallets before Warehouse Delivery

Does the Quality Assurance Department have a quality checklist to ensure that the injected plastic pallets are good enough to turn clients away? We will identify the reject plastic pallets, which require mending, as soon as we assess the quality if the plastic pallets are not superior. However, clients can still deliver orders using plastic pallets that have previously received an injection for inspection—delivered to the warehouse in preparation for client delivery.

Conclusion

Injection systems with high and low pressures are crucial to producing plastic pallets. The industry opted for this method of production for its plastic pallets because, over the past several years, there has been a trend in the plastic injection industry towards equipment that is quieter, smaller, faster, and with a reduced environmental impact. Additionally, these advancements have led to more controlled hydraulic systems and energy consumption.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#hdpeplastic#injectionmoldedpallet

0 notes

Text

Choice Between Plastic Pallet Molding Process: Roto Molding vs. Injection Molding

When it comes to manufacturing plastic pallets, choosing the right molding process is crucial for achieving the desired quality, cost-effectiveness, and efficiency. Two popular methods, roto molding (rotational molding) and injection molding, offer distinct advantages and are suitable for different applications.

Consulting with experienced plastic molding professionals, swift technoplast, can help guide you towards the most suitable process for your application.

What is Rotomolding?

Rotational molding, commonly known as roto molding, is a plastic molding process that involves heating and rotating a hollow mold filled with a powdered resin. The rotation distributes the resin evenly, creating a uniform thickness and shape as it cools and solidifies. Roto molding is often used for large, hollow objects such as tanks, containers, and playground equipment.

What advantages does the Rotomolding Process offer?

1. Design Flexibility:

Roto Molding offers excellent design flexibility, allowing the creation of complex shapes and structures with minimal constraints. It is particularly suitable for producing large, hollow parts such as tanks, containers, and playground equipment.

2. Cost-Effectiveness:

The tooling costs associated with Roto Molding are relatively low compared to Injection Molding, making it a cost-effective option for low to medium volume production. However, unit costs may be higher for smaller production runs due to longer cycle times.

3. Uniform Wall Thickness:

Roto Molding enables the production of parts with uniform wall thickness, resulting in consistent strength and durability throughout the product.

4. Limited Material Selection:

While Roto Molding supports a wide range of materials, including polyethylene, PVC, and nylon, it may not be suitable for all types of plastics. Material selection is crucial to ensure desired properties such as UV resistance, chemical resistance, and color stability.

Limitations of Roto Molding:

1. Longer Cycle Times:

Roto molding typically has longer cycle times compared to injection molding, which can affect production efficiency for high-volume runs.

2. Limited Material Options:

While roto molding supports various thermoplastic materials, it may not be suitable for all types of resins, limiting material options compared to injection molding.

3. Surface Finish:

What is Injection Molding?

Injection molding is a plastic molding process that involves injecting molten resin into a mold cavity under high pressure. Once the resin cools and solidifies, the mold opens, and the finished part is ejected. Injection molding is widely used for producing a wide range of plastic products, including automotive components, consumer goods, and electronics.

What advantages does Injection molding offer?

1. High Precision and Complexity:

Injection Molding offers exceptional precision and repeatability, making it ideal for producing intricate parts with tight tolerances. It is suitable for high-volume production of small to medium-sized parts used in automotive, electronics, and consumer goods industries.

2. Fast Cycle Times:

Injection Molding typically has shorter cycle times compared to Roto Molding, allowing for faster production rates and higher throughput. This makes it well-suited for mass production scenarios where efficiency and speed are paramount.

3. Wide Material Selection:

Injection Molding supports a vast array of thermoplastic and thermosetting materials, offering flexibility in material selection to meet specific performance requirements. From commodity plastics like polyethylene and polypropylene to engineering plastics like ABS and polycarbonate, Injection Molding can accommodate diverse material needs.

4. Surface Finish Options:

Injection molding can achieve a wide range of surface finishes, from smooth and glossy to textured and matte, without additional processing.

