#metal stamping supplier

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

Metal Stamping Supplier - Types and Meanings of Metal Stamping

Today, many industries require complex metal structures or finished metal parts to manufacture their components. There is a growing need to meet these requirements across many industries, including automotive, aviation, medical, engineering, food processing, and more. Metal stamping is the process of turning flat metal sheets into different shapes of finished metal products. This process is used to produce these complex metal structures. Increasing demand for these metal parts has led to an increase in the number of metal stamping service providers across the globe.

How do metal stamping companies work?

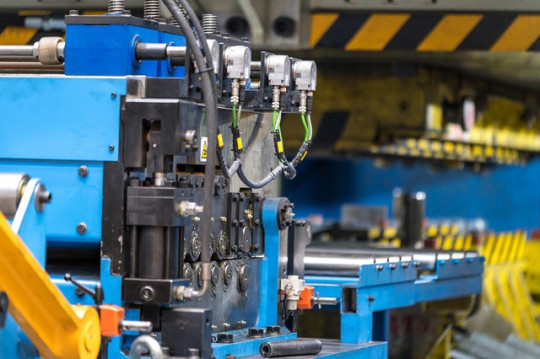

A Metal Stamping supplier uses sophisticated tools to shape and design raw metal sheets in a way that suits their clients' needs. A series of processes is used to transform the sheets into the final metal structures, including blanking, bending, punching, and more.

An overview of metal stamping

These procedures are commonly followed by metal stamping service providers when they convert raw metal into a finished product. While the basic process may be modified to meet the client's needs, the steps remain the same in most businesses. These steps are:

During the initial pressing process, raw metal or metal stamping blanks are inserted into a mold-like device called a metal stamping press. This first process is called pressing since the sheets of metal in coil form or blank form are pressed into the metal stamping press.

Several tools and die surfaces are found inside a metal stamping press. They are used to cut and design the metal stamping blanks or coils placed within the press. Punching, blanking, bending, coining, embossing and flanging are the most important techniques used to turn blanks into finished products.

The tools inside the press use advanced design techniques such as CAD or CAM to ensure perfection and accuracy in every curve and bend of the final metal part manufactured. Engineering experts in most industries are responsible for these complex processes. A slight error in this process will definitely impact the final quality of the finished metal product, leading to financial loss and loss of reputation for the metal stamping service provider.

Following the creation of the correct designs and tooling, the company uses various finishing techniques, such as machining, to complete production.

Uses of a metal stamping press

To convert metal stamping blanks into desired shapes, metal stamping service providers use a metal stamping press. For these techniques, a metal stamping press is used. In order to give you a better understanding of how metal stamping presses work, here is a brief description of these techniques:

Perforating metal stamping blanks with a die

Getting the outline or rough shape of the product right to avoid burrs is known as blanking

The process of embossing is used to create raised or indented designs on sheets of metal

The sheet metal is stamped with a design on both sides before being embossed or coined for the same purpose as embossing

When metal has to be bent into a U or V shape, press brakes are used to achieve the perfect curve

The process of flanging involves bending the sheet metal near the holes at a perfect 90 degree angle in order to create rims on all sides

Common types of metal stamping presses

One of the most important tools used by metal stamping service providers today is the metal stamping press, which helps to press and fold sheet metal in different shapes.

When the sheet metal is compressed against the die surface, the ram at the top of the press triggers motion. These presses have one ram, which allows them to perform a single operation at a time.

The double-acting presses have two rams, and can perform two operations simultaneously. Here, one ram holds the blanks for punching and stamping, and the other ram holds the blanks for holding.

In the mechanical stamping press, a motor is attached to the mechanical flywheel to produce varying speeds consistently while stamping shallow or simple metal structures. Pressing speed varies from 20 to 1500 strokes per minute, while size can range between 20 and 6000 tons.

Presses that use hydraulic liquid at high pressure are used to stamp sheet metal into the necessary shapes. Depending on their size, they can handle between 20 and 10000 tons, and they have adjustable strokes and speeds.

