#sustainable industry

Explore tagged Tumblr posts

Text

Sustainable Furniture: Sabai

Sabai about:

[...] In 2019, [Phantila] Phataraprasit co-founded Sabai—a Thai word that roughly translates to comfortable or relaxed—with business partner and college friend Caitlin Ellen.

[...] “The core of why we wanted to start Sabai is to make sustainable furniture that was accessible to people in our demographic, knowing that we are part of an age group that cares the most about this and wants to purchase according to those values, but are limited by things like budget, lifestyle and convenience,” she says.

Sabai CEO interview:

[Phataraprasit]: [...] We started an Instagram account that served as a great tool to leverage our community to understand what they cared about. When we started the design process, we would always go back to the Instagram community and poll them on, "What do you use your couch for?" "Do you like wide arms?" "Do you like thin arms?" It seems so simple in terms of, obviously, a couch is for sitting, but the insights that we received from that were helpful in informing the design process."

[...] It was definitely difficult for two relatively young women who had never started this type of company before and in a relatively traditional space to find any factory that was willing to work with us and basically take a bet on us. [...] When we finally did find a manufacturer who wanted to work with us, that was amazing, [...], but for us, we [...] had to find the sustainable alternatives to every component of the product so that was definitely a whole process in and of itself.

Sabai Materials blog post:

[...] OEKO-TEX certified hemp fabric is used in our Evergreen slipcovers [...] We wanted to ensure we were using [natural fibers] that uses less water than the cotton and linen options we’ve seen offered.

In place of traditionally used polyester upholstery fiber, we are using a natural fiber material made from a mix of coconut fibers and natural rubber wherever possible. The wooden legs are finished in a water based finish and the frame construction uses a non-toxic, solvent free glue.

[Sabai furniture] are designed to be assembled and disassembled easily with standard hardware and tools. Second, both seating collections are made to be repaired, individual parts can be purchased to replace in case of damage and cushion covers and slipcovers can be replaced to ensure the longevity of the product.

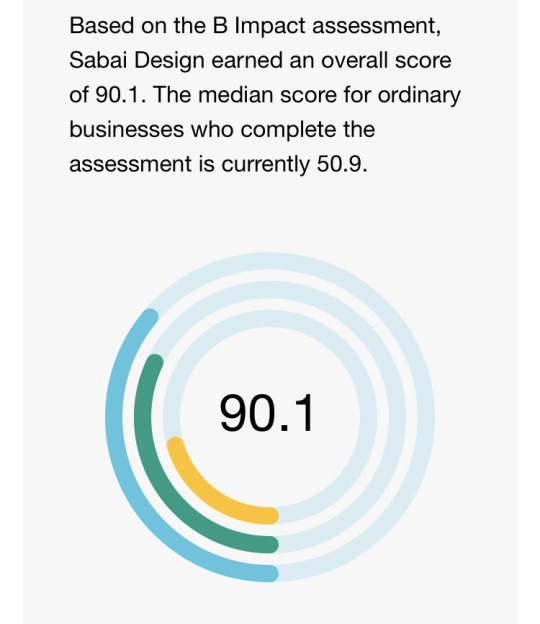

B Corp status of Sabai:

Sabai third-party product review:

#found this while considering shopping for a new couch#i think i might just invest in getting mine reupholstered/framed fixed to extend its longivity but#found this company in my search (for future reference) for sustainable furniture thats not necessarily second hand#my greens#sabai#sabai furniture#aapi#sustainable economy#sustainable furniture#furniture#interior design#non toxic#sustainable industry#women owned business#home health#green link

1 note

·

View note

Text

Images and text from this Reuters article.

"OPEC cut its forecast for global oil demand growth this year and next on Tuesday, highlighting weakness in China, India and other regions, marking the producer group's fourth consecutive downward revision in the 2024 outlook."

#oil#natural gas#fossil fuels#global warming#climate change#good news#economics#economy#fossil fuel industry#hope#climate anxiety#climate grief#environment#clean energy#sustainability#sustainable energy

192 notes

·

View notes

Text

I say this as a design student myself but like…. Design As An Academic Degree would be far more enjoyable if lecturers believed in design as a creative problem solving measure that can take whatever forms of creative approach it wants and actually encourage a wide variety of subject matter, style, and ideas and Not design as in a monolithic cliquey subgenre of modern/contemporary art defined by white collar avant garde collages profiting off of aestheticising systemic issues, governed by some of the most socially ignorant people you’ve ever met. The entire ethos of this course is pretty much “I don’t know how to tell you what design is, you just have to know how to do it” and then going “No that’s not it” to anything you show them and when you ask them why not they give you a different answer Every Time. This is the only course I’ve ever done that’s given me like negative net information if that’s somehow even possible. My only take away is that whoever runs these degrees isn’t actually teaching design, they’re just teaching you how to be trendy. This is exemplified by the fact not once in two years did we ever take a class or discuss what design even is, how to do it, how to contextually and realistically apply it, and how it has changed over the centuries, yet had an entire year long module, twice, on social networking and gallery exhibiting. Doesn’t help the whole lot is made worse by the fact that lecturers who refuse to acknowledge their style bias will stop at nothing to impose that onto a project to the point you’re nearly having to appease them over the client. Hoping it’s just where I live but I’m sadly gathering this is not an isolated issue

#a lecturer straight up told us she had ‘never considered the economic sustainability of a country’#as in like how classism and rising living costs have an effect on the creative industries#how is that not your first thought as the person Running This Course#I’m actually so done I don’t even care if I don’t get the honours#BA is enough#rather jump off a bridge than have to hear the word Mark Making again#illustration was WAY better

125 notes

·

View notes

Text

The Real Cost of the Fashion Industry

Atacama Desert, in Alto Hospicio, Iquique, Chile. (source)

The textile industry is destroying the world. The industry is wasting massive amounts of energy and materials, and polluting the air, the ground and the water supplies. It overwhelmingly exploits it's labour and extracts wealth from colonized countries, especially in Asia. I assume we all broadly understand this, but I think it's useful to have it all laid out in front of you to see the big picture, the core issues causing this destruction and find ways how to effectively move forward.

The concerning trend behind this ever-increasing devastation are shortening of trend cycles, lowering clothing prices and massive amount of wasted products. Still in year 2000 it was common for fashion brands to have two collections per year, while now e.g. Zara produces 24 collections and H&M produces 12-16 collections per year. Clothing prices have fallen (at leas in EU) 30% from 1996 to 2018 when adjusted to inflation, which has contributed to the 40% increase in clothing consumption per person between 1996 and 2012 (in EU). (source) As the revenue made by the clothing industry keep rising - from 2017 to 2021 they doubled (source) - falling prices can only be achieved with increasing worker exploitation and decreasing quality. I think the 36% degrees times clothing are used in average during the last 15 years (source) is a clear indication on the continuing drop in quality of clothing. Clothing production doubled between 2000 and 2015, while 30% of the clothes produced per year are never sold and are often burned instead (source), presumably to prevent the returns from falling due to oversupply.

These all factors are driving people to overconsume. While people in EU keep buying more clothes, they haven't used up to 50% of the clothes in their wardrobe for over a year (source). This overconsumption is only made much worse by the new type of hyper fast fashion companies like SHEIN and Temu, which are using addictive psychological tactics developed by social media companies (source 1, source 2). They are cranking up all those concerning trends I mentioned above.

Under the cut I will go through the statistics of the most significant effects of the industry on environment and people. I will warn you it will be bleak. This is not just a fast fashion problem, basically the whole industry is engaging in destructive practices leading to this damage. Clothing is one of those things that would be actually relatively easy to make without massive environmental and human cost, so while that makes the current state of the industry even more heinous, it also means there's hope and it's possible to fix things. In the end, I will be giving some suggestions for actions we could be doing right now to unfuck this mess.

