#surface mount heaters

Explore tagged Tumblr posts

Photo

Transitional Porch in Indianapolis Inspiration for a large transitional tile screened-in back porch remodel with a roof extension

#backyard#nano wall#collapsible glass wall#surface mount heaters#lakehouse exterior#contemporary cable handrail

0 notes

Photo

Backyard Porch Indianapolis An example of a large transitional tile screened-in back porch design with a roof extension.

#game room#outdoor living space#exterior tile floor#surface mount heaters#indoor-outdoor living space

0 notes

Text

Transitional Porch - Porch

Idea for a sizable back porch with a screen and transitional tiles

#collapsible wall#indoor-outdoor living space#nano wall#indoor-outdoor living ideas#surface mount heaters#pool deck area

0 notes

Note

RE: the whole boiler thing, I'm a building services engineer in the UK so I design these systems.

Generally, most homes and a decent proportion of other buildings will have a combi boiler (a boiler that provides water for heating and hot water), usually fueled by gas. They're usually wall mounted, and measurements of 70cm tall, 50cm wide and 30cm deep is fairly typical of a domestic boiler. Larger buildings may have a separate hot water cylinder which may be independently heated or supplied with hot water by the boiler.

In the UK boilers usually provide water at 70-80C - to prevent legionella in the hot water supply it needs to be heated to over 60C.

Radiators have the hot water (not steam in the UK) supplied via pipes and heat the room via convection - they heat the air around them which the circulates. From descriptions the radiators you've seen in media are older cast iron column radiators, which do still exist (typically in older buildings) but modern ones have a different design to increase the surface area of the radiator.

Most buildings in the UK do not have mechanical ventilation (so no air conditioning or forced air systems) and underfloor heating which is fancier than radiators is usually also hydronic (supplied with hot water), although at lower temperatures (45-55C).

How are Australian buildings usually heated?

In my experience, Australian buildings usually aren't heated.

On the farm we always had a fireplace in the home somewhere and if it got cold then everyone would go to the room with a fireplace. In towns people sometimes have an electric or gas heater built into a wall that does the same thing, and in recent years, I've noticed a lot of people have reverse cycle air conditioning. I'm not familiar with any other heating techniques in common use in Australia, although one of my friends did get this cool underfloor heating thing when converting his parents' shed into a granny flat.

The rest of us just buy a space heater from kmart.

184 notes

·

View notes

Text

A Scent Called You

Paring: Omega!Felix/Alpha!FemReader

Genre: 18+ Smut/Hybrid AU

Summary: You and your best friend Felix decided to take the weekend off and chill out in a small cabin, but things start to heat up when Felix gets a whiff of your heat.

Note: A smut collab with @inkandtension

✨💜Warning below the cut💜✨

Warnings: unprotected sex, knotting, cussing, begging, Felix in rut, whimpering, pet names, mounting

The cabin was quiet, the soft hum of the heater filling the space as snow swirled outside. You and Felix had come here for a weekend getaway, an escape from the noise of the city and the stress of daily life. It was supposed to be peaceful—a chance to relax. But the sharp, scent hit the air without warning.

Your heat.

It wasn’t supposed to happen now. You’d taken suppressants before the trip, sure they would hold you over. But the warmth spread through your body, a relentless tide of heat spreading from your core. Your scent filled the air like a lush storm: rich, sweet, and utterly intoxicating. It made your legs falter, your breath hitch as the undeniable truth settled over you.

Across the room, Felix froze.

The Omega's nose twitched, his big brown eyes widening as your scent washed over him. The instant it hit, his pupils dilated. He let out a soft whimper, the sound low and needy.

“Y/N…” His voice trembled, his usual sunshine demeanor replaced by something raw. “You’re in heat.”

You swallowed hard, your Alpha instincts roaring to the surface as his scent began to change too, you looked at him, unable to resist the urge to bit his neck when he threw his head back and his adams apple bobbed. His own heat-triggered rut hit like a tidal wave—a primal, heady mix of need and submission rolled into one. Felix’s cheeks flushed pink, and his breathing grew ragged.

“Alpha…” His voice was a shaky whisper, almost unrecognizable.

Shit.

He sat up abruptly, his eyes glowing with an intensity you hadn’t seen before. A low, guttural growl slipped from his throat. He shifted in his seat, fidgeting as though his skin had suddenly become too tight.

“Y-Your scent…” he stammered, his hands gripping the edge of the couch so hard his knuckles turned white. A faint sheen of sweat started to glisten on his brow, and his chest rose and fell in rapid, shallow breaths. “It’s too much. I—”

He stopped, his words dissolving into a needy whimper. You could see the exact moment his rut overtook him. His pupils, already dilated, became inky pools, swallowing the warm brown of his irises. His tongue darted out to lick his lips, which were parted slightly as he panted. His body trembled as he stood, swaying slightly, as though his legs could barely hold him upright.

“Alpha, please…” His voice cracked, thick with desperation as he took a step toward you.

“I can’t—I need to…” His words dissolved into a whine, his body trembling with barely restrained need. He dropped to his knees in front of you, his hands clutching at your thighs as his head bowed. “Please, Alpha. Let me… let me help you.”

His scent filled the air now, mixing with yours and creating a heady, overwhelming cocktail of need and want. It was rich and musky, tinged with the sweetness, and it sent a fresh wave of heat crashing through you.

Felix’s hands clenched into fists against the floor as he fought to steady himself. “I need you,” he whispered, his voice rough and pleading. “It hurts, Alpha. I—please, I’ll be good. I’ll be so good for you. Just—just let me…”

He looked up at you then, his expression needy.

“I need to touch you,” he begged, his voice trembling as he crawled closer. “I need to—need to take care of you. Please, Alpha. Let me… let me breed you.”

The last words came out in a choked gasp, as though saying them aloud had made his need all the more real. His hands reached out tentatively, brushing against your knees before clutching them desperately.

“I’ll make you feel so good,” he whimpered possessively. “I’ll take care of you, I promise. Just—just let me…” His voice trailed off into another growl, his body trembling violently as he leaned forward to bury his face in the crook of your neck.

The contact seemed to push him over the edge. His entire body shuddered as he inhaled deeply, letting your scent flood his senses. “Alpha,” he groaned, the sound raw and guttural. “I can’t—I need you. Please, please…”

His lips brushed against your skin, his sharp canines grazing lightly as he nuzzled into you. Every part of him screamed submission, but there was a desperate, primal edge to it—a deep, aching need that only you could satisfy.

“Say yes,” he pleaded, his voice barely a whisper. “Tell me I can have you. Tell me I can be yours.”

But then, he froze.

His hands, which had been wandering instinctively, gripped your hips harder as a flicker of clarity broke through the haze. His body tensed, and he pulled back just enough to meet your gaze. His eyes were still dark with lust, but there was a glimmer of hesitation beneath the hunger.

“Alpha,” he murmured, his voice low and hoarse. “If… if you say yes…” He swallowed hard, his throat bobbing as he fought to steady himself. “I won’t be able to stop. I can feel it—my rut’s taken over, and I… I don’t want to hurt you.”

His words were pained, his usual soft demeanor breaking through the haze of his instincts. His tail, which had been curling around your leg possessively, stilled as he stared at you, his brows furrowed in anguish.

“You have to say no,” he whispered, his voice cracking. “Please, Alpha. Tell me no. I—” He shook his head, his hands trembling as he gripped your hips harder. “I can’t control it if you say yes. The sane part of me is begging you… to stop this before I lose myself. Only you can-”

You reached out, cupping his flushed cheeks with your hands. His skin was hot to the touch, his ears drooping as he leaned into your palm, his breath hitching. “Felix,” you said softly, your voice steady despite the whirlwind of heat and desire coursing through you. “I trust you.”

