#stainless steel stamping parts

Text

How long is the service life of automotive stamping mold?

The useful life of an automotive stamping mold varies with a number of factors, including material, design, processing, and conditions of use. Generally speaking, high-quality stamping dies can be used thousands to hundreds of thousands of times, or even more. The following are some factors that may affect the service life of stamping dies:

Material: Stamping dies are usually made of high-hardness, high-strength alloy steel materials. The wear resistance and strength of these materials are very important for extending the service life.

Processing: The manufacture of stamping dies needs to go through multiple processes, such as forging, precision machining, heat treatment, etc., and each link will affect the service life. Therefore, the processing quality of the stamping die is very important.

Conditions of use: The environment and conditions of use also have an important impact on the life of stamping dies. For example, factors such as temperature, humidity, cleanliness and oil film all have an impact on the wear and corrosion of the mold.

Maintenance: Regular maintenance and lubrication are also one of the key factors in extending the life of stamping dies. Measures such as regular cleaning, oiling, and timely replacement of worn parts can reduce mold wear.

In short, the service life of stamping dies varies due to many factors, and maintenance and inspection are required during use to ensure that they function to the maximum and prolong their service life.

0 notes

Text

#Car parts manufacturer#Automotive aftermarket industry of Pakistan#bike spare parts suppliers#stamping stainless steel parts#stainless steel stampings suppliers#stainless steel stamping parts#gm spring hill stamping steel plant#Body Parts manufacturer

0 notes

Text

Ferrous & Non-Ferrous Stamping Components Supplier in India

Supra India - Supplier of metal stamping parts (0.5mm to 5mm) and ferrous-non-ferrous metal immersion covers from India

#Customized assemblies in Brass and Stainless Steel supplier from India#Ferrous - Non-Ferrous Metal Immersion Covers Supplier from India#Metal Stamping Parts 0.5mm to 5mm Supplier India#SS 304#SS316 Bulkhead and Spacers used in the heating elements supplier from India

0 notes

Text

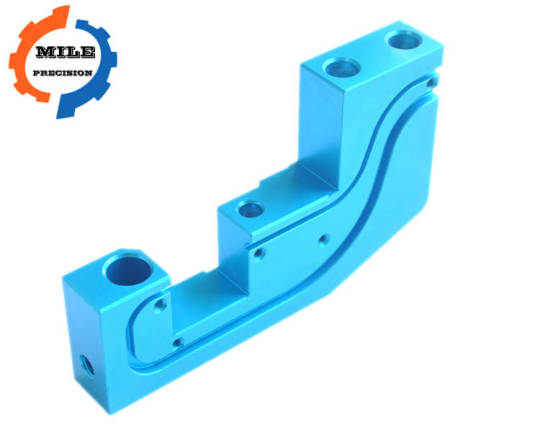

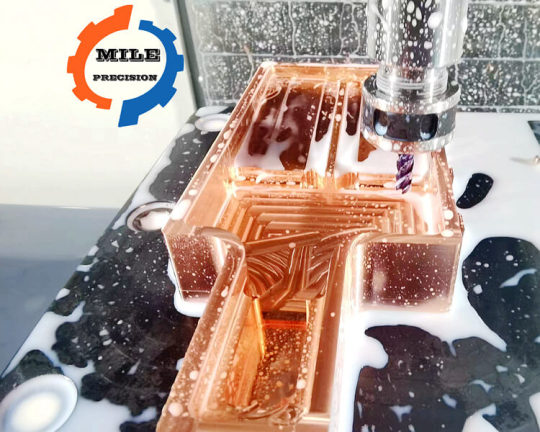

We are an experienced Custom precision machining services supplier, manufacturer in China

Our main industrial part products include turned parts, CNC machined parts, metal stamping parts and CNC milling.

Products include: hydraulic parts, pneumatic components, auto parts, medical equipment, photographic equipment, injection molding machine parts, etc.