Carbon emissions

The textile industry is responsible for roughly 10% of the global CO2 emissions, more than aviation and shipping industry combined. This is due to the massive supply chains and energy intensive production methods of fabrics. Most of it can be contributed to the fashion sector since around 60% of all the textile production is clothing. Polyester, a synthetic fiber made from oil which accounts for more than half of the fibers used in the textile industry, produces double the amount of carbon emissions than cotton, accounting for very large proportions of all the emissions by the industry. (source 1, source 2)

Worker exploitation

Majority of the textiles are produced in Asia. Some of the worst working conditions are in Bangladesh, one of the most important garment producers, and Pakistan. Here's an excerpt from EU Parliament's briefing document from 2014 after the catastrophic Rana Plaza disaster:

The customers of garment producers are most often global brands looking for low prices and tight production timeframes. They also make changes to product design, product volume, and production timeframes, and place last-minute orders without accepting increased costs or adjustments to delivery dates. The stresses of such policies usually fall on factory workers.

The wage exploitation is bleak. According to the 2015 documentary The True Cost less than 2% of all garment factory workers earned a living wage (source). Hourly wages are so low and the daily quotas so high, garment workers are often forced through conditions or threats and demand to work extra hours, which regularly leads to 10-12 hour work days (source) and at worst 16 hour workdays (source), often without days off. Sometimes factories won't compensate for extra hours, breaching regulations (source).

Long working hours, repetitive work, lack of breaks and high pressure leads to increased risks of injuries and accidents. Small and even major injuries are extremely common in the industry. A study in three factories in India found that 70% of the workers suffered from musculosceletal symptoms (source). Another qualitative study of female garment workers and factory doctors in Dhaka found that long hours led to eye strain, headaches, fatigue and weight loss in addition to muscular and back pains. According to the doctors interviewed, weight loss was common because the workers work such long hours without breaks, they didn't have enough time to eat properly. (source) Another study in 8 factories in India found that minor injuries were extremely common and caused by unergonomic work stations, poor organization in the work place and lack of safety gear, guidelines and training (source). Safety precautions too are often overlooked to cut corners, which periodically leads to factory accidents, like in 2023 lack of fire exists and fire extinguishers, and goods stacked beyond capacity led to a factory fire in Pakistan which injured dozens of workers (source) or like in 2022 dangerous factory site led to one dead worker and 9 injured workers (source).

Rana Plaza collapse in 2013 is the worst industrial accident in recent history. The factory building did not have proper permits and the factory owner blatantly ignored signs of danger (other businesses abandoned the building a day before the collapse), which led to deaths of 1 134 workers and injuries to 2 500 workers. The factory had or were at the time working for orders of at least Prada, Versace, Primark, Walmart, Zara, H&M, C&A, Mango, Benetton, the Children's Place, El Corte Inglés, Joe Fresh, Carrefour, Auchan, KiK, Loblaw, Bonmarche and Matalan. None of the brands were held legally accountable for the unsafe working conditions which they profited off of. Only 9 of the brands attended a meeting to agree on compensation for the victim's families. Walmart, Carrefour, Auchan, Mango and KiK refused to sight the agreement, it was only signed by Primark, Loblaw, Bonmarche and El Corte Ingles. The compension these companies provided was laughable though. Primemark demanded DNA evidence that they are relatives of one of the victims from these struggling families who had lost their often sole breadwinner for a meager sum of 200 USD (which doesn't even count for two months of living wage in Bangladesh (source)). This obviously proved to be extremely difficult for most families even though US government agreed to donate DNA kits. This is often said to be a turning point in working conditions in the industry, at least in Bangladesh, but while there's more oversight now, as we have seen, there's clearly still massive issues. (source 1, source 2)

One last major concern of working conditions in the industry I will mention is the Xinjiang raw cotton production, which is likely produced mainly with forced labour from Uighur concentration camps, aka slave labour of a suspected genocide. 90% of China's raw cotton production comes from Xinjiang (source). China is the second largest cotton producer in the world, after India, accounting 20% of the yearly global cotton production (source).

Pollution

Synthetic dyes, which synthetic fibers require, are the main cause of water pollution caused by the textile industry, which is estimated to account for 20% of global clean water pollution (source). This water pollution by the textile industry is suspected of causing a lot of health issues like digestive issues in the short term, and allergies, dermatitis, skin inflammation, tumors and human mutations in the long term. Toxins also effect fish and aquatic bacteria. Azo dyes, one of the major pollutants, can cause detrimental effects to aquatic ecosystems by decreasing photosynthetic activity of algae. Synthetic dyes and heavy metals also cause large amounts of soil pollution. Large amounts of heavy metals in soil, which occurs around factories that don't take proper environmental procautions, can cause anaemia, kidney failure, and cortical edoem in humans. That also causes changes in soil texture, decrease in soil microbial diversity and plant health, and changes in genetic structure of organisms growing in the soil. Textile factory waste water has been used for irrigation in Turkey, where other sources of water have been lacking, causing significant damage to the soil. (source)

Rayon produced through viscose process causes significant carbon disulphide and hydrogen sulphide pollution to the environment. CS2 causes cardiovascular, psychiatric, neuropsychological, endocrinal and reproductive disorders. Abortion rates among workers and their partners exposed to CS2 are reported to be significantly higher than in control groups. Many times higher amounts of sick days are reported for workers in spinning rooms of viscose fiber factories. China and India are largest producers of CS2 pollution, accounting respectively 65.74% and 11,11% of the global pollution, since they are also the major viscose producers. Emission of CS2 has increased significantly in India from 26.8 Gg in 2001 to 78.32 Gg in 2020. (source)

Waste

The textile industry is estimated to produce around 92 million tons of textile waste per year. As said before around 30% of the production is never sold and with shortening lifespans used the amount of used clothing that goes to waster is only increasing. This waste is large burned or thrown into landfills in poor countries. (source) H&M was accused in 2017 by investigative journalists of burning up to 12 tonnes of clothes per year themselves, including usable clothing, which they denied claiming they donated clothing they couldn't sell to charity instead (source). Most of the clothing donated to charity though is burned or dumbed to landfills (source).

Most of the waste clothing from rich countries like European countries, US, Australia and Canada are shipped to Chile (source) or African countries, mostly Ghana, but also Burkina Faso and Côte d'Ivoire (source). There's major second-hand fashion industries in these places, but most of the charity clothing is dumbed to landfills, because they are in such bad condition or the quality is too poor. Burning and filling landfills with synthetic fabrics with synthetic dyes causes major air, water and soil pollution. The second-hand clothing industry also suppresses any local clothing production as donated clothing is inherently more competitive than anything else, making these places economically reliant on dumbed clothing, which is destroying their environment and health, and prevents them from creating a more sustainable economy that would befit them more locally. This is not an accident, but required part of the clothing industry. Overproduction let's these companies tap on every new trend quickly, while not letting clothing the prices in rich countries drop so low it would hurt their profits. Production is cheaper than missing a trend.

Micro- and nanoplastics

There is massive amounts of micro- and nanoplastics in all of our environment. It's in our food, drinking water, even sea salt (source). Washing synthetic textiles accounts for roughly 35% of all microplastics released to the environment. It's estimated that it has caused 14 million tonnes of microplastics to accumulate into the bottom of the ocean. (source)

Microplastics build up into the intestines of animals (including humans), and have shown to probably cause cause DNA damage and altered organism behavior in aquatic fauna. Microplastics also contain a lot of the usual pollutants from textile industry like synthetic dyes and heavy metals, which absorb in higher quantities to tissues of animals through microplastics in the intestines. Studies have shown that the adverse effect are higher the longer the microplastics stay in the organism. The effects cause major risks to aquatic biodiversity. (source) The health effects of microplastics to humans are not well known, but studies have shown that they could have adverse effects on digestive, respiratory, endocrine, reproductive and immune systems. (source)

Microplastics degrade in the environment even further to nanoplastics. Nanoplastic being even smaller are found to enter blood circulation, get inside cells and cross the blood-brain barrier. In fishes they have been found to cause neurological damage. Nanoplastics are also in the air, and humans frequently breath them in. Study in office buildings found higher concentration of nanoplastics in indoor air than outdoor air. Inside the nanoplastics are likely caused mostly by synthetic household textiles, and outdoors mostly by car tires. (source) An association between nanoplastics and mitochondrial damage in human respiratory cells was found in a recent study. (source)

Micro and nano plastics are also extremely hard to remove from the environment, making it even more important that we reduce the amount of microplastics we produce as fast as possible.

