#smartenergy hashtag

Explore tagged Tumblr posts

Text

What are the most effective methods for managing power factor in your system?

`What's Power Factor?

In an energy management system, the power factor gauges the efficiency of electrical power usage. It is defined as the ratio of real power to apparent power (the total power supplied). A high power factor signifies efficient use of electrical power, which minimizes energy losses and enhances system performance.

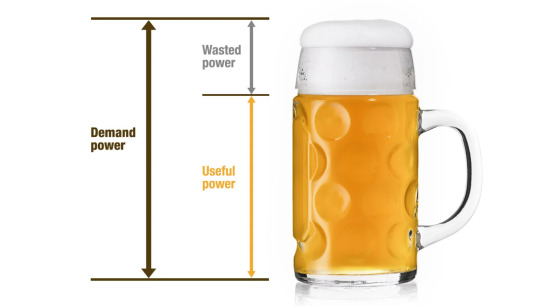

Beer is active power (kW)—the useful power, or the liquid beer, is the energy that is doing work. This is the part you want.

Foam is reactive power (kVAR)—the foam is wasted power or lost power. It’s the energy being produced that isn't doing any work, such as the production of heat or vibration.

The mug is apparent power (kVA)—the mug is the demand power, or the power being delivered by the utility.

Understanding Low Power Factor?

A low power factor is primarily caused by inductive loads, including motors, transformers, and lighting ballasts, which draw reactive power. This reactive power is essential for generating and sustaining magnetic fields but does not contribute to useful work, increasing apparent power and consequently lowering the power factor. Moreover, harmonics from nonlinear loads, such as electronic devices and variable frequency drives, further reduce the power factor by introducing additional reactive power.

Benefits of High Power Factor

A high power factor decreases the apparent power and current drawn from the source, which can lower energy bills as some utilities impose charges for low power factor or provide incentives for maintaining a high power factor. It enhances voltage regulation and stability, increases system capacity and efficiency by reducing losses and heating, and lessens the effects of harmonics, thereby improving overall power quality.Benefits of Power Factor

Measuring Power Factor

Power factor is measured using a power meter or analyzer that monitors real, reactive, and apparent power, or with a power factor meter for direct readings. Measurements should be taken at various points in the system and at different times to account for load variations.

Correcting Low Power Factor

The most effective way to correct a low power factor is by installing power factor correction devices such as capacitors or synchronous condensers. These devices provide reactive power locally, reducing the flow of reactive power and improving the power factor. Depending on the load characteristics and desired power factor levels, they can be installed centrally or near specific inductive loads.

Controlling Power Factor Correction Devices

Power factor controllers, which can be either manual or automatic, are used to manage correction devices. Manual controllers rely on human adjustments based on meter readings, whereas automatic controllers use sensors and microprocessors to adjust devices. Automatic controllers can also be programmed to optimize performance under varying load conditions.

Optimizing Power Factor Management

Optimizing power factor management requires balancing cost, performance, maintenance, and safety. Essential practices include regular evaluation and adjustment, proper maintenance to prevent overloading and overheating, and compliance with utility codes and standards. This comprehensive approach ensures improved efficiency, stability, and cost-effectiveness of your electrical system.

#SmartEnergy hashtag#Sustainability hashtag#RenewableEnergy hashtag#EnergyEfficiency hashtag#SmartMeterRevolution hashtag#Niraltek hashtag#NiraltekTeam hashtag#InternetOfThings hashtag#ESP32 hashtag#ESP32Development hashtag#ESP32Project hashtag#ConnectedDevices hashtag#IoTInnovation hashtag#IoTProject hashtag#IoTDevices hashtag#IoTSecurity hashtag#IoTApplications hashtag#IoTDevelopment hashtag#IoTTechnology hashtag#ESP32Electronics hashtag#ESP32Innovation hashtag#IIoTTechnology hashtag#IIoTInnovation hashtag#IndustrialIoT hashtag#EnergyUsage hashtag#IoT hashtag#SmartCities hashtag#SmartMeter hashtag#powerfactor

0 notes

Text

BLIIoT Industrial 4G Edge Router R40 Used in Smart Charging Piles Monitoring

I. Introduction

1. A brief introduction to smart charging piles

In today's society, with the progress and development of customers, people pay more and more attention to smart energy. At present, electric vehicles have become the choice of more and more people. As the number of electric vehicles increases, so does the demand for smart charging piles. In order to improve the intelligence and convenience of charging piles, Industrial 4G Edge Router R40 can be used to realize remote monitoring and control in smart charging piles. In this article, we will discuss how to use an Industrial 4G Edge Router R40 to implement a monitoring solution for smart charging piles.