OEM parts manufacturers,

Welcome to our website www.milemetal.com

Contact Us [email protected]

NINGBO MILE PRECISION MACHINERY CO.,LTD

#cnc milling#cnc machining#cnc turning#metal parts#oem parts#oem#stainless steel#stamping#casting#forging#auto parts

0 notes

Text

Did I find a bargain! This cute little home with a nice front porch in Gillespie, IL has 2bds, 1ba, and is only $69,900! And, guess what? It's already decorated with murals. You will think you're in a mansion. Take a look at this. Only 7 days on the market and it already has a sale pending.

Enter the front door into the living room, and you've got faux wainscoting in the Romanesque style.

I don't know what's happening in the rest of the room, though. Maybe they tried to remove it before it went up for sale.

The dining room looks like you're eating in a Roman villa. Note the built-in shelving, too.

I'm a bit confused by the kitchen. Is that mural glued onto the cabinets, or have the cabinets been removed? Note the cabinet over the microwave that looks like a little china cabinet. There's so much to see in this home. Then, it looks like they left a matching painting on an easel on the counter. Plus, the modern stainless steel farmhouse sink.

There's an additional cabinet under the window with shelving, as well as a shelf mural.

The kitchen has a large eat-in area, and you can see the granite countertops on the left.

The kitchen has a pantry thru which you enter the bath.

The part of the large bath by the sink, has a faux stone wall. There's also a mirrored closet.

Then, by the toilet and shower, there's a dark undersea mural. Isn't this mysterious?

Judging by the mural by the toilet, it looks like something out of "20,000 Leagues Under the Sea."

This bedroom has direct access to the bath. I'm very disappointed in the bedrooms, though. No murals.

But, then again, they're blank slates waiting for the new owner to put their stamp on them.

There's a nice deck in the back and it looks like the eat-in kitchen has a door to the yard.

Beautiful yard on a 7,405 sq ft lot. Not bad at all for the price. My parents started out in a small home like this.

https://www.zillow.com/homedetails/402-E-Maple-St-Gillespie-IL-62033/89979953_zpid/

139 notes

·

View notes

Note

Plastic, resin, and stainless steel (obviously) don't rust or stain, but what about locks? They seem to be brass, bronze, or copper (at least, the neat little ones, not the rattly external padlocks), how does one keep them from degrading?

Also, looking at how crude the designs were even ten years ago makes me glad I live now. This interest cannot have been fun in the earlier days, some of those older designs look like they easily weigh 200 grams or more, all suspended from the last place anyone wants to suspend weight.

🔒 Tom here. Yes, there are an amazing number of cage styles and materials now. Back when I first got involved, we had to make our own cages from mastodon tusks and pterodactyl wings.

Locks, for the most part, are brass, and fairly resistant to the mild elements that most wearers would expose them to. While they might become a little bit discolored, it won't affect the operation.

I have to stress that the good, German made Burg Wachter ME/2 barrel locks are great. Unfortunately, most of the ME/2 Chinese knock offs are absolutely horrible, and will fail - sometimes before you've even had a chance to use them. You can tell the crappy ones because the tumblers and springs are held in with a cheap stamped strip of brass. The better ones use individually pressed brass pins to hold each spring & tumbler.

I still maintain that stainless steel cages are easier to clean than plastic, and while they are heavier, some new designs are lighter weight than older cages, and (in my opinion) are still the best choice for permanent wear.

108 notes

·

View notes

Text

Because I’ve seen this a lot, I thought I’d throw a little bit of knowledge downrange for all y’all making quasi-period-accurate western/gunslinger OCs:

There’s a world of difference between a modern revolver and a period-appropriate model, like the Colt 1851 above- when looking for reference pics, it’s important to keep that in mind!

A modern revolver, like the colt python above, is made from finished steel and made from milled parts- you see that cut-out on the bottom of the barrel, or how the barrel and cylinder are shaped, how there are almost no visible bolts or screws? That’s because modern manufacturing techniques allow for precisely-milled metal like that!

The 1851, our first example, is mostly made from stamped, even forged steel, often lacking any sort of finish. It’s very simplistically shaped and has a lot of screws keeping everything together- people in the 1800’s didn’t really have access to modern mills or the sorts of metallurgy we do now, so that’s gonna be what you get. Old guns look old for a reason!