What can we do?

This is a question that deserves it's own essays and articles written about it, but I will leave you with some action points. Reading about these very bleak realities can easily lead to overwhelming apathy, but we need to channel these horrors into actions. Whatever you do, do not fall into apathy. We don't have the luxury for that, we need to act. These are industry wide problems, that simply cannot be fixed by consumerism. Do not trust any clothing companies, even those who market themselves as ethical and responsible, always assume they are lying. Most of them are, even the so called "good ones". We need legislation. We cannot allow the industry to regulate itself, they will always take the easy way out and lie to their graves. I will for sure write more in dept about what we can do, but for now here's some actions to take, both political and individual ones.

Political actions

Let's start with political actions, since they will be the much more important ones. While we are trying to dismantle capitalism and neocolonialism (the roots of these issues), here's some things that we could do right now. These will be policies that we should be doing everywhere in the world, but especially rich countries, where most of the clothing consumption is taking place. Vote, speak to others, write to your representative, write opinion pieces to your local papers, engage with democracy.

Higher requirements of transparency. Right now product transparency in clothing is laughably low. In EU only the material make up and the origin country of the final product are required to be disclosed. Everything else is up to the company. Mandatory transparency is the only way we can force any positive changes in the production. The minimum of transparency should be: origin countries of the fibers and textiles in the product itself; mandatory reports of the lifecycle emissions; mandatory reports of whole chain of production. Right now the clothing companies make their chain of production intentionally complex, so they have plausible deniability when inevitably they are caught violating environmental or worker protection laws (source). They intentionally don't want to be able to track down their production chain. Forcing them to do so anyway would make it very expensive for them to keep up this unnecessarily complex production chain. These laws are most effective when put in place in large economies like EU or US.

Restrictions on the use of synthetic fibers. Honestly I think they should be banned entirely, since the amount of microplastics in our environment is already extremely distressing and the other environmental effects of synthetic fibers are also massive, but I know there are functions for which they are not easily replaced (though I think they can be replaces in those too, but that's a subject of another post), so we should start with restrictions. I'm not sure how they should be specifically made, I'm not a law expert, but they shouldn't be used in everyday textiles, where there are very easy and obvious other options.

Banning viscose. There are much better options for viscose method that don't cause massive health issues and environmental destruction where ever it's made, like Lyocell. There is absolutely no reason why viscose should be allowed to be sold anywhere.

Governmental support for local production by local businesses. Most of the issues could be much more easily solved and monitored if most clothing were not produced by massive global conglomerations, but rather by local businesses that produce locally. All clothing are made by hand, so centralizing production doesn't even give it advantage in effectiveness (only more profits for the few). Producing locally would make it much more easier to enforce regulations and it would reduce production chains, making production more effective, leaving more profits into the hands of the workers and reducing emissions from transportation. When the production is done by local businesses, the profits would stay in the producing country and they could be taxed and utilized to help the local communities. This would be helpful to do in both exploited and exploiter countries. When done in rich countries who exploit poorer ones, it would reduce the demand for exploitation. In poor countries this is not as easily done, since poor means they don't have money to give around, but maybe this could be a good cause to put some reparations from colonizers and global corporations, which they should pay.

Preventing strategic accounting between subsidiaries and parent companies. Corporate law is obviously not my area of expertise, but I know that allowing corporations to move around the accounting of profits and losses between subsidiaries and parent companies in roughly 1980s, was a major factor in creating this modern global capitalist system, where corporations can very easily manipulate their accounting to utilize tax heavens and avoid taxes where they actually operate, which is how they are upholding this terrible system and extracting the profits from the production countries. How specifically this would be done I can't tell because again I know shit about corporate law, so experts of that field should plan the specifics. Overall this would help deal with a lot of other problems than just the fashion industry. Again for it to be effective a large economic area like EU or US should do this.

Holding companies accountable for their whole chain of production. These companies should be dragged to court and made to answer for the crimes they are profiting of off. We should put fear back into them. This is possible. Victims of child slavery are already doing this for chocolate companies. If it's already not how law works everywhere, the laws should be changed so that the companies are responsible even if they didn't know, because it's their responsibility to find out and make sure they know. They should have been held accountable for the Rana Plaza disaster. Maybe they still could be. Sue the mother fuckers. They should be afraid of us.

Individual actions

I will stress that the previous section is much more important and that there's no need to feel guilty for individual actions. This is not the fault of the average consumer. Still we do need to change our relationship to fashion and consumption. While it's not our fault, one of the ways this system is perpetuated, is by the consumerist propaganda by fashion industry. And it is easier to change our own habits than to change the industry, even if our own habits have little impact. So these are quite easy things we all could do as we are trying to do bigger change to gain some sense of control and keep us from falling to apathy.

Consume less. Better consumption will not save us, since consumption itself is the problem. We consume too much clothing. Don't make impulse purchases. Consider carefully weather you actually need something or if you really really want it. Even only buying second-hand still fuels the industry, so while it's better than buying new, it's still better to not buy.

Take proper care of your clothing. Learn how to properly wash your clothing. There's a lot of internet resources for that. Never wash your wool textiles in washing machine, even if the textile's official instructions allow it. Instead air them regularly, rinse them in cool water if they still smell after airing and wash stains with water or small amount of (wool) detergent. Never use fabric softener! It damages the fabrics, prevents them from properly getting clean and is environmentally damaging. Instead use laundry vinegar for making textiles softer or removing bad smells. (You can easily make laundry vinegar yourself too from white vinegar and water (and essential oils, if you want to add a scent to it) which is much cheaper.) Learn how to take care of your leather products. Most leather can be kept in very good condition for a very long time by occasional waxing with beeswax.

Use the services of dressmakers and shoemakers. Take your broken clothing or clothing which doesn't fit anymore to your local dressmaker and ask them if they can do something about it. Take your broken and worn leather products to your local shoemaker too. Usually it doesn't cost much to get something fixed or refitted and these expert usually have ways to fix things you couldn't even think of. So even if the situation with your clothing or accessory seems desperate, still show it to the dressmaker or shoemaker.

If it's extremely cheap, don't buy it. Remember that every clothing is handmade. Only a small fraction of the cost of the clothing will be paying the wages of the person who made it with their hands. If a shirt costs 5 euros (c. 5,39 USD), it's sewer was only payed mere cents for sewing it. I'm not a quick sewer and it takes me roughly 1-2 hours to cut, prepare and sew a simple shirt, so I'm guessing it would take around half an hour to do all that for a factory worker on a crunch, at the very least 15 minutes. So the hourly pay would still be ridiculously low. However, as I said before, the fact that the workers in clothing factories get criminally low pay is not the fault of the consumer, so if you need a clothing item, and you don't have money to buy anything else than something very cheep, don't feel guilty. And anyway expensive clothing in no way necessarily means reasonable pay or ethical working conditions, cheep clothing just guarantee them.