The mechanical servo press is faster than the hydraulic press, as it uses mechanical motors instead of flywheels to control the stroke, speed, and slide. click here

Metal stamping company Tentral has been in business in China for more than 15 years. Precision metal stamping parts have been our specialty since 2005, serving customers in industries such as automobiles, lighting, construction, medicine, and energy. As the leading manufacturer of metal stamping, we have a professional team and advanced facilities to supply our customers with the most reliable metal stamping parts and sheet metal fabrication parts.

0 notes

Text

Exploring the Art and Science of Sheet metal stamping

In the industrial process known as sheet metal stamping, metal sheets are formed, cut, and shaped into the necessary shapes. The procedure is normally carried out with the aid of a stamping press, which uses mechanical pressure to shape raw materials into finished goods using a sequence of dies and punches. Let’s break the procedure down into its essential steps: Tooling and Design…

View On WordPress

#Metal Stamping China#Metal Stamping Manufacturer#Metal Stamping supplier#Precision Metal Stamping#Sheet metal stamping

0 notes

Text

Ferrous & Non-Ferrous Stamping Components Supplier in India

Supra India - Supplier of metal stamping parts (0.5mm to 5mm) and ferrous-non-ferrous metal immersion covers from India

#Customized assemblies in Brass and Stainless Steel supplier from India#Ferrous - Non-Ferrous Metal Immersion Covers Supplier from India#Metal Stamping Parts 0.5mm to 5mm Supplier India#SS 304#SS316 Bulkhead and Spacers used in the heating elements supplier from India

0 notes

Text

Sunrise Brass Industries are Manufacturer, Exporter, Supplier of customized Components in Brass, Stainless Steel, Copper, Bronze, Gun Metal and special alloys at Jamnagar. https://www.sunriseind.co.in/index.html

#Sunrise Brass Industries are Manufacturer#Exporter#Supplier of customized Components in Brass#Stainless Steel#Copper#Bronze#Gun Metal and special alloys at Jamnagar.#https://www.sunriseind.co.in/index.html#brassproduct#steel#copper#aluminium#zinc#nickel#polishing#stainlesssteel#specialalloys#electric#casting#forging#stamping#machining#surfacefinishing#testing#packaging#brassjamnagar#electrical#electronicsapplications#pipefittings#conduitfittings

1 note

·

View note

Text

Niraj Industrie’s Sheet Metal Pressed Parts Manufacturers in India

When your industry requires high-caliber precision parts, you need a stamping company that meets the most stringent quality standards. Niraj Industries, a registered company, has been manufacturing precision tools for companies worldwide since 1994. Today, we produce over 1 million highly detailed parts every week for even the most technologically advanced applications.

We, at Niraj Industries have positioned ourselves as one of the major Press Parts Manufacturers and Suppliers located in Mumbai. We manufacture all types of strips in CRGO M6 M5 M4 Grade.

At Niraj Industries you will find global Press Parts in Nashik. Niraj Industries you will find global suppliers and manufacturers ready to meet your demands. No matter where you are, you can easily get your products without going beyond your national borders. As a leading platform, we cater to listed manufacturers and suppliers.

For More Details Contact us: +91 92251 28155

For more information on Press Parts in Nashik visit our site:-https://www.nirajinds.com/press-parts-crgo.php

#Press Parts & Crgo Stamping#Press Parts Suppliers#Sheet Metal Press Parts Suppliers in Nashik#Press Parts in Nashik#Pressed Metal Parts in Nashik#Metal Stamping Services in Nashik

0 notes

Text

GI Flanges Manufacture in Assam

Assam, a state known for its tea gardens and rich biodiversity, is also carving out a niche in the manufacturing of Galvanized Iron (GI) flanges. With a strategic focus on industrial development, Assam’s manufacturing sector is expanding, particularly in the area of metal fabrication. This growth is driven by both local demand and the potential for export to neighboring states and countries.

