#siemens drive repair

Explore tagged Tumblr posts

Text

Rejuvenate Your Operations - Siemens Drive Repair Services for Continuous Performance

Industrial Automation Repair Ltd. provides dependable Siemens Drive Repair services to help you revitalise your industrial operations. Our trained experts have significant experience diagnosing and repairing Siemens drives, assuring optimal operation and efficiency. We reduce costly downtime and increase the lifespan of your drives with our industry-leading solutions, enhancing overall productivity. Our extensive Siemens Drive Repair services are geared to fit your unique needs, whether you require repairs for variable frequency drives (VFDs) or servo drives. You can rely on Industrial Automation Repair Ltd. to offer outstanding outcomes and keep your operations running smoothly. Contact us today to maximise the performance of your equipment and enjoy unrivalled service quality.

0 notes

Text

Siemens MicroMasters AC Drive Repair & Supply -CNC Tools LLC

Looking for reliable Siemens MicroMasters AC Drive repair and supply? CNC Tools LLC offers expert repair services and high-quality replacements to keep your operations running smoothly. Fast turnaround & competitive pricing. Contact us today!

0 notes

Text

I'm starting to warm up to Train Sim World 3, a game I got via Microsoft's game subscription model. A huge part of that is because it has a lot of good tutorials for all the very non-obvious parts of it. Those non-obvious parts are there for realism, to be clear; most trains aren't designed to be obvious, they're designed to be run by trained personnel who got special training for all the details of each train they're on.

Anyway, the basic tutorials are all set in a fantasy location, the Training Center. It's a magic place where you will find German, British and American trains all next to each other on decidedly German infrastructure.

The setting is all over the place, with some alpine stuff, a lake, several station platforms, and the whole thing is notably not an A-to-B line. Instead it's a combination of different loops and sidings for shunting around that feels more like a model railroad than a real thing.

Clearly this is completely made up, right?

Well, no. While all the scenery is purely fantasy and quite a bit of the details are wrong, the track layout is in fact a real piece of railroad infrastructure. Specifically, this is the track layout of the Siemens Test Centre in Wegberg-Wildenrath, Germany, near… well, not really anything, but Mönchengladbach is the closest city.

This facility, built on the site of a former British airfield, is where Siemens (and to a small extent other manufacturers) tests new trains, both prototypes and sometimes individual ones. All the tracks are for testing trains at different speeds and in different conditions, and a lot also for storing trains. There are also big workshops, used for finishing touches, indoor tests, but also as an independent repair and maintenance facility, and to assemble trains built in other places.

According to its own description, it's the most modern of such test centres. I have no way of checking that. It is definitely not the biggest, that is VUZ in Velim in the Czech Republic, which has a much bigger outer loop allowing for higher speeds, but less other equipment and tracks as far as satellite images say. VUZ is still seeing a lot of use, though. Maybe they'll use that one as the training centre for Train Sim World 4.

Access to the Wegberg facility is difficult for rail fans. It isn't hidden by any means, it's about an hour's drive from where I live, but all the really fun parts are hidden behind gates and fences, and security patrols the area. They held I think like two open days for the public, in total, and the last one as far as I can tell was in 2012.

And of course I was there.

Hey, remember those days when the Vectron was fresh and new, and Siemens was still actively selling the class 189 (ES64F4) and that in-between generation they only ever sold to Portugal, Belgium and Lithuania? That sure was a while ago, now they've sold well over a thousand Vectrons and those beasts are everywhere.

First big difference between video game and reality: In reality, the outer loop is only single track, while the video game has it double-tracked.

The video game also gives me a top speed of 300 km/h for this outer loop. In reality, as far as I know the limit ist 160 km/h. Apparently the track gets checked and realigned weekly, to be sure that the measurement results are all accurate.

Yes, that is an Uerdinger Schienenbus. Yes, that did retroactively become a Siemens product, because the Uerdinger Waggonfabrik that built this dinky little rail bus ended up becoming Siemens's Krefeld plant (specifically the Uerdingen part of Krefeld, no longer an independent town), where they build all their high speed trains among others. Surprised the hell out of me too.

In the game, all lines are electrified and have British style third rail power. In reality, that is actually fairly close. Many tracks are not electrified, though (they have diesel shunters to deal with that, including some hilariously old ones). Even fewer have the British style third rail, although that is in use because Siemens does sell a lot of trains to Britain. Instead, some tracks, such as the inner loop, feature Berlin style third rail, raised, with a plastic cover and designed for bottom contact.

And in fact there's a fourth rail here, which the video game doesn't have. This is to test meter gauge trains; generally speaking that means trams. However, for the opening ceremony 25 years ago, they apparently did have a steam train from nearby historic steam railroad Selfkantbahn. Definitely the second-greatest historic steam railroad around Aachen.

Anyway, the point of this is… none whatsoever. I just thought it's funny. The makers of the game aren't hiding that they just took the Wildenberg-Wegrath track layout, you can find a number of news articles referencing this. But if you just downloaded the game because you got Game Pass and it says "train something", as you do, then you may never notice unless you're already aware of this test centre.

7 notes

·

View notes

Text

How the Siemens G120 Drive Enhances Industrial Automation

Industrial automation needs operations to work ever so efficiently and reliably because these are two primary factors which influence any process toward its successful accomplishment. This led Siemens, the world's largest supplier of automation and drive technology, to invent the SINAMICS G120 drive, one of the most advanced variable frequency drives-to really show how energy can be saved, systems improved, and basically the control of processes made easier across different industries.

What is the SINAMICS G120 Drive?

The SINAMICS G120 drive is somewhat of a modular frequency converter characteristic of good motor control, with balance on its energy efficiency versus its flexibility. This drive finds applicability in segments including manufacturing, automotive, food processing, and chemical plants. It can cater to ever-simple to much-complicated applications.

The modular design thus enables the user to configure the G120 drive flexibly, either by choosing different power modules or control units for its application. This design feature is further beneficial in terms of being able to repair and service the G120 drive, contributing to limiting downtime and minimizing costs associated with maintenance.

Some Features of the Siemens G120 Drive

1. Modular Design: The modular architecture of the Siemens G120 drive separates the control unit from the power module and allows great flexibility for customization. Separation of the two components allows independent component replacement and hence minimizes maintenance downtime and costs.

2. Excellent Safety Features: Safety is of the utmost importance in industrial practice. The G120 drive features integrated safety functions, including Safe Torque Off (STO) and Safe Stop (SS1), which provide a comfortable level of safety with minimal use of additional hardware.

3. High Energy Efficiency: When it comes to reducing operational expenses, energy efficiency is of prime interest to various businesses. Features such as regenerative feedback contribute to energy efficiency while helping SINAMICS G120 drives minimize their carbon footprint and aid their sustainability drive.

4. Comprehensive Communication: The Siemens G120 drive supports a comprehensive array of communication protocols��PROFINET, PROFIBUS, and Modbus—to allow truly seamless integration into existing automation systems. This makes connection enhanced and allows for real-time data monitoring to improve system performance.

5. Straightforward Operation and Commissioning: The drive is equipped with a user-friendly interface, including easy parameterization, which provides quick configuration and simple operation. The commissioning process has been greatly simplified with SINAMICS Startdrive software to enable quick setup and parameter changes.

Applications of SINAMICS G120 Drive

The application areas of the G120 drive are highly flexible and varied:

Pumps and Fans – Speed control optimization and energy saving.

Conveyance and Material Handling – Smooth acceleration and deceleration allow precise control.

Machine Tools – Improves the precision with which cutting, drilling, and milling operations are done.

HVAC – Controls all air conditioning and ventilation units much better.

Textile and Paper Industry- Motion control with precision enhances the performances of various production lines.