The smart charging pile monitoring system is a solution based on the Industrial IoT 4G Edge Router R40, which can realize real-time monitoring and management of charging piles. In addition to the basic charging pile status monitoring function, the system also has data analysis and forecasting functions, which can be analyzed based on historical data and real-time data to help users better understand the usage and trends of charging piles, and then make better decisions. management decisions.

2. Industrial 4G Edge Router R40

Industrial 4G Edge Router R40 have many features, including DI (2 channels), DO (2 channels), AI (4 channels), support protocols (Modbus RTU, Modbus TCP, MQTT, SNMP protocols), 4G network, support SMS Query DI/DO/AI status and value, support 4G wireless Internet access, support edge computing, two SIM card slots, support GPS, VPN, interface (support RS485 and RS232 serial port transparent transmission and MODBUS RTU to TCP), support MODBUS master Station, support address mapping, support monitoring the online status of network devices connected to the LAN port, link switching, platform connection, alarm, timer, upgrade, POE power supply and other features. These features allow Industrial 4G Edge Router R40 to realize remote monitoring and control in smart charging piles.

II. Application of Industrial 4G Edge Router R40 in smart charging piles

1. Real-time monitoring:

The smart charging pile monitoring system needs to be able to monitor the status, usage and charging speed of charging piles in real time. Through these data, operators can understand the usage of charging piles in real time, detect faults and repair them in time, and improve the quality and efficiency of charging services.

The Industrial 4G Edge Router R40 can be connected to the camera, supports POE power supply and network supply, and can realize real-time monitoring of the surrounding environment of the smart charging pile in real time, improving the safety and reliability of the charging pile.

2. Remote management:

The IoT Industrial 4G Edge Router R40 can provide remote management functions for the smart charging pile monitoring system. Operators can remotely view the status of charging piles, control the switching of charging piles, adjust charging power and other operations through the network. In this way, operators can manage charging piles more conveniently, while improving operational efficiency and reducing labor costs.

3. Data analysis:

The smart charging pile monitoring system needs to be able to analyze the monitored data, extract valuable information and display it. For example, analyzing the usage frequency, usage time period, charging speed and other data of charging piles can help operators optimize the layout and usage strategy of charging piles, and improve the satisfaction of charging services. At the same time, using big data technology to analyze charging pile usage data can also help operators understand user habits and needs and provide more personalized services.

4. Alarm and remote maintenance:

Through Industrial 4G Edge Router R40, real-time monitoring and abnormal alarms for charging piles can be realized. When there is an abnormality in the charging pile, the system will automatically trigger an alarm, and at the same time, it can be sent to the relevant personnel by text message or email, so as to deal with the problem in time. In addition, the Industrial 4G Edge Router R40 also supports remote upgrades, which can remotely perform firmware upgrades and configuration adjustments for charging piles, which is convenient for maintenance personnel to perform remote maintenance and management.

III. Features and advantages of Industrial 4G Edge Router R40

1. Multiple input and output types:

The Industrial 4G Edge Router R40 supports multiple input and output types such as DI (2 channels), DO (2 channels) and AI (4 channels), which can meet the needs of different scenarios. For example, for smart charging piles, the status and power of the charging piles can be monitored through the DI and AI interfaces, and the switching control of the charging piles can be realized through the DO interfaces.

2. Multiple communication protocols:

The router supports multiple communication protocols, including Modbus RTU, Modbus TCP, MQTT and SNMP protocols, etc., which can realize seamless communication between different devices. For example, in the smart charging pile scenario, the communication with the charging pile controller can be realized through the Modbus protocol, and the communication with the cloud platform can be realized through the MQTT protocol.

3. Edge Computing:

The router supports edge computing, which can realize real-time data processing and response on site. For example, in the scenario of smart charging piles, this function can be used to realize real-time calculation of charging pile power and timely processing of charging pile failures.

4. Dual card switching and link switching:

The router supports dual card switching and link switching, which can improve the stability of the network connection of the device. For example, in the smart charging pile scenario, this function can be used to realize the switching of the charging pile network connection and the automatic repair of faults.

