#stamping parts supplier

Explore tagged Tumblr posts

Text

#manufacturer#Stamp Parts in Mumbai#Stamp Parts Manufacturers in Mumbai#Stamp Parts Exporters in Mumbai#Stamp Parts Suppliers in Mumbai#Stamp Parts Stockists in Mumbai.

0 notes

Text

1 note

·

View note

Text

PTFE Stamped and Turned Parts Components Supplier from India

Rubber Gaskets for Sealing and Teflon Components supplier from India, specializing in PTFE Stamped (Sheet) and Turned Parts (Rod)

#Rubber Gaskets for Sealing and Teflon Components supplier from India#PTFE Stamped(Sheet) and Turned Parts( Rod) components supplier from India

0 notes

Text

Niraj Industrie’s Sheet Metal Pressed Parts Manufacturers in India

When your industry requires high-caliber precision parts, you need a stamping company that meets the most stringent quality standards. Niraj Industries, a registered company, has been manufacturing precision tools for companies worldwide since 1994. Today, we produce over 1 million highly detailed parts every week for even the most technologically advanced applications.

We, at Niraj Industries have positioned ourselves as one of the major Press Parts Manufacturers and Suppliers located in Mumbai. We manufacture all types of strips in CRGO M6 M5 M4 Grade.

At Niraj Industries you will find global Press Parts in Nashik. Niraj Industries you will find global suppliers and manufacturers ready to meet your demands. No matter where you are, you can easily get your products without going beyond your national borders. As a leading platform, we cater to listed manufacturers and suppliers.

For More Details Contact us: +91 92251 28155

For more information on Press Parts in Nashik visit our site:-https://www.nirajinds.com/press-parts-crgo.php

#Press Parts & Crgo Stamping#Press Parts Suppliers#Sheet Metal Press Parts Suppliers in Nashik#Press Parts in Nashik#Pressed Metal Parts in Nashik#Metal Stamping Services in Nashik

0 notes

Text

The Series Of Unfortunate Events That Lead To Putting Carrots In A Cake

Joshua Rosfield X Reader

This is the second version of this request. It's a bit similar in some parts, but I like having fic variants. ( ^_^ ) b

Rating: General Audiences

Word Count: 1.3k

Tags: Baker!Reader, Finally Getting Joshua To Eat Some Gosh Darn Vegetables, Fluff, Teasing, Unedited, Fun, Cutesy.

It was truly a wonder how this recipe book had fallen into your hands.

A trader from the Crystalline Dominion had been making his way to Rosaria when a flock of chocobos had attacked his wagon. Clive had happened to cross the man’s path and while most of the man’s merchandise had been destroyed, he was still able to repay Clive’s kindness with a tattered recipe book. And yet, as Clive was returning from Rosaria, the book toppled over a cliff, never to be found again. However, as luck would have it, a group of bandits happened across the book. They tossed it in with their collection and forgot about it. Months later, the bandits stole from a supply caravan that was carrying goods meant for the Hideaway. Otto had intended for the Cursebreakers to retrieve their stolen goods, but Joshua offered to go instead. After some convincing, Otto agreed. Joshua, Jote, and Torgal confronted the bandits. Joshua had intended to only take what the Hideaway needed, but one of the bandits called Torgal a mangy mutt, causing his mercy to dissipate. After a short battle, Joshua and Jote hitched the wagons to some chocobos and made for the Hideaway. During their travels, Joshua rummaged through their loot until he found something suitable for you. A baker’s book. Perfect. He grinned, ignorant of the way the stars aligned for this one moment.

Now, you leaned against the counter of the Ale Hall, leisurely flipping through the pages of recipes. A recipe rut had been plaguing you for the past week and you were hoping that this new book might put an end to it. You had just turned to the next page when commotion on the Main Deck caught your attention. You turned your head a little to see Gav rising from placing down a heavy-looking, wooden crate. One of many, from what you can see.

“Founder,” Gav muttered, “what a mess this is.”

“It could be worse,” Cole commented, having dropped off a box of his own. “They could be turnips.”

“Eugh, turnips.”

Gav crossed the Main Deck and ordered a mug of ale. You leaned closer to him. “What’s with all the boxes?” you ask.

