#steering electric power assist system

Explore tagged Tumblr posts

Text

AEAUTO latest generation AE6500 EPS System

Nanjing AE System released the latest generation of steering electric power assist system AE6500, which brings higher safety and better comfort to heavy-duty trucks and commercial vehicles. The system not only saves fuel consumption, but also has advanced functions such as lane-keeping assist, side wind compensation, and trailer assist.

European Market Strategic Planning

At the IAA exhibition in Hannover, Germany in September, Nanjing AE Sysystem plans to introduce the most advanced steering electric power assist system for commercial vehicles to Europe. This latest electric drive solution for light, medium, and heavy vehicles is an integrated and modular electric drive system that can help the automotive industry move towards a more sustainable future. AEAUTO plans to sell its products throughout Europe in 2025.

Assisting in the Transformation of Heavy-Duty Trucks

Our latest EPS system allows larger vehicles such as heavy-duty trucks to switch from hydraulic power steering (HPS) to EPS. This way, the unique steering feel of heavy-duty truck brands is retained while the advanced safety, comfort and fuel economy of EPS are obtained.

Market Status and Opportunities

Currently, most of the heavy-duty truck and light commercial vehicle markets still use HPS systems. However, Esteering electric power assist system(EPS) provides OEMs with an opportunity to stand out in the fierce market competition, attract consumers' attention, and increase their productloyalty.

Technological Breakthroughs and Applications

Electric steering systems can also be used in heavy trucks. A few years ago, achieving a 24 kN steering load based on a 12-volt electric system was considered impossible. Still, today. AEAUTO EPS has been successfully used in heavy trucks and commercial vehicles.

Continuous Innovation and Looking Forward to the Future

Customers are under tremendous pressure to implement zero-emission technology, and the AE6500 is a technology we are proud of. We never rest on our laurels and always insist on developing and continuously improving EPS products, hoping to bring more benefits to OEMs and drivers, realize the implementation of the electrification transformation strategy, and meet the demand for one-stop solutions.

0 notes

Text

BYD eMAX 7 Superior: The Ultimate Electric MUV for Families

₹29.9 Lakh Overview and General Features The BYD eMAX 7 Superior is an all-electric Multi-Utility Vehicle (MUV) that offers a spacious 7-seater configuration, making it suitable for larger families or anyone requiring a high level of interior space. The model comes in four attractive colors: Quartz Blue, Cosmos Black, Crystal White, and Harbour Grey. It features a 6-year/1.5 lakh kilometers…

#201.15 bhp#310 Nm torque#530 km range#7-seater#AC Permanent Magnet Synchronous Motor#Adaptive cruise control#Advanced Driver Assistance Systems#airbags#automotive technology#BYD eMAX 7 Superior#driving dynamics#eco-friendly#Electric Mobility#Electric Power Steering#Electric Powertrain#Electric vehicle#family vehicle#Fast charging#forward collision warning#high-speed performance#Infotainment System#lane departure warning#Lithium-Ion Battery#Luxury SUV#MUV#Panoramic Sunroof#Performance#regenerative braking#safety features#suspension

0 notes

Text

1966 Dodge Charger

1966 Dodge Charger

1966 Dodge Charger

1966 Dodge Charger

The first year of Dodge's fabled Charger

This 1966 Dodge Charger was delivered new to the Dodge Regional Office in Kansas City, Missouri, and it was purchased by the current owner in 2018 and subsequently underwent a refurbishment that was completed in 2021. The car is finished in turquoise over black vinyl upholstery, and power comes from a 426ci Hemi V8 paired with a TorqueFlite three-speed automatic transmission and a Sure-Grip rear end with a 3.23:1 final drive. It's listed now with no reserve on BaT!

Equipment includes dual Carter four-barrel carburetors, an aftermarket oil pan, a custom skid plate, a dual exhaust system with headers and electric cutouts, power-assisted drum brakes, power steering, Magnum 500–style 14″ wheels, a rear spoiler, and a RetroSound stereo.

#dodge charger#dodge#muscle car#classic car#charger#musclecars#car#cars#american muscle#mopar#moparperformance#moparnation#moparworld

133 notes

·

View notes

Text

Disgrace Chapter 9 : Crosshair x F!OC

It's been a bumpy ride and it's only getting bumpier as our story plunges into the depths of the pleasure planet. Our heroes are shaken and feeling a fear that runs deeper than the chasm they find themselves entombed in. As they quake from the struggles that have gripped them, deep underground, some truths may come to the surface. Is a confession still true if it's whispered in the dark?

Chapter Specific Warnings: Smut, PiV+ Cπ, skin to skin comfort, lots of talking, Crosshair slowly becoming allergic to clothing (not literal) Angst, Crying.

-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-

Authors Note: Not much going on visually this chapter, but we're back baby! Tie up some lose ends and ease you guys into the second half of this book.

-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-=-

Word Count: 6746

Dynamic: Princess x Guard, Speed running Co-dependancy, A Mangy Cat and his Aggressive little Chihuahua. She's a damsel, she's in distress- she can handle it. Murder is his love language.

<-Previous Chapter - Read On Ao3 {START HERE}

Music Inspo- Like A Prayer, Bigod 20 Cover

Listen on Spotify - Listen on Youtube

Chapter 9: Like a Prayer

It was a bumpy trip, as we slid down through the open chasm. The headlights danced wildly as rocks caught the undercarriage with the sound of tearing mineral, tipping the speeder to free fall several meters, back end pointed down. We hit a smooth, slanted plane that crumpled the trunk compartment with a crunch of twisting metal and a painful jolt through my neck. The engine sputtered out and the headlights died as we pitched forward with a crash, sliding down the glossy slope, first with a slow shriek and then rapidly, faster and faster, we plunged further into the abyss.

I wrestled with the handling, trying to keep us straight and away from the eerily smooth walls, but with the engine out I was steering blind without the headlights or power assist.

Crosshair had thrown himself against my seat as we plunged through the open rock, binding me in place with strong arms thrown about me for dear life. His arms still wrapped about my chest was the only thing reassuring me he hadn't fallen out.

I was pumping the breaks, but without the engine they were useless. The starter was clicking as I punched the button which wasn't connected anymore, I'd have to get at the wires again… not happening at this speed, even if I could see what I was doing.

The slope sharpened into a narrow tunnel, sections collapsing behind us as our crashing vehicle destabilized the tunnel, sparks shooting off the side of the speeder as it drifted against the tight walls.

We were slowing, gradually as the tunnel evened out. Eventually we were spat out into a wider cavern, the dragging speeder catching in the sand, finally grinding to a stop.

Listening to the tink and clicks of the cooling engine with my eyes closed… I felt like I had gone def at the sudden absence of shrieking, sparking metal. Our heavy breathing reverberated through the cave, adding to the soft, ethereal soundscape filtering through the shock. I opened my eyes slowly, half expecting to find we hadn't actually survived that. My knuckles were white where they gripped the steering, then I looked around.

The vision that greeted me pulled a gasp from my rattled lungs.

The cave system we came to rest in was deep… the dark enclosing rock far overhead. The stone had the same blue tinge as most Ga'haiian bedrock, though the walls had been worn to a polished shine, evidence of long extinct glacial flows. The old water channels spread in all directions from this main vein, twisting in impossible shapes.

None of that was the remarkable part however.

Quartz deposits, clear from years of pressure, were embedded throughout the walls of stone. Occasionally these clear patches would glow with a crackling snap of white electricity, the current arcing through the stone to resemble lightning strikes dancing along the cave systems tunnels, providing a constant, flickering light.

“What is that?”

“It's Iotryke. A conductive kind of quartz, we landed in a vein.”

“Why's it doing… that?”

“I-I've heard it's ‘cause of the storm… lightning striking the mountains or something.”

The mundane exchange was calming our nerves… it wasn't just me that was rattled. He wouldn't let on, but I could feel the tremors in his arms binding me to the seat.

I didn't want to think about the whiplash we'd be nursing.

He moved, tossing off his helmet before unlocking my buckle and lacing his hands under my arms, hoisting me up and over into the back with him. I fell against his chest. My legs were still caught on the back of front seat, but his arms were fixed tight, not allowing me to right myself.

…

“… you okay, Crosshair?”

“I'm sorry.”

“... For what?”

“I shouldn't have told you to run, I miscalculated,”

…

“You got me back… don't beat yourself up over it,”

His arms only tightened on me.

“It was stupid. What if I had taken longer to get to you?”

“I would have kept stalling… look, things always seem obvious from this side of it but I assure you all those other plans going through your head could have easily gone just as wrong.”

Scrambling to loosen his grip, I shifted carefully to sit on his thighs holding his face.