Manufacturers in Assam are increasingly adopting advanced technologies to produce high-quality GI flanges. The process typically involves sourcing raw materials from local suppliers, which helps to support the regional economy. After procuring the necessary steel, manufacturers engage in processes like cutting, stamping, and galvanizing to create flanges that are durable and resistant to rust and corrosion. These flanges find application in various industries, including construction, water supply systems, and oil and gas.

The state’s industrial policy actively promotes the MSME sector, providing financial assistance and incentives for new and existing businesses in the manufacturing space. Many small and medium enterprises in Assam are receiving support to upgrade their production facilities and enhance their product offerings. This governmental push is vital for improving the quality of GI flanges manufactured in the state and increasing their competitiveness in the market.

Moreover, the demand for GI flanges is on the rise, fueled by ongoing infrastructure projects and urbanization within Assam. The government’s efforts to improve transportation and connectivity have also opened up new markets for manufacturers, allowing for better distribution of products. The ability to transport finished goods efficiently is crucial for maintaining competitiveness, particularly in regions with emerging markets.

Assam's rich cultural heritage and community values also play a role in its industrial landscape. Many manufacturers are adopting sustainable practices, such as recycling and reducing waste in their production processes. This commitment to sustainability not only helps in protecting the environment but also aligns with the growing consumer preference for eco-friendly products.

As Assam continues to develop its manufacturing capabilities, the GI flange industry is expected to grow significantly. The combination of supportive government policies, a focus on quality, and an increasing demand for infrastructure will drive this sector forward, contributing to the state's economic development and job creation.

#GIFlanges#FlangeManufacturing#IndustrialFlanges#GalvanizedIron#ManufacturingIndia#MetalFabrication#Assam#MakeInAssam#MSMESector#SustainableManufacturing#InfrastructureDevelopment#LocalEconomy#ConstructionIndustry#WaterSupply#OilAndGas#GovernmentSupport#ManufacturingGrowth#EcoFriendlyProducts#JobCreation#CulturalHeritage#EmergingMarkets

2 notes

·

View notes

Text

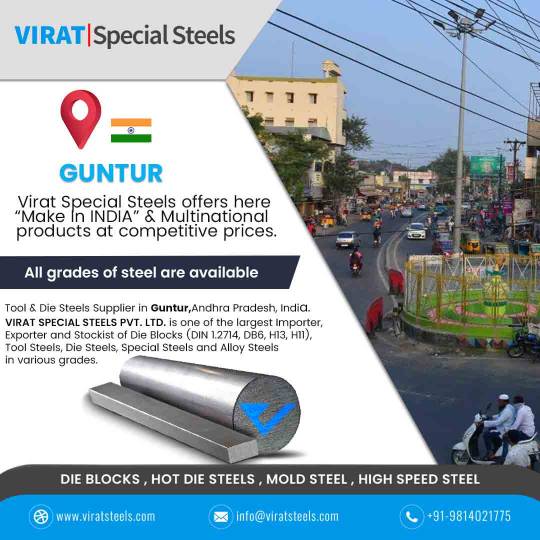

Exploring the top-notch Tool and Die Steel Supplier in Guntur, Andhra Pradesh?

Tool and Die Steel Supplier in APIIC Guntur Industrial Area. Look no further! Virat Special Steels delivers excellence.

Whether it’s tool steel, die steel, mold steel or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Andhra Pradesh!

A significant part of this industrial development is the tool and die steel sector. Tool and die steel are crucial components in manufacturing, used to create a variety of tools, dies, molds, and other essential parts for industries like Forging and Stamping Companies, Metal Fitting, Automotive, Aerospace, and Medical devices.

For tool and die steel requirements in APIIC Guntur, you can consider suppliers like VIRAT SPECIAL STEELS PVT. LIMITED , INDIA . They offer a wide range of tool and die steels, including:

Die Steel (HH 370 – 410 BHN) (DB6 / DIN-1.2714 / AISI L6)

Hot Work Steels (DIN 2343, 2344 / AISI H11, H13)

Plastic Mould Steels (DIN 2738, 2311 / AISI P20)

High Speed Steels (DIN 3243, 3343 / AISI M2, M35)

Cold Work Steels – HCHCr (DIN 2379, 2080 / AISI D2, D3)

Alloy Steels (EN-Series, etc.)