“Carrots. Blasted things. You know, it really is quite the story, how they got here.” You wordlessly motioned for him to continue. After a swig of ale, he did. “One of our suppliers, ah, one that has a deal with Clive’s uncle, was meant to be sending us a shipment of vegetables. Well, at the docks, his son made a mistake. Put all the carrots on one boat, all the turnips on another, and all the potatoes on another. Ordinarly, something like that doesn’t just slip by unnoticed, but the man in charge of inspections had eaten a bad breakfast, didn’t agree with his stomach, so he just stamped the papers before running off to deal with his, uh, returning breakfast.” You wrinkled your nose at that. “So the ships set sail, all with the wrong contents. Now, we’re stuck with a dozen crates of carrots and no potatoes.”

“And no turnips,” you pointed out.

This time, it was Gav’s turn to wrinkle his nose. However, his attention was quickly caught by the book laying out in front of you. He motioned to it as he lifted his mug for another drink. “What’s that?”

You glanced down at the book. “Oh, this? It’s just something Joshua brought me after…” You did a double take, something on the age having caught your eye. You trailed off as you began to read.

“Hm?”

“Ah, right, sorry, it’s just…”

The book spread out the solution to your problems in one simple, sweet, perfect recipe. You grin widely. “I know what to do with the carrots.”

“All of them?”

You rolled your eyes. “No, not all of them, but some of them.”

Without bothering to explain further, you leapt from your seat and began dashing around to get to work. Otto gave you a skeptical look when you asked to take from the supply of carrots, but agreed without need for any further convincing. The recipe was completely new to you and, as strange as it sounded, you knew you had to give it a try. Perhaps it was even because it sounded strange that you knew you couldn’t just let it pass you by. The opportunity was perfect. And your curiosity was insatiable.

In a matter of hours, you had baked enough cake for the entire Hideaway. Just in time, too, as supper was coming to an end.

“There’s a sweetness in the air that completely distracted me from my supper,” Joshua teased as he approached the bakery’s counter. He had an easy smile on his face as he leaned against the wooden edge. “Must you tease me so?���

“A bit of anticipation can be a good thing,” you countered. “But, worry not, your wait can finally be over. They’re ready.” He took a seat on one of the stools, eyes wide and expectant. You stifle a giggle. “So eager.”

“You haven’t seen the half of it. He was glancing in the direction of the bakery for the entire duration of our meal,” said Clive as he and Jill approached. “I thought he might get up and run off if I so much as glanced away from him.”

“Clive…” Joshua casted his brother a look that only made him chuckle.

You laugh behind closed lips. “Alright, alright. Here, Joshua, you can have one of the first slices.”

His expression immediately brightened. He accepted the small plate with a grin, one that he quickly flashed at Clive in an almost boastful manner. You resisted the urge to roll your eyes as you continued passing out slices of cake.

Joshua made an approving sound at his first bite. “This is quite delicious. Well, that much should be expected. It is your baking we’re speaking of.”

A blush dusted your cheeks. Jill nodded her agreement as she had her first taste of the treat. “Truly remarkable.”

“You’ve outdone yourself. This is… different, somehow, from what you’ve made in the past.” Joshua looked up from his plate. “What is it?”

“Carrot cake,” you declared.

He froze. Jill’s chewing slowed. The corners of Clive’s lips twitched upwards as his gaze glided towards his little brother.

Your brows knit together with concern. “Joshua?”

Complicated emotions pass over his face. Confusion and horror, as well as a handful of other things you couldn’t quite place. It seemed that Clive was unable to hold back his amusement any longer. A sharp laugh escaped from his chest. Joshua glared at him, but the expression lacked any true anger. Clive’s laughter only grew louder, encouraging giggles from Jill as well.

“Not you too,” Joshua muttered.

“I’m sorry, it’s just–” She couldn’t even finish her sentence for the mirth that stole the words from her mouth.

Joshua sighed and shook his head. “What sort of unfortunate series of events leads to putting carrots in a cake?”

“You don’t like carrots?” You frowned. “I’m sorry, truly. I–I didn’t know–”

He soothed your worries with another shake of his head. “No, no, you have nothing to apologize for.” He looked back down at the cake. “I suppose I shouldn’t complain. If I couldn’t tell in the first place…”

“It seems we have found the only way Joshua will eat his vegetables.” Clive snickered. “Baked into a cake.”

“All they have to be is coated in sugar and cream,” Jill added.

Joshua gave them both a tired look. It only made them laugh more.