“Today it worked out, we'll learn from it tomorrow… for now, well… we're trapped in a cave,”

He looked away, trying to find his pride somewhere other than my eyes. Then his gaze flicked back to me. He cocked an eyebrow, lifting the leather jacket with a finger to scan the tan, stitched together two-piece.

“What… exactly, are you wearing?”

I guess the nature of my dress hadn't really registered in the frenzy of the rescue. I put on a haughty tone,

“A respectful representation of our first peoples,”

“... Uh huh,”

He cupped my cheek, pulling me into a soft kiss, before resting his forehead against mine. The cold shiver in us was difficult to ignore, bringing our attention back to the shaken feeling we could sense on each other. It was more than the bumpy ride through the cave.

I was scared… truly… truly scared.

I wrapped my arms around his neck, something breaking in me, pouring out through sudden, hot tears rolling off my cheeks to fall against his.

Crying again… twice in one day.

But I couldn't stop it, a slow stream of salt, muscles rigid as the day's events sank into me.

His lips were finding each stray tear, kissing away the wet stains on my skin…

“I'm sorry… so sorry, Tahny”

I pressed hard against him, finding his mouth with mine. I needed him… I needed to not feel like this. Weak, fragile.

“I don't need apologies,”

My hands had already started tracing the lines of his breastplate, searching for a hold to pry it off.

His hand closed around my wandering fingers.

“Tahny, slow down,”

“I don't want to…Crosshair, please…”

His name had become a cry of desperation on my tongue, begging for the peace I only felt with him…

He kissed me again, his gentleness in sharp contrast to my rough escapism.

“Just slow down,”

He reached up and the breastplate came off, sliding from between us. The series of clacks echoed sharply against the acoustic stone hall, pieces of armor falling away one by one.

I slid my hands under the hem of the tight black top as it was exposed, taking his lead, pacing myself. Just feeling his skin, his lips against mine.

More clicks, and I rolled the hem up and over, lips parting a moment as I tugged the shirt off of him. He slid the jacket from my shoulders, and started to pick at the leather knots lacing my vest closed. The article hung open as the straps were loosened from their eyelets, and I hugged tight to him again, pressing my skin against his. His warmth sunk into me, chasing the stubborn chill from my bones.

He held me there against him, hushing sobs that were already starting to slow.

“He really got to you, didn't he?...I should have gotten there sooner,”

I shook my head… that's all wrong.

“He shouldn't have been able to… I'm not so easily threatened, I shouldn't be scared of someone like him… somethings wrong with me,”

Why was I so shaken?

He was stroking my hair, confused and a little concerned at my rapidly swinging reactions.

…

“So you're afraid to die, I think that's normal, Tahny… you’re supposed to care what happens to you…”

I looked at him through the curtain of my hair. That was exactly it. Somewhere, somehow… I lost the sense of invincibility that came with embracing death.

“It's all your fault,”

“Excuse me?”

“Me, caring about things… it's been happening ever since you showed up,”

His lips twitched, the corners turning up briefly with a short exhale before he forced his usual serious expression, clearing his throat.

“Is that so? What's so bad about caring?”

I groaned.

“Caring karken kriffs, Cross… it makes you want to change things you can't and have hope and all that… hopeful stuff.”

“So I… make you hopeful?”

This time he let the smirk fly, squeezing me with his usual mischievous spark glinting back at me in the flickering light.

I rolled my eyes, letting my head fall to his shoulder with a thump.

“That is the sappiest interpretation possible,”

“You didn't say I was wrong,”

His voice purred against my ear, sending sparks down my spine. I hissed at him,

“Your foolishness is contagious.”

He lifted me, crushing his lips to mine.

The side door thumped open, Cross kicking it wide to give us room as he angled me to lay on the firm bench seat, not letting our lips part. His hips snugged between my thighs, and I sighed, wrapping my legs about him.

I was trailing my fingers down his back, the muscles flexing against them as Crosshair moved over me. I found the dimples of his pelvis between his hips and paused a moment, tracing the dips before sliding around front, guided by his hip bones, to unhitch his belt letting it slide to the floor.

Lips were tracing a warm trail across my jaw, Crosshair leading himself to the sensitive spot on my neck to graze his teeth against it, making me shiver.

“I need you, Crosshair…”

The confession was whispered in his ear, pulling a low groan of desire from the man who clamped to the tender flesh of my jugular, sucking a new mark into the skin. I tugged at his waistband, pulling his blacks down to his thighs, trying to hide the notion I might mean more than his body; not entirely sure if I was trying to fool him or myself.

His half hard shaft fell free to lay on my belly and he pinned me like that, in no particular hurry to rush into the next step. The feeling of his hardening length pressed between us was causing a heat to rise desperately in my skin, my core. Need.

Channeling my frustration I ran my tongue up his neck to take his earlobe in my teeth. The salt of his sweat stung my lips as I nipped him.

“Let me have you li’nen… take it slow if you must but do so inside me,”

“...the things you say.”

His voice was a smooth vibration against my skin as he continued to leave small love marks down my neck and over my collarbone, ignoring my request. I tried to reach for him but he pressed harder against me, blocking me.

The cock in question was sliding over the thin leather of the tiny skirt and thong, making me quiver pathetically as he bit his way down to my chest, licking over a breast before sucking the nipple between his lips, teasing it with his tongue.

I groaned at the rush of electricity through me... I wanted to disappear into the feeling. Crosshair had other ideas.

Releasing my breast with a soft ‘pop’ he came even with me again, framing my face with his forearms to look into my eyes, pulling me back to focus with his protective posturing.

“I won't let it happen again, I promise… so you don't need to be afraid,”

You can't promise such things…

I was about to protest, but a look in his eyes caught me, bringing me to the meaning behind his words… a plead for me, needing me, to believe it… begging me to, so that he could.

The gears in me whirred as I contemplated taking the weight of such responsibility.

I can do that… if I want to believe you I can.

I cradled his chin in my hands,

“Don't you dare break such a promise.”

His lips found mine with a renewed fervor, a restored sense of purpose as he slipped a hand between my legs to tug the thin strip of leather separating us aside.

I moaned into his lips as he adjusted to press himself into my folds, coaxing his length into me, interlocking. The seat creaked as he shifted his weight to his pelvis, sinking as deep as he could. My legs snaked around his, hooking the heels of my boots around his calves.

An ache bloomed trough my pelvis, my flesh was tender after our previous days together and I inhaled sharply at the stretching sensation.

“Did I hurt you?”

“No, just a little bruised,”

“...I should have known, should I stop?”

I shook my head, pressing my cheek against his.

“Just, this once… be gentle,”

He hummed back, our arms wrapping tighter about each other as he reclaimed my lips.

We sprawled over the backseat, entangled as he warmed himself in me, not yet moving. There was no frantic race to get as much out of this as we could, frankly, we weren't going anywhere anytime soon.

His shooting hand cupped the back of my neck, calluses rough against my nape as his tongue dove against mine, pulling me into deeper and deeper kisses. Moans rose softly from me against his lips, letting out an occasional squeak when he'd grind his hips, sending a sudden wave of pleasure through me with the friction.

Cross pulled his lips from me, whispers hot in my hair.

“How long’s it been?...Since the night we picked you up?”

It was a difficult question to focus on, pinned to the seat as I was. Four days on the transport, the moon and all the in betweens…

“Two weeks tomorrow,”

I mumbled into his neck, tightening my thighs about him.

“Kriff, really?”

“Mhmm”

…

“Just two weeks…”

His pelvis pulled back a moment, thrusting back home, I bit into his neck, stifling the moan that ripped through me. His hips kept that rhythm, slow, forceful, sinking my hips into the back seat with each thrust.

I let his skin slip from my teeth, harsh gasps spilling from my lips to whisper back to me from the cave walls punctuated with pitched moans in time with Cross’s movements.

“Say it again, Tahny... That you need me,”

“I need you.”

It barely left me before his mouth was on mine again, ungraceful and frantic as his thrusts picked up pace. I lifted my thighs to wrap higher around his back, angling him to hit that spot just right, bruises be damned.

With his free hand his knuckles drifted down, dragging against my skin till he sunk his fingers into my hips to hold me still; Carefully, Crosshair stroked into me, the weight of his bare chest pressing hard against my arching form as he moved his hips. My eyes fluttered against the waves of bliss pulsing through my brain.

“I'm so close… take me there, Cross,”

My thoughts felt fuzzy and warm, the skin against mine hot and heavy and comforting. His breath was becoming ragged against his own rising pleasure.

“You're mine Tahny,”

He moaned it against my lips, thrusting hips starting to snap in an erratic desperation.