So remember- if you’re looking for period appropriate, non-modern revolvers, keep in mind that they’re gonna be kinda crude, made with hand tools, and simplistically shaped- if it’s made of stainless steel and has lots of small flourishes and details, it’s probably a modern one!

65 notes

·

View notes

Text

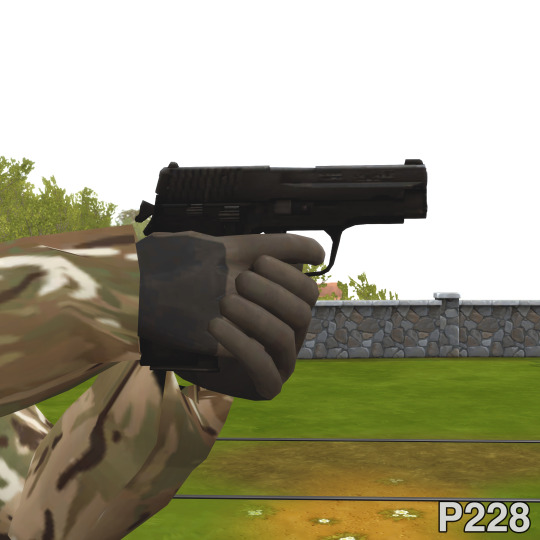

SIG-Sauer Pistols CC Collection

Began in 1975, with an aquisition of a German arms factory of J.P Sauer und Sohn GmbH by the Swiss SIG AG, SIG-Sauer produces many variants of pistols including :

SIG P220

The very first patent since the joint of these two companies. Launched in 1975 to fill the position of the police issue sidearm. Also this model is a principle of the next SIG-Sauer pistol designs.

SIG P226

Issued in 1985 as a development of P220 with advanced features. Actually participated in US DoD's XM9 program, but instead the Beretta 92F was chosen. Later acquired by the US Navy as M11. One of Original "Wonder 9" Member who Successfully toppled the Revolver's Domination during 1980s inside Law Enforcement and Military alike.

SIG P228/P229

A compact variant of P226 basically some length was chopped from the barrel and slide, as well as from the grip. The P229, was developed especially for the US market and is assembled in the USA using both German and US-made parts. It’s identical to the P228 except for a heavier slide. The P229 slide is made by machining a bar of steel as opposed to stamping and forming from sheet steel. The heavier slide on the P229 is necessary because of the comparatively more powerful calibers used in this pistol.

SIG Pro

Sig Sauer's Attempt on Modernizing their Sig Sauer Series to make it relevant for current Polymer frame Pistol Trend and stay relevant in Military Industries. The SIG Pro is a series of semi-automatic pistols developed by SIG Sauer in Exeter, New Hampshire. It became the first polymer-frame handgun from SIG Sauer and one of the first pistols to feature a built-in universal accessory rail and interchangeable grips. Offerings in the series are chambered in .40 S&W, .357 SIG, or 9×19mm Parabellum. As of March 2020, only the SP 2022 variant is still listed on the SIG Sauer website. The SIG Pro was marketed as a lightweight. and compact alternative to the "legacy" SIG Sauer handguns in an increasingly competitive and budget-oriented law enforcement market.

SIG P320 (M17 And M18 )

A further development of previous model SIG P250 which issued by SIG Arms Inc. USA. Released in 2014 as a SIG participation in the US DoD's XM17 next sidearm program. After some evaluation, this model won the contract and acquired as M17 in the US Army in 2017. US Marine Corps acquired it's compact variant known as M18. The full-sized model was designated the M17, and the shorter length carry model, the M18. The guns have subsequently been adopted by the Army, Navy, Marine Corps, Air Force, and Space Force. The pistol replaces the Beretta M9, as well as several other handguns across the services. There are two color variants, coyote brown and black, for both the M17 and M18, though almost all have been produced in brown.