You reached out, taking his hand in yours. “But, you liked it, right?”

He seemed to have sensed that you were in need of more reassurance, for he forsook his brother’s teasing and focused his attention on you. His closed his other hand over yours. “Of course, my dear.” He brought your hand to his lips and pressed a kiss on your knuckles. “I would love anything these hands crafted.”

The blush returns to your cheeks, accompanied by a bashful smile. “Then, you’ll keep eating, right?”

A flicker of wariness flashed across his face, but it was gone as soon as his eyes met yours. “Gladly.”

#ff16#ffxvi#final fantasy xvi#final fantasy 16#ffxvi spoilers#final fantasy 16 spoilers#final fantasy xvi spoilers#ff16 spoilers#joshua rosfield x reader#joshua rosfield#fanfic

152 notes

·

View notes

Text

Roots

Author's notes: Zaarius in Husbandry

Past =-= Next

Warnings: Let me know if I need to add anything.

Summary: Zaarius, happy from collecting the items from his Loyalist clients, the intel, and other resources that they paid in response for his Delights. Now, he just needs to trade with Hura so that he gets stuff from him.

Tagged: @barn-anon, @bleedingichorhearts, @c-u-c-koo-4-40k, @egrets-not-regrets, @kit-williams,

Tagged continued: @sleepyfan-blog, @whorety-k, @ms--lobotomy @bispecsual @thevoidscreams

Tagged continued: @i-am-a-dragon34, @gra93fruit-blog

Zaarius hums to himself pleased at how much he’d received from his Loyalist clients making sure to carefully put his trade goods in carefully protective crates with his name stamped on them. He knows that will only have some of those within the Base hesitate briefly before rifling through his stuff for their own benefit.

Now- he’s got an Apothecary to trade with, he’s heard the complaints from some of the Apothecaries about how stingy the Loyalists are with sharing supplies in certain kinds of medications and other sorts of supplies that they need. Some of those supplies are growing ever lesser, and thus more valuable to trade for.

Which has him grin sharply, and has those who are smart, avoiding him, while also watching him carefully for his Shenanigans. He pushes the crate on a rolling cart, it’s annoying that they don’t have any anti-gravitation hover carts, which are a much more elegant way to move things.

“Hura, dear cousin!” Zaarius calls out with a churring trill in his voice. “I am glad that we were able to have time to discuss something with each other.”

He’d requested some of Hura’s time, knowing that the other is very busy being a higher ranking Apothecary who’s really good at his job and isn’t an entirely sadistic piece of work, which can be a trend among the Renegade, and more particularly, the Chaos Apothecary Space Marines.

Hura inclines his head as he looks down at his smaller fellow Chaos Marine, Zaarius could be quite the entertaining fellow. So long as he wasn’t in a Spiteful mood, Hura gestures for Zaarius to follow after him.

“My office is just down the way,” Hura says, looking at the crate filled with something. ”What’s that you have there?”

“Supplies I traded some Loyalists for,” Zaarius says with a grin, his six sets of eyes squinting a little as he gives out a bit of a pleased trill. “That is why I wanted to meet with you Hura, is some of the supplies I gathered, I figured you would be interested, what with some of the supply issues that the Medicae of Chaos have been having due to that little squabble that you lot have been having recently.”

“Just what kinds of supplies did you acquire?” Hura asks, “and how did you acquire them?”

“I acquired them through honest, legal trade with some Loyalists who are interested in my particular services that I can personally do,” Zaarius says honestly, “how they acquired the goods is not my care to know.”

Hura looks at him steadily, for a few hearts beat, slowly taking in what the other has said and looks at the crate again before looking at Zaarius, “What kind of medical supplies did you legally acquire?”

Zaarius grins up at him and with one of his extra arms he carefully lifts up the crate and grabs out some of the medical supplies, a sample of each of the medications that they are starting to sorely lack that the Loyalists have a decent supply of.

“A little of this, a little of that,” Zaarius replies as he hands over the samples, so that Hura can test the quality of the supplies for himself. “Please tell me if the quality is off so I can discuss with my suppliers the foolishness of their actions, please Hura?”

If they aren’t of the quality that he’d requested, then he’s going to ensure that those Loyalist clients of his will be properly punished for their hubris and foolishness for trying to short their Dealer of their rightful due.