“Say it… I need you to say it,”

…

“I'm yours, Crosshair,”

The delirium took us, my body taught and rigid as I came for him. Cross pulled my hips against his, groaning softly as he poured into me.

He was trembling from the intensity of the release, hips still bucking weakly as if to deny the pleasure should end.

Our gasping breaths chorused back to us, filling the cavern we were stranded in. I listened to the sounds of our mingled voices, watching the false lighting zig zag across the ceiling, slowly coming back down to the backseat of the wrecked speeder.

“Just two weeks?”

He breathed it against my neck, air hot from exertion. I shrugged,

“We can pretend it's been longer,”

“I'm not sure that's the point…”

~~~

My shoulder burned from the stretched position leaning into the hood of the vehicle. I found another loose wire and clipped it in.

“Okay, tap it again.”

Crosshair touched the wires under the dash together and waited.

Clicking, but no start.

I flicked the vibroblade open again in a huff, angling it into the thin space to try to see with the dim light it cast.

No, all these connections are plugged here fine…

I leaned a little farther, wedging my slight form deeper into the tight space. Couldn't see much… but,

There was a faint ‘tink’ of something dripping.

I carefully wiggled to face the fuel tank and sure enough, a gasket was knocked ajar of its clamps. Readjusting the fitting and tightening the fasteners I finally worked my way out of the engine block.

“Alright, try again.’

To my surprise the engine finally roared to life and I thunked the hood back down, Casting a look at the man in the driver's seat wearing a mildly impressed expression.

“You actually did it,”

Not wanting to waste water I scooped sand off the floor and scrubbed at the grime on my hands. I scoffed back, masking my shared disbelief,

“Told you, these things can take a beating,”

The rest of the speeder was rough, paint stripped from either side and trunk mostly crumpled but it was up and hovering again.

Thank the void.

The idea of walking from here to any part of civilization was far from appealing. Not like we could try to get back to Estkle from here, the southern tunnel that dropped us in here was steep and who knows how far down we really were. There was no way to get the speeder up to the opening again anyways. The cavern was riddled with passages but there was only one that was ground level.

So, according to the dash-comp, North it was, and further down too from the looks of it, but the path was wide enough to drive through. We had the fuel, might as well use it.

I slipped into the passenger side as Cross shifted us into gear angling the nose of the vehicle down the corridor we had decided on. Yanking my bag from where it had gotten wedged under the seat, I pulled out some dry rations and handed one over to him while I counted the rest. We hadn't touched them since leaving the moon but there was only half a duffle of food. Maybe five days if we're careful, but we'll most likely be in trouble if we don't find an alternative at some point.

Especially if we can't find a way back above ground…

I scanned about the wide cavern flickering with spectral lightning. There was no light leaking into the chamber, no way to tell how far underground we really were. We were betting a lot on the water trails leading… somewhere, but with us sliding down so far I wasn't sure anyone would be able to find us if they tried to follow from the surface.

“Ready?”

Crosshair was biting down on his nutrient bar looking to me for the final word before we broke the first rule of being lost and left the cavern.

“There’s got to be another side, right? Might as well get started.”

He pressed the accelerator, gradually increasing our speed when no immediate obstacles presented themselves till we were at a comfortable cruising speed.

We moved ahead in a shared anxious silence, the sandy floors of the cavern passing smoothly under us as we drove further into the dark shaft.

Hours went by, quietly at first as we basked in the seclusion of the tunnel system, then with light conversation, shouted over the car noise. A comment about the stone, a wonder about the water, a lesson on the geological makeup of a tidal locked world.

It was boring, the tunnel tight and uniform as it stretched under the mountain. There were fewer fragments of quartz in the long channels so the headlights guided us through. No obstacles, no turn offs, just a dark tunnel that seemed to go on for ages.

The clock on the radio worked, and if it was correct, it would be early evening Ga'haiian. Too bad we couldn't get any signal down here for some music, the sound of the engine reverberating from the rocky walls was somewhat maddening and made the chit chat difficult.

So I sat, leaning against my door watching the clone drive. He was relaxed, angled into his own door's armrest steering one handed. His armor plates were carefully stacked in the back seat, black top folded with them, leaving Crosshair in only the skin tight bottoms and boots.

He casually gave the accelerator more pressure, feeling my eyes on him, and our speed started to edge on reckless.

“Ease up, fuel burns faster like that…”

I had to shout to be heard but we decelerated.

“That's no fun,”

He sighed, and I understood the lament. There wasn't even anything to look at down here.

I etched the time, direction and our speed onto the dash with my vibroblade, calculating how far we'd traveled and trying to remember how many kilometers it was from Estkle to the Trimecca farm lands between the range and Sohn. We were no doubt still a ways off.

The tunnel gradually widened and dropped into another dried out reservoir. Crosshair slowed and pulled the speeder to a stop.

The new bur offered us a few routes to take, the tunnels spitting into two wide enough for the vehicle. I stepped out, walking to the mouth of the first passage. The air was still and dark and I debated the cost of fuel versus calories in scouting out which one might be more useful. Cross spoke up from the car,

“Maybe we should rest here for now…”

I didn't like the idea of extending our stay, but it wasn't worth pushing ourselves. Standing was already releasing some of the tension from the long drive… Might as well stretch our legs.

I nodded and he cut the engine, plunging us into momentary darkness as our eyes adjusted to the inconsistent Iotryke flicker.

We spent some time pacing about the new cave. I ran my hand over the smooth walls, warm wherever the sparking quartz was exposed. The caves were cool now, but the closer we got to Sohn the hotter it would get. I wasn't sure how far we'd be able to travel beneath the surface, or how far the atmosphere shields of Sohn extended.

I was starting to get overwhelmed. The immensity of what it meant to be lost down here crushed into me all at once. Closing my eyes I filled my lungs, holding it a moment before sighing it back out.

Heat gave away what the soft sand didn't as Cross came near, drawn by my tense exhale.

He enclosed me in his arms, warm skin pressing against my back.

“Credit for your accounts?”

“Just trying to calculate our way out of here.”

“What if we’re here forever?”

He whispered it through a smile in my hair and I tilted my head back to look up at him.

“There's nothing alive down here Cross, that doesn't bode well for making a life of it,”

“You so sure about that?”

He tilted his chin to guide my gaze to a shadowy crevice in the otherwise smooth walls. If you squinted, and looked long enough… it shimmered with movement.

I made my way to the wall, as close as I could get to the elevated crack. In the dark, fist sized… crustations? Clamored about each other, disappearing and reappearing in small burrows in the exposed rock.

“We could always eat the wall bugs,”

I shot him a look for his word choice, but it was good to see something thriving.

“No way to know if they're poisonous…”

I was bluffing slightly, given enough time I could usually figure out how to butcher something safely. I've had to learn some odd skills to keep my father's clients happy.

“My stomach can handle it,”

“That explains the thirty two rotations…”

“Does it?”

“No. You're going to have to… expand on your story, How the kark did you manage that again?”

“That would take a while,”

“All we have down here is time,”

That smile again, making me chuckle in exasperation,

“I don't believe you, we're trapped and you're happy about it,”

“If we weren't, and we had made that train we would have what… hours?”

Maybe less. Kark, my father must be looking for me by now.

“And you prefer certain death?”

He sloped over, pushing me against the wall,

“We won't die, I won't let you, though… I could get used to the idea of having you the rest of my life,”

He leaned in to nip my neck and my face flushed.

“Let's try to make it a long one, yeah?... What do you think’s in the trunk?

I squirmed out from under him and he groaned in frustration.

~~~

Nektu, becktu, nah men’dah…

I threw the tight ball of plastic ration packaging up again, catching it as I stared hard at the tunnel openings from where I was sprawled on the speeder hood.

Nektu, becktu, nah men’dah…

It wasn't the most accurate way to make a travel decision…

Nektu, becktu, nah men’dah…

That and my mind was wandering.

“You’re quiet again, what's eating you?”

Crosshair huffed and leaned against the trunk he had been messing with, insistent he could get the damaged lock pried open with the tiny vibroblade. He was working up a sweat trying to prove himself right. I was staring and he raised an eyebrow.

“Just… who was Rah’dehko working for… and how they're related to my Vah'hadarr”

“What makes you think your father's involved?”

“Rah'dehko Den. After our little run in, Va’hah would have wanted to keep tabs on him…whoever he answered to has to have ties to my family,”

“What does it matter?”

“Did you notice his gang?”

“Was hard to miss them,”

I shot him a look, trying to be serious.

“Zygarrions. A few of them… separate from the rest.”

“Slavers.”

“Slavers.”

Zygarrions were almost never seen on Ga’hah, having both a bad history with the Katjarl clans and opposing cultural views on free will with the planet at large.