IV. Benefits of using Industrial 4G Edge Router R40 in smart charging piles

1. Realize intelligent remote management and control

Using an Industrial 4G Edge Router R40 can connect the charging pile to the Internet for remote monitoring and control. This means that managers can access the data of charging piles anytime and anywhere, including charging amount, charging duration, charging voltage and current, etc. Managers can use remote control, such as remote switching, adjusting charging power, setting charging mode, etc., to better manage charging piles and improve the efficiency of charging piles and charging experience.

2. Improve the stability and safety of charging piles

Real-time monitoring and fault alarm of charging piles can be realized by using Industrial 4G Edge Router R40. When the charging pile fails, the Industrial 4G Edge Router R40 will automatically send an alert to the management personnel. In this way, managers can take timely measures to reduce downtime and improve the stability and safety of charging piles.

3. Reduce maintenance costs and increase efficiency

Using an Industrial 4G Edge Router R40 can also reduce maintenance costs and improve efficiency. Industrial 4G Edge Router R40 can realize automatic diagnosis and maintenance, reducing manual intervention. Managers can better manage and maintain charging piles through remote monitoring and control, reducing downtime and maintenance costs.

V. Conclusion

In general, the emergence of smart charging piles has brought great convenience to our lives, but at the same time it also requires remote management and control to ensure its stability and safety. As a high-performance network device, the Industrial 4G Edge Router R40 can meet the needs of remote management and control of smart charging piles, while improving its stability and security, reducing maintenance costs and improving efficiency. Therefore, it is a very wise choice to use industrial-grade 4G edge computing routers in the application field of smart charging piles, and it will be widely used in more smart device application scenarios in the future.

More information about the Industrial 4G Edge Router: https://www.bliiot.com/industrial-iot-edge-gateway-p00307p1.html

#iot hashtag#iotsolutions hashtag#smartcity hashtag#smartenergy hashtag#smartcharging hashtag#smartparking hashtag#iotdevices hashtag#gateway hashtag#router hashtag#rtu hashtag#iomodule hashtag#logiccontrol hashtag#edgecomputing hashtag#vpn hashtag#poe hashtag#gps hashtag#modbus hashtag#mqtt hashtag#snmp hashtag#datacollection hashtag#remotemonitoring#hashtag#awscloud hashtag#thingsboard hashtag#alibabacloud hashtag#huaweicloud hashtag#openwrt#BLIIoT#BLIIoT Applications

0 notes

Text

SmartMark CEO Talks “Smart Cities” at 2019 Southern California Public Power Authority Annual Conference

SmartMark CEO Talks “Smart Cities” at 2019 Southern California Public Power Authority Annual Conference

Industry Expert Addresses the Need to Keep Customers at the Focus of Technology Investments and Smart Cities Planning

BURBANK, Calif.–(BUSINESS WIRE)–lt;a href="https://twitter.com/hashtag/customer?src=hash" target="_blank"gt;#customerlt;/agt;–SmartMark Communications, LLC and SmartEnergy IPTM announced that their founder and CEO, Juliet Shavit, will speak today at the 2019 Southern…

View On WordPress

0 notes

Text

BLIIoT Industrial PLC Protocol Conversion Gateway BL102 for Industrial Automation Monitoring System

I. Industrial Automation Monitoring System and Its Importance

① Definition of Industrial Automation Monitoring System

Industrial automation monitoring system refers to a system that applies modern automation technology to industrial production process to realize comprehensive monitoring and control of industrial production process to improve production efficiency and quality.

② The importance of industrial automation monitoring system

Industrial automation monitoring system plays an important role in modern industry. It can realize comprehensive monitoring and control of industrial production process, improve production efficiency and quality, and reduce labor cost and waste of resources. In addition, it can reduce the risk of accidents, improve work safety and reliability, and ensure the continuity and stability of the production process.

II. BLIIoT Industrial PLC Data Acquisition Protocol Conversion Gateway BL102 and its functions

① What is PLC Gateway?

Definition of PLC gateway: PLC gateway is a device that realizes real-time monitoring and control of industrial automation systems by collecting various types of PLC data and connecting to OPC UA, servers, and 4G wireless or Ethernet access to IoT cloud platforms.

② Functions of BLIIoT PLC Gateway BL102

Support docking directly through the PLC itself protocol, no separate programming is required;

Support to collect various types of PLC through Modbus RTU and Modbus TCP at the same time;

Support two links of serial port and network port;

Support PLC program wireless remote upload and download, convenient for debugging and managing PLC;

Support Boolean, numerical and other types of data acquisition and control output;

Protocol conversion: support the conversion of various PLCs such as Siemens, Mitsubishi, Omron, Delta, Schneider, etc.