Reasons to Choose Siemens G120 Drive

For outstanding performance, flexibility, and reliability, the Siemens G120 drive is preferred by industries around the globe. Here are some distinguishing features of this drive:

Build tough and ready for the worst industrial environments.

Easy integration within Siemens automation systems.

Technically advanced, ready for the 4th Industrial revolution.

Global support by Siemens service and maintenance.

Conclusion

The SINAMICS G120 drive is, in fact, an advanced solution for industries in pursuit of energy-saving motion control technology, effective technology, and reliability. For these reasons, its modular design, safety features, and interconnectivity have made it the choice of many industries wanting to optimize their automation processes. Whether in manufacturing, material handling, or HVAC applications, the G120 drive by Naksh Technology Solutions LLP boasts high performance and operational efficiency.

0 notes

Text

AI in Manufacturing: Transforming Supply Chains and Logistics

Artificial Intelligence (AI) is revolutionizing the manufacturing sector, particularly in the realms of supply chains and logistics. As industries strive for greater efficiency, reduced costs, and improved accuracy, AI-powered solutions are playing a crucial role in automating processes, optimizing inventory management, and enhancing predictive capabilities. This blog explores how AI is transforming supply chains and logistics, its key benefits, and real-world applications.

The Role of AI in Supply Chain Optimization

1. Predictive Analytics for Demand Forecasting

One of the most significant contributions of AI in supply chain management is predictive analytics. AI algorithms analyze vast amounts of historical data, market trends, and external factors (such as economic shifts and weather patterns) to accurately forecast demand. This enables businesses to:

Reduce inventory waste

Prevent stockouts and overstocking

Optimize production schedules

2. Real-time Inventory Management

AI-powered inventory management systems use IoT sensors and machine learning algorithms to monitor stock levels in real-time. This technology helps businesses to:

Automate restocking processes

Improve warehouse efficiency

Reduce carrying costs and losses due to obsolescence

3. Smart Procurement and Supplier Management

AI-driven procurement systems analyze supplier performance, pricing trends, and market conditions to assist businesses in selecting the best vendors. AI helps in:

Automating supplier negotiations

Identifying cost-saving opportunities

Enhancing supplier relationships through data-driven insights

AI in Logistics: Enhancing Efficiency and Accuracy

1. Route Optimization and Fleet Management

AI plays a crucial role in logistics by optimizing delivery routes and fleet management. Machine learning algorithms analyze traffic conditions, weather forecasts, and vehicle data to suggest the most efficient routes, leading to:

Reduced fuel consumption

Faster delivery times

Lower operational costs

2. Autonomous Vehicles and Robotics

The adoption of autonomous vehicles and warehouse robotics is transforming logistics operations. AI-powered robots and self-driving trucks improve:

Warehouse automation

Last-mile delivery efficiency

Safety and accuracy in handling goods

3. AI-powered Predictive Maintenance

AI algorithms analyze data from machinery and vehicles to predict when maintenance is required. This proactive approach helps companies:

Prevent unexpected breakdowns

Reduce downtime and repair costs

Enhance overall operational efficiency

Case Studies: AI in Action

1. Amazon’s AI-driven Supply Chain

Amazon leverages AI for demand forecasting, warehouse automation, and robotic order fulfillment. Machine learning algorithms optimize logistics operations, ensuring faster deliveries and improved inventory management.

Siemens uses AI-powered predictive maintenance and IoT-enabled supply chain optimization to enhance production efficiency and reduce operational disruptions.

3. DHL’s AI-enhanced Logistics

DHL integrates AI in route optimization, autonomous warehouse robotics, and predictive analytics, leading to significant cost savings and improved delivery accuracy.

Challenges and Considerations

While AI offers numerous benefits, there are challenges in its adoption, such as:

High initial investment costs

Data security and privacy concerns

Integration with legacy systems

Need for skilled workforce

Conclusion

AI in manufacturing is undeniably transforming supply chains and logistics, bringing efficiency, cost savings, and increased accuracy to the manufacturing sector. As AI technology continues to evolve, its role in optimizing supply chain operations and logistics will only grow stronger. Businesses that embrace AI-driven solutions today will be better positioned to stay competitive and thrive in the future.

0 notes

Text

Automation Parts Supplier: Key Considerations for Choosing the Right One

In the fast-paced industrial environment, automation is crucial for streamlining operations, improving productivity, and reducing downtime. One key to maintaining seamless automation processes is selecting a reliable automation parts supplier. Automation Warehouse, a prominent online supplier, offers a diverse range of automation components that can meet the needs of industries worldwide. From surplus and refurbished parts to brand-new items, this supplier provides cost-effective, high-quality solutions. Let's take a closer look at why choosing the right automation parts supplier is so essential.

1. Wide Range of High-Quality Products

Automation systems depend on a variety of components such as controllers, sensors, drives, and power supplies. A trusted automation parts supplier should provide a wide selection of products from top manufacturers like Siemens, ABB, and Allen Bradley. Automation Warehouse delivers on this front by offering a broad inventory, including surplus, new, and refurbished parts. This variety enables businesses to find the perfect match for their specific automation needs, whether for a new project, system upgrade, or repair.

2. Cost-Effective Solutions

One of the main advantages of sourcing from a dedicated automation parts supplier is cost savings. Automation Warehouse specializes in surplus and refurbished components, which are rigorously tested to meet high-performance standards. These options provide a more affordable alternative to brand-new parts while maintaining excellent quality. For companies operating within strict budget constraints, refurbished components can be a wonderful way to reduce costs without sacrificing reliability.

3. Global Shipping and Fast Delivery

Another key benefit of working with Automation Warehouse is their global shipping network. With customers in over 76 countries, they ensure fast and reliable delivery of automation parts to businesses worldwide. Whether in the United States, Europe, Asia, or any other region, you can rely on their secure and prompt shipping services to keep your operations running smoothly.

4. Expert Customer Support

A knowledgeable customer support team is an invaluable resource when navigating the complexities of automation parts. Automation Warehouse excels in this area, offering expert guidance to help customers select the right components and troubleshoot any issues. Their technical support ensures that businesses can make informed decisions and integrate automation parts seamlessly into their existing systems, minimizing downtime and maximizing efficiency.

5. Convenient Online Shopping Experience

When sourcing automation parts, ease of purchase is essential. Automation Warehouse provides an intuitive online platform, allowing businesses to quickly find the parts they need. The site is user-friendly and offers detailed product specifications to ensure customers are well-informed before making a purchase. Streamlined ordering and tracking features further enhance the experience, ensuring that your order is processed quickly and delivered on time.

Conclusion: Why Choose Automation Warehouse?

Choosing the right automation parts supplier can significantly impact your business’s operational efficiency. With Automation Warehouse, businesses can enjoy access to a wide range of high-quality parts, cost-effective solutions, fast global shipping, expert customer support, and a convenient online shopping experience. Whether you are in need of new, surplus, or refurbished components, Automation Warehouse is a reliable partner for companies looking to optimize their automation systems and reduce downtime.

To learn more about Automation Warehouse and explore their offerings, visit their website.

0 notes

Text

Siemens Washing Machine Service Solutions: Efficiency at Its Best

In today’s fast-paced world, a washing machine is more than just a household appliance; it’s a necessity. Among the myriad of brands available, Siemens stands out for its exceptional build quality, cutting-edge technology, and reliability. However, even the most advanced washing machines require proper maintenance and occasional repairs to ensure they function at peak efficiency. This is where Siemens washing machine service solutions come into play.

Siemens Washing Machine Service in Coimbatore

Why Regular Service is Essential for Siemens Washing Machines

Siemens washing machines are engineered for high performance and longevity. However, over time, factors such as water quality, detergent residue, and mechanical wear can impact their performance. Regular servicing ensures:

Optimal Performance: Regular maintenance keeps your washing machine running smoothly and efficiently, saving energy and time.