Hura takes the samples, and uses part of his assessor array to test the quality of the medicines, which are what they are labeled to be as of the high quality that can be made on ancient terra with the limited supplies and technology that they have available.

He informs Zaarius of such, he seems most pleased with the answer, he knows that this crate of supplies is not going to be given to him, or to the Medicae at the base, but is something he’s going to trade for something he needs or wants instead.

Such is the way of Chaos, even in these unprecedented times, so long as supplies are hoarded too much and theft is kept at a minimum those in charge are willing to look the other way, because trying to fight over petty stuff will leave them at a serious disadvantage with the Loyalists and Renegades.

Not to mention the factions within the baseline humans that could also take advantage of such disharmony. So Hura negotiates with Zaarius for the supplies, discussing with him the details of the trade, and doing his best to not have to give the other too much.

Hura manages to get a good deal out of Zaarius, but reminding the other that he lives on this Base as well, and how they do need to maintain a professional relationship with one another.

Also, that he or one of his fellow Death Guard Apothecaries are going to be the ones to do his next health assessment. And then he gives the other one of his pleasant smiles. Zarius’s main eyes stare at him and narrow slightly, while the other sets of eyes dart around a little as he thinks over his next response.

Zaarius decides to make the smart decision and not try to be too greedy with his request with only some minor Slanneshi Space Marine dramatics. Which mildly amuses and annoys Hura at the same time.

Zaarius gives half of the supplies, waiting on the recompense for the trade that he just made with Hura. Following after the other and humming one of those stupid Ancient Terran human songs that are so annoyingly catchy.

Hura gets the requested trade supplies and he makes sure to double count them as he watches Hura take the supplies that he’d gotten in trade with the Loyalists. Pleased that Hura hadn’t tried to short him he takes the supplies and plans where he’s going to keep the supplies and not have them stolen from him by some bastard either a wanderer or a resident of the base.

#warhammer 40k#space marine husbandry sentience#space marine husbandry#warhammer#adeptus astartes#oc: Zaarius#emperor's children#chaos marine#oc: Hura#Death Guard#poor unfortunate souls

20 notes

·

View notes

Text

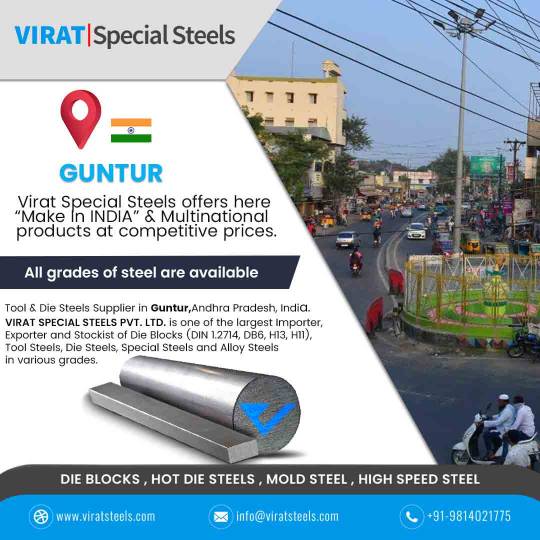

Exploring the top-notch Tool and Die Steel Supplier in Guntur, Andhra Pradesh?

Tool and Die Steel Supplier in APIIC Guntur Industrial Area. Look no further! Virat Special Steels delivers excellence.

Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Andhra Pradesh!

A significant part of this industrial development is the tool and die steel sector. Tool and die steel are crucial components in manufacturing, used to create a variety of tools, dies, molds, and other essential parts for industries like Forging and Stamping Companies, Metal Fitting, Automotive, Aerospace, and Medical devices.

For tool and die steel requirements in APIIC Guntur, you can consider suppliers like VIRAT SPECIAL STEELS PVT. LIMITED , INDIA . They offer a wide range of tool and die steels, including:

Die Steel (HH 370 – 410 BHN) (DB6 / DIN-1.2714 / AISI L6)

Hot Work Steels (DIN 2343, 2344 / AISI H11, H13)

Plastic Mould Steels (DIN 2738, 2311 / AISI P20)

High Speed Steels (DIN 3243, 3343 / AISI M2, M35)

Cold Work Steels – HCHCr (DIN 2379, 2080 / AISI D2, D3)

Alloy Steels (EN-Series, etc.)