The SIG Sauer P365

Modern Derringer is here.. with superior compact size over the smallest modern Handgun that ever known, Glock 42 (5.8 inch on P365 Vs 5.94 inch on Glock 42) also the Best Seller on "Concealed Carry" Category in United States. perfect for anyone who looking for smaller Pistol as Third Sidearms or Perfect pistol for Political Assassination 3:)

SIG Sauer P365 is a striker-fired subcompact semi-automatic pistol manufactured by SIG Sauer, intended for everyday carry. It is offered with Tritium XRAY3 Day/Night Sights and two 10-round magazines; one flush fit and the other with an extended finger tab, and a stainless steel frame with polymer grip module. It is primarily chambered in 9×19mm Parabellum and is rated for +P (higher pressure) ammunition while utilizing offset double-stack magazines. A variant chambered in .380 ACP was introduced in February 2022. The P365, which replaced the P290RS, is produced in Newington, New Hampshire. In both 2018 and 2019, it was the best selling handgun in the United States.

Shoutout To @honeyssims4 & @r-jayden For M17 Pose...

@ts4-poses @ts4-poses-masterlist @cctreasuretrove

DOWNLOAD LINK:https://www.patreon.com/posts/63376609

#thesims4#the sim#the sims 4#the sims#the sims 4 gun#ts4cc#ts4acc#The Sims military#Ts4 military#The sims 4 Weapon#TS4Weapon#ts4 custom content#ts4 cc#ts4 cas#ts4military#ts4 accessories#ts4gun#ts4#the sims 4 custom content#the sims 4 cc#ts4cc download#ts4 gun

82 notes

·

View notes

Text

This is a Parker 50 Falcon “Flighter” fountain pen c. 1979. This 5 1/8 inch long cartridge / converter fountain pen is noted for its integrated stainless steel nib. The nib is essentially an extension of the section all the way to the slit for the tines and the tipping material. The gripping part of the section has a matte finish. The brushed stainless steel finish was complemented with gold plated trim. PARKER over MADE IN U.S.A. is stamped on the back cap lip. This example has a feathered clip like the Parker Systemark rather than the plainer clip usually seen on the Falcon. Available nib grades were extra fine, fine, medium and broad.

15 notes

·

View notes

Text

Casio Royale AE-1200 modded

This was a fun little project that took about 30 minutes to complete. I got this classic Casio AE-1200 "Casio Royale" (so nicknamed by watch collectors for it's similarities to a Seiko digital watch worn by Roger Moore when he played James Bond).

It's actually a great little retro watch from "God Tier" watch maker Casio, with some amazing World Time features, but it's case is overly wordy and made from cheap metallic painted plastic resin, and it's crystal is clear acrylic plastic! The worst part is the bracelet which is made with the old style hair pulling folded metal links and a cheap stamped metal clasp.

To address these shortcomings, I ordered an upgrade kit from SKX MOD that only requires removing four screws and the stainless steel back from the original watch case, removing the Casio module and dial plate, and putting them in the kit's new matte stainless steel case and closing the case with the custom titanium back and new screws. The new case also replaces the original grey plastic bezel with a black ceramic bezel and upgrades the original plastic crystal with a scratch proof sapphire crystal! Best of all is the upgraded matte stainless steel bracelet with solid links and a milled clasp.

The end result looks virtually the same, but the new fully stainless steel case, bracelet, titanium case back, ceramic bezel and sapphire crystal are all huge improvements, and it looks much better without the excessive text on the case!

3 notes

·

View notes

Text

Detroit Metal Finishing Services Offered By Automotive Tumbling! Call 313-925-7450 or visit https://automotivetumbling.com/

DETROIT METAL FINISHING & DEBURRING

Automotive Tumbling stands at the forefront of superior metal finishing, setting the benchmark for excellence. Operating from its headquarters in Detroit, the company caters to a diverse range of industries, encompassing automotive, heavy truck, fastener, agricultural, structural, recreational, military, medical, marine, appliance, furniture, and plumbing sectors. Our unwavering commitment lies in fulfilling the unique needs of every industry we serve. Above all, we adhere to a resolute motto: to not just meet, but consistently surpass your expectations with every interaction.