Prolonged Lifespan: Proper care prevents major breakdowns, extending the life of your appliance.

Cost Savings: Timely repairs and servicing can prevent expensive replacements or extensive repairs in the future.

Consistent Cleaning Quality: A well-maintained machine ensures your clothes are cleaned effectively without damage.

Common Issues with Siemens Washing Machines

Even with Siemens’ renowned durability, issues may arise over time. Common problems include:

Water Leakage: Caused by worn-out seals, clogged drain hoses, or faulty pumps.

Noisy Operation: Often due to worn bearings, unbalanced loads, or foreign objects in the drum.

Drum Not Spinning: Caused by motor issues, drive belt problems, or sensor failures.

Water Not Draining: Indicates blockages in the drain pump or hose.

Error Codes: Modern Siemens washing machines display error codes to indicate specific problems, such as E18 for drainage issues or E23 for leakage concerns.

Siemens Washing Machine Service in Coimbatore

Siemens Washing Machine Service Solutions

Siemens offers a range of service solutions to address these issues and ensure your washing machine operates efficiently. Here’s what to expect:

1. Professional Inspection and Diagnosis

Certified Siemens technicians use advanced diagnostic tools to identify and resolve issues efficiently. This ensures that no underlying problem goes unnoticed.

2. Original Spare Parts

Siemens emphasizes the use of genuine spare parts for repairs. This not only restores your washing machine to its original performance but also ensures durability and reliability.

3. Preventive Maintenance Plans

Preventive maintenance services include cleaning filters, checking hoses, inspecting seals, and calibrating sensors. Regular maintenance reduces the risk of unexpected breakdowns and keeps your machine in top condition.

4. Emergency Repair Services

For urgent issues, Siemens offers quick response times through its dedicated service network. This minimizes downtime and inconvenience.

Siemens Washing Machine Service in Coimbatore

5. Comprehensive Service Packages

Siemens provides tailored service packages that cater to different customer needs. These packages may include annual maintenance contracts, extended warranties, and priority repair services.

How to Access Siemens Washing Machine Services

Getting your Siemens washing machine serviced is simple and hassle-free. Follow these steps:

Locate Authorized Service Centers: Visit the official Siemens website or contact customer support to find the nearest authorized service center.

Book a Service Appointment: Schedule a service appointment online or through the Siemens customer care hotline.

Provide Appliance Details: Share your washing machine’s model number and a brief description of the issue to ensure the technician is well-prepared.

Avail On-Site Service: Most minor repairs can be handled on-site. For complex issues, the appliance may be taken to the service center.

Follow-Up Support: Siemens’ after-service support ensures customer satisfaction and offers guidance on maintaining the appliance.

DIY Maintenance Tips for Siemens Washing Machines

While professional servicing is crucial, you can take simple steps to maintain your washing machine between services:

Clean the Drum Regularly: Run an empty cycle with a drum-cleaning solution to remove detergent buildup and odors.

Inspect and Clean Filters: Check and clean the lint filter and inlet filters periodically to ensure smooth water flow.

Check the Door Seal: Wipe the door seal after each use to prevent mold and mildew growth.

Avoid Overloading: Overloading can strain the motor and affect cleaning performance.

Use Recommended Detergents: Always use high-quality detergents designed for washing machines to prevent residue buildup.

Benefits of Choosing Authorized Siemens Services

Opting for authorized Siemens service solutions offers several advantages:

Expertise: Certified technicians have in-depth knowledge of Siemens appliances and can handle complex issues with ease.

Warranty Compliance: Repairs and servicing by authorized centers ensure your warranty remains intact.

Quality Assurance: Original spare parts and standardized procedures guarantee optimal performance.

Convenience: Authorized service centers provide efficient and reliable support, minimizing disruptions.

Siemens Washing Machine Service in Coimbatore

Conclusion

Siemens washing machines are an excellent investment, offering top-notch performance and advanced features. However, like any appliance, they require regular care and servicing to maintain their efficiency and longevity. With Siemens washing machine service solutions, you can enjoy peace of mind knowing your appliance is in expert hands.

From professional inspections and genuine spare parts to preventive maintenance and emergency repairs, Siemens’ comprehensive service offerings ensure that your washing machine operates at its best. By combining professional services with regular DIY maintenance, you can maximize your appliance’s lifespan and enjoy consistent cleaning results.

Choose Siemens washing machine service solutions for efficiency at its best, and experience the perfect blend of performance, reliability, and convenience.

0 notes

Text

AI Development Services in Manufacturing: Enhancing Innovation and Productivity

AI is transforming the manufacturing landscape, driving improvements in productivity, quality, and operational efficiency. Through AI development services, manufacturers can utilize automation, data insights, and predictive analytics to optimize production processes, reduce costs, and elevate product quality.

AI development companies offer tailored solutions to tackle critical challenges in manufacturing, including predictive maintenance, production automation, quality assurance, and supply chain management. By collaborating with these companies, manufacturers gain access to AI-driven tools that streamline tasks, deliver real-time insights, and enable smarter decision-making.

Major Advantages of AI in Manufacturing:

Workflow Automation: AI handles repetitive tasks, minimizing manual work and increasing productivity.

Predictive Maintenance: AI analyzes equipment data to anticipate potential failures, allowing for scheduled maintenance and reducing unplanned downtime.

Automated Quality Assurance: AI-driven computer vision systems detect flaws early, ensuring consistent quality and reducing dependence on manual inspections.

Optimized Supply Chain: AI improves supply chain efficiency by forecasting demand, refining inventory control, and optimizing resource use, which results in cost savings.

Smart Manufacturing: AI enables connected and data-informed systems that optimize production and facilitate real-time decision-making.

Real-World AI Applications in Manufacturing

Examples of AI’s impact in manufacturing include:

Siemens: Uses AI to support predictive maintenance, reducing equipment downtime and improving efficiency.

BMW: Applies AI-driven quality control to inspect parts, maintaining high standards and minimizing defects.

Tesla: Employs AI-powered robots for tasks like welding and assembly, enhancing production speed and accuracy.

Frequently Asked Questions

1. What do AI development services involve in manufacturing?AI development services encompass AI-powered solutions that enhance manufacturing operations, such as predictive maintenance, quality assurance, and supply chain optimization.

2. How does predictive maintenance benefit manufacturers?By monitoring equipment in real time, AI identifies potential problems early, reducing repair costs and preventing unexpected downtime.

3. Can AI help reduce energy consumption?Yes, AI can optimize energy usage, leading to lower costs and supporting sustainability initiatives.

4. How do AI-driven robots improve production?AI-powered robots automate repetitive tasks with precision, adapt to production demands, and collaborate with human workers.

5. How does AI enhance quality control?AI systems inspect products in real time, ensuring quality consistency and minimizing defects.

0 notes

Text

Smart Railways Market Set to Skyrocket from $106.7 Billion in 2023 to USD 805.34 Billion by 2033, Growing at 22.4% CAGR

Global smart railways market is expected to be valued at US$ 106.7 billion in 2023 and to reach a valuation of US$ 805.34 billion by 2033. The demand for smart railways is estimated to grow at a steady 22.4% CAGR.

The use of big data analytics is becoming increasingly important for smart railways by analyzing large volumes of data from various sources, smart railways can gain insights into passenger behavior, operational efficiency, and maintenance needs. Big data analytics can also help in predicting passenger demand and optimizing train schedules, improving the overall efficiency of railway operations.

Remote monitoring and control is a trend that is gaining traction in the smart railways market. This involves the use of remote sensors and control systems to monitor and manage railway systems from a central location. This approach reduces the need for on-site maintenance and repair, enabling faster response times and reducing downtime. Remote monitoring and control also improve the safety and security of rail services, as it reduces the need for personnel to be present on-site.