With a state-of-the-art plant in Gurugram and Ludhiana, they ensure quality and reliability. Their strong distribution network across India makes them accessible to customers nationwide.

You can explore their offerings here: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-guntur/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#steel#andhrapradesh#guntur#APIIC#DieSteels#ToolSteel#SteelTrades#H11Steel#H13Steel#DB6Steel#DIN2714

2 notes

·

View notes

Text

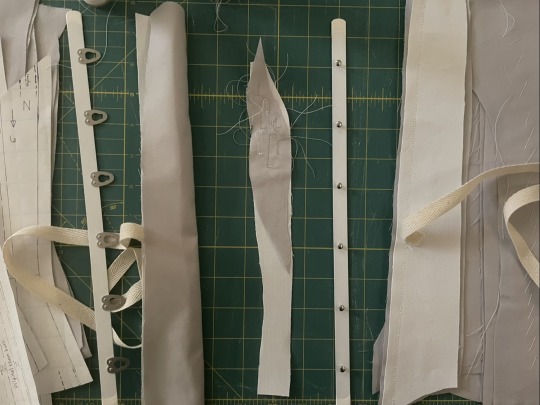

Pt. 2 of the stem of my corset-making ✨mistakes✨

So as we last left off, I was in the throes of complete and utter Audacity, thinking I could make the corset perfectly, with zero(0) experience with corsets. So, I made a mock up with cotton muslin and 1/2” twill tape, as seen below, wrote down my alterations and tried applying them.

Jk, I started having DoubtsTM, not helped by the fact that I was wavering over how wide the waist actually was, because my mockup and the description of the pattern’s measurement weren’t the same, whether to leave a few in. gap in the back or making it meet perfectly center back after lacing up (as is historically and og pattern accurate), getting confused when my mockup did not have the measurements as a costuber who was using the same pattern, and last but not least, I was fitting only one half of the corset and without any boning/busk, because I hadn’t gotten them yet. :/

Fml the pics got cropped weirdly

anyways, eventually I caved after trying to make another mockup as seen above and still not sure but unwilling to use up more fabric and time because I wanted it all done by December, and decided to run with the Etsy description measurement and add 1” on both halves of the corset, but split evenly between the panels 5, 6, & 7, because I thought they were too small, and extend the bust line on the other panels by half a cm to cover my nips, but hey at least my boobs weren’t bulging unseemly so over the bust of the corset so that part was clearly Fine otherwise. Mind you, I didn’t sew in the bone channels except like 2 and that was more for funsies than actually helpful in fitting a mock up. I also made a little make-shift pattern around the end of November for the top band of boning in the cups since that wasn’t provided but appeared to be added only after sewing panels 2, 3, & 4 together. Also, sometime in August to September, my busk and metal stamps had arrived and I made time to try and stamp the flowers onto the metal loops. Even though I had bought them in the smallest size available, the stamps were still too big to fit on the loops, which I ALREADY KNEW when I bought them, but I was in Denial :D I still tried, but quickly realized that for some godforsaken reason, the metal stamps weren’t stamping no matter how hard I hit it with a hammer (because we don’t have any softer mallets) and I’m✨ a cheapskate✨ so no buying another tool. Just to make sure, we tried stamping the actual um, hmmm would u call it a body? of the busk just to test whether it was the stamps or the small surface space, but even then they refused to properly create the stamped image so ig it was the metal?? *leans into the metaphorical mic* So that was a failure. AND AND just to top it all off, I realized that the busk I ordered was too long for the pattern, and because I didn’t want to make the front longer at the bottom, I had to order a shorter one, which also took time.

So, around mid to late September, like any good young individual, I was so confident things were going great that I drew up my altered pattern pieces all nice and official-like. Clearly, several months and a pound of blood, sweat, and tears later, that was wrong, cause I now am having to go back and scrap all of them except panels 1 and 7 >:///// but since I was oh so proud then of my work, here’s the general lineup, partially obscured out of respect for the pattern maker. Also, I had later decided to double the bones in panels 5 6 7 because I only realized after drawing them up that the bones I got, 3/16”, were like half the width of the og pattern bones, and pls don’t ask me about the smaller vertical bones in panel 7, because even I don’t remember what the fuck was going on there and u can’t erase ink. And if ur asking, well why the fuck didn’t u just buy bones in the correct width? Well, the supplier I ordered them from took like, 2 weeks to a month to arrive which wouldnt arrive in time for my deadline and were expensive as fuck, so I thought that I could just skate on by on my thiccc panels of tiny bones. It was already December 6 by the time I realized this mind u, so I also had to push my deadline back to December 20 as the latest I could tolerate, because I wanted to wear it for an event at the end of the year.