With a state-of-the-art plant in Gurugram and Ludhiana, they ensure quality and reliability. Their strong distribution network across India makes them accessible to customers nationwide.

You can explore their offerings here: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-guntur/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#steel#andhrapradesh#guntur#APIIC#DieSteels#ToolSteel#SteelTrades#H11Steel#H13Steel#DB6Steel#DIN2714

2 notes

·

View notes

Text

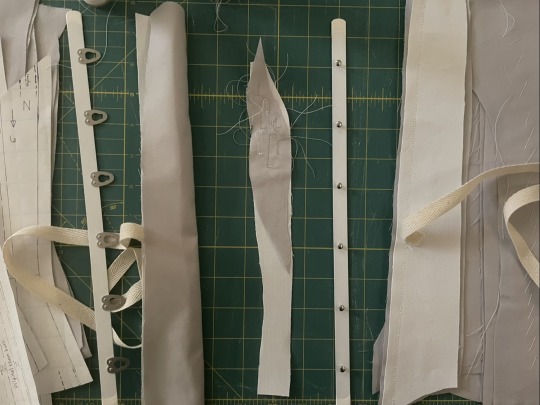

Pt. 2 of the stem of my corset-making ✨mistakes✨

So as we last left off, I was in the throes of complete and utter Audacity, thinking I could make the corset perfectly, with zero(0) experience with corsets. So, I made a mock up with cotton muslin and 1/2” twill tape, as seen below, wrote down my alterations and tried applying them.

Jk, I started having DoubtsTM, not helped by the fact that I was wavering over how wide the waist actually was, because my mockup and the description of the pattern’s measurement weren’t the same, whether to leave a few in. gap in the back or making it meet perfectly center back after lacing up (as is historically and og pattern accurate), getting confused when my mockup did not have the measurements as a costuber who was using the same pattern, and last but not least, I was fitting only one half of the corset and without any boning/busk, because I hadn’t gotten them yet. :/

Fml the pics got cropped weirdly

anyways, eventually I caved after trying to make another mockup as seen above and still not sure but unwilling to use up more fabric and time because I wanted it all done by December, and decided to run with the Etsy description measurement and add 1” on both halves of the corset, but split evenly between the panels 5, 6, & 7, because I thought they were too small, and extend the bust line on the other panels by half a cm to cover my nips, but hey at least my boobs weren’t bulging unseemly so over the bust of the corset so that part was clearly Fine otherwise. Mind you, I didn’t sew in the bone channels except like 2 and that was more for funsies than actually helpful in fitting a mock up. I also made a little make-shift pattern around the end of November for the top band of boning in the cups since that wasn’t provided but appeared to be added only after sewing panels 2, 3, & 4 together. Also, sometime in August to September, my busk and metal stamps had arrived and I made time to try and stamp the flowers onto the metal loops. Even though I had bought them in the smallest size available, the stamps were still too big to fit on the loops, which I ALREADY KNEW when I bought them, but I was in Denial :D I still tried, but quickly realized that for some godforsaken reason, the metal stamps weren’t stamping no matter how hard I hit it with a hammer (because we don’t have any softer mallets) and I’m✨ a cheapskate✨ so no buying another tool. Just to make sure, we tried stamping the actual um, hmmm would u call it a body? of the busk just to test whether it was the stamps or the small surface space, but even then they refused to properly create the stamped image so ig it was the metal?? *leans into the metaphorical mic* So that was a failure. AND AND just to top it all off, I realized that the busk I ordered was too long for the pattern, and because I didn’t want to make the front longer at the bottom, I had to order a shorter one, which also took time.