With the increasing use of digital technologies, cybersecurity is becoming a major concern for smart railways. Cyber-attacks can disrupt railway operations, compromise passenger safety, and result in significant financial losses. smart railways are implementing advanced cybersecurity measures to protect their systems from cyber threats. This includes the use of firewalls, encryption, and other security measures to protect against cyber-attacks.

Key Takeaways

The adoption of IoT, big data analytics, and cloud computing in the railway market is driving market growth.

The Asia Pacific region is expected to dominate the smart railways market due to the size of its railway network and government initiatives to upgrade infrastructure.

Smart railway technologies are being adopted to improve safety, reduce operational costs, and increase efficiency.

The integration of various hardware and software systems can be challenging, particularly when integrating with legacy infrastructure.

Cybersecurity concerns remain a significant restraint for the market, particularly with the increasing use of connected devices and data sharing.

The deployment of smart railway technologies is expected to reduce carbon emissions and contribute to sustainable transportation.

Competitive Landscape

The competitive landscape in the smart railways market is highly fragmented, with numerous established players, startups, and small to medium-sized companies vying for market share. The market is dominated by companies such as Siemens, ABB, and Cisco Systems, which have a significant market presence and wide product portfolios.

In recent years, startups and emerging companies have entered the market with innovative solutions and technologies, creating an environment of intense competition. Some notable startups in the smart railways market include Sqills, Sensible 4, Cervello, and N-SIDE.

These startups are focused on developing technologies that improve operational efficiency, passenger experience, and safety in the rail services sector. They are leveraging advanced technologies such as artificial intelligence, Internet of Things, and big data analytics to provide solutions that are faster, more efficient, and cost-effective.

The startup ecosystem in the smart railways market is supported by various incubators, accelerators, and venture capital firms that provide funding, mentorship, and resources to help these companies grow and succeed. Some of the prominent accelerators and incubators in this market include Alchemist Accelerator, Plug and Play Tech Center, and Seedcamp.

Key Segments

Smart Railways Market by Device and Component:

Rail Sensors

Video Surveillance Cameras

Smart Cards

Networking & Connectivity Devices (Router, Wi-Fi, Switches, etc.)

Others (Multimedia Displays)

Smart Railways Market by Service:

Professional Services

Cloud Services

Integration Services

Smart Railways Market by System:

Passenger Information Systems (PIS)

Railway Traffic Management System (RTMS)

Advanced Security Management Systems (ASMS)

Smart Ticketing Systems (STS)

Rail Operations Management Systems

Rail Communication & Networking Systems

Others (Rail Analytics Systems and Freight Information Systems)

Smart Railways Market by Region:

North America Smart RailwaysMarket

Latin America Smart RailwaysMarket

Europe Smart RailwaysMarket

East Asia Smart RailwaysMarket

South Asia & Pacific Smart RailwaysMarket

Middle East & Africa (MEA) Smart RailwaysMarket

0 notes

Text

Smart Factories: The Next Leap in Manufacturing

As the manufacturing sector evolves, the rise of smart factories marks a transformative leap into the future. Powered by the Internet of Things (IoT), predictive maintenance, and advanced robotics, these intelligent production environments are redefining efficiency, innovation, and scalability across industries worldwide. In this blog, we’ll explore how these technologies drive change, examine global trends, and highlight real-world case studies showcasing their profound impact.

The Essence of Smart Factories

A smart factory is more than an automated facility; it’s an ecosystem where physical production processes are seamlessly integrated with digital technologies. Leveraging interconnected devices, data analytics, and intelligent automation, smart factories enhance operational efficiency while minimizing downtime and waste. They embody the principles of Industry 4.0, propelling manufacturing into a digitally optimized future.

Key pillars of smart factories include:

IoT-enabled Devices: Real-time monitoring and communication across machines and systems.

Predictive Maintenance: Anticipating failures before they occur, reducing costly disruptions.

Robotics and AI: Enhancing precision, speed, and adaptability in production lines.

Digital Twins: Virtual simulations of physical processes to optimize design and operation.

The Role of IoT in Manufacturing

The Internet of Things (IoT) is the backbone of smart factories, enabling devices, sensors, and systems to exchange data in real-time. This connectivity drives unprecedented transparency, allowing manufacturers to monitor operations and make data-driven decisions.

Global Trends in IoT Manufacturing

Edge Computing: Processing data closer to where it’s generated reduces latency, enabling faster responses in production environments.

5G Connectivity: Ultra-fast, low-latency networks are critical for real-time communication between IoT devices.

Smart Supply Chains: IoT enhances supply chain visibility, tracking goods from raw materials to finished products.

Case Study: Siemens Amberg Electronics Plant

At Siemens’ Amberg plant in Germany, IoT plays a pivotal role. The factory achieves a production efficiency of over 99% by connecting 1,000 IoT devices across its production line. These devices analyze data to detect anomalies, optimize workflows, and maintain product quality.

Predictive Maintenance: The Game-Changer

Traditional maintenance models often involve reactive or scheduled maintenance, which can lead to unnecessary costs or unexpected downtime. Predictive maintenance, driven by IoT and AI, changes the game by identifying potential equipment failures before they happen.

How Predictive Maintenance Works

Data Collection: Sensors on machines gather data on temperature, vibration, and other parameters.

Analysis: AI algorithms detect patterns indicating wear or failure.

Actionable Insights: Operators receive alerts to perform maintenance at the optimal time.

Benefits of Predictive Maintenance

Reduced Downtime: Machines are serviced only when needed, ensuring maximum uptime.

Cost Efficiency: Minimizes unnecessary maintenance and avoids expensive repairs.

Extended Equipment Lifespan: Prevents excessive wear and tear.

Case Study: General Motors (GM)

GM employs predictive maintenance across its assembly plants using IoT sensors and analytics platforms. This approach has resulted in a 50% reduction in unexpected downtime, saving millions annually while improving production efficiency.

Advanced Robotics: The Workforce of the Future

Robotics has been integral to manufacturing for decades, but today’s smart robots are powered by AI, making them more versatile and capable than ever. These robots not only execute repetitive tasks with precision but also adapt to complex environments.

Trends in Robotics

Collaborative Robots (Cobots): Designed to work alongside humans, cobots enhance productivity without replacing human workers.

AI-powered Robots: Machine learning enables robots to learn and improve over time, adapting to new tasks.

Autonomous Mobile Robots (AMRs): These robots navigate factory floors independently, transporting materials efficiently.

Case Study: Tesla Gigafactories

Tesla’s Gigafactories exemplify cutting-edge robotics. Robots perform tasks such as welding, assembly, and material handling, ensuring consistency and speed in electric vehicle production. The integration of AI enables these robots to adjust operations dynamically, reducing errors and waste.

Digital Twins: Bridging the Physical and Digital Worlds

A digital twin is a virtual replica of a physical system, enabling manufacturers to simulate, monitor, and optimize operations. This technology provides invaluable insights, from design to production, enhancing both speed and accuracy.

Applications of Digital Twins

Product Design: Simulate prototypes to refine designs without costly physical trials.

Process Optimization: Test and adjust manufacturing workflows digitally.

Performance Monitoring: Track real-time performance and predict potential issues.

Case Study: Boeing

Boeing uses digital twins to streamline aircraft production. By simulating assembly processes, the company reduces errors and shortens production cycles, ensuring faster delivery without compromising quality.

Global Trends Shaping Smart Factories

1. Sustainability

Smart factories prioritize energy efficiency and waste reduction. By analyzing energy usage patterns, manufacturers can minimize their environmental footprint. Example: Schneider Electric’s smart factory in India reduced energy consumption by 10% and water usage by 20% using IoT and analytics.

2. Resilience

The COVID-19 pandemic highlighted the need for resilient supply chains. Smart factories enhance agility, enabling manufacturers to adapt quickly to disruptions. Example: Procter & Gamble leveraged IoT and AI to maintain production during the pandemic, ensuring consistent supply despite fluctuating demand.