His eyes widened, and a soft whimper escaped his lips. “Don’t… don’t say that,” he begged, his voice trembling. “If you say yes, I won’t be able to hold back. I—”

“Please,” you interrupted, your voice firm yet laced with vulnerability. Your thumbs brushed against his cheeks, grounding him as your eyes locked onto his. “I want this. I want you, my omega.”

His resolve shattered.

His body moved on instinct, his arms wrapping around you tightly as he let out a guttural growl.

“Alpha,” he groaned, his voice raw and primal as he buried his face in your neck. “I’m sorry—I can’t stop anymore.”

His lips claimed yours in a fervent, desperate kiss, his hands roaming your body as though trying to memorize every curve. His tail swayed erratically behind him, his body trembling as he surrendered completely to the instincts driving him.

“You’re mine, my alpha, mine, mine” he growled against your lips, his voice dripping with possessiveness and need. “I’ll take care of you—I’ll make you feel so good, I'll make my alpha feel good. Alpha, I promise.”

His words were a mix of devotion and desperation, his actions fueled by both love and the need to claim.

The desperate and hazy kissing quickly ended when Felix picked you up, one quick scoop was all it took for him to be carrying you princess-style to his bed.

The whole way praise never stopped leaving his lips, like a fountain it poured out. “Make you feel good Alpha, wanna mount you Alpha, feel you and your pretty pussy.”

Once in his bedroom, he shut the door with his foot and flopped you down on his bed, not hard but enough to make your head spin as his scent fumed off of the bed. Wrapping you in its soft and sweet glory, his scent made you feel dizzy as it filled your lungs, intoxicating you into some sort of trance.

Felix positioned himself between your legs, his tail hitting your feet that hung over his bed, tickling you with each lazy sway.

He hooked a finger in your pants, catching your underwear with it. Looking up at you he let out a soft whine, his eyes turned soft and blue as he checked one last time that this was in fact ok. He was hurting and you could see that, knowing it was Felix made the indecisiveness skip your brain.

You slipped your leg between his in confirmation, sliding your foot up his penis causing him to buck into the air.

His fingers on your skin were soft, as he frantically ripped off your pants and underwear, throwing them across the room and flipping you over.

“Slide down Alpha,” he said unbuckling his belt and springing his cock free, already hard and leaking with precum.

You slid down till your feet touched the floor, still warm from where Felix was standing, and bent over his bed.

As soon as Felix’s penis made contact with your wet folds he was pushing in hard, trying and failing to muffle the sound of his whimpers.

The intoxicating scent of you and Felix mixing soon filled the room, almost like a libido booster you became more horny with each breath. Desperately, you fought the urge not to just flip around and pin him down, riding his cock like you knew you so easily could.

“Felix such a Good Boy for me, dragging your cock head against my soft spot. Such a Good Boy Felix,” your words sent Felix wild, and any part of him that was still sane was now completely gone.

He pushed in quick yet long, letting his full length drag across your vaginal walls, making your stomach flutter and your walls clench around him. With his head dragging against your G-spot and his tail brushing against your clit with each deep thrust, you knew you wouldn't last long.

“Should I breed my Alpha, fill her up make her feel full-luh luh,” he growled as his tongue flopped out of his mouth and his knot started to form, making it hard for you to hold it anymore.

His soft comforting smell, the way he holds you from the back so gently as he fucks you so roughly, his cock hitting all the right spots like he was meant for you. You knew you were the Alpha and he the Omega, but sometimes you wanted to be held too, feel vulnerable, and let your guard down now and then. Who better to share these moments with than Felix your loving and forever understanding Omega.

“Fill me” you moaned breathlessly, pushing your ass back and your vagina up to better let him fuck you.

As Felix’s knot got bigger your release soon was upon you, the warm feeling of his cum filling you up was like heaven when your orgasm was at its peak.

Felix let out a guttural and deep moan as he slowly stopped moving, his fingers covered in mixed cum that was leaking down your ass.

With Felix now stuck to you, he climbed up behind you, gently wrapping his whole body (tail included) around you to keep warm.

He traced small circles on your chest as he rested his head on your back, his warm cheek flush to the skin of your back as he breathed with you, trying his best to calm the both of you down.

“Such a Good Boy, filling me up with your pups,” you said leaning back to kiss his bare shoulder, Felix shuddered in response, his whole body got chills from the simple gesture.

“I hoped I did good, I wanted to make you feel good Alpha,” he said letting out a sigh.

“How could you have any doubt Felix? My vagina is still leaking cum and your knot is still stretching my achy walls, this is by far the best I’ve ever been treated during my heat.”

A tint of pink spread over Felix’s cheeks as he let out a sigh of relief. Now he could fully let himself be comfortable, wrapped around you snuggly as the two of you dozed off to sleep. At one point in the night, Felix’s scent was spicy, animalistic even something you’d never smelled before that instantly turned you on, but now it was back to the way you remember it sweet, soft, and safe.

#skz#stray kids#my pookie#my pookies#kpop#smut#skz smut#skz au#stray kids smut#stray kids au#skz lee felix#alpha x omega#stray kids lee felix#skz x reader#alpha reader#stray kids felix#skz felix#lee felix#i love y’all💜#omegaverse#alphaverse#hybrid au#hybrid smut#felix smut#fantasy smut#hybrid#kpop smut#stray kids x female reader#stray kids fantasy au#collaboration

306 notes

·

View notes

Text

Back home

Summary: Javi returns home and you guys have some fun 😜 (I'm bad at summaries haha)

A/N: I wrote this before Halloween ended so forgive the Halloween activities. I can't be bothered to change it. Also I don't really know what perspective this is written in..?

I have not proofread this so I'm sorry if there's any confusing bits or mistakes. Lmk if there's anything major!

Javier Peña x f!reader

Word count: 1858

Warnings- pet names, smut (oral f receiving, PiV) fluff

DO NOT COPY THIS WORK IN ANY WAY PLS AND TY.

°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°

He turned off his car and walked outside, unlocking the door to his apartment and stepping inside, admittedly a little excited to finally see his girlfriend after a long mission abroad.

As he opened the door, she jumped up and ran over to him, crushing him with a hug as she practically jumped on him.

"Javi! I missed you so much!" She squealed.

He laughed heartily, catching her in his arms as she leaped towards him. He spun her around once before setting her back down on the ground, kissing her passionately. "I missed you too, mi amor. It feels good to be home."

Pulling away, he took a step back to look at her, taking in every detail of her appearance. Her hair was longer than he remembered, and there was a new sparkle in her eyes that made his heart skip a beat.

"You look more beautiful than ever." He said sincerely, reaching up to tuck a stray strand of hair behind her ear. "How have you been holding up while I was away?"

"Been good.. kinda bored though, without you. I did some decorating as you can see..." She said, nodding her head in the direction of the Halloween decorations strung up thoughout the apartment.

His eyes lit up as he took in the festive decorations adorning their home. Skeletons hung from the ceiling, cobwebs were draped across corners, and pumpkins sat on every available surface.

"Wow, you really went all out." He remarked with a grin. "Looks like we're ready for Halloween."

He wrapped an arm around her waist, pulling her closer as they surveyed the scene together.

"So what do you say we make the most of my first night back? We could watch a scary movie, eat some popcorn...maybe even carve a pumpkin or two."

"Oh, scary movie marathon was already on my list of stuff to force you into. Sit, I'll go bring some popcorn. Put a movie on too, you get first pick as a courtesy of mine." She winked before kissing him again then going to get the popcorn ready.

He chuckled, watching her walk away before turning his attention to the television. Flipping through the channels, he settled on a classic horror film - one that had given him nightmares as a kid but seemed strangely comforting now.

By the time she returned with a steaming bowl of popcorn, the opening credits were rolling. She handed him a large handful before settling in next to him on the couch, resting her head against his shoulder.

"This better not give me nightmares," she teased, reaching for another handful of popcorn. "But if it does, at least I know who to blame."