So, around mid to late September, like any good young individual, I was so confident things were going great that I drew up my altered pattern pieces all nice and official-like. Clearly, several months and a pound of blood, sweat, and tears later, that was wrong, cause I now am having to go back and scrap all of them except panels 1 and 7 >:///// but since I was oh so proud then of my work, here’s the general lineup, partially obscured out of respect for the pattern maker. Also, I had later decided to double the bones in panels 5 6 7 because I only realized after drawing them up that the bones I got, 3/16”, were like half the width of the og pattern bones, and pls don’t ask me about the smaller vertical bones in panel 7, because even I don’t remember what the fuck was going on there and u can’t erase ink. And if ur asking, well why the fuck didn’t u just buy bones in the correct width? Well, the supplier I ordered them from took like, 2 weeks to a month to arrive which wouldnt arrive in time for my deadline and were expensive as fuck, so I thought that I could just skate on by on my thiccc panels of tiny bones. It was already December 6 by the time I realized this mind u, so I also had to push my deadline back to December 20 as the latest I could tolerate, because I wanted to wear it for an event at the end of the year.

my fabric arrived in late September to early October and this was when I realized my second mistake, which was that instead of greige, I got cool grey toned to purple, so that was fun :/ like I like that color but it still wasn’t what I was originally going for, so a lesson in always buying a swatch first ig. Also it looked less like a sateen and more like a plain weave, and I was expecting something with a sheen like my moodfabrics cotton sateen, so another lesson in the reliability of quality from random suppliers. ://// I gave them both a thorough soak in clean water before leaving the to dry on the line for like 2 days? Just as a precaution if I ever get the corset wet so that it doesn’t shrink or warp, and also any excess dye for the sateen. I had finished drawing and cutting out my patterns sometime during all this too. Then I also ironed them both out to get rid of wrinkles, which I did over 3-5 days I think. I was also trying to buy cotton thread in a similar color to the fabric, but my first spool ended up being too light and in a fit of desperation, I tried dying it, failed miserably in terms of efficiency, and finally gave up that attempt to buy actually similar colored thread with a sample of some of my sateen. :|

From there, there’s multiple options on how you cut ur pattern out, but since coutil is so dense and sturdy, I decided that I would cut the pattern pieces out of that first, baste them wrong sides together to the sateen, then cut them out using the coutil pieces as the pattern for the sateen, which is much lighter and delicate. Obviously, you have to make sure to cut them according to the grainlines, and then for me, also baste them to match the sateen’s grainline. I spent a good chunk of time doing this, all the way into the beginning of November. I can remember because I vividly recall sewing basting through Halloween instead of getting out of the house. I don’t have any pics of this because I was so focused on making that I didn’t remember to take pics. 😔✌️ I did start sewing panel 1, my new busk, and the twill tape and did in fact remember to try testing the sewing machine on scraps of coutil and sateen first, but was again delayed when I had to face the fact that I had to get an actual awl and not just use the thin knitting needles I already had access to in order to poke holes for the pegs of the busk to poke through because I didn’t want to cut the fabric and compromise the stability of the corset, which would be under quite a bit of tension. I was also taking classes so I got delayed several times, increasingly so as we got closer to the end of the year/term. Even then, it was only until the beginning of December that I finally got to properly start sewing everything together. And by then, everything I had ordered had also arrived, which is good. Well, not rlly in regards to the grommets haha ha….

2 notes

·

View notes

Video

youtube

In Buying Precious Metals and Stones and Costume Jewellery Online

The Jewellery Supermarket is one of the UK's leading retail suppliers of jewellery, accessories and watches.

There are ways to test the genuineness of precious metals and stones you own. Because these precious metals and stones such as silver,In Buying Precious Metals and Stones and Costume Jewellery Online Articles gold and platinum are all in the periodic table, it means they can be tested just like the way chemists read more here perform experiments on them. If you want to check if your jewellery is fake or not, you can experiment with the tips given in this article.

Precious metals and stones made in certain places have an obligatory hallmarking procedure. These are markings that signify the jewellery's authenticity such as number of carat or a letter stamp with a date. However, there are some real precious metals and stones that do not have such markings, especially those made in the United States. You can use a magnifying glass to look for the markings.