TUMBLING AND VIBRATORY DEBURR DETROIT

Both tumbling and vibratory deburr techniques employ abrasive media to eliminate unwanted sharp edges and burrs from stamped or machined parts. These components are introduced into a vibratory machine, where they undergo a tumbling or vibrating process while being rotated in abrasive media. This effectively smoothens rough surfaces and eliminates any sharp corners, resulting in a refined product. For specific applications requiring careful handling, such as camshafts, telescoping magnesium steering columns, and stainless steel IV stands in the medical industry, Vibratory deburring in Detroit is particularly well-suited. Furthermore, these methods find application in creating precise cosmetic surfaces, as well as in the cleaning and descaling processes. Automotive Tumbling possesses the expertise to perform vibratory tumbling to achieve a specific RA/RZ profile, and handles all types of metal tumbling and deburring in Detroit and its surrounding areas.

DETROIT DEBURRING PROCESSES FOR BUSINESSES OF ALL TYPES AND SIZES

Automotive Tumbling has the capabilities to provide deburring for virtually any type of industrial operation, regardless of size. We can even take on high production deburring and finishing projects for which other Detroit metal finishing industry companies may not have the knowledge or resources to meet the high quality standards you demand and deserve.

AUTOMOTIVE TUMBLING IS YOUR DETROIT DEBURRING SOURCE

Automotive Tumbling offers cost-effective Detroit vibratory deburring processes that are an invaluable asset in your quest to improve quality, reduce lead times and enhance your competitive position in the marketplace. We provide our value-added metal finishing services in Detroit to industries such as automotive, manufacturing, electronics and telecommunications. As a customer-focused metal finishing company, we are committed to achieving total customer satisfaction.

Detroit Metal Finishing Services Offe...

Detroit Metal Finishing Services Offered By Automotive Tumbling! Call 313-925-7450 or visit https://automotivetumbling.com/

2 notes

·

View notes

Text

Which Company is Best for Car Parts Manufacturer in Pakistan?

There are many Bike Spare Parts suppliers in India. These suppliers are grouped according to their state, city, and service areas. The page provides you with detailed information about each one. To buy parts online, you need to search for a trusted supplier. You can find these suppliers by following some simple steps. To start, you need to look for a supplier that specializes in bike spare parts. Alternatively, you can look for a distributor in your city or state.

The Metaline Group directory of stainless steel stampings suppliers provides you with the contact details of the top decision makers. You can find their name and address, and even LinkedIn profiles. The directory also contains strategic information about each shipment. It is recommended to look for companies with the same business ethics and a proven track record. Using this directory to source your Bike parts will make your buying experience more seamless. The convenience and ease of Metaline Group makes finding suppliers easier than ever.

Can Pakistan Become A Hub Of Auto Exports?

When choosing a bike spare part supplier, make sure to choose a brand that is reputable. Car parts are often more expensive than aftermarket ones, as they are produced by the same manufacturer. They also bear the dealership's brand, so you'll pay more for them. However, they are better than aftermarket parts. In fact, many aftermarket manufacturers improve upon original parts to increase their quality. This means you'll get your bike back in no time!

Online shopping can be an easy way to find the parts you need for your bike. Metaline Group offers a wide range of car and bike accessories from trusted brands. The site features everything you need to maintain your bike. You can even use Metaline Industries Pvt LTD to find the perfect spare part for your bike. If you need a spare part for your gm spring hill stamping steel plant, there's an online bike accessory store with thousands of affordable and stylish options.

#stamping stainless steel parts#stainless steel stampings suppliers#stainless steel stamping parts#gm spring hill stamping steel plant#steel letter stamps#Automotive aftermarket industry of Pakistan#Die and Tool making companies#Stamping tool and die companies#Car parts manufacturer

0 notes

Text

Blast From the Past?

A look at Brownells Retro Style 20 round mags.

With the popularity of Retro ARs these days, it was no surprise Brownells supplied and encouraged the trend. With their line of Retro parts, one can build a clone of the rifles of the past. One part of any XM177, Colt 601, or M16A1 clone is the twenty round mags common to the era.

With this rise in popularity, the price of original mags from the era has risen. The Colt and Universal Industry Mags have gotten to the point of price no one but die hard cloners and collectors were buying them. Why spend $20-$25 for an old mag, when new GI style could be had for $12? That’s where Brownells stepped in. The 20 round Brownells mags come in at about $15. A much better price than some of the old original mags. But are they exact clones? Let’s take a look.