“So it's about the recording then?”

“This is all about the recording… isn't it?”

A loud screech and a triumphant grunt brought my attention back behind me. The crumpled trunk finally popping open to creak up lazily.

“You got it!”

I slid off the hood making my way to Crosshair's side.

“Too bad… nothing really of use in here.”

He was right. The empty fuel canisters and hover dolly weren't exactly gonna blast a hole for us. It was high hopes to think we might have some extra food or water… I reached in and pulled out some dingy shop blankets.

“These might make camping in the car more comfortable…”

He took the blankets from me, tossing them into the back of the speeder. Reaching in for his belt and a fresh toothpick.

“So your father deals in slaves.”

It wasn't a question, and ice slipped down my spine. It had been a suspicion ever since we overheard that secret conversation, but it hurt a little for him to say it so openly.

“Slavery is a very blatant term suggesting conquer and all that, here on Ga’hah it would be more…contractual,”

“... What's the difference?”

“Mm. Slavery is… was frowned upon by the Republic. They wouldn't have traded with a planet that deals in flesh traditionally… So there's the Ga'haiian cultural loophole.”

“Do tell,”

He was leaning on the side of the car, watching me. His interest in the topic seemed to be wanning. I ducked under his arm to slide between him and the speeder.

“Ga'hah is a culture steeped in the pursuits of pleasure, One such being complete devotion, or more bluntly, to be completely owned by another… voluntary,”

Cross paused a moment as the meaning hit him. His hand came up to cup my chin, crooning suggestively,

“A willing slave…”

I shot him a look of incredulity,

“Willing being the operative word, the Republic looks the other way as long as there’s measures to make sure the contracts are entered into by choice,”

“Semantics, the jist is your father is building a sex den for a political figure… it's not exactly mold breaking, Tahny,”

Not just any politician.

Neither of us wanted to say that part aloud, though that was something that bothered me too. This was one figure in the whole political scene of Coruscant who was reputedly as squeaky clean as they came, and from my brief observations… not interested in the ecstasy held in flesh. What he'd want with an array of slaves picked with my father's expertise, to a preference no less…

Either way it would be a scandal if the new Emperor was found to be dealing in trafficking right out the gate. Thinking back to the recorded conversation, trying to remember why it sounded familiar. Who was my father talking to? I was there, I know I had heard it before… and I must have been seen… is it really just me though?

I looked up at the man stroking my jaw, more focused on my lips than the conversation.

“Crosshair? You said my parents were supposed to be on the transport… right?”

The military vessel assigned to us by his eminence himself, stocked with those of shakey loyalty to the new regime, or maybe simply… disposable.

“Up until the last minute,”

“And when were you assigned to the escort?”

His eyes focused back on me, narrowing.

“About an hour before we left Coruscant.”

It had to have been Crosshair that tipped him off.

The clone in question had caught up to my reasoning, leaning back slightly,

“If he was spooked by me, why leave you on the ship?”

“The ship still needed to keep to the expected schedule, and he can't have known I would be targeted off of Coruscant… or at least thought it less likely,”

Crosshair scoffed at that and my brow furrowed in irritation. He can't be under the impression my father would sacrifice me and more importantly,

“Why would you be instructed to take me to the safe house if Va'hah thought you were an assassin?”

His cheeks suddenly flushed and he stepped away, running a hand over the back of his head which was… an odd response.

“Cross…what is it?”

He turned back to me, biting his pick in half as he thought a moment before spitting it out, licking his lips and leaning back over me.

“It was supposed to be Hervos.”

“Hervos?”

“Lieutenant Hervos was supposed to escort you to the moon.”

I raised my brows.

“How was he supposed to do that?”

“He couldn’t have, he'd never have been able to keep you safe,”

Debatable. A diplomatic approach might not have been so bad a move…

“So… no, Crosshair, how did you get the encryption code?”

He leaned in closer, resting his forehead against mine with his eyes closed.

“The Lieutenant kept it on him, I took it as we were leaving.”

“You picked his pocket?”

“No, I looked him in the eye and took it, what was he going to do? Stop me?”

I pulled back, catching his eyes in the flickering light.

“What happened to following orders?”

“The last orders given to me was to guard you from harm, get you home…”

“So you stole it?”

…

“I stole you,”

His hands trailed the length of my arms to lace his fingers in mine.

“If you were going to be stranded alone with any one… it was going to be me.”

…

“Then why were you so hesitant to have me… once we were alone?”

“It wasn't about that, if I had let any one of those… any one else and you would have died, it's my job to make sure that doesn't happen,”

He was suddenly tense as he leaned against me, his palms coming up to cup my cheeks,

“I wasn't worried about having you, you're invitation was… clear, but you had to be safe, I was supposed to get you home first… but I needed you that night and- you couldn't die, I couldn't let you go knowing you would die,”

I went rigid, a sudden overwhelming feeling making my face hot and my eyes sting.

That's not fair…

“What's wrong?”

Everything.

My voice came out strained,

“This was supposed to be simple, idiot.”