Limitations of Injection Molding:

1. Higher Tooling Costs:

Injection molding tooling can be expensive, especially for complex molds with multiple cavities and features, which may impact initial investment costs.

2. Design Constraints:

While injection molding offers excellent design flexibility, certain geometries and features may require draft angles, undercuts, or additional tooling considerations.

3. Material Waste:

Injection molding generates scrap material, such as sprues and runners, which may increase material waste and production costs.

Choosing the Right Plastic Molding Process:

When deciding between Roto Molding and Injection Molding, several factors should be considered:

1. Production Volume:

For low to medium volume production, Roto Molding may offer a more cost-effective solution due to lower tooling costs. Injection Molding becomes more economical for high-volume production runs.

2. Part Complexity:

If your parts have intricate designs or require tight tolerances, Injection Molding may be the preferred choice. For large, hollow parts with simpler geometries, Roto Molding provides greater design flexibility.

3. Material Requirements:

Consider the specific material properties required for your application, as well as factors such as UV resistance, chemical resistance, and color stability. Ensure that the chosen molding process can accommodate the desired material effectively.

Ultimately, the choice between roto molding and injection molding depends on the specific needs of your project, balancing factors such as design complexity, production volume, material properties, and budget constraints.

Conclusion

Both roto molding and injection molding are valuable plastic molding processes manufacturing, each offering unique advantages and applications. By understanding the differences, advantages, and limitations of these molding techniques, manufacturers can make informed decisions to optimize product quality, production efficiency, and cost-effectiveness for their specific requirements.

Consulting with experienced plastic molding professionals can help guide you towards the most suitable process for your application.

Swift Technoplast helps you in carefully evaluating your needs and considering the advantages and considerations of each pallet type, we help you to make an informed decision that optimizes efficiency and productivity in your material handling operations.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#hdpepallets#plasticproducts#hdpeplastic#rotomoldedpallet#injectionmoldedpallet

0 notes

Text

Types And Benefits Of Spill Containment Pallet

Spill Containment Pallet is the necessity, if your company transports dangerous substances like oils, fuels, and chemicals, you know the harm a leak may provide and how vital spill management and containment are. In early December 2020, 9 News reported an accident involving a truck in Sydney’s south. The incident resulted in the flow of up to 500 liters of petrol and oil. The incident brought down a neighbouring power pole, and a minor fire was started nearby. This illustration shows how risky it is to work around toxic liquids and how crucial it is to transport hazardous liquids throughout the nation using spill-proof pallets.

Let’s examine the intricacies of spill containment pallets and the advantages they provide in more detail. Understanding these items’ characteristics can help you know how valuable they are to your business.

Types of Pallets

Roto-molded pallets:

Rotational molding creates roto-molded pallets, available in conventional sizes and affordable options. Steel frames can strengthen them to boost their load-bearing capability. Industries where cleanliness is essential utilize roto-molded pallets.

Injection-molded pallets:

Flat pallets in conventional sizes and colors are available as injection-molded pallets. Forklifts, loaders, or jacks can easily move them, and they serve to raise things during transit. HDPE injection-molded pallets are corrosion-free, recyclable, and long-lasting.

Block pallets:

Pallets made of blocks may be raised in all four directions. Twelve columns support the top deck, and a lower tier may or may not exist. Block pallets of wood, plastic, or metal offer exceptional handling efficiency.

Stringer pallets:

Over block pallets, stringer pallets provide more stability. Additional support is provided by two boards that run on opposite ends of the pallet between the top and bottom decks. However, This limitation only allows stringer pallets to be raised from two open sides. Four-way stringer pallets, thanks to a notch cut in the stringer, enable forklifts to pick them up.

Double-face pallet:

Typically, pallets only have a top deck. You can use both sides of a double-face pallet, which has a top and bottom deck. They are robust and suitable for use in demanding jobs.