Learn to recognize higher quality. In addition to exploitation, low price also means low quality, but again high price doesn't guarantee high quality. High quality allows you to buy less, so even if it's not as cheep as low quality, if you can afford it, when you need it, it will be cheaper in long run, and allows you to consume less. Check the materials. Natural fibers are your friends. Do not buy plastic, if it's possible to avoid. Avoid household textiles from synthetic fibers. Avoid textiles with small amounts of spandex to give it stretch, it will shorten the lifespan of the clothing significantly as the spandex quickly wears down and the clothing looses it's shape. Also avoid clothing with rubber bands. They also loose their elasticity very quickly. In some types of clothing (sport wear, underwear) these are basically impossible to avoid, but in many other cases it's entirely possible.

Buy from artisans and local producers, if you can. As said better consumption won't fix this, but supporting artisans and your local producers could help keep them afloat, which in small ways helps create an alternative to the exploitative global corporations. With artisans especially you know the money goes to the one who did the labour and buying locally means less middlemen to take their cut. More generally buy rather from businesses that are located to the same country where the production is, even if it's not local to you. A local business doesn't necessarily produce locally.

Develop your own taste. If you care about fashion and style, it's easy to fall victim to the fashion industry's marketing and trend cycles. That's why I think it's important to develop your personal sense of style and preferences. Pay attention at what type of clothes are comfortable to you. Go through your wardrobe and track for a while which clothing you use most and which least. Understanding your own preferences helps you avoid impulse buying.

Consider learning basics of sewing. Not everyone has the time or interest for this, but if you in anyway might have a bit of both, I suggest learning some very simple and basic mending and reattaching a button.

Further reading on this blog: How to see through the greenwashing propaganda of the fashion industry - Case study 1: Shein

Bibliography

Academic sources

An overview of the contribution of the textiles sector to climate change, 2022, L. F. Walter et al., Frontiers in Environmental Science

How common are aches and pains among garment factory workers? A work-related musculoskeletal disorder assessment study in three factories of south 24 Parganas district, West Bengal, 2021, Arkaprovo Pal et al., J Family Med Prim Care

Sewing shirts with injured fingers and tears: exploring the experience of female garment workers health problems in Bangladesh, 2019, Akhter, S., Rutherford, S. & Chu, C., BMC Int Health Hum Rights

Occupation Related Accidents in Selected Garment Industries in Bangalore City, 2006, Calvin, Sam & Joseph, Bobby, Indian Journal of Community Medicine

A Review on Textile and Clothing Industry Impacts on The Environment, 2022, Nur Farzanah Binti Norarmi et al., International Journal of Academic Research in Business and Social Sciences

Carbon disulphide and hydrogen sulphide emissions from viscose fibre manufacturing industry: A case study in India, 2022, Deepanjan Majumdar et al., Atmospheric Environment: X

Microplastics Pollution: A Brief Review of Its Source and Abundance in Different Aquatic Ecosystems, 2023, Asifa Ashrafy et al., Journal of Hazardous Materials Advances

Health Effects of Microplastic Exposures: Current Issues and Perspectives in South Korea, 2023, Yongjin Lee et al., Yonsei Medical Journal

Nanoplastics and Human Health: Hazard Identification and Biointerface, 2022, Hanpeng Lai, Xing Liu, and Man Qu, Nanomaterials

Other sources

The impact of textile production and waste on the environment (infographics), 2020, EU

Chile’s desert dumping ground for fast fashion leftovers, 2021, AlJazeera

Fashion - Worldwide, 2022 (updated 2024), Statista

Fashion Industry Waste Statistics & Facts 2023, James Evans, Sustainable Ninja (magazine)

Everything You Need to Know About Waste in the Fashion Industry, 2024, Solene Rauturier, Good on You (magazine)

Textiles and the environment, 2022, Nikolina Šajn, European Parliamentary Research Service

Help! I'm addicted to secondhand shopping apps, 2023, Alice Crossley, Cosmopolitan

Addictive, absurdly cheap and controversial: the rise of China’s Temu app, 2023, Helen Davidson, Guardian

Workers' conditions in the textile and clothing sector: just an Asian affair? - Issues at stake after the Rana Plaza tragedy, 2014, Enrico D'Ambrogio, European Parliamentary Research Service

State of The Industry: Lowest Wages to Living Wages, The Lowest Wage Challenge (Industry affiliated campaign)

Fast Fashion Getting Faster: A Look at the Unethical Labor Practices Sustaining a Growing Industry, 2021, Emma Ross, International Law and Policy Brief (George Washington University Law School)

Dozens injured in Pakistan garment factory collapse and fire, 2023, Hannah Abdulla, Just Style (news media)

India: Multiple factory accidents raise concerns over health & safety in the garment industry, campaigners call for freedom of association in factories to ‘stave off’ accidents, 2022, Jasmin Malik Chua, Business & Human Rights Resource Center

Minimum Wage Level for Garment Workers in the World, 2020, Sheng Lu, FASH455 Global Apparel & Textile Trade and Sourcing (University of Delaware)

Rana Plaza collapse, Wikipedia

Buyers’ compensation for Rana Plaza victims far from reality, 2013, Ibrahim Hossain Ovi, Dhaka Tribune (news media)

World cotton production statistics, updated 2024, The World Counts

Dead white man’s clothes, 2021, Linton Besser, ABC News

#fashion#fashion industry#sustainability#sustainable fashion#sustainable clothing#environment#climate change#i will be continuing the series of how to see through fashion industry propaganda at some point#i just felt compelled to write this because i feel like people so often miss the forest for the trees in this conversation

505 notes

·

View notes

Text

possibly controversial take but it shocks me how many people are still willingly and eagerly continuing to play Netflix's game of watching them hold your favorite new shows hostage under threat of them being cancelled if you don't campaign day and night for every single person on earth to binge the entire thing in one day. like . . . y'all haven't become disillusioned yet?

#nothing you do is going to save this industry#many more incredible stories are going to end up on the chopping block if everyone continues to perpetuate these cycles#i cannot wait to pop some champagne on the day that Netflix falls and the streaming industry crumbles#because it's so far from sustainable#it'll happen one day :)#netflix

124 notes

·

View notes

Text

Scientists in Switzerland have invented a way to make chocolate healthier and more sustainable.

Typically, only cocoa beans and pulp are extracted for our chocolate bars. But researchers at the ETH Zurich federal technology institute have discovered that the cocoa pod husk can be used

Their new recipe involves taking what’s known as the endocarp, the inner layer of the fruit shell, and mixing it with some of the pulp surrounding the beans to make a sweet cocoa jelly.

“This means that farmers can not only sell the beans, but also dry out the juice from the pulp and the endocarp, grind it into powder and sell that as well,” explains Kim Mishra, lead author of the study published in the journal Nature Food.

#chocolate#cocoa plants#chocolate industry#science#switzerland#sustainability#good news#environmentalism#food#farming#agriculture#sustainable farming#environment

55 notes

·

View notes

Text

[In February, 2023], a small warehouse in the English city of Nottingham received the crucial final components for a project that leverages the power of used EV batteries to create a new kind of circular economy.

Inside, city authorities have installed 40 two-way electric vehicle chargers that are connected to solar panels and a pioneering battery energy storage system, which will together power a number of on-site facilities and a fleet of 200 municipal vehicles while simultaneously helping to decarbonize the UK’s electrical grid.

Each day Nottingham will send a combination of solar-generated energy — and whatever is left in the vehicles after the day’s use — from its storage devices into the national grid. The so-called “vehicle to grid” chargers deliver this energy just when it’s needed most, during peak evening demand, when people are home cooking, using hot water or watching TV. Later, the same chargers pull energy from the grid to recharge the vehicles in the wee hours of the night, when folks are sleeping and electricity is cheaper and plentiful.

“We are trying to create a virtual power station,” says Steve Cornes, Nottingham City Council’s Technical Lead. “The solar power and battery storage will help us operate independently and outside of peak times, making our system more resilient and reducing stress on the national grid. We could even make a profit.” ...