Modbus TCP, MQTT, OPC UA, Huawei Cloud IoT, Alibaba Cloud IoT, AWS IoT, BLIIoT Cloud,

Thingsboard, Ignition and other protocols;

Support data collection from PLC, touch screen, RS485 devices, etc., and connect to OPC UA, configuration and 4G at the same time

Wireless access to IoT cloud platform;

Support network port and serial port to collect 100 devices and 4000 variables at the same time;

Support 7 simultaneous online of multiple IoT cloud platforms, configurations, and host systems in the local and cloud;

Support data TSL/SSL, X.509 certificate, key encryption, OpenVPN, APN private network,

Security gateway functions such as offline caching;

Integrated router function, convenient to provide network for other devices, more convenient and save money;

Support local task management, threshold alarm, linkage control;

Support wireless remote configuration of gateway parameters and firmware upgrades;

Support software and hardware watchdog, with high reliability;

Support custom development of protocols to meet the data collection of non-standard equipment.

III. How to use PLC gateway to realize real-time monitoring and control in industrial automation monitoring system.

The PLC gateway can collect PLC, touch screen and other data, connect to OPC UA, configuration and 4G wireless access to the IoT cloud platform to realize real-time monitoring and control.

① Collect PLCs, Devices data

The PLC gateway supports direct docking through the PLC itself protocol, and also supports collecting various types of PLCs through Modbus RTU and Modbus TCP. At the same time, the PLC gateway also supports two links of serial port and network port, which can collect data such as PLC, touch screen, RS485 equipment, etc., and supports network port and serial port to simultaneously collect 100 devices and 4000 variables.

② Docking OPC UA, configuration and 4G wireless access IoT cloud platform

The PLC gateway supports the conversion of various PLCs such as Siemens, Mitsubishi, Omron, Delta, and Schneider to protocols such as Modbus TCP, MQTT, OPC UA, Huawei Cloud IoT, Alibaba Cloud IoT, AWS IoT, King Pigeon Cloud, Thingsboard, and Ignition. The collected data can be transmitted to the cloud platform through these protocols for storage, analysis, control and other operations to achieve real-time monitoring and control.

③ Enable real-time monitoring and control

The data collected through the PLC gateway can be transmitted to the cloud platform in real time for real-time monitoring and control. For example, in industrial production, by collecting data such as temperature, humidity, pressure, and flow, the operating status of equipment can be monitored in real time, and problems can be found and controlled in time. At the same time, functions such as threshold alarm and linkage control can be set to make the production process more automated and efficient.

IV. Application scenarios

Industrial Production Monitoring

Real-time monitoring and control of industrial automation systems can be achieved by collecting data from machines, PLCs, etc., and uploading data through 4G wireless or Ethernet access to IoT cloud platforms or servers. It can monitor data such as equipment status and process parameters, find abnormal conditions and control them in time to improve production efficiency and reduce costs.

V. Summary

Industrial automation monitoring system is an essential link in industrial production. By collecting data from various devices and connecting to the cloud platform, real-time monitoring and control of the industrial production process can be realized, which can improve production efficiency, reduce labor costs, and ensure production safety. As a bridge connecting various devices and cloud platforms, the PLC gateway has the characteristics of high efficiency, safety and reliability, and plays an important role in the industrial automation monitoring system. In the future, with the continuous development of industrial automation technology, the application scenarios of PLC gateways will become more and more extensive, and its functions and performance will be further improved and perfected.

More information about the BLIIoT PLC Gateway BL102: https://www.bliiot.com/plc-gateway-p00306p1.html

#iot hashtag#iotdevices hashtag#iotgateway hashtag#protocolconversion hashtag#dataacquisition hashtag#remotemonitoring hashtag#industrialautomation hashtag#smartfactory hashtag#smartwater hashtag#smartenergy hashtag#smartcities hashtag#modbus hashtag#mqtt hashtag#opcua hashtag#awscloud hashtag#thingsborad hashtag#ignition hashtag#scada hashtag#huaweicloud hashtag#alibabacloud hashtag#siemens hashtag#omron hashtag#mitsubishi hashtag#schneider hashtag#ab hashtag#abb hashtag#meter BLIIoT#BLIIoT Applications

0 notes