Another test is to check if your precious metals and stones can be magnetized. If they can, these are fake. Precious metals and stones such as silver, gold and platinum, cannot be magnetized at all. You can also try bending your precious metals and stones. Genuine ones that are thin are flexible. If the metal under the plating of your pieces can be filed easily, these are real. If they cannot, this means these are not authentic. If you are the type of person who loves costume jewellery instead, you should know the right tips on how to buy them. The advantage of costume jewellery is that they are not expensive and they come in different colors, shapes and sizes to complement various outfits. There are those that look expensive but are very cheap.

Buying costume jewellery online is now the trend. When you look for costume jewellery online, look for those that are of high-quality. Make sure they are strong and stable and they have stones that shine brightly. Their plating must also be smooth. Ensure the weight of the pieces you are interested in is specified on the website where they are sold. Costume jewellery online that are heavy means they are of good quality. When you consider buying costume jewellery online, make sure you have the clothes that will go well with them. Assess each piece based on color, shape, size and design so that when you wear them, you will look good and well-coordinated.

A simple dress can look elegant with the right costume jewellery online. Look for pieces that have diamond chips so that they sparkle when you wear them.There is also vintage costume jewellery online that has a great imitation of precious stones and metals. These are very hard to find in shops nowadays. Try scouting for them in department stores and boutiques. You can also try discount stores and costume jewellery online auctions. There are also rummage sales, garage sales, and second hand shops that have such vintage costume jewellery.Buying jewellery, whether genuine or fake, is entirely up to the kind of personality you have. There are those who are comfortable with costume jewellery and there are those who are not. Whatever your choice is, be they fake or precious metals and stones, the important thing is you buy something you really like.

2 notes

·

View notes

Text

Meghmani Metal Industries is a trusted Manufacturer and Supplier of Stainless Steel Coils in Indore, Madhya Pradesh, India. We are based in Ahmedabad, Gujarat, India. SS Coils (Stainless Steel Coils) are continuous rolls of stainless steel that have been rolled into thin sheets or strips, typically used for further processing, including cutting, stamping, and welding. The stainless steel coils offered by Meghmani Metal Industries are available in various grades and finishes, catering to different industrial needs. SS coils are produced through a rolling process that involves heating the steel to a specific temperature and then passing it through rollers to achieve the desired thickness. The end product is a flexible and durable material that can be further processed into a wide variety of forms and shapes. Types of SS Coils: Hot Rolled Coils Cold Rolled Coils Precision SS Coils Polished Coils Features of SS Coils: Corrosion Resistance: Protection against rust and chemical damage. High Strength: Excellent mechanical properties for durability. Aesthetic Appeal: Sleek finish for decorative applications. Temperature Resistance: Suitable for high-temperature environments. Versatility: Available in various grades (304, 316, 430, etc.) and dimensions. Meghmani Metal Industries is a Stainless Steel Coils in Indore, Madhya Pradesh, India including locations like Pithampur, Sagar, Jabalpur, Katni, Dewas, Jhabua, Dhar, Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar. Contact us today to discuss your requirements or get a quote. View Product: Click Here Read the full article

0 notes

Text

Exceptional Sheet Metal and Stamped parts supplier | ViolinTec

Violin Technologies is your reliable supplier for premium sheet metal and stamped parts. See our continuous pursuit of excellence: https://www.violintec.com.

0 notes

Text

Why South India is the Hub for TMT Bar Manufacturing Excellence

South India has established itself as a premier hub for TMT bar manufacturing excellence, driven by a blend of advanced infrastructure, skilled workforce, and abundant resources. This region plays a pivotal role in meeting the growing demands of the construction and infrastructure sectors in India and beyond. Let’s explore the key reasons why South India leads in the production of TMT bars and related steel products.

1. Advanced Manufacturing Facilities

South India boasts state-of-the-art steel factories equipped with cutting-edge technology. These facilities are designed to produce top-quality TMT bars with superior strength and flexibility. The presence of well-established steel pipe manufacturers and TMT dealers in the region ensures that the production process adheres to international standards, catering to both domestic and export markets.