my fabric arrived in late September to early October and this was when I realized my second mistake, which was that instead of greige, I got cool grey toned to purple, so that was fun :/ like I like that color but it still wasn’t what I was originally going for, so a lesson in always buying a swatch first ig. Also it looked less like a sateen and more like a plain weave, and I was expecting something with a sheen like my moodfabrics cotton sateen, so another lesson in the reliability of quality from random suppliers. ://// I gave them both a thorough soak in clean water before leaving the to dry on the line for like 2 days? Just as a precaution if I ever get the corset wet so that it doesn’t shrink or warp, and also any excess dye for the sateen. I had finished drawing and cutting out my patterns sometime during all this too. Then I also ironed them both out to get rid of wrinkles, which I did over 3-5 days I think. I was also trying to buy cotton thread in a similar color to the fabric, but my first spool ended up being too light and in a fit of desperation, I tried dying it, failed miserably in terms of efficiency, and finally gave up that attempt to buy actually similar colored thread with a sample of some of my sateen. :|

From there, there’s multiple options on how you cut ur pattern out, but since coutil is so dense and sturdy, I decided that I would cut the pattern pieces out of that first, baste them wrong sides together to the sateen, then cut them out using the coutil pieces as the pattern for the sateen, which is much lighter and delicate. Obviously, you have to make sure to cut them according to the grainlines, and then for me, also baste them to match the sateen’s grainline. I spent a good chunk of time doing this, all the way into the beginning of November. I can remember because I vividly recall sewing basting through Halloween instead of getting out of the house. I don’t have any pics of this because I was so focused on making that I didn’t remember to take pics. 😔✌️ I did start sewing panel 1, my new busk, and the twill tape and did in fact remember to try testing the sewing machine on scraps of coutil and sateen first, but was again delayed when I had to face the fact that I had to get an actual awl and not just use the thin knitting needles I already had access to in order to poke holes for the pegs of the busk to poke through because I didn’t want to cut the fabric and compromise the stability of the corset, which would be under quite a bit of tension. I was also taking classes so I got delayed several times, increasingly so as we got closer to the end of the year/term. Even then, it was only until the beginning of December that I finally got to properly start sewing everything together. And by then, everything I had ordered had also arrived, which is good. Well, not rlly in regards to the grommets haha ha….

2 notes

·

View notes

Text

Being subtle is questionable (Osakita drabble)

Note: So I made this in a whim from a chat with a dear friend known as BKAK colleague about certain affairs, and I know I have to write this story 😉😉, and this is being my first subtly NSFW story, some discretion would be advised, thank you BKAK colleague to be my bouncing point to my Osakita madness

In Onigiri Miya, it is expected to see the round of gossips from his regulars and new faces, when they munch upon Osamu’s onigiris, it goes simply as one drunken salesman ranting about how shitty how his job is, along with the rounds of draft beer, tourists who flocked by, with their otherwise mediocre Japanese- fumbling over the correct terms of the food, which thankfully one of his quick-witted part-timers managed to navigate through the language barrier thanks to her self-learning Spanish in her free time. (His English is mediocre at best, but he learned it along the way), and young families flocking to Onigiri Miya, which Osamu took the time to high-five every energetic kid that comes by the shop.

However Osamu’s ears perked at the sound of the chime, to see the tanned white haired man Kita, huffing a little from the long journey from driving from his farm to his little restaurant. “Special delivery for Osamu Miya!!”, Osamu monetarily paused his motion of fluffing the rice, running over to Kita, who heaved a little deep breath. “Give me a moment….” He called one of the smaller male part-timers to help him to carry the rice packets.

Osamu’s eyes widened to Kita peeling the banana from his pocket, slowly shoving the fruit slowly in his mouth

“Your delivery order…..” Kita whispered quietly, fluttering his eyelashes in fake bliss, before finishing the banana in one gulp. “Samu”. Osamu withheld a cough, shit this is my supplier, I just need to forget a few nights ago when we actually snog that hard at the counter. His cheeks growing more flushed at Kita’s hand purposely brushing to him.