Halfway through the movie, she moved to sit between his legs on the couch and pulled the blanket on top of them, muttering something about being cold and Javier's body being a 'fucking heater'.

He laughed softly, wrapping his arms around her waist and pulling her closer. As the tension mounted on screen, he couldn't help but feel a sense of peace wash over him - there was no place he'd rather be than right here, with her.

She moved to tug the blanket tighter around them as she complained how cold it was when it was barely November.

"You're cold?" He asked playfully. "Let me help you with that."

With a mischievous grin, he began to tickle her sides, eliciting a fit of giggles from her. When she tried to retaliate, he captured her wrists in his hands, holding her still as they both dissolved into laughter.

"Okay, okay," she gasped, breathless. "I surrender!" But he didn't let up.

"Javi, stop!" She shrieked as her face went red from laughing so hard. "I'm gonna piss myself, stop!"

His eyes twinkled with amusement as he relented, releasing her wrists and leaning back against the couch. But even as the movie continued, his gaze remained fixed on her - taking in every curve of her body, every freckle on her skin.

"You know," he said softly, running a finger down her arm. "There's only one way to make sure you don't have nightmares tonight."

Leaning in, he brushed his lips against hers in a gentle kiss. She responded eagerly, her hands tangling in his hair as they lost themselves in the moment.

"We need to make sure you stay awake," he whispered, making her breath hitch slightly as she turned to face him fully.

"How do you plan on doing that?" She pressed, any attention she was paying to the movie before long gone.

A smile played at the corner of his mouth as he traced a finger along her collarbone, leaving a trail of goosebumps in its wake. His voice was low and husky when he spoke, sending shivers down her spine.

"I have a few ideas," he murmured, leaning in to capture her lips once again. This time, there was nothing gentle about their kiss - it was fierce and hungry, fueled by weeks apart.

Breaking away, he looked into her eyes, his own dark with desire. "Are you game?"

"Am I game?" She laughed before moving to sit completely on his lap.

"Yeah, I'm game."

His heart raced as she straddled him, her warmth enveloping him like a second skin. He cupped her face in his hands, kissing her deeply before trailing kisses down her neck.

"Good," he growled against her skin. "Because I've missed you too much to wait any longer."

With that, he stood up effortlessly, carrying her bridal style towards the stairs. She buzzed with excitement as he climbed each step, her arms wrapped tightly around his neck.

"It's really hot how you can just carry me like this." She said with a little giggle as she looked up at him.

He chuckled, pressing a kiss to her forehead before answering.

"Years of working in the DEA have paid off, I guess." He flashed her a grin as they reached the bedroom door. Setting her down gently on the bed, he took a moment to admire the sight before him - her flushed cheeks, her tousled hair, the heat in her eyes.

"Now," he said softly, crawling towards her on the bed. "Where were we?"

"I think we were here." She said as she straddled him once more and leaned back slightly to pull her top off.

His eyes widened in appreciation as she revealed her perfect breasts, her nipples already hard from their earlier encounter. Leaning in, he took one into his mouth, teasing it with his tongue before switching to the other.

"Fuck, you're beautiful," he groaned, his hands wandering over her body. Reaching behind her, he unclasped her bra completely and let it fall to the floor, revealing even more of her smooth skin.

She gasped as the cold night air hit her breasts before her hands came to grab for his shirt, fumbling to get it off.

Laughing softly, he helped her remove his shirt before moving on top of her. His lips trailed down her stomach, leaving a path of kisses in their wake. Reaching her jeans, he undid them quickly, sliding them down her legs along with her panties.

"So wet for me," he murmured appreciatively. "Just like I knew you would be."

Dipping his head, he ran his tongue over her clit, causing her to cry out in pleasure. Her taste was intoxicating - sweet and tangy at the same time. He lapped at her folds greedily, drinking in her essence.

"Oh my god" she moaned, head tipping back as she fisted his curls tightly, begging him for more.

Encouraged by her reaction, he redoubled his efforts, using his fingers to massage her clit while his tongue delved deeper inside her. She was so close - he could feel it in the way her body trembled beneath him.

"That's it, baby," he growled, adding another finger to increase the pressure. "Come for me."

And with a loud cry, she did just that, her orgasm crashing over her like a wave. He held her through it, his arms wrapped around her waist as she rode out the aftershocks.

"Wow," she breathed finally, looking up at him through heavy-lidded eyes.

"You're really good at eating pussy." She said with an airy chuckle as she leaned forward on her forearms.

He grinned at the compliment, leaning in to steal a kiss. "I aim to please," he said cheekily.

Rolling onto his back, he pulled her on top of him, enjoying the feeling of her naked body pressed against his. Her breasts were soft against his chest, her thighs slick with sweat where they rested on either side of his hips.

"Your turn," he said, reaching down to cup her ass. "I'm not done with you yet."

"You better not be." She murmured against his lips before pushing herself up and steadying herself with her palms against his chest, starting to rock slowly against his erect length.

His breath caught in his throat at the sensation of her moving against him. It felt amazing - the friction of her wetness against his cock driving him wild. He could feel himself getting closer to the edge, but he didn't want it to end yet.

Reaching up, he grabbed her hips, guiding her movements until she was riding him just right. Her moans spurred him on, and soon they were both lost in the rhythm, their bodies moving together in perfect harmony.

"Querida," he groaned, unable to form coherent words anymore. All he knew was that he needed more of her - needed to be inside her.

"What?" She teased as she slowed her movements slightly, head resting sideways on her shoulder.

Gritting his teeth, he tried to hold back, but it was no use. He lifted her up and pulled her back down on him in one swift movement, barely giving her a chance to breath before he was thrusting rapidly inside of her.

Her head fell back and he bent down, attaching his lips to her nipple once more and swirling his tongue around it, his pace inside of her still relentless.

Her hands tugged on his disheveled hair when he angled his hips a little differently, making his cock hit that perfect spot inside of her.

"Fuck, don't stop! I'm gonna come, Javi!" She moaned.

"Come on baby, come on. Soak my cock. Come on." He urged, moving faster and faster until she finally came undone, clenching around him and making her pussy impossibly tight around his dick.

With a final thrust, he came inside her, his release so powerful it left him weak and breathless. As the last of his orgasm subsided, he pulled her down onto him, wrapping his arms around her tightly.

"Fuck," he breathed against her neck. "That was...amazing."

She smiled, pressing a kiss to his jawline. "It certainly was," she agree before resting her head in the crook of his neck until her breathing slowed and they both came down from their highs.

He lay down in a more comfortable position after a moment and she shuffled to the side slightly so her head was resting on his chest, slowly drifting to sleep.

°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°~°

Thank you so much for reading, I hope you enjoyed! Likes, comments, and reblogs are always appreciated and requests are open! 💞

#pedro pascal#pedro pascal characters#javier peña smut#javier peña angst#javier peña fanfiction#javier peña#javier peña x reader#narcos#javier peña narcos#amyispxnk fics

160 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

What is the installation space requirement and power consumption?

Planning for both production capacity and practical installation needs—namely, power consumption and floor space—is crucial when thinking about buying a square-bottom paper bag maker. Your factory layout, monthly operating expenses, and long-term scalability are all directly impacted by these two variables.

At Prakash Machineries Pvt. Ltd., we design our square-bottom paper bag machines to be Whether you’re running a large industrial setup or launching a small startup, our machines are built to integrate smoothly into your workspace without demanding major infrastructure upgrades.

In this guide, we explain the power and space requirements of our square-bottom paper bag machines and how you can prepare your facility for successful installation and operation.