Additionally, the region is home to leading sheet metal stamping units, which support the production of high-grade steel components, enhancing the versatility of the steel industry in South India.

2. Abundance of Raw Materials

South India benefits from easy access to raw materials like iron ore and coal, which are essential for steel production. This proximity reduces transportation costs and ensures a steady supply for steel dealers and manufacturers. The availability of high-quality raw materials is a key factor contributing to the consistent production of durable TMT bars and related products such as seamless pipes and metal pipes.

3. Skilled Workforce

The region is renowned for its skilled workforce, trained in the latest technologies and manufacturing processes. From the production of stainless pipes to high-quality TMT bars, South India’s labor force is adept at meeting the precise requirements of modern construction and engineering projects. This expertise has solidified the reputation of stainless steel pipe suppliers and TMT bar dealers in the region.

4. Strategic Location for Export

With well-connected ports like Chennai, Cochin, and Mangalore, South India serves as a strategic hub for exporting steel products, including stainless steel pipes and seamless pipes, to global markets. The region’s robust logistics infrastructure ensures timely delivery, making it a preferred destination for international clients seeking reliable ss pipe suppliers and steel dealers.

5. Innovation and Sustainability

South India’s steel industry is committed to innovation and sustainability. Many steel factories in the region focus on eco-friendly practices, such as recycling and energy-efficient manufacturing processes. The production of durable metal pipes, stainless pipes, and TMT bars reflects the industry’s dedication to quality and environmental responsibility.

6. Growing Construction Demand

The rapid urbanization and infrastructure development in South India have fueled the demand for high-quality TMT bars and steel products. This growth has further strengthened the network of TMT dealers, steel pipe manufacturers, and stainless steel pipe suppliers, ensuring that the region remains a leader in the steel industry.

CONCLUSION:

South India’s dominance in TMT bar manufacturing excellence is the result of its advanced facilities, resource availability, skilled workforce, and strategic export advantages. The region’s thriving steel industry, supported by trusted TMT bar dealers, steel dealers, and ss pipe suppliers, continues to set benchmarks for quality and innovation. Whether it’s seamless pipes, metal pipes, or sheet metal stamping, South India remains a crucial player in meeting the steel needs of modern industries.

0 notes

Text

Sunrise Brass Industries are Manufacturer, Exporter, Supplier of customized Components in Brass, Stainless Steel, Copper, Bronze, Gun Metal and special alloys at Jamnagar. https://www.sunriseind.co.in/index.html

#brassjamnagar#entrepreneur#commercial#Sunrise Brass Industries are Manufacturer#Exporter#Supplier of customized Components in Brass#Stainless Steel#Copper#Bronze#Gun Metal and special alloys at Jamnagar.#https://www.sunriseind.co.in/index.html#brassproduct#steel#copper#aluminium#zinc#nickel#polishing#stainlesssteel#specialalloys#electric#casting#forging#stamping#machining#surfacefinishing#testing#packaging#electrical#electronicsapplications

1 note

·

View note

Text

China metal stamping parts manufacturer Custom sheet metal strips.

#metal stamping#china metal parts#china supplier#mxmparts#stamping#stamping parts#sheet metal strips#metal parts#sheet metal parts#sheet metal component#stamping factory

1 note

·

View note

Text

When your industry requires high-caliber precision parts, you need a stamping company that meets the most stringent quality standards. Niraj Industries, a registered company, has been manufacturing precision tools for companies worldwide since 1994. Today, we produce over 1 million highly detailed parts every week for even the most technologically advanced applications.

For More Details Contact us: +91 92251 28155

For more information on Press Parts in Nashik visit our site:-https://www.nirajinds.com/press-parts-crgo.php

#Press Parts & Crgo Stamping#Press Parts Suppliers#Sheet Metal Press Parts Suppliers in Nashik#Press Parts in Nashik#Pressed Metal Parts in Nashik#Metal Stamping Services in Nashik

1 note

·

View note