I need to focus on signing the order and stamping it, he should be gone.

Osamu shut his eyes, trying to think of the worst situation, and right now he could think it is Atsumu stealing the last pudding cup in the fridge. “Oh….Thank you….” Constantly adjusting his cap, Kita smiled a little, unaware of the stamp slipping away from Osamu’s sweaty palms.

“Boss….the rice where do you want to put the sacks of rice….” The young part-timer Hiro shouted to him. “You seems to be dazed….” Osamu shake his head, noticing Kita giving a cheeky smile, lost in his words. “If you need any more, come by my farm to see the new crops, my grandma asked for you though she did not…”

“I’ll come by your farm whenever you like….”

Kita’s complexion turned red, “Yeah, excuse me….” And in thin air, Kita seems to disappear, which Osamu heaved a sigh of relief, unaware that one of the older ladies Aiko gave a side eye to Osamu. “Samu-kun…..may I have my order” Osamu gave a bow to her “Oh I am sorry….” continuously folding the onigiri back and forth.

“What is going between you two…”, Osamu frowned a little, focusing his efforts to plate it prettily . “Aiko-san….I”, The wind chime to Akaashi, Bokuto’s husband shouting his order. “One umeboshi and one Ikura Onigiri please!” Osamu quickly distracted himself to greeting Akaashi. “Yep, coming up…” Though he hid his reddening expression with marvellous grace, focusing on making Akaashi’s order.

“Miya-san…..” Akaashi quietly muttered to Osamu. “Thanks, seems that new author is driving me nuts…..” Osamu bowed to him. “Oh, sorry, welcome….” he quickly passed the plate of rice balls to him. “How is everything, and your husband Bokuto-san….”

“Good, expect that I heard from Bokuto-san, that your brother Atsumu may accidentally received …I would say….suggestive texts during practice, and it is addressed to Kita, your former captain….”, and perhaps too coincidentally one of his servers passed a customer broiled eggplant. Osamu gulped to himself. “Akaashi-san, do you know what is the context of the texts….”

“I do not pry on gossip like that…..” Akaashi mutter quietly, munching the onigiri. “You should ask your brother…”, Osamu gulped to himself, trying to think of few nights back when he made his way to his farm, which they drank themselves too silly, reminiscing happy moments in their volleyball team, and perhaps get themselves too frisky. “All I know that Bokuto seems curious about this, and I do not see Atsumu being frisky with Kita….“

Osamu heaved a little. “Perhaps, curiosity will do bad for us….”, forcing himself to fold the onigiris over and over again. If he got the chance, there would be a heated FaceTime call with Atsumu over the contents of the texts.

“I am keeping my lips sealed for now Akaashi….”

“I know….” Akaashi nodded a little. “Try to be subtle next time….”

Subtleness is perhaps not their forte after all

#writing#writers on tumblr#haikyuu#haikyuu fanfiction#Osakita#kita shinsuke#inuyasha#Osamu x Kita#humour#I swear I am dying just writing this

6 notes

·

View notes

Text

What is African wax print fabric?

African wax print fabric is a 100% cotton fabric most popular in West African countries, including. Nigeria, Ghana, Senegal, Gambia, Kenya and Tanzania.

History

African wax print fabric has its roots in Indonesian batik, which was brought to Africa by Dutch traders in the 19th century. The designs were initially produced in Holland and exported to the Dutch colonies in Indonesia, but were eventually brought to West Africa where they became popular.

In the early 20th century, European textile manufacturers began producing the fabric in Europe and exporting it to Africa. However, the fabric was not widely accepted by Africans until it was adapted to suit local tastes and needs. African entrepreneurs, particularly in Ghana and Nigeria, began producing their own versions of the fabric, incorporating local designs and motifs.

Today, the fabric is produced and worn throughout Africa, and has become an important part of African fashion. It is used to make traditional clothing such as dresses, skirts, and head wraps, as well as modern clothing such as shirts, pants, and even shoes.