After around a decade, an EV battery no longer provides sufficient performance for car journeys. However, they still can retain up to 80 percent of their original capacity, and with this great remaining power comes great reusability.

“As the batteries degrade, they lose their usefulness for vehicles,” says Matthew Lumsden, chairman of Connected Energy. “But batteries can be used for so many other things, and to not do so results in waste and more mining of natural resources.”

The E-STOR hubs come in the form of 20-foot modular containers, each one packed with 24 repurposed EV batteries from Renault cars. Each hub can provide up to 300kW of power, enough to provide energy to dozens of homes. One study by Lancaster University, commissioned by Connected Energy, calculated that a second life battery system saved 450 tons of CO2 per MWh over its lifetime...

Battery repurposing and recycling is set to play a massive role over the coming years as the automobile industry attempts to decarbonize and the world more broadly attempts to fight waste. The production of EVs, which use lithium-ion batteries, is accelerating. Tesla, for example, is aiming to sell 20 million EVs per year by 2030 — more than 13 times the current level. In turn, 12 million tons of EV batteries could become available for reuse by 2030, according to one estimate.

“Over the next decade we are going to see this gigantic wave,” says Jessica Dunn, a senior analyst at the Union of Concerned Scientists. “Companies are recognizing this is a necessary industry. They need to ramp up infrastructure for recycling and reuse.”

-via Reasons to Be Cheerful, March 13, 2023

#ev#ev charger#electric vehicle#electric cars#batteries#battery recycling#lithium ion battery#auto industry#sustainability#circular economy#recycling#reuse#uk#nottingham#england#good news#hope

217 notes

·

View notes

Text

Capitalism and colonialism took community away from us and I want it back. I’ve heard about it from my grandparents and in books and articles online. All throughout history and still today in some parts of the world. People looking out for each other. Regularly. Relentlessly. Neighbors watching each others children, having enough food to share and actually sharing it, being invested in each others lives because everyone has different strengths.

Today community has been strategically painted as a weakness and something to be skeptical of because it is a threat to the very foundations of capitalism. And that’s a real fucking shame because in reality, growing up with community and still having that through adulthood would probably make most people generally happier and less perpetually tired and stressed. It is renewable resilient versatile adaptable self-sustaining and kind of the Ultimate Resource.

#I wish I could bake a cake filled with rainbows and smiles and everyone would eat and be happy#fuck capitalism#global community#local community#communities#community#fuck colonialism#fuck western media#settler colonialism#land back#indigenous liberation#indigenous communities#indigenous culture#human rights#renewable resources#sustainability#intersectional social justice#disability advocacy#social reformer#racial justice#wealth redistribution#healthcare reform#economic justic#environmental justice#generational healing#ancestral healing#industrialization#anti imperialism#religious tolerance#coexistence

39 notes

·

View notes

Text

Our solarpunk business themes and trends are entering the mundane world under the guise of 'sustainability industry'...

Whatever the name, this pivot at the systems level - the emergence of entirely novel industrial sectors - can only benefit the planet.

However, everything will depend on how the notion of "growth" will be defined and pursued.

The report, titled ‘Turning Challenges into Industrial Solutions: The New Era of Industrial Policy,’ commends Indonesia for pursuing a green industrial policy in manufacturing and services. The country’s achievement is advancing in reducing energy consumption with the support of technical assistance from development partners, including UNIDO.

Green industry encompasses a wide range of sectors and technologies that prioritize environmental sustainability while fostering economic growth. In Indonesia, the potential for green industrial development is vast and diverse, including:

Renewable Energy: Indonesia boasts abundant renewable resources like solar, geothermal, and wind energy. Investing in renewable energy infrastructure, such as solar panels and wind farms, can reduce reliance on fossil fuels and contribute to energy security while mitigating carbon emissions. According to the Ministry of Energy and Mineral Resources, Indonesia aims to achieve a 23% renewable energy mix by 2025.

Sustainable Agriculture: Embracing practices like organic farming, precision agriculture, and water-efficient irrigation systems can significantly reduce environmental impact. This includes exploring technologies like vertical farming and hydroponics to improve agricultural productivity within a smaller footprint.

Circular Economy: Transitioning towards a circular economy, where resources are reused and recycled, offers tremendous potential. This encompasses initiatives like waste-to-energy plants, upcycling and composting facilities, and promoting sustainable product lifecycles.

Green Manufacturing: Implementing eco-friendly practices in manufacturing processes, such as energy-efficient equipment, cleaner production technologies, and waste reduction initiatives, can significantly reduce environmental footprint and resource consumption.

#solarpunk#solarpunk business#solarpunk business models#solar punk#solarpunk energy transition#solarpunk industrial transformation#Indonesia#sustainability transformation

8 notes

·

View notes

Text

I’m not indigenous so maybe I’ve gotten this wrong but I feel like there’s a certain disrespect for indigenous practices amongst vegans. I often see statements that equates to “everyone who eats meat is evil and hates animals”. But there are indigenous communities who have kept animals and hunted for centuries and still do it sustainably today. And so it just rubs me the wrong way when some vegans equates eating meat to a moral failure, and rarely talk about the huge problems within the modern western meat industry instead.

#there are other reasons for why I don’t like the narrative of non-vegans being evil as well but that’s a bit besides the point#climate justice#veganism#vegan#meat#indigineous people#meat industry#sustainability

15 notes

·

View notes

Text

chopped firewood. sustainable energy concept. wood texture. outdoor scene of everyday rural life. ecological fuel background

#firewood#wood#texture#background#energy#rural#fuel#chopped#outdoor#concept#ecological#sustainable#scene#everyday#life#wooden#pattern#material#timber#natural#rough#cut#brown#lumber#log#industry#rustic#stack#woodpile#pile

9 notes

·

View notes

Text

Weeee I got my first in person job interview.

#fingies crossed i dont spill my spaghetti#its just at a retail store...and it's sport related which *looks at myself in the mirror* uh im not exactly a skinny legend or a fitness nu#BUT im excited to see what this leads to#just a soft reminder the animation industry sucks and is not at all sustainable i wish people stopped glorifying it#unless youre consistently working your arms off or you happen to have big dick connections youre forgotten#looking forward to beginning my normie wage slavery

13 notes

·

View notes

Text

One gram of salt + 6tsp koolaid in 710ml = cheaper than salt pills and mostly concealed salt flavour

#salt pills are so expensive#so if I can do that for every water I have to drink#it would halve my dose of salt down#to only 5 pills needing to be taken instead of 10#industrial sized salt bag#and cheap bulk koolaid#much more sustainable financially

16 notes

·

View notes

Text

How to see through the greenwashing propaganda of the fashion industry - 1

For some background info I made an overview about the impact of fashion industry.

In the light of the Shein brand trip nonsense, I was thinking about how literally every clothing company now engages in greenwashing, even when it's such obvious lie like with Shein. And while most people are not fooled in such blatant cases like that, most cases are not as blatant. To see through the less obvious propaganda often needs a lot of knowledge of the clothing industry, which the average person doesn't have, yet the average person still needs clothing. So instead of trying to expose every company for their bad practices, I thought it might be more helpful to make a post on how to detect greenwashing. I'm going to use four examples, all in the different levels of honesty and responsibility, Shein, H&M, Burberry and Tentree. First I will go into frankly unnecessary amount of detail on Shein, because I fell into a horrifyingly fascinating research rabbit hole and I think it's excellent example on how companies can get away with blatant crimes (allegedly of course). In this first part we will just look into Shien, it's propaganda and reality behind it.