3. Workforce Evolution

Automation does not eliminate the need for human workers; instead, it shifts their roles toward higher-value tasks like strategy and oversight. Upskilling programs are critical to prepare the workforce for this transition. Example: Foxconn’s “automation-first” strategy includes extensive training programs to reskill employees for new roles alongside robots.

Challenges and the Path Forward

While smart factories offer immense potential, they also face challenges:

Cybersecurity: Increased connectivity poses risks of cyberattacks. Robust security protocols are essential.

High Initial Costs: The adoption of advanced technologies requires significant investment.

Skill Gaps: The transition to smart manufacturing demands a skilled workforce comfortable with digital tools.

Future Outlook

Despite these challenges, the momentum toward smart factories is unstoppable. By 2030, the global smart manufacturing market is projected to reach $514 billion, driven by advances in AI, IoT, and robotics. Governments and private sectors must collaborate to address barriers, ensuring equitable access to these transformative technologies.

Conclusion: A New Era of Manufacturing

Smart factories represent the pinnacle of manufacturing innovation, combining IoT, predictive maintenance, robotics, and digital twins to revolutionize the industry. From enhanced efficiency to greater sustainability, the benefits are undeniable. As companies like Siemens, GM, and Tesla lead the way, the future of manufacturing promises to be smarter, faster, and more resilient.

The next leap in manufacturing is already here. Embracing smart factory technology isn’t just an option — it’s an imperative for companies aiming to stay competitive in an increasingly dynamic global market.

So, is your business ready to step into the future of manufacturing?

#Tech4bizsolutions #SmartFactories #Industry40 #ManufacturingInnovation#DigitalTransformation #IoTInManufacturing #AIInManufacturing #PredictiveMaintenance #IndustrialAutomatio #RoboticsInManufacturing #SmartManufacturing #FactoryOfTheFuture#AdvancedManufacturing #TechInIndustry #AutomationRevolution #SustainableManufacturing#DigitalTwins #SupplyChainInnovation #FutureOfManufacturing #IndustrialIoT #ManufacturingTechnology

0 notes

Text

Unlock Competitive Siemens V20 VFD Prices with Chandigarh’s Top Dealer

If you’re on the lookout for a good quality, affordable VFD, the Siemens V20 is definitely a good choice. Favorable for its simplicity, the more-reliable energy efficiency profile makes this drive system suitable for a broad array of industrial applications. To companies in Chandigarh, NMA Group is the top price vendor of Siemens V20 VFD. Here we see why the Siemens V20 VFD is a must for any operation, and how NMA Group can help you get that best deal.

Why Choose the Siemens V20 VFD?

These options guarantee the best performance of the Siemens V20 VFD at a minimum energy consumption and operating costs. It is well known for its ease of use, easy installation, and a wide array of features for different motor control applications. They include pumps, fans, compressors, and conveyors, to name but a few of the systems where the Siemens V20 can optimize the efficiency of your system and extend the life of your equipment.

Cost-Effectiveness: Through varying motor speed to complement any load condition, the Siemens V20 VFD saves energy, which translates to lower utilities. This holds it at an advantage in a day where sustainable practices are enforced.

User-Friendly Setup: Installing the Siemens V20 VFD is painless and direct. Thus, this VFD drives home at extreme benefits for firms with less operating time. The quicker the installation time, its use should be hassle-free, more so for facilities with limited technical know-how.

Durability and Performance: Being from high-class quality of Siemens environment, V20 VFD deserves that reputation. It must be able to work well even in the most serious industrial conditions and minimize the number of repair times and costs.

Versatility: Flexibility is the first significant advantage of this V20 VFD by Siemens: it might be used under various conditions, so that anyone could use this kind in any sort of industry – from HVAC and food and beverage to manufacturing and many others.

Once you finalize NMA Group as the vendor for Siemens V20 VFD Price from Chandigarh, then get the advantage of services from the technical experts who are well aware of the product and its financials, giving the right purchase option at the right price.

Why Buy from a Siemens V20 VFD Price Dealer in Chandigarh?

Now, why choose to buy through a Siemens V20 VFD Price dealer like NMA Group in Chandigarh? Here’s the multiple benefits of having help from a trusted local dealer.

Localized Knowledge: NMA Group knows all the requirements of different industries in Chandigarh. Hence, it gives you recommendations that will comply with the local regulatory requirement, local operating environment, and common applications in the industrial sector.

Competitive Pricing: Being a reputable Siemens V20 VFD price trader in Chandigarh, NMA Group offers you transparent, competitive pricing. The team can advise on the opportunities of cost saving and energy-efficient solutions cutting down the costs for operations.

On-Hand Inventory and Support: A local dealer guarantees availability; you do not have to wait for parts or replacement. NMA Group stocks a wide range of Siemens V20 VFD models and offers technical support to troubleshoot any problem.

After-Sales Service: A good price Siemens V20 VFD dealer like NMA Group offers after-sales support whenever installation, maintenance, and repairs become necessary.

Key Features of the Siemens V20 VFD

There are various unique features that make the Siemens V20 VFD favorite in the industrial circle.

Dynamic Control: Siemens V20 VFD can dynamically control the speed of the motor as desired. This makes a significant amount of waste in energy be minimized, and this indirectly creates increased equipment life.

Integrated Functions: Some of the inbuilt features like PID control are provided with the Siemens V20 VFD, thus it can be used for process control without any additional equipment.

Compact Design: It is suited for small spaces, in installations where space might be limited. It has strong performance relative to its size.

Energy-Saving Mode: This energy-saving mode of the V20 VFD helps save power during low-demand hours for businesses, making this ideal for businesses that focus more on cost cuts.

With such features, it is not hard to understand why many industries have been dependent on the Siemens V20 VFD when it comes to running their motors efficiently. For businesses in Chandigarh looking for affordability, NMA Group offers the best possible Siemens V20 VFD price.

How to Get the Best Siemens V20 VFD Price in Chandigarh

To secure the best Siemens V20 VFD price, it’s important to understand a few factors:

Usage Requirements: Observe first your specific application needs, as some may actually be a better fit than others. NMA Group can lead you to better select the model for most efficient use of your operations.

Energy Savings: Energy savings in the long run: Although the models may be more expensive up-front, they generally save money in the long run due to the saving of energy.

Warranty and Support: Make sure you obtain complete warranty cover and local support from your Siemens V20 VFD price dealer in Chandigarh. NMA Group provides strong support for technical assistance and after-sales service.

Comparative Pricing: Compare the prices of a Siemens V20 VFD by different dealers. However, quality and support do not take a back seat. Here, price will not be compromised at NMA Group as we shall make sure you get the best of both product authenticity and service.

The Benefits of Working with NMA Group for Your Siemens V20 VFD Needs

NMA Group has rightly established itself as a reputed vendor for Siemens V20 VFD price within the city of Chandigarh to supply the best quality in reliable products to companies. Some benefits of associating with NMA Group include:

Personalized Service: NMA Group’s team understands what makes one client unique as compared to others so that you get a solution that fits your business’ specific needs.

Authorized Dealer: Authorized Dealer of Siemens V20 VFD Price in Chandigarh so you get Genuine Products with Manufacturer’s Warranty.

Skilled Technical Team: NMA Group has technically strong and experienced team, from installation support to solving any kind of fault to ensure your Siemens V20 VFD is always under optimal condition.

Quick and Easy Transactions: As NMA Group is a local dealer, the purchase and support procedures are ensured to be most efficient so that you will not have a difficult time getting the Siemens V20 VFD that you need.

Flexible Pricing Options: Such arrangements may include flexible pricing and financing options that appropriately address the budgeting needs of the clients, making the Siemens V20 VFD an achievable investment for companies of all sizes.