⚡ Power Consumption: Designed for Energy Efficiency

Our machine is equipped with servo-driven motors, automated PLC controls, and energy-optimized components to ensure high productivity with minimal energy use. On average, the power consumption of our square-bottom paper bag-making machine falls between

✅ 10 kW to 14 kW per hour

(Depending on the machine model, size range, and optional attachments)

🔋 Breakdown of Power Usage:

Component Approximate Load Main motor (servo drive) 5–7 kW Vacuum pump 2–3 kW Gluing system & heater (if any) 1–2 kW Control panel and sensors 0.5–1 kW Optional attachments (printer, handle unit) 1–2 kW

This efficient power profile means that you won’t need industrial-scale electricity infrastructure to run the machine. Even for startups or medium-scale units, a standard 3-phase connection with a 20–25 HP (horsepower) supply is typically sufficient.

✅ Monthly Cost Estimate:

Assuming 8 hours/day of operation at an average of 12 kW/hr:

12 kW × 8 hours × 30 days = 2,880 kWh/month

At ₹8/kWh (approx. industrial rate in India), monthly electricity cost = ₹23,000

This makes our machine a cost-effective production solution, especially when you compare the high output capacity (up to 192,000 bags/day) with the low operational expense.

📐 Required Space for Installation

Our square-bottom paper bag machines are compact, modular, and engineered to occupy minimal floor space while still offering full production capabilities.

✅ Recommended Installation Area:

20 feet (L) × 8 feet (W) for standard machines 25 feet (L) × 10 feet (W) if optional units (e.g., printer, handle pasting) are included

🏭 Ideal Layout Plan Includes:

Machine footprint—main operational unit

Paper roll loading area—space for jumbo rolls (up to 1 m wide)

Bag collection table—output stacking and packing zone

Operator movement zone—minimum 3 ft clearance on each side

Electrical control cabinet—attached or wall-mounted

Optional space—for printer unit, handle applicator, or lamination feeder (if installed)

Our machines can be installed in a production unit as small as 500–600 sq. ft. You do not need a massive industrial hall. Even a startup with a moderate factory space can begin production seamlessly.

🛠️ Site Preparation Checklist

Before installation, ensure the following infrastructure is in place:

✔️ Electrical Requirements:

3-phase power connection (415V)

A stabilizer or UPS recommended for voltage fluctuation zones

Isolated circuit breaker and control panel for machine safety

✔️ Space & Foundation:

Flat, concrete floor surface (leveling required)

Dust-free, dry environment for optimal performance

Space for operators to safely move around machine

✔️ Ventilation & Safety:

Basic ventilation or exhaust fans (especially in hot climates)

Fire safety measures as per industrial compliance

Proper lighting for operator visibility

💡 Why This Matters to Your Business

Understanding your power and space needs in advance helps you

Avoid delays in installation

Ensure uninterrupted production

Optimize your floor plan for raw material, output, and manpower

Control operational costs with energy-efficient planning

This is especially crucial for startups, small businesses, or factories expanding capacity, where space and energy planning affect both short-term efficiency and long-term profitability.

🔧 Our Support Includes:

At Prakash Machineries Pvt Ltd, we don’t just deliver machines—we offer end-to-end installation support, including:

Pre-installation guidance (electrical, civil layout)

Custom floor plans for your site

On-site machine setup and calibration

Operator training and troubleshooting

Maintenance and after-sales service

🏁 Conclusion: Compact. Efficient. Installation-Ready.

Our square-bottom paper bag-making machines are designed to be energy-efficient and space-friendly—ideal for both high-output factories and compact manufacturing setups. With low power consumption (10–14 kW) and a compact footprint (under 250 sq. ft.), you can begin or scale up your paper bag production with minimal infrastructure investment.

📞 Plan Your Factory Setup With Us

Want help designing your factory layout? Need a customized installation guide for your plant? We’re here to help.

👉 Contact Prakash Machineries Pvt Ltd to get a personalized site layout, electrical requirement checklist, or expert consultation to prepare your facility for high-speed, efficient paper bag production.

#manufacturer#paper bag manufacturer#paper bag#paper#machines#flexo#v bottom#square bottom#alien stage#baking#bags#cake#chris sturniolo#cooking#critical role#dan and phil#delicious#breakfast#chocolate

1 note

·

View note

Text

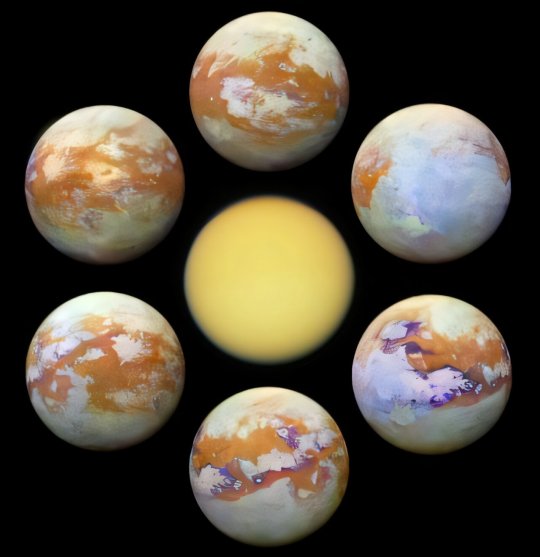

Student-led study reveals extraterrestrial explosions may blow hot and cold

Mount Vesuvius, Krakatoa, Mount St. Helens: Since the formation of Earth approximately 4.5 billion years ago, the convection and release of hot magma in its mantle layer has famously led to some of the deadliest eruptions in history. But what if the same explosions occurred when a geological feature and nearby chemical compounds became too cold?

Confirming this shocking phenomenon was the centerpiece of fifth-year doctoral student Shaelyn Raposa and recent NAU alumna Anna Engle's study published last month in the Journal of Geophysical Research: Planets.

Focusing on materials found on the icy glaciers of Pluto and the lakes of Titan, Saturn's largest moon, the researchers initially set out to examine how these compounds, which exist as gases on Earth, behave in below-freezing temperatures.

They were met with a surprise, however, when the chilly conditions of Wettaw's Astrophysical Materials Laboratory led to drastic pressure spikes and minor explosions when their chemical mixtures began to freeze, an event the researchers dubbed an "outburst."

"These outbursts occur when cooling a mixture, similar to the aftermath of leaving a soda in the freezer for too long," Raposa said. "However, when it comes to geologic eruptive processes, we think of them as a consequence of warming something up, like volcanoes for example. In both cases, a change in temperature causes a change in pressure, which makes sense, but we weren't expecting to see a pressure spike after our mixtures froze."

Completing the study in 2023, Raposa and Engle made mixtures with varying levels of nitrogen, ethane, carbon monoxide or methane—all compounds found in liquid form on Pluto and Titan—and injected them into aluminum alloy sample cells. These cells were then cooled in a helium refrigerator and temperature-controlled using two nichrome heaters, replicating the -300°-temperatures of the outer solar system.

Using spectroscopy, the researchers could then confirm the exact conditions that led to phase changes in each compound mixture, from gaseous forms to solid ices. This study was a rare effort to accurately replicate extraterrestrial conditions on Earth, only made possible by a unique lab space at NAU.

"It's expensive to send physical missions to places like Pluto and Titan to study the surface, which is why it's nice to be able to study how these materials behave in a laboratory setting,"Raposa said. "There are difficulties, however, because you need a lab setup similar to ours designed to study mixtures at low temperatures. Not many of these exist, and the result is that there has been very little prior research studying the behaviors of these materials."

When the mixtures were at or below their freezing points, the fluid trapped below the solidifying ice began bursting and bulging, representing a release of latent heat and a pressure spike that outmatched the strength of the confining solid.

This reaction could possibly be the answer to countless explosive mysteries plaguing our solar system and beyond, from ice or mud volcanism on Mars to sharp-edge depressions on Titan's surface.

"Under the right conditions, we might see eruptive phenomena caused by cooling on both icy and rocky worlds," Raposa said. "Outbursts like the ones we saw in the lab may provide alternative explanations for the explosion craters found in Siberia and perhaps the geysers and plumes detected on Europa, a moon of Jupiter, and Enceladus, another moon of Saturn."