But before I go deeper into this, I want to stress one thing: this is not to say that you can never buy from any brand engaging in dishonest greenwashing, because then you couldn't buy almost any clothing, and you do need clothing. Though I will say, please don't buy from Shein if you in any way can afford not to. There is levels of how bad business practices can be, and they can't be much worse than Shein's, and even beside that, even when super cheep, it's not worth your money. There are other cheep options too. Though I won't hold it against anyone if they buy individual pieces from Shein from time to time, but I would implore at least to considerate, if they really need it and if it might be possible to get something similar from somewhere else. But my point in this is not necessarily to help you make better consumer decisions, because consumption will not save us, but to see through the corporate propaganda and not become complaisant after hearing comforting lies. The corporations are doing everything they can to make you believe they are already fixing the problems within the industry and there's no need for government intervention pinky promise, just keep consuming. But that's all bullshit and government intervention is exactly what is needed.

Before taking a look at our cases, I'll outline the key things I think are good to look for, when presented with sustainability PR.

TRANSPARENCY - Companies are not required to publish much of the information about their practices, but as it has become clear to everyone that the whole fashion industry is a massive problem, opacity has become rightly seen as suspicious. It has become also a sort of marketing method to disclose any evidence of good practices, so when a company is not doing that, and missing out on well working marketing, it raises the question, what are they hiding. Companies may try to give the appearance of transparency, without actually disclosing information. They might write in an easily accessible page about all their lofty goals, promises and achievements in a very vague language, they might talk about being transparent and publishing their data, but that data might be buried somewhere, where it's not easily accessible. Good sign on the other hand would be for example providing supply chain information for a product in the product description.

RELIABLE INFORMATION - Usually it's safer for a company to be vague or silent than to lie, because that might lead to legal consequences, but by cherry-picking and subtly twisting data, it can be turned to be flattering for them. Small companies might provide raw evidence of their facilities and supply chain, like photos, locations, contractor names etc. to give proof for their word. For bigger companies this is not of course possible as their supply chains might be massive and they might have thousands of facilities. However, there are many different independent and governmental organizations that give different kinds of certifications. The certifications are meant to give some reassurance of quality and/or accurate information. However not all certifications are made equal. Most reliable certifications don't have ties to the industry (aka are actually independent, not just in name), have governmental oversight and are given access to the data, from which they do the research themselves.

SUPPLY CHAIN - Giving the origin country of the final product is nowadays standard information to give, as it's required by law for example in EU. It's a red flag, if it's produced in a country, that has lacking environmental or labour laws, poor oversight and/or little protections for people. However, this does not mean that all production in those countries is unethical or questionable, but the risk for that is higher and the need for evidence of the working conditions is also higher. This is however just one part of the production. Before clothing can be sewn, the raw material for fiber must be made/acquired, that material must be turned into fiber, which must be turned into yarn and then the yarn must be woven into fabric. All of these steps in the process need workers, who deserve good working conditions. And depending on what fabric is in question, there's potential for major environmental issues in the different processes. This is why it's important to know more than just the country where the clothing was sewn. There could be certification for ethical sourcing of the fabric for example. With supply chain it's also better if the materials are sourced as locally as possible, to avoid a lot of extra carbon emissions from transportation. Best case scenario would be if the company manages the supply chain themselves locally, so they can know for sure where their materials come from and also avoid middlemen.

BUSINESS MODEL - The reason why it's often so hard to get information on the supply chain is that many companies, especially the large ones, outsource as much as possible. This might seem unintuitive, as the middlemen make production less efficient and costly as everyone takes a cut. However, they do it to outsource risks and responsibility. They don't have to invest into factories or raw material production and they have plausible deniability, if and when there's issues in their supply chain. The complexity of the supply chain provides opacity that is impossible and unreasonable to monitor, which allows the company to buy materials that are unreasonably cheep, while feigning ignorance of worker exploitation. How much the clothing cost can also give some idea on their business model. If it's super cheep, the only way for it to be that cheep is if workers are not payed enough and everything is poorly made. Cheep is always a red flag, though, if it's fairly cheep and I mean basic clothing is not much more than 100 eur (little more in USDs) but not much less than 50 eur, it can be okay or even good quality and with proper pay for workers, if the company doesn't take massive margins and don't have a ton of middlemen in their supply chain. However, expensive is not insurance of quality or good pay for workers. Many expensive brands take massive margins while their production has little difference to fast fashion and their products are poor quality.

CASE STUDY 1: SHEIN

Let's start with the propaganda. In Shein's About Us page, they say:

"SHEIN is a global fashion and lifestyle e-retailer committed to making the beauty of fashion accessible to all."

You see, their goal is to make fashion accessible to everyone, not just privileged few. They back this up by informing how they work in 150 countries, have very wide variety of clothing, are one of the most popular shopping apps, connect with the customers on where they are - social media - and, of course, have ridiculously low prices. Their team of nearly 10,000 employees (of which 58% are women for your information) loves to serve their many many customers, who are most important for Shein. They use "cutting-edge technology" and digitized agile supply chain to track sales and demand and adjust their manufacturing in real time. When they notice a new trend, they immediately put something trendy on sale, make prototypes and order small batches from factories. This is how they keep their inventory waste low and get products quickly to their customers. In their own words:

"By developing proprietary logistics and ecommerce technology, we are disrupting the fashion space and improving outcomes for manufacturers, suppliers and consumers."

We will see, if the "outcomes" are really "improved".

Shein group's website has very extensive information about their sustainability goals and efforts, giving the impression of transparency. It's pretty clear this is in an effort to combat all the allegations towards them. To make their business sustainable in addition to their reduced inventory waste they are "accelerating their transition" to use recycled polyester, promoting their "peer-to-peer resale platform" for Shein products, "eshtablishing" a recycling program for end-of-life products, tracing the material supply chain through their own material tracking platform and conserving forests by replacing viscose with "next generation fibers".

Most of the information they provide is fully meaningless corporate speak and should be taken with the biggest bucket of salt, so let's ask some questions.

DO THEY PROVIDE SPECIFIC DATA ABOUT THEIR PRODUCTION? Surprisingly Shein is much more transparent than I expected. (Though of course the info is in different website than where the average consumer would go.) Shein hasn't taken the standard route, which is to provide as little information as possible, and keeping it vague too, se they could just keep feigning ignorance. As I said, I think it's pretty clear they are providing this much information because their reputation is so bad. Their lack of transparency has been taken as an admission of guilt, so it's not working anymore, and they have taken a new approach into maintaining their plausible deniability. In their website, they provide a sustainability report from years 2021 and 2022. I took a look at the latest one. In it there's a lot of fluff, but they show actual numbers of how many code of conduct violations have been found in audits to supplier facilities, the carbon emissions of their supply chain and the amounts of different fabrics they have used during 2022. That's not nothing, so we have a relatively good start here.

WHO DID THE RESEARCH? The research is not at all independent, but done in-house. They have all the financial incentives to cherry-pick and frame their research in a way that shows them in the best possible light, even if we assumed they would not tamper with their own evidence, which I don't think we can fully assume either. There's an attempt though to convince us to believe the data they are showing:

"We have reported with reference to the Global Reporting Initiative (GRI) 2021 standard for certain sections of this report. Selected information in this report was assured, to the limited assurance standard, by an external independent assurer as per ISAE 3000."

Emphasis by me. So even if they did the research themselves, they did get it independently audited to get an assurance that they did follow the GRI standards in their reporting and that it doesn't contain lies. However, the "certain sections" and "selected information" with "limited assurance" does not give me much assurance, in fact, my assurance is very limited. To understand what does this actually mean, I did a bit of googling and delved into the annex of the report.

ISAE 3000 is a standard for auditing financial information issued by International Auditing and Assurance Standards Board, which an independent body that has governmental oversight. Financial information can get either reasonable assurance or limited assurance. Reasonable assurance is the most assurance this standard allows. Limited assurance is given, if the information provided to the assurer, time or extent of the procedure is lacking, but from those limited resources the assurer doesn't find anything that suggests "the subject matter information is materially misstated" aka that the company is lying. GRI is the most used reporting standard for sustainability for businesses and other organizations. I'm a bit suspicious of how effective their standards are, if they are most widely used, since most companies are absolutely terrible about sustainability yet they all claim they are great with it. So I decided to check who is in the board. Unsurprisingly it's mostly representatives of massive corporations, including Coca Cola and DuPond, a professor of accounting, national research director of Australia's Mining and Energy Union and one (1) environmental scientist.