Conclusion

Choosing the right Siemens V20 VFD Price Dealer in Chandigarh can make all the difference in getting the best value for your investment. Among the trusted versatile products, Siemens V20 VFD provided to industries that desire control of their motors in an efficient way to bring down the energy cost is one. NMA Group will cater to the competitive pricing, original products, and excellent support for the customers as your Siemens V20 VFD price dealer in Chandigarh.

For the intelligent investment in motor control technology, it really cannot get better than the Siemens V20 VFD: efficient, long-lasting, and simple, all in one solid package. Take advantage of partnering with the NMA Group to get the best price for Siemens V20 VFD in Chandigarh so your business is going to be really up to date with the latest in VFD technology.

Originally Published Here:-

0 notes

Text

United Kingdom Wind Turbine Services Market Assessment and Future Development Predictions 2024 - 2032

The United Kingdom Wind Turbine Services Market is experiencing significant growth as the country continues to invest in renewable energy sources. With an increasing number of wind farms being developed, the demand for specialized services related to wind turbine maintenance, installation, and operation has surged. This article provides an in-depth analysis of the United Kingdom Wind Turbine Services Market, highlighting key trends, challenges, and future opportunities.

Overview of the Wind Turbine Services Market

Wind turbine services encompass a range of activities designed to ensure the efficient operation and maintenance of wind turbines. These services include installation, regular maintenance, repairs, and performance optimization. As the UK aims to enhance its renewable energy capacity, the wind turbine services market is becoming an essential component of the energy sector.

Current Market Landscape

The United Kingdom is one of the leading countries in wind energy production, thanks to favorable geographic conditions and government support for renewable initiatives. Several factors are driving the growth of the wind turbine services market:

Government Policies and Incentives: The UK government has set ambitious targets for renewable energy, providing incentives for the development of wind energy projects and associated services.

Technological Advancements: Innovations in turbine technology and service methodologies are improving efficiency and reducing operational costs, making wind energy more competitive.

Environmental Awareness: Growing concerns about climate change are prompting investments in clean energy, further fueling the demand for wind turbine services.

Key Players in the Market

The wind turbine services market in the UK is characterized by the presence of several key players, including:

Siemens Gamesa Renewable Energy

Vestas Wind Systems

GE Renewable Energy

Nordex SE

These companies are pivotal in delivering comprehensive service solutions, leveraging their expertise to enhance turbine performance and longevity.

Trends Influencing the Market

Increased Focus on Maintenance Services

As wind turbines age, the need for maintenance services becomes critical. Predictive maintenance, utilizing advanced analytics and IoT technologies, is gaining traction, enabling service providers to anticipate issues before they arise and minimize downtime.

Digital Transformation

The adoption of digital technologies, such as remote monitoring and data analytics, is transforming the wind turbine services landscape. These technologies enhance operational efficiency, improve safety, and enable real-time decision-making for maintenance and repairs.

Sustainability Initiatives

With a growing emphasis on sustainability, wind turbine service providers are increasingly focusing on eco-friendly practices. This includes optimizing turbine performance to reduce energy waste and implementing recycling programs for turbine components at the end of their lifecycle.

Challenges Facing the Market

Despite the positive outlook, the UK wind turbine services market faces several challenges:

Skilled Labor Shortages: The demand for skilled technicians and engineers in the wind energy sector is outpacing supply, creating workforce challenges.

Regulatory Hurdles: Navigating the regulatory landscape can be complex, and changes in policies may impact project timelines and costs.

Market Competition: As more companies enter the market, competition is intensifying, potentially leading to price pressures and reduced profit margins.

Future Opportunities

Expansion of Offshore Wind Farms

The UK is a global leader in offshore wind energy, with plans for significant expansion in this sector. This growth presents ample opportunities for service providers to develop specialized offerings tailored to the unique challenges of offshore wind turbine maintenance.

Technological Innovations

Continued advancements in turbine technology, such as larger and more efficient turbines, are expected to drive demand for enhanced services. Companies that invest in innovation will be well-positioned to capture market share.

Collaboration and Partnerships

Strategic partnerships between manufacturers, service providers, and energy companies can foster innovation and enhance service delivery. Collaborative efforts will be crucial in addressing the complexities of wind turbine maintenance and operation.

Conclusion

The United Kingdom Wind Turbine Services Market is poised for substantial growth, driven by government support, technological advancements, and a heightened focus on sustainability. As the demand for wind energy continues to rise, service providers must navigate challenges while seizing opportunities to enhance their offerings. With a strong commitment to innovation and efficiency, the UK wind turbine services market is set to play a vital role in the transition to a greener energy future.

Related Reports

Gas Turbine

Battery

Biodiesel

Cryocooler

0 notes

Text

Unités de réparation de puits hydrauliques, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 13 Premières Entreprises

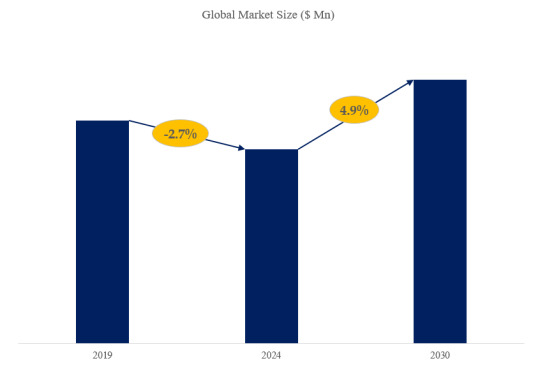

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Unités de réparation de puits hydrauliques 2024-2030”, publié par QYResearch, la taille du marché mondial de Unités de réparation de puits hydrauliques devrait atteindre 2228 millions de dollars d'ici 2030, à un TCAC de 4.9% au cours de la période de prévision.

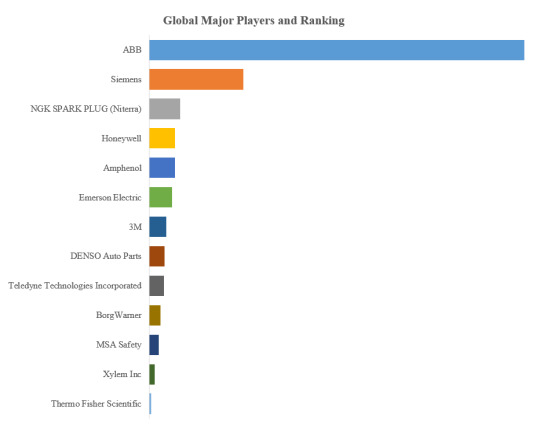

Figure 1. Taille du marché mondial de Unités de réparation de puits hydrauliques (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Unités de réparation de puits hydrauliques comprennent ABB, Siemens, NGK SPARK PLUG (Niterra), Honeywell, Amphenol, Emerson Electric, 3M, DENSO Auto Parts, Teledyne Technologies Incorporated, BorgWarner, etc. En 2023, les cinq premiers acteurs mondiaux détenaient une part d'environ 62.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 13 premiers acteurs mondiaux de Unités de réparation de puits hydrauliques (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The Hydraulic Workover Units (HWUs) market experiences growth due to several influential factors, reflecting the evolving needs of the oil and gas industry. Key drivers include:

: As global energy demand rises, exploration and production activities in both conventional and unconventional oil and gas fields are expanding. HWUs play a crucial role in these operations by facilitating workovers, completions, and interventions, which are necessary to maintain or enhance well productivity.

: Compared to conventional rig-based workover operations, HWUs offer a more efficient and cost-effective solution. They can perform tasks such as tubing/packer changeouts, stimulation, and repairs with minimal downtime, reducing overall operational expenses.

: The growth in shale gas and tight oil production has significantly increased the demand for hydraulic workover units. These resources require frequent stimulation and maintenance, making HWUs indispensable for their extraction processes.