Although magma and grueling heat may not be prominent factors on other planetary bodies billions of miles away, Raposa and Engle's study ensures scientists won't have to put their explorations on ice.

Data regarding how temperature and pressure changes influence compounds outside of Earth can prove critical for making accurate models of places like Pluto and Titan, ultimately leading to more discoveries surrounding each astronomical object.

With this study's valuable insights into thermodynamics, astronomers are one step closer to bringing the solar system's cosmic rumbling giants to our terrestrial laboratories.

TOP IMAGE: Titan’s thick atmosphere blocks views of its surface, creating images like the view of Titan in the center. Instead, astronomers use infrared technology to create visual approximations of its appearance. Credit: NASA/JPL/Caltech/Space Science Institute/University of Nantes/University of Arizona

LOWER IMAGE: Credit: NASA/Johns Hopkins University Applied Physics Laboratory/Southwest Research Institute

2 notes

·

View notes

Text

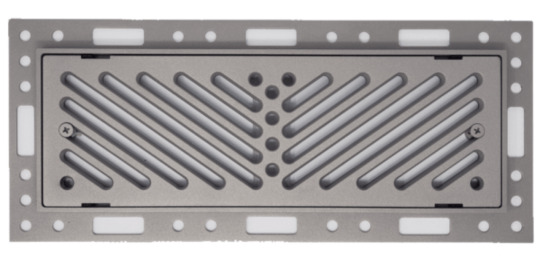

How to Give Your House Better Air with Tough Metal Floor Vents?

Good ventilation keeps the indoors healthy and comfy. Most people lean on ceiling fans or open windows to push air around, yet forgotten floor vents carry just as much weight. Swapping the old grate for a sturdy metal vent can supercharge that hidden breeze. These hard-working, good-looking pieces last for years and lend a tidy touch to rooms. In the post below, we'll walk through the quick swap and show why metal floor vents are worth every cent.

Knowing Why Floor Vents Matter?

Air needs to move up, down, and sideways so every corner feels even. Because warm air rises, heaters pipe heat through the floor grates, and the warmth floats upward on its own. When summer hits, that same design stops hot pockets from crowding the ceiling and keeps cooler air at shoulder level.

If your heating or cooling system seems weak, the problem might not be the blower, but the vents. Registers that are old, clogged, bent, or simply placed in the wrong spot can break the airflow. That is exactly why many homeowners turn to metal floor vents.

Why Upgrade to Metal Floor Vents?

Metal registers offer clear benefits over plastic or wood models:

Durability - Metal shrugs off heavy foot traffic, moisture, and wild temperature swings much better than its rivals. Whether in busy hallways or humid basements, these vents keep their shape.

Efficient Airflow - Built with tight tolerances, metal registers let air flow steadily, easing the load on your HVAC unit.

Design Versatility - Offered in finishes such as brushed nickel or matte black, and in flush-mount or surface-mount forms, metal vents match almost any decor.

Easy Maintenance - A quick wipe keeps them clean, and they won’t chip, crack, or warp the way wood sometimes can.

Types of Metal Floor Vents:

You will find several styles of metal vents, but the two most common are:

• Surface-Mount Vents - These sit right on top of the floor, making them a breeze to install or swap out. That quick-and-easy trait makes surface-mount vents perfect for fast upgrades.

Flush mount metal floor vents sit even with the floor instead of standing proud. Because they blend into the surface, they look sharp, cut down on trips, and keep the room feeling tidy.

Every vent style comes with a cover or grille that either snaps off for cleaning or stays in place, depending what you need.

Steps to Improve Ventilation Using Metal Floor Vents:

1. Evaluate Existing Vent Placement:

Walk room to room and check where vents land. Are there enough in big areas? Do couches or sheers block airflow? Poor spots slow comfort and waste energy.

2. Replace Old Registers:

Rusty, bent, or water-damaged wooden registers drag performance. Measure the opening and grab sturdy metal replacements for a snug seal.

3. Choose Flush Mount for Modern Appeal:

For an ultra-clean, on-trend look, pick flush mount metal vents. They call for a pro or a careful DIYer but reward you with better style and airflow.

4. Keep Vents Clean and Unblocked:

Routine cleaning is vital. Dust, crumbs, and pet hair pile up on the grates, choking airflow. Pop off the covers now and then, then give them a quick vacuum or a wipe in soapy water.

5. Install Vents That Match Each Room:

Some metal registers have tiny levers that let you open or close the slot. Put these in guest rooms or halls, then push more air into the rooms you really live in.

6. Seal Leaky Duct Joints:

If warm or cool air whistles away behind the walls, loose or torn duct joints are probably to blame. Seal the cracks with mastic or duct tape, or call a pro to check the whole run.

Conclusion:

Dressing your floors with metal registers is an easy, sharp-looking way to upgrade ventilation. Whether you pick flush-mount grilles or surface-mounted styles, the sturdy metal stands up to feet while guiding air smoothly. Best of all, these vents clean in a snap and keep your HVAC humming, so your home stays comfy all year long.

If you are eager to breathe cleaner air indoors while giving your rooms a fresh look, think about adding metal floor vents. Swing by Metal Vents Basket to scout cool styles and smart finishes, then take the simple step toward healthier, sharper home ventilation.

#metalfloorvents#metalvents#floorvents#metalfloorvent#metalvent#flush mount metal floor register#flush mount metal floor registers#flush mount metal floor vents#flush mount metal vent#Floor Vents#Metal Vent#Metal Vents#Metal Register#Metal Registers#Metal Floor Register#Metal Floor Vent#Metal Floor Vents#Metal Floor Registers#Flush Mount Metal Floor Vent#Flush Mount Metal Floor Vents#Flush Mount Metal Floor Register#Flush Mount Metal Floor Registers#Flush Metal Vent#Flush Metal Vents#Flush Floor Register#Flush Floor Registers#Flush Floor Vent#Flush Mount Vent#Flush Mount Vents#Flush mount metal vent

0 notes

Text

4 Deceptively Easy Home Improvement Projects to Try

There are plenty of challenging, time-consuming home improvement projects that might seem daunting. But there are also quite a few that are easier than you might think. For example, installing premium tool storage in your garage doesn’t need to be a huge project. It might take time to install a wall full of cabinets, but it can also be easy to get done. Here are a few deceptively simple projects to try.

Installing Decorative Ceiling Tiles

Installing decorative ceiling tiles doesn’t have to be a lengthy project. Simply measure out the number of tiles you need and prepare the surface so it’s clean and debris-free. Apply an adhesive to the back of a tile, press it firmly against the ceiling, and then repeat. You can create your own patterns or designs with the tiles. All that’s left is to trim the excess for a clean look.

You can even use grid systems for a precise installation, ensuring it looks professional.

You can find tiles for ceilings for many rooms in your home, from offices to kitchens and living rooms, and you can finish the project in a weekend.

Adding Garage Tool Storage Solutions

Garage tool storage can be as easy as assembling a large, wheeled toolbox or a bit more complex, like mounting cabinet garage storage options. But even the cabinets are fairly easy to install and can have a huge impact on your garage’s functionality and organization.

The hard part is figuring out what you need and how you will place the cabinets. Some systems are more modular than others, so you can adjust the layout and design to fit your workflow.

Replacing Your Deck Boards

Composite boards are far easier to install than normal wood boards. This is because the dimensions are typically more consistent, and the boards are usually much straighter. Plus, many have a handy hidden fastening system, making the actual installation process a breeze.

The most challenging part of the project might be loading and unloading them from your truck, but once you have the old boards removed, you can install the new deck boards over the weekend.

Integrating Connected Smart Home Devices

A smart home hub only takes a few minutes to set up, and the hardest part is finding a place to plug it in and connecting it to your Wi-Fi. There are plenty of options for a smart home, from thermostats to video doorbells. You can even get a smart garage door opener with a camera. The hardest part is making sure every piece will communicate with your smart hub of choice and getting everything working in concert.