I hopped up to perch on the door, wrapping my legs about his waist to pull his lips to mine in a fervent, frantic desperation.

~~~

A whimper cut through my wispy dream state, too soft to echo but stirring me from my light sleep. My eyes were already adjusting and taking in the darkened cave. The crumpled trunk hood was still raised from us prying it open, lightning flashes reflecting wildly down on me from the dented metal.

My skin was hot and I reached down for a bottle from my bag, taking a small sip of water, before sitting up and shifting to lean over Crosshair. He was sleeping in the reclined driver's seat, a whimper low in his throat again as I watched, face twisting into a pained grimace. I ran my fingertips over his brow bone and cheek, soothing his twitching muscles.

“Shh, li’nen…”

He gasped awake, jerking under my hand, fingers snapping to the side of his head as he half sat upright.

“It's okay, Cross, I'm here… we're alone,”

“Where-”

Eyes widening, he follows the lightning across the ceiling.

“We're in the Iotryke caves,”

“The… the caves.”

He closed his eyes and leaned back again. I stroked his cheekbone resting my forehead on his brow and his breathing started to slow, hands finding mine in the bright darkness.

“... Where were you?”

He was quiet, thumb stroking the hollow of my palm. I pressed him this time,

“Kamino?”

“...No, before that…”

His fingers brushed his scar and he flinched, as if it hurt anew.

I pressed a kiss to his temple.

“Tell me… how'd you get this?”

He looked away… it was subtle, but he was suddenly avoiding my eyes. His brow was knitted with concern, fingers tapping mine in an agitated kind of way.

“I'm not gonna force you, but… you can tell me, don't think you can chase me off now…”

“We're trapped in a cave.”

“And we could have all the stars between us, yet I'll still stand at your back,”

…

“... Ion Cannon,”

“... Like on a ship?”

“Yes,”

“You… you what? Got too close?”

“... Yes,”

“Crosshair.”

His eyes flicked to mine in the dark, holding my gaze a moment before sighing,

“It was clone force 99.”

“Otherwise known as your brothers…”

His brow pinched again, but he corrected,

“My brothers.”

…

“Burned you with a ship's Ion Cannon?”

…

“How’d they manage that?”

He sighed, breathing deep,

“They blew up the casing after I trapped them inside… and had my men fire it. I ended up in the line of fire instead, and they escaped.”

He spat his words, looking away again with the defensive air of ‘are you happy now?’ I should've been more surprised at his words… but I wasn't. I understood the story though it wasn't told in a language I knew.

“So you tried to fry 'em up but got burned?”

He winced, pointedly avoiding my gaze.

I crawled into his seat, resting my body against his chest. Brushing my lips to his, I whispered against him.

“And you think this would frighten me?”

“It should… if you were sane,”

The guilt in his voice was obvious; The unsure tenor of someone now doubtful of actions they felt justified in the distant moment. If this was to make him a threat to me… no. I've known far worse monsters, ones who torment for the thrill of it… for fun. At times I've been one.

“I'm perfectly sane and I say it doesn't,”

He rolled his eyes but the tension started to leave him, strong arms founding their way around my back.

“Maybe Hunter deserved it anyways…”

“Oh yeah? What’d he do to deserve being melted?”

“He wouldn't have been melted,”

He looked almost annoyed I would suggest it, adding pridefully,

“They’re too good for that,”

“That's a varp of a heavy gamble, Cross, even for you…”

“I out maneuvered them and the imps at every turn. If I wanted them dead… they know damn well if I wanted them dead they would be. Hunter…”

There it was again, the name of the ninety nine’s leader accompanied with a distant hurt in his eyes.

…

“He knew about the inhibitor chips.”

I tensed,

“The what chips…Cross?”

His turn to stiffen but it didn't last as he crumpled beneath me, defeated, surrendering the secrets he'd been holding.

“The clones are programmed. Controlled.”

He formed a gun with his fingers, and pressed it over his ear.

“Through a chip. It's how they got them to do it. Turn on the generals… ‘Good soldiers follow orders,’... Buzzing through their heads, their words and thoughts, it's like they're hypnotized,”

A chill dropped through me… compulsion was, well… blasphemous. Not to mention the depth of government secrets he just revealed. He shouldn't be telling me this…

“And Hunter knew what exactly?”

“... That I…”

He gritted his teeth,

“He knew there was a possibility I may have been controlled, and left me to that… fate.”

There were hints of shame in his voice.

“With what you just told me, you think he could have bested you?... Taken you against your will?”

“Of course not.”

“Well now you're contradicting yourself. What was he supposed to do?”

…

“So… Were you being controlled?”

“Does it matter?”

“I don't think you would have fired a ships engine with them inside of it and just… trusted that they'd get themselves out, not without some external reason,”

“And what if there wasn't a reason, what if I really wanted them to burn for leaving me behind?”

“That still sounds like a reason… just less noble.”

He snorted dryly.

“Well… you have more confidence in me than he did… asking when it stopped influencing me.”

“I don't think he meant anything b-”

“I don't want to be around people who think I would choose to hurt them. The fact that he even considered I would try to kill them, the child, uninfluenced…”

He was coiling tight with a disembodied indignation.

“They don't know me. If that's what they think I'm capable of, they never did. Harsh, yes, willing to do what they won't. Always… but I'm not a child killer, All those years as comrades for nothing.”

He sighed, some of the fight going out of his words. His fingers brushed the melted scar over his ear, eyes clouded in reminisce.

“There was fire, and pain, searing pain… and then it was like I woke up; Burned, confused, the lights of the Marauder leaving me behind… again. I tried to pursue, scuttle their engines and catch up… but they left, I suppose more like ‘got away’... The result is the same, I've had no idea what to do since, every decision seems wrong,”

I kissed him again, desperate to steal some of the hurt from his voice, as if I could draw it from him like venom from a wound. He pressed back, subdued and broken, making my heart ache.

“I'm gonna have to have a word with this ‘Hunter’”

…

His brow furrowed,

“That would be to exchange words, not…?”

I grinned against his cheek,

“I'm going to fight him.”

His lip twitched at that,

“You think you can take Hunter?”

“I have my ways, he'll never see it coming,”

He chuckled, nuzzling the hair against my neck,

“That's my girl…”

He met my lips again, less reserved, pulling me to press into his bare chest. His hands roamed down my back feeling the shape of me.

Shifting back and crossing my arms on his chest, I rested my head to look up at him.

“What does it mean… to be yours?”

…

“I'm still working that out myself…”

“Do you wish to be mine?”

…

He fell silent, running his fingers through my hair, letting the strands fall slowly to catch the sparks like dew in a spiderweb.

“Can’t you see, Tahny?”

His husky voice was barely a whisper, like a private prayer, yet…it echoed through the silent chamber.

+=+=+=+=+=+=+=+=+=+=+=+=+=+=+=+=+

Tags: @feral-ferrule @thecoffeelorian

+=+=+=+=+=+=+=+=+=+=+=+=+=+=+=+=+

#the bad batch#tbb crosshair#tbb fanfiction#star wars fanfiction#crosshair x f!oc#tbb#sw oc#sw oc: tah'nyem ra#imperial crosshair#sw ff: disgrace#Spotify#oc sunday

19 notes

·

View notes

Text

How Do F1 Cars Work?: Power, Transmit, Suspend

Alright part 2 everyone. Let's go.

1.Power Units

You have probably heard lots of yammering about power unit components before. Things like 'they took on too many and now have a grid penalty' are common to hear. But what is the power unit, and what does that mean?

So the power unit refers to the engine system that helps power the car. The modern F1 car is a hybrid, a mix between a typical Internal Combustion Engine (ICE) and Energy Recover Systems (ERS). The modern F1 ICE is a 1.6 liter V6 turbocharged engine and can rev up to 15,000 RPM. It uses gasoline and generates a majority of the power. I've explained how it works in an older post, but briefly it compresses air and fuel and ignites it to create combustion which generates energy. The turbocharger is a part of the ICE that helps condense air more, in turn forcing the engine to create more energy.

The ERS has two components. The first is Motor Generator Unit-Kinetic (MGU-K), which recovers energy from braking, stores it in the battery (which stores energy from the two units), and can be used as a boost to power. The second is Motor Generator Unit- Heat (MGU-H). This unit recovers heat energy from the turbocharger and converts it to electrical energy. It can either charge the battery directly or assist the ICE.

When teams get in trouble taking too many power units it essentially means they have replaced something like the MGU-H too many times. There is a cap for how many times you can replace a power unit component, but with the addition of more races every year the FIA is under pressure to increase this limit. Almost every single car takes the penalty at some point.

2. Transmission

The transmission is the semi-automatic gear box inside of F1 cars, which for them is 8-speed. It is located at the rear of the car and connects to the power unit. This is a part of the car that is famous for having issues, and often when a drivers car retires it is due to a gear box failure. With paddle shifters located under the steering wheel, drivers can change the gear in which they are driving. Different gears effect the traction, grip, fuel economy, and speed of the car and are used strategically throughout the race. Part of the transmission is the differential. The differential distributes power between the rear wheels when cornering, allowing the inside tire to rotate slower than the outside tire. The final majorly important part of the transmission is the clutch. In F1 the clutch, which is a device that connects the engine and transmission to the car is automated and controlled by electronics. It is usually used when starting the race or leaving the pit lane.