: Offshore oil and gas fields pose unique challenges due to their remote locations and harsh environments. HWUs, with their compact size and mobility, are well-suited for offshore applications where space is limited and quick response times are critical.

: Technological advancements in HWUs, such as improved hydraulic systems, remote operation capabilities, and enhanced safety features, have increased their efficiency and operational flexibility, further driving market demand.

: With the focus on maximizing the output from existing wells, workover operations are becoming more frequent. HWUs enable operators to conduct interventions that extend well life and enhance recovery rates, making them a strategic investment.

: Stricter environmental regulations are pushing the industry towards less intrusive and more environmentally friendly methods of operation. HWUs, with their targeted and controlled intervention capabilities, align with these requirements.

: Many mature oilfields require retrofitting and upgrading to maintain production levels. HWUs are ideal for conducting such operations, including slot recovery, sand cleanouts, and installation of artificial lift systems.

: HWUs offer a wide range of applications beyond workovers, including well testing, coiled tubing operations, and snubbing services, making them a versatile asset for oilfield service companies.

: While the world transitions towards renewable energy sources, oil and gas companies are focusing on optimizing their existing assets to ensure profitability during the transition period. HWUs support these efforts by maintaining and enhancing well productivity.

These market drivers indicate a robust outlook for the Hydraulic Workover Units market, as they continue to be an essential tool in maintaining and enhancing oil and gas production efficiency in the face of complex operational challenges and evolving industry dynamics.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

The Astonishing Scope of Mechanical Engineering in 2024

https://krct.ac.in/blog/2024/06/06/the-astonishing-scope-of-mechanical-engineering-in-2024/

The Astonishing Scope of Mechanical Engineering in 2024

Mechanical engineering stands as an essential field in the realm of engineering, celebrated for its broad applicability across numerous industries. In India, this field remains robust, offering a wealth of opportunities for graduates. From crafting cutting-edge automobiles and developing sustainable energy solutions to advancing the field of robotics, mechanical engineers drive technological progress. KRCT graduates are particularly well-prepared to seize these opportunities due to their rigorous education and training.

Understanding Mechanical Engineering

Mechanical engineering is a fundamental branch of engineering focused on the design, production, and maintenance of machinery. Also, it integrates the principles of engineering, physics, and materials science to analyse, design, manufacture, and maintain mechanical systems. Further, utilizing mathematical and scientific principles, mechanical engineers create and evaluate devices, engines, and other mechanical structures. In addition, their expertise extends to understanding how these systems interact with forces and environments. Moreover, the field covers a wide range of areas including thermodynamics, fluid mechanics, materials science, robotics, and control systems.

Career Prospects in Mechanical Engineering in India

Indeed, mechanical engineering is one of the most time-honoured and esteemed engineering disciplines in India. It offers abundant opportunities across sectors such as automotive, aerospace, energy, and construction. The Indian government’s significant investment in infrastructure and technology further fuels the demand for skilled mechanical engineers. Also, Graduates with a B.E / B. Tech or M.E / M. Tech in mechanical engineering can look forward to competitive salaries, strong job prospects, and ongoing professional development.

Career Paths and Job Opportunities for KRCT Graduates

For KRCT graduates, mechanical engineering offers a diverse and promising career landscape. Here are some detailed career paths and job opportunities:

Design Engineer

Design engineers use computer-aided design (CAD) software to create and develop new products and systems. They work on the conceptualization, development, and testing of product designs. Opportunities abound in sectors such as automotive, aerospace, consumer electronics, and industrial machinery, with employers like Tata Motors, Mahindra & Mahindra, and HAL (Hindustan Aeronautics Limited).

Manufacturing Engineer

Manufacturing engineers focus on designing and implementing production systems, managing production schedules, and ensuring cost-effective manufacturing processes. Roles in this field are available in industries such as automotive, electronics, heavy machinery, and consumer goods, with companies like Bosch, Godrej, and Larsen & Toubro.

Quality Control Engineer

Quality control engineers ensure that products meet required quality standards through rigorous testing and analysis. Further, they develop quality control processes, conduct inspections, and ensure compliance with industry standards, working in industries like pharmaceuticals, automotive, aerospace, and manufacturing. Employers include Bharat Heavy Electricals Limited (BHEL), Siemens, and Maruti Suzuki.

Maintenance Engineer

Maintenance engineers are tasked with maintaining and repairing mechanical systems and equipment to ensure optimal performance. They plan maintenance schedules, troubleshoot issues, and ensure minimal downtime in industries such as power generation, manufacturing, transportation, and oil and gas. Key employers include Reliance Industries, Indian Oil Corporation, and NTPC Limited.

Research and Development Engineer

Research and development engineers innovate new technologies and products through research and experimentation. They collaborate with scientists and other engineers in industries like technology, pharmaceuticals, automotive, and aerospace, with organizations such as DRDO (Defence Research and Development Organisation), ISRO (Indian Space Research Organisation), and Tata Consultancy Services.

Automotive Engineer

Automotive engineers design and develop vehicles such as cars, trucks, and motorcycles, focusing on engines, aerodynamics, and safety features. Employers in this field include Tata Motors, Ashok Leyland, and Maruti Suzuki.

Aerospace Engineer

Aerospace engineers work on the design and development of aircraft, spacecraft, and satellites, concentrating on aerodynamics, propulsion systems, and structural design. Industries like HAL, ISRO, Airbus, and Boeing provide career opportunities in this field.

Energy Engineer

Energy engineers specialize in developing renewable energy systems such as wind turbines and solar panels, aiming for efficient and sustainable designs. They find roles in companies like Suzlon Energy, Tata Power Solar, and Adani Green Energy.

Robotics Engineer

Robotics engineers design and build robots for industrial and personal use, developing robotic systems and automation solutions. This field offers opportunities with employers such as ABB, Kuka Robotics, and Tata Robotics.

Biomechanical Engineer

Biomechanical engineers develop medical devices, prosthetics, and implants, blending mechanical engineering with biomedical sciences. Opportunities exist in companies like Stryker, Medtronic, and GE Healthcare.

Materials Engineer

Materials engineers innovate new materials for various applications, including aerospace and medical fields, focusing on materials with specific properties. Employers include Tata Steel, Hindalco, and Jindal Steel & Power.

HVAC Engineer

HVAC engineers design heating, ventilation, and air conditioning systems, ensuring they are efficient, sustainable, and compliant with regulatory standards. Companies like Voltas, Blue Star, and Johnson Controls offer opportunities in this field.

Average Salary

Salaries for mechanical engineers in India vary based on qualifications and experience. However, Aerospace Engineers typically start at around INR 6 LPA, Maintenance Engineers at INR 2.5 LPA, and Automotive Engineers at INR 4 LPA. Control and Instrumentation Engineers, as well as Mechanical Engineers, generally begin with a salary of about INR 3 LPA. Furthermore, these figures reflect the diverse earning potential within the field.

To Conclude

The future of mechanical engineering in India is bright, with continuous advancements and growing demand for skilled professionals. So, if you are considering pursuing a Mechanical Engineering course, KRCT provides exceptional educa

tion, placement opportunities, and internships to give students a competitive edge in the industry. Thus, with a distinguished faculty and high-quality education, KRCT is the perfect choice for aspiring mechanical engineers.