An Original Universal Industries on the left, Brownells on the Right.

The Brownells mag features a few changes from originals. Most likely this steams from updated manufacturing processes. The first thing is the follower. The originals feature an aluminum follower. These followers appear to have anti tilt properties(which do not matter in any case for straight mags). The Brownells is a black plastic that’s appears to be identical to the aluminum original, but isn’t anti-tilt(again no issue).

The brownells has a stainless steel spring, and the original has a blued steel spring. The body construction is slightly different processes also between the two. The originals were stamped from one piece of aluminum, and spot welded on the rear spine of the mag. The brownells is like the current style of 30 round mags, with two half’s spot welded on front and rear.

Noticed the half’s welded together on the Brownells mag. The original has 3 rivets on the front to hold the floor plate retention spring.

The floor plate is also slight different. The originals have a piece of spring steel in the body riveted to the body via 3 rivets on the front of the mag. By pressing down on the spring retention, the floor plate slides out. On the Brownells mags it is like a modern 30 round. To retention ears on the rear, and you slightly lift up to slide it out.

How do they run, and are they right for clone rifles?

I’ve had zero issues with the Brownells mags. They fit all my rifles fine, and feed ammo fine. Are they clone correct? Most people won’t even notice it’s not exactly constructed like the originals. I feel like they did a good job updating them to newer materials, and giving them the correct look, while also implementing modern construction practices. And for the money it’s a great way to get the look you want, for around $5+ less per mag over finding originals.

If you’d like to have some yourself they can be found at the link below. If you spend more than $150, use my friend Alex’s (he can be found on here and IG under the handle pipeguy) discount code : pipeguy10 to save you 10%.

2 notes

·

View notes

Text

Understanding Bolt Grades: What Do the Numbers on Bolts Mean

Caliber Enterprise is one of the leading Bolts Manufacturers in India. When working with bolts, understanding their grades is crucial to ensuring the success and safety of your project. Bolt grades help indicate the material's strength, its ability to withstand tension and pressure, and its overall durability.

What Are Bolt Grades?

Bolt grades are a classification system used to define the strength and composition of the material from which a bolt is made. These numbers are typically stamped on the head of the bolt, and they signify its tensile strength—the maximum stress a material can endure before breaking.

The higher the grade number, the stronger the bolt. However, this doesn’t necessarily mean that you always need the highest-grade bolt for every job. Choosing the right grade depends on the load and environmental conditions the bolt will face. We are also a well-known Fasteners Manufacturers in India.

Common Bolt Grades and Their Meaning

Grade 2 Bolts: Grade 2 bolts are the most basic type of bolt, usually made from low or medium carbon steel. They are inexpensive and suitable for non-critical applications where low strength is sufficient. These bolts are not marked with a grade number but can be identified by the absence of markings on their head.

Tensile Strength: Around 60,000 psi. We are also a leading Hex Bolts Manufactures in India.

Common Use: Light-duty applications, such as household projects or securing small parts.

Grade 5 Bolts: Grade 5 bolts are medium-strength fasteners made from medium carbon steel and are heat-treated to increase their toughness. They are stronger than Grade 2 bolts and are commonly marked with three radial lines on the head.

Tensile Strength: Around 105,000 psi.

Common Use: Automotive and construction applications where higher strength is required but not at extreme levels.

Grade 8 Bolts: Grade 8 bolts are high-strength fasteners, made from medium carbon alloy steel and hardened for added durability. These bolts are usually marked with six radial lines on the head and are significantly stronger than both Grade 2 and Grade 5 bolts.

Tensile Strength: Around 150,000 psi.

Common Use: Heavy machinery, industrial equipment, and structural applications where the highest strength is essential.

Stainless Steel Bolts: Stainless steel bolts are highly resistant to corrosion and are ideal for environments exposed to moisture or chemicals. While they may not have the highest tensile strength, their resistance to rust makes them a popular choice in marine and outdoor applications.

Tensile Strength: Varies based on the alloy, typically around 70,000 psi to 100,000 psi.

Common Use: Marine equipment, outdoor structures, and corrosive environments.