Grip levels, cornering speeds, and straight-line speeds all play a crucial role in gear ratio calculations. The teams have to find the perfect balance between acceleration, top speed, and adaptability. The team’s engineers use advanced simulations and data analysis to calculate the optimal ratios for each gear. They also take into account factors like tire wear and fuel consumption to fine-tune their calculations. All of this information can be gathered from electronic data gatherers inside of the car, running simulations, and also the drivers reporting themselves. Its why radio communication is so important in F1. This decision can make or break a race, and we have seen drivers lose due to an incorrect gear decision.

3. Suspension

The suspension system works to keep the tires in contact with the road and helps absorb the shocks F1 cars experience. This is created through a variety of springs, shock absorbers, sway bars, etc. Without the suspension, the chassis would be experiencing the full extent of the shaking and pressure, which would do damage to the car and be very painful for the driver. Anytime you see a driver shaking like crazy in the car, it usually means there is something off with the suspension. Suspension also allows the force of the bumps and the kinetic energy to be stored by a spring, which is then compressed, absorbing the energy transferred by that bump in the road and allowing all four tires to grip the road. The biggest difference between street car suspension and F1 suspension is that in an F1 car each tire is independently sprung, which means that they move on their own, useful around corners.

In F1 cars they have a pushrod or pullrod suspension. These systems transfer pressure from the wheels to the suspension dampers and springs. In a push-rod system, the rocker arms are placed at the highest point in the car. As such, the rod is under pressure as it transfers compression forces upwards into the rocker arms. In a pull-rod system however, the rocker arms are located between the upper and lower control arms, at the center of the car This means every time it hits a bump or curb, the wheel pulls on the spring which causes the pull-rod to go up and outwards from the chassis. Both are regularly used suspension types.

Teams regularly change how their suspension is functioning, and it is by far one of the most tweaked systems on the car. Truly, a weak suspension can make any car one of the slowest cars on the grid. So next time you hear a. driver complain about how slow they are on the straights, or how much their back hurts, it usually means their suspension is not where it should be.

That's all for this post, next one should be about braking, the various electronics/sensors, cooling systems, and wrap up of how everything works together.

Cheers,

-B

19 notes

·

View notes

Text

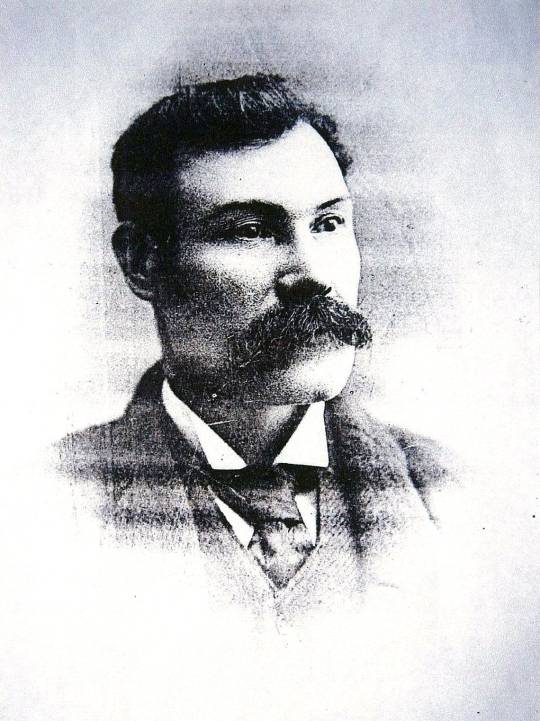

On 17th September 1910 Andrew Blain Baird, working as a blacksmith in Rothesay, made the first flight by an entirely Scottish designed and built aeroplane.

Andrew Blain Baird was born in 1862 in Sandhead on Luce Bay in the Rhinns of Galloway, Scotland. One of three sons, his father was a fisherman and handloom weaver. He became an apprentice to a blacksmith in Sandhead, worked as a lighthouse keeper on Lismore, then as an ironworker at Smith and McLean’s on the Clyde shipyards before finally setting up on his own as a blacksmith at 113 High Street in Rothesay, Isle of Bute, when he was 25.

Baird was a daring thinker, a pioneer and innovator. He created many improvements to the plough, built a unique model of the triple expansion engine powered by electricity and was one of the original members of the Scottish Aeronautical Society.

Eager to expand his knowledge of aviation, Baird corresponded with the early aviators Louis Bleriot and S. F. Cody and exchanged information about construction of aircraft and their flight. Inspired by a visit to Blackpool for England’s first ever Aviation Week in October 1909, he returned to Rothesay ready to design and build his own sophistocated monoplane similar to Bleriot’s but with an engine built by the Alexander Brothers in Edinburgh that was 4-cylinder, air-cooled and with water-cooled valves. The control system he would design for his aircraft would be unlike anything that had been developed at the time. His wife sewed brown trussore silk for the wings.

The Baird monoplane, once completed in his own shop in the summer of 1910, went on show at an exhibition in the Esplanade Flower Garden at the front of Bute. and then to the amazement and excitement of all it was moved to the Bute Highland Games on 20 August 1910.

From there it was taken for storage and readying directly to a barn owned by Willie Dickie at his farm at Cranlasgvourity, Bute.

Scottish aviation history was about to be made when in the very early morning of 17 September 1910, the Baird Monoplane was taken by a Mr Scott on his horse-drawn wagon to Ettrick Bay - with its wide expanse of sand reminiscent of the Kitty Hawk N.C. site chosen by the Wright Brothers for their historic flight.

In the sunshine and amid the wide golden sands of Ettrick Bay the first entirely Scottish designed and built plane sat ready to make history.

Andrew Baird was, on that day, assisted by his friend Ned Striven who was an Electrical Engineer with the Burgh of Rothesay and who had assisted him with the engine and related design considerations.

There on the wide expanse of Ettrick Bay beach, Baird and Ned Striven started the engine. All was ready. Hearts raced with anticipation. A small crowd looked on in amazement. And the flight into history began.

Flight Magazine on 24 September 1910,[1] described it as follows:

“Mr Baird was seated in the machine and on the engine being started the plane travelled along the sands at good speed. Naturally, on clearing the ground, the swerving influence of the axle ceased and the influence of the steering wheel brought the machine sharply round to the right causing it to swoop to the ground. The contact was so sharp that the right wheel buckled and the right plane suffered some abrasion by scraping along the beach.”

Andrew Blain Baird had realised his dream - he had flown in an aircraft of his own design and construction.

His was the first entirely Scottish flight of a heavier than air powered craft.

Noted pioneer aircraft manufacturer Tommy Sopwith sailed his yacht into Rothesay Bay in 1910 to visit the Marquess and to attend the Highland Games and there viewed the on display Baird monoplane. Very impressed, he was given permission to incorporate some of Baird’s innovations into the aircraft he was designing and which would have such a great impact on the course of World War I. Over the years, many others from around the world involved in aviation consulted Andrew Baird and learned from his pioneering experience and innovative mind.

12 notes

·

View notes

Text

Teams Purchasing Components

There is a list of car parts that teams can purchase from other manufacturers as a way to keep development costs down, this can be beneficial for smaller teams but it also has the disadvantage of using parts that aren’t designed for your specific car.

There are at least 4 teams who purchase multiple components from other manufacturers, they are Haas from Ferrari, AlphaTauri from Red Bull and Aston Martin and Williams from Mercedes.

The full list of TRCs is

Rear impact structure

Gearbox

Clutch

Front suspension

Rear suspension

Power-assisted steering

Some fuel system components

Hydraulic pump and sensors

Power unit mountings

Exhaust system

Electrical looms

Williams purchase the fewest components out of the mentioned teams, they use the Mercedes Gearboxes and hydraulics.

Aston Martin essentially purchase the whole rear of the car from Mercedes, the gearbox, rear suspension, hydraulics, exhaust.

Haas purchase all of the TRCs from Ferrari

AlphaTauri will also be purchasing multiple TRCs from Red Bull this year.

The purchased parts do not need to be the current spec, for example Haas could be purchasing 2022 spec parts from Ferrari rather than the 2024 spec parts, if they wanted to save money.

These purchases do fall under the cost cap.

41 notes

·

View notes

Photo

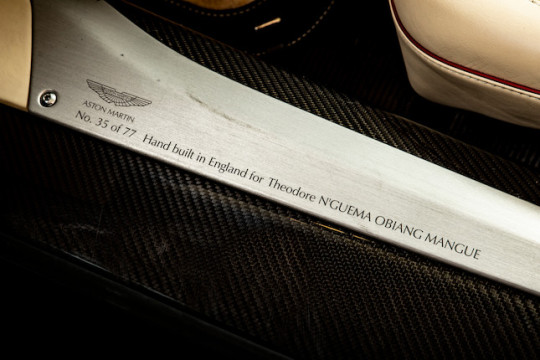

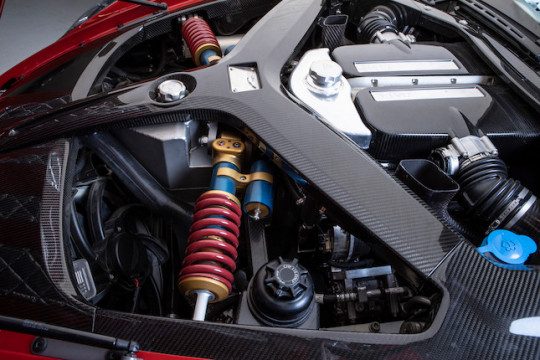

Aston Martin One-77 (property — before being seized by Swiss authorities — of the son of the leader of one of the most corrupt governments in Central Africa)

In keeping with its tradition of producing limited edition, hand crafted exotica for the wealthy aficionado, best exemplified by the DB4 GT Zagato of the 1960s, Aston Martin previewed its proposed One-77 'hypercar' at the 2008 Paris Motor Show. 'The finished One-77 made its official debut in April 2009 at the Concorso d'Eleganza Ville d'Este, held on the shores of Lake Como in Italy, winning the 'Award for Concept Cars and Prototypes'. Designed by Marek Reichman, it was the fastest and most powerful Aston Martin ever built, with a top speed of 220mph, and also the most expensive, carrying a price tag of £1,150,000. Hailed by its maker as "possibly the world's most desirable automotive art form", the One-77 with its long bonnet and short tail was every inch the classically proportioned Gran Turismo, combing muscular pugnacity and feline grace in equal measure. A two-seater closed coupé, the One-77 featured advanced technology in the form of an immensely rigid and lightweight carbon fibre monocoque chassis, which carried a seamless body traditionally handcrafted in aluminium. Made from a single sheet of aluminium, each front wing was said to take one craftsman three weeks to produce. Other state-of-the-art features included bi-xenon headlamps with integrated LED side lights and direction indicators, LED rear lamps (fog and reverse), carbon fibre front splitters, carbon fibre rear diffuser, and active aerodynamics with deployable spoiler. Providing the horsepower needed to breach the magic 200mph barrier was a stretched (to 7.3 litres) version of Aston Martin's existing 48-valve V12 engine. Extensively reworked by Cosworth Engineering, it produced 750bhp and 553lb/ft of torque, and was the world's most powerful normally aspirated road-car engine at the time of the One-77's introduction. Cosworth's extensive re-engineering included fitting dry-sump lubrication, which enabled the V12 to be carried 100mm lower in the One-77's chassis than in that of the DB9. Like the V8 in the One-77's Vantage sister car, the V12 engine was mounted towards the centre of the chassis, well aft of the front axle line in the interests of optimum weight distribution, to which end the six-speed automatic/manual transmission was located at the rear in the form of an integrated transaxle. Power was transmitted to the limited-slip differential by a carbon fibre prop shaft encased in a magnesium alloy torque tube, reaching the road surface via 20" forged alloy wheels - 7-spoke or 10-spoke - shod with Pirelli P Zero Corsa tyres.