The annex revealed quite interesting details. The only information that was AssuredTM (in a limited manner) for accurate information was the data on Shein's emissions and that of code of conduct violations. Only the report on emissions was AssuredTM (in a limited manner) to follow GRI standards. Shein got to select and prepare the relevant data for the audition, which was according to it, lacking. Crucially the audition report states that they didn't verify the results of supply audits or any potential violations of labor law found in them, rather they just checked that the math on the grading of the audits matched with Shein's stated criteria and that they actually did the audits. So if you really think about it, the (limited) assurance is that they graded themselves like they promised they would, not that their reporting of the amounts of violated labor laws or even just their own code of conduct was accurate. Additionally assurance of the accuracy of the emissions was only of Shein's own facilities, which do not produce any of their products, but not of their supply chain. 99,7% of their emissions come from their supply chain. So keep all this in mind when we look at the data itself.

WHAT ARE THEIR CARBON EMISSIONS AND HOW ARE THEY CALCULATED? Shein's emissions were 9,17 million tonnes of CO2, or 9,22 million tonnes if we don't count them purchasing Renewable Energy Credits. To put it into perspective that would be around 0,27-0,3% of the estimation of the annual emissions of the whole textile industry. Now that would be pretty low. In fact, suspiciously low. The fact that they got their own emissions auditioned, but not the emissions of their supply chain, suggests to me that perhaps, their numbers don't hold up to scrutiny. They also don't disclose their methodology for the numbers of the supply chain, like they do with their own facilities. Of course their response would be to say it's so much easier for them to calculate their own emissions than their suppliers. But I say that's not a bug, that's a feature.

Though looking at the methodology of the emissions from their own operating sites, which includes warehouses and offices, they don't take into account at all any emissions from building anything. They grew massively between 2021 and 2022 and I find it hard to believe they didn't built any of the new offices or warehouses they gained. Certainly they would have bought a lot of new equipment even if they moved to existing buildings. But none of this is taken into account in their calculations. And I must assume, it's not taken into account in their supply chain calculations either.

Even if we took them at their word, by their own admission, their carbon emissions have grown from 2021 to 2022 52%, which is alarming. (Interestingly they use the 2021 numbers in their actual website, which I think is so misleading that it's basically a lie.) They write it off as just side effect of their massive growth in production volume, which had 57% increase during the same time frame.

"We are at the beginning of our mitigation journey and began implementing decarbonization programs at the end of fiscal year 2022."

So they first scale their business as fast as they can, having absolutely no care of the environmental effect, so that when they have massive market share, and they reduce their massive emissions slightly, they can be like "oh look we did something!" They can then moan and wail how hard and time consuming it is to reduce the emissions of an existing supply chain, when they were the ones who decided to not take that into account from the start. Their "science based goal" (which they repeatedly stress in their website) is to reduce their emissions 25% by 2030. It's nothing. Less than nothing. They scaled without care their production in a time, when our ecology is collapsing, and then they claim that it's just science we possibly can't do anything about it. Apparently it's a natural law that they just have to make more and more money, like gravity.

WHAT MATERIALS DO THEY USE? Last year 64% of Shein's clothing (measured in weight) was polyester. Production of polyester is estimated to count for 40% of all carbon emissions of the textile industry. It's also a plastic made out of oil, so we have to take into account the fracking and refinement of oil and the eventual release of the CO2 from the oil that would have been secured in the ground otherwise. This most certainly is not counted into the supply chain emissions. Shein loves to pay lip service to the idea of circular economy, but they don't actually think about it. Because if they did, they would have taken into account the microplastics polyester fabric sheds when it's washed. When microplastics get into the soil and freshwater, they get into the organs of animals, including us, and they don't easily come off. Already it has been shown that they have led to the decrease of small soil fauna, which are very important for the fertility of the soil. Over time microplastics also break down further into nanoplastics. There's already evidence of nanoplastics being small enough to pass through veins into the brain, and that causing behavioral changes in fish. We don't know the long term consequences off this micro and nano plastic pollution yet, and we're just seeing the effects they have on small animals, but as they built up over years and decades inside our organs, we well likely see much larger effects.

Important for the lifecycle thinking is not just focusing on how much burden the production puts on the environment, but also how long it lasts and how can it be reused and eventually the impact of the end of it's lifecycle. If you remember from the beginning, Shein claims to take all this into account by having a resale program, somewhere in the future establishing a recycling program for unusable old clothes and increasing their share of recycled polyester. This is nothing. Again it's less than nothing. Polyester is not only bad fabric because of the things I've already said, but it's also just as a material for clothing very weak. It's not warm or breathable, which makes it at the same time sweaty and cold. It has no anti-bacterial qualities at all (which basically all natural fabrics have at least to small extent), so when you get easily sweaty in it, it starts also smelling very easily, and so needs washing very often. On top of washing releasing microplastics, it also weakens the fabric, because polyester doesn't get stronger when wet unlike plant fibers, like cotton and linen. Other synthetic fibers even get weaker when wet. Polyester is also very hard to dye effectively and has bad color retaining properties, so it needs chemical treatments and strong industrial dyes, all of which adds to it's carbon footprint and toxic pollution. Bad color retaining properties though also mean it looses it's color quite easily when washed. All of this makes it's life span significantly shorter than natural fabrics. I mean with some natural fabrics like wool and silk we are talking about multiple decades, with polyester it's easily in the low one digit years. These are inherent issues with polyester, but Shein clothes have repeatedly got complaints of their poor quality in general. This makes the resale program frankly meaningless.

On the surface the recycling program for polyester sounds good, right? You don't have to use more oil and use as much energy in making of it (according to Shein themselves, which again not a trustworthy source, it saves up to 70% emissions). Shein has promised to increase their share of recycled polyester to 31% of their polyester usage by 2030. Currently less than 1% of their production is recycled polyester. This is however a terrible solution. It still sheds microplastics and it's even worse as a fabric than virgin polyester. It is weaker and stiffer, making it impossible to use on it's own in fabric but when mixed with other fibers in a fabric significantly shortens it's life span. When we take into account the lifecycle of a clothing, the length of it and it's lifetime emissions become much more important than the production emissions. If you have to produce from scratch new clothing three times, in the time you could be using another clothing, it doesn't really matter if the emissions during the production were somewhat lower. (There's little reliable and comparable data available on production emissions of different fabrics, so I don't know how exactly recycled polyester compares to different natural fabrics.) Especially when we take into account the consumer use emissions, which in the case of polyester are 30% of it's lifetime emissions. And wast majority of it comes from washing, which you have to do more with polyester (how much more depends on what fabric you compere it to). Any responsible disposal of polyester at the end of it's lifecycle, especially any attempts at recycling it, cause additional emissions, unlike with natural fibers, which naturally degrade.

WHERE ARE THE SUPPLIERS? Shein boasts having fully integrated digital supply chain and with it they can track the whole supply chain of individual product. However they don't reveal any of that information publicly. Or rather only thing we know is that their factories making the end products are in China. But the question is, where does their fabrics come from? There's no countries listed in their report in any capacity and none of their products have any information of their origins nor the origins of the fabrics. This is very suspicious in my opinion. We can get no indication on how fibers might have been produced and made into fabric from the labor and environmental laws and practices of different countries. However, there is an interesting bit in the report about cotton:

"For cotton products, to further enhance our compliance with US laws, we request that our manufacturing suppliers only source cotton from Australia, Brazil, India, the United States and other approved regions."