Tags:

10 mechanical engineering scope in futureadmissionBest autonomous College of Technology in Trichybest companies for mechanical engineersbest Mech collegebtech mechanical engineering jobsclub activitiescollege hostal facilitydemand of mechanical engineeringEngineering counselling result tamilnaduengineering cutoff tamilnaduerp krct loginfuture of mechanical engineering in indiahighest paying mechanical engineering jobsis mechanical engineering a good career for girlsk. ramakrishnan college of engineeringKRCTlow engineering fees collegesmechanical designer jobsmechanical engineering job opportunitiesmechanical engineering jobs abroadmechanical engineering positionsmechanical maintenance engineermy camumy camu loginremote jobs for mechanical engineersscope after mechanical engineeringscope of mechanical engineering in india after 4 yearssenior mechanical engineerTop 10 engineering college in indiauniversity college of engineering trichy fees structurework from home mechanical e

#best autonomous college of technology in trichy#best college of technology in trichy#krct the best college of technology in trichy#the top college of technology in trichy krct#The best Mechanical engineering college#The best Mechanical engineering placement college in tamilnadu india#Government job after mechanical engineering#Tamilnadu government jobs after mechanical engineering#Future opportunities for mechanical engineering#top college of technology in trichy#Government jobs for mechanical engineer graduates in india#Mechanical engineering job in good scale#Mechanical engineering job in abroad#Is mechanical engineering have scope in future?#Is mechanical engineering have future job opportunities?#Mechanical engineering in next 4years#my camu

1 note

·

View note

Text

SINAMICS G120 Drive: The Key to Energy-Efficient and Safe Industrial Operations

In the ever-evolving landscape of industrial automation, efficiency, precision, and adaptability are paramount. Siemens' SINAMICS G120 is a versatile drive system designed to meet the diverse needs of modern industries. With its advanced features and robust performance, the SINAMICS G120 stands out as a reliable solution for various applications, from simple motor control to complex, multi-axis motion control systems.

What is SINAMICS G120?

Known for its flexibility and efficiency, the SINAMICS G120 is a modular frequency converter drive system. It consists of separate power modules and control units that allow for easy customization as well as scalability. Whether you are in manufacturing, process industries or infrastructure this drive system can be tailored to specific operational requirements.

Key Features of SINAMICS G120

Modular Design: Keeping difficult phrases at the very back can also contribute to lowering perplexity and raising burstiness. Specifically, SINAMICS G120’s modular construction eases assembly as well as alteration. Drive systems consisting of G120 power modules plus control units can be put together according to user specifications. Modularity streamlines both installation procedures and maintenance activities.

Energy Efficiency: Energy efficiency is a key factor in today’s industries. The drive G120 has energy saving features that aids in reducing operational costs. The SINAMICS G120 optimizes energy use with its advanced motor control algorithms, making industrial processes more sustainable.

Comprehensive Safety Features: The prevention of accidents is of paramount importance to any industrial environment. The SINAMICS G120 contains embedded protective functions which safeguard its functionality in different situations. Among those, Safe Torque Off (STO) and Safe Stop 1 (SS1) play crucial roles for the security of both workers and machines.

High Performance and Reliability: Designed for high speed, precision control of motors even under harsh conditions, the G120 power module features advanced technology. It boasts a durable build, which enhances its lifespan and reduces the need for constant repairs.

User-Friendly Interface: The operation of G120 drive is simplified due to its user-friendly interface. Simple the setup and commissioning processes that this drive system offers therefore lessening the operators’ learning curve. In addition, SINAMICS Startdrive software has tactfully integrated with TIA Portal such that it supports effective engineering and monitoring functions.

Applications of SINAMICS G120

The SINAMICS G120 is suitable for a wide range of industrial applications, including:

Pumps, Fans, and Compressors: The G120 power module is best utilized in HVAC systems, water treatment facilities and other infrastructural projects where maximum output efficiency will lead to reduced power consumption rates.

Conveyors and Material Handling: The conveyor belts, lifts, as well as other instruments like these grow more effective due to G120 drives that maintain them on the right course entirely.

Production Lines: Within industrial production sectors, SINAMICS G120 provides a reliable approach while also reducing the probability of machine shutdown or lack of production as it eases the process of running an assembly line.

Process Industries: The SINAMICS G120 ensures product quality and process integrity by offering reliable and safe motor control for industries such as chemicals, pharmaceuticals, and food processing.

Conclusion

The SINAMICS G120 is an advanced drive system that plays a fundamental role in optimizing industrial automation. This drive system is essential for any industry wishing to improve its operations, due to its modular design, energy efficiency, and robust performance. Whether you want to upgrade already existing systems or introduce new solutions, SINAMICS G120 with G120 power module and user-friendly interface gives you the freedom of choice as well as reliability required by your automation objectives.

By investing in SINAMICS G120 one is investing in a solution that is future proof and adaptable to changes in modern-day industry demands.

0 notes

Text

MRI Machine Price: What Buyers Need to Know

Purchasing an MRI machine is a significant investment for any healthcare facility. The cost of an MRI machine can vary widely based on several factors, including technology, features, and brand. Understanding these factors is crucial for making an informed decision that balances cost with quality and functionality. This article explores what buyers need to know about MRI machine prices and the key considerations that influence these costs.

Understanding the Cost Components

The price of an MRI machine is influenced by multiple factors, each contributing to the overall cost. Here are the primary components that buyers should consider:

Technology and Specifications

Magnetic Strength: The strength of the magnet, measured in Tesla (T), significantly impacts the price. Standard MRI machines have strengths of 1.5T or 3T, with higher strengths typically leading to higher costs due to improved image quality and faster scan times.

Imaging Capabilities: Advanced imaging features such as functional MRI (fMRI), diffusion tensor imaging (DTI), and spectroscopy add to the cost. These capabilities enhance diagnostic accuracy and expand the range of possible examinations.

Software and Hardware: The inclusion of state-of-the-art software for image processing, patient management, and diagnostic support can drive up the price. Hardware components like gradient coils and radiofrequency (RF) systems also contribute to the overall cost.

Brand and Model

Reputation and Reliability: Leading brands like Siemens, GE Healthcare, and Philips are known for their reliability, advanced technology, and comprehensive service support. While these brands often come with a higher price tag, the investment can be justified by their performance and durability.

Model Variations: Within each brand, different models cater to various needs and budgets. Entry-level models may offer essential features at a lower cost, while high-end models provide advanced functionalities and superior image quality.

New vs. Refurbished Machines

New Machines: Purchasing a new MRI machine ensures the latest technology, longer warranties, and the assurance of optimal performance. However, new machines are significantly more expensive, with prices ranging from $1 million to over $3 million, depending on the specifications.

Refurbished Machines: Refurbished MRI machines offer a more affordable alternative, often costing 30-50% less than new machines. These machines are thoroughly inspected, upgraded, and certified by manufacturers or third-party vendors. While they provide cost savings, it’s essential to ensure they come with a reliable warranty and support services.

Installation and Maintenance

Installation Costs: The cost of installing an MRI machine can be substantial, involving site preparation, shielding, and infrastructure adjustments. These costs should be factored into the total budget.

Maintenance and Repairs: Ongoing maintenance is crucial for the efficient operation of an MRI machine. Annual maintenance contracts, which cover regular servicing and potential repairs, can add to the overall cost. Buyers should consider these recurring expenses when budgeting for an MRI machine.

Training and Support

Staff Training: Adequate training for technicians and radiologists on the new equipment is essential to ensure optimal use and patient safety. Training programs provided by the manufacturer can incur additional costs.

Technical Support: Access to robust technical support can minimize downtime and ensure continuous operation. This service is often included in the purchase price for a limited period but may require additional fees for extended support.

Financing Options and Return on Investment

Given the high cost of MRI machines, exploring financing options is crucial. Leasing, financing through loans, or entering into partnerships with diagnostic imaging centers are viable options that can spread out the financial burden. Additionally, evaluating the return on investment (ROI) is essential. Consider factors such as increased patient throughput, improved diagnostic capabilities, and potential revenue from expanded services.

Hidden Costs to Consider

Beyond the purchase price, several hidden costs can impact the total investment:

Energy Consumption: MRI machines are energy-intensive, leading to higher utility bills.