Spill Containment Pallet Benefits Your Business and the Environment

Utilizing our bunded spill pallets is advantageous for your company, as we’ve already established, and it reduces costs and better safeguards your personnel and goods. Bunded pallets are drum spill containment devices intended to capture any drips or leaks from goods kept on top of them. However, the additional protection that these goods provide for the environment is yet another advantage.

When carrying a poisonous or hazardous liquid, if it leaks or spills onto the ground, it can cause significant harm to the surrounding ecosystem. If these pollutants get up in locations like water reservoirs, the surrounding plant life, wildlife, and even human populations might all suffer. Our bunded spill pallets safeguard the environment and the people who live nearby by capturing harmful pollutants before they reach the ecosystem.

The use of plastic in constructing pallets rather than wood positively affects the environment. The former may appear more environmentally friendly, but this is no longer the case. Forests suffer a great deal as a result of the production of wooden pallets. According to Range International, the production of wooden pallets uses over 40% of the world’s total timber supply. It implies that wooden pallets are disproportionately impacting the world’s continuous deforestation, which we might prevent if more businesses switched to plastic pallets.

Wood is far more difficult to recycle than plastic, which is another advantage plastic has over wood in terms of the environment. Wooden pallets are more likely to become contaminated by the contents they transport because of their porous nature. Additionally, they frequently mix with other materials like nails, making recycling more challenging.

Pallet manufacturers and recyclers widely seek our pallets for their strength, resilience, and resistance to moisture. There is such high demand for the material that many businesses are ready to pay for old pallets. This indicates that it is theoretically possible to earn money while recycling your old pallets. Some companies provide free pallet pickup and reimbursement for recycled pallets as an extra service to their clients.

Lastly, plastic pallets may be made from recycled and reused materials, reducing the amount of garbage that enters the globe. They are also substantially sturdy and long-lasting. Because of their durability, they don’t undergo the same high rate of production, acquisition, and trash that wooden pallets do.

When taking all the factors above into account and considering your company’s environmental policy, the only logical conclusion is to use plastic pallets for your shipping needs.

What Sectors Ought to Use Bunded Spill Containment Pallet?

A bunded pallet is advantageous for any liquid transport. Even when the compounds included are not hazardous in and of themselves, spills and leaks can pose a safety issue. Bunded pallets are particularly beneficial for

Oil shipments

hazardous substances

flammable substances

prescription liquids

food and drink deliveries

What Effect Can Spill Containment Pallet Have In This Case?

Look no further than the selection from the leading manufacturer of pallets if you’re searching for a trustworthy transport solution with a good spill control reputation. The pallet must provide a reliable solution for your hazardous liquid transportation and comply with all international spill control laws.

The drum spill containment pallets stand out from the competitors due to their distinctive chemical makeup. The pallets, made of high-density polyethylene and chemically resistant to numerous substances, provide you peace of mind during an accident while driving. Bunded pallets that can store up to four drums or containers should be available from the firm. This specific item has good chemical resistance against acids and alkalis and is simple to clean and sterilize.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#spillpallet#drum spill#drumpallets#spill containment pallets

1 note

·

View note

Text

Rotational Molding: A Closer Look at the Products It Creates

The modern world has seen various new inventions in recent times. As the countries became more connected after the Industrial Revolution, there way many innovations that took place in this area. One such innovation happened in the logistical industry. The invention of rotational molding technology in the making of Rotoplast. So, it is important for the business person or manufacturers how this technology works so they can set their production lines according to it. In this blog, we’ll understand everything around the roto-molding concept.

What is rotational molding?

Rotational molding which is also known as roto-molding is a manufacturing process that produces hollow plastic products. Traditional methods such as injection molding are different from rotational molding. Rotational molding involves heating a plastic material in a mold while simultaneously rotating it on two perpendicular axes. The plastic material coats the interior of the mold forming the desired shape as it cools and solidifies.

There are several benefits of using this process. Benefits like the ability to create large, complex, and seamless products. Also, less pressure in the molding process minimizes the stress points, resulting in durable and stress-resistant end products. It is also a cost-effective method for manufacturing low-volume, high-quality plastic products.