This sentence is there pretty obviously because they have been caught selling clothing with cotton grown in Xinjiang in US markets, which US has banned. This is because Xinjiang, the Autonomous Uighur region, where 90% of China's raw cotton is grown, has been accused of genocidal oppression of the Uighur population, including having massive forced labour camps for Uighurs. Because of the police state nature of Xinjiang, there's no reliable numbers on how much of the cotton is produced with forced labour, but presumably most of it. Moreover, China limits the imports of cotton, which is why only 20% of cotton used by the textile industry in China is imported. Shein claims they know exactly where their fabrics come from, but the wording of the sentence above makes it clear they don't even plan on enforcing any policy to use imported cotton by their suppliers. Cotton is just 10% of fabric they used last year, but given their massive production volume, it's still a lot. This gets us to our next question.

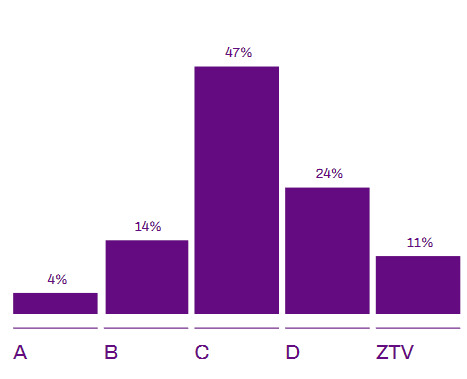

IS THERE PROOF OF GOOD WORKING CONDITIONS? Shein reports doing in total 2 812 audits into 1 941 of their 5 400 contract manufacturers. According to them it accounted for 84% of their Shein branded products (so not their other 10 brands). This information, if you remember, was given limited assurance, by the audition into their numbers. However, we are to trust Shein alone that the reports of their auditions are accurate. I'm not really willing to trust them, but let's sustain our disbelief for a moment to look at their findings. From their report:

"A: 90 points and above: minor flaws. Continued improvement is advised. B: 75 to 90 points: some general risks. Continued improvement is advised. C: 60 to 75 points: 1-3 major risks. Corrective action is required. D: below 60 points: >3 major risks. Corrective action is required. ZTV: Zero Tolerance Violation detetected. Immediate corrective action is required."

Even without knowing what do these things mean in practice, I don't think this paints a pretty picture. Only 4% of their manufacturing facilities had minor flaws and 82% of their facilities have major risks or worse? Does that mean none of their manufacturers fully comply with their Code of Conduct? They try to make it sound like it looks this bad because they have tightened their criteria and still the numbers are better than last year, but even with all of that, this is imo unacceptable. But it gets worse.

The report shows the amount of each ZTV found in the audits. This was explicitly not assured in any way by an independent party, so considering this information is given despite the lack of oversight and the interests of Shein, it's grim. Most of the 11% of ZTVs were gross safety violations. For example 4,2% of the audits, which means 118 facilities, found lacking emergency exits. However, they also found child labour in 6 facilities and forced labour in 3 facilities. So according to their own reporting, their manufacturers have used child labour and forced labour. And just to remind you, this is covering just 36% of their contract manufacturers. What I found interesting (read disturbing), was that violence or sexual misconduct against workers were not among Zero Tolerance Violations. I know it's not a situation, where they don't consider it violation of Code of Conduct, but rather just calls the police and let them handle it, because the violations counted here are based on their CoC, in which there's an item 7 named "No harassment or abuse of employees", which explicitly forbids physical, sexual, mental and verbal abuse. They don't however breakdown the make up of the non-ZTV violations that have occured, nor do their reveal how are they graded the ratings, so there's really no way to know what the 71% of their manufacturers have done to warrant their low (C or D) grading.

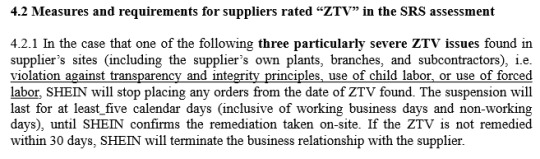

Would you at this point be surprised, if I told you it gets worse? Yeah, their so called Zero Tolerance Violations are not very zero tolerance after all. You might think zero tolerance means, that if manufacturers are caught doing it, their contract is immediately terminated and they are reported to authorities? Well, let's look what is the "immediate corrective action" outlined in their Responsible Sourcing Policy. Among the ZTVs they define even more zero tolerance violations, let's say negative tolerance violations. These are 1. forging documents, bribery or refusing to get assessed 2. child labour and 3. forced labour. Surely these lead to immediate contract termination and reporting to authorities?

So if Shein encounters slavery or probable coverup of it in their facilities, they stop placing new orders until the enslaved people and children are taken somewhere else or otherwise their contracts are fixed (at least for now), so there's no more slavery in sight, when someone comes back to assess them again and decides it's all good to continue business as usual. They have 30 days to make everything look like there's no issues, which sounds pretty easy task, and after that they can grab the kids and the slaves back there like nothing happened. Also notice how they didn't say they demand stopping the work entirely in the facility, just that they'll stop placing orders? Yeah, they don't stop production even if they find literal children or enslaved people producing them. Gotta get those dresses to the customer.

If they find any other ZTV, they come back in 30 days, and if the violation continues, they give a warning, come back again in 30 days, and if still the issue is there, then they stop placing orders. After that it continues like with child or forced labour violations. If after another 30 days it's not fixed, the contract is terminated. If a supplier gets two ZTVs within two years, they go straight to the even less than zero tolerance model straight away. If they get three ZTVs in two years, then their contract is immediately terminated. Nothing different happens though, if you get caught doing child or forced labour two times in two years, so you can just get caught once a year as long as you always pretend to stop doing it. But even if you do get caught third time in two years, or fail to pretend you fixed it, it's fine, you'll just have to do other stuff for the next year, and then you can apply again to work with Shien. Also the policy does not at any point require reporting these alleged crimes to authorities. If they at some point stop placing orders for a supplier (for example because of child or forced labour), they have to just sent all the files and documents of the goods that are produced by that supplier during the time they aren't giving them new orders to the relevant tax and customs authorities.

To answer the question I started this section with, sounds like Shein provides more evidence of bad working conditions in their suppliers' facilities, than they provide evidence of good working conditions. They even give evidence that their monitoring of those conditions is just a joke, and they have no mechanisms to actually get rid of suppliers who have inhumane working conditions. Elsewhere they try to give very weak evidence of good working conditions. The influencer brand trip to their facility in China was a PR stunt like that. However, it's easily dismissable, as the facility was not at one of the factories, where their clothing is made, all of which are third parties, but Shien's own facility they call Innovation Center. There they innovate new technologies, train their suppliers to use their new technologies and consult their suppliers on how to make new factories, which I assume means they have factory templates to give to their suppliers.

However, independent sources give much more reliable evidence of terrible working conditions in their factories. Like when undercover operation into one of their factories found employees working 18 hours a day earning 2 cents per item. When asked for comment, they answered: "Any non-compliance with this code is dealt with swiftly, and we will terminate partnerships that do not meet our standards." This is not severe ZTV, so what they mean by "dealt with swiftly" is "told to stop breaking labour laws, given some time, given warning, given more time, stopped giving new orders, given even more time and if after three months they have not stop then they gotta go". Because yes, they do terminate those who don't meet their standards. Their standards are just in the gutter.

HOW IS THE COMPANY STRUCTURED? While falling down this rabbit hole I came to the realization that Shein is the Uber of fashion. It's just the gig economy all over again. Let me explain. Unlike traditional fashion companies, Shein has outsourced even the sewing of the clothing. Shein itself is an app company, like Uber, though they technically do design their own clothes. I say technically because they have been repeatedly accused of copyright infringement to the point where they are now sued for racketeering. Allegation from the lawsuit:

"Shein has grown rich by committing individual infringements over and over again, as part of a long and continuous pattern of racketeering, which shows no sign of abating."