Unusually for a road car, the One-77's all-independent suspension featured pushrod actuation of the adjustable mono-tube dampers, a system more commonly found in modern competition cars. There were double wishbones at all four corners: the front incorporating anti-dive geometry, and the rear anti-squat and anti-lift. The suspension was also electrically adjustable for both ride height and rate change.

The rack and pinion was power assisted, delivering 3.0 turns lock-to-lock, while the steering column was adjustable for both tilt and reach. Braking was supplied by carbon ceramic discs all round, gripped by six-piston callipers at the front, four-piston callipers at the rear. Dynamic Stability Control (DSC), Anti-lock Braking System (ABS), Electronic Brakeforce Distribution (EBD), Emergency Brake Assist (EBA), and traction control were all incorporated in the interests of controllability and safety. Releasing the driver's door, which swings out and arcs upwards, the One-77's fortunate owner would be confronted by a leather-trimmed sports steering wheel, electrically adjustable lightweight memory seats, and dual-stage driver/passenger front airbags. Other interior features included automatic temperature control, a trip computer, and touch-sensitive map-reading LED lights. Powerfold exterior memory mirrors came as standard, while front/rear parking cameras were an option. Number '35' of the 77 built, this EU model has a legend engraved on the door sill stating that it was 'Hand built in England for Theodore N'Guema Obiang Mangue'. Finished in red with red-piped cream interior, the car is offered with Equatorial Guinea registration papers.

#Aston Martin One-77#DB4 GT Zagato#Paris Motor Show#Concorso d'Eleganza Ville d'Este#Marek Reichman#Theodore N'Guema Obiang Mangue

76 notes

·

View notes

Note

im so excited to send things here i have SO many things to ask..

first (and im going to say this in way more words than i need to.. but idk how to not yap) why do older f1 cars look so much harder to control than modern ones?

f1 cars' steering and controllability seem to have smoothed out a ton in the 00s (could be wrong bc i dont watch a lot of onboards regrettably.. but thats my recollection) and in the present day it feels like almost every movement of the steering wheel is exactly what the driver intends for the car to move. but if you look at older onboards like even as recent as senna and alesi in the 90s, its like theyre wrangling a bull by the horns!! its like the car is this wild animal the driver has to keep at bay, the drivers hands on the wheel are wibblewobbling back and forth like crazy throughout every turn and it looks like they have the most insane reflexes on the planet in order to keep the car on track. it blows my mind every time!

so anyways what created that change in how manageable the car is? does it have anything to do with tyre or engine or balance changes, is it just new innovations in the steering column, is it just having the luxury of power steering?????????? even if you dont have a solid idea on the answer to this id LOVE love love to see what you think, and im souper excited to watch this acc grow :3 random super detailed extremely miniscule historical f1 fact blog sounds like actual heaven to me so i hope you have fun with it and keep filling my brain with nifty stuff!!!!!!!!!!!!!!

For some background, I didn’t have the time for a massive massive deep dive on this but I’m doing my best from memory and also I do go and check some of the more specific things I throw in.

Okay, so there’s a few things you gotta think about with this:

Engines

Tires

Aerodynamics

Electronic systems

Let's go down the list.

Engines have changed a lot over the years. The further back you go, the more wild the engines get, and the rules shift all the time. V10, V12, V16, turbos, rocket fuel, shifts in how much fuel can be used at a time, shifts in whether they could refuel (both of these could make cars heavy or light to a massively varying degree wildly affecting handling over the course of just a lap), etc.

Tires have also changed. At one point there was more than one manufacturer of tires (remind me to tell y'all about that one US Grand Prix). At one point there was like five or six compounds, including a "supersoft" built for insane lap times. For a while there in the 1990's-2010's we ran grooved tires, no slicks. Imagine everyone always using intermediates. That would affect grip levels like crazy. (does everyone know how F1 tire compounds work? maybe I should write about that)

As aero restrictions change, the downforce levels shift to an unprecedented degree. There was a time where there as technically no limit on how many wings a car could have, leading to some very interesting double wing, mini wing, and no-wing cars all racing at the same time. No-wing cars died out pretty fast once the benefits of wings became obvious, but it did happen. Peugeot ran the 9X8, a car with no rear wing, in the WEC LMH (Le Mans Hypercar) category for a little quite recently. Like, 2022-recently.

Anyway, the downforce changes definitely affect handling

The last, and most important, is electrical systems. The thing about those is that they change all the time. Sometimes, power steering was allowed, sometimes it wasn't. Assisted Braking Systems? Occasionally. Active suspension? Not anymore.

If you do go watch onboards, you'll see driving styles change with the cars. Nowadays, the style is a very smooth turn, no jerky or sudden movements of the wheel unless they've saving a slide. This is due to a combination of all those factors above -- it's just he driving style that fits the current restrictions. If you look in the 2000's you see the style get WAY more jerky, with micro-adjustments all the time.

As you noted (you being the lovely perfect amazing anon who asked a question, like the lovely perfect amazing anon that you are), in the 1980's and further back yes those cars we're absolute NIGHTMARE'S to control. If you watch Lewis Hamilton’s drive of Senna’s McLaren at São Paulo this year, you’ll notice the camera attached to the car bounces like crazy. The cars just weren’t the most stable — everyone had nailed down that power-to-weight ratio, but the fast-evolving and quickly-restricted aerodynamics innovations led to a bit of a mess on the downforce end of things. AND, they were still using stickshifts, and if you get far back enough it was H pattern shifting instead of sequential.

Imagine driving a V12 turbocharged rocketship on wheels and barely enough downforce with ONE HAND because you're trying to upshift out of a chicane while fending off some Brazilian kid on a warpath to take the world championship before the age of 30.

In the rain.

#bucket !!#formula 1#formula one#f1 facts#ayrton senna#f1 mechanics#f1 engineering#f1 tires#f1 engines#f1 electronics#f1 aerodynamics#wings#but like the racing kind#rear wings?#too specific lol#also#fia wec#but like mentioned

4 notes

·

View notes

Text

Exploring the Future of Efficiency and Comfort: Honda Jazz Hybrid

In the world of compact cars, where efficiency meets innovation, the Honda Jazz Hybrid stands out as a beacon of modern automotive engineering. Combining Honda's renowned reliability with hybrid technology, the Jazz Hybrid offers a compelling package for eco-conscious drivers who refuse to compromise on comfort and versatility.

Honda Jazz Hybrid Specifications

The heart of the Honda Jazz Hybrid lies in its advanced hybrid powertrain. Under the hood, you'll find a responsive 1.5-litre i-VTEC engine paired seamlessly with an electric motor, delivering a harmonious blend of power and efficiency. This setup not only enhances fuel economy but also reduces emissions, making the Jazz Hybrid a responsible choice for environmentally aware consumers.

Engine Specifications:

- Engine: 1.5-litre i-VTEC 4-cylinder

- Electric Motor: Integrated Motor Assist (IMA) system

- Combined Output: Approximately 110 horsepower

The hybrid powertrain is complemented by Honda's innovative e: HEV technology, which intelligently manages the engine and electric motor for optimal efficiency in various driving conditions. This synergy ensures that whether you're navigating city streets or cruising on the highway, the Jazz Hybrid delivers a smooth and responsive performance.

User Experience: Driving the Honda Jazz Hybrid

Driving the Honda Jazz Hybrid is an experience that blends practicality with a touch of sophistication. The cabin welcomes you with a thoughtfully designed interior that maximizes space and comfort. Despite its compact exterior dimensions, the Jazz Hybrid surprises with its roomy interior, offering ample headroom and legroom for both front and rear passengers.

Interior Features:

- Magic Seats: Honda's versatile Magic Seats system allows for multiple configurations, enabling easy adaptation to accommodate various cargo shapes and sizes.

- Infotainment: The Jazz Hybrid boasts a modern infotainment system with a touchscreen display, offering connectivity options such as Apple CarPlay® and Android Auto™ integration.

The driving dynamics of the Jazz Hybrid are tuned to provide a balanced blend of agility and stability. Whether you're manoeuvring through narrow city streets or tackling curvy roads, accurate steering and quick handling provide a sense of assurance while driving. The regenerative braking system not only enhances efficiency but also contributes to a smooth braking experience, seamlessly transitioning between electric and friction braking.