Once everything is installed, you’ll find your home is more convenient, and you’ll wonder how you lived without these devices for so long.

About Menards®

Whether breathing new life into your home with a fresh coat of paint or renovating your backyard deck, you can trust Menards® for quality service and products to bring your ideas to life. Menards® is every fixer-upper, do-it-yourselfer, and remodeler’s one-stop home improvement shop. With high-quality tools, materials, and supplies to transform the inside and outside of your home, Menards® can help you turn your DIY ideas into successful home improvement projects. You can find everything you need to improve, organize, and protect your home, from electric hot water heaters to tool storage and locks to a gun safe on sale. With over 300 locations across the Midwest, from West Virginia to Wyoming, you can find friendly store associates ready to help you brainstorm new projects, answer questions, and Save Big Money at Menards®.

Find everything you need to make home improvement projects easy at https://www.menards.com/

Original Source: https://bit.ly/4jQHtlz

0 notes

Text

How Excel Heaters Delivers Precision-Engineered Nozzle Heating Solutions

Plastic injection moulding requires very precise control of temperature. Even a small variation can lead to defects in the moulded product. If the plastic is too cold, it won’t flow properly. If it’s too hot, it might burn or degrade. That’s why a reliable heater is essential.

At Excel Heaters, we understand this need and have focused our designs on accuracy, uniform heating, and long life.

Our Design Philosophy: Quality First

Every heater at Excel Heaters is built with a commitment to quality, safety, and performance. Here’s how we ensure that:

1. Material Selection

We use high-grade brass for the outer body of our sealed nozzle heaters. Brass offers excellent thermal conductivity and corrosion resistance, making it perfect for tough industrial conditions.

2. Advanced Heating Elements

Inside every heater is a high-quality nichrome wire, wound in a way that ensures even heating across the surface. We take great care in selecting insulation materials that improve heat transfer while keeping electrical components safe.

3. Sealed Construction

One of the standout features of our nozzle heaters is the sealed construction. This prevents moisture or plastic residue from entering the heater and damaging the coil. As a result, the heaters last longer and perform better in damp or dusty environments.

Customization as per Industry Needs

We know that every machine and moulding setup is different. That’s why we offer customization options for:

Diameter and Length

Wattage and Voltage

Lead wire exit direction

Mounting method (clamp or band)

Whether you need an 8mm heater or an 8.5mm, high wattage or standard, we can manufacture it as per your machine's requirements.

Key Benefits of Excel Heaters' Nozzle Heaters

Our sealed brass nozzle heaters are designed to provide several practical benefits:

Uniform Heat Distribution – No cold spots, resulting in better flow of plastic.

Energy Efficiency – Quick heat-up and recovery times save electricity.

Longer Life – Moisture-proof design protects the inner coil.

Easy to Install – Lightweight and compact design.

Consistent Performance – Suitable for long production cycles.

These features make our heaters suitable for plastic processing, packaging, printing, and more.

Industries We Serve

Excel Heaters supplies to a wide range of industries including:

Plastic Injection Moulding

Blow Moulding Machines

Thermoforming

Automotive Component Manufacturing

Consumer Goods & Electronics

Our heaters are used across India, including major hubs like Mumbai, Delhi, Pune, Ahmedabad, and Chennai.

Customer Support & After-Sales Service

Buying from Excel Heaters doesn’t end with delivery. We are committed to supporting our customers every step of the way. Our technical team can help you with:

Choosing the right heater

Installation guidance

Troubleshooting

Replacements and spares

Our goal is to build long-term relationships based on trust and performance.

Why Choose Excel Heaters?

With over a decade of experience, Excel Heaters has become a reliable name in the industrial heating segment. Here’s why manufacturers prefer us:

Made in India, Trusted Worldwide

Quick Turnaround Time

Stringent Quality Control

Affordable Prices

Custom Manufacturing Capabilities

When you choose Excel Heaters, you choose consistency, durability, and peace of mind.

Final Thoughts

In a fast-paced manufacturing environment, you can’t afford to take chances with heating elements. With Excel Heaters’ sealed brass nozzle heaters, you get reliable performance, precise temperature control, and long-lasting service — all in one compact, efficient product.

If you are upgrading your moulding machines or starting a new production line, trust Excel Heaters. They will power your process accurately.

0 notes

Text

The Complete Guide to Ventilation: How to Prevent Mold and Improve Air Quality in Your Bathroom

Proper bathroom ventilation is essential for maintaining a healthy, comfortable, and mold-free home environment. Without adequate airflow, excess humidity can lead to mold growth, unpleasant odors, and even structural damage over time. This guide will help you understand the importance of ventilation systems, explore the different types of fans, and learn best practices for maintaining excellent indoor air quality in your bathroom.

Key Points of the Blog

Understand why bathroom ventilation is crucial for health and home integrity.

Choose the right type of fan for your bathroom’s size and layout.

Install and position your fan for optimal moisture removal.

Run the fan during and after showers or baths to minimize humidity.

Combine mechanical ventilation with natural airflow when possible.

Keep your bathroom clean and dry to prevent mold and odors.

Communicate your ventilation needs with your contractor or designer.

Celebrate small upgrades every improvement helps.

Stay flexible and open to new ventilation solutions.

Enjoy the benefits of a fresh, healthy bathroom environment.

Why Bathroom Ventilation Matters

Bathrooms are hotspots for moisture, thanks to showers, baths, and even sinks. This humidity creates the perfect environment for mold and mildew to thrive, which can cause health issues and damage your home’s structure. Proper ventilation removes excess moisture, prevents condensation, and keeps the air fresh and clean.

Types of Bathroom Ventilation Systems

There are several effective ways to ventilate your bathroom:

Ceiling-Mounted Exhaust Fans: The most common and effective solution. These fans pull moist air out of the bathroom and vent it directly outside, preventing moisture from lingering in your home.

Wall-Mounted Exhaust Fans: Ideal for bathrooms without attic access. These fans are installed on an exterior wall and vent moisture directly outside.

Inline Exhaust Fans: Installed within the ductwork, these fans are quieter and can serve larger bathrooms or multiple rooms.

Windows and Natural Ventilation: Opening windows can help, but is often not enough in humid or cold climates. Natural ventilation is best paired with a mechanical fan for consistent results.

Humidity-Sensing Fans: These automatically turn on when humidity levels rise, ensuring moisture is removed without you having to remember to flip a switch.

Ventilation with Heaters: Some systems combine a fan with a heater for added comfort and improved moisture removal.

Best Practices for Bathroom Ventilation

To get the most out of your ventilation system, follow these tips:

Run the Fan During and After Showers: Turn on the exhaust fan before you start your shower and leave it running for at least 30 minutes after you finish to remove excess moisture.

Keep the Bathroom Door Closed: This helps contain humidity in the bathroom and makes the fan more effective at removing it.

Open Windows When Possible: Allow fresh air to circulate, especially on dry days.

Clean and Maintain Your Fan: Regularly clean the fan and check for obstructions in the vent to ensure it works efficiently.

Choose the Right Fan Size: Select a fan with the appropriate CFM (cubic feet per minute) rating for your bathroom’s size to ensure effective moisture removal.

Vent Outside, Not Into the Attic: Always vent your fan to the outdoors, not into an attic or crawl space, to prevent mold and moisture problems elsewhere in your home.

How to Improve Indoor Air Quality

Good ventilation is just one part of maintaining healthy air quality in your bathroom:

Keep It Clean: Regularly clean surfaces to prevent dust, dirt, and mold from accumulating.

Use Eco-Friendly Cleaning Products: These reduce chemical fumes and are better for your health and the environment.

Consider an Air Purifier: A compact air purifier can help filter out allergens and odors, especially in bathrooms with limited ventilation.

Monitor for Signs of Poor Air Quality: Persistent odors, mold growth, and excessive humidity are indicators that you need to improve ventilation.