BASIC STEPS IN AFRICAN WAX PRINT FABRIC PRODUCTION

1. Preparation

2. Raw cotton fibres

3. Spinning the cotton to make yarn

4. Using the yarn to produce grey cloth

- Design

- Wax Printing

- Indigo Dyeing

- Crackling Effect

- Colouration

- Washing

- Finishing

Production

African wax print fabric is produced through a process called wax-resist dyeing. The fabric is first washed and bleached, then a wax design is stamped or printed onto the fabric using a copper stamp or roller. The fabric is then dyed, and the wax is removed, leaving a design that is resistant to the dye. This process can be repeated multiple times to create intricate and colorful designs.

Symbolism

African wax print fabric has a rich symbolic meaning in African culture. The patterns and colors used in the fabric often have specific meanings related to cultural traditions, spirituality, and social status. For example, some patterns may be associated with specific tribes or regions, while others may be worn for special occasions such as weddings or funerals.

The fabric has also become a symbol of African identity and resistance, particularly during the colonial era. It was often worn as a symbol of African pride and cultural independence, and was even used as a form of protest against colonial rule.

Conclusion

African wax print fabric is a beautiful and important part of African culture and fashion. Its complex history and rich symbolism make it a fascinating subject of study, and its vibrant colors and designs make it a popular choice for clothing and accessories. Whether worn as a traditional garment or incorporated into modern styles, African wax print fabric in Rajkot, Gujarat will continue to be a symbol of African culture and identity for generations to come.

For more:

Where Can I Get Authentic African Fabric Supplier In India?

Why You Should Pay Attention To African Printed Fabric?

African Fabric Supplier In Zambia

1 note

·

View note

Text

Exceptional Sheet Metal and Stamped parts supplier | ViolinTec

Violin Technologies is your reliable supplier for premium sheet metal and stamped parts. See our continuous pursuit of excellence: https://www.violintec.com.

0 notes

Text

Ferrous & Non-Ferrous Stamping Components Supplier in India

Supra India - Supplier of metal stamping parts (0.5mm to 5mm) and ferrous-non-ferrous metal immersion covers from India

#Customized assemblies in Brass and Stainless Steel supplier from India#Ferrous - Non-Ferrous Metal Immersion Covers Supplier from India#Metal Stamping Parts 0.5mm to 5mm Supplier India#SS 304#SS316 Bulkhead and Spacers used in the heating elements supplier from India

0 notes

Text

China metal stamping parts manufacturer Custom sheet metal strips.

#metal stamping#china metal parts#china supplier#mxmparts#stamping#stamping parts#sheet metal strips#metal parts#sheet metal parts#sheet metal component#stamping factory

1 note

·

View note

Text

When your industry requires high-caliber precision parts, you need a stamping company that meets the most stringent quality standards. Niraj Industries, a registered company, has been manufacturing precision tools for companies worldwide since 1994. Today, we produce over 1 million highly detailed parts every week for even the most technologically advanced applications.

For More Details Contact us: +91 92251 28155

For more information on Press Parts in Nashik visit our site:-https://www.nirajinds.com/press-parts-crgo.php

#Press Parts & Crgo Stamping#Press Parts Suppliers#Sheet Metal Press Parts Suppliers in Nashik#Press Parts in Nashik#Pressed Metal Parts in Nashik#Metal Stamping Services in Nashik

1 note

·

View note

Text

440C Stainless Steel Ball

●Diameter range: 0.3mm~Ø60mm, special specifications can also be customzed

●Available grade: G10-G500

●Surface: polished, finely ground

●440C stainless steel ball(9Cr18Mo), martensitic steel, high precision, hardness up to Rockwell 56-58 degrees, magnetic, good corrosion resistance, rust resistance and wear resistance.

●Application: bearings, stamping/hydraulic parts, valves, aerospace devices, seals, refrigeration equipment, high-precision instruments, etc.

0 notes

Text

About Mulan Group

Mulan Group has been engaged in custom metal parts production services for over 18 years. With two manufacturing companies and three processing plants, we provide one-stop metal forming services to buyers from more than 30 countries worldwide. Our services include sheet metal processing, sheet metal design, metal stamping, metal laser cutting, surface treatment, and more, meeting the diverse needs for metal-formed components across various industries.

Mulan Group leverages advanced processing equipment, a scientific quality management system, an efficient sales team, cost-effective pricing, and robust manufacturing resources to deliver one-stop custom metal parts production solutions for global suppliers.

We can provide instant quotes for custom metal parts within 24 hours. Simply let us know the material, color, quantity, and surface treatment. All orders can be quickly quoted, produced, and delivered.

1 note

·

View note