Design and Technology

The Honda Jazz Hybrid's design ethos revolves around functionality and aerodynamic efficiency. Its sleek exterior lines not only enhance its visual appeal but also contribute to its fuel-saving capabilities. LED headlights and daytime running lights provide enhanced visibility, while the aerodynamically optimized body minimizes drag for improved efficiency.

Safety Features:

- Honda Sensing® Suite: Standard on most trims, Honda Sensing® includes features like Collision Mitigation Braking System™ (CMBS™), Lane Keeping Assist System (LKAS), Adaptive Cruise Control (ACC), and Road Departure Mitigation System (RDM).

- Multi-Angle Rearview Camera: Assists in parking and reversing manoeuvres, providing multiple viewing angles for enhanced awareness.

Ownership and Sustainability

Owning a Honda Jazz Hybrid extends beyond the joy of driving. It demonstrates a dedication to promoting sustainability and ethical living practices. With its hybrid powertrain, the Jazz Hybrid helps reduce your carbon footprint without compromising on performance or convenience. Honda's reputation for reliability ensures peace of mind, backed by a strong warranty and comprehensive service network.

Fuel Efficiency: The Honda Jazz Hybrid boasts impressive fuel efficiency figures, making it an ideal choice for daily commuting and long-distance journeys alike. With its hybrid powertrain, expect to achieve excellent mileage and fewer stops at the pump.

Conclusion

In conclusion, the Honda Jazz Hybrid stands as a testament to Honda's dedication to innovation and sustainability. It combines the practicality of a compact car with the efficiency of hybrid technology, offering a compelling choice for discerning drivers who prioritize both performance and environmental consciousness. Whether you're drawn to its fuel-saving capabilities, spacious interior, or advanced safety features, the Jazz Hybrid promises a driving experience that is as rewarding as it is responsible.

As the automotive industry continues to evolve, the Honda Jazz Hybrid remains a frontrunner in the realm of efficient and comfortable urban mobility. With its blend of cutting-edge technology and timeless Honda reliability, the Jazz Hybrid is poised to lead the charge towards a more sustainable future on the roads.

For those seeking a vehicle that not only meets but exceeds expectations, the Honda Jazz Hybrid emerges as a clear winner in the competitive landscape of hybrid compact cars. Embrace the future of efficient and comfortable driving with the Honda Jazz Hybrid — where innovation meets inspiration on every journey.

4 notes

·

View notes

Text

But what models can you choose? As at August 2024, there are two key options to consider including:

Long Range Single Motor - from £59,990 this standard model benefits from the plus pack for Harman Kardon premium sound, HUD, Zinc Deco, Pixel LED lights, powered-operated tailgate, auto-dimming exterior mirrors, rear control screen (for the passenger), 12-way adjustable seats, power reclining rear seats, heated front/rear seats and steering wheel, 3-zone climate control, air filtration and 22kW AC charging. The car also includes camera-based interior mirror, LED interior and exterior lights, rain sensing wipers, automated crash protection, hill hold and descent control, 10.2” driver LCD display, 11-exterior camera system, 15.4” central display, wireless smartphone charging, adaptive cruise control, insurance telematics, launch mode, dashcam, keyless entry, alarm and battery preconditioning; and

Long Range Dual Motor - from £66,990 this allows you to get the Performance pack including the 22” Performance alloys.

Colours include Magnesium (free) or the chargeable Snow, Electron, Storm, Space and Gold. Inside, you can go for the Charcoal or Mist with the Zinc deco or upgrade the Nappa leather. In terms of packs, you have the Pilot Pack (Piot Assist and change assist), Pro Pack (21” Pro wheels and Swedish gold seats) and the Performance Pack (22” alloys, Engineering chassis tuning, Brembo brakes and Swedish gold accents). Other options include the Electrochromic glass roof (which replaces the standard panoramic roof), body-coloured lower-claddings and the privacy glass. You can add the fully-electrically retractable towbar too.

But how does the Polestar 4 perform - is it a good EV?

Long Range Single Motor - The RWD SUV option will have a 94 kWh usable battery which will offer 0 – 62 times of 7.4 seconds, 112 mph top speeds and 200 kW (or 268 hp). Expect a combined winter range of 260 miles with warmer weather allowing for 350 miles. On charging, the 22 kW AC max will allow 5 hours and 15 min 0 – 100% charging times with the 200 kW DC maximum allowing 31 minute 10 – 80% times. A cargo volume of 526L is available with this car. It has a vehicle fuel equivalent of 131 mpg. This option can tow 750kg (unbraked) and 1500kg (braked). There will be Bidirectional charging with the V2L announced for this option. A Heat Pump is standard and

Long Range Dual Motor - the AWD SUV option will have a 94 kWh usable battery which will offer 0 – 62 times of 3.8 seconds, 124 mph top speeds and 400 kW (or 536 hp). Expect a combined winter range of 245 miles with warmer weather allowing for 325miles. On charging, the 22 kW AC max will allow 5 hours and 15 min 0 – 100% charging times with the 200 kW DC maximum allowing 31 minute 10 – 80% times. A cargo volume of 526L is available with this car. It has a vehicle fuel equivalent of 123 mpg. This option can tow 750kg (unbraked) and 1500kg (braked). There will be Bidirectional charging with the V2L announced for this option. A Heat Pump is standard.

#polestar#polestar 4#car lease#car leasing#leasing#lease#EV#electric#polestar 4 lease#polestar 4 leasing

3 notes

·

View notes

Text

imagine an internal combustion car right. but instead of puttin gas into the engine which makes electricity for all the Bits, theres a freakin. biodiesel fermentation tank you toss corn into, and thats attached to a whole MESS of hoses that take tiny little bits of gas to all the different components. and theres a tiny little engine in each tail light to power it when it needs power, and theres a tiny little engine in the steering system to power the assisted steering, and theres tiny little engines in each of the doors to run the locks. wild right?

now imagine that theres STILL electrical wiring all throughout the car but its ONLY used for signals not power. you push the window button and it sends an electrical signal down to the window engine to tell it to turn on and it starts burning the biodiesel to roll down the window.

3 notes

·

View notes

Text

7 Things That Will Happen to Your EV If It Discharges

Discharging a car park EV charger installation Sydney is a situation that most drivers aim to avoid. However, if it does occur, there are several implications that extend beyond the immediate inconvenience.

The following list details some of the critical consequences you may face when your electric vehicle's power source depletes completely, alongside practical insights to help you navigate such scenarios effectively.

Loss of Essential Functions

When the power source fully discharges, you lose more than the ability to operate the vehicle. Critical systems, such as power steering, braking assistance, and even emergency lights, may cease to function. These features rely on the reserve energy of the vehicle, which is usually minimal once the main energy is depleted. This can pose significant safety risks, especially if it happens in transit or in less accessible locations. To mitigate this, always monitor energy levels and plan ahead for any trips to ensure a safe margin of power.

Increased Stress on the Battery

Allowing the power source to discharge entirely can have a detrimental effect on its lifespan. Most modern energy units are designed to handle a range of partial discharges but may degrade faster when subjected to complete depletion. Over time, this can result in reduced storage capacity, leading to shorter travel ranges and more frequent stops to replenish energy. Regular maintenance and adherence to recommended energy usage patterns can help prolong the life of the unit.

Potential Damage to Auxiliary Systems

A fully depleted power source can also harm secondary systems, such as heating, cooling, and infotainment features. These systems draw energy directly from the main power unit, and frequent complete discharges can weaken their efficiency or cause malfunctions over time. Ensuring that the power level remains within a safe range can help avoid such issues, keeping both your comfort and the vehicle’s auxiliary systems intact.

Extended Replenishment Time

Once the energy source is completely discharged, replenishing it takes considerably longer than a partial recharge. This is because most systems are programmed to replenish gradually to prevent overheating or damage. Waiting for the system to regain full functionality can disrupt schedules and create additional inconveniences. Using apps or in-vehicle monitors to track energy levels can help you avoid scenarios where you’re left stranded with an empty power source.

Possible Software Errors

Many modern vehicles rely heavily on advanced software to manage energy distribution and overall performance. A full discharge can sometimes reset or disrupt these systems, leading to errors or glitches that require professional intervention. For instance, navigation, diagnostics, and user preferences may be temporarily inaccessible or reset to factory settings. Keeping your system software updated and performing regular diagnostics can minimise the likelihood of these issues.

Increased Wear on Energy Storage Systems

Every time the energy source is fully depleted, it goes through a deep cycle, which is more taxing than regular shallow cycles. Over time, this can lead to increased wear and tear on the components, reducing the overall efficiency and reliability of the vehicle. Deep cycles are unavoidable in some cases, but minimising their occurrence by topping up energy levels before they fall too low can extend the system’s durability.

Risk of Being Stranded