Metric Bolt Grades

In the metric system, bolt grades are indicated by two numbers separated by a dot (e.g., 8.8, 10.9, 12.9). The first number represents one-tenth of the bolt’s nominal tensile strength in megapascals (MPa), while the second number shows the proportion of yield strength relative to the tensile strength.

8.8 Bolts: Moderate strength bolts used in general applications.

10.9 Bolts: High-strength bolts used in critical load-bearing applications.

12.9 Bolts: Extra high-strength bolts used in heavy-duty, industrial applications.

Choosing the Right Bolt Grade

Caliber Enterprise is also a leading Bolt Manufacturer in Ahmedabad. When selecting bolts for your project, you need to consider both the strength required and the environmental conditions the bolt will face. For example, Bolts Manufacturers in India offer a wide variety of grades, including corrosion-resistant stainless steel bolts for humid climates or marine applications, and high-strength Grade 8 bolts for heavy-duty machinery.

Understanding bolt grades is key to ensuring the safety and durability of your projects. From Grade 2 to Grade 8 and metric bolts, each type has its specific application. By choosing the right grade for your job, whether it's light-duty household work or heavy industrial use, you can guarantee better performance and safety. For all your fastening needs, it’s essential to source quality products from reliable Bolts Suppliers in India, ensuring that the bolts meet the necessary standards for strength and durability.

0 notes

Link

Check out this listing I just added to my Poshmark closet: Fossil Watch JR9951 Floating Gears Silver Case White Leather Band White Face.

0 notes

Text

All You Need to Know About Sheet Metal Fabrication with HLH

Modern manufacturing relies largely on sheet metal fabrication, a process that turns plain metal sheets into complex parts and structures used in everything from consumer electronics to aircraft. Leading the industry in sheet metal fabrication, HLH combines modern technology with expert production to provide full solutions for customers.

Everything you need to know about using HLH for sheet metal manufacturing is provided here.

An Overview of Sheet Metal Fabrication:

The method includes bending, cutting, and assembling flat metal sheets into a variety of different parts. These components are necessary for industries like construction, electronics, automotive, and aerospace. Depending on the needs of the application, the manufacturing procedure usually begins with a sheet of metal, which can be aluminum, steel, copper, or another alloy.

The fabrication process includes several steps:

Sheet Metal Fabrication Process

Design and Planning: CAD Modeling, Material Selection

Cutting: Shearing, Laser Cutting, Plasma Cutting & Waterjet Cutting

Forming: Bending, Stamping, Rolling, Embossing

Joining: Welding, Riveting, Adhesive Bonding & Fastening

Finishing: Deburring, Polishing,Painting or Powder Coating, & Anodizing

Inspection/Quality Control: Dimensional Inspection, Material Testing, Functional Testing

Assembly: Final Assembly & Functional Testing

HLH’s Expertise in Sheet Metal Fabrication

HLH has established itself as a trusted manufacturing company for sheet metal fabrication, providing a complete range of services customized for each project. Here's what makes HLH stand out in the industry:

HLH Rapid is a leading company in sheet metal fabrication. The company achieve this by using modern equipment such as high-precision laser cutters and CNC press brakes, which allow them to create complex parts with precise measurements and reliable quality.

HLH Rapid has vast experience with various metals, including copper, stainless steel, aluminium, and speciality alloys, allows them to select the ideal material for any application while keeping cost, weight, and strength in mind.

The company provides flexible manufacturing as well as rapid prototyping, enabling prompt turnarounds and effective large-scale runs while upholding high standards through strict requirements and inspections at every point. We also provide customisable assembly procedures, specialised finishes, and custom tooling, all of which are catered to the particular needs of each client.

Conclusion:

Sheet metal fabrication is a critical process in modern manufacturing, enabling the production of a wide range of components across various industries. We have the capabilities to deliver high-quality, customized solutions that meet your specific needs.

By choosing HLH for your sheet metal fabrication projects, you’re ensuring that you receive precision, reliability, and excellence every step of the way.

If you would like to discuss your requisites, please send us an email at [email protected] or upload your CAD file here to get an instant quote.

0 notes