Communicate with Your Contractor

If you’re renovating or upgrading your bathroom, discuss your ventilation needs with your contractor or designer. They can help you choose the right system, ensure proper installation, and recommend additional features like humidity sensors or heat recovery ventilation for maximum comfort and efficiency.

Celebrate Progress and Stay Flexible

Every improvement, no matter how small, helps create a healthier bathroom environment. Stay open to new technologies and solutions, and don’t hesitate to upgrade your system as needed.

Frequently Asked Questions

Q: How long should I run my bathroom exhaust fan? A: Run the fan during your shower or bath and leave it on for at least 30 minutes afterward to remove excess moisture.

Q: What is the best type of fan for my bathroom? A: Ceiling-mounted exhaust fans that vent outside are the most effective for most bathrooms. For smaller spaces or those without attic access, wall-mounted or inline fans are good alternatives.

Q: Can I rely on a window for bathroom ventilation? A: Windows can help, but they are not always sufficient, especially in humid or cold climates. A mechanical exhaust fan is recommended for consistent moisture removal.

Q: How do I know if my fan is working properly? A: If your bathroom remains damp, foggy, or smells musty after a shower, your fan may not be powerful enough or may be venting improperly. Check for obstructions and consider upgrading to a higher CFM fan.

Q: What should I do if I see mold in my bathroom? A: Clean the affected area with a mold-killing solution, improve ventilation, and address any leaks or persistent moisture issues. If the problem persists, consult a professional.

Looking for Expert Bathroom Ventilation Solutions?

If you’re in the Greater Toronto Area and want to upgrade your bathroom’s ventilation, our team specializes in modern, effective ventilation systems tailored to your needs. Contact us for a free quote and enjoy a fresher, healthier bathroom.

Disclaimer: The information in this article is for general guidance only. Every home and bathroom is different, and results may vary. Always consult with a qualified professional before making major renovation decisions. For optimal results, collaborate with experienced contractors who understand your specific needs.

0 notes

Note

Hi *waves*. May I request Hybrid Omega Felix with Alpha female reader when she goes into heat out of no where and it sends him into instant rut? Could this include him begging to mount her? Maybe him saying he wants to breed her, and knotting? Lots of praise for him too? Being a good boy? If it's not too much to ask, that is. Please and thank you!

A Scent Called You

Paring: Omega!Felix/AlphaFemReader

Genre: 18+ Smut/Hybrid AU

Summary: You and your best friend Felix decided to take the weekend off and chill out in a small cabin, but things start to heat up when Felix gets a whiff of your heat.

Note: A smut collab with @inkandtension

Link to the post will be at bottom

The cabin was quiet, the soft hum of the heater filling the space as snow swirled outside. You and Felix had come here for a weekend getaway, an escape from the noise of the city and the stress of daily life. It was supposed to be peaceful—a chance to relax. But the sharp, scent hit the air without warning.

Your heat.

It wasn’t supposed to happen now. You’d taken suppressants before the trip, sure they would hold you over. But the warmth spread through your body, a relentless tide of heat spreading from your core. Your scent filled the air like a lush storm: rich, sweet, and utterly intoxicating. It made your legs falter, your breath hitch as the undeniable truth settled over you.

Across the room, Felix froze.

The Omega's nose twitched, his big brown eyes widening as your scent washed over him. The instant it hit, his pupils dilated. He let out a soft whimper, the sound low and needy.

“Y/N…” His voice trembled, his usual sunshine demeanor replaced by something raw. “You’re in heat.”

You swallowed hard, your Alpha instincts roaring to the surface as his scent began to change too, you looked at him, unable to resist the urge to bit his neck when he threw his head back and his adams apple bobbed. His own heat-triggered rut hit like a tidal wave—a primal, heady mix of need and submission rolled into one. Felix’s cheeks flushed pink, and his breathing grew ragged.

“Alpha…” His voice was a shaky whisper, almost unrecognizable.

Shit.

He sat up abruptly, his eyes glowing with an intensity you hadn’t seen before. A low, guttural growl slipped from his throat. He shifted in his seat, fidgeting as though his skin had suddenly become too tight.

“Y-Your scent…” he stammered, his hands gripping the edge of the couch so hard his knuckles turned white. A faint sheen of sweat started to glisten on his brow, and his chest rose and fell in rapid, shallow breaths. “It’s too much. I—”

He stopped, his words dissolving into a needy whimper. You could see the exact moment his rut overtook him. His pupils, already dilated, became inky pools, swallowing the warm brown of his irises. His tongue darted out to lick his lips, which were parted slightly as he panted. His body trembled as he stood, swaying slightly, as though his legs could barely hold him upright.

“Alpha, please…” His voice cracked, thick with desperation as he took a step toward you.

“I can’t—I need to…” His words dissolved into a whine, his body trembling with barely restrained need. He dropped to his knees in front of you, his hands clutching at your thighs as his head bowed. “Please, Alpha. Let me… let me help you.”

His scent filled the air now, mixing with yours and creating a heady, overwhelming cocktail of need and want. It was rich and musky, tinged with the sweetness, and it sent a fresh wave of heat crashing through you.

Felix’s hands clenched into fists against the floor as he fought to steady himself. “I need you,” he whispered, his voice rough and pleading. “It hurts, Alpha. I—please, I’ll be good. I’ll be so good for you. Just—just let me…”

He looked up at you then, his expression needy.

“I need to touch you,” he begged, his voice trembling as he crawled closer. “I need to—need to take care of you. Please, Alpha. Let me… let me breed you.”

The last words came out in a choked gasp, as though saying them aloud had made his need all the more real. His hands reached out tentatively, brushing against your knees before clutching them desperately.

“I’ll make you feel so good,” he whimpered possessively. “I’ll take care of you, I promise. Just—just let me…” His voice trailed off into another growl, his body trembling violently as he leaned forward to bury his face in the crook of your neck.

The contact seemed to push him over the edge. His entire body shuddered as he inhaled deeply, letting your scent flood his senses. “Alpha,” he groaned, the sound raw and guttural. “I can’t—I need you. Please, please…”

His lips brushed against your skin, his sharp canines grazing lightly as he nuzzled into you. Every part of him screamed submission, but there was a desperate, primal edge to it—a deep, aching need that only you could satisfy.

“Say yes,” he pleaded, his voice barely a whisper. “Tell me I can have you. Tell me I can be yours.”

But then, he froze.

His hands, which had been wandering instinctively, gripped your hips harder as a flicker of clarity broke through the haze. His body tensed, and he pulled back just enough to meet your gaze. His eyes were still dark with lust, but there was a glimmer of hesitation beneath the hunger.

“Alpha,” he murmured, his voice low and hoarse. “If… if you say yes…” He swallowed hard, his throat bobbing as he fought to steady himself. “I won’t be able to stop. I can feel it—my rut’s taken over, and I… I don’t want to hurt you.”

His words were pained, his usual soft demeanor breaking through the haze of his instincts. His tail, which had been curling around your leg possessively, stilled as he stared at you, his brows furrowed in anguish.

“You have to say no,” he whispered, his voice cracking. “Please, Alpha. Tell me no. I—” He shook his head, his hands trembling as he gripped your hips harder. “I can’t control it if you say yes. The sane part of me is begging you… to stop this before I lose myself. Only you can-”

You reached out, cupping his flushed cheeks with your hands. His skin was hot to the touch, his ears drooping as he leaned into your palm, his breath hitching. “Felix,” you said softly, your voice steady despite the whirlwind of heat and desire coursing through you. “I trust you.”

His eyes widened, and a soft whimper escaped his lips. “Don’t… don’t say that,” he begged, his voice trembling. “If you say yes, I won’t be able to hold back. I—”

“Please,” you interrupted, your voice firm yet laced with vulnerability. Your thumbs brushed against his cheeks, grounding him as your eyes locked onto his. “I want this. I want you, my omega.”