This process has several benefits against the older methods. Firstly, this process can create large, complex, and seamless products. Also, because of the less pressure in the molding process, it helps in minimizing stress points, resulting in durable and stress-resistant products. This process is cost-effective and suitable for producing low-volume and high-quality plastic products.

What Materials Go Into Making Roto Molded Plastic Products?

It’s very important to choose the right material in the rotational molding process. The choice of material decides the quality, strength, and durability of the product. The most common materials used in the process are polyethylene, polypropylene, and PVC. These materials are used because of their flexibility, impact resistance, and ability to withstand various environmental conditions

One of the most famous ones in this is Polyethylene. They’re known for their versatility. They can easily be used to create products with different levels of density ranging from low-density polyethylene (LDPE) to high-density polyethylene (HDPE). This allows manufacturers to utilize the material’s potential to the fullest and offer distinct variants according to the specific requirements of the end product.

What Types of Products Are Made With Rotomolded Plastic?

With the kind of material used in rotational molding and the versatility of the process itself, one can create a wide range of products. Starting from industrial containers to consumer goods. Here are some curated examples of it.

Fish Tubs

Roto plast or rotomolded plastic fish tubs are made through the rotational molding method. These tubs are used in the fishing and seafood industry. These are designed to handle harsh marine environments, ensuring the safe transportation and storage of freshly caught fish. Construction of rotomolded fish tubs prevents leaks and contaminations in the product inside. They help maintain the overall hygiene standard of the industry.

Plastic Pallets

One of the most common products is Plastic pallets which are again very necessary for the transportation and logistics industry. Traditional wooden pallets are not as durable and hygienic as their alternative plastic pallets. They are good at resisting moisture, chemicals, and temperature variations. These benefits make them an obvious choice for the transportation of various goods.

Ice Box

Ice boxes commonly known as coolers are made through this process. Due to this, it gained immense popularity. Its robust construction and exceptional insulating property made it a go-to choice for many vendors and customers across the world. Also, because easy-to-handle properties they are the perfect choice for outdoor activities, camping, and events for keeping goods chilled for longer periods.

Learn: How Insulated Ice Boxes Benefit Various Industries

Milk Can

This is one of the commonly seen products of rotational molding method and polyethylene. These containers are known for their durability, easy cleaning, and corrosion resistance properties. Rotomolded milk cans provide a reliable solution for the safe storage and transportation of dairy products.

Roto Moulded Plastic Dustbins

Dustins which you usually see are made of polyethylene material and through the rotational molded method. These dustbins can be seen in residential, commercial, and industrial settings. Due to their sturdy construction and weather-resisting nature, they’re the perfect choice for waste disposal. Also, these dustbins are good at preventing dirt accumulation and bacteria which ensures cleaner waste management.

Why Choose Allwin for Rotational Molding?

Allwin is a well-known brand in manufacturing and selling rotational molded products. We specialize in delivering high-quality molded products worldwide. From the selection of materials to designing, manufacturing, and ensuring proper safety instruction we tick marks every box. This makes us one of the most trusted and reliable manufacturers of rotational molded products. We provide quality rotational molding products like Plastic Pallets, Fish tubes, Ice boxes, Doff baskets, Milk Cans, Dustbins, Safbins & Pallet containers under one roof.

We also offer custom-designed containers for industrial applications or innovative consumer products. Plastic pallets Allwin is dedicated to providing the best quality products to their customers. With rotational molding capabilities, you can bring your vision to life.

At last, rotational molding is a very effective and versatile manufacturing process that helps manufacturers create a diverse range of high-quality plastic products. Understanding material helps you create a range of products. So, it’s very important to choose a reliable partner like Allwin that helps suppliers and vendors get high-quality rotomolded products. As the industry needs more durable, cost-effective, and easy-to-handle solutions the demand for rotomolded products will go high and Allwin is the best solution for that.

0 notes