His resolve shattered.

His body moved on instinct, his arms wrapping around you tightly as he let out a guttural growl.

“Alpha,” he groaned, his voice raw and primal as he buried his face in your neck. “I’m sorry—I can’t stop anymore.”

His lips claimed yours in a fervent, desperate kiss, his hands roaming your body as though trying to memorize every curve. His tail swayed erratically behind him, his body trembling as he surrendered completely to the instincts driving him.

“You’re mine, my alpha, mine, mine” he growled against your lips, his voice dripping with possessiveness and need. “I’ll take care of you—I’ll make you feel so good, I'll make my alpha feel good. Alpha, I promise.”

His words were a mix of devotion and desperation, his actions fueled by both love and the need to claim.

The desperate and hazy kissing quickly ended when Felix picked you up, one quick scoop was all it took for him to be carrying you princess-style to his bed.

The whole way praise never stopped leaving his lips, like a fountain it poured out. “Make you feel good Alpha, wanna mount you Alpha, feel you and your pretty pussy.”

Once in his bedroom, he shut the door with his foot and flopped you down on his bed, not hard but enough to make your head spin as his scent fumed off of the bed. Wrapping you in its soft and sweet glory, his scent made you feel dizzy as it filled your lungs, intoxicating you into some sort of trance.

Felix positioned himself between your legs, his tail hitting your feet that hung over his bed, tickling you with each lazy sway.

He hooked a finger in your pants, catching your underwear with it. Looking up at you he let out a soft whine, his eyes turned soft and blue as he checked one last time that this was in fact ok. He was hurting and you could see that, knowing it was Felix made the indecisiveness skip your brain.

You slipped your leg between his in confirmation, sliding your foot up his penis causing him to buck into the air.

His fingers on your skin were soft, as he frantically ripped off your pants and underwear, throwing them across the room and flipping you over.

“Slide down Alpha,” he said unbuckling his belt and springing his cock free, already hard and leaking with precum.

You slid down till your feet touched the floor, still warm from where Felix was standing, and bent over his bed.

As soon as Felix’s penis made contact with your wet folds he was pushing in hard, trying and failing to muffle the sound of his whimpers.

The intoxicating scent of you and Felix mixing soon filled the room, almost like a libido booster you became more horny with each breath. Desperately, you fought the urge not to just flip around and pin him down, riding his cock like you knew you so easily could.

“Felix such a Good Boy for me, dragging your cock head against my soft spot. Such a Good Boy Felix,” your words sent Felix wild, and any part of him that was still sane was now completely gone.

He pushed in quick yet long, letting his full length drag across your vaginal walls, making your stomach flutter and your walls clench around him. With his head dragging against your G-spot and his tail brushing against your clit with each deep thrust, you knew you wouldn't last long.

“Should I breed my Alpha, fill her up make her feel full-luh luh,” he growled as his tongue flopped out of his mouth and his knot started to form, making it hard for you to hold it anymore.

His soft comforting smell, the way he holds you from the back so gently as he fucks you so roughly, his cock hitting all the right spots like he was meant for you. You knew you were the Alpha and he the Omega, but sometimes you wanted to be held too, feel vulnerable, and let your guard down now and then. Who better to share these moments with than Felix your loving and forever understanding Omega.

“Fill me” you moaned breathlessly, pushing your ass back and your vagina up to better let him fuck you.

As Felix’s knot got bigger your release soon was upon you, the warm feeling of his cum filling you up was like heaven when your orgasm was at its peak.

Felix let out a guttural and deep moan as he slowly stopped moving, his fingers covered in mixed cum that was leaking down your ass.

With Felix now stuck to you, he climbed up behind you, gently wrapping his whole body (tail included) around you to keep warm.

He traced small circles on your chest as he rested his head on your back, his warm cheek flush to the skin of your back as he breathed with you, trying his best to calm the both of you down.

“Such a Good Boy, filling me up with your pups,” you said leaning back to kiss his bare shoulder, Felix shuddered in response, his whole body got chills from the simple gesture.

“I hoped I did good, I wanted to make you feel good Alpha,” he said letting out a sigh.

“How could you have any doubt Felix? My vagina is still leaking cum and your knot is still stretching my achy walls, this is by far the best I’ve ever been treated during my heat.”

A tint of pink spread over Felix’s cheeks as he let out a sigh of relief. Now he could fully let himself be comfortable, wrapped around you snuggly as the two of you dozed off to sleep. At one point in the night, Felix’s scent was spicy, animalistic even something you’d never smelled before, that instantly turned you on but now it was back to the way you remember it sweet, soft, and safe.

Link

#skz#stray kids#fandom#my pookie#my pookies#kpop#skz x reader#smut#stray kids x reader#ask meh#asks#anon ask#skz felix#skz lee felix#hybrid smut#felix#felix smut#werewolf au#alpha x omega#werewolves#skz au#stray kids smut#stray kids au#hybrid au#hybrid#stray kids x female reader#stray kids felix#stray kids lee felix#lee felix#i love y’all💜

138 notes

·

View notes

Text

Open Coil Heater Manufacturer Heat Master International is a prominent manufacturer of high-capacity open coil heaters, optimized for speedy heating and efficient heat transfer. The heaters are suitable for air and gas heating purposes in plastics, automotive, and HVAC industries. Our open coil heaters are constructed with precision and quality raw materials, ensuring ruggedness and exceptional thermal performance.

Flanged Tubular Heaters Our flanged tubular heaters are specifically designed for heavy-duty industrial use in applications that demand consistent and reliable heat distribution. Our products are suited for mounting in pressure vessels and tanks to heat liquids and gases. Heat Master International produces custom flanged heaters with unique flange sizes, sheaths, and watt densities according to precise client specifications.

Industrial Heaters Heat Master International provides an extensive array of industrial heaters suited to various industries such as chemical processing, food manufacturing, and manufacturing. Our heaters are renowned for their efficiency, safety, and versatility to suit different industrial operations. We offer standard and custom heaters to address the specific needs of our customers.

Mica Band Heaters Our mica band heaters are designed to heat efficiently on the surface, typically applied on barrels, nozzles, and dies. With great heat transfer and good grip, these heaters provide uniform temperature control. Heat Master International mica band heaters are found in different designs, voltages, and wattage, making them applicable to plastic processing and extrusion industries.

Industrial Immersion Heaters Designed for the direct heating of liquids like water, oil, and chemicals, our immersion heaters are relied upon in numerous industrial processes. Our heaters are simple to install and energy-efficient, provided in screw plug, flanged, and over-the-side designs. Heat Master International tests every unit for safety, durability, and performance.

Nozzle Heaters Specifically designed for injection molding machines, our nozzle heaters introduce accurate heat to provide smooth flow of plastic and avoid freezing at the nozzle. With fast heating elements and space-saving designs, Heat Master International's nozzle heaters offer superior performance even in extreme conditions.

Duct Heaters Heat Master International's duct heaters are designed for HVAC and process air heater systems. Both slip-in and flanged designs are available, making them suitable for warming forced air in ducts. They can be adapted with controls, sensors, and safety devices for use in commercial or industrial airflow systems.

Tubular Heater Manufacturers As reliable tubular heater suppliers, we provide a broad range of high-efficiency tubular elements that can be bent into any configuration for easy installation. Our heaters are ideal for heating solids, liquids, and gases in various industrial settings. Heat Master International guarantees excellent sheath materials and insulation for extended service life.

0 notes

Text

Black rain shower Singapore

Black rain shower Singapore is a type of shower head that emits water from a huge, flat surface, mimicking the feeling of being showered by the rain. The offered shower is used to provide a luxurious and soothing showering experience, with the rain shower head usually being ceiling-mounted for a wider spray. It a popular luxury bathroom fixture that replicates the feeling of standing in the rain while